28 KiB

Nano Hexapod - Obtained Design

Introduction ignore

Detail design phase:

- key elements were optimized such as: actuator and flexible joints

- relative motion sensor (an encoder) was also selected

- specific kinematics of the Stewart platform (i.e. position of joints and orientation of struts) was not found to be too critical for this application. Yet, the geometry was fixed in Section […]

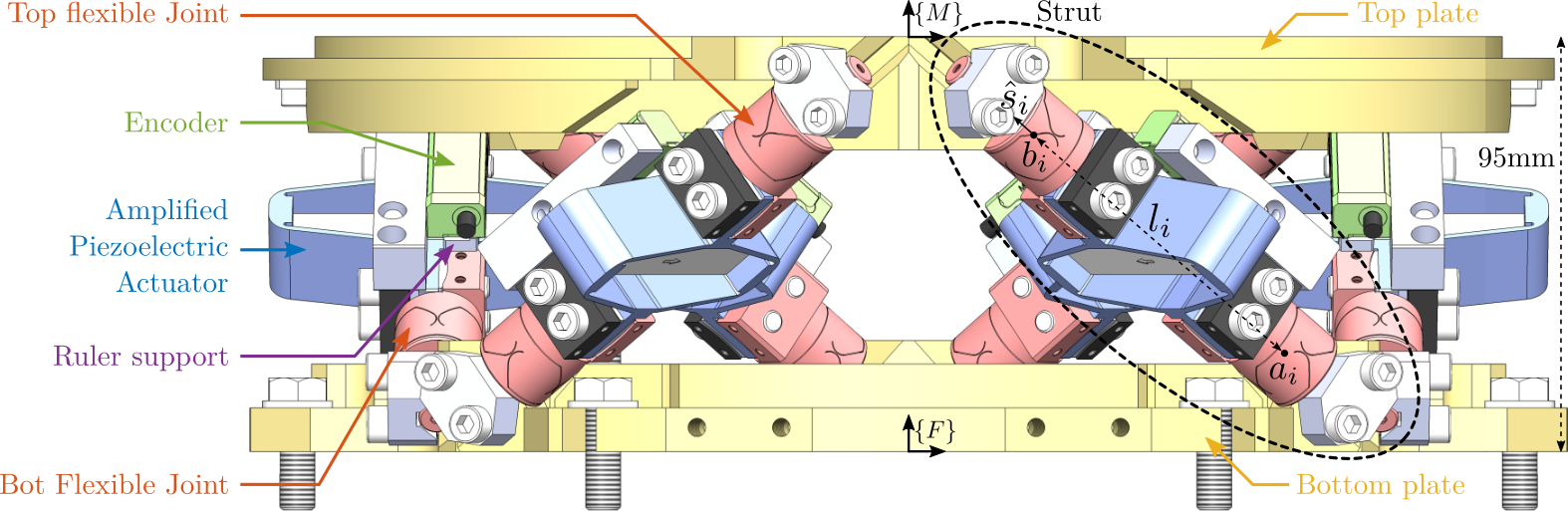

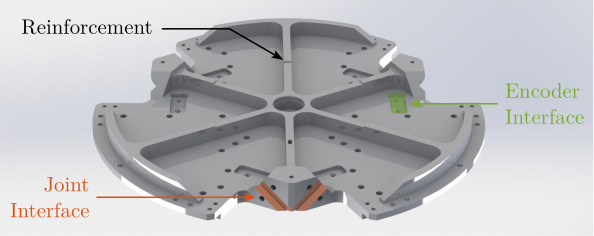

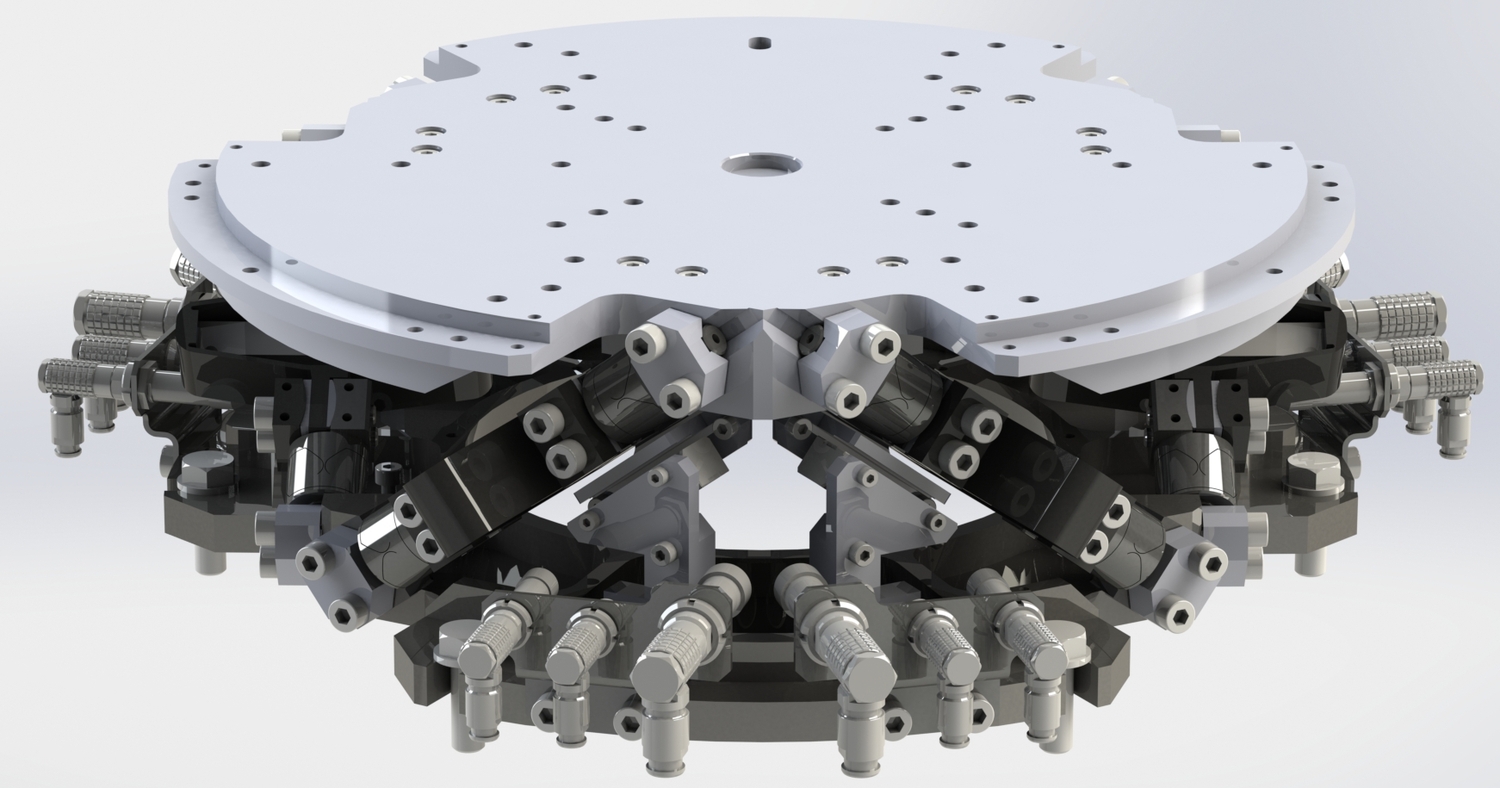

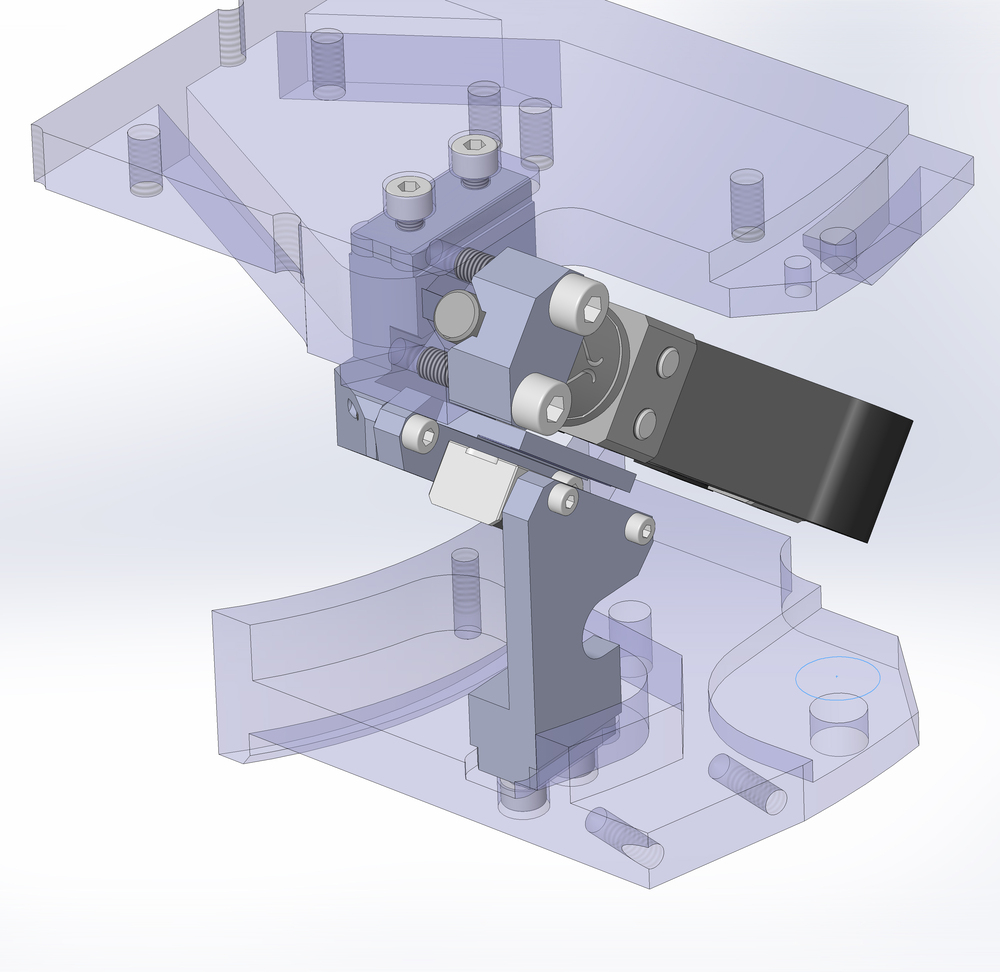

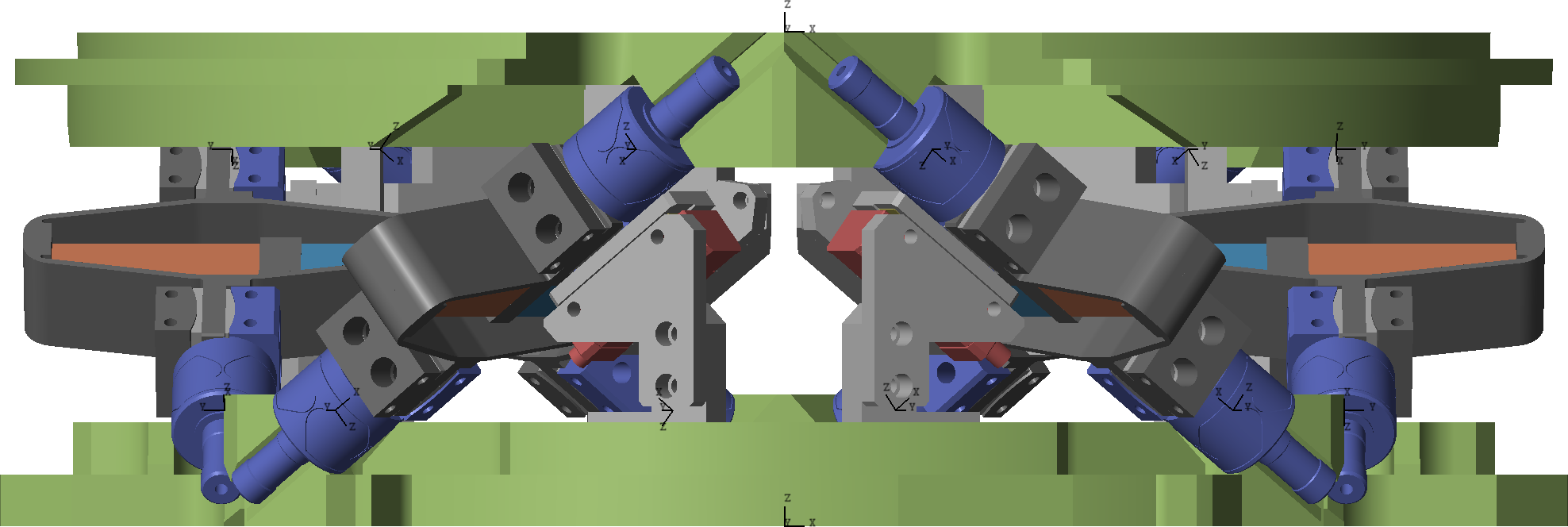

