43 KiB

43 KiB

Glossary and Acronyms - Tables

| label | name | description |

|---|---|---|

| ka | \ensuremath{k_a} | Actuator Stiffness in |

| phi | \ensuremath{ɸ} | A woody bush |

| key | abbreviation | full form |

|---|---|---|

| mimo | MIMO | Multiple-Inputs Multiple-Outputs |

| siso | SISO | Single-Input Single-Output |

| nass | NASS | Nano Active Stabilization System |

| lti | LTI | Linear Time Invariant |

Title Page

Abstract

Résumé

Acknowledgments

Table of Contents

Introduction

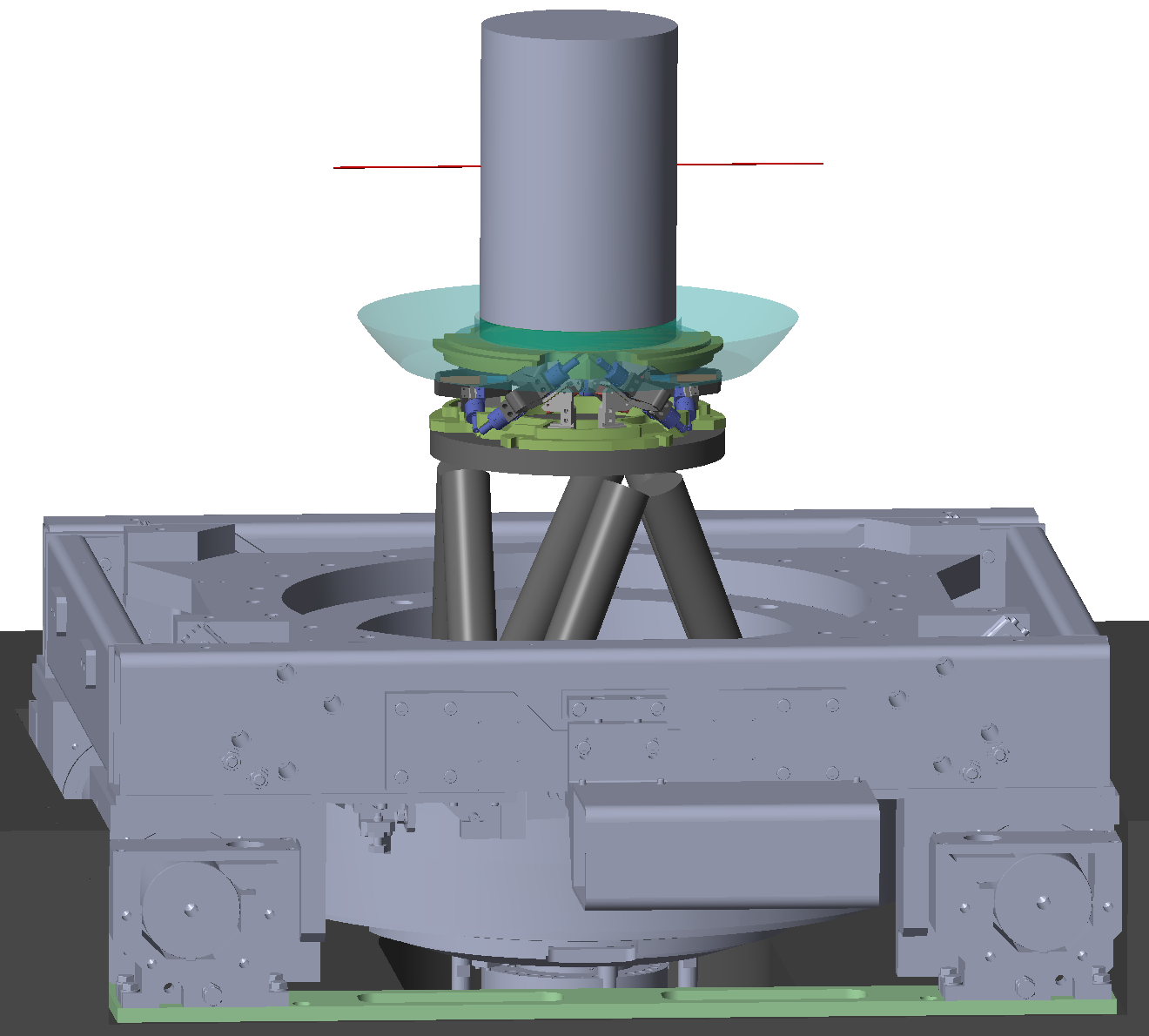

Context of this thesis / Background and Motivation

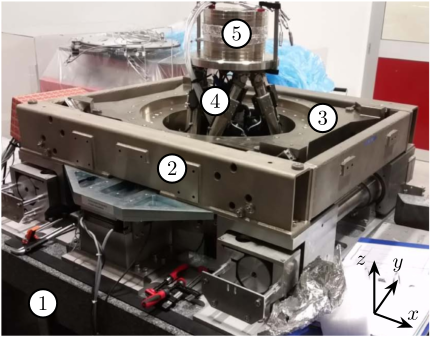

- ESRF (Figure fig:esrf_picture)

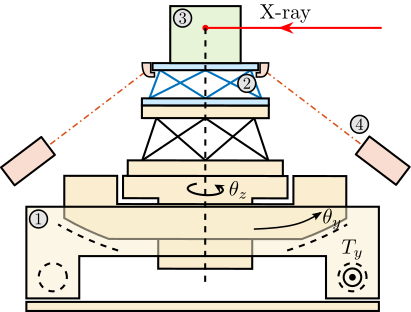

- ID31 and Micro Station (Figure fig:id31_microstation_picture)

\begin{tikzpicture}

\node[inner sep=0pt, anchor=south west] (photo) at (0,0)

{\includegraphics[width=0.39\textwidth]{/home/thomas/Cloud/documents/reports/phd-thesis/figs/exp_setup_photo.png}};

\coordinate[] (aheight) at (photo.north west);

\coordinate[] (awidth) at (photo.south east);

\coordinate[] (granite) at ($0.1*(aheight)+0.1*(awidth)$);

\coordinate[] (trans) at ($0.5*(aheight)+0.4*(awidth)$);

\coordinate[] (tilt) at ($0.65*(aheight)+0.75*(awidth)$);

\coordinate[] (hexapod) at ($0.7*(aheight)+0.5*(awidth)$);

\coordinate[] (sample) at ($0.9*(aheight)+0.55*(awidth)$);

% Granite

\node[labelc] at (granite) {1};

% Translation stage

\node[labelc] at (trans) {2};

% Tilt Stage

\node[labelc] at (tilt) {3};

% Micro-Hexapod

\node[labelc] at (hexapod) {4};

% Sample

\node[labelc] at (sample) {5};

