13 KiB

Flexible Joint - Measurement of the Bending Stiffness

- Introduction

- Finite Element Model

- Setup

- Effect of Bending

- Computation of the bending stiffness

- Effect of Shear

- Effect of Torsion

- Full stroke measured displacement and applied force as a function of $H$

- Negligible bending of the supporting bar

- Conclusion

Introduction ignore

The goal is to design a test bench to measure the bending stiffness of a flexible joint with 1% accuracy.

Finite Element Model

<<sec:fem>>

From the Finite Element Model, the stiffnesses and strokes of the flexible joint have been computed.

ka = 94e6; % Axial Stiffness [N/m]

ks = 13e6; % Shear Stiffness [N/m]

kb = 5; % Bending Stiffness [Nm/rad]

kt = 260; % Torsional Stiffness [Nm/rad]Fa = 469; % Axial Force before yield [N]

Fs = 242; % Shear Force before yield [N]

Fb = 0.118; % Bending Force before yield [Nm]

Ft = 1.508; % Torsional Force before yield [Nm]Xa = Fa/ka; % Axial Stroke before yield [m]

Xs = Fs/ks; % Shear Stroke before yield [m]

Xb = Fb/kb; % Bending Stroke before yield [rad]

Xt = Ft/kt; % Torsional Stroke before yield [rad]| Stiffness [N/um] | Max Force [N] | Stroke [um] | |

|---|---|---|---|

| Axial | 94 | 469 | 5 |

| Shear | 13 | 242 | 19 |

| Stiffness [Nm/rad] | Max Torque [Nmm] | Stroke [mrad] | |

|---|---|---|---|

| Bending | 5 | 118 | 24 |

| Torsional | 260 | 1508 | 6 |

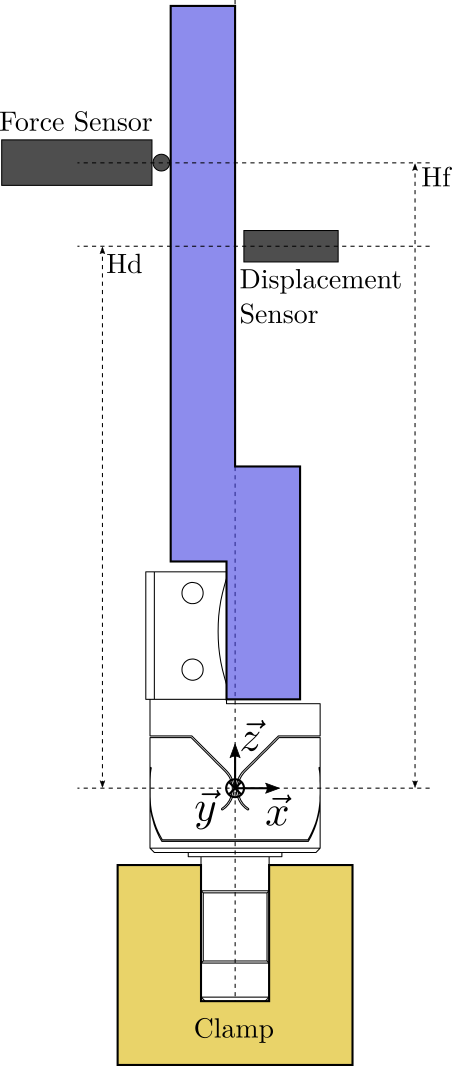

Setup

Effect of Bending

<<sec:bending>>

The torque applied is:

\begin{equation} M_b = F \cdot H_F \end{equation}The flexible joint is experiencing a rotation $R_b$ due to the torque $M_b$:

\begin{equation} R_b = \frac{M_b}{k_b} = \frac{F \cdot H_F}{k_b} \end{equation}This rotation is then measured by the displacement sensor. The measured displacement is:

\begin{equation} D_b = H_D \tan(R_b) = H_D \tan\left( \frac{F \cdot H_F}{k_b} \right) \label{eq:bending_meaured_disp} \end{equation}Computation of the bending stiffness

From equation eqref:eq:bending_meaured_disp, we can compute the bending stiffness:

\begin{equation} k_b = \frac{\tan^{-1}\left( \frac{D_b}{H_D} \right)}{F \cdot H_F} \end{equation}And therefore, to precisely measure $k_b$, we need to:

- precisely measure the motion $D_b$

- precisely measure the applied force $F$

- precisely know the height from the flexible joint's center to the measurement point $H_D$

- precisely know the height from the flexible joint's center to the force application point $H_F$