In this section, the mechanical design of the active platform, shown in Figure ref:fig:detail_design_nano_hexapod_elements, is detailed.

The main design objectives are:

- Well defined kinematics: Good positioning of the top flexible joint rotation point $\bm{b}_i$ and correct orientation of the struts $\hat{\bm{s}}_i$. The goal is to have a well defined geometry such that the Jacobian matrix is well defined.

- Space constrains: it should fit within a cylinder with radius of $120\,\text{mm}$ and height of $95\,\text{mm}$

- As good performances were obtained with the multi-body model. The final design should behave as close as possible to "perfect" stewart platform. This means that the frequency of flexible modes that could be problematic for control must be made as high as possible.

- Easy mounting and alignment.

- Easy maintenance: the struts should be easily changed in case for failure.

Mechanical Design

<<sec:detail_design_mechanics>>

Introduction ignore

Struts

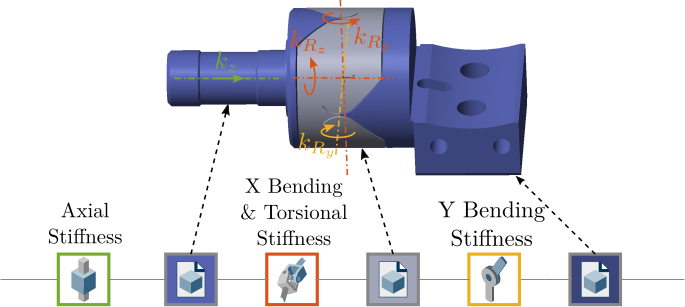

The strut design is shown in Figure ref:fig:detail_design_strut.

The design of the struts was driven by:

- having stiff interface between the amplified piezoelectric actuator and the two flexible joints

- having stiff interface between the flexible joints and the two places (discussed afterwards)

-

Because the angular stroke of the flexible joints is fairly limited, it is important to be able to mount the strut such that the two cylindrical interfaces are coaxial. Do to so:

-

A mounting bench was designed The mounting procedure will be described in Section […]

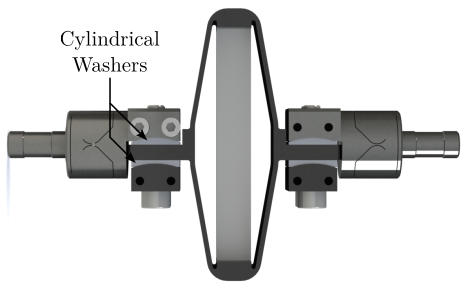

- Cylindrical washers, shown in Figure ref:fig:detail_design_strut_without_enc, were integrated to allow for adjustments. The issue was that the flatness between the two interface planes of the APA shown in Figure ref:fig:detail_design_apa could not be guaranteed. With the added cylindrical washers and the mounting tool, it should be possible to well align the struts even in the presence of machining inaccuracies.