% Axis

\begin{scope}[shift={($0.07*(aheight)+0.87*(awidth)$)}]

\draw[->] (0, 0) -- ++(55:0.7) node[above] {$y$};

\draw[->] (0, 0) -- ++(90:0.9) node[left] {$z$};

\draw[->] (0, 0) -- ++(-20:0.7) node[above] {$x$};

\end{scope}

\end{tikzpicture}

Alternative: id31_microstation_cad_view.png (CAD view)

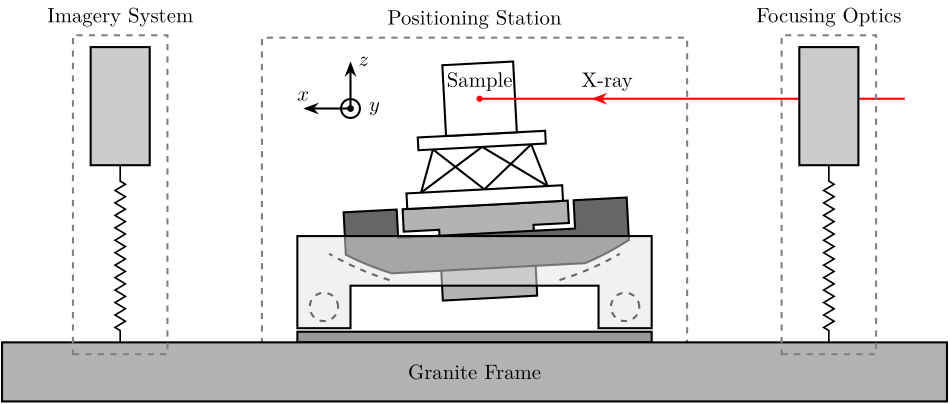

- X-ray beam + detectors + sample stage (Figure fig:id31_beamline_schematic)

\begin{tikzpicture}

% Parameters

\def\blockw{6.0cm}

\def\blockh{1.2cm}

\def\tiltdeg{3}

\coordinate[] (rotationpoint) at (0, 4.5*\blockh);

\begin{scope}[rotate around={\tiltdeg:(rotationpoint)}]

% Tilt

\path[] ([shift=(-120:4*\blockh)]rotationpoint) coordinate(beginarc) arc (-120:-110:4*\blockh) %

-- ([shift=(-70:4*\blockh)]rotationpoint) arc (-70:-60:4*\blockh)%

|- ++(-0.15*\blockw, 0.6*\blockh) coordinate (spindlene)%

|- ($(beginarc) + (0.15*\blockw, 0.2*\blockh)$) coordinate (spindlesw) -- ++(0, 0.4*\blockh) coordinate(tiltte) -| cycle;

% Spindle

\coordinate[] (spindlese) at (spindlesw-|spindlene);

\draw[fill=black!30] ($(spindlese)+(-0.1,0.1)+(-0.1*\blockw, 0)$) -| ($(spindlene)+(-0.1, 0)$) -| coordinate[pos=0.25](spindletop) ($(spindlesw)+(0.1,0.1)$) -| ++(0.1*\blockw, -\blockh) -| coordinate[pos=0.25](spindlebot) cycle;

% \draw[dashed, color=black!60] ($(spindletop)+(0, 0.2)$) -- ($(spindlebot)+(0,-0.2)$);

% Tilt

\draw[fill=black!60] ([shift=(-120:4*\blockh)]rotationpoint) coordinate(beginarc) arc (-120:-110:4*\blockh) %

-- ([shift=(-70:4*\blockh)]rotationpoint) arc (-70:-60:4*\blockh)%

|- coordinate (tiltne) ++(-0.15*\blockw, 0.6*\blockh) coordinate (spindlene)%

|- ($(beginarc) + (0.15*\blockw, 0.2*\blockh)$) coordinate (spindlesw) -- ++(0, 0.4*\blockh) -| cycle;

% Micro-Hexapod

\begin{scope}[shift={(spindletop)}]

% Parameters definitions

\def\baseh{0.22*\blockh} % Height of the base

\def\naceh{0.18*\blockh} % Height of the nacelle

\def\baser{0.22*\blockw} % Radius of the base

\def\nacer{0.18*\blockw} % Radius of the nacelle

\def\armr{0.2*\blockh} % Radius of the arms

\def\basearmborder{0.2}

\def\nacearmborder{0.2}

\def\xnace{0} \def\ynace{\blockh-\naceh} \def\anace{0}

\def\xbase{0} \def\ybase{0} \def\abase{0}

% Hexapod1

\begin{scope}[shift={(\xbase, \ybase)}, rotate=\abase]

% Base

\draw[fill=white] (-\baser, 0) coordinate[](uhexabot) rectangle (\baser, \baseh);

\coordinate[] (armbasel) at (-\baser+\basearmborder+\armr, \baseh);

\coordinate[] (armbasec) at (0, \baseh);

\coordinate[] (armbaser) at (\baser-\basearmborder-\armr, \baseh);

\begin{scope}[shift={(\xnace, \ynace)}, rotate=\anace]

\draw[fill=white] (-\nacer, 0) rectangle (\nacer, \naceh);

\coordinate[] (uhexatop) at (0, \naceh);

\coordinate[] (armnacel) at (-\nacer+\nacearmborder+\armr, 0);

\coordinate[] (armnacec) at (0, 0);

\coordinate[] (armnacer) at (\nacer-\nacearmborder-\armr, 0);

\end{scope}

\draw[] (armbasec) -- (armnacer);

\draw[] (armbasec) -- (armnacel);

\draw[] (armbasel) -- coordinate(mhexaw) (armnacel);

\draw[] (armbasel) -- (armnacec);

\draw[] (armbaser) -- (armnacec);

\draw[] (armbaser) -- coordinate(mhexae) (armnacer);

\end{scope}

\end{scope}

% Sample

\begin{scope}[shift={(uhexatop)}]

\draw[fill=white] (-0.1*\blockw, 0) coordinate[](samplebot) rectangle coordinate[pos=0.5](samplecenter) node[pos=0.5, above]{Sample} (0.1*\blockw, \blockh) coordinate[](samplene);

\coordinate[](samplenw) at (-0.1*\blockw, \blockh);

\end{scope}

\end{scope}

\begin{scope}[shift={(0, -0.3*\blockh)}]

% Translation Stage - fixed part

\draw[fill=black!40] (-0.5*\blockw, 0) coordinate[](tyb) rectangle (0.5*\blockw, 0.15*\blockh);

\coordinate[] (measposbot) at (0.5*\blockw, 0);

% Translation Stage - mobile part

\draw[fill=black!10, fill opacity=0.5] (-0.5*\blockw, 0.2*\blockh) -- (-0.5*\blockw, 1.5*\blockh) coordinate[](tyt) -- (0.5*\blockw, 1.5*\blockh) -- (0.5*\blockw, 0.2*\blockh) -- (0.35*\blockw, 0.2*\blockh) -- (0.35*\blockw, 0.8*\blockh) -- (-0.35*\blockw, 0.8*\blockh) -- (-0.35*\blockw, 0.2*\blockh) -- cycle;

% Translation Guidance

\draw[dashed, color=black!60] ($(-0.5*\blockw, 0)+( 0.075*\blockw,0.5*\blockh)$) circle (0.2*\blockh);

\draw[dashed, color=black!60] ($( 0.5*\blockw, 0)+(-0.075*\blockw,0.5*\blockh)$) circle (0.2*\blockh);

% Tilt Guidance

\draw[dashed, color=black!60] ([shift=(-107:4.1*\blockh)]rotationpoint) arc (-107:-120:4.1*\blockh);

\draw[dashed, color=black!60] ([shift=( -73:4.1*\blockh)]rotationpoint) arc (-73:-60:4.1*\blockh);

\end{scope}

% % Vertical line

% \draw[dashed, color=black] (samplecenter) -- ++(0, -4*\blockh);

% \begin{scope}[rotate around={\tiltdeg:(samplecenter)}]

% \draw[dashed, color=black] (samplecenter) -- ++(0, -4*\blockh);

% \node[] at ($(samplecenter)+(0, -2.3*\blockh)$) {\AxisRotator[rotate=-90]};

% \node[right, shift={(0.3,0)}] at ($(samplecenter)+(0, -2.3*\blockh)$) {$\theta_z$};

% \end{scope}

% \draw[->] ([shift=(-90:3.6*\blockh)]samplecenter) arc (-90:-87:3.6*\blockh) node[right]{$\theta_y$};

% Laser

\begin{scope}[shift={(samplecenter)}]

\draw[color=red, -<-=0.3] (samplecenter) node[circle, fill=red, inner sep=0pt, minimum size=3pt]{} -- node[pos=0.3, above, color=black]{X-ray} ($(samplecenter)+(1.2*\blockw,0)$);

\end{scope}

% Axis

\begin{scope}[shift={(-0.35*\blockw, 3*\blockh)}]

\def\axissize{0.8cm}

\draw[->] (0, 0) -- ++(0, \axissize) node[right]{$z$};

\draw[->] (0, 0) -- ++(-\axissize, 0) node[above]{$x$};

\draw[fill, color=black] (0, 0) circle (0.05*\axissize);

\node[draw, circle, inner sep=0pt, minimum size=0.4*\axissize, label=right:$y$] (yaxis) at (0, 0){};

% \node[draw, circle, inner sep=0pt, cross, minimum size=0.4*\axissize, label=left:$y$] (yaxis) at (0, 0){};

\end{scope}

\node[fit={($(-0.6*\blockw, -0.5*\blockh)$) ($(0.6*\blockw, 4*\blockh)$)}, inner sep=0pt, draw, dashed, color=gray, label={Positioning Station}] (possystem) {};

\draw[fill=black!30] ($(tyb)+(-5, -1)$) coordinate[](granitesw) rectangle node[pos=0.5]{Granite Frame} ($(measposbot)+(5, 0)$) coordinate[](granitene);

% Focusing Optics

\draw[fill=black!20] ($(granitene)+(-1.5, 3)$) rectangle ++(-1, 2);

\draw[spring] ($(granitene)+(-2, 0)$) -- ++(0, 3);

\node[fit={($(granitene)+(-2.8, -0.2)$) ($(granitene)+(-1.2, 5.2)$)}, inner sep=0pt, draw, dashed, color=gray, label={Focusing Optics}] () {};

% Measurement Optics

\draw[fill=black!20] ($(granitesw)+(1.5, 4)$) rectangle ++(1, 2);

\draw[spring] ($(granitesw)+(2, 1)$) -- ++(0, 3);

\node[fit={($(granitesw)+(2.8, 0.8)$) ($(granitesw)+(1.2, 6.2)$)}, inner sep=0pt, draw, dashed, color=gray, label={Imagery System}] () {};

\end{tikzpicture}- Few words about science made on ID31 and why nano-meter accuracy is required

- Typical experiments (tomography, …), various samples (up to 50kg)

- Example of picture obtained (Figure fig:id31_tomography_result)

- Explain wanted positioning accuracy and why micro-station cannot have this accuracy (backlash, play, thermal expansion, …)

Challenge definition

- 6DoF vibration control platform on top of a complex positioning platform

- Goal: Improve accuracy of 6DoF long stroke position platform

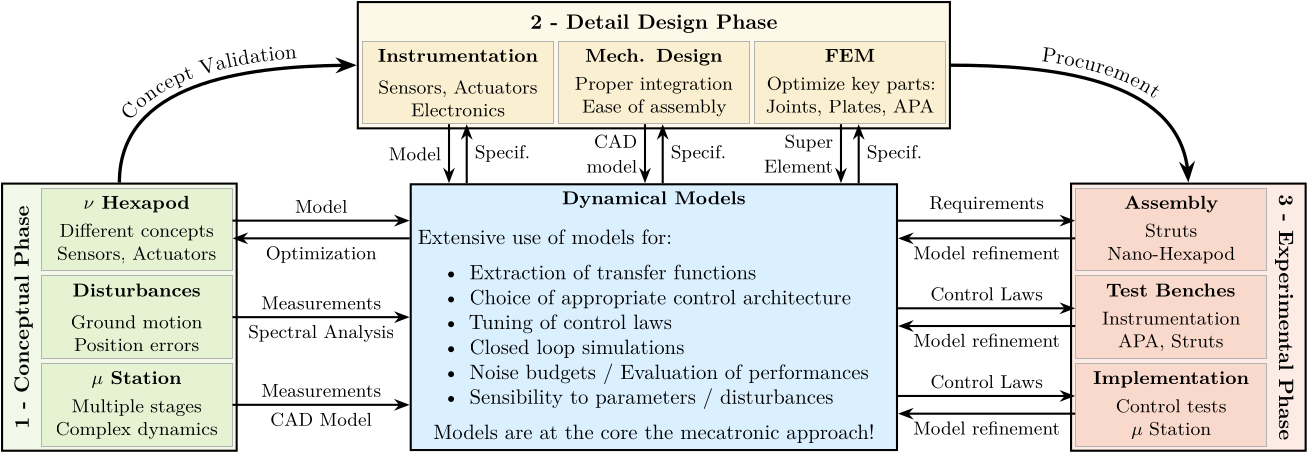

- Approach: Mechatronic approach / model based / predictive

- Control: Robust control approach / various payloads. First hexapod with control bandwidth higher than the suspension modes that accepts various payloads?