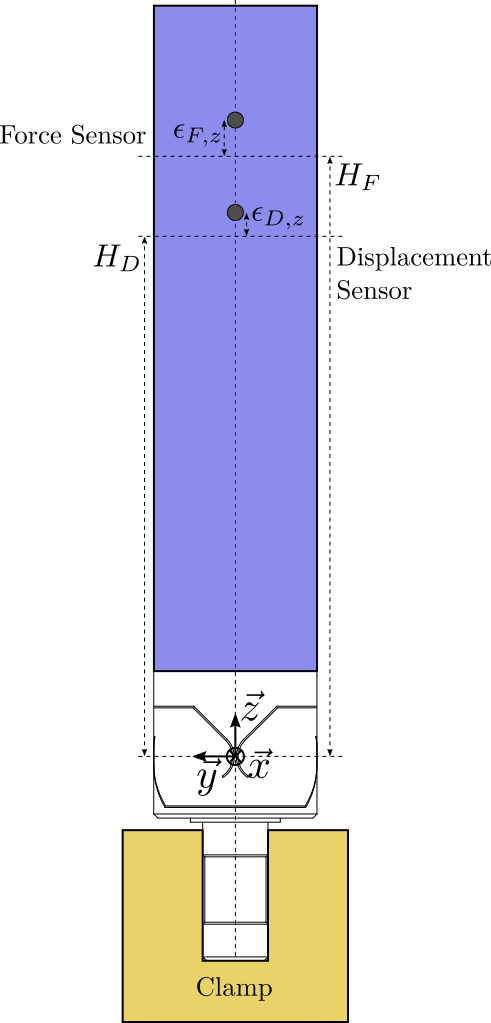

If there are estimation errors for $H_D$ or $H_F$ as shown in Figure fig:bending_effect_error_vertical, this will induce an error for the estimation of the stiffness.

For 1% accuracy estimation of $k_b$, we can write the following approximate requirements:

| Accuracy | |

|---|---|

| Force Measurement | 1% |

| Displacement Measurement | 1% |

| $H_D$ | 1% |

| $H_F$ | 1% |

Effect of Shear

<<sec:shear>>

The effect of Shear on the measured displacement is simply:

\begin{equation} D_s = \frac{F}{k_s} \end{equation}We would like to have this displacement much smaller than the displacement induced by the bending effects:

\begin{equation} D_b \gg D_s \end{equation}Which is equivalent as to have:

\begin{equation} H_D \tan\left( \frac{F \cdot H_F}{k_b} \right) \gg \frac{F}{k_s} \end{equation}Here to simplify, we suppose $FH_F/k_b \ll 1$ (which is the case in practice), and we suppose $H_D = H_F = H$.

The obtained condition is then:

\begin{equation} H \gg \frac{k_b}{k_s} \end{equation}| 10% error | 1% error | 0.1% error | |

|---|---|---|---|

| $H\,[mm]$ | 6 | 62 | 620 |

In order to limit the effect of shear of less than 1%, the height from the joint's center to the force application point and to the measurement point should be larger than 62mm.

H = 62e-3; % [m]Effect of Torsion

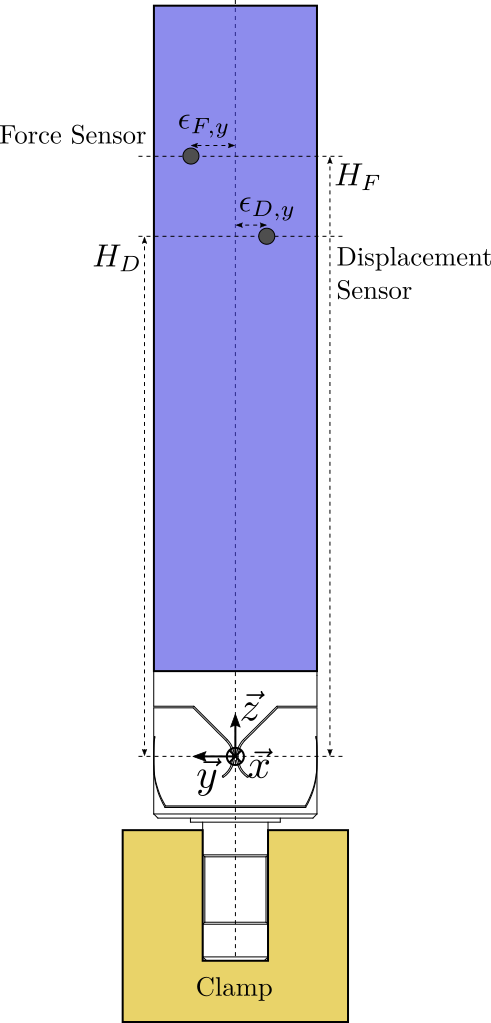

<<sec:torsion>>

If the application force is not aligned with the vertical axis of the flexible joint, this will induce a torsion motion that will induce a measurement error (Figure fig:bending_effect_torsion).