-

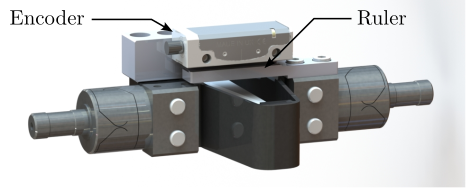

- Possibility to fix the encoder parallel to the strut, as shown in Figure ref:fig:detail_design_strut_with_enc

The flexible joints are manufactured using wire-cut electrical discharge machining, allowing for:

-

very tight tolerances:

- allowing good location of the center of rotation with respect to the plate interfaces (red surfaces shown in Figure ref:fig:detail_design_flexible_joint)

- allowing correct neck dimension to have the wanted properties (stiffness and angular stroke)

- Such part is fragile, mainly due to its small "neck" dimension of only $0.25\,\text{mm}$ Such machining technique has little to no cutting forces.

The flexible joints are made from a stainless steel referenced as "X5CrNiCuNb16-4" (also called "F16Ph"). This material is chosen for:

- its high yield strength: specified >1GPa using heat treatment.

- its high fatigue resistance

Figure ref:fig:detail_design_flexible_joint

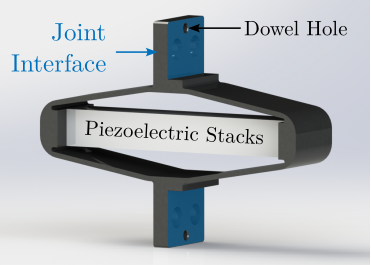

- Interface with the APA has a cylindrical shape to allow the use of cylindrical washers A slotted hole has been added to align the flexible joint with the APA using a dowel pin.

- Two threaded holes on the sides can be used to mount the encoders

- The interface with the plate will be latter described.

The amplified piezoelectric actuators are APA300ML. Modification of the mechanical interfaces were asked to the manufacturer. Two planes surfaces and a dowel hole were used, as shown in Figure ref:fig:detail_design_apa. The amplifying structure, is also made of stainless steel.

To correctly measure the relative motion of each strut, the encoders need to measure the relative motion between the two flexible joint's rotational centers. Two interface parts, made of aluminum, are used to fix the encoder and ruler to the two fleible joints as shown in Figure ref:fig:detail_design_strut_with_enc.

Plates

The two plates of the active platform were designed to:

- Maximize the frequency of flexible modes

- have good positioning of the top flexible joints, and good/known orientation of the struts.

To maximize the flexible joints, finite element analysis were used iteratively. While topology optimization could have been used, a network of reinforcing ribs was used as shown in Figure ref:fig:detail_design_top_plate.

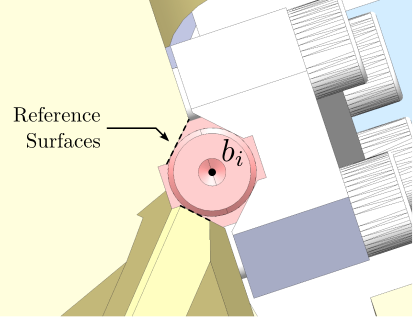

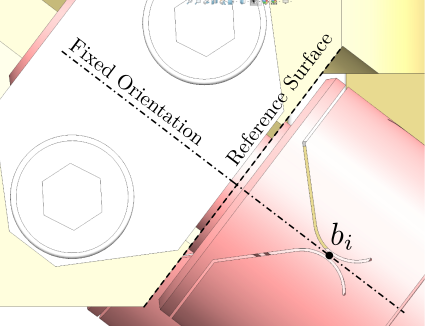

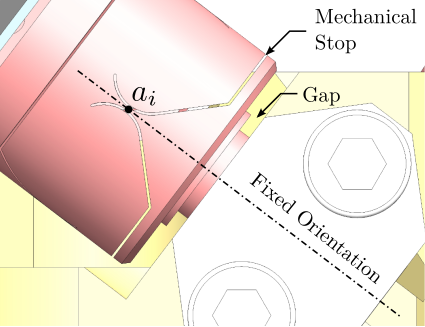

The fixation interface for the joints and "V-grooves". The cylindrical part of the flexible joint is located (or constrained) within the V-groove via two distinct line contacts (Figure ref:fig:detail_design_fixation_flexible_joints). Therefore, these grooves are defining the initial strut orientation High machining accuracy is required, such that during the mounting of the active platform, the flexible joints are that "rest" position

The "flat" interface of each top flexible joint is also in contact with the top platform, as shown in Figure ref:fig:detail_design_location_top_flexible_joints, such that the center of rotation of the top flexible joints $\bm{b}_i$ are well located with respect to the top platform.

The bottom flexible joints are not Figure ref:fig:detail_design_location_bot_flex

The two plates are made with a martensitic stainless steel "X30Cr13":

- It has high hardness, such that the reference surfaces to not deform when fixing the flexible joints

- This should allow to assemble and disassemble the struts many times if necessary

Finite Element Analysis

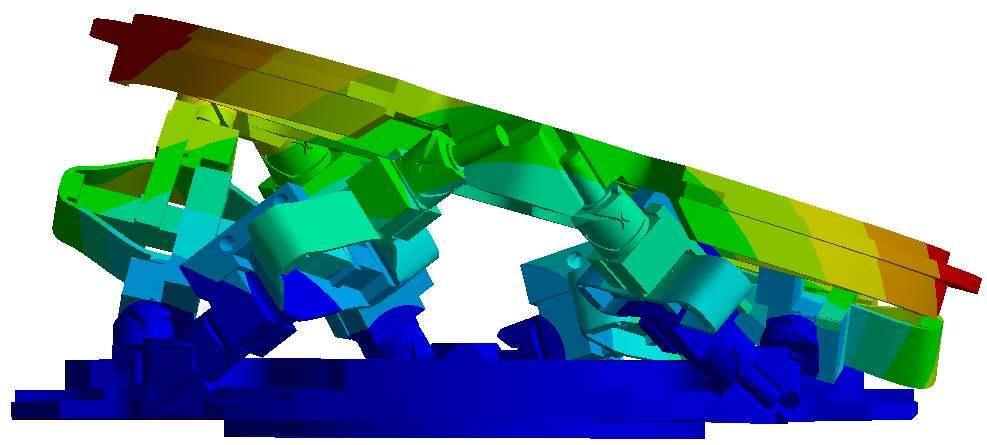

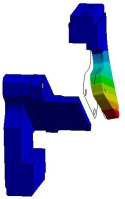

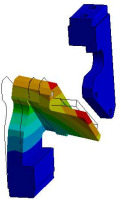

Finite element analysis of the complete active platform was performed to identify problematic modes (Figure ref:fig:detail_design_fem_nano_hexapod):

- First six modes were found to be "suspension" modes were the top plate moves as a rigid body, and the six struts are only moving axially (Figure ref:fig:detail_design_fem_rigid_body_mode)