- Rotation aspect

- Compactness? (more related to mechanical design)

Literature Review

- Hexapods cite:li01_simul_fault_vibrat_isolat_point cite:bishop02_devel_precis_point_contr_vibrat cite:hanieh03_activ_stewar cite:afzali-far16_vibrat_dynam_isotr_hexap_analy_studies cite:naves20_desig

- Positioning stations

- Mechatronic approach? cite:rankers98_machin cite:monkhorst04_dynam_error_budget cite:jabben07_mechat

Outline of thesis / Thesis Summary / Thesis Contributions

Mechatronic Design Approach / Model Based Design:

- cite:&monkhorst04_dynam_error_budget high costs of the design process: the designed system must be first time right. When the system is finally build, its performance level should satisfy the specifications. No significant changes are allowed in the post design phase. Because of this, the designer wants to be able to predict the performance of the system a-priori and gain insight in the performance limiting factors of the system.

% \graphicspath{ {/home/thomas/Cloud/thesis/papers/dehaeze21_mechatronics_approach_nass/tikz/figs-tikz} }

\begin{tikzpicture}

% Styles

\tikzset{myblock/.style= {draw, thin, color=white!70!black, fill=white, text width=3cm, align=center, minimum height=1.4cm}};

\tikzset{mylabel/.style= {anchor=north, below, font=\bfseries\small, color=black, text width=3cm, align=center}};

\tikzset{mymodel/.style= {anchor=south, above, font=\small, color=black, text width=3cm, align=center}};

\tikzset{mystep/.style= {->, ultra thick}};

% Blocks

\node[draw, fill=lightblue, align=center, label={[mylabel, text width=8.0cm] Dynamical Models}, minimum height = 4.5cm, text width = 8.0cm] (model) at (0, 0) {};

\node[myblock, fill=lightgreen, label={[mylabel] Disturbances}, left = 3 of model.west] (dist) {};

\node[myblock, fill=lightgreen, label={[mylabel] $\mu$ Station}, below = 2pt of dist] (mustation) {};

\node[myblock, fill=lightgreen, label={[mylabel] $\nu$ Hexapod}, above = 2pt of dist] (nanohexapod) {};

\node[myblock, fill=lightyellow, label={[mylabel] Mech. Design}, above = 1 of model.north] (mechanical) {};

\node[myblock, fill=lightyellow, label={[mylabel] Instrumentation}, left = 2pt of mechanical] (instrumentation) {};

\node[myblock, fill=lightyellow, label={[mylabel] FEM}, right = 2pt of mechanical] (fem) {};

\node[myblock, fill=lightred, label={[mylabel] Test Benches}, right = 3 of model.east] (testbenches) {};

\node[myblock, fill=lightred, label={[mylabel] Assembly}, above = 2pt of testbenches] (mounting) {};

\node[myblock, fill=lightred, label={[mylabel] Implementation}, below = 2pt of testbenches] (implementation) {};

% Text

\node[anchor=south, above, text width=8cm, align=left] at (model.south) {Extensive use of models for:\begin{itemize}[noitemsep,topsep=5pt]\item Extraction of transfer functions \\ \item Choice of appropriate control architecture \\ \item Tuning of control laws \\ \item Closed loop simulations \\ \item Noise budgets / Evaluation of performances \\ \item Sensibility to parameters / disturbances\end{itemize}\centerline{Models are at the core the mecatronic approach!}};

\node[mymodel] at (mustation.south) {Multiple stages \\ Complex dynamics};

\node[mymodel] at (dist.south) {Ground motion \\ Position errors};

\node[mymodel] at (nanohexapod.south) {Different concepts \\ Sensors, Actuators};

\node[mymodel] at (instrumentation.south) {Sensors, Actuators \\ Electronics};

\node[mymodel] at (mechanical.south) {Proper integration \\ Ease of assembly};

\node[mymodel] at (fem.south) {Optimize key parts: \\ Joints, Plates, APA};

\node[mymodel] at (mounting.south) {Struts \\ Nano-Hexapod};

\node[mymodel] at (testbenches.south) {Instrumentation \\ APA, Struts};

\node[mymodel] at (implementation.south) {Control tests \\ $\mu$ Station};

% Links

\draw[->] (dist.east) -- node[above, midway]{{\small Measurements}} node[below,midway]{{\small Spectral Analysis}} (dist.east-|model.west);

\draw[->] (mustation.east) -- node[above, midway]{{\small Measurements}} node[below, midway]{{\small CAD Model}} (mustation.east-|model.west);

\draw[->] ($(nanohexapod.east-|model.west)-(0, 0.15)$) -- node[below, midway]{{\small Optimization}} ($(nanohexapod.east)-(0, 0.15)$);

\draw[<-] ($(nanohexapod.east-|model.west)+(0, 0.15)$) -- node[above, midway]{{\small Model}} ($(nanohexapod.east)+(0, 0.15)$);

\draw[->] ($(fem.south|-model.north)+(0.15, 0)$) -- node[right, midway]{{\small Specif.}} ($(fem.south)+(0.15,0)$);

\draw[<-] ($(fem.south|-model.north)-(0.15, 0)$) -- node[left, midway,align=right]{{\small Super}\\{\small Element}} ($(fem.south)-(0.15,0)$);

\draw[->] ($(mechanical.south|-model.north)+(0.15, 0)$) -- node[right, midway]{{\small Specif.}} ($(mechanical.south)+(0.15,0)$);

\draw[<-] ($(mechanical.south|-model.north)-(0.15, 0)$) -- node[left, midway,align=right]{{\small CAD}\\{\small model}} ($(mechanical.south)-(0.15,0)$);

\draw[->] ($(instrumentation.south|-model.north)+(0.15, 0)$) -- node[right, midway]{{\small Specif.}} ($(instrumentation.south)+(0.15,0)$);

\draw[<-] ($(instrumentation.south|-model.north)-(0.15, 0)$) -- node[left, midway]{{\small Model}} ($(instrumentation.south)-(0.15,0)$);

\draw[->] ($(mounting.west-|model.east)+(0, 0.15)$) -- node[above, midway]{{\small Requirements}} ($(mounting.west)+(0, 0.15)$);

\draw[<-] ($(mounting.west-|model.east)-(0, 0.15)$) -- node[below, midway]{{\small Model refinement}} ($(mounting.west)-(0, 0.15)$);

\draw[->] ($(testbenches.west-|model.east)+(0, 0.15)$) -- node[above, midway]{{\small Control Laws}} ($(testbenches.west)+(0, 0.15)$);

\draw[<-] ($(testbenches.west-|model.east)-(0, 0.15)$) -- node[below, midway]{{\small Model refinement}} ($(testbenches.west)-(0, 0.15)$);

\draw[->] ($(implementation.west-|model.east)+(0, 0.15)$) -- node[above, midway]{{\small Control Laws}} ($(implementation.west)+(0, 0.15)$);

\draw[<-] ($(implementation.west-|model.east)-(0, 0.15)$) -- node[below, midway]{{\small Model refinement}} ($(implementation.west)-(0, 0.15)$);

% Main steps

\node[font=\bfseries, rotate=90, anchor=south, above] (conceptual_phase_node) at (dist.west) {1 - Conceptual Phase};

\node[font=\bfseries, above] (detailed_phase_node) at (mechanical.north) {2 - Detail Design Phase};

\node[font=\bfseries, rotate=-90, anchor=south, above] (implementation_phase_node) at (testbenches.east) {3 - Experimental Phase};

\begin{scope}[on background layer]

\node[fit={(conceptual_phase_node.north|-nanohexapod.north) (mustation.south east)}, fill=lightgreen!50!white, draw, inner sep=2pt] (conceptual_phase) {};

\node[fit={(detailed_phase_node.north-|instrumentation.west) (fem.south east)}, fill=lightyellow!50!white, draw, inner sep=2pt] (detailed_phase) {};

\node[fit={(implementation_phase_node.north|-mounting.north) (implementation.south west)}, fill=lightred!50!white, draw, inner sep=2pt] (implementation_phase) {};

% \node[above left] at (dob.south east) {DOB};

\end{scope}

% Between main steps

\draw[mystep, postaction={decorate,decoration={raise=1ex,text along path,text align=center,text={Concept Validation}}}] (conceptual_phase.north) to[out=90, in=180] (detailed_phase.west);

\draw[mystep, postaction={decorate,decoration={raise=1ex,text along path,text align=center,text={Procurement}}}] (detailed_phase.east) to[out=0, in=90] (implementation_phase.north);

% % Inside Model

% \node[inner sep=1pt, outer sep=6pt, anchor=north west, draw, fill=white, thin] (multibodymodel) at ($(model.north west) - (0, 0.5)$)

% {\includegraphics[width=5.6cm]{simscape_nano_hexapod.png}};

% \node[inner sep=1pt, outer sep=6pt, anchor=south west, draw, fill=white, thin] (simscape) at (model.south west)

% {\includegraphics[width=5.6cm]{simscape_picture.jpg}};

% % Feedback Model

% \node[inner sep=3pt, outer sep=6pt, anchor=north east, draw, fill=white, thin] (simscape_sim) at ($(model.north east) - (0, 0.5)$)

% {\includegraphics[width=3.6cm]{simscape_simulations.pdf}};

% % FeedBack

% \node[inner sep=3pt, outer sep=6pt, anchor=south east, draw, fill=white, thin] (feedback) at (model.south east)

% {\includegraphics[width=3.6cm]{classical_feedback_small.pdf}};

\end{tikzpicture}Conceptual Design Development

minitoc

Abstract

Schematic that summarizes this phase. Uniaxial => Rotation => Multi body => Simulations

Constrains on the system

- Size

- Payload

- Connections to samples

-

… should justify the nano-hexapod design

- choice of parallel architecture

- Picture/schematic of the micro-station with indicated location of Nano-Hexapod

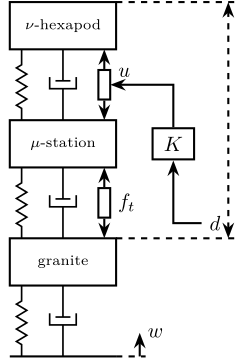

Uni-axial Model

Introduction

- Explain what we want to capture with this model

- Schematic of the uniaxial model (with X-ray)

- Identification of disturbances (ground motion, stage vibrations)

- Optimal nano-hexapod stiffness/actuator: Voice coil VS Piezo (conclusion?)

- Control architecture (IFF, DVF, …)?

- Conclusion

\begin{tikzpicture}

% ====================

% Parameters

% ====================

\def\bracs{0.05} % Brace spacing vertically

\def\brach{-12pt} % Brace shift horizontaly

% ====================

% ====================

% Ground

% ====================

\draw (-0.9, 0) -- (0.9, 0);

\draw[dashed] (0.9, 0) -- ++(0.5, 0);

\draw[->] (1.3, 0) -- ++(0, 0.4) node[right]{$w$};

% ====================

% ====================

% Granite

\begin{scope}[shift={(0, 0)}]

\draw[fill=white] (-0.9, 1.2) rectangle (0.9, 2.0) node[pos=0.5]{$\scriptstyle\text{granite}$};

\draw[spring] (-0.7, 0) -- ++(0, 1.2);

\draw[damper] ( 0, 0) -- ++(0, 1.2);

\draw[dashed] ( 0.9, 2.0) -- ++(2.0, 0) coordinate(xg);

% \draw[decorate, decoration={brace, amplitude=8pt}, xshift=\brach] %

% (-0.9, \bracs) -- ++(0, 2.0) node[midway,rotate=90,anchor=south,yshift=10pt]{Granite};

\end{scope}

% ====================

% ====================

% Stages

\begin{scope}[shift={(0, 2.0)}]

\draw[fill=white] (-0.9, 1.2) rectangle (0.9, 2.0) node[pos=0.5]{$\scriptstyle\mu\text{-station}$};

\coordinate (mustation) at (0.9, 1.6);

\draw[spring] (-0.7, 0) -- ++(0, 1.2);

\draw[damper] ( 0, 0) -- ++(0, 1.2);

\draw[actuator] ( 0.7, 0) -- ++(0, 1.2) node[midway, right=0.1](ft){$f_t$};

% \draw[decorate, decoration={brace, amplitude=8pt}, xshift=\brach] %

% (-0.9, \bracs) -- ++(0, 2.0) node[midway,rotate=90,anchor=south,yshift=10pt]{$\mu\text{-station}$};

\end{scope}

% ====================

% ====================

% NASS

\begin{scope}[shift={(0, 4.0)}]

\draw[fill=white] (-0.9, 1.2) rectangle (0.9, 2.0) node[pos=0.5]{$\scriptstyle\nu\text{-hexapod}$};

\draw[dashed] (0.9, 2.0) -- ++(2.0, 0) coordinate(xnpos);

\draw[spring] (-0.7, 0) -- ++(0, 1.2) node[midway, left=0.1]{};

\draw[damper] ( 0, 0) -- ++(0, 1.2) node[midway, left=0.2]{};

\draw[actuator] ( 0.7, 0) -- ++(0, 1.2) coordinate[midway, right=0.1](f);

% \draw[decorate, decoration={brace, amplitude=8pt}, xshift=\brach] %

% (-0.9, \bracs) -- ++(0, 2.2) node[midway,rotate=90,anchor=south,yshift=10pt]{$\nu\text{-hexapod}$};

\end{scope}

% ====================

% ====================

% Measured Displacement

\draw[<->, dashed] ($(xg)+(-0.1, 0)$) node[above left](d){$d$} -- ($(xnpos)+(-0.1, 0)$);

% ====================

% ====================

% IFF Control

% \node[block={2em}{1.5em}, right=0.6 of fsensn] (iff) {$K_{\scriptscriptstyle IFF}$};

% \node[addb] (ctrladd) at (f-|iff) {};

\node[block={2em}{1.5em}, right=0.6 of mustation] (ctrl) {$K$};

% \draw[->] (fsensn.east) -- node[midway, above]{$\tau_m$} (iff.west);

% \draw[->] (iff.south) -- (ctrladd.north);

% \draw[->] (ctrladd.west) -- (f.east) node[above right]{$u$};

\draw[->] (d.west) -| (ctrl.south);

\draw[->] (ctrl.north) |- (f) node[above right]{$u$};

% ====================

\end{tikzpicture}Effect of support compliance

- goal: make the nano-hexapod independent of the support compliance

- Simple 2DoF model

- Generalized to any support compliance

- conclusion: frequency of nano-hexapod resonances should be lower than first suspension mode of the support

Effect of payload dynamics

- goal: be robust to a change of payload

- Simple 2DoF model

- Generalized to any payload dynamics

Active Damping

Conclusion: IFF is better for this application

Integral Force Feedback

- Mass spring damper model

- Root Locus

- Sensitivity to disturbances

Direct Velocity Feedback

- Mass spring damper model

- Root Locus

- Sensitivity to disturbances

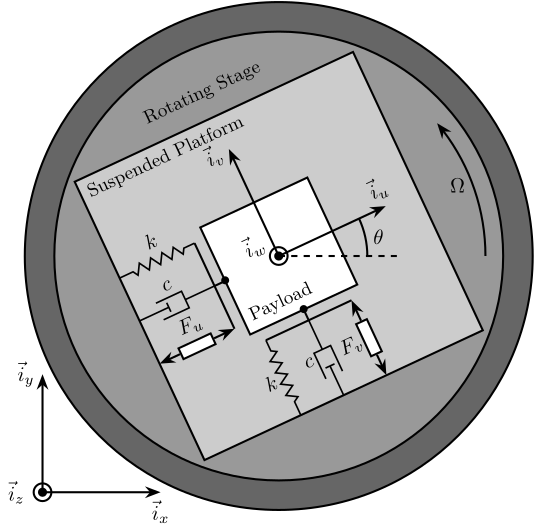

Effect of rotation

Introduction

X-Y rotating platform model

- x-y-Rz model

- explain why this is representing the NASS

- Equation of motion

- Centrifugal forces, Coriolis

\begin{tikzpicture}

% Angle

\def\thetau{25}

% Rotational Stage

\draw[fill=black!60!white] (0, 0) circle (4.3);

\draw[fill=black!40!white] (0, 0) circle (3.8);

% Label

\node[anchor=north west, rotate=\thetau] at (-2.5, 2.5) {\small Rotating Stage};

% Rotating Scope

\begin{scope}[rotate=\thetau]

% Rotating Frame

\draw[fill=black!20!white] (-2.6, -2.6) rectangle (2.6, 2.6);

% Label

\node[anchor=north west, rotate=\thetau] at (-2.6, 2.6) {\small Suspended Platform};

% Mass

\draw[fill=white] (-1, -1) rectangle (1, 1);

% Label

\node[anchor=south west, rotate=\thetau] at (-1, -1) {\small Payload};

% Attached Points

\node[] at (-1, 0){$\bullet$};

\draw[] (-1, 0) -- ++(-0.2, 0) coordinate(cu);

\draw[] ($(cu) + (0, -0.8)$) coordinate(actu) -- ($(cu) + (0, 0.8)$) coordinate(ku);

\node[] at (0, -1){$\bullet$};

\draw[] (0, -1) -- ++(0, -0.2) coordinate(cv);

\draw[] ($(cv) + (-0.8, 0)$)coordinate(kv) -- ($(cv) + (0.8, 0)$) coordinate(actv);

% Spring and Actuator for U

\draw[actuator={0.6}{0.2}] (actu) -- node[above=0.1, rotate=\thetau]{$F_u$} (actu-|-2.6,0);

\draw[spring=0.2] (ku) -- node[above=0.1, rotate=\thetau]{$k$} (ku-|-2.6,0);

\draw[damper={8}{8}] (cu) -- node[above left=0.2 and -0.1, rotate=\thetau]{$c$} (cu-|-2.6,0);

\draw[actuator={0.6}{0.2}] (actv) -- node[left, rotate=\thetau]{$F_v$} (actv|-0,-2.6);

\draw[spring=0.2] (kv) -- node[left, rotate=\thetau]{$k$} (kv|-0,-2.6);

\draw[damper={8}{8}] (cv) -- node[left=0.1, rotate=\thetau]{$c$} (cv|-0,-2.6);

\end{scope}

% Inertial Frame

\draw[->] (-4, -4) -- ++(2, 0) node[below]{$\vec{i}_x$};

\draw[->] (-4, -4) -- ++(0, 2) node[left]{$\vec{i}_y$};

\draw[fill, color=black] (-4, -4) circle (0.06);

\node[draw, circle, inner sep=0pt, minimum size=0.3cm, label=left:$\vec{i}_z$] at (-4, -4){};

\draw[->] (0, 0) node[above left, rotate=\thetau]{$\vec{i}_w$} -- ++(\thetau:2) node[above, rotate=\thetau]{$\vec{i}_u$};

\draw[->] (0, 0) -- ++(\thetau+90:2) node[left, rotate=\thetau]{$\vec{i}_v$};

\draw[fill, color=black] (0,0) circle (0.06);

\node[draw, circle, inner sep=0pt, minimum size=0.3cm] at (0, 0){};

\draw[dashed] (0, 0) -- ++(2, 0);

\draw[] (1.5, 0) arc (0:\thetau:1.5) node[midway, right]{$\theta$};

\draw[->] (3.5, 0) arc (0:40:3.5) node[midway, left]{$\Omega$};

\end{tikzpicture}Effect of rotational velocity on the system dynamics

- Campbell diagram

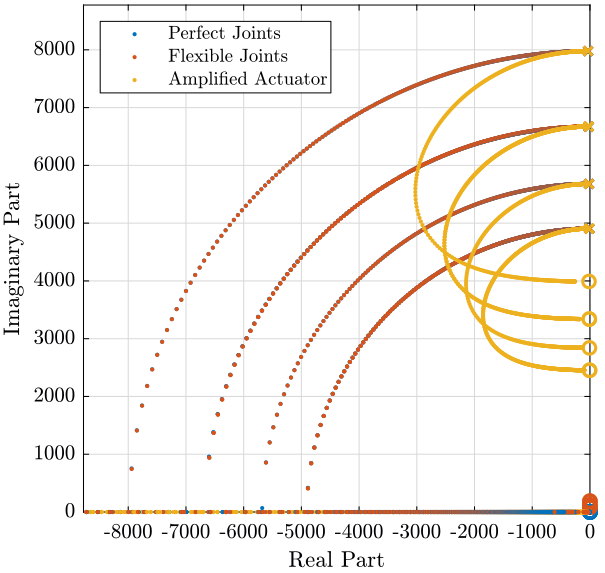

Decentralized Integral Force Feedback

- Control diagram

- Root Locus: unstable with pure IFF

Two proposed modification of IFF

- Comparison of parallel stiffness and change of controller

- Transmissibility

Conclusion

- problem with voice coil actuator

- Two solutions: add parallel stiffness, or change controller

- Conclusion: minimum stiffness is required

- APA is a nice architecture for parallel stiffness + integrated force sensor (have to speak about IFF before that)

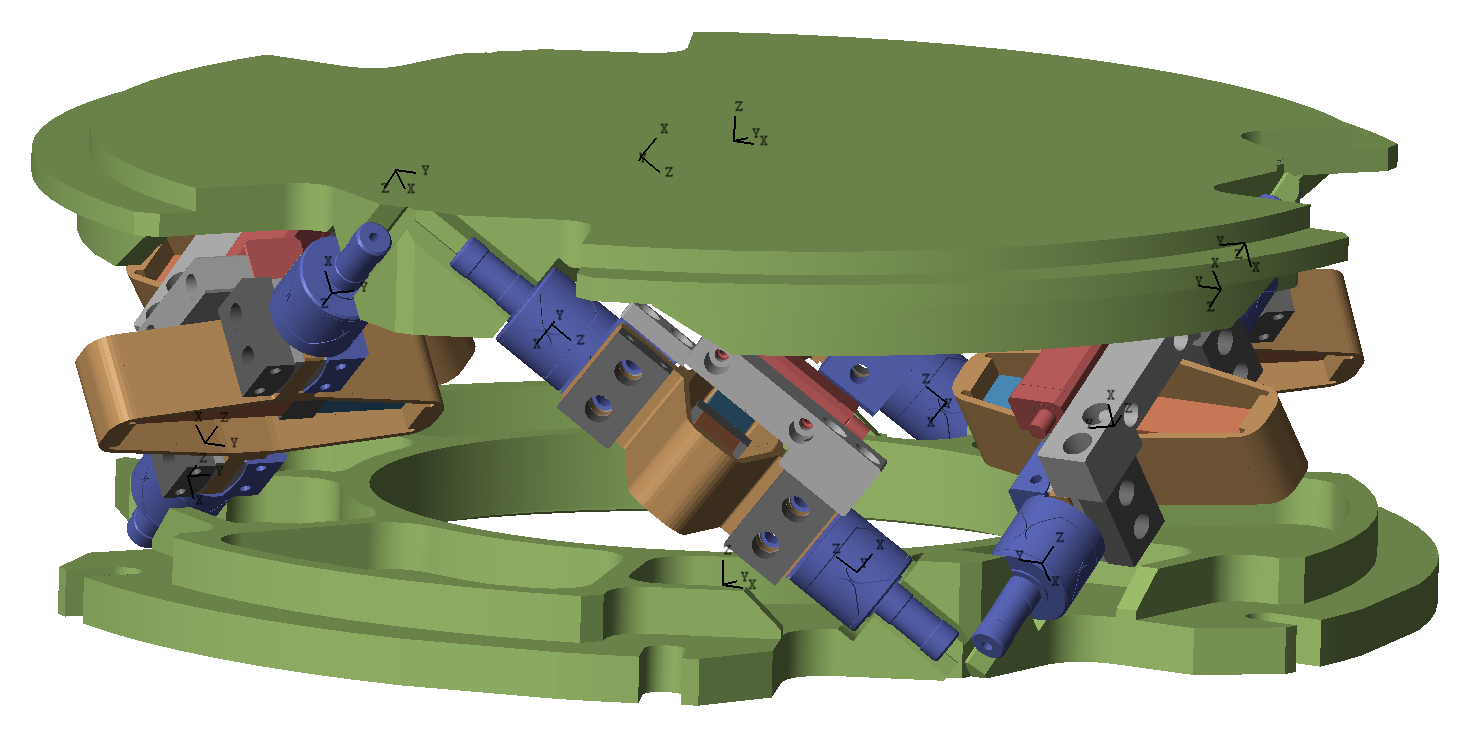

Multi Body Model - Nano Hexapod

Introduction

- What we want to capture with this model

- Explain what is a multi body model (rigid body, springs, etc…)

- Key elements (plates, joints, struts): for now simplistic model (rigid body elements, perfect joints, …), but in next section, FEM will be used

- Matlab/Simulink developed toolbox for the study of Stewart platforms

Stewart Platform Architecture

Kinematics

- Well define elements, frames, …

- Derivation of jacobian matrices: for forces and for displacement

- Explain this is true for small displacements (show how small)

Model of an Amplified Piezoelectric Actuator

- APA test bench

- Piezoelectric effects

- mass spring damper representation (2dof)

- Compare the model and the experiment

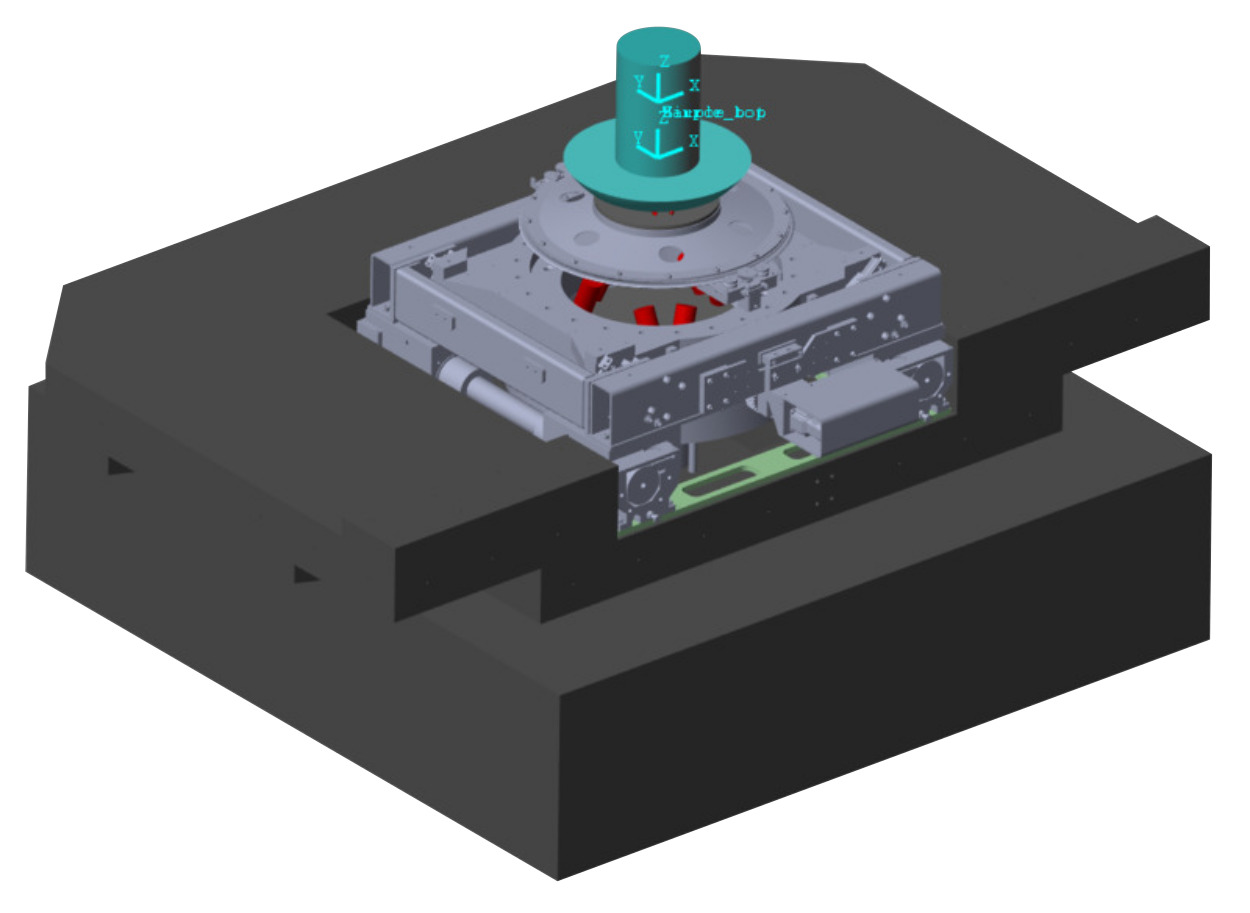

Multi Body Model - Micro Station

Kinematics

- Small overview of each stage and associated stiffnesses / inertia

- schematic that shows to considered DoF

- import from CAD

Modal Analysis

- Picture of the experimental setup

- Location of accelerometers

- Show obtained modes

- Validation of rigid body assumption

- Explain how this helps tuning the multi-body model

Validation of the Model

- Most important metric: support compliance

- Compare model and measurement

Control Architecture

Introduction

Discussion of:

- Transformation matrices / control architecture

- Control in the frame of struts or cartesian?

- Effect of rotation on IFF? => APA

- HAC-LAC

High Authority Control - Low Authority Control (HAC-LAC)

- general idea

- case for parallel manipulator: decentralized LAC + centralized HAC

Decoupling Strategies for parallel manipulators

- Jacobian matrices, CoK, CoM, …

- Discussion of cubic architecture

- SVD, Modal, …

Decentralized Integral Force Feedback (LAC)

- Root Locus

- Damping optimization

Control Kinematics

- Explain how the position error can be expressed in the frame of the nano-hexapod

- block diagram

- Explain how to go from external metrology to the frame of the nano-hexapod

Decoupled Dynamics

- Centralized HAC

- Control in the frame of the struts

- Effect of IFF

Centralized Position Controller (HAC)

- Decoupled plant

- Controller design

Simulations - Concept Validation

Conclusion

Detailed Design

minitoc

Abstract

CAD view of the nano-hexapod with key components:

- plates

- flexible joints

- APA

- required instrumentation (ADC, DAC, Speedgoat, Amplifiers, Force Sensor instrumentation, …)

Optimal Nano-Hexapod geometry

Introduction

-

Geometry?

- Cubic architecture?

- Kinematics

- Trade-off for the strut orientation

- Sensors required

Optimal strut orientation

Cubic Architecture: a Special Case?

Including Flexible elements in the Multi-body model

Introduction

Reduced order flexible bodies cite:brumund21_multib_simul_reduc_order_flexib_bodies_fea

- Used with APA, Flexible joints, Plates

Reduced order flexible bodies

- Quick explanation of the theory

- Implementation with Ansys (or Comsol) and Simscape

Numerical Validation

- Numerical Validation Ansys VS Simscape (APA)

- Figure with 0 and 1kg mass

Experimental Validation

- Test bench

- Obtained transfer functions and comparison with Simscape model with reduced order flexible body

Amplified Piezoelectric Actuator

Model

Experimental System Identification

- Experimental validation (granite test bench)

- Electrical parameters

- Required instrumentation to read force sensor?

- Add resistor to include high pass filtering: no risk of saturating the ADC

- Estimation of piezoelectric parameters

Validation with Simscape model

- Tuned Simscape model

- IFF results: OK

Flexible Joints

Introduction

Effect of flexible joint characteristics on obtained dynamics

- Based on Simscape model

- Effect of axial stiffness, bending stiffness, …

- Obtained specifications (trade-off)

Flexible joint geometry optimization

- Chosen geometry

- Optimisation with Ansys

- Validation with Simscape model

Experimental identification

- Experimental validation, characterisation (study)

- Visual inspection

- Test bench

- Obtained results

Instrumentation

Obtained Design

- CAD view of the nano-hexapod

- Chosen geometry, materials, ease of mounting, cabling, …

Experimental Validation

minitoc

Abstract

Schematic representation of the experimental validation process.

- APA

- Strut

- Nano-hexapod on suspended table

- Nano-hexapod with Spindle

Amplified Piezoelectric Actuator (link)

APA alone:

- Goal: Tune model of APA

- FRF and fit with FEM model

- Show all six FRF and how close they are

- IFF

Struts

Strut (APA + joints):

- FRF, tune model

- Issue with encoder (comparison with axial motion)

- IFF

Nano-Hexapod

Mounting

Test bench on top of soft table:

- Goal: Tune model of nano-hexapod, validation of dynamics

- modal analysis soft table (first mode at xxx Hz => rigid body in Simscape)

- FRF + comp model (multiple masses)

- IFF and robustness to change of mass

Rotating Nano-Hexapod

ID31 Micro Station

- Goal: full validation without the full metrology

Conclusion and Future Work

Appendix

Stewart Platform - Kinematics

Comments on something

Bibliography

List of Publications

Glossary

Footnotes

1this is a footnote with citation cite:&dehaeze21_mechat_approac_devel_nano_activ_stabil_system.