1.0 MiB

Glossary and Acronyms - Tables

| key | abbreviation | full form |

|---|---|---|

| adc | ADC | Analog to Digital Converter |

| apa | APA | Amplified Piezoelectric Actuator |

| asd | ASD | Amplitude Spectrum Density |

| cas | CAS | Cumulative Amplitude Spectrum |

| cl | CL | Closed Loop |

| cmif | CMIF | Complex Modal Indication Function |

| cok | CoK | Center of Stiffness |

| com | CoM | Center of Mass |

| dac | DAC | Digital to Analog Converter |

| dvf | DVF | Direct Velocity Feedback |

| dof | DoF | Degrees of Freedom |

| ebs | EBS | Extremely Brilliant Source |

| edm | EDM | Electrical Discharge Machining |

| esrf | ESRF | European Synchrotron Radiation Facility |

| fea | FEA | Finite Element Analysis |

| fem | FEM | Finite Element Model |

| frf | FRF | Frequency Response Function |

| hac | HAC | High Authority Control |

| lac | LAC | Low Authority Control |

| haclac | HAC-LAC | High Authority Control / Low Authority Control |

| hpf | HPF | High Pass Filter |

| iff | IFF | Integral Force Feedback |

| lpf | LPF | Low Pass Filter |

| lqg | LQG | Linear Quadratic Gaussian |

| lsb | LSB | Least Significant Bit |

| lti | LTI | Linear Time Invariant |

| lvdt | LVDT | Linear Variable Differential Transformer |

| mif | MIF | Modal Indication Function |

| mimo | MIMO | Multi Inputs Multi Outputs |

| nass | NASS | Nano Active Stabilization System |

| np | NP | Nominal Performance |

| ns | NS | Nominal Stability |

| ol | OL | Open Loop |

| pi | PI | Proportional Integral |

| pid | PID | Proportional Integral Derivative |

| psd | PSD | Power Spectral Density |

| pzt | PZT | Lead Zirconate Titanate |

| poi | PoI | Point of Interest |

| rdc | RDC | Relative Damping Control |

| rga | RGA | Relative Gain Array |

| rms | RMS | Root Mean Square |

| rpm | RPM | Rotations Per Minute |

| rp | RP | Robust Performance |

| rs | RS | Robust Stability |

| siso | SISO | Single Input Single Output |

| sps | SPS | Samples per Second |

| svd | SVD | Singular Value Decomposition |

| vc | VC | Voice Coil |

Title Page

Members of the Examination Committee

Prof. Loïc Salles (President of the Committee)≠wline University of Liège (Liège, Belgium)

Prof. Christophe Collette (Supervisor)≠wline University of Liège (Liège, Belgium)

Prof. Olivier Bruls≠wline University of Liège (Liège, Belgium)

Dr. Jonathan Kelly≠wline Diamond Light Source (Oxfordshire, United Kingdom)

Prof. Gérard Scorletti≠wline École Centrale de Lyon, Laboratoire Ampère (Écully, France)

Dr. Olivier Mathon≠wline European Synchrotron Radiation Facility (Grenoble, France)

Abstract

The $4^{\text{th}}$ generation synchrotron light sources have yielded X-ray beams with a 100-fold increase in brightness and sub-micron focusing capabilities, offering unprecedented scientific opportunities while requiring end-stations with enhanced sample positioning accuracy. At the European Synchrotron (ESRF), the ID31 beamline features an end-station for positioning samples along complex trajectories. However, its micrometer-range accuracy, limited by thermal drifts and mechanical vibrations, prevents maintaining the point of interest on the focused beam during experiments.

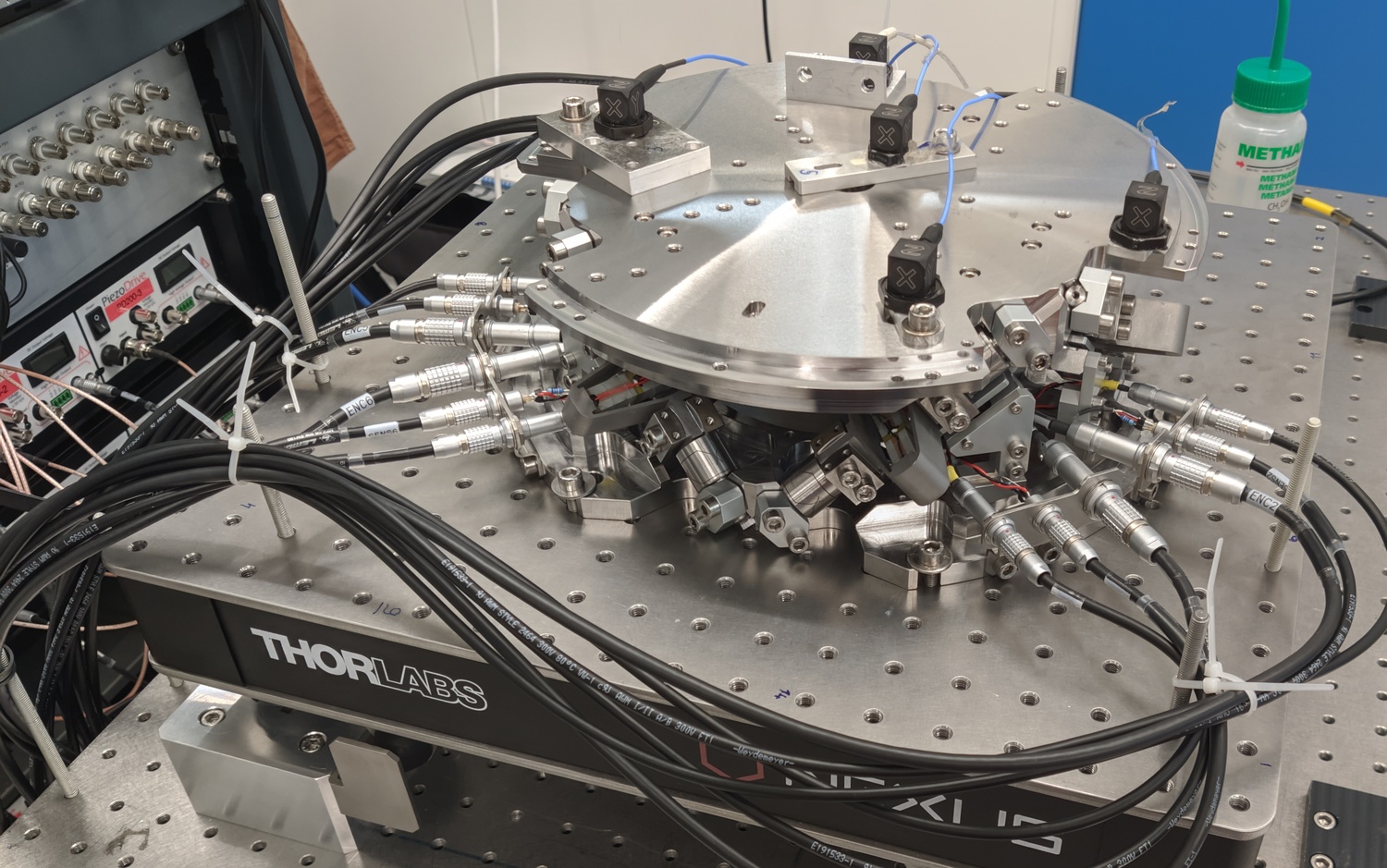

To address this limitation, this thesis aims to develop a system for actively stabilizing the sample's position down to the nanometer range while the end-station moves the sample through the beam. The developed system integrates an external metrology for sample position measurement, an active stabilization stage mounted between the end-station and the sample, and a dedicated control architecture. The design of this system presented key challenges, first of which involved the design process. To effectively predict how this complex mechatronic system would perform, a series of dynamical models with increasing accuracy were employed. These models allowed simulation of the system's behavior at different design stages, identifying potential weaknesses early on before physical construction, ultimately leading to a design that fully satisfies the requirements. The second challenge stems from control requirements, specifically the need to stabilize samples with masses from $1$ to $50\,\text{kg}$, which required the development of specialized robust control architectures. Finally, the developed Nano Active Stabilization System underwent thorough experimental validation on the ID31 beamline, validating both its performance and the underlying concept.

\vspace{-1em} \begingroup ≤t\clearpage\relax \chapter*{Résumé} \endgroup

L'avènement des sources de lumière synchrotron de $4^{\text{ème}}$ génération a produit des faisceaux de rayons X avec une luminosité multipliée par 100 et des capacités de focalisation sub-microniques, offrant des opportunités scientifiques sans précédent tout en nécessitant des stations expérimentales avec une précision de positionnement d'échantillons améliorée. À l'Installation Européenne de Rayonnement Synchrotron (ESRF), la ligne de lumière ID31 dispose d'une station expérimentale conçue pour positionner des échantillons le long de trajectoires complexes. Cependant, sa précision de l'ordre du micromètre, limitée par des effets tels que les dérives thermiques et les vibrations mécaniques, empêche de maintenir le point d'intérêt sur le faisceau focalisé durant les expériences.

Pour remédier à cette limitation, cette thèse vise à développer un système permettant de stabiliser activement la position de l'échantillon pendant que la station expérimentale déplace l'échantillon à travers le faisceau. Le système développé intègre une métrologie externe pour la mesure de la position de l'échantillon, une platine de stabilisation active montée entre la station expérimentale et l'échantillon, et une architecture de contrôle dédiée. La conception de ce système présente des défis majeurs, dont le premier concerne le processus de conception lui-même. Pour prédire efficacement les performances, une série de modèles dynamiques ont été utilisés. Ces modèles ont permis de simuler le comportement du système aux différentes étapes de conception, identifiant ainsi les limitations potentielles, pour aboutir à une conception répondant aux spécifications. Le deuxième défi provient des exigences de contrôle, notamment la nécessité de stabiliser des échantillons dont la masse peut varier de $1$ à $50\,\text{kg}$, ce qui a nécessité le développement d'architectures de contrôle robustes. Enfin, le Système de Stabilisation Active développé a fait l'objet d'une validation expérimentale sur la ligne de lumière ID31, validant à la fois ses performances et le concept sous-jacent.

Acknowledgments

First and foremost, I would like to express my deepest gratitude to my advisor, Professor Christophe Collette, for his constant support throughout this journey. His ability to challenge my thinking and dedication to mentoring my growth as a researcher has been invaluable. His door was always open, and he generously shared his time and expertise, providing feedback and guidance at every stage of the research process. Our discussions during the regular journeys between Liege and Brussels laboratories transformed routine travel into moments of scientific inspiration. His passion and dedication for research were truly inspiring, and I could not have wished for a better advisor.

I am honored that Professor Loïc Salles accepted the role of president of the jury for this thesis. My sincere appreciation goes to my thesis committee members, Professor Olivier Bruls and Professor Jean-Claude Golinval, for following my work and providing insightful advice through the years.

I extend my gratitude to the jury members: Dr. Jonathan Kelly, Professor Gérard Scorletti, Dr. Olivier Mathon and Professor Olivier Bruls for their willingness to participate in the examination committee of this doctoral thesis. Their time, expertise, and careful consideration of my work are greatly appreciated.

My time at the Precision Mechatronics Laboratory during the first two years of this project was enriched by interesting discussions and collaborations with Ahmad, Mohit, Jennifer, Vicente, Guoying, and Haidar. I am particularly grateful for the opportunity to have worked alongside such talented and dedicated individuals. Thank you, my friends, for making my stay in Belgium such a wonderful souvenir.

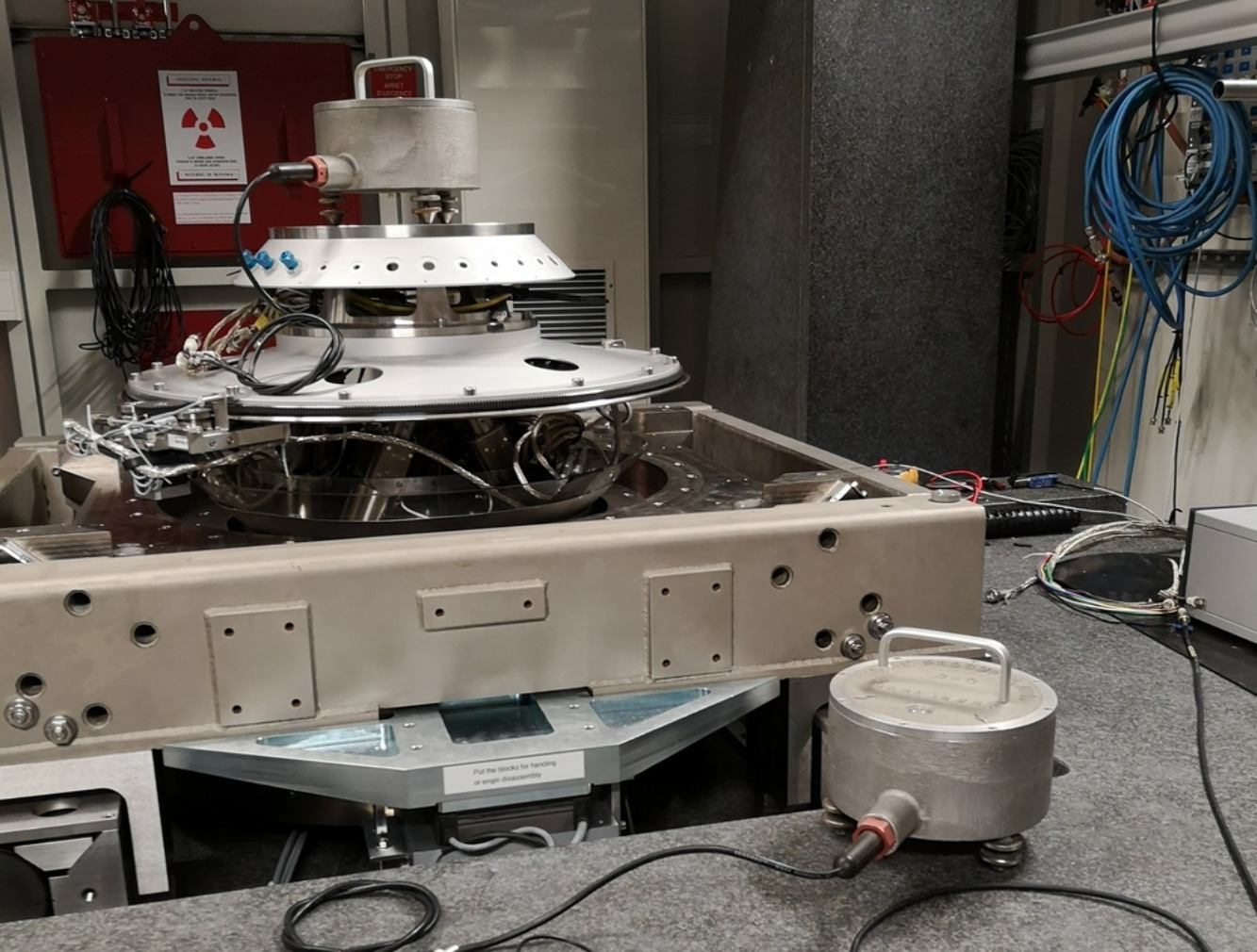

The subsequent five years at the ESRF were made possible by several key individuals: Veijo Honkimaki (ID31's Scientist), Michael Krisch (Head of the Instrumentation Division), Philippe Marion (Head of the Mechanical Engineering Group), Yves Dabin (Head of the Analysis and Modelling group), and Muriel Magnin-Mattenet (Mechanical Engineer in charge of ID31). I especially want to acknowledge their efforts in providing me with the resources, facilities, and technical expertise necessary to conduct my research at the ESRF.

The technical aspects of this work benefited greatly from various collaborations. I am grateful for the fruitful collaboration on mechanical design with Julien Bonnefoy and Damien Coulon. Special thanks to Philipp Brumund for his invaluable Finite Element Analysis expertise and constant encouragement to complete my PhD thesis. I am especially thankful to Marc Lesourd for introducing me to the world of vibration measurements and modal analysis, and Noel Levet for our interesting discussions about dimensional metrology and his tremendous support with the alignment of the developed instrument. The remarkable technical support from Pierrick Got and Kader Amraoui in electronics allowed smooth implementation of the developed system on the ID31 beamline. I also thank Hans Peter and Ludovic for granting me access to the outstanding mechatronics laboratory at the ESRF.

I am grateful to the master thesis students I had the chance to supervise: Adrien Jublan for his work on multi-body modelling, Youness Benyaklhef for his contribution to the metrology system and Caio Belle for his research on multi-variable control.

Finally, my profound thanks go to my family and close friends. To my father, who inspired me to pursue research, and my mother, whose unwavering support has been precious beyond words. And to Juliette, for being incredibly supportive through the inevitable tough times that are part of the PhD journey.

Reproducible Research

The foundation of this PhD thesis is built upon the principles of reproducible research. Reproducible research is the practice of ensuring that the results of a study can be independently verified by others using the original data, code, and documentation.

This approach was adopted to increase transparency and trust in the presented research findings. Furthermore, it is anticipated that the methods and data shared will facilitate knowledge transfer and reuse within the scientific community, thereby reducing research redundancy and increasing overall efficiency. It is hoped that some aspects of this work may be reused by the synchrotron community.

The fundamental objective has been to ensure that anyone should be capable of reproducing precisely the same results and figures as presented in this manuscript. To achieve this goal of reproducibility, comprehensive sharing of all elements has been implemented. This includes the mathematical models developed, raw experimental data collected, and scripts used to generate the figures.

For those wishing to engage with the reproducible aspects of this work, all data and code are freely accessible cite:&dehaeze25_nano_activ_stabil_zenodo. The organization of the code mirrors that of the manuscript, with corresponding chapters and sections. All materials have been made available under the MIT License, permitting free reuse.

This approach represents a modest contribution towards a more open, reliable, and collaborative scientific ecosystem.

Grants

The research presented in this manuscript has been possible thanks to the Fonds de la recherche scientifique (FRS-FNRS) through a FRIA grant given to Thomas Dehaeze.

Table of Contents

Introduction

<<chap:introduction>>

Context of this thesis

Synchrotron Radiation Facilities

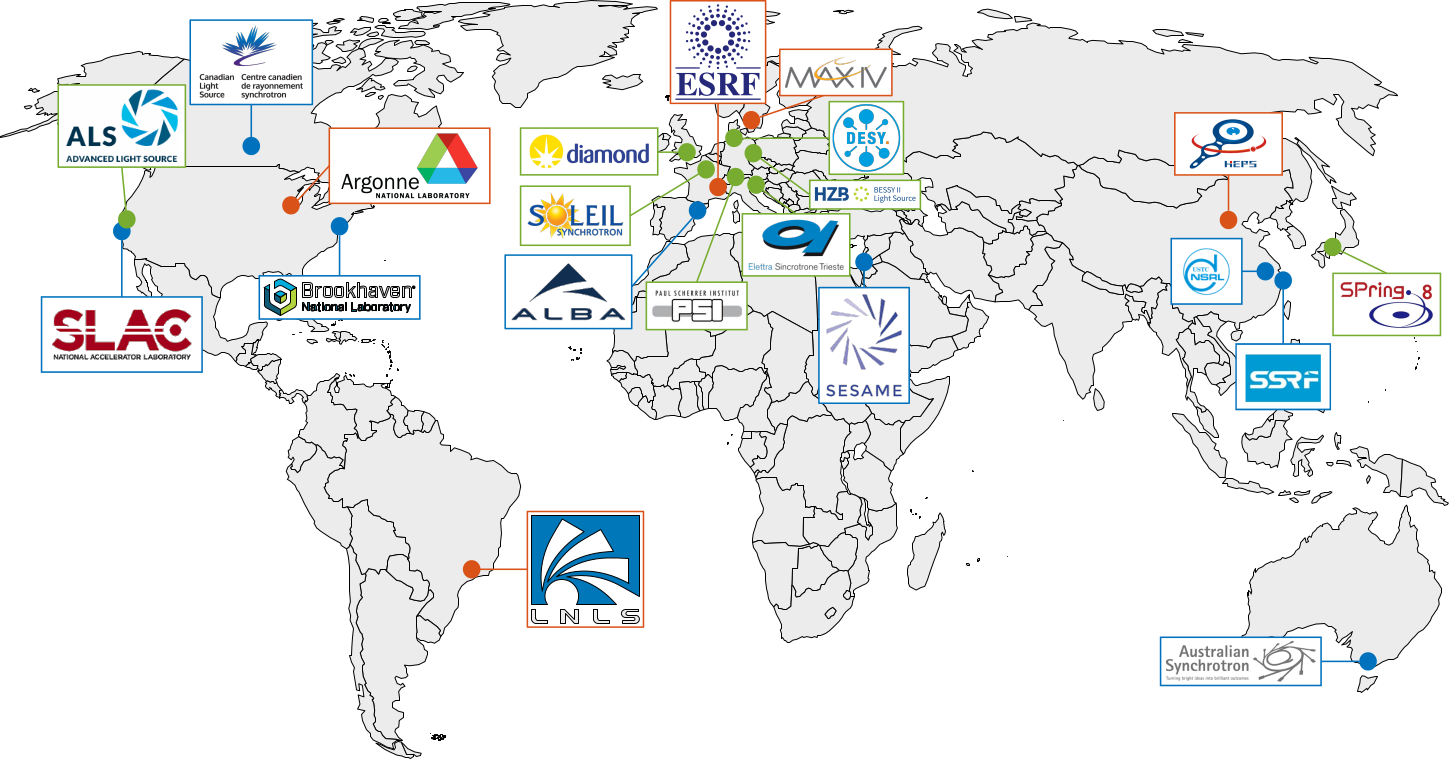

Synchrotron radiation facilities are particle accelerators where electrons are accelerated to near the speed of light. As these electrons interact with magnetic fields, typically generated by insertion devices or bending magnets, they produce exceptionally bright light known as synchrotron light. This intense electromagnetic radiation, centered mainly in the X-ray spectrum domain, is subsequently used for the detailed study of matter. Approximately 70 synchrotron light sources are operational worldwide, some of which are indicated in Figure ref:fig:introduction_synchrotrons. This global distribution of such facilities underscores the significant utility of synchrotron light for the scientific community.

These facilities fundamentally comprise two main parts: the accelerator and storage ring, where electron acceleration and light generation occur, and the beamlines, where the intense X-ray beams are conditioned and directed for experimental use.

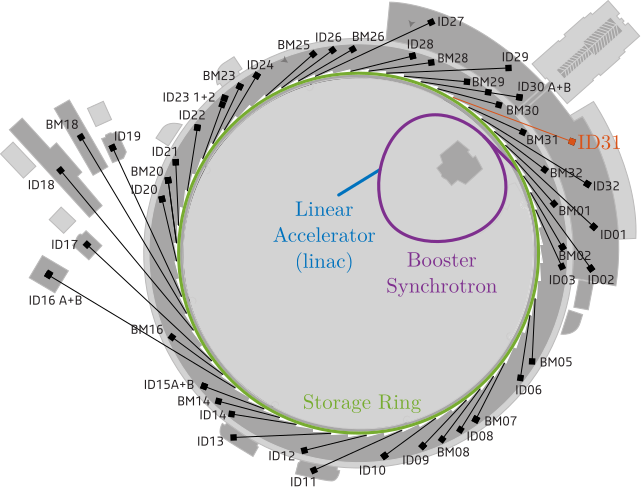

The acrfull:esrf, shown in Figure ref:fig:introduction_esrf_picture, is a joint research institution supported by 19 partner nations. The acrshort:esrf started user operations in 1994 as the world's first third-generation synchrotron. Its accelerator complex, schematically depicted in Figure ref:fig:introduction_esrf_schematic, includes a linear accelerator where electrons are initially generated and accelerated, a booster synchrotron to further accelerate the electrons, and an 844-meter circumference storage ring where electrons are maintained in a stable orbit.

Synchrotron light is emitted in more than 40 beamlines surrounding the storage ring, each having specialized experimental stations. These beamlines host diverse instrumentation that enables a wide spectrum of scientific investigations, including structural biology, materials science, and study of matter under extreme conditions.

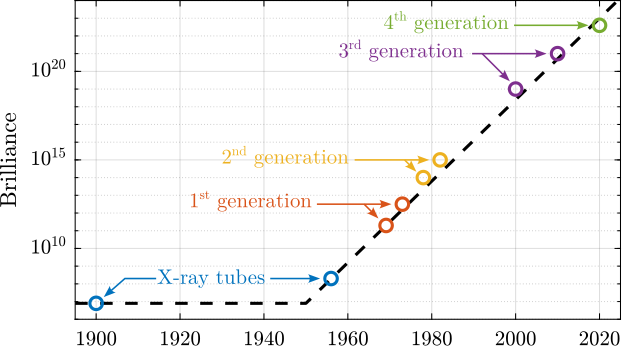

In August 2020, following an extensive 20-month upgrade period, the acrshort:esrf inaugurated its acrfull:ebs, establishing it as the world's premier fourth-generation synchrotron cite:&raimondi21_commis_hybrid_multib_achrom_lattic. This upgrade implemented a novel storage ring concept that substantially increases the brilliance and coherence of the X-ray beams.

Brilliance, a measure of the photon flux, is a key figure of merit for synchrotron facilities. It experienced an approximate 30-fold increase with the implementation of acrshort:ebs, as shown in the historical evolution depicted in Figure ref:fig:introduction_moore_law_brillance. While this enhanced beam quality presents unprecedented scientific opportunities, it concurrently introduces considerable engineering challenges, particularly regarding experimental instrumentation and sample positioning systems.

The ID31 ESRF Beamline

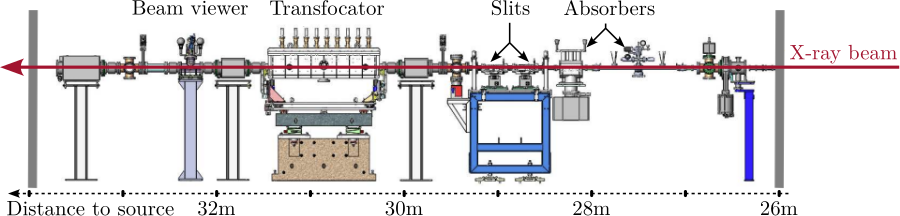

Each beamline begins with a "white" beam generated by the insertion device. This beam carries substantial power, typically exceeding kilowatts, and is generally unsuitable for direct application to samples.

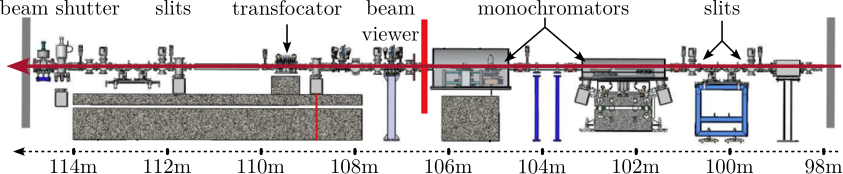

The goal of the beamline is therefore to filter and shape the X-rays to the desired specifications using a series of optical elements such as absorbers, mirrors, slits, and monochromators. These components are housed in multiple Optical Hutches, as depicted in Figure ref:fig:introduction_id31_oh.

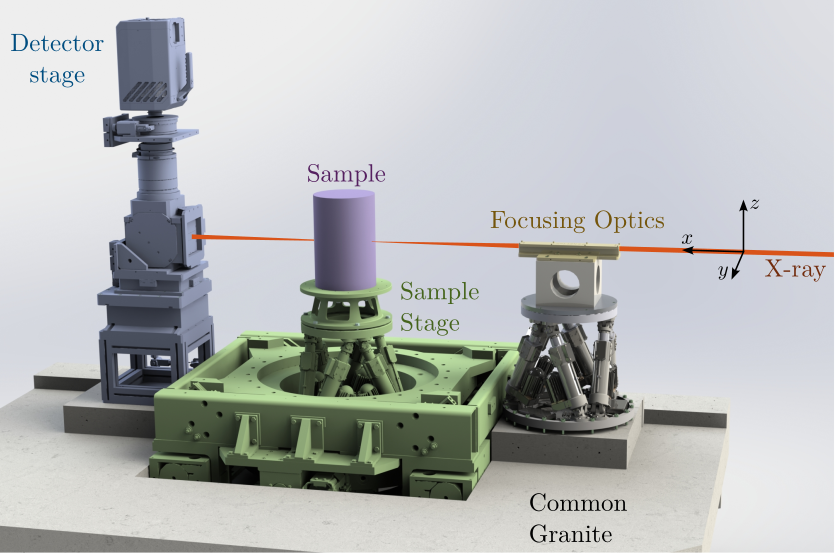

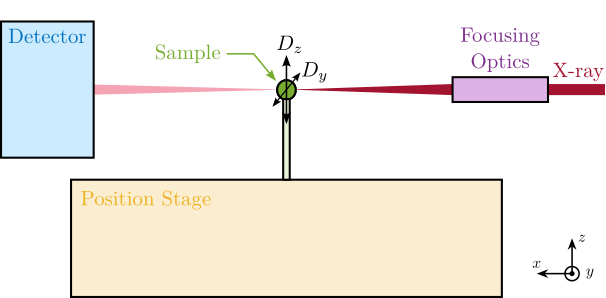

Following the optical hutches, the conditioned beam enters the Experimental Hutch (Figure ref:fig:introduction_id31_cad), where, for experiments pertinent to this work, focusing optics are used. The sample is mounted on a positioning stage, referred to as the "end-station", which enables precise alignment relative to the X-ray beam. Detectors are used to capture the X-rays beam after interaction with the sample.

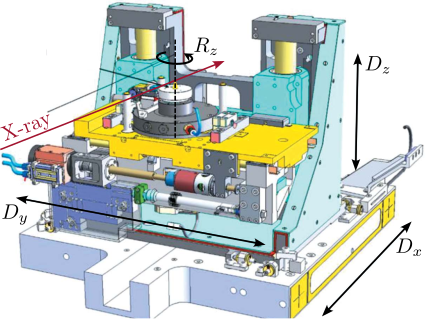

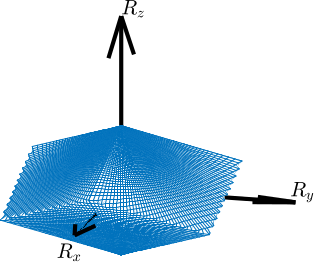

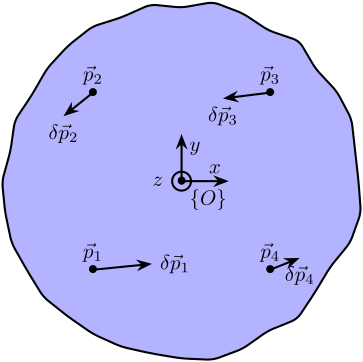

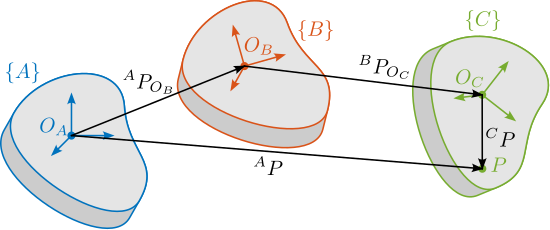

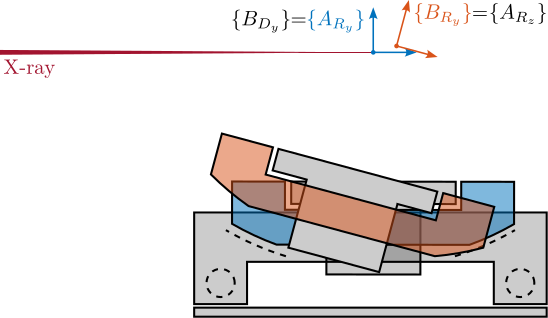

Throughout this thesis, the standard acrshort:esrf coordinate system is adopted, wherein the X-axis aligns with the beam direction, Y is transverse horizontal, and Z is vertical upwards against gravity.

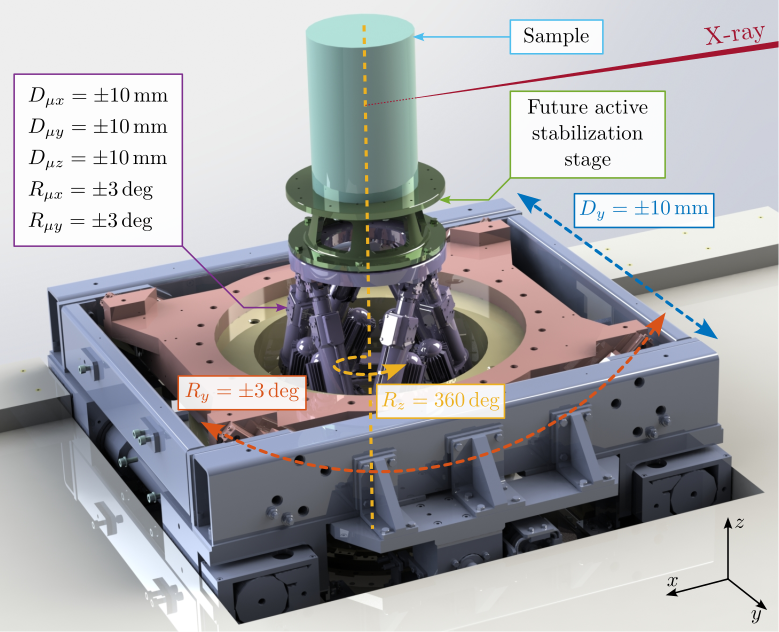

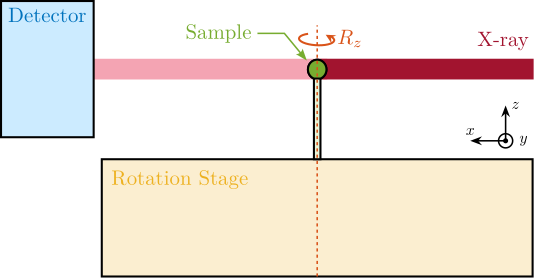

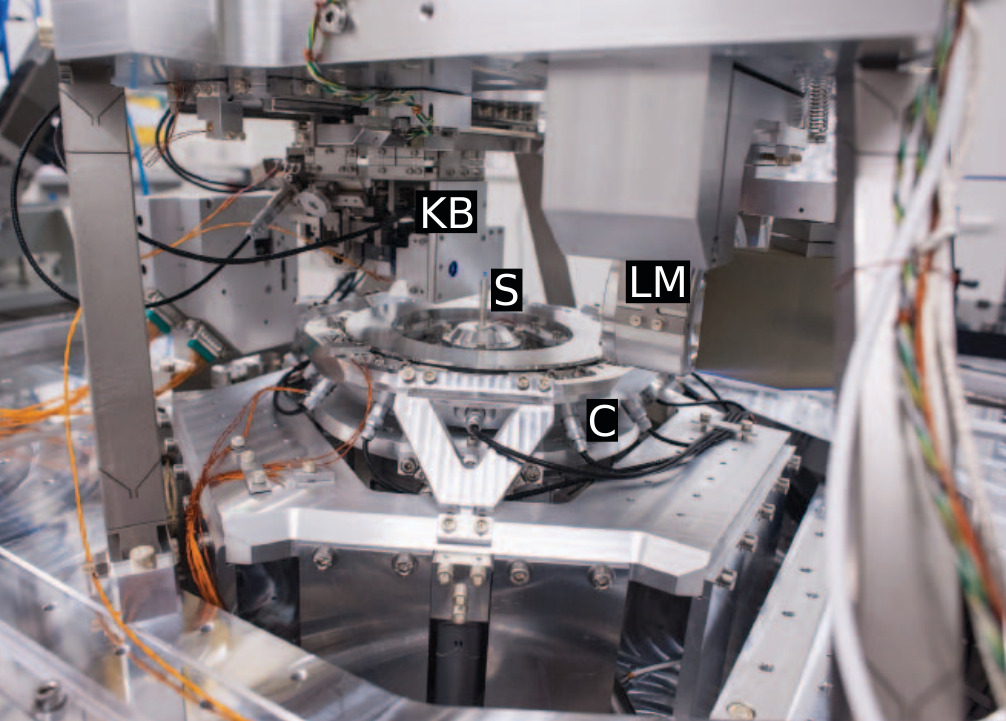

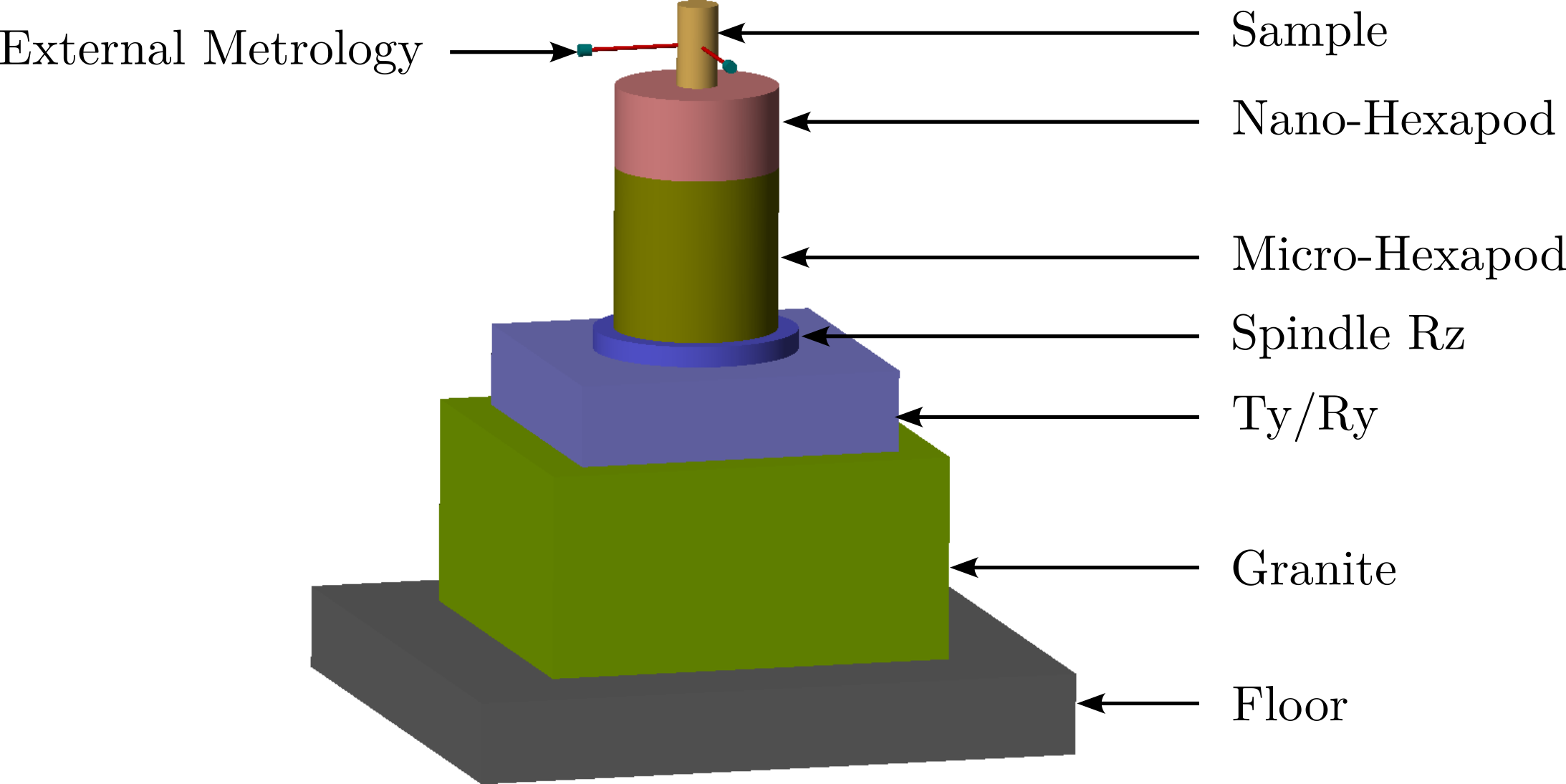

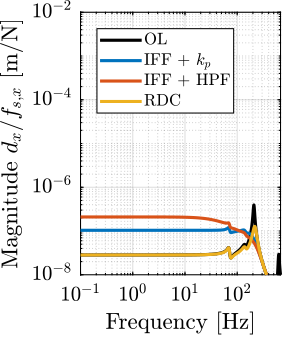

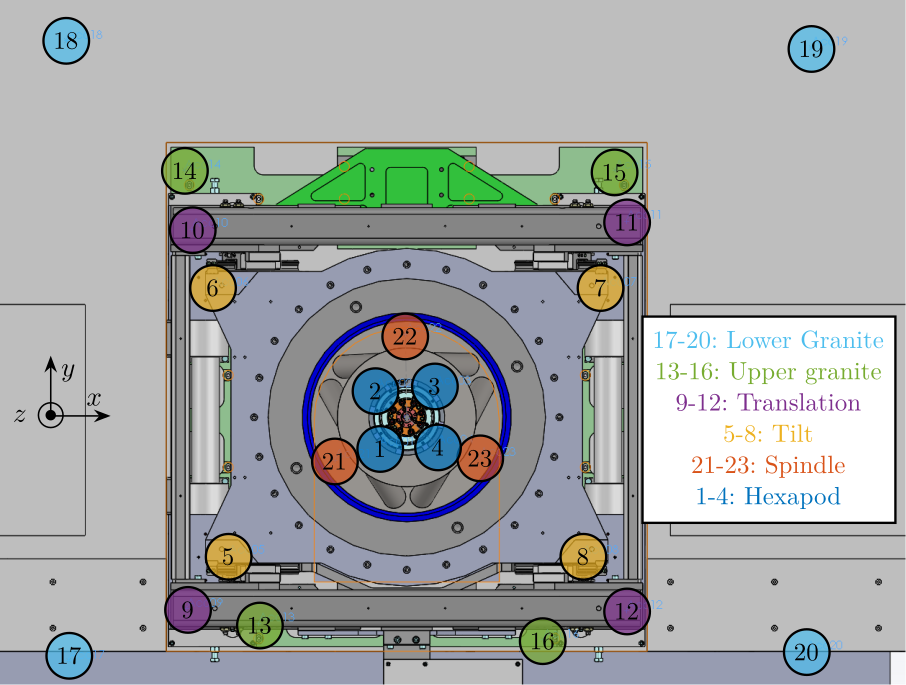

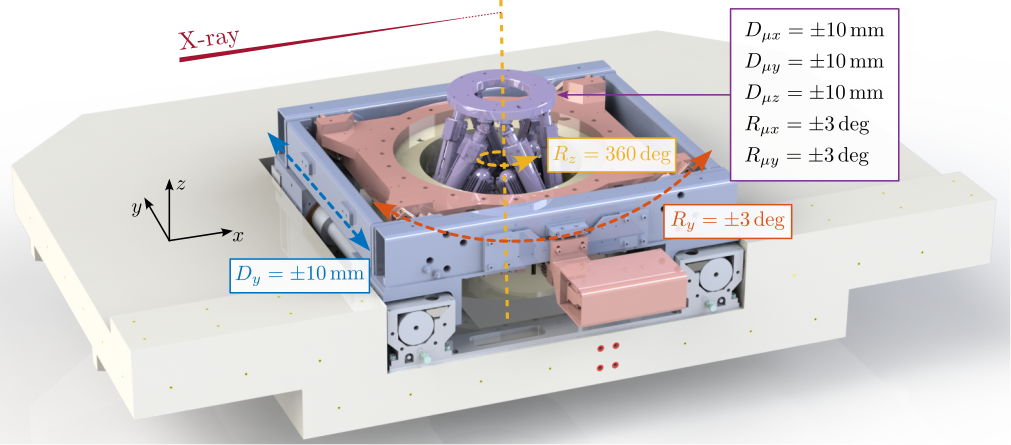

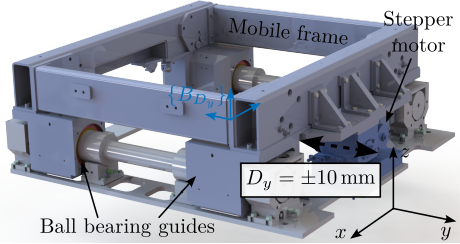

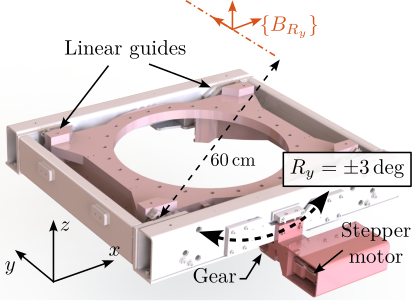

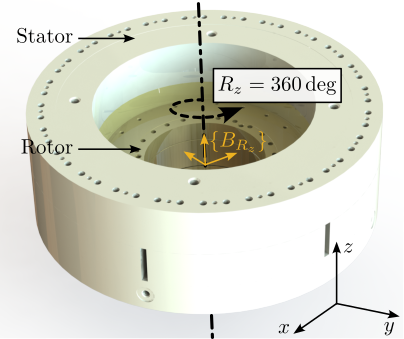

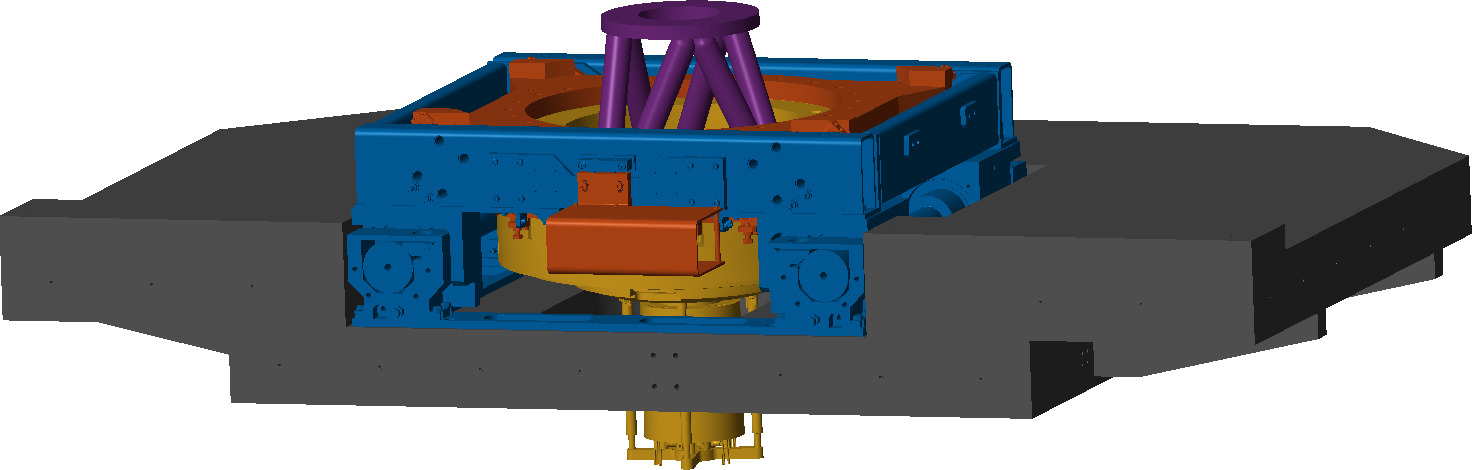

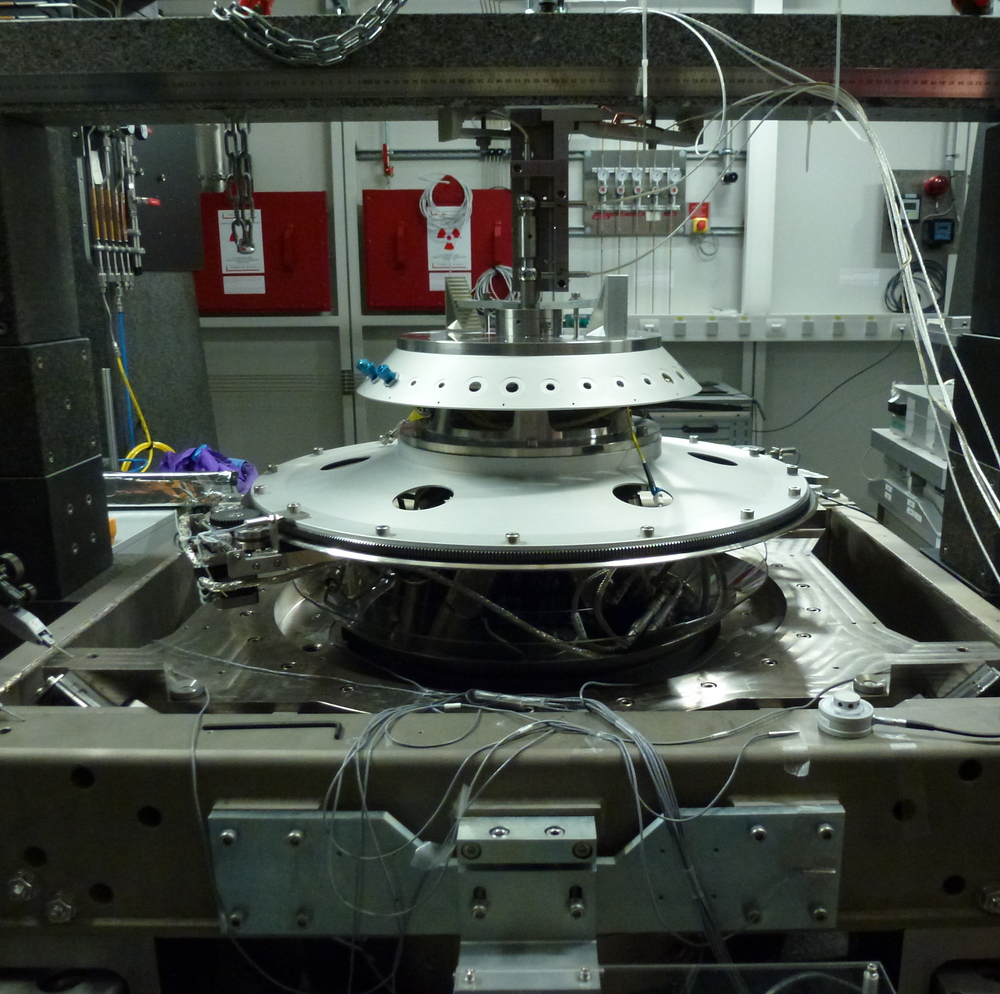

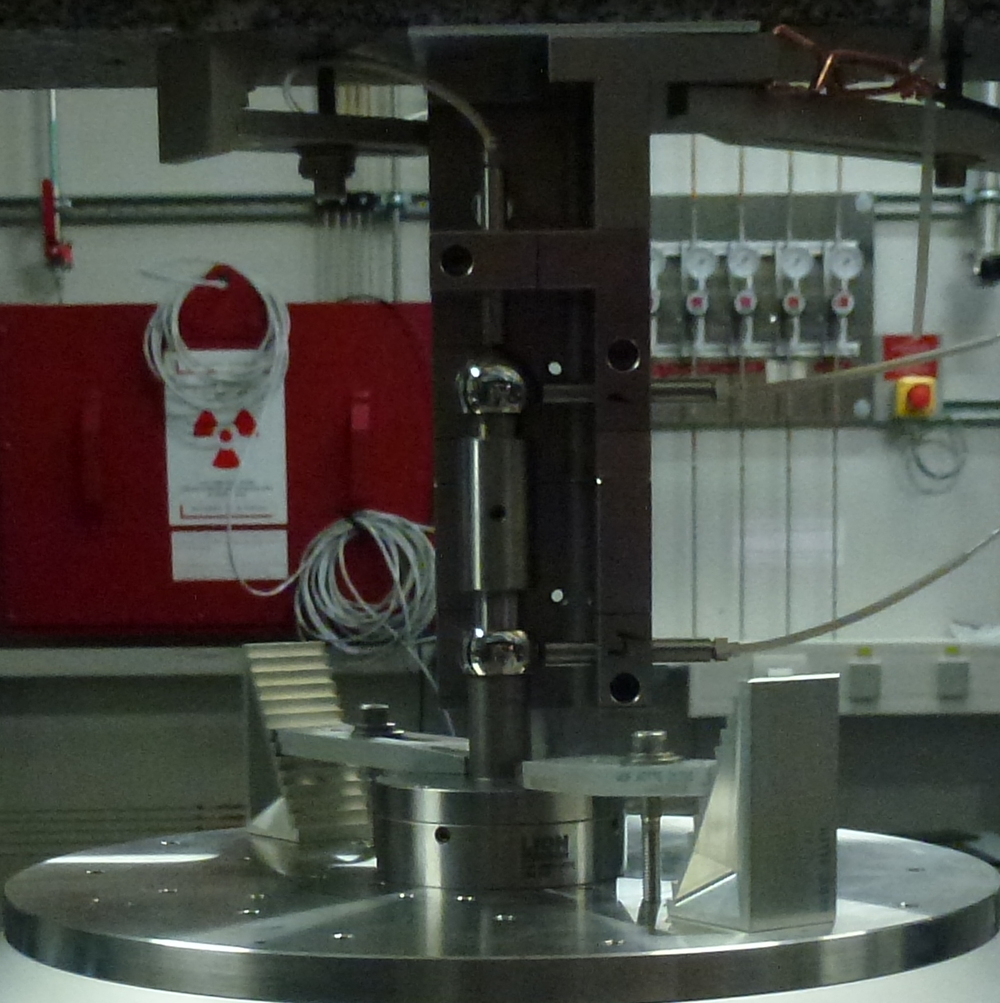

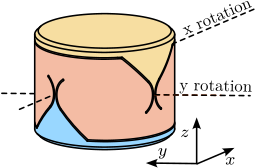

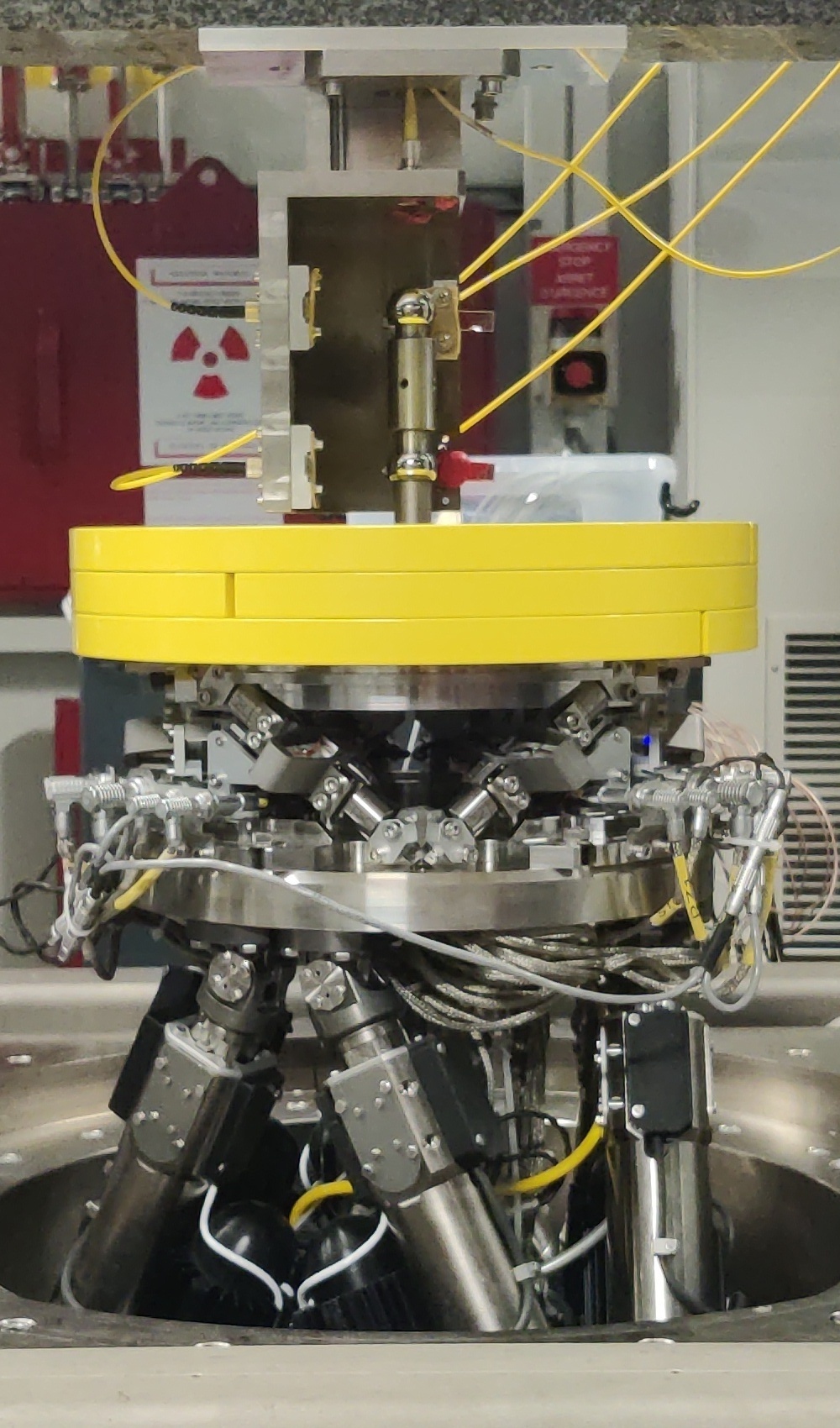

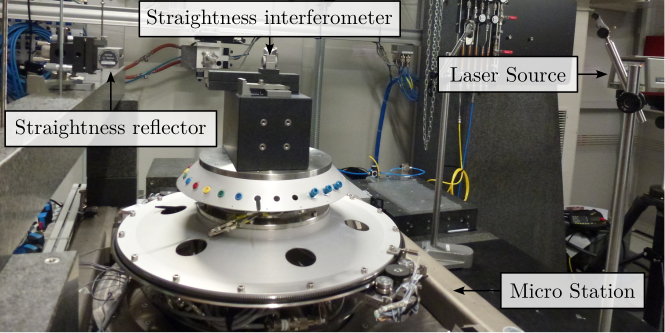

The specific end-station employed on the ID31 beamline is referred to as the "micro-station". As depicted in Figure ref:fig:introduction_micro_station_dof, it comprises a stack of positioning stages: a translation stage (in blue), a tilt stage (in red), a spindle for continuous rotation (in yellow), and a positioning hexapod (in purple). The sample itself (cyan), potentially housed within complex sample environments (e.g., for high pressure or extreme temperatures), is mounted on top of this assembly. Each stage serves distinct positioning functions; for example, the positioning hexapod enables fine static adjustments, while the $T_y$ translation and $R_z$ rotation stages are used for specific scanning applications.

The "stacked-stages" configuration of the micro-station provides high mobility, enabling diverse scientific experiments and imaging techniques. Two illustrative examples are provided.

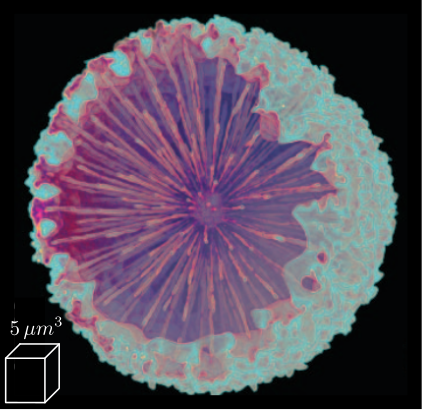

Tomography experiments, schematically represented in Figure ref:fig:introduction_tomography_schematic, involve placing a sample in the X-ray beam path while controlling its vertical rotation angle using a dedicated stage. Detector images are captured at numerous rotation angles, allowing the reconstruction of three-dimensional sample structure (Figure ref:fig:introduction_tomography_results) cite:&schoeppler17_shapin_highl_regul_glass_archit. This reconstruction depends critically on maintaining the sample's acrfull:poi within the beam during the rotation process.

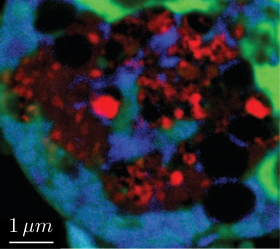

Mapping or scanning experiments, depicted in Figure ref:fig:introduction_scanning_schematic, typically use focusing optics to have a small beam size at the sample's location. The sample is then translated perpendicular to the beam (along Y and Z axes), while data are collected at each position. An example cite:&sanchez-cano17_synch_x_ray_fluor_nanop of a resulting two-dimensional map, acquired with $20\,\text{nm}$ step increments, is shown in Figure ref:fig:introduction_scanning_results. The fidelity and resolution of such images are intrinsically linked to the focused beam size and the positioning precision of the sample relative to the focused beam. Positional instabilities, such as vibrations and thermal drifts, inevitably lead to blurring and distortion in the obtained image. Other advanced imaging modalities practiced on ID31 include reflectivity, diffraction tomography, and small/wide-angle X-ray scattering (SAXS/WAXS).

Need of Accurate Positioning End-Stations with High Dynamics

Continuous progress in both synchrotron source technology and X-ray optics have led to the availability of smaller, more intense, and more stable X-ray beams. The ESRF-EBS upgrade, for instance, resulted in a significantly reduction of the horizontal source size, coupled with a decrease of the beam horizontal divergence, leading to an increased brilliance, as illustrated in Figure ref:fig:introduction_beam_3rd_4th_gen.

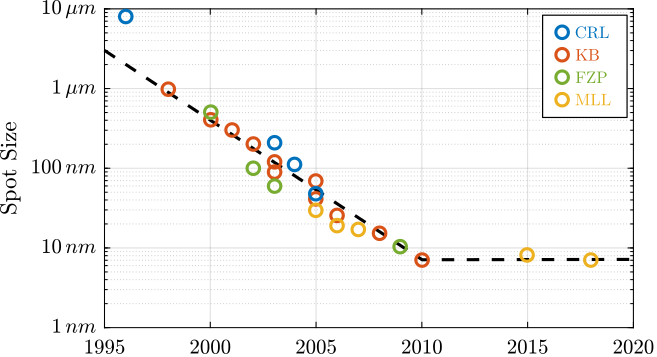

Concurrently, substantial progress has been made in micro- and nano-focusing optics since the early days of acrshort:esrf, where typical spot sizes were on the order of $10\,\upmu\text{m}$ cite:&riekel89_microf_works_at_esrf. Various technologies, including Fresnel Zone Plates (FZP), Kirkpatrick-Baez (KB) mirrors, Multilayer Laue Lenses (MLL), and Compound Refractive Lenses (CRL), have been developed and refined, each presenting unique advantages and limitations cite:&barrett16_reflec_optic_hard_x_ray. The historical reduction in achievable spot sizes is represented in Figure ref:fig:introduction_moore_law_focus. Presently, focused beam dimensions in the range of 10 to 20 nm (Full Width at Half Maximum, FWHM) may be achieved on specialized nano-focusing beamlines.

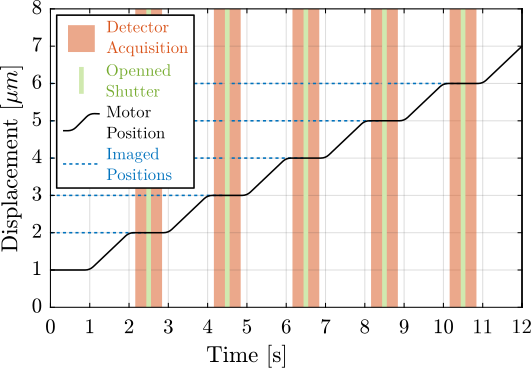

The increased brilliance introduces challenges related to radiation damage, particularly at high-energy beamlines like ID31. Consequently, long exposure of a single sample area to the focused beam must be avoided. Traditionally, experiments were conducted in a "step-scan" mode, illustrated in Figure ref:fig:introduction_scan_step. In this mode, the sample is moved to the desired position, the detector acquisition is initiated, and a beam shutter is opened for a brief, controlled duration to limit radiation damage before closing; this cycle is repeated for each measurement point. While effective for mitigating radiation damage, this sequential process can be time-consuming, especially for high-resolution maps requiring numerous points.

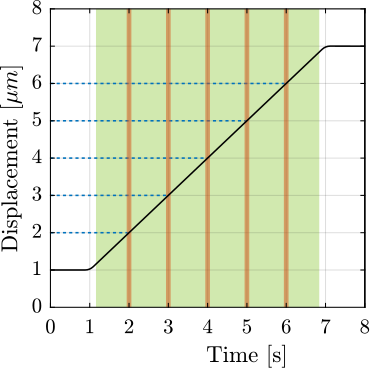

An alternative, more efficient approach is the "fly-scan" or "continuous-scan" methodology cite:&xu23_high_nsls_ii, depicted in Figure ref:fig:introduction_scan_fly. Here, the sample is moved continuously while the detector is triggered to acquire data "on the fly" at predefined positions or time intervals. This technique significantly accelerates data acquisition, enabling better use of valuable beamtime while potentially enabling finer spatial resolution cite:&huang15_fly_scan_ptych.

Recent developments in detector technology have yielded sensors with improved spatial resolution, lower noise characteristics, better efficiency, and substantially higher frame rates cite:&hatsui15_x_ray_imagin_detec_synch_xfel_sourc. Historically, detector integration times for scanning and tomography experiments were in the range of 0.1 to 1 second. This extended integration effectively filtered high-frequency vibrations in beam or sample position, resulting in apparently stable but larger beam.

With higher X-ray flux and reduced detector noise, integration times can now be shortened down to approximately 1 millisecond, with frame rates exceeding $100\,\text{Hz}$. This reduction in integration time has two major implications for positioning requirements. Firstly, for a given spatial sampling ("pixel size"), faster integration necessitates proportionally higher scanning velocities. Secondly, the shorter integration times make the measurements more sensitive to high-frequency vibrations. Therefore, not only the sample position must be stable against long-term drifts, but it must also be actively controlled to minimize vibrations, especially during dynamic fly-scan acquisitions.

Existing Nano Positioning End-Stations

To contextualize the system developed within this thesis, a brief overview of existing strategies and technologies for high-accuracy, high-dynamics end-stations is provided. The aim is to identify the specific characteristics that distinguish the proposed system from current state-of-the-art implementations.

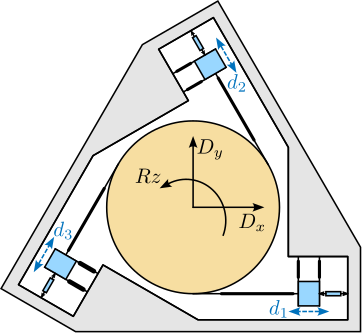

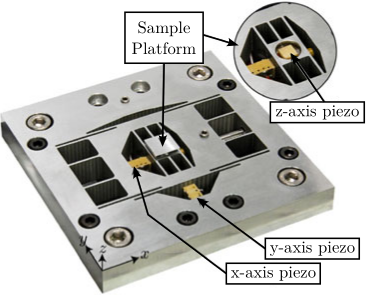

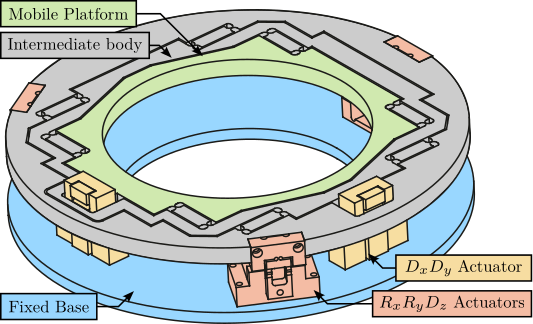

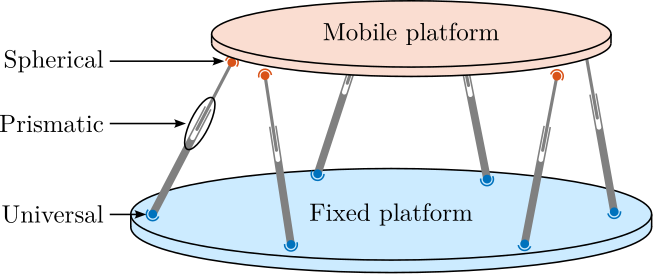

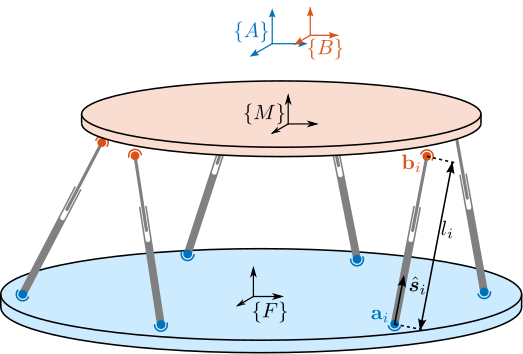

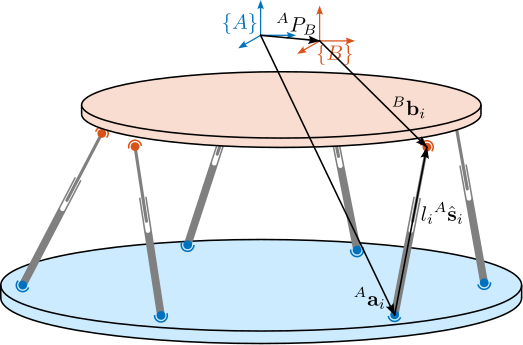

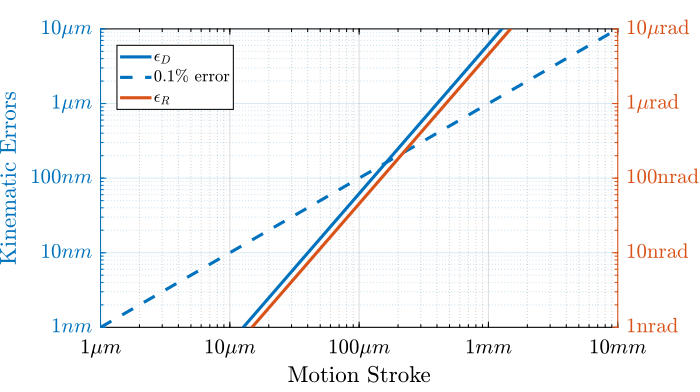

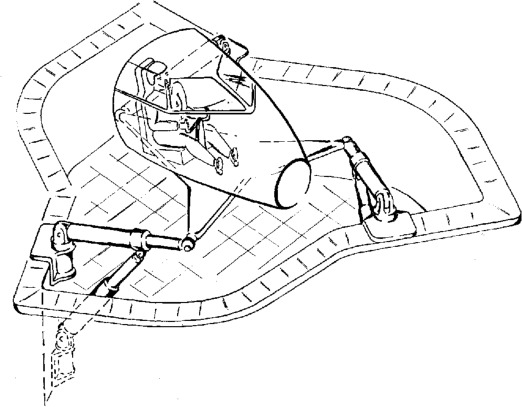

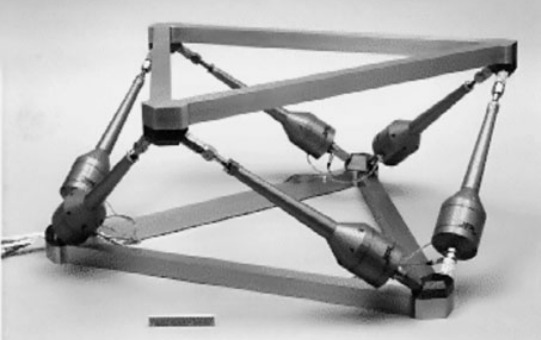

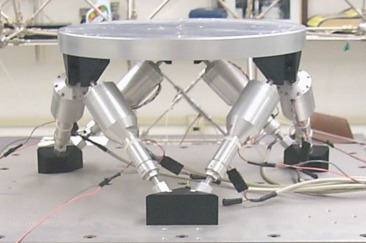

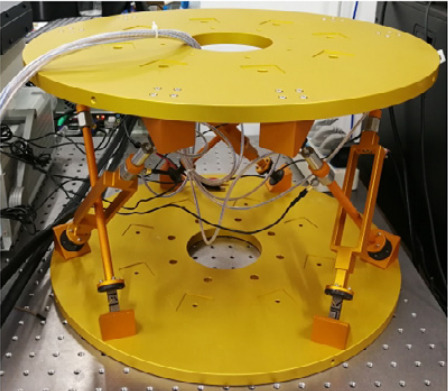

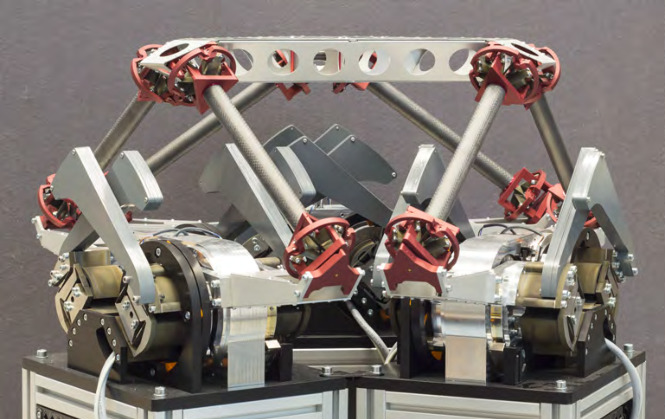

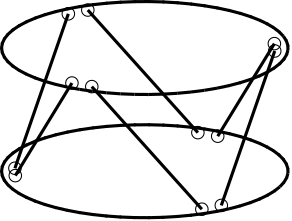

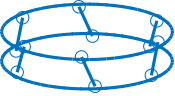

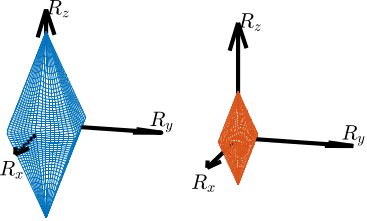

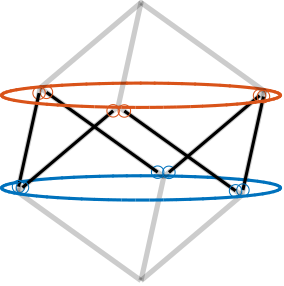

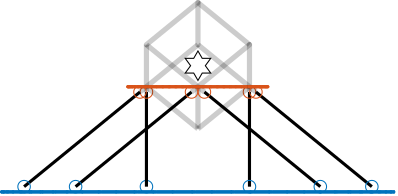

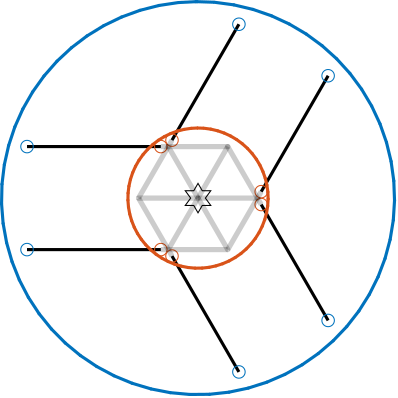

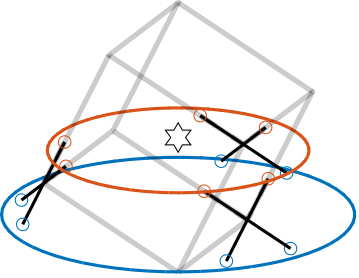

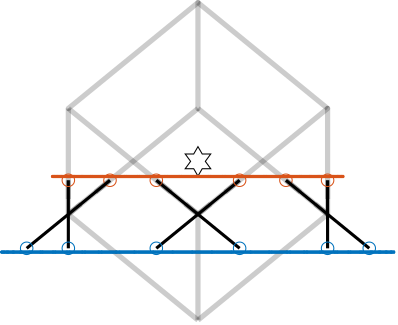

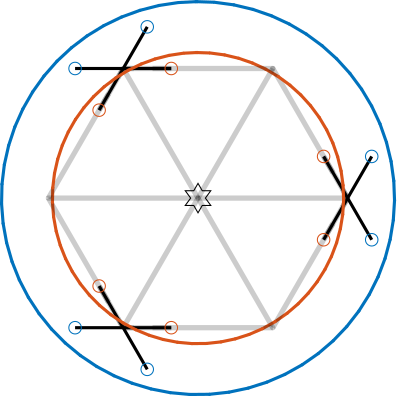

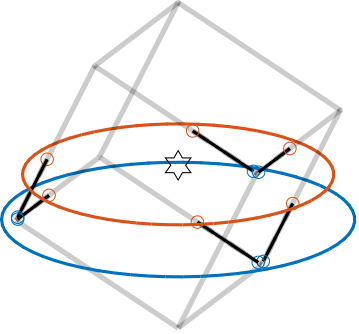

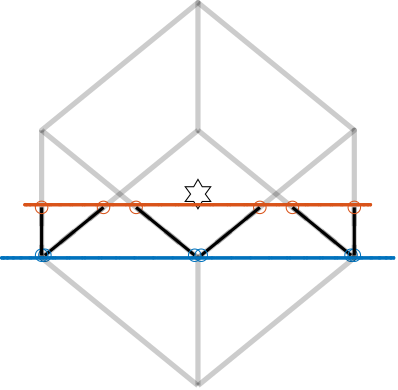

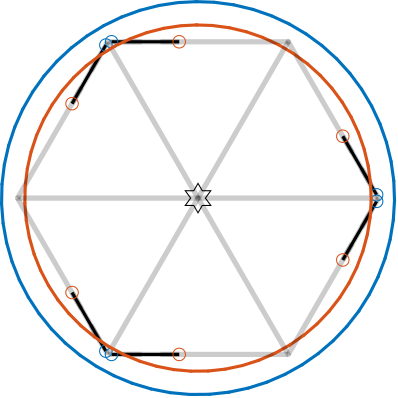

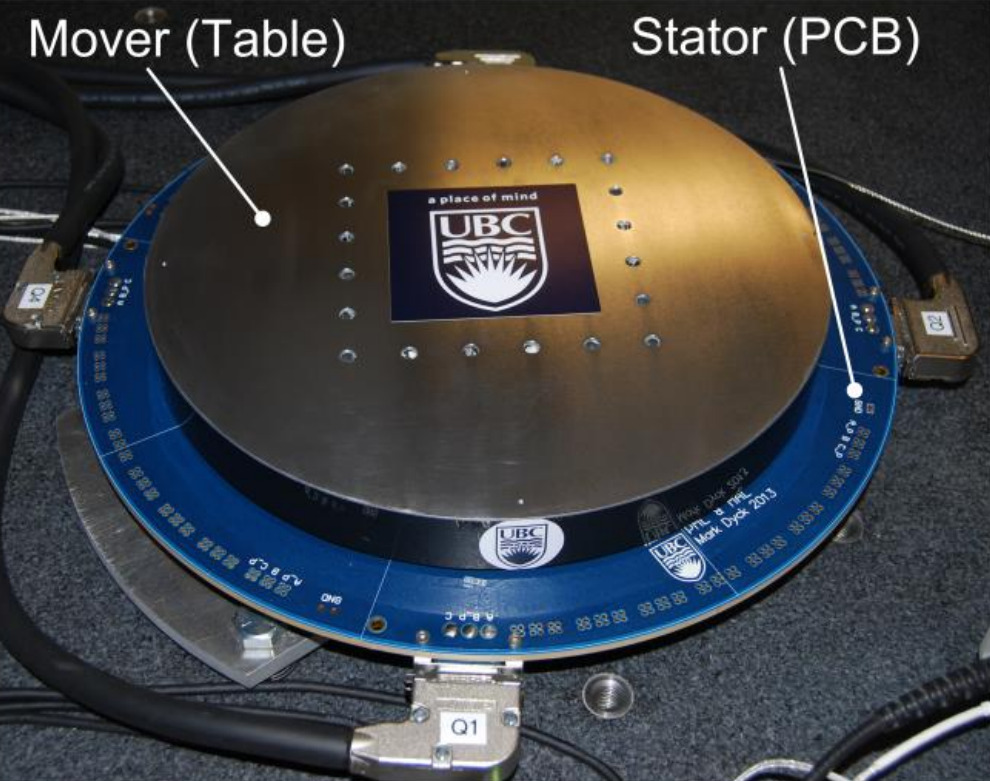

Positioning systems can be broadly categorized based on their kinematic architecture, typically serial or parallel, as exemplified by the 3-Degree-of-Freedom (DoF) platforms in Figure ref:fig:introduction_kinematics. Serial kinematics (Figure ref:fig:introduction_serial_kinematics) is composed of stacked stages where each acrshort:dof is controlled by a dedicated actuator. This configuration offers great mobility, but positioning errors (e.g., guiding inaccuracies, thermal expansion) accumulate through the stack, compromising overall accuracy. Similarly, the overall dynamic performance (stiffness, resonant frequencies) is limited by the softest component in the stack, often resulting in poor dynamic behavior when many stages are combined.

Conversely, parallel kinematic architectures (Figure ref:fig:introduction_parallel_kinematics) involve the coordinated motion of multiple actuators to achieve the desired end-effector motion. While theoretically offering the same controlled degrees of freedom as stacked stages, parallel systems generally provide limited stroke but significantly enhanced stiffness and superior dynamic performance.

Most end stations, particularly those requiring extensive mobility, employ stacked stages. Their positioning performance consequently depends entirely on the accuracy of individual components. Strategies include employing a limited number of high-performance stages, such as air-bearing spindles cite:&riekel10_progr_micro_nano_diffr_at, and maintaining extremely stable thermal environments within the experimental hutch, often requiring extended stabilization times cite:&leake19_nanod_beaml_id01. Examples of such end-stations, including those at beamlines ID16B cite:&martinez-criado16_id16b and ID11 cite:&wright20_new_oppor_at_mater_scien, are shown in Figure ref:fig:introduction_passive_stations. However, when a large number of degrees of freedom are required, the cumulative errors and limited dynamic stiffness of stacked configurations can make experiments with nano-focused beams extremely challenging or infeasible.

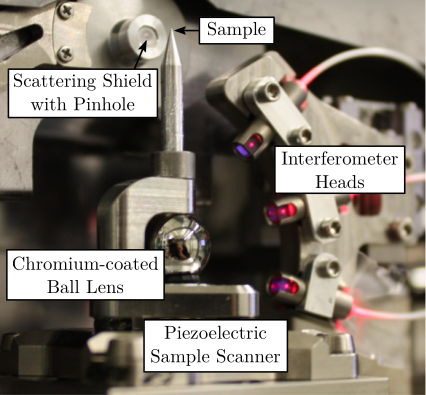

The concept of using an external metrology to measure and potentially correct for positioning errors is increasingly used for nano-positioning end-stations. Ideally, the relative position between the sample's acrfull:poi and the X-ray beam focus would be measured directly. In practice, direct measurement is often impossible; instead, the sample position is typically measured relative to a reference frame associated with the focusing optics, providing an indirect measurement.

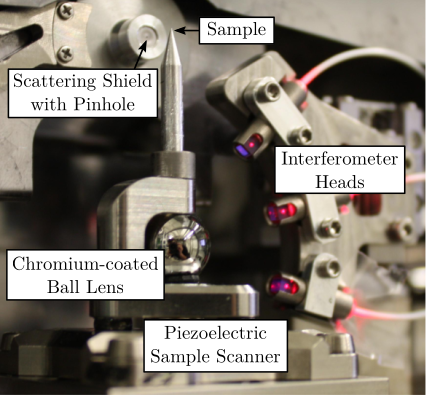

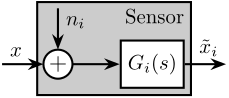

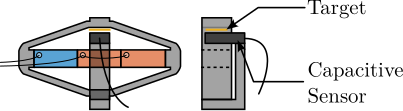

This measured position can be used in several ways: for post-processing correction of acquired data; for calibration routines to compensate for repeatable errors; or, most relevantly here, for real-time feedback control. Various sensor technologies have been employed, with capacitive sensors cite:&schroer17_ptynam;&villar18_nanop_esrf_id16a_nano_imagin_beaml;&schropp20_ptynam and, increasingly, fiber-based interferometers cite:&nazaretski15_pushin_limit;&stankevic17_inter_charac_rotat_stages_x_ray_nanot;&holler17_omny_pin_versat_sampl_holder;&holler18_omny_tomog_nano_cryo_stage;&engblom18_nanop_resul;&schropp20_ptynam;&nazaretski22_new_kirkp_baez_based_scann;&kelly22_delta_robot_long_travel_nano;&xu23_high_nsls_ii;&geraldes23_sapot_carnaub_sirius_lnls being prominent choices.

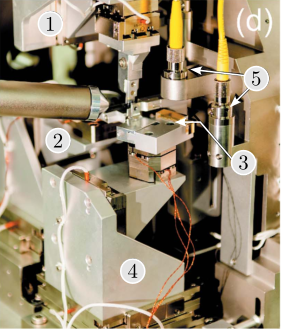

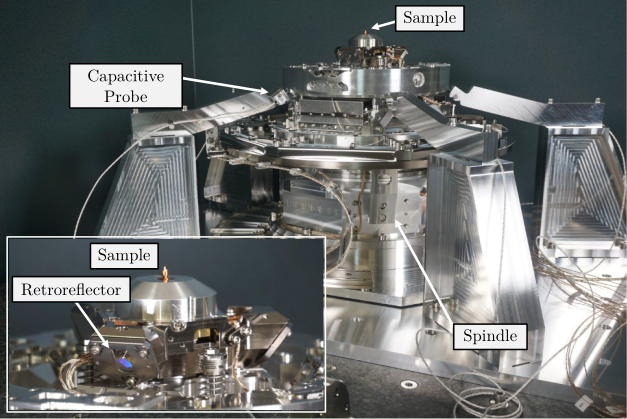

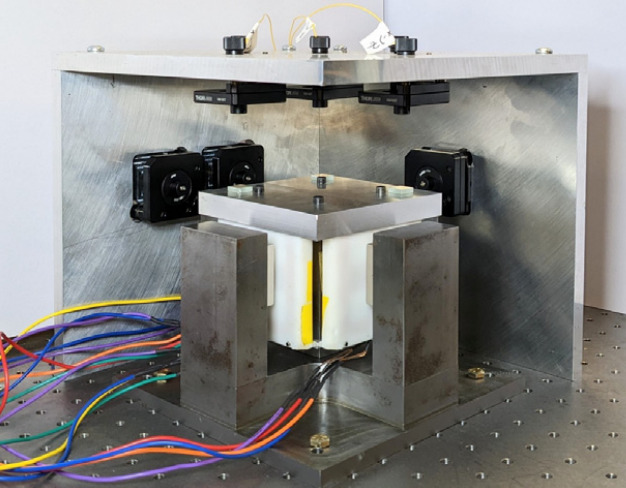

Two examples illustrating the integration of online metrology are presented in Figure ref:fig:introduction_metrology_stations. The system at NSLS X8C (Figure ref:fig:introduction_stages_wang) used capacitive sensors for rotation stage calibration and image alignment during tomography post-processing cite:&wang12_autom_marker_full_field_hard. The PtiNAMi microscope at DESY P06 (Figure ref:fig:introduction_stages_schroer) employs interferometers directed at a spherical target below the sample for position monitoring during tomography, with plans for future feedback loop implementation cite:&schropp20_ptynam.

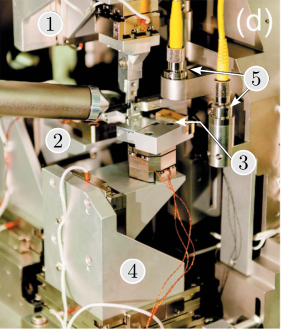

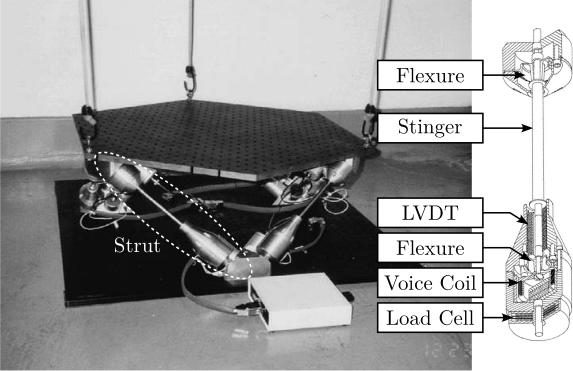

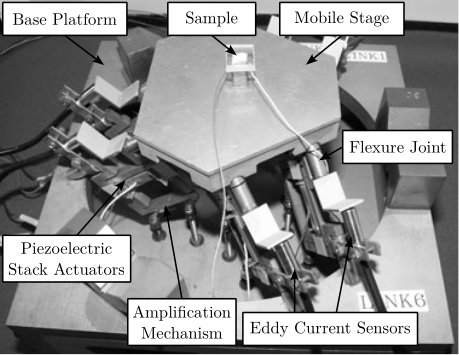

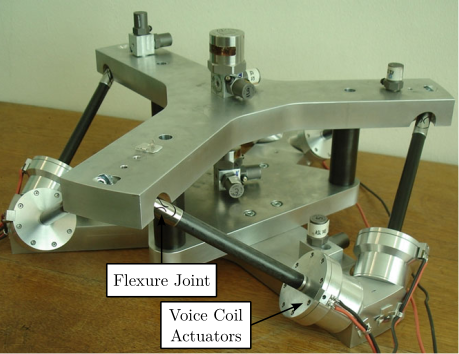

For applications requiring active compensation of measured errors, particularly with nano-beams, feedback control loops are implemented. Actuation is typically achieved using piezoelectric actuators cite:&nazaretski15_pushin_limit;&holler17_omny_pin_versat_sampl_holder;&holler18_omny_tomog_nano_cryo_stage;&villar18_nanop_esrf_id16a_nano_imagin_beaml;&nazaretski22_new_kirkp_baez_based_scann, 3-phase linear motors cite:&stankevic17_inter_charac_rotat_stages_x_ray_nanot;&engblom18_nanop_resul, or acrfull:vc actuators cite:&kelly22_delta_robot_long_travel_nano;&geraldes23_sapot_carnaub_sirius_lnls. While often omitted, feedback bandwidth for such stages are relatively low (around $1\,\text{Hz}$), primarily targeting the compensation of slow thermal drifts. More recently, higher bandwidths (up to $100\,\text{Hz}$) have been demonstrated, particularly with the use of voice coil actuators cite:&kelly22_delta_robot_long_travel_nano;&geraldes23_sapot_carnaub_sirius_lnls.

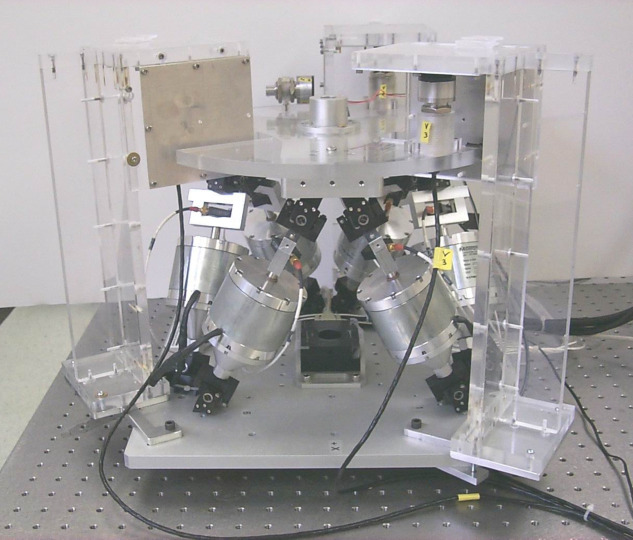

Figure ref:fig:introduction_active_stations showcases two end-stations incorporating online metrology and active feedback control. The ID16A system at acrshort:esrf (Figure ref:fig:introduction_stages_villar) uses capacitive sensors and a piezoelectric Stewart platform to compensate for rotation stage errors and to perform accurate scans cite:&villar18_nanop_esrf_id16a_nano_imagin_beaml. Another example, shown in Figure ref:fig:introduction_stages_nazaretski, employs interferometers and piezoelectric stages to compensate for thermal drifts cite:&nazaretski15_pushin_limit;&nazaretski17_desig_perfor_x_ray_scann. A more comprehensive review of actively controlled end-stations is provided in Section ref:sec:nhexa_platform_review.

For tomography experiments, correcting spindle guiding errors is critical. Correction stages are typically placed either below the spindle cite:&stankevic17_inter_charac_rotat_stages_x_ray_nanot;&holler17_omny_pin_versat_sampl_holder;&holler18_omny_tomog_nano_cryo_stage;&villar18_nanop_esrf_id16a_nano_imagin_beaml;&engblom18_nanop_resul;&nazaretski22_new_kirkp_baez_based_scann;&xu23_high_nsls_ii or above it cite:&wang12_autom_marker_full_field_hard;&schroer17_ptynam;&schropp20_ptynam;&geraldes23_sapot_carnaub_sirius_lnls. In most reported cases, only translation errors are actively corrected. Payload capacities for these high-precision systems are usually limited, typically handling calibrated samples on the micron scale, although capacities up to 500g have been reported cite:&nazaretski22_new_kirkp_baez_based_scann;&kelly22_delta_robot_long_travel_nano. The system developed in this thesis aims for payload capabilities approximately 100 times heavier (up to $50\,\text{kg}$) than previous stations with similar positioning requirements.

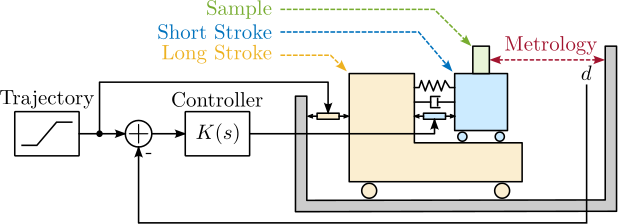

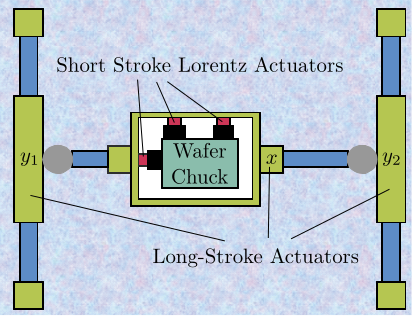

End-stations integrating online metrology for active nano-positioning often exhibit limited operational ranges, typically constrained to a few degrees of freedom with strokes around $100\,\upmu\text{m}$. Recently, acrfull:vc actuators were used to increase the stroke up to $3\,\text{mm}$ cite:&kelly22_delta_robot_long_travel_nano;&geraldes23_sapot_carnaub_sirius_lnls An alternative strategy involves a "long stroke-short stroke" architecture, illustrated conceptually in Figure ref:fig:introduction_two_stage_schematic. In this configuration, a high-accuracy, high-bandwidth short-stroke stage is mounted on top of a less precise long-stroke stage. The short-stroke stage actively compensates for errors based on metrology feedback, while the long-stroke stage performs the larger movements. This approach allows the combination of extended travel with high precision and good dynamical response, but is often implemented for only one or a few degrees of freedom, as seen in Figures ref:fig:introduction_two_stage_schematic and ref:fig:introduction_two_stage_control_h_bridge.

Challenge definition

Introduction

The advent of fourth-generation light sources, coupled with advancements in focusing optics and detector technology, imposes stringent new requirements on sample positioning systems.

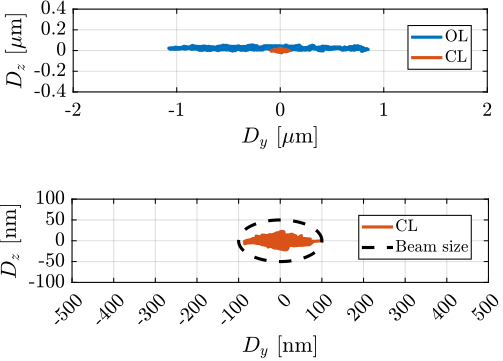

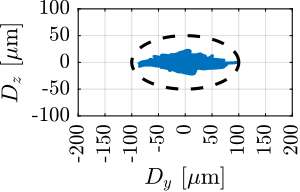

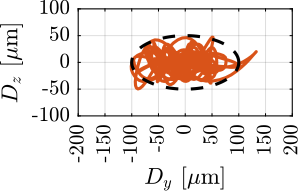

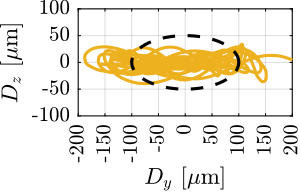

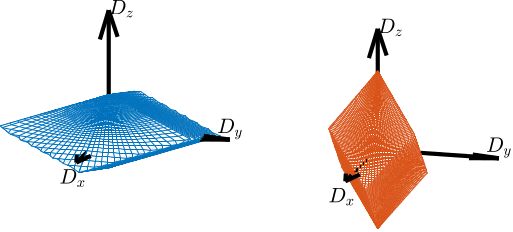

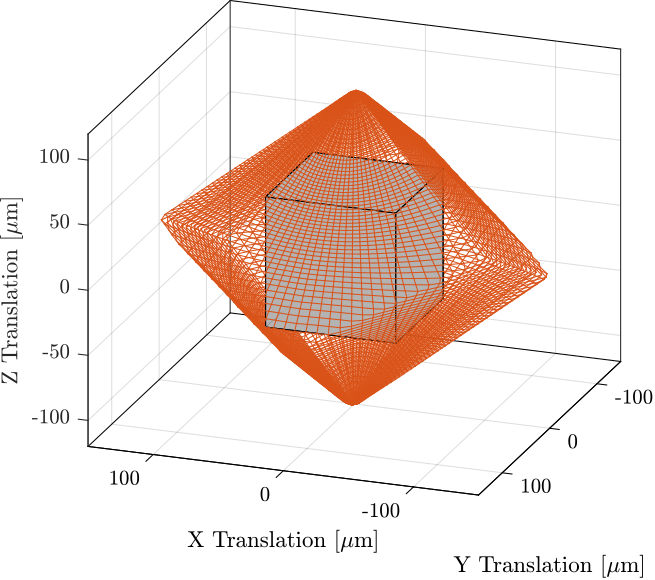

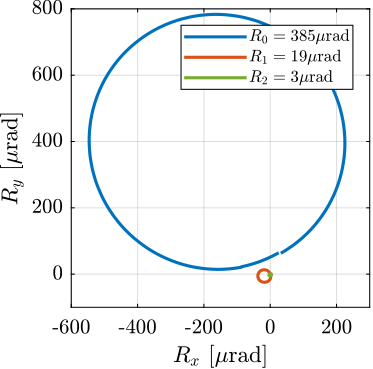

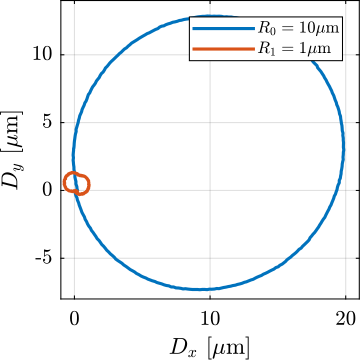

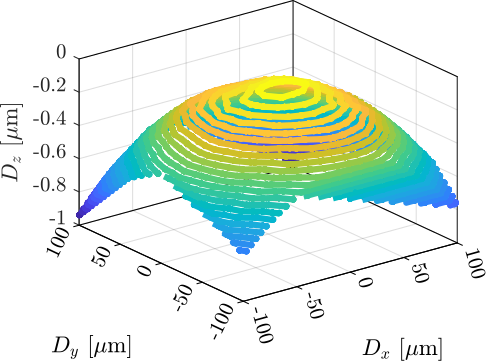

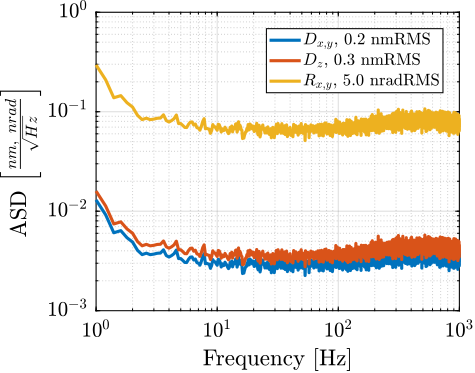

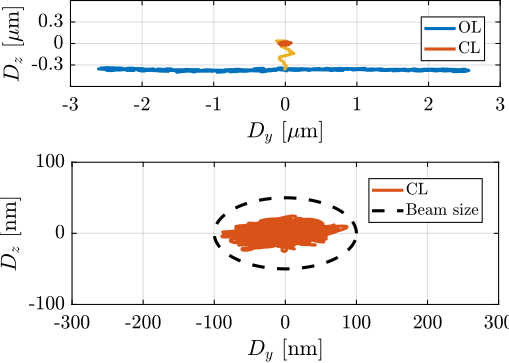

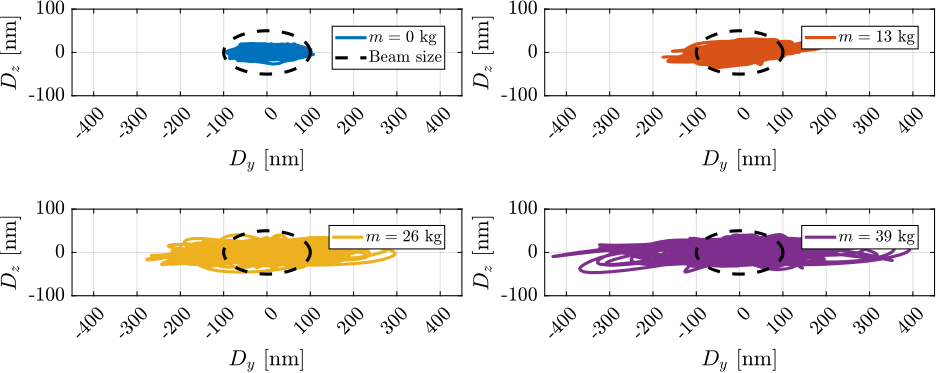

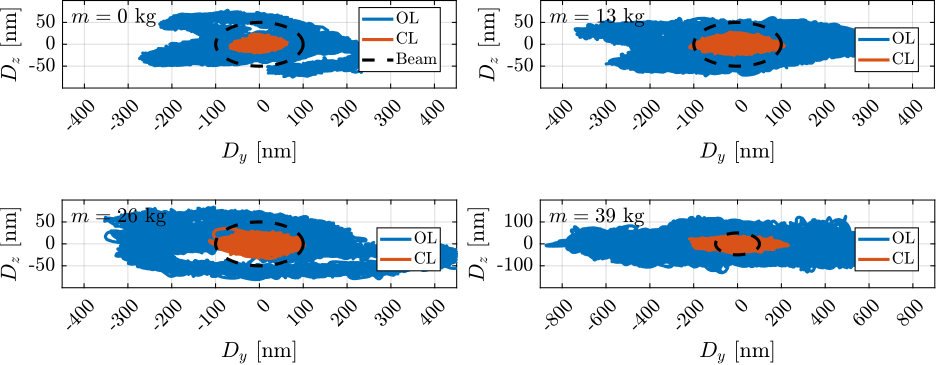

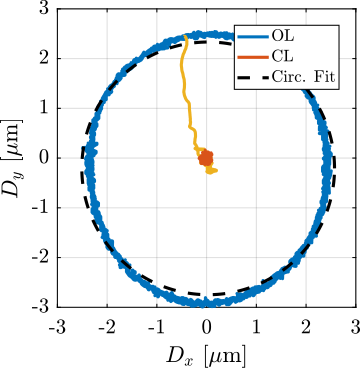

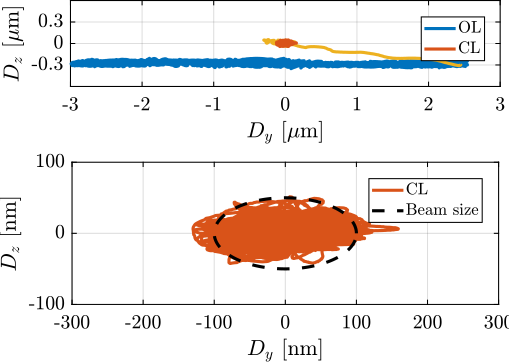

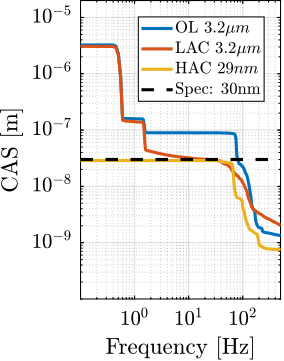

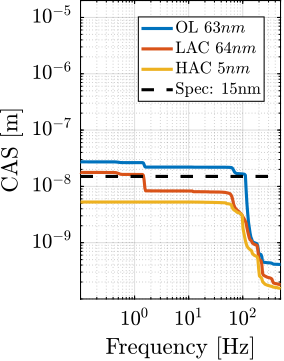

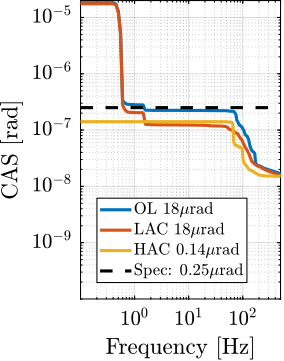

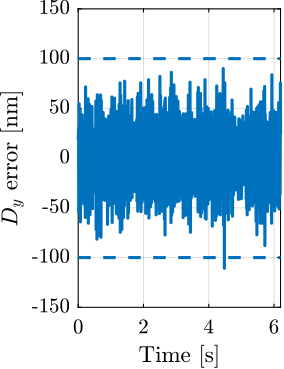

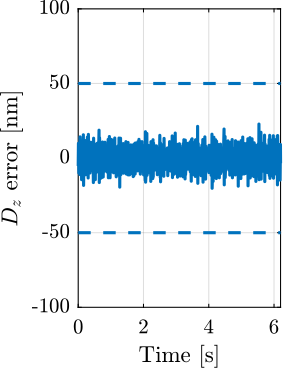

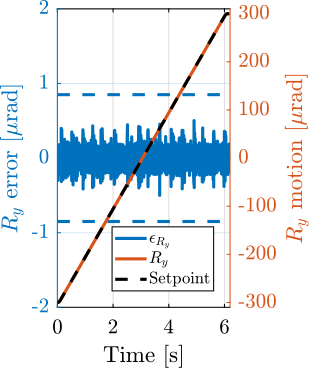

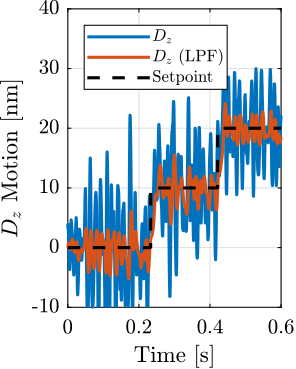

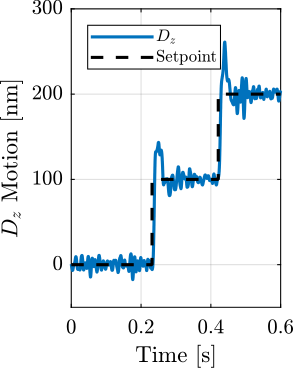

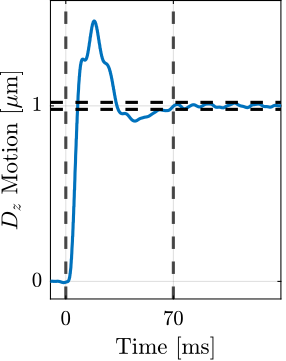

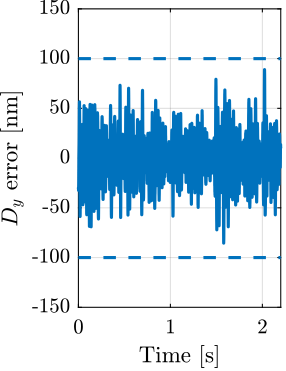

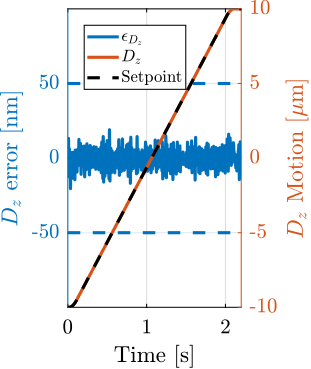

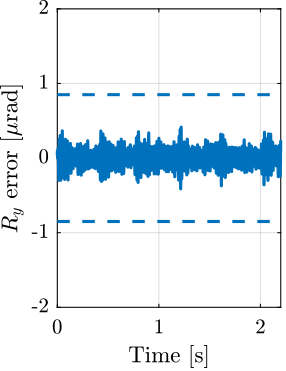

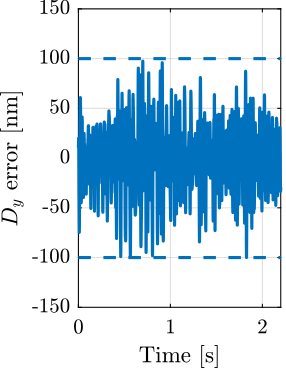

With ID31's anticipated minimum beam dimensions of approximately $200\,\text{nm}\times 100\,\text{nm}$, the primary experimental objective is maintaining the sample's acrshort:poi within this beam. This necessitates peak-to-peak positioning errors below $200\,\text{nm}$ in $D_y$ and $200\,\text{nm}$ in $D_z$, corresponding to acrfull:rms errors of $30\,\text{nm}$ and $15\,\text{nm}$, respectively. Additionally, the $R_y$ tilt angle error must remain below $0.1\,\text{mdeg}$ ($250\,\text{nrad RMS}$). Given the high frame rates of modern detectors, these specified positioning errors must be maintained even when considering high-frequency vibrations (typically up to $1\,\text{kHz}$).

These demanding stability requirements must be achieved within the specific context of the ID31 beamline, which necessitates the integration with the existing micro-station, accommodating a wide range of experimental configurations requiring high mobility, and handling substantial payloads up to $50\,\text{kg}$.

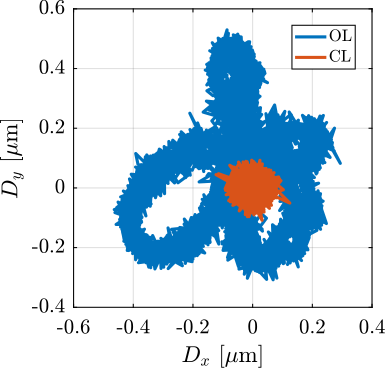

The existing micro-station, despite being composed of high-performance stages, has a positioning accuracy limited to approximately $10\,\upmu m$ and $10\,\upmu\text{rad}$ (peak to peak) due to inherent factors such as backlash, thermal expansion, imperfect guiding, and vibrations.

The primary objective of this project is therefore defined as enhancing the positioning accuracy and stability of the ID31 micro-station by roughly two orders of magnitude, to fully leverage the capabilities offered by the ESRF-EBS source and modern detectors, without compromising its existing mobility and payload capacity.

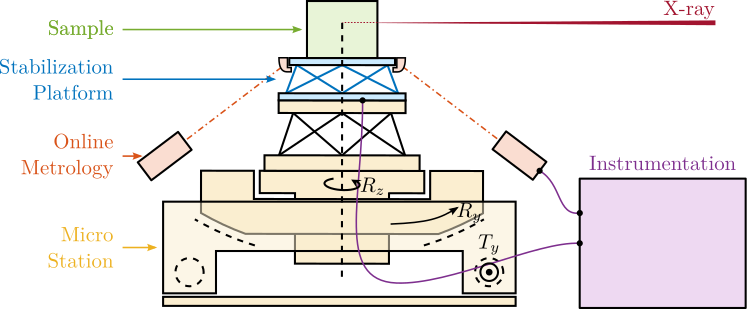

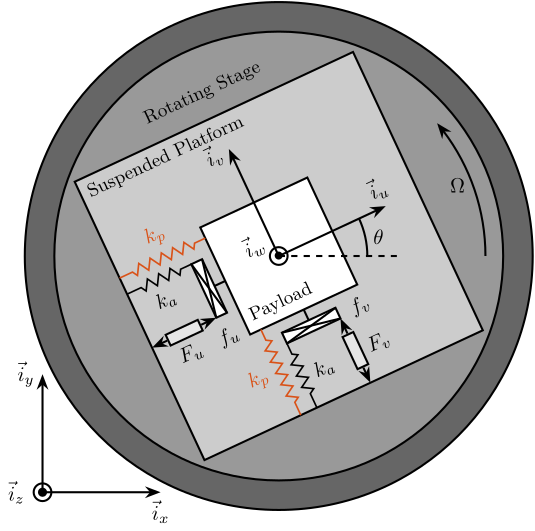

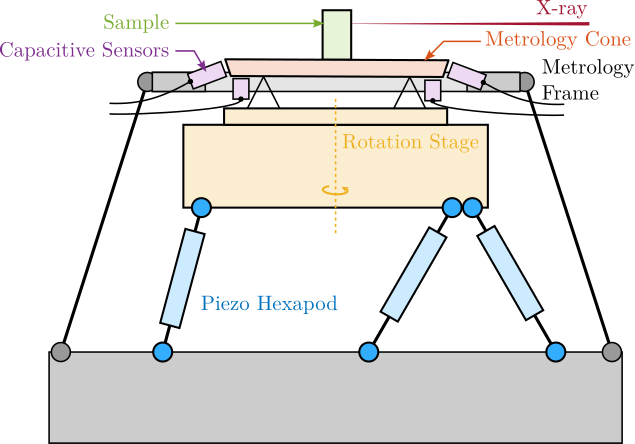

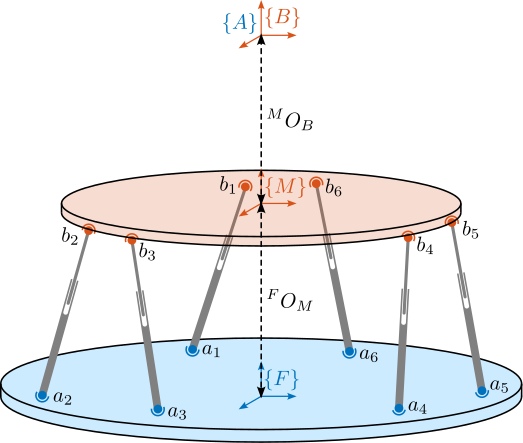

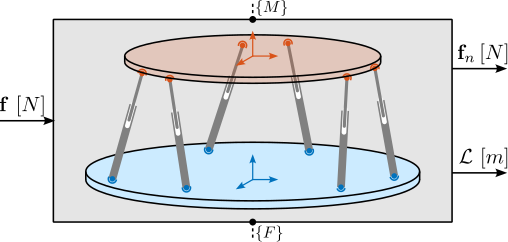

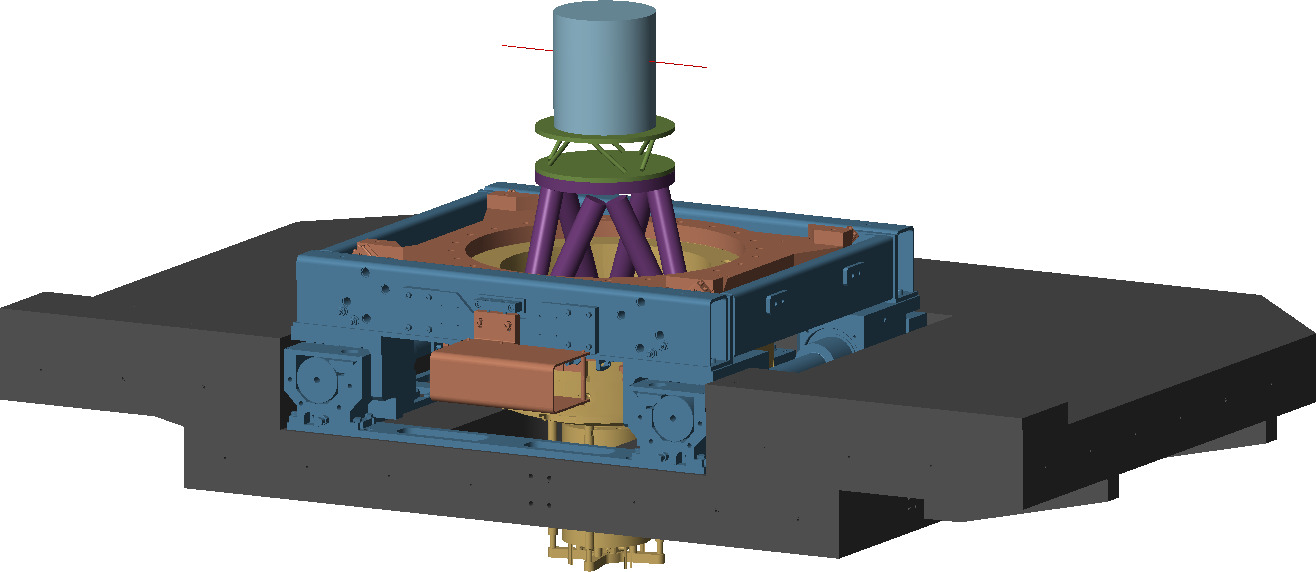

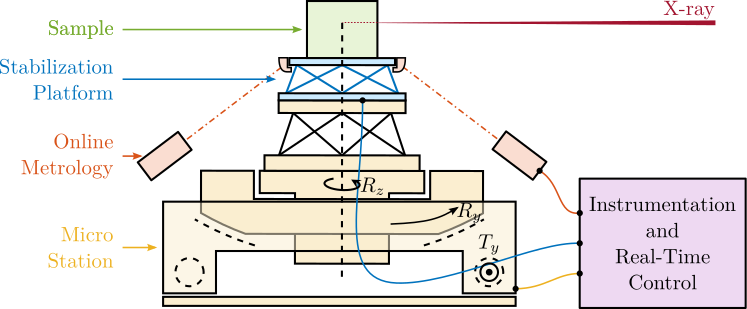

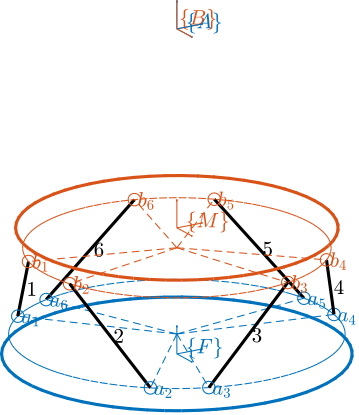

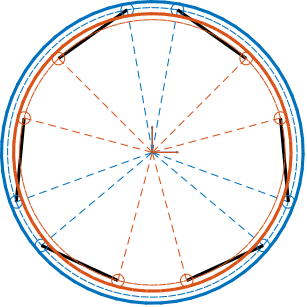

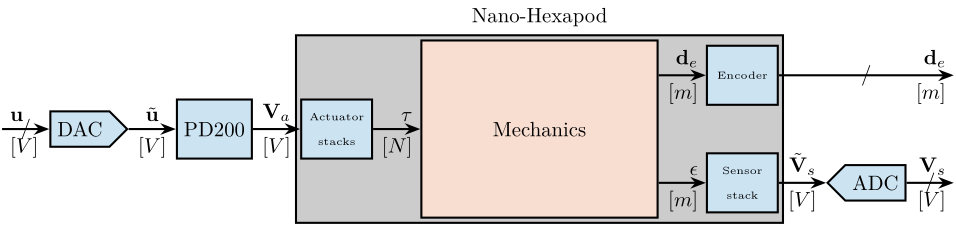

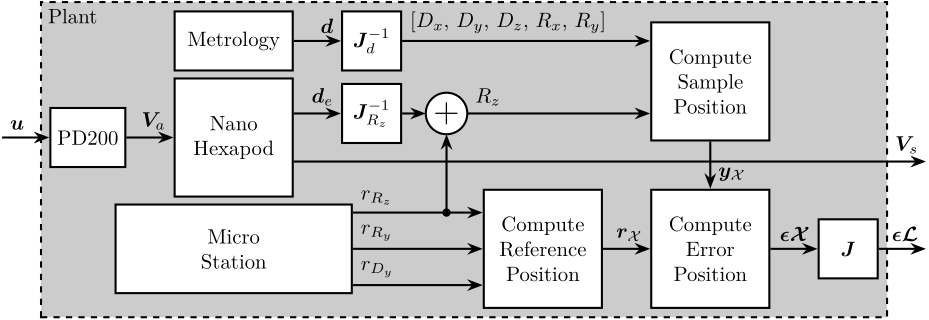

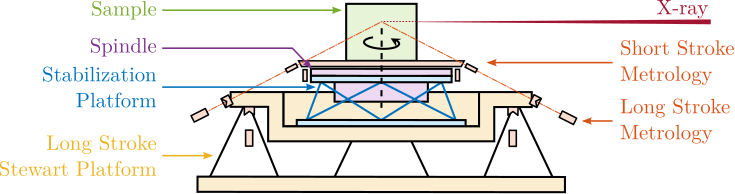

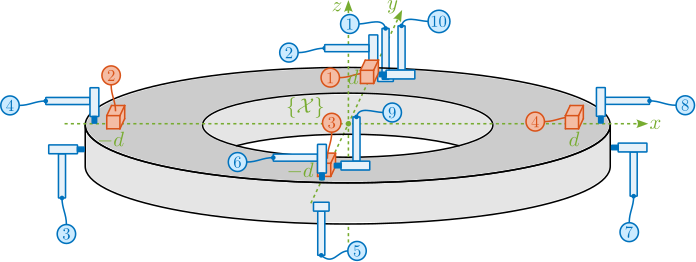

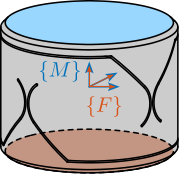

The Nano Active Stabilization System Concept

To address these challenges, the concept of a acrfull:nass is proposed. As schematically illustrated in Figure ref:fig:introduction_nass_concept_schematic, the acrshort:nass comprises three principal components integrated with the existing micro-station (yellow): a 5-DoF online metrology system (red), an active stabilization platform (blue), and the associated control system and instrumentation (purple). This system essentially functions as a high-performance, multi-axis vibration isolation and error correction platform situated between the micro-station and the sample. It actively compensates for positioning errors measured by the external metrology system.

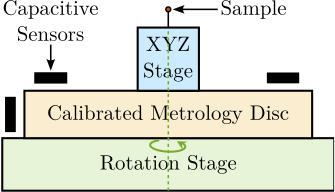

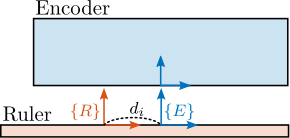

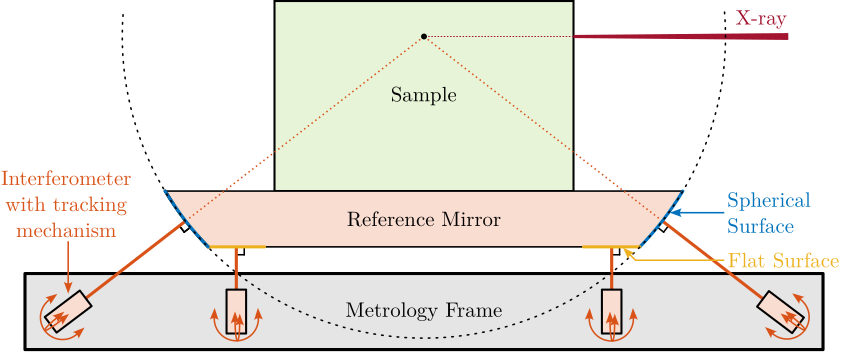

Online Metrology system

The performance of the acrshort:nass is fundamentally reliant on the accuracy and bandwidth of its online metrology system, as the active control is based directly on these measurements. This metrology system must fulfill several criteria: measure the sample position in 5-DoF (excluding rotation about the vertical Z-axis); possess a measurement range compatible with the micro-station's extensive mobility and continuous spindle rotation; achieve an accuracy compatible with the sub-100 nm positioning target; and offer high bandwidth for real-time control.

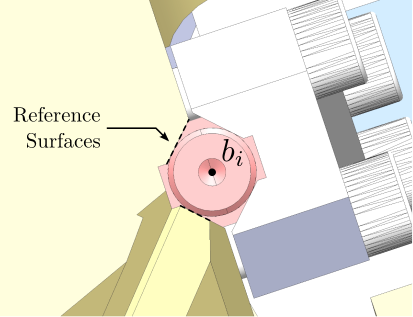

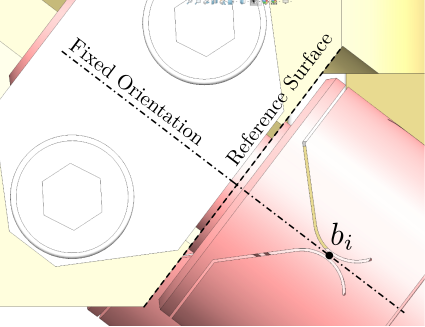

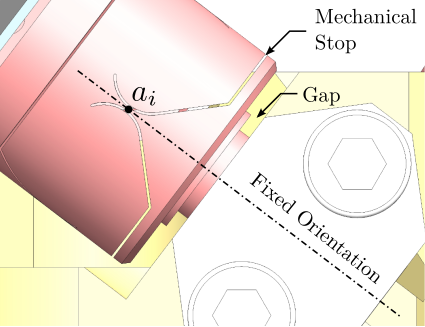

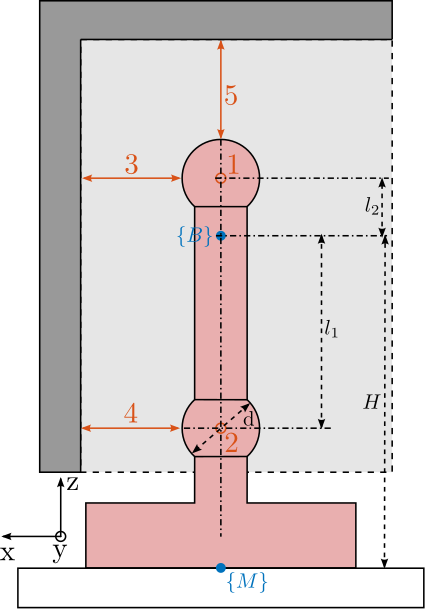

A proposed concept (illustrated in Figure ref:fig:introduction_nass_metrology) features a spherical reflector with a flat bottom attached below the sample, with its center aligned to the X-ray focus. Fiber interferometers target both surfaces. A tracking system maintains perpendicularity between the interferometer beams and the mirror, such that Abbe errors are eliminated. Interferometers pointing at the spherical surface provides translation measurement, while the ones pointing at the flat bottom surface yield tilt angles. The development of this complex metrology system constitutes a significant mechatronic project in itself and is currently ongoing; it is not further detailed within this thesis. For the work presented herein, the metrology system is assumed to provide accurate, high-bandwidth 5-DoF position measurements.

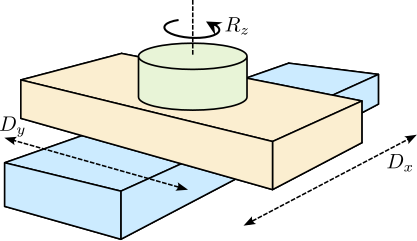

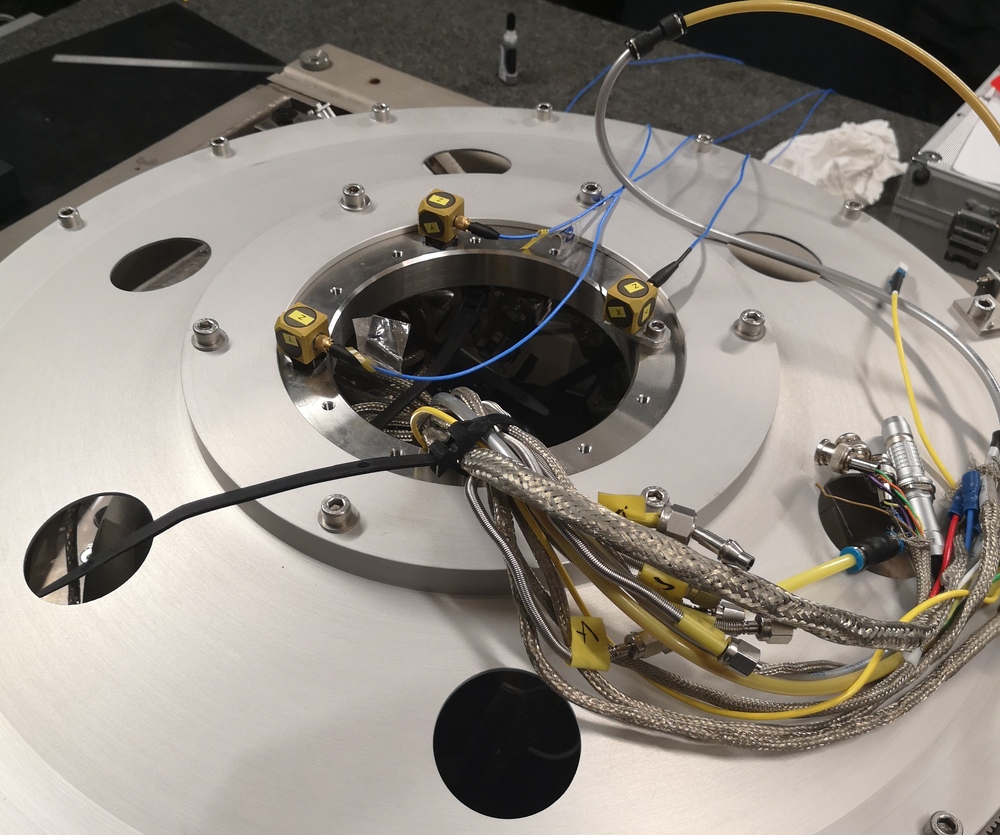

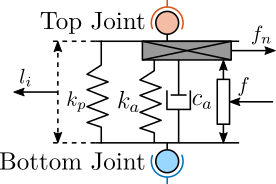

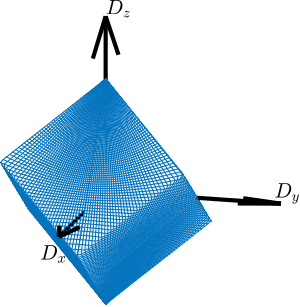

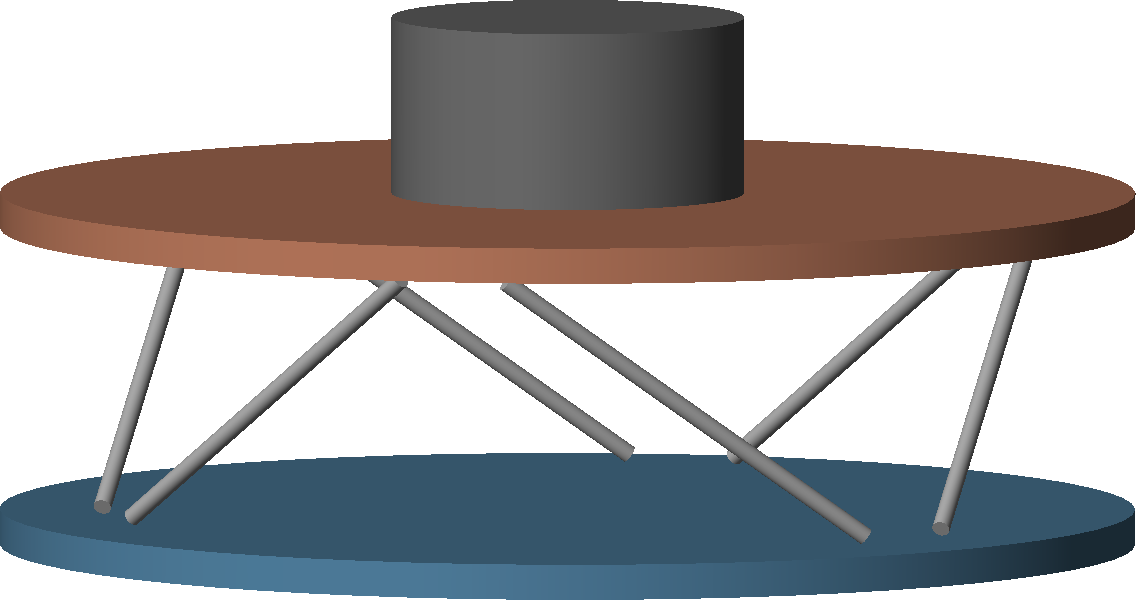

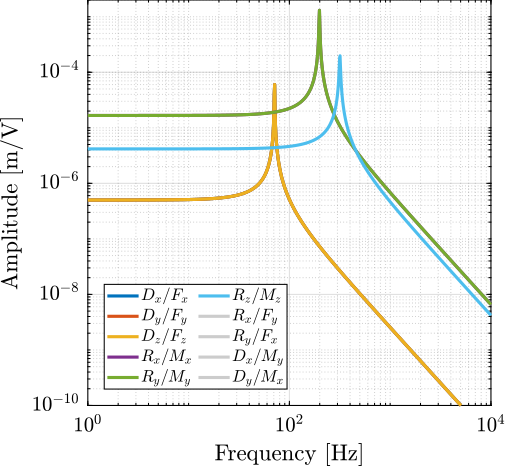

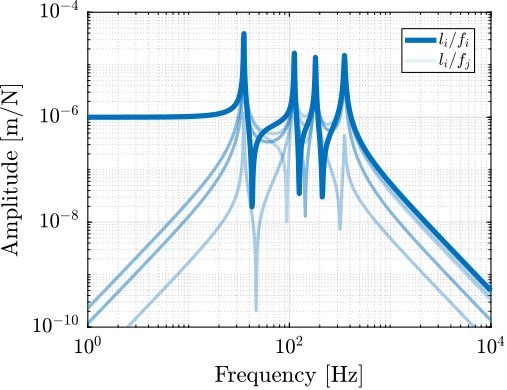

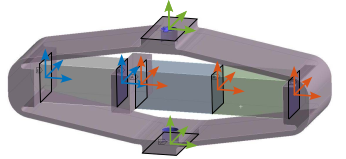

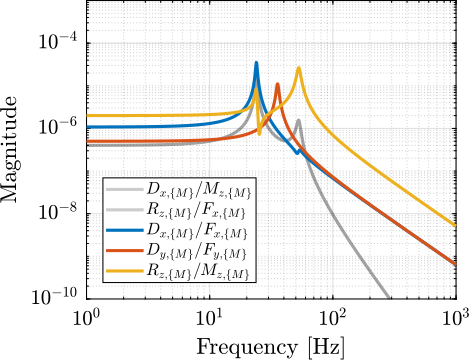

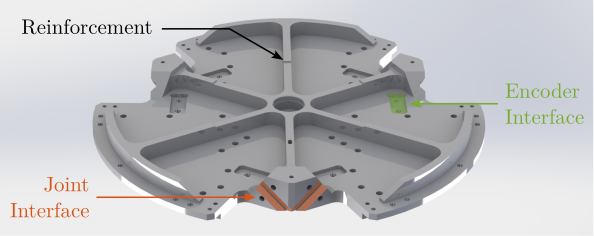

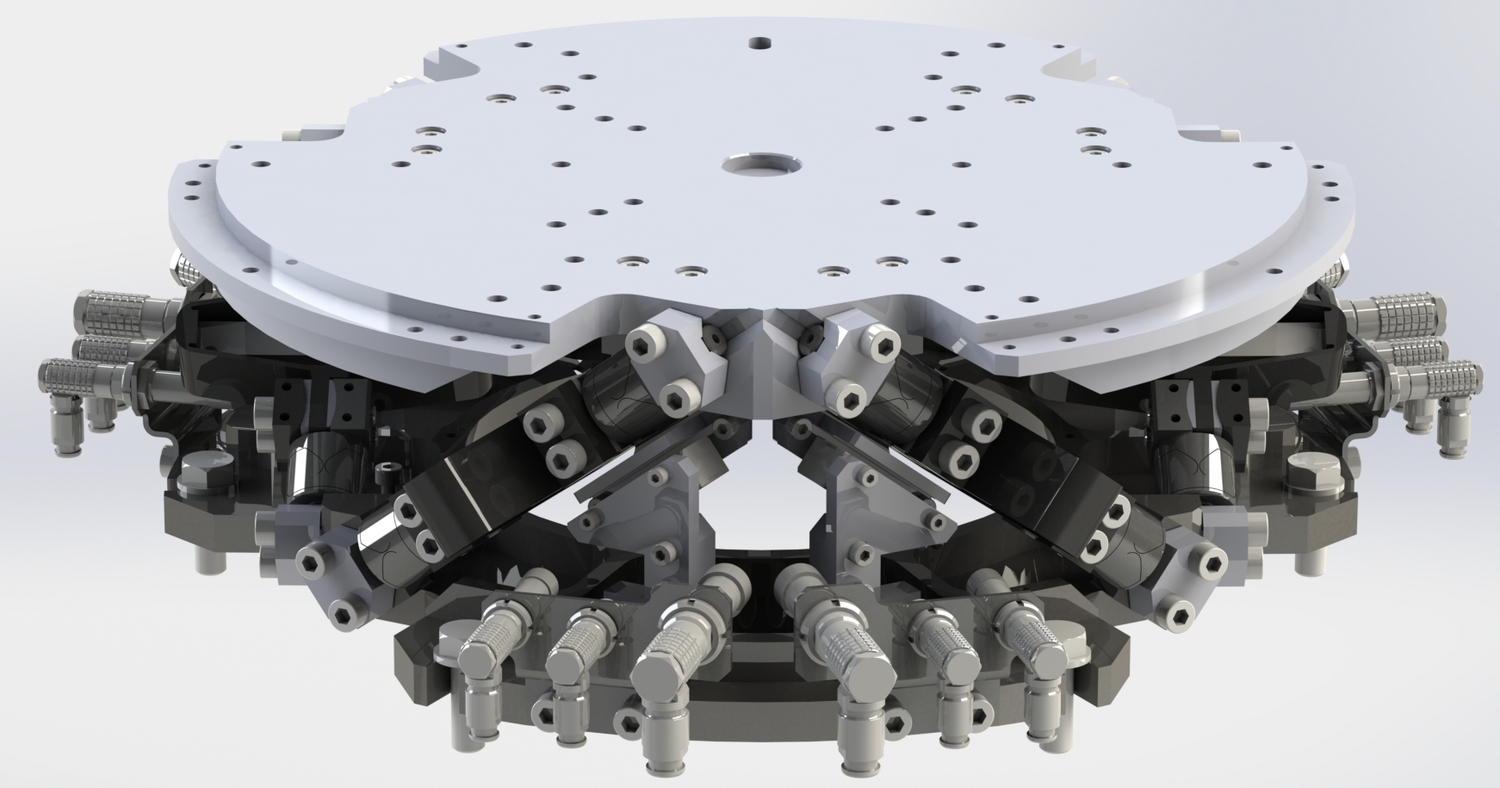

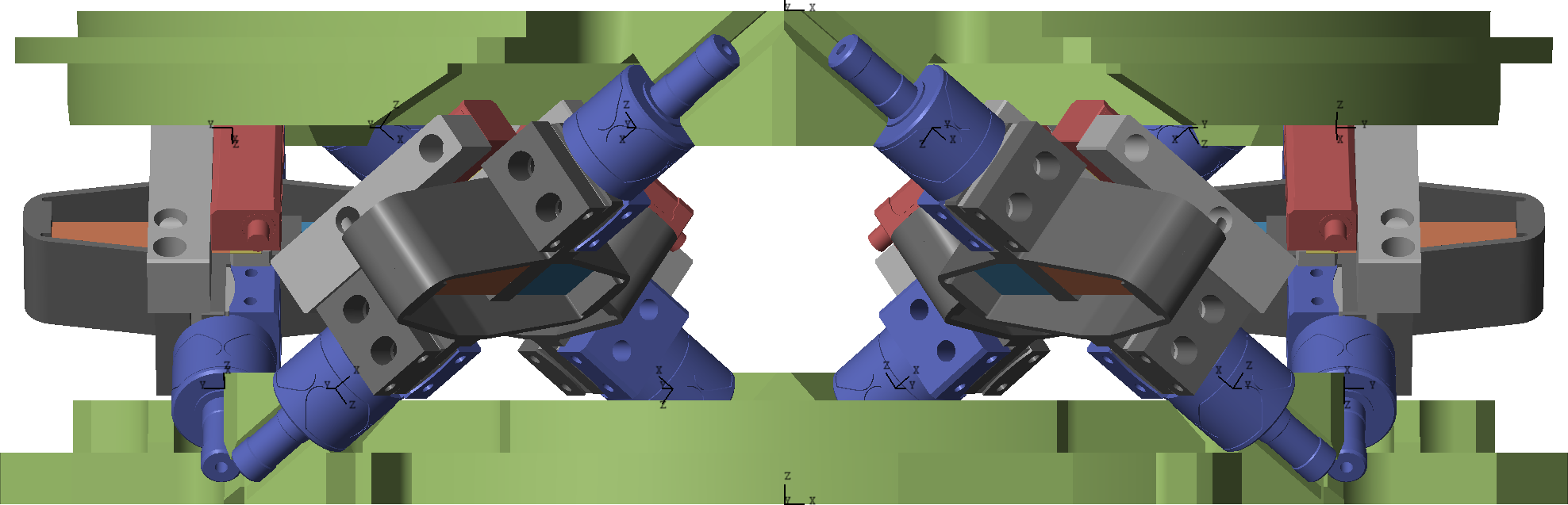

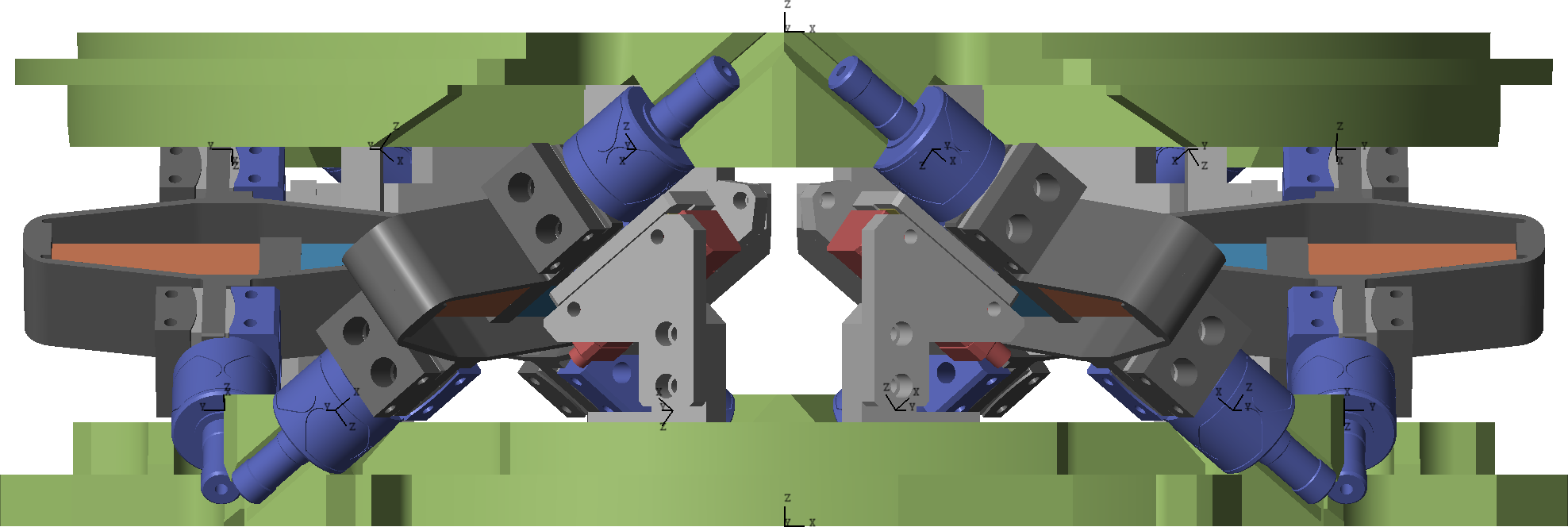

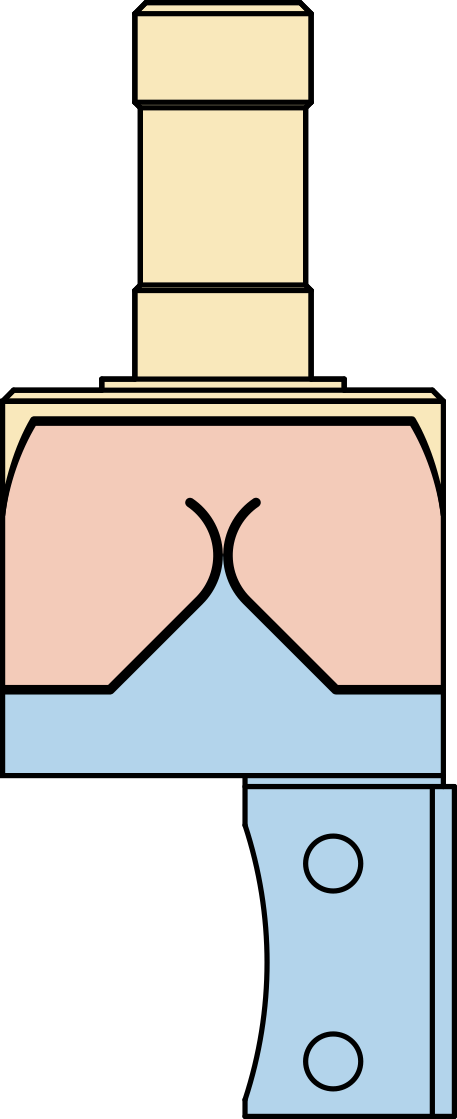

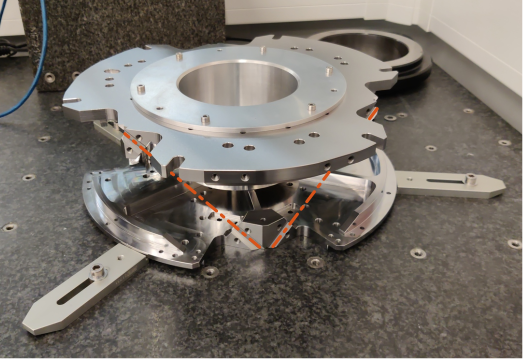

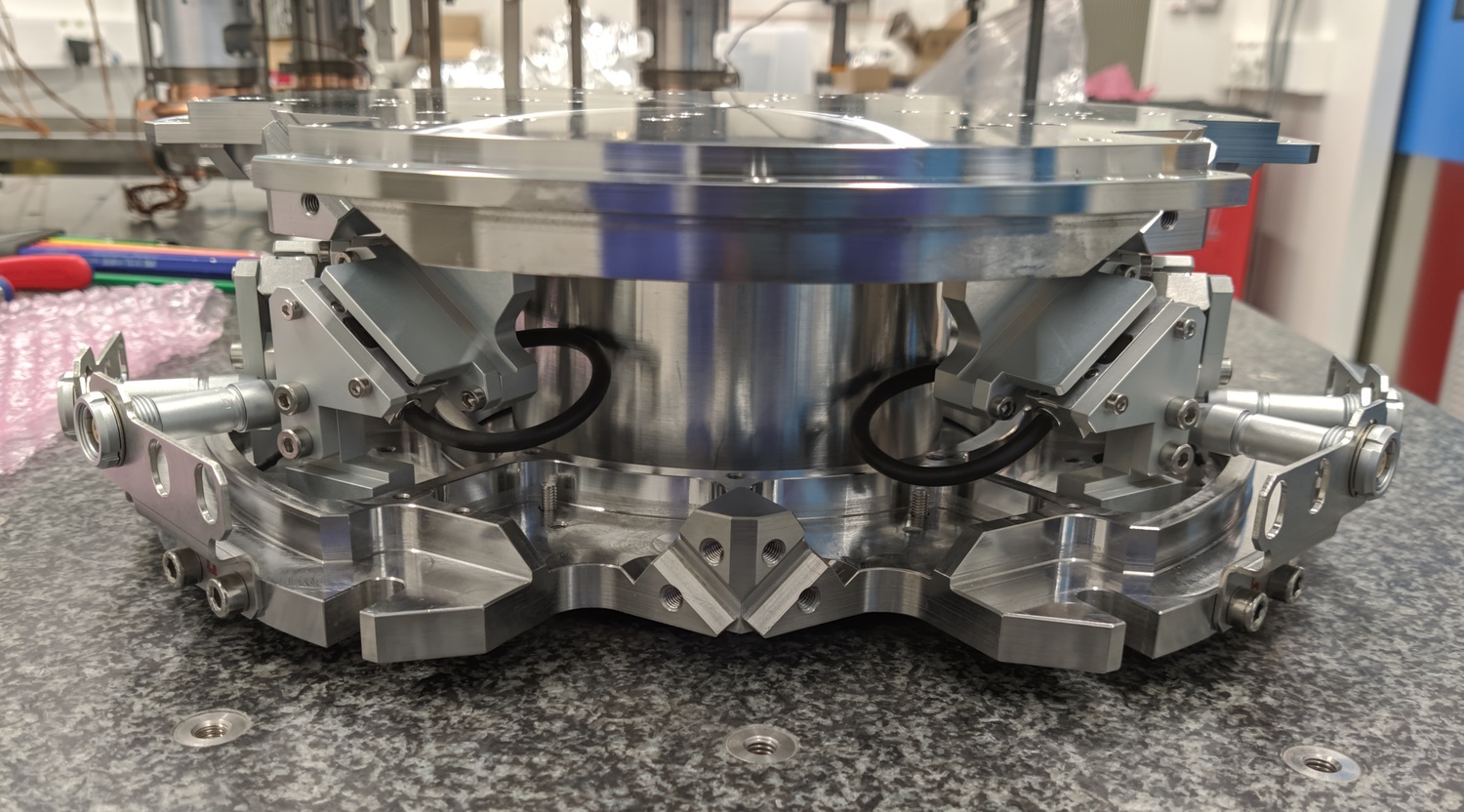

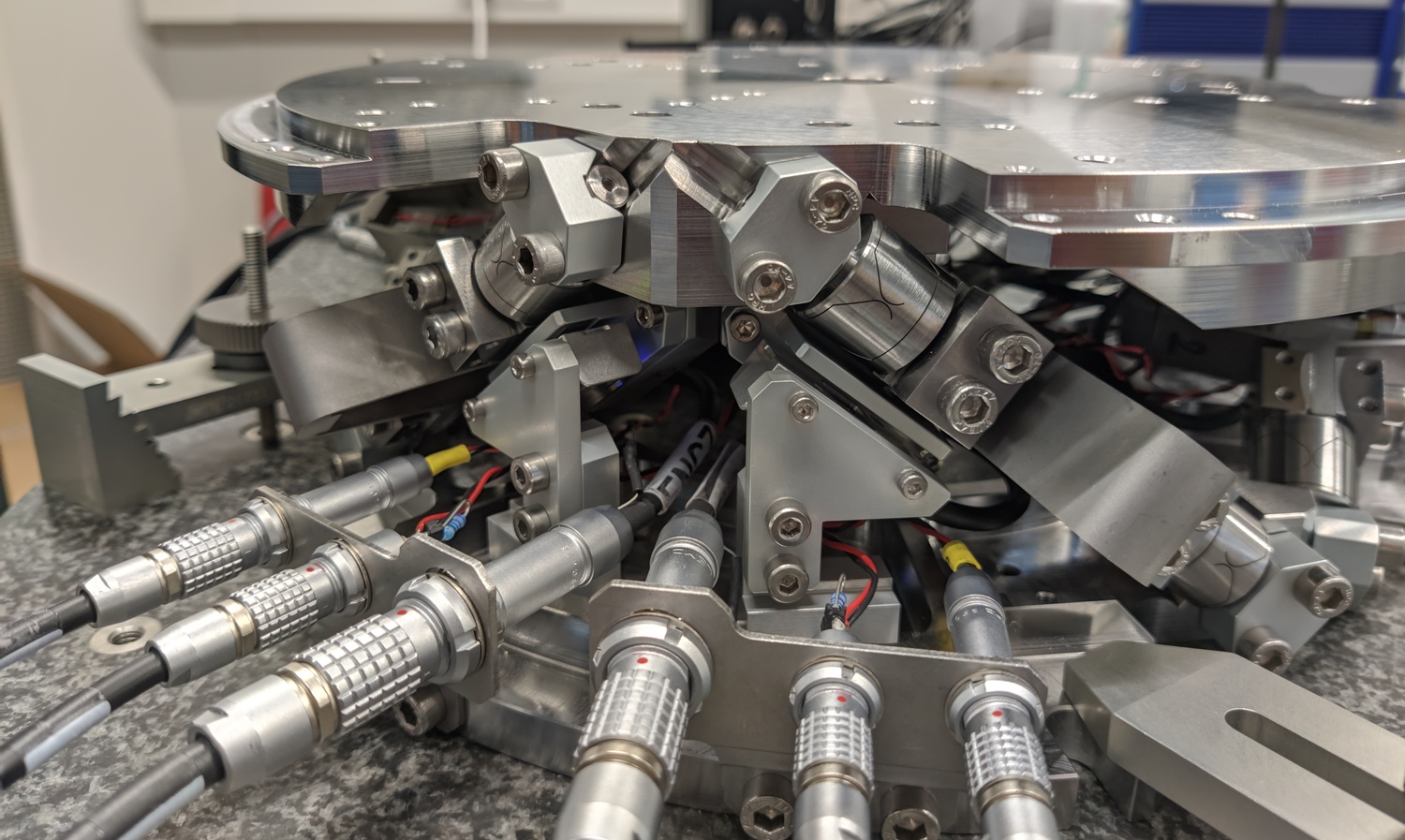

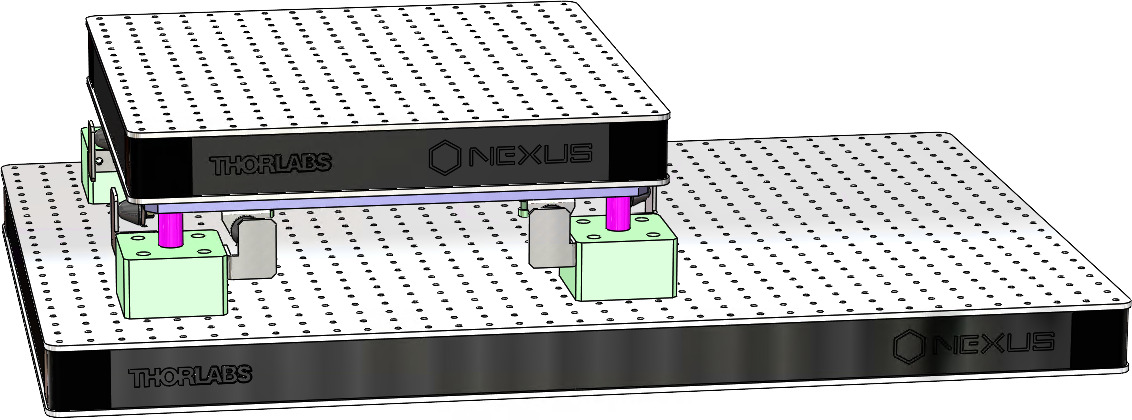

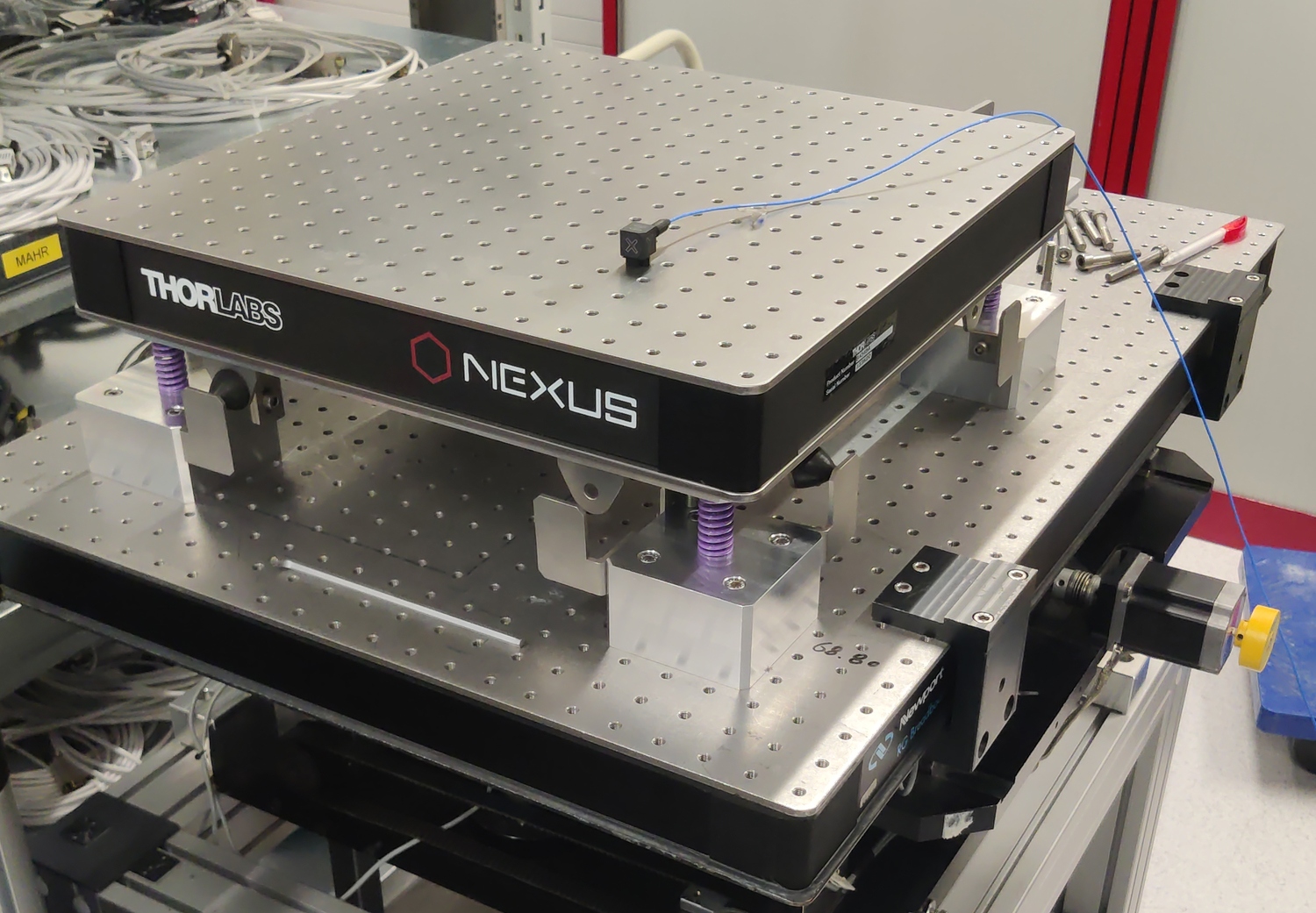

Active Stabilization Platform Design

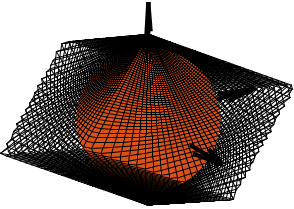

The active stabilization platform, positioned between the micro-station top plate and the sample, must satisfy several demanding requirements. It needs to provide active motion compensation in 5-DoF ($D_x$, $D_y$, $D_z$, $R_x$ and $R_y$). It must possess excellent dynamic properties to enable high-bandwidth control capable of suppressing vibrations and tracking desired trajectories with nanometer-level precision. Consequently, it must be free from backlash and play, and its active components (e.g., actuators) should introduce minimal vibrations. Critically, it must accommodate payloads up to $50\,\text{kg}$.

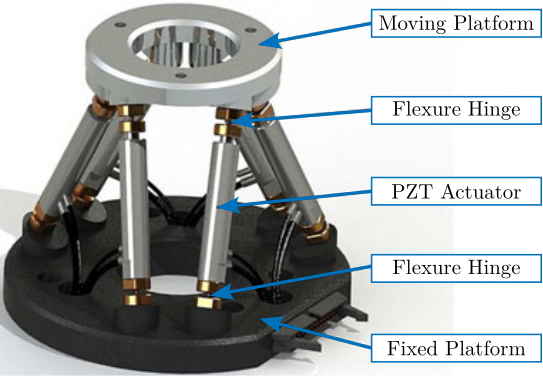

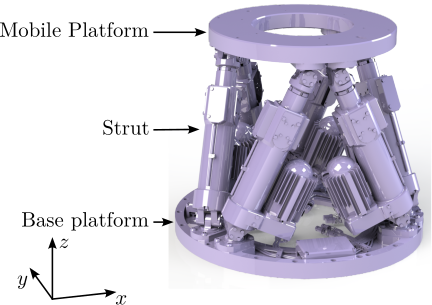

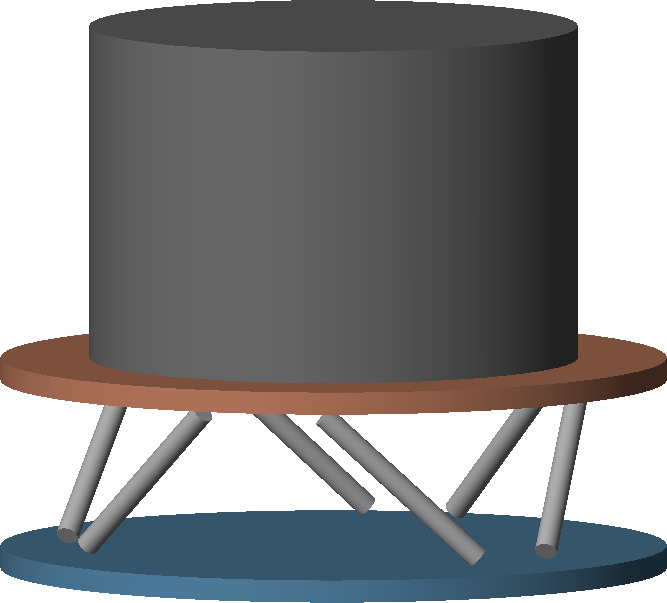

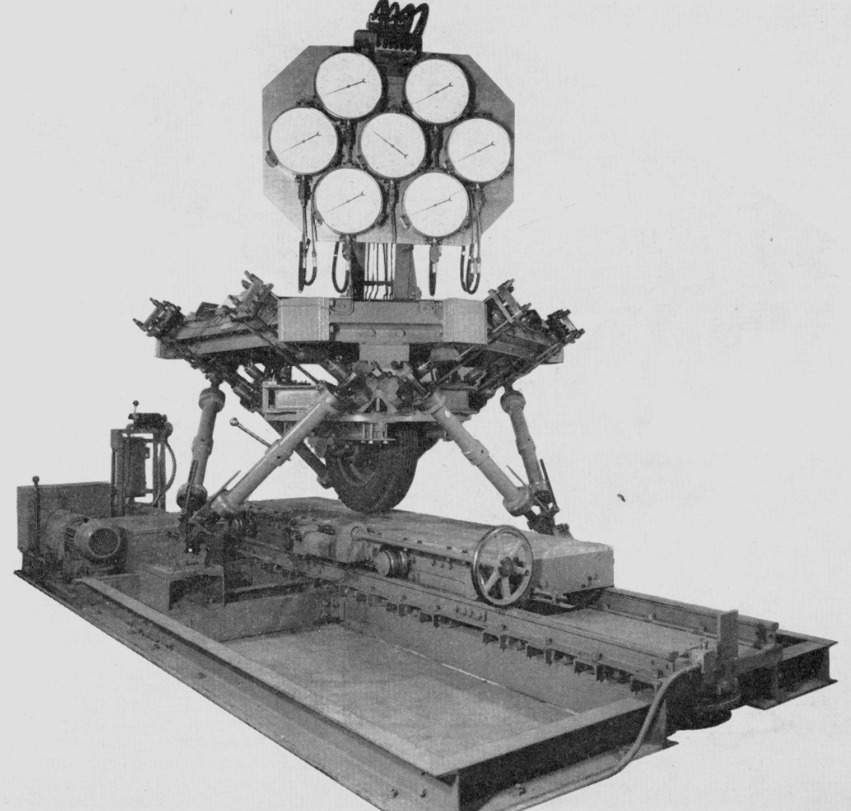

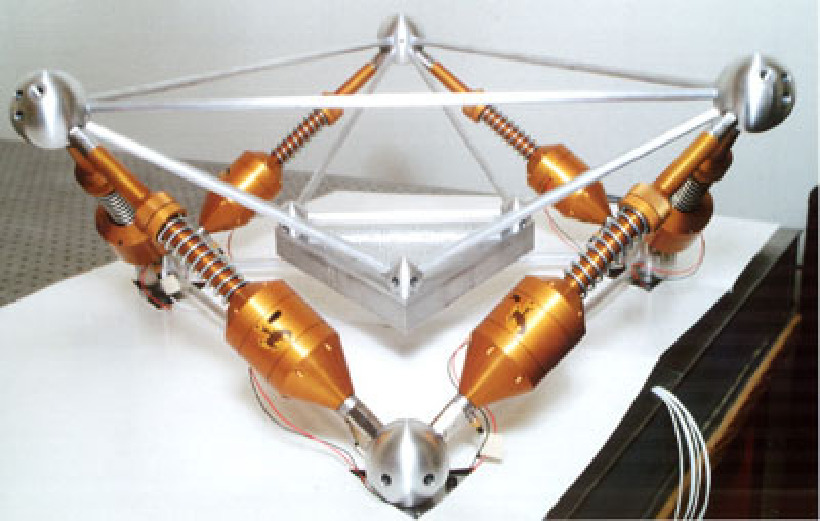

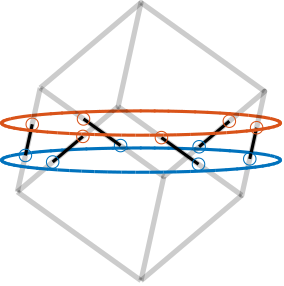

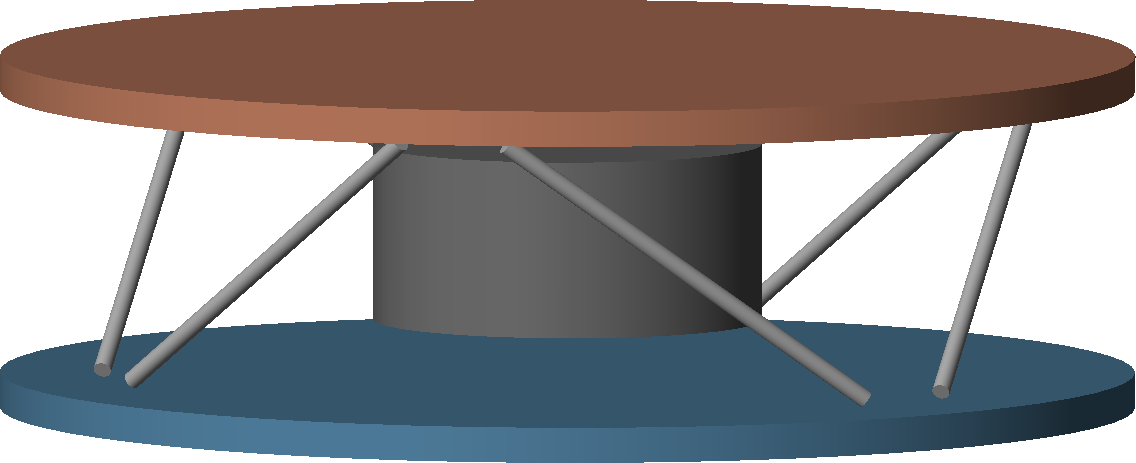

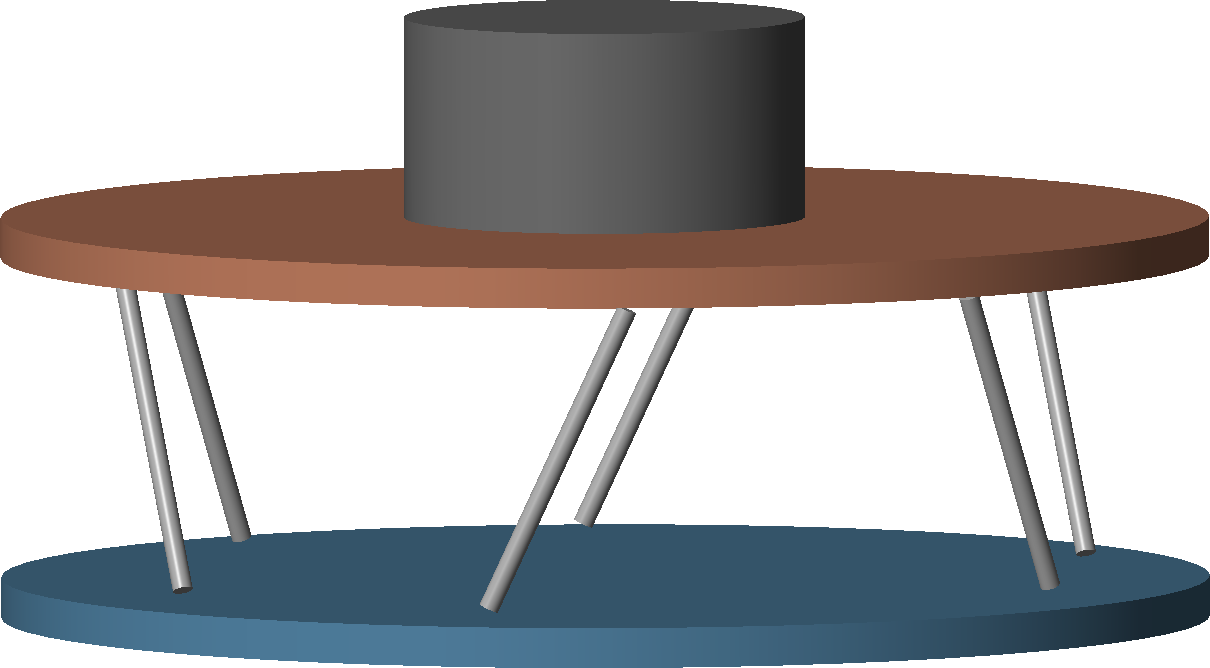

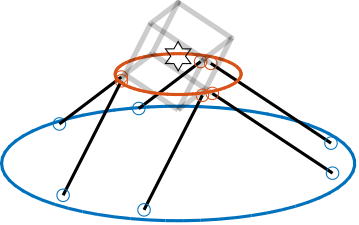

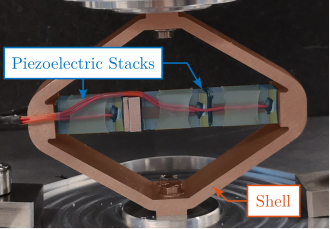

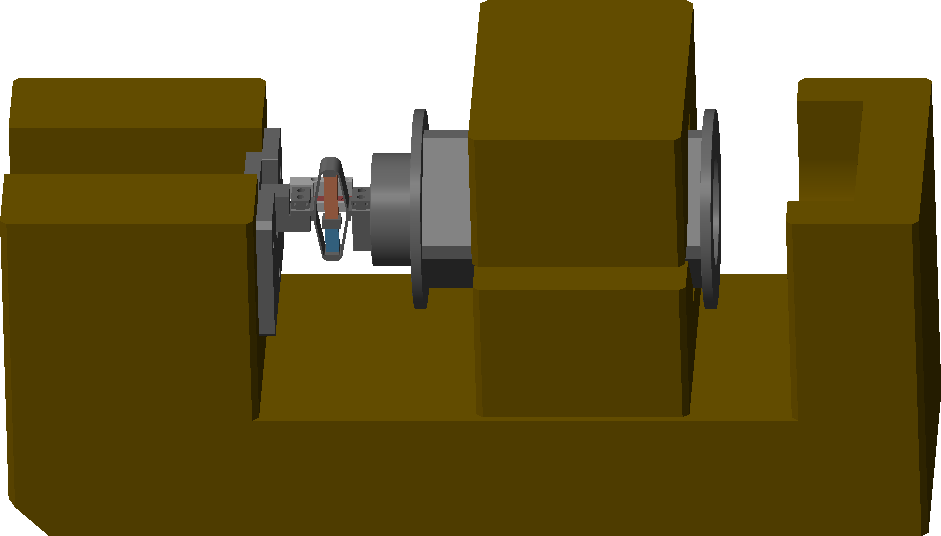

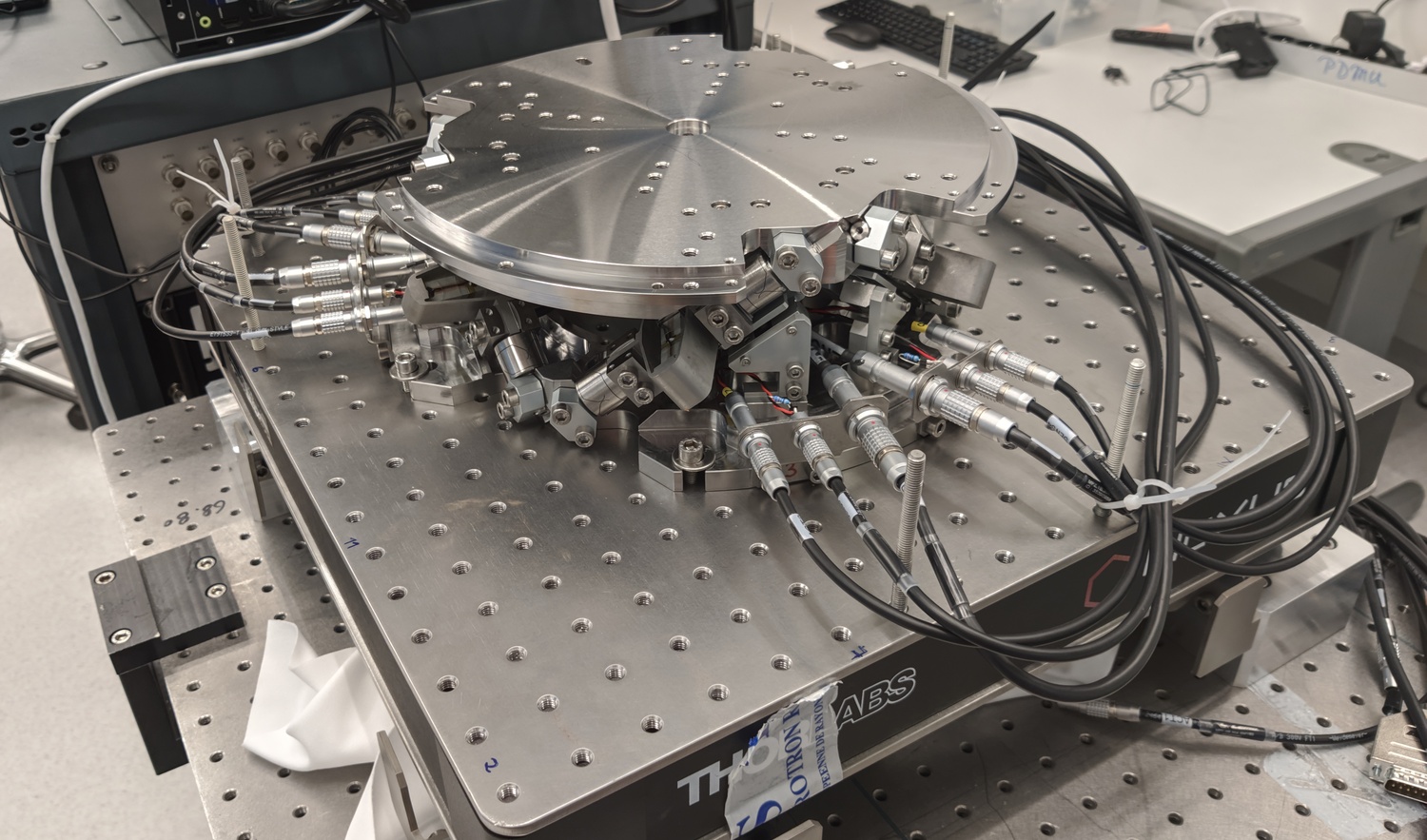

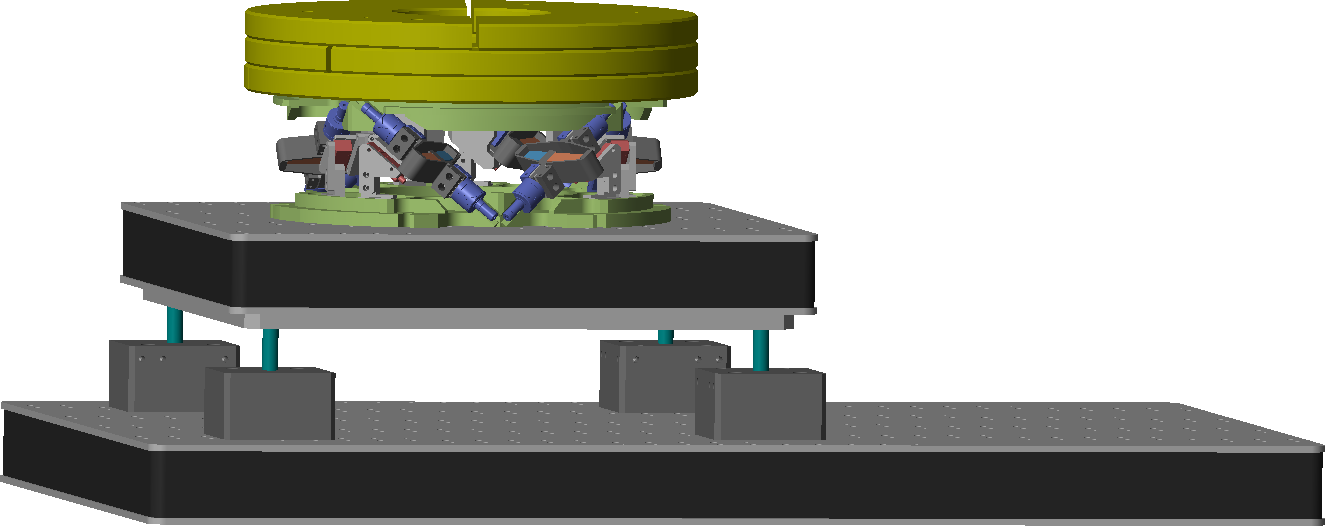

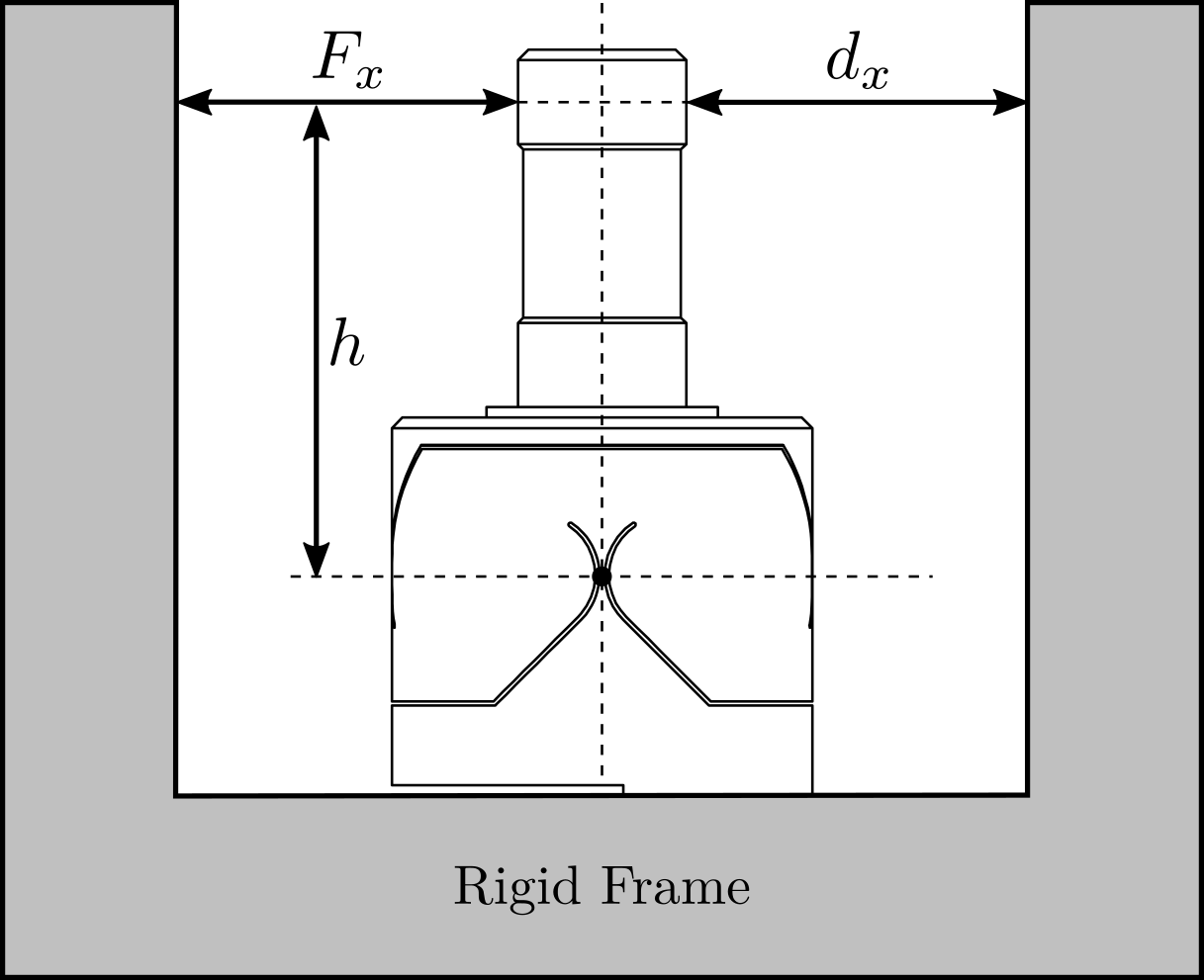

A suitable candidate architecture for this platform is the Stewart platform (also known as "hexapod"), a parallel kinematic mechanism capable of 6-DoF motion. Stewart platforms are widely employed in positioning and vibration isolation applications due to their inherent stiffness and potential for high precision. Various designs exist, differing in geometry, actuation technology, sensing methods, and control strategies, as exemplified in Figure ref:fig:introduction_stewart_platform_piezo. A central challenge addressed in this thesis is the optimal mechatronic design of such an active platform tailored to the specific requirements of the NASS. A more detailed review of Stewart platform and its main components will be given in Section ref:sec:detail_kinematics_stewart_review.

Robust Control

The control system must compute the position measurements from the online metrology system and computes the reference positions derived from each micro-station desired movement. It then commands the active platform in real-time to stabilize the sample and compensate for all error sources, including stage imperfections, thermal drifts, and vibrations. Ensuring the stability and robustness of these feedback loops is crucial, especially within the demanding operational context of a synchrotron beamline, which requires reliable 24/7 operation with minimal intervention.

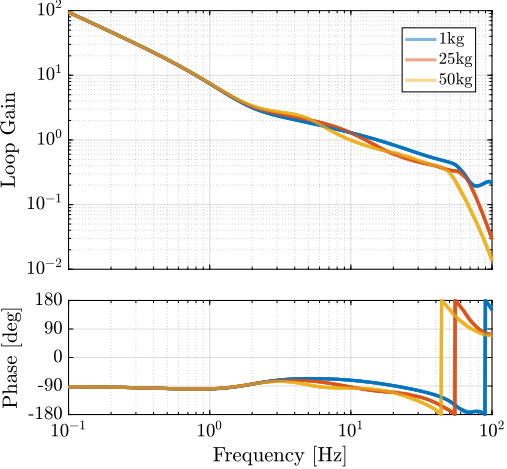

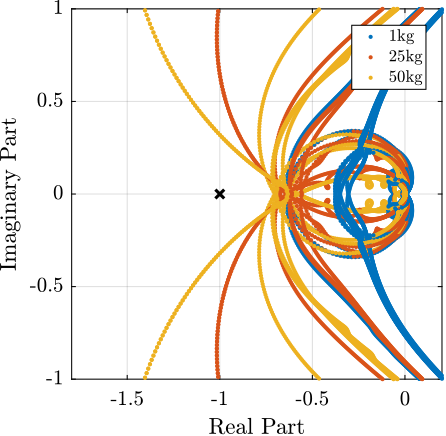

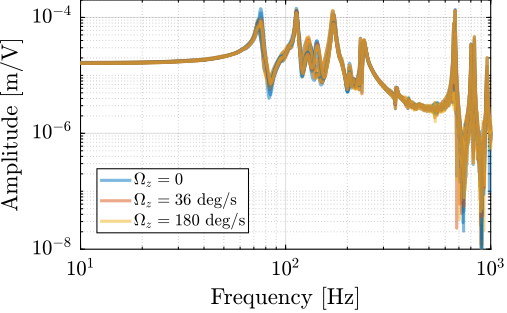

Several factors complicate the design of robust feedback control for the NASS. First, the system must operate under across diverse experimental conditions, including different scan types (tomography, linear scans) and payloads' inertia. The continuous rotation of the spindle introduces gyroscopic effects that can affect the system dynamics. As actuators of the active platforms rotate relative to stationary sensors, the control kinematics to map the errors in the frame of the active platform is complex. But perhaps the most significant challenge is the wide variation in payload mass ($1\,\text{kg}$ up to $50\,\text{kg}$) that the system must accommodate. Designing for robustness against large payload variations typically necessitates larger stability margins, which can compromise achievable performance. Consequently, high-performance positioning stages often work with well-characterized payload, as seen in systems like wafer-scanners or atomic force microscopes.

Furthermore, unlike many systems where the active stage and sample are significantly lighter than the underlying coarse stages, the NASS payload mass can be substantially greater than the mass of the micro-station's top stage. This leads to strong dynamic coupling between the active platform and the micro-station structure, resulting in a more complex acrfull:mimo system with significant cross-talk between axes.

These variations in operating conditions and payload translate into significant uncertainty or changes in the plant dynamics that the controller must handle. Therefore, the feedback controller must be designed to be robust against this plant uncertainty while still delivering the required nanometer-level performance.

Predictive Design

The overall performance achieved by the NASS is determined by numerous factors, such as external disturbances, the noise characteristics of the instrumentation, the dynamics resulting from the chosen mechanical architecture, and the achievable bandwidth dictated by the control architecture. Ensuring the final system meets its stringent specifications requires the implementation of a predictive design methodology, also known as a mechatronic design approach. The goal is to rigorously evaluate different concepts, predict performance limitations, and guide the design process. Key challenges within this approach include developing appropriate design methodologies, creating accurate models capable of comparing different concepts quantitatively, and converging on a final design that achieves the target performance levels.

Original Contributions

Introduction

This thesis presents several original contributions aimed at addressing the challenges inherent in the design, control, and implementation of the Nano Active Stabilization System, primarily within the fields of Control Theory, Mechatronic Design, and Experimental Validation.

6-DoF vibration control of a rotating platform

Traditional long-stroke/short-stroke architectures typically operate in one or two degrees of freedom. This work extends the concept to six degrees of freedom, with the active platform designed not only to correct rotational errors but to simultaneously compensate for errors originating from all underlying micro-station stages. The application of a continuously rotating Stewart platform for active vibration control and error compensation in this manner is believed to be novel in the reviewed literature.

Mechatronic design approach

A rigorous mechatronic design methodology was applied consistently throughout the NASS development life-cycle cite:&dehaeze18_sampl_stabil_for_tomog_exper;&dehaeze21_mechat_approac_devel_nano_activ_stabil_system. Although the mechatronic approach itself is not new, its comprehensive application here, from initial concept evaluation using simplified models to detailed design optimization and experimental validation informed by increasingly sophisticated models, potentially offers useful insights to the existing literature. This thesis documents this process chronologically, illustrating how models of varying complexity can be effectively used at different project phases and how design decisions were systematically based on quantitative model predictions and analyses. While the resulting system is highly specific, the documented effectiveness of this design approach may contribute to the broader adoption of mechatronic methodologies in the design of future synchrotron instrumentation.

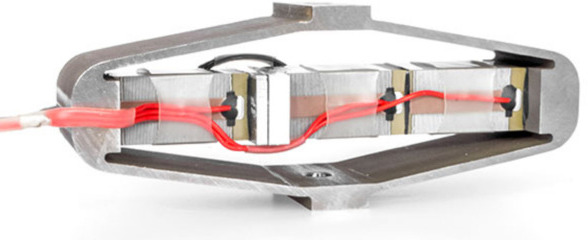

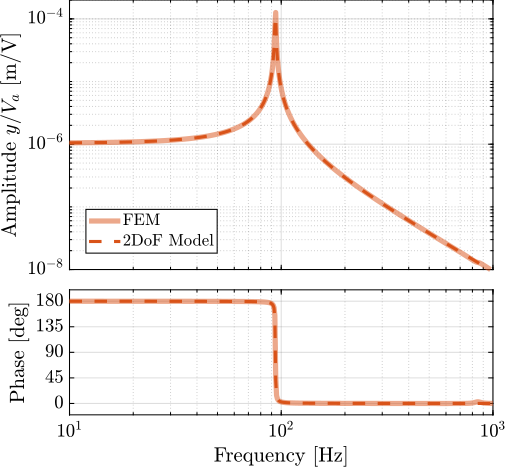

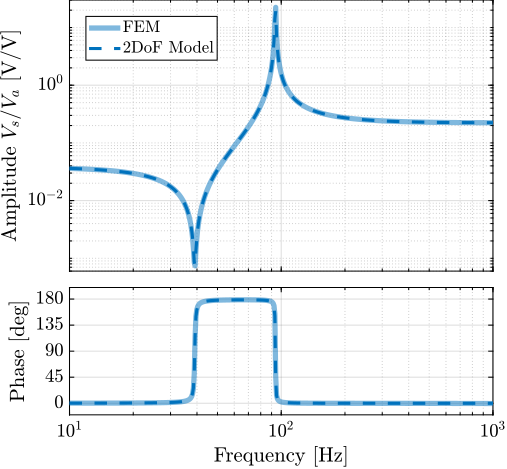

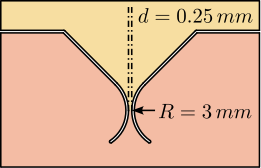

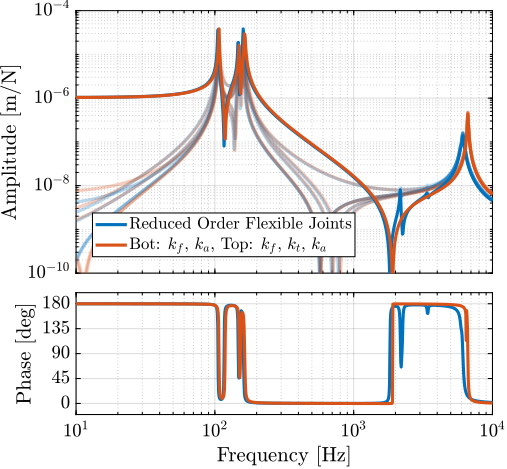

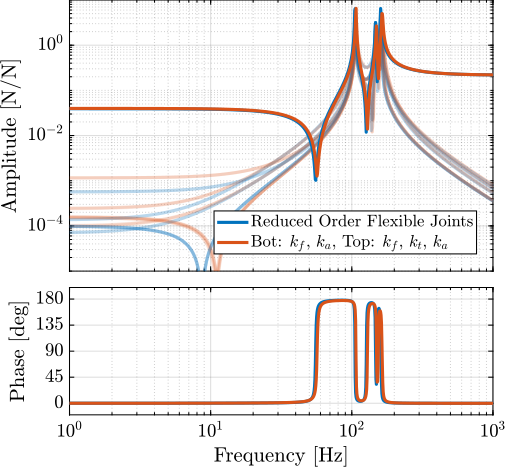

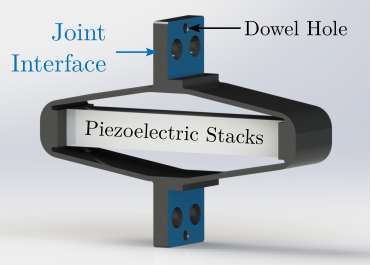

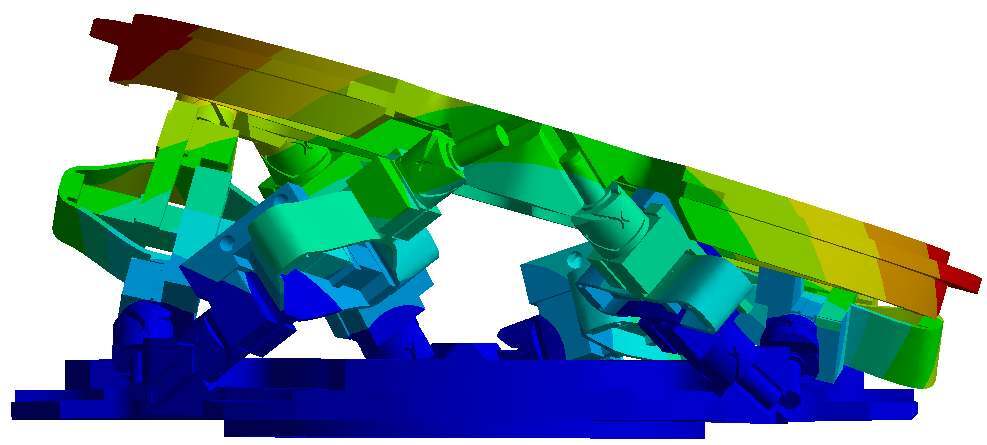

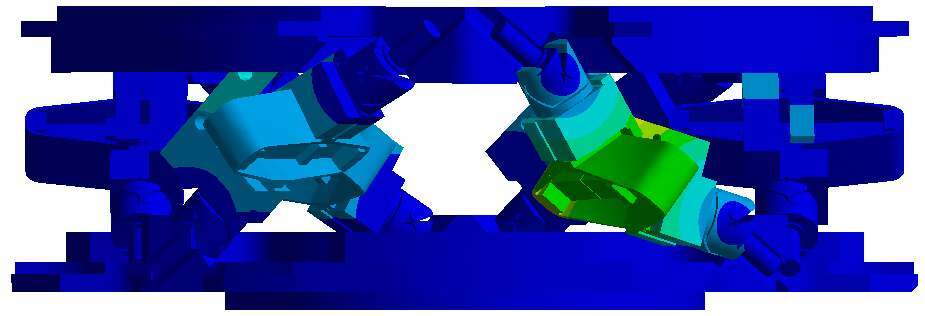

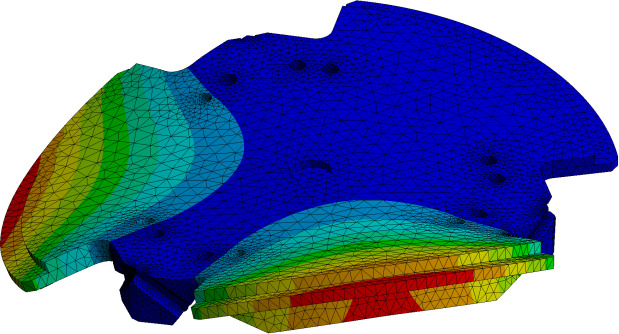

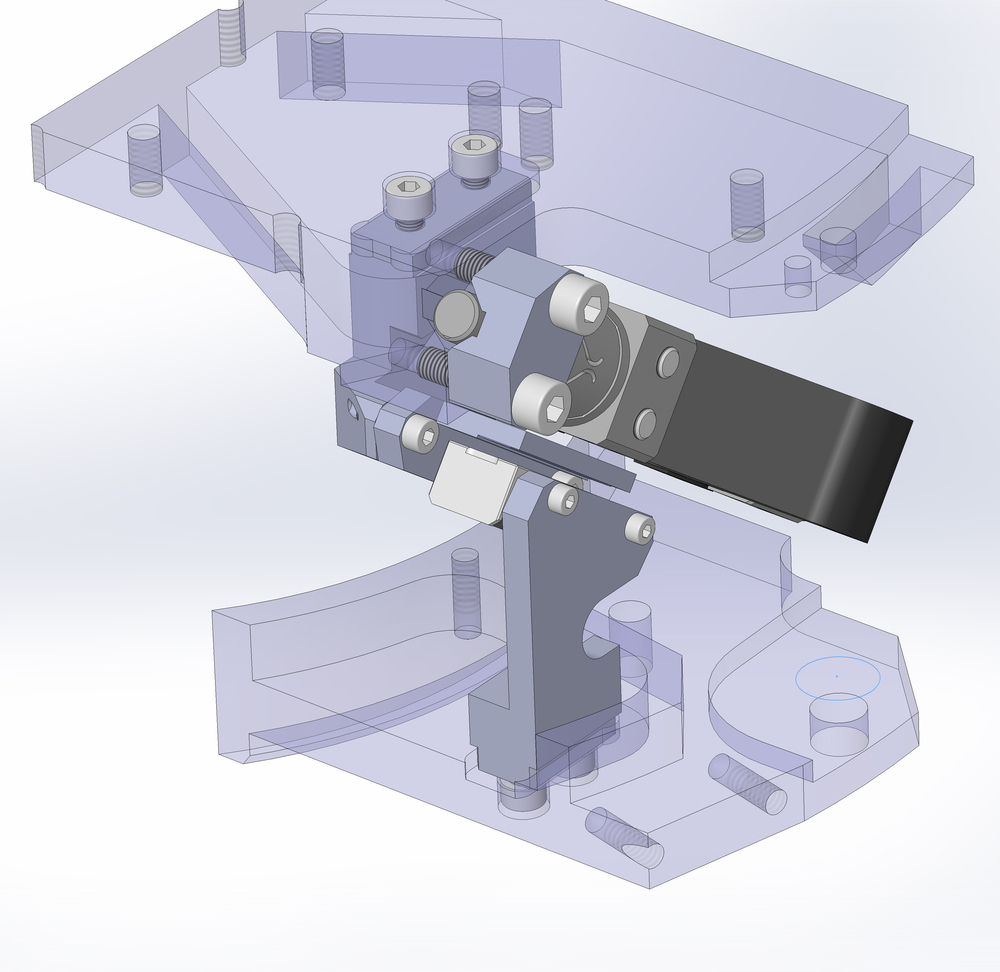

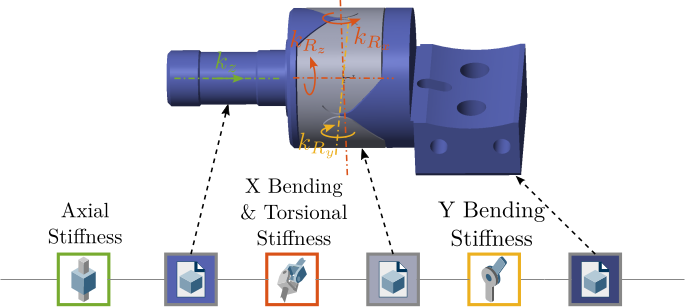

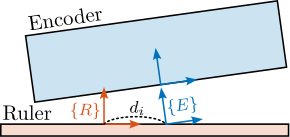

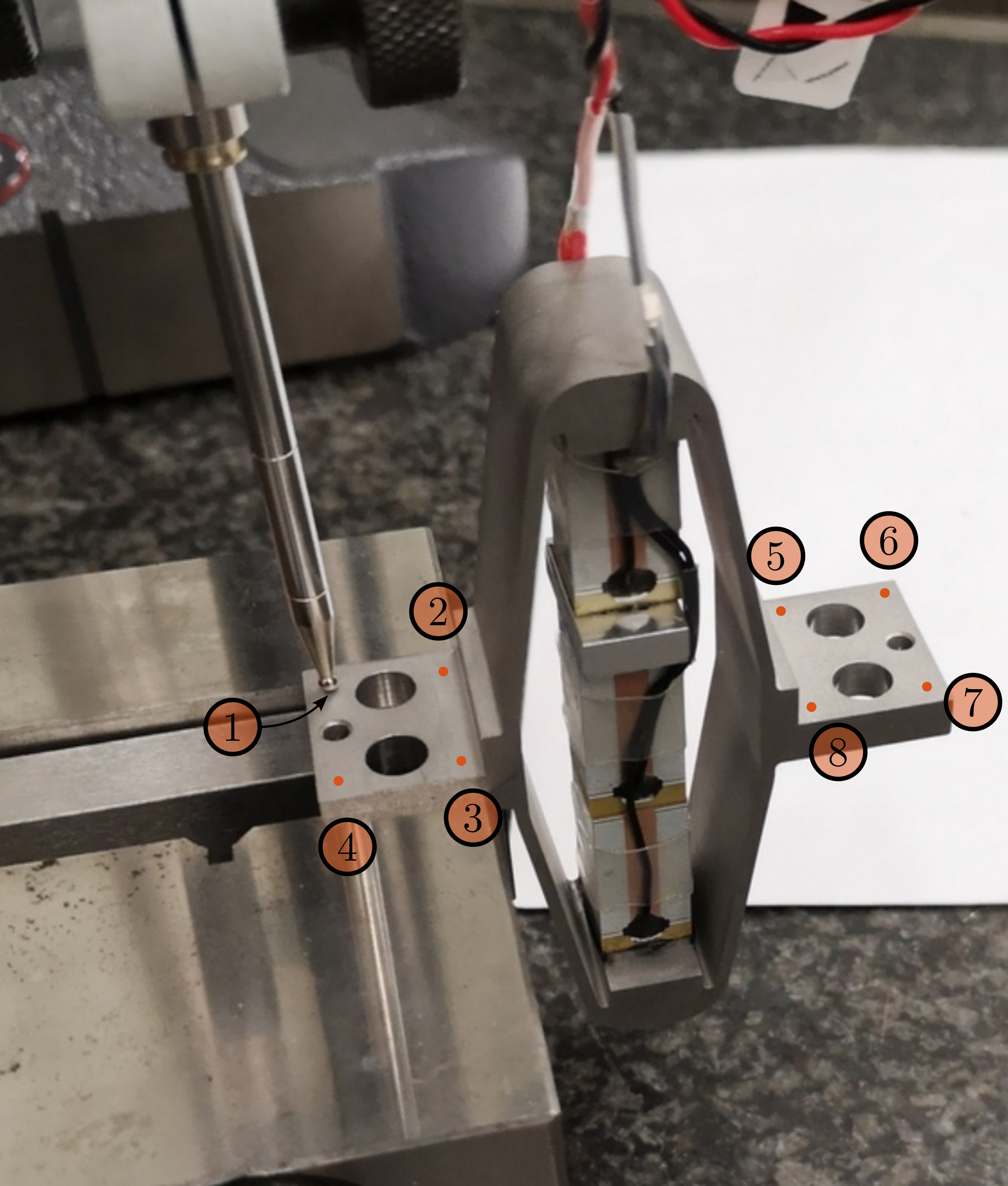

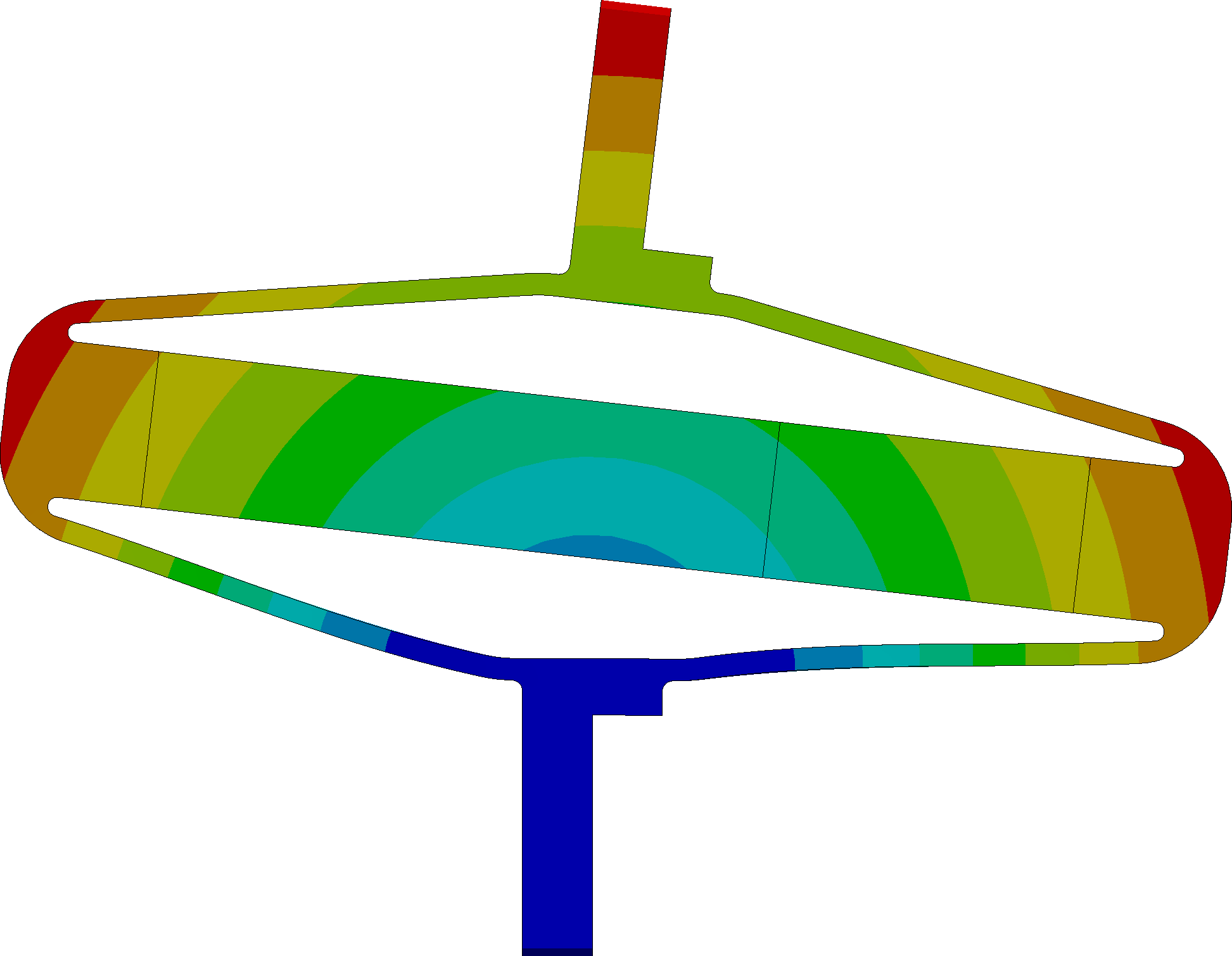

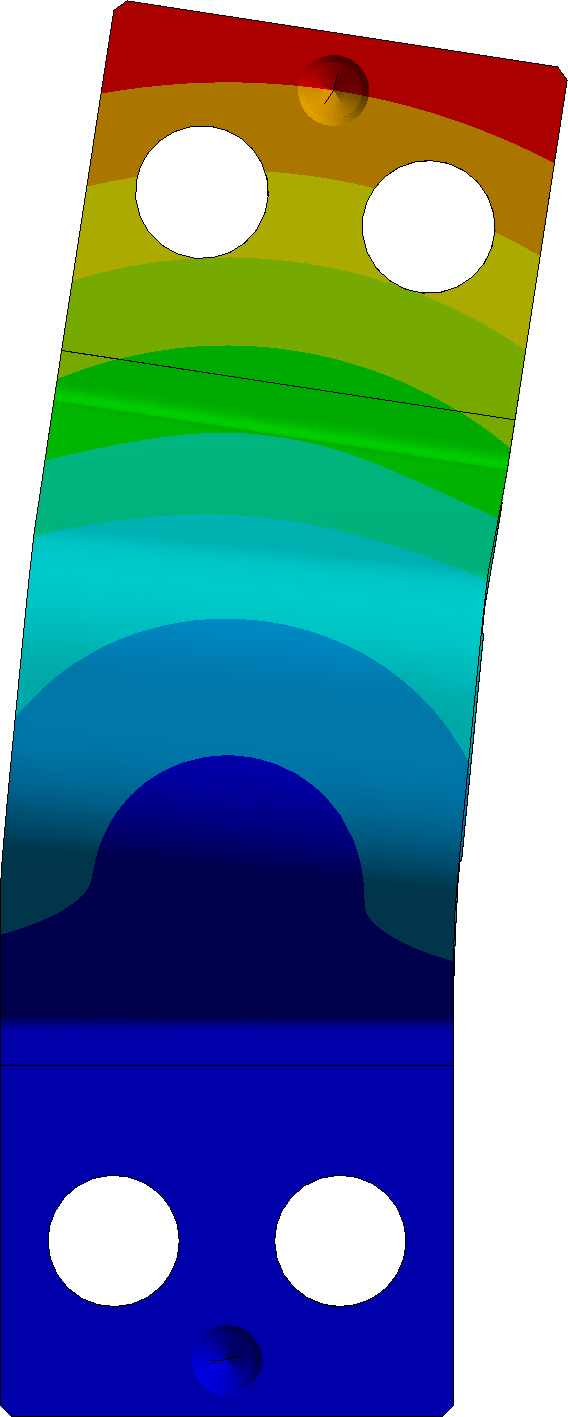

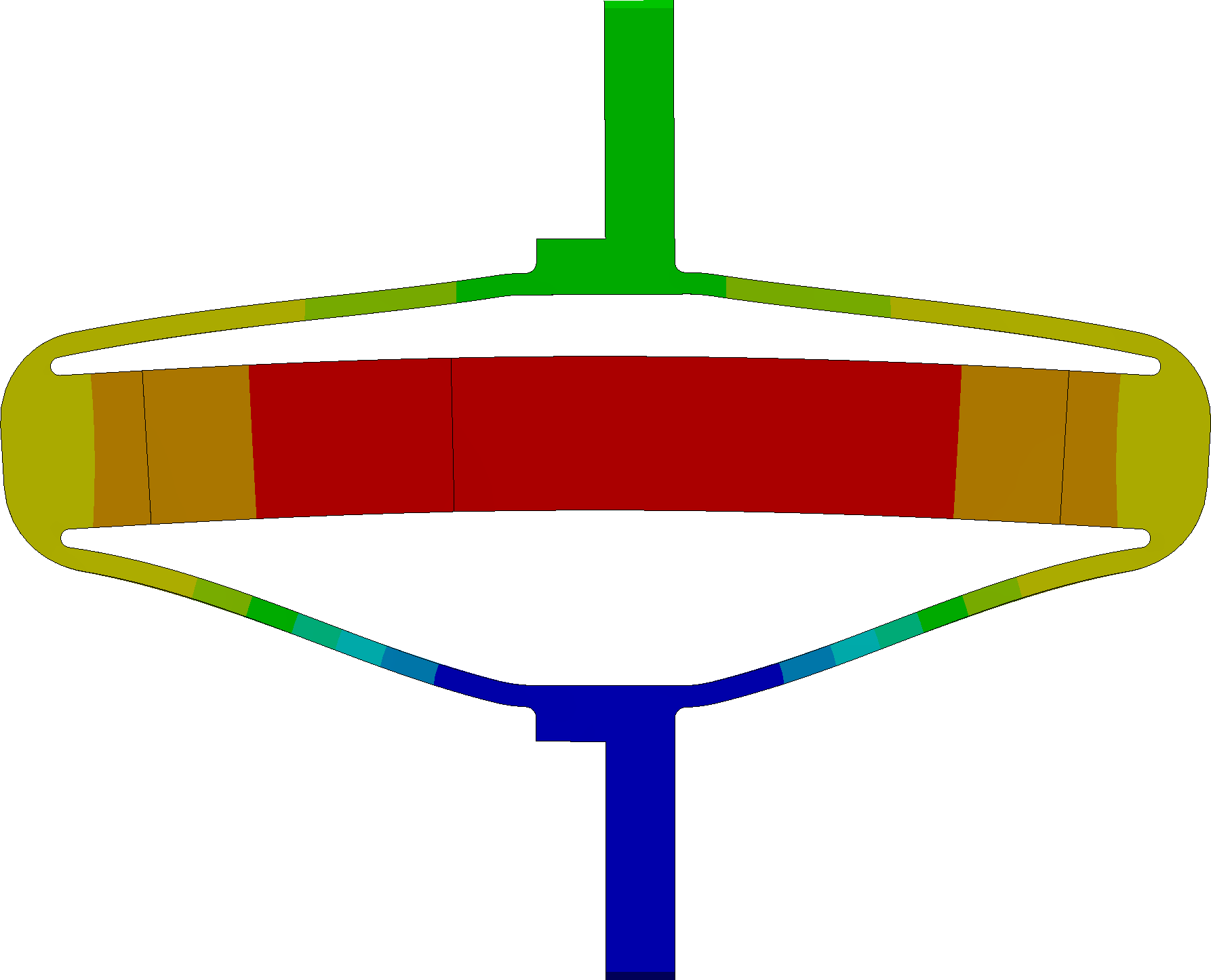

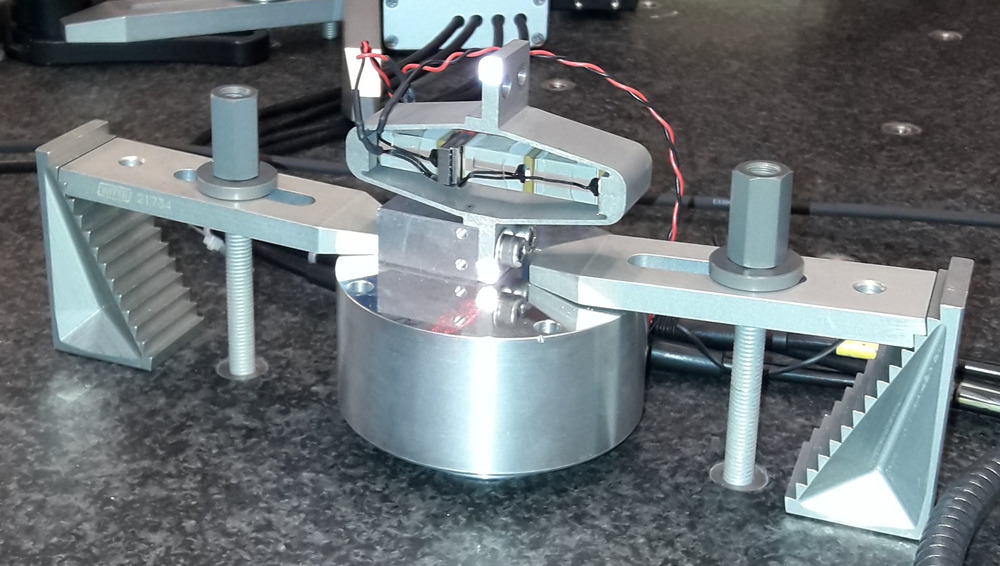

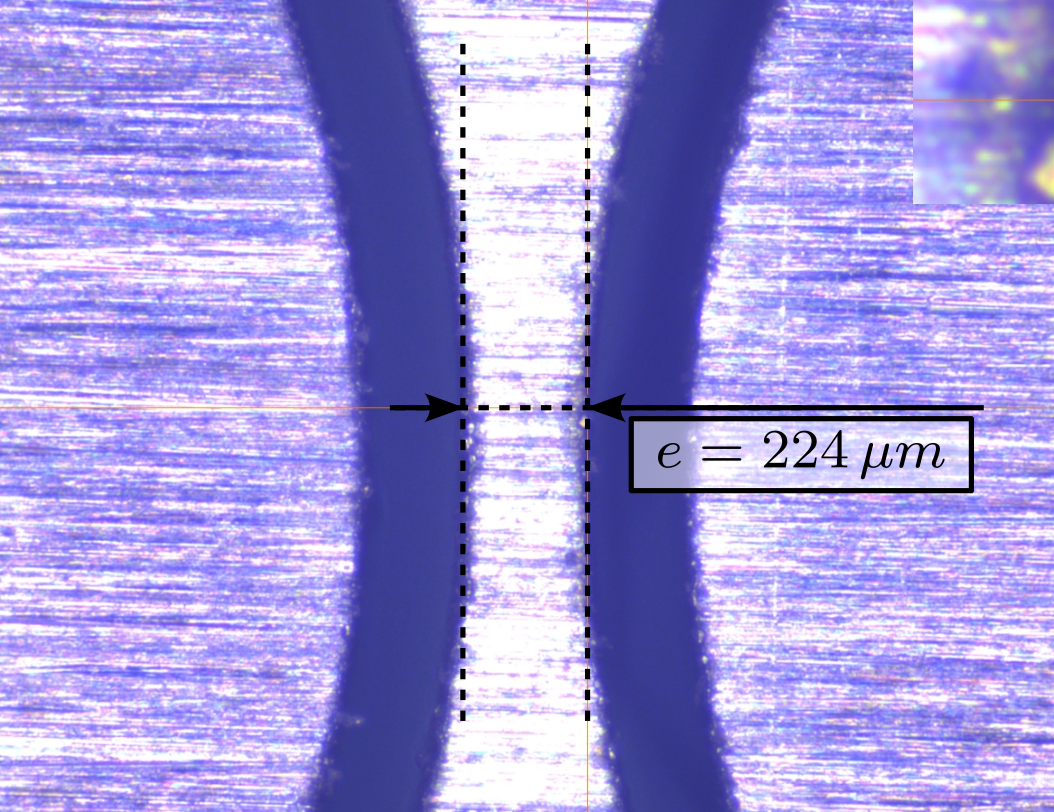

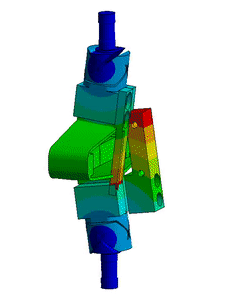

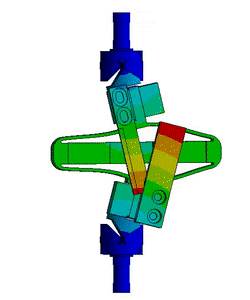

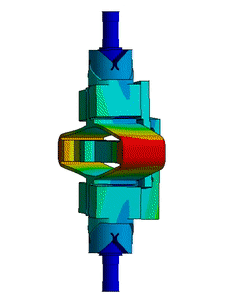

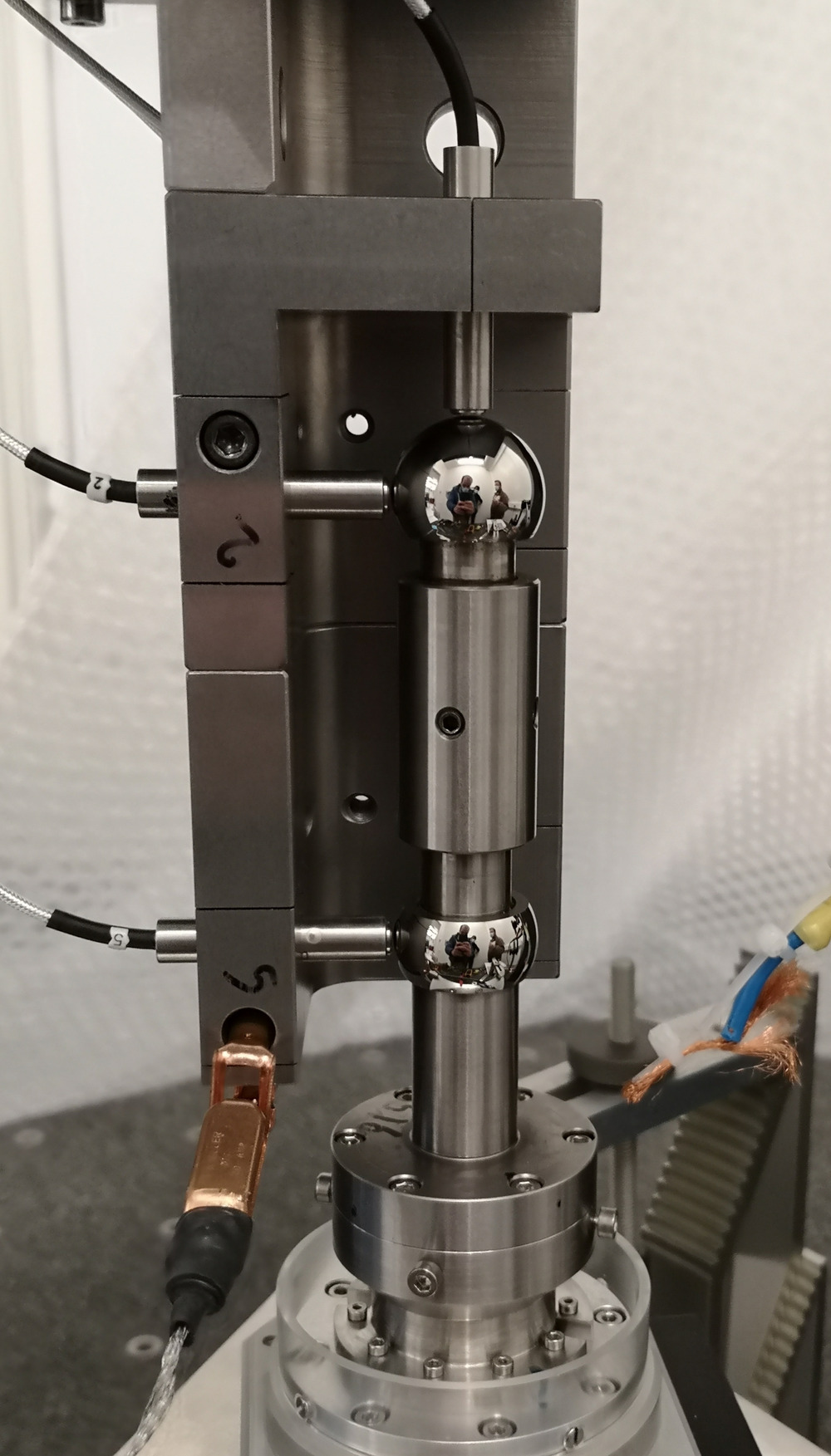

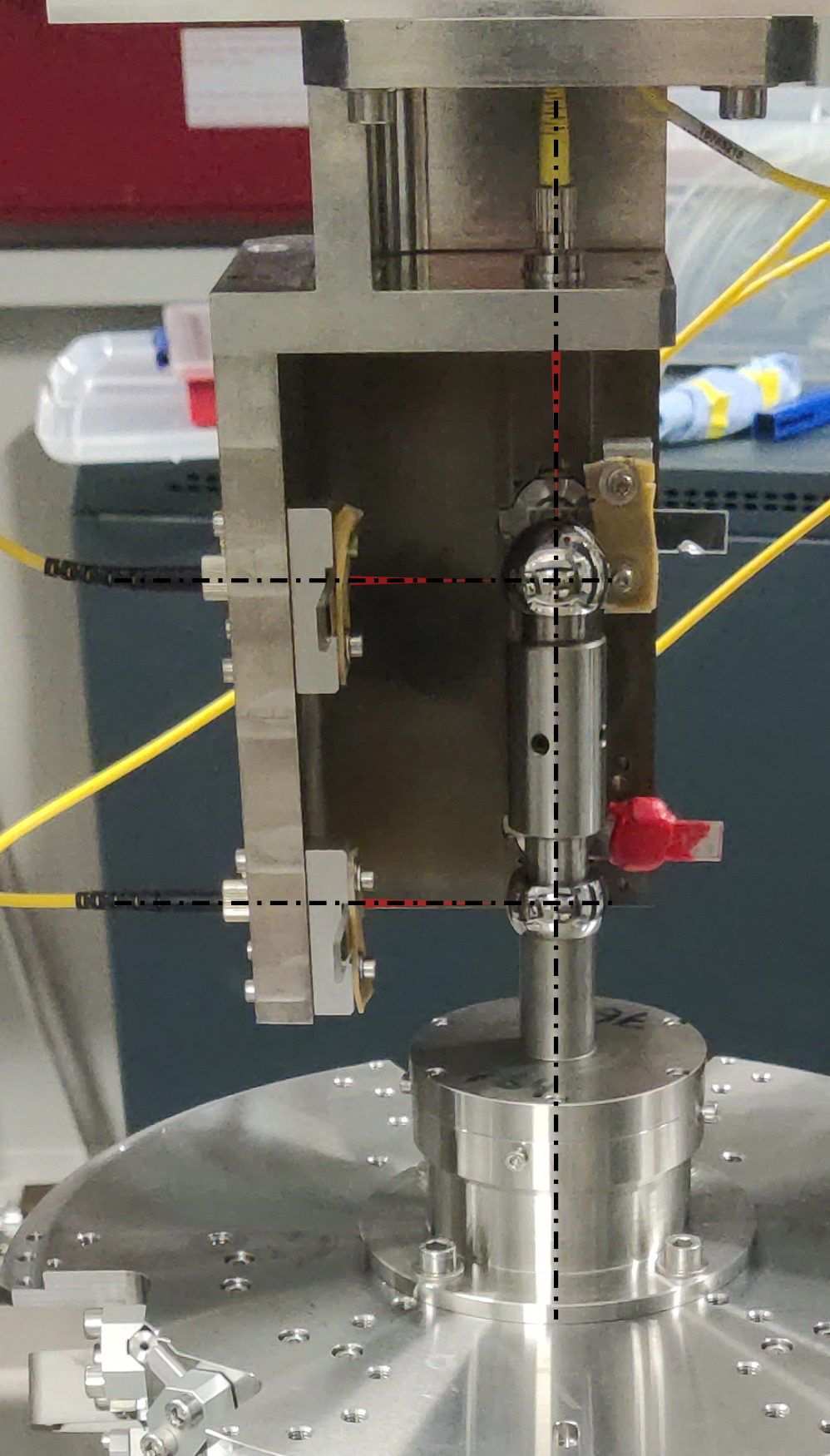

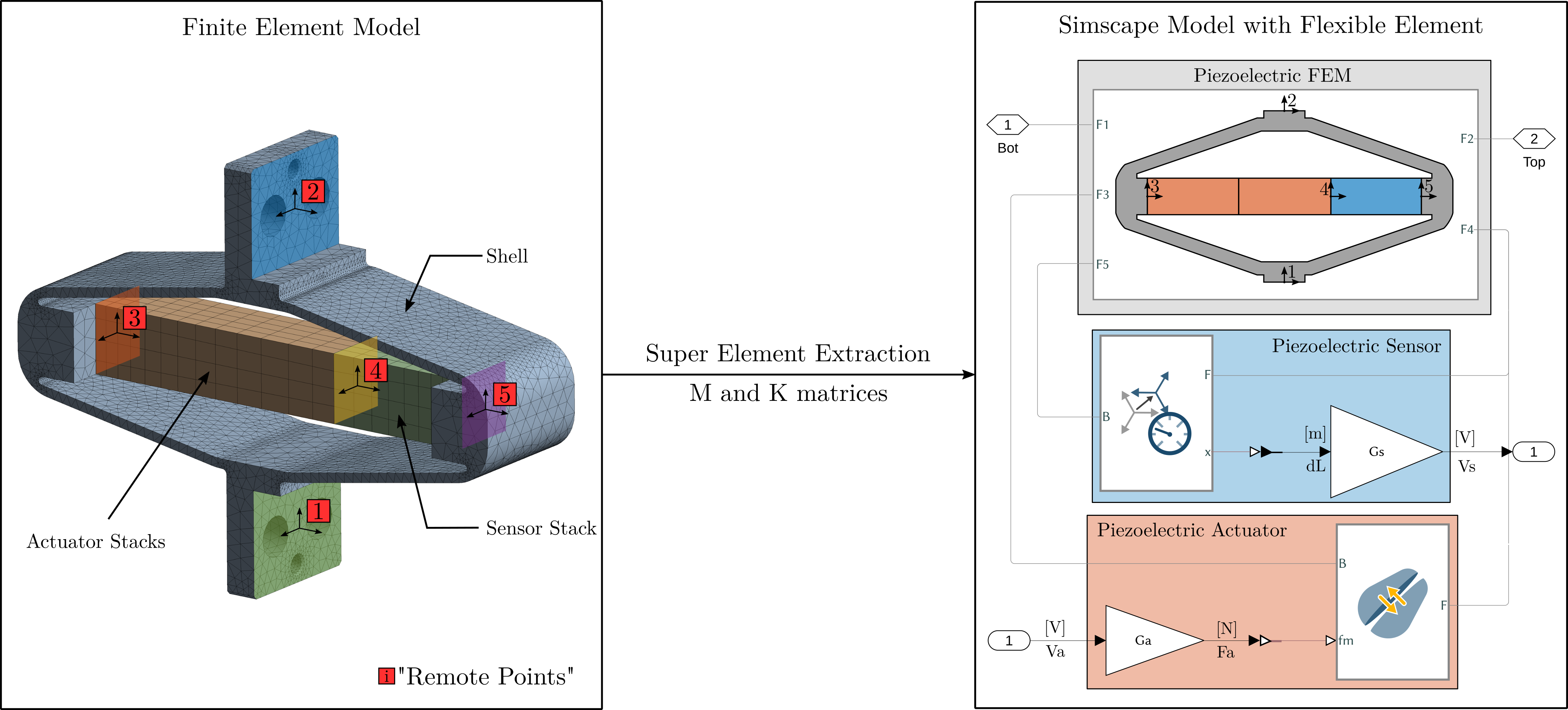

Experimental validation of multi-body simulations with reduced order flexible bodies obtained by FEA

A key tool employed extensively in this work was a combined multi-body simulation and acrfull:fea technique, specifically using Component Mode Synthesis to represent flexible bodies within the multi-body framework cite:&brumund21_multib_simul_reduc_order_flexib_bodies_fea. This hybrid approach, while established, was experimentally validated in this work for components critical to the NASS, namely amplified piezoelectric actuators and flexible joints. It proved invaluable for designing and optimizing components intended for integration into a larger, complex dynamic system. This methodology, detailed in Section ref:sec:detail_fem, is presented as a potentially useful tool for future mechatronic instrument development.

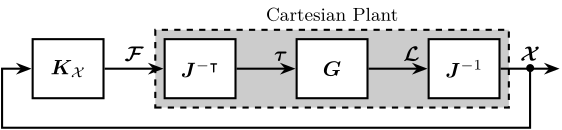

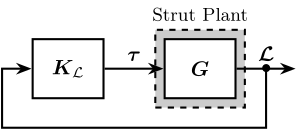

Control Robustness by design

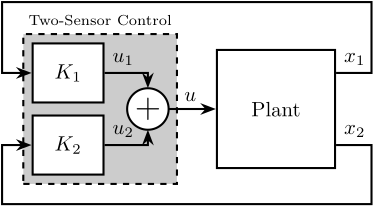

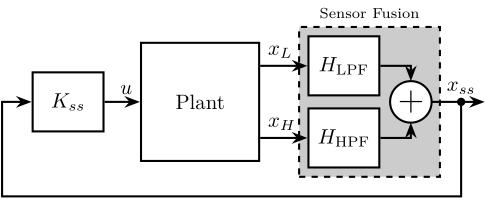

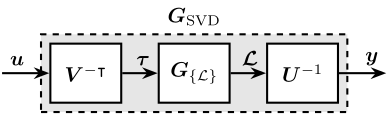

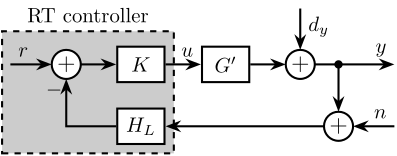

The requirement for robust operation across diverse conditions—including payloads up to $50\,\text{kg}$, complex underlying dynamics from the micro-station, and varied operational modes like different rotation speeds—presented a critical design challenge. This challenge was met by embedding robustness directly into the active platform's design, rather than depending solely on complex post-design control synthesis techniques such as $\mathcal{H}_\infty\text{-synthesis}$ and $\mu\text{-synthesis}$. Key elements of this strategy included the model-based evaluation of active stage designs to identify architectures inherently easier to control, the incorporation of collocated actuator/sensor pairs to leverage passivity-based guaranteed stability, and the comparison of architecture to combine several sensors such as sensor fusion and High Authority Control / Low Authority Control (HAC-LAC). Furthermore, decoupling strategies for parallel manipulators were compared (Section ref:sec:detail_control_decoupling), addressing a topic identified as having limited treatment in the literature. Consequently, the specified performance targets were met using controllers which, facilitated by this design approach, proved to be robust, readily tunable, and easily maintained.

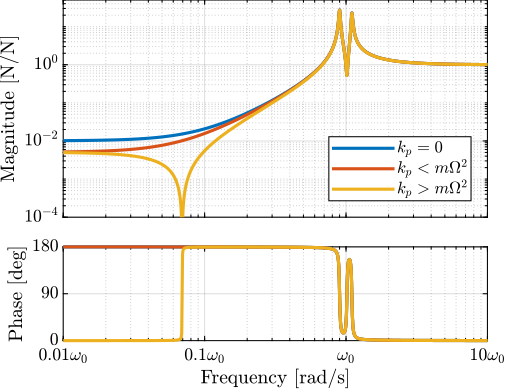

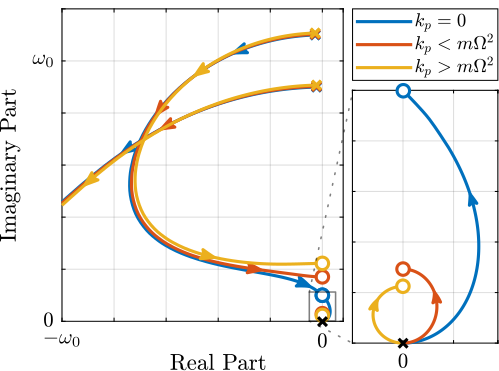

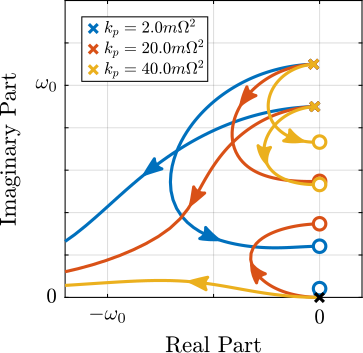

Active Damping of rotating mechanical systems using Integral Force Feedback

During conceptual design, it was found that the guaranteed stability property of the established active damping technique known as acrfull:iff is compromised when applied to rotating platforms like the NASS. To address this instability issue, two modifications to the classical IFF control scheme were proposed and analyzed. The first involves a minor adjustment to the control law itself, while the second incorporates physical springs in parallel with the force sensors. Stability conditions and optimal parameter tuning guidelines were derived for both modified schemes. This is further discussed in Section ref:sec:rotating and was the subject of a publication cite:&dehaeze21_activ_dampin_rotat_platf_using.

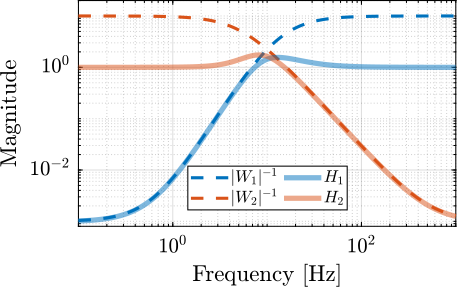

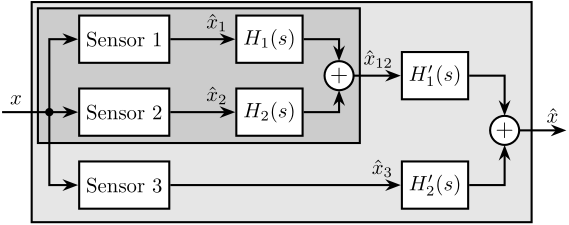

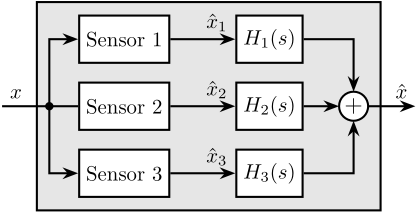

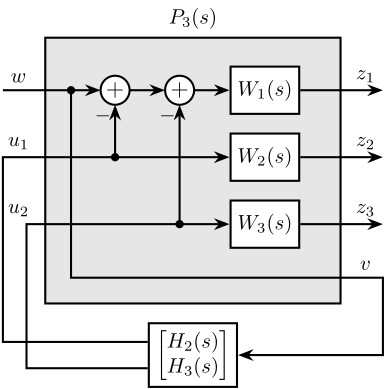

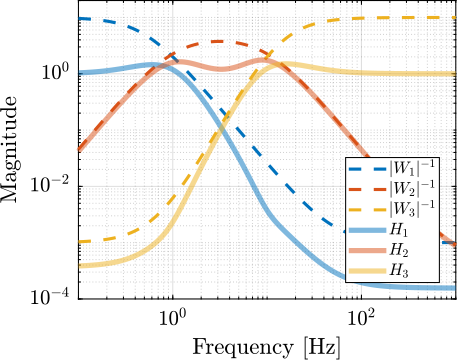

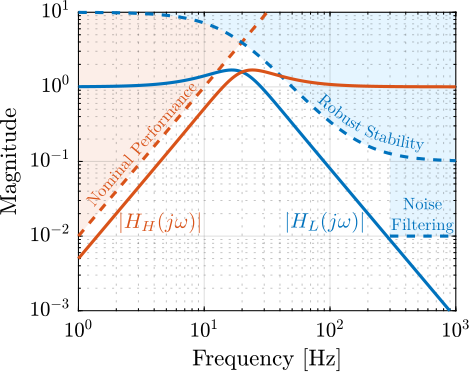

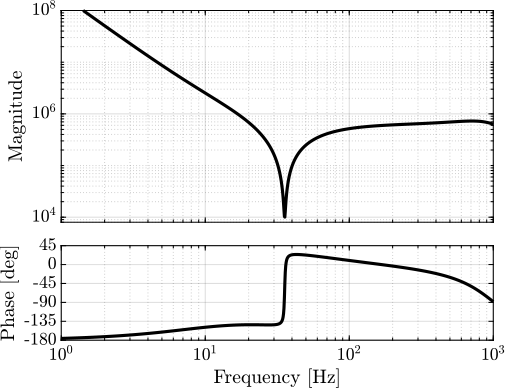

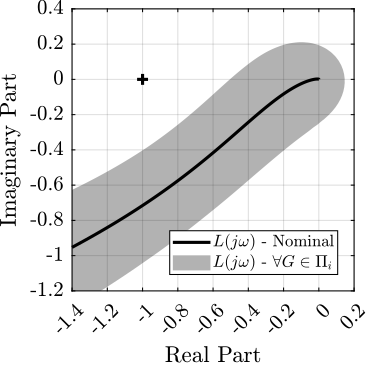

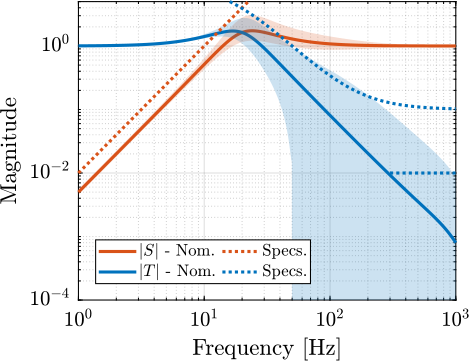

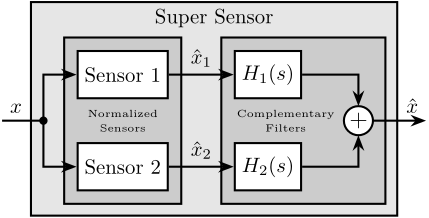

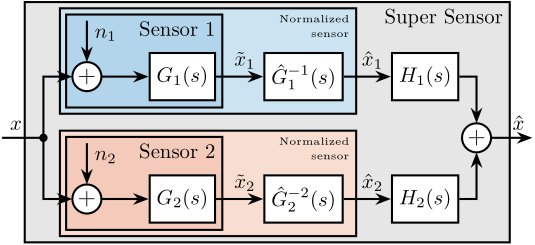

Design of complementary filters using $\mathcal{H}_\infty$ Synthesis

For implementing sensor fusion, where signals from multiple sensors are combined, complementary filters are often employed. A novel method for designing these filters using $\mathcal{H}_\infty$ synthesis techniques was developed cite:&dehaeze19_compl_filter_shapin_using_synth. This method allows explicit shaping of the filter norms, providing guarantees on the performance of the sensor fusion process. This synthesis technique, discussed further in Section ref:sec:detail_control_sensor, has subsequently found application in optimizing sensor fusion for gravitational wave detectors cite:&tsang22_optim_sensor_fusion_method_activ. The integration of such filters into feedback control architectures can also lead to advantageous control structures, as proposed in cite:&verma20_virtual_sensor_fusion_high_precis_contr and further studied in Section ref:sec:detail_control_cf.

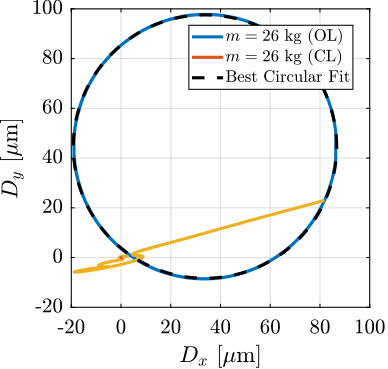

Experimental validation of the Nano Active Stabilization System

The conclusion of this work involved the experimental implementation and validation of the complete NASS on the ID31 beamline. Experimental results, presented in Section ref:sec:test_id31, demonstrate that the system successfully improves the effective positioning accuracy of the micro-station from its native $\approx 10\,\upmu\text{m}$ level down to the target $\approx 100\,\text{nm}$ range during representative scientific experiments. Crucially, robustness to variations in sample mass and diverse experimental conditions was verified. The NASS thus provides a versatile end-station solution, uniquely combining high payload capacity with nanometer-level accuracy, enabling optimal use of the advanced capabilities of the ESRF-EBS beam and associated detectors. To the author's knowledge, this represents the first demonstration of such a 5-DoF active stabilization platform being used to enhance the accuracy of a complex positioning system to this level.

Outline

Introduction

This is divided into three chapters, each corresponding to a distinct phase of this methodology: Conceptual Design, Detailed Design, and Experimental Validation. While the chapters follow this logical progression, care has been taken to structure each chapter such that its constitutive sections may also be consulted independently based on the reader's specific interests.

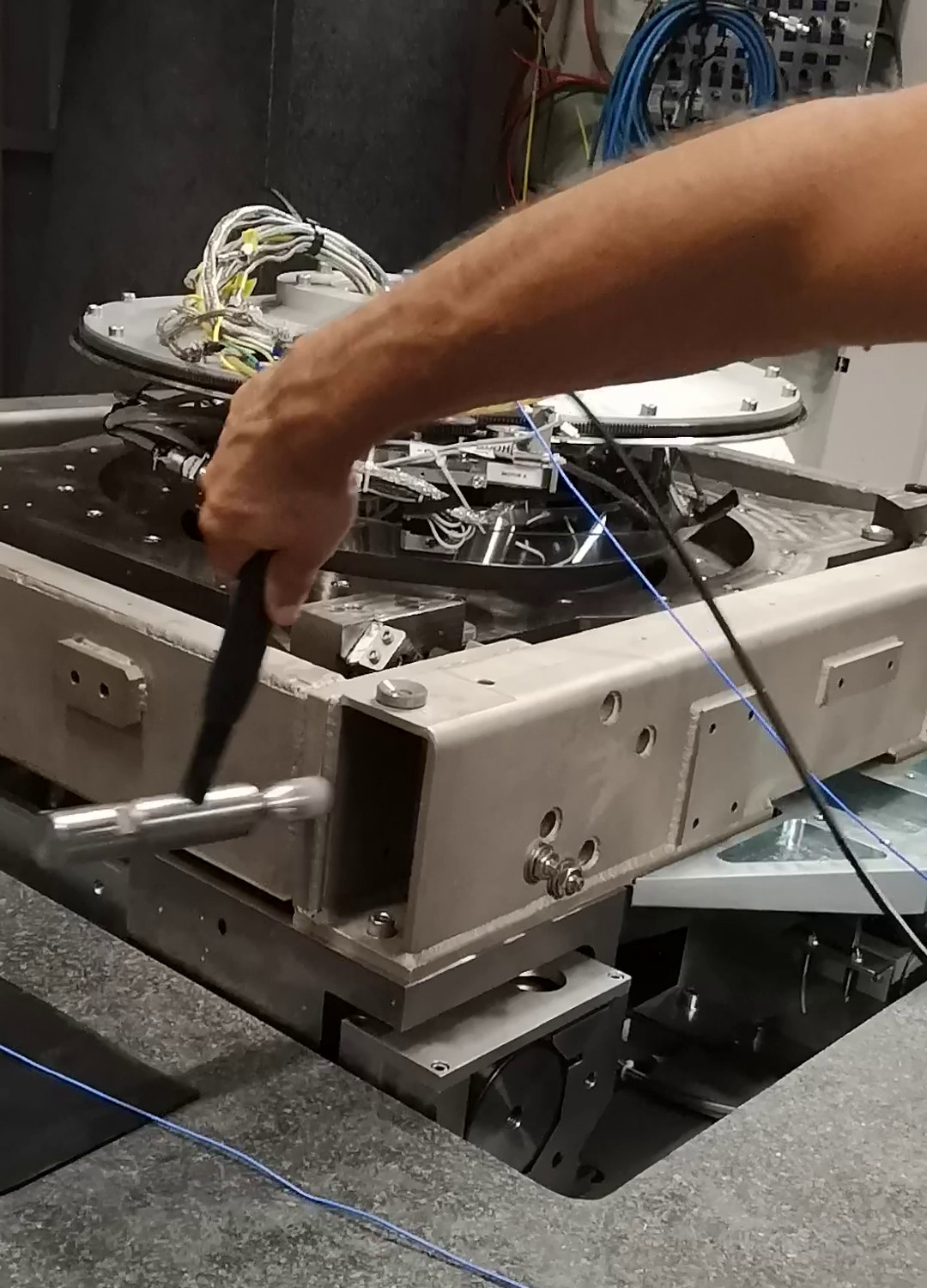