-

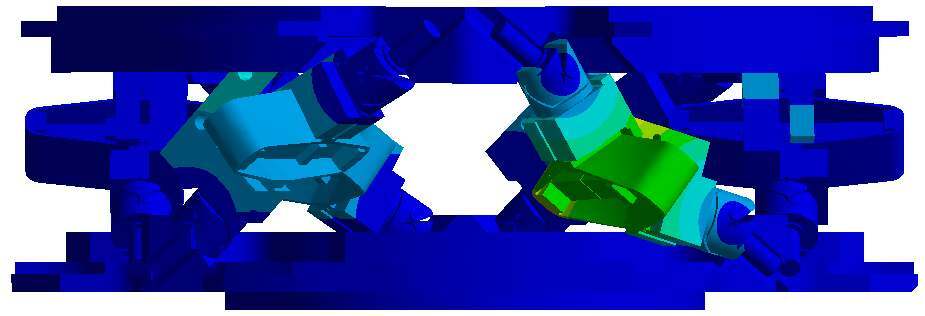

Then, between $205\,\text{Hz}$ and $420\,\text{Hz}$ many "local" modes of the struts were observed. On is represented in Figure ref:fig:detail_design_fem_strut_mode. While these modes seem not to induce any motion of the top platform, it induces a relative displacement of the encoder with respect to the ruler. Therefore, when controlling the position of the active platform using the encoders, such modes could be problematic. Whether these modes are problematic is difficult to estimate at this point as:

- it is not known if the APA will "excite" these modes

- theoretically, if the struts are well aligned, these modes should not be observed

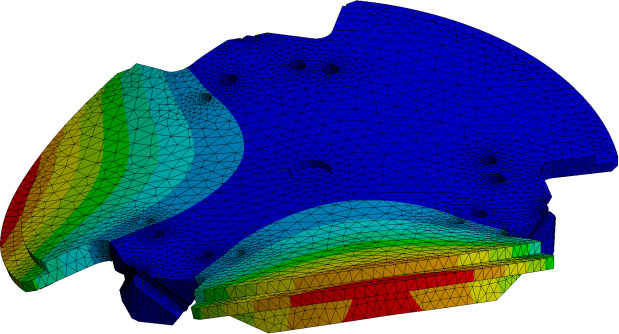

Then, flexible modes of the top plate are appearing above $650\,\text{Hz}$ (Figure ref:fig:detail_design_fem_plate_mode)

Alternative Encoder Placement

To anticipate potential issue with local modes of the struts, an alternative fixation for the encoder is planned:

- Instead of being fixed to the struts, the encoders are fixed to the plates instead, as shown in Figure ref:fig:detail_design_enc_plates_design.

- The support are made of aluminum, and it is verified that the natural modes are at high enough frequency (Figure ref:fig:detail_design_enc_support_modes).

- The positioning of the encoders are made using pockets in both plates as shown in Figure ref:fig:detail_design_top_plate.

- The encoders are aligned parallel to the struts, but yet they don't exactly measure the relative motion of each strut.

- This means that if relative motion of the active platform is performed based on the encoders, the accuracy of the motion may be affected. The issue is that the Kinematics may not be correct.

Multi-Body Model

<<sec:detail_design_model>>

Introduction ignore

Before all the mechanical parts were ordered, the multi-body model of the active platform was refined using the design parts.

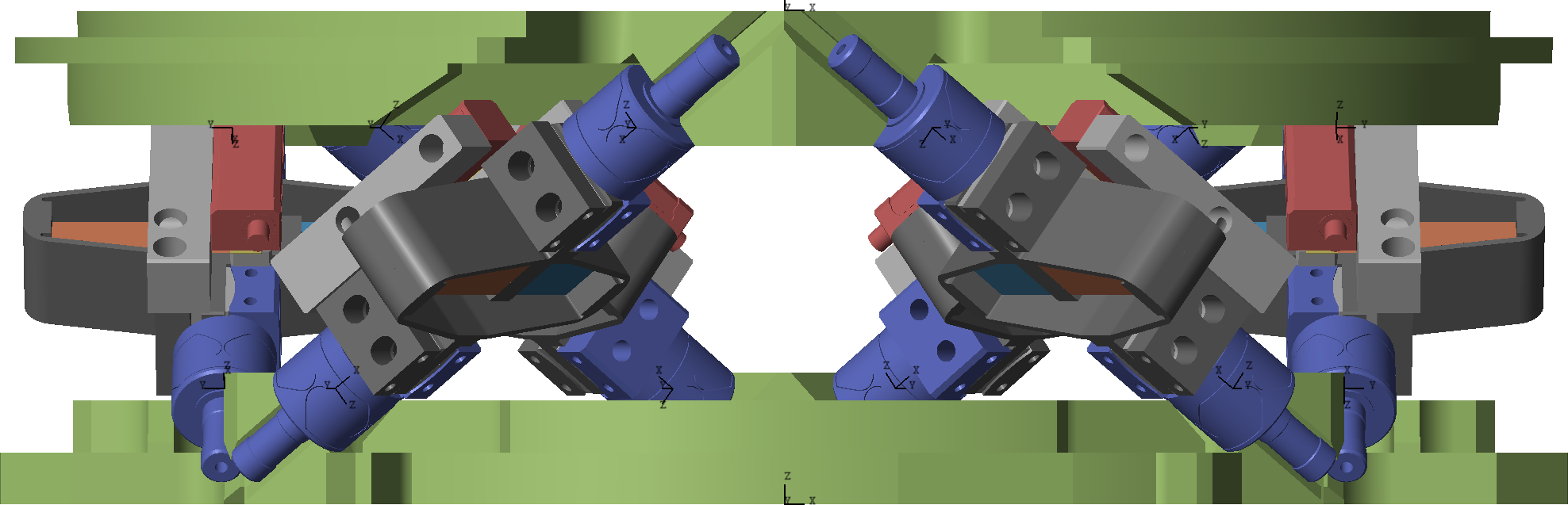

Two configurations, displayed in Figure ref:fig:detail_design_simscape_encoder, were considered:

- Encoders fixed to the struts

- Encoders fixed to the plates

Plates were modelled as rigid bodies, with inertia computed from the 3D shape.

Flexible Joints

Different models of the flexible joints where considered:

- 2DoF: only bending stiffnesses

- 3DoF: added torsional stiffness

- 4DoF: added axial stiffness

The multi-body model for the 4DoF configuration is shown in Figure ref:fig:detail_design_simscape_model_flexible_joint. It is composed of three solid bodies connected by joints whose stiffnesses are computed from the finite element model.

Amplified Piezoelectric Actuators

The amplified piezoelectric actuators are modelled as explained in Section [..].

Two different models can be used in the multi-body model:

- a 2DoF "axial" model

- a "super-element" extracted from the finite element model

Encoders

Up to now, relative displacement sensors were implemented as a relative distance measurement between $\bm{a}_i$ and $\bm{b}_i$.

As shown in the previous section, flexible modes of the struts may negatively impact the encoder signal. It was therefore necessary to better model the encoder.

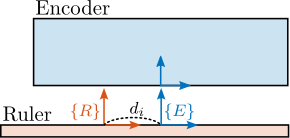

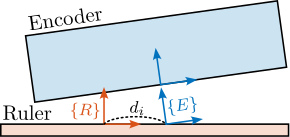

The optical encoder works:

- Encoder heads contains a light source shine on the ruler, and a photo-diode. This is represented by frame $\{E\}$ in Figure ref:fig:detail_design_simscape_encoder.

- ruler or scale with a grating (here with a $20\,\mu m$ pitch). A reference frame is indicated by $\{R\}$

Therefore, the measured displacement is the relative position of $\{E\}$ (i.e. there the light "hits" the scale) with respect to frame $\{R\}$, in the direction of the scale.

In that case, a rotation of the encoder, as shown in figure ref:fig:detail_design_simscape_encoder_disp induces a measured displacement.

Simulation

Based on this refined model:

- the active platform could be integrated on top of the micro-station's model.

- the obtained dynamics was considered good

- simulations of tomography experiments were performed, and similar performance were obtained as during the conceptual design

-

this is not presented here as results are very similar to the simulations performed in Section […]

Conclusion

<<sec:detail_design_conclusion>>