Let's note the offset of the force sensor $\epsilon_{F,y}$ and the offset of the measurement point $\epsilon_{D,y}$. The vertical torque (torsion) will be equal to:

\begin{equation} M_t = F \cdot \epsilon_{F,y} \end{equation}And the induced torsion:

\begin{equation} R_t = \frac{M_t}{k_t} = \frac{F \cdot \epsilon_{F,y}}{k_t} \end{equation}The effect on the measured displacement is:

\begin{equation} D_t = \epsilon_{D,y} \tan \left( R_t \right) = \epsilon_{D,y} \tan\left( \frac{F \cdot \epsilon_{F,y}}{k_t} \right) \end{equation}And we would like to have:

\begin{equation} D_b \gg D_t \end{equation}Which is equivalent as to have:

\begin{equation} H_D \tan\left( \frac{F \cdot H_F}{k_b} \right) \gg \epsilon_{D,y} \tan\left( \frac{F \cdot \epsilon_{F,y}}{k_t} \right) \end{equation}Supposing $H_F = H_D = H$ and $\epsilon_{F,y} = \epsilon_{D,y} = \epsilon_{y}$, the condition becomes:

\begin{equation} \epsilon_{y} \ll H \sqrt{\frac{k_t}{k_b}} \end{equation}| 10% error | 1% error | 0.1% error | |

|---|---|---|---|

| $\epsilon_y\,[mm]$ | 44.7 | 4.5 | 0.4 |

For 1% error, the lateral positioning errors $\epsilon_y$ for both the force sensor and the displacement sensor should be less than 4.5mm.

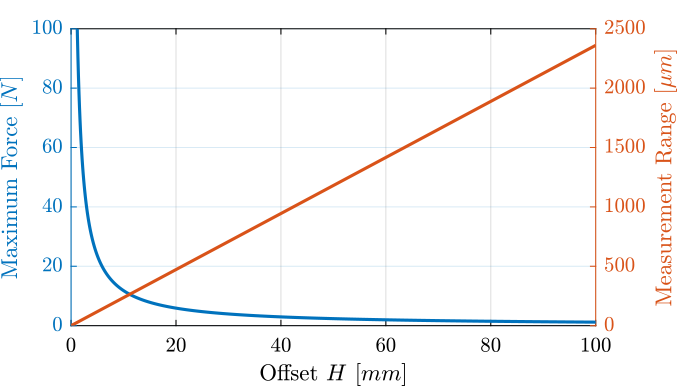

Full stroke measured displacement and applied force as a function of $H$

Applying a force with a large height $H$ means the induced rotation (for constant force) will be larger. This also means that the measured displacement $D_b$ will also be larger.

Note that we here suppose the force axis is co-linear with the measurement axis ($H_F = H_D = H$).

Let's compute:

- $D_b$ as a function of $H$ \[ D_b \approx H \tan (R_b) \]

- the applied force $F_{\text{max}}$ to induce the maximum rotation as a function of $H$ \[ F_{\text{max}} \approx \frac{X_b \cdot k_b}{H} \]

With an offset of 62mm, we obtained values shown in Table tab:disp_force_range.

| $D_b\,[mm]$ | $F_m\,[N]$ |

|---|---|

| 1.5 | 1.9 |

Negligible bending of the supporting bar

This should be confirmed with FEM.

Conclusion

| Range | Accuracy | |

|---|---|---|

| Force Measurement | 2 N | 1% = 0.02 N |

| Displacement Measurement | 1.5 mm | 1% = 15 um |

| Value | Precision | Comment | |

|---|---|---|---|

| $H_D$ | 62mm | For negligible Shear | |

| $H_F$ | 62mm | Same | |

| $\epsilon_y$ | 0 | 4.5mm | For negligible Torsion |

| $\epsilon_z$ | 0 | 1% = 0.6mm | For torque estimation precision |

Load cells:

- https://www.te.com/usa-en/product-CAT-FLS0020.html?q=&n=510872&d=681051%20564247&type=products&samples=N&inStoreWithoutPL=false&instock=N#mdp-tabs-content

- https://www.digikey.com/en/products/detail/honeywell-sensing-and-productivity-solutions/FSS005WNSB/6056404

Displacement sensors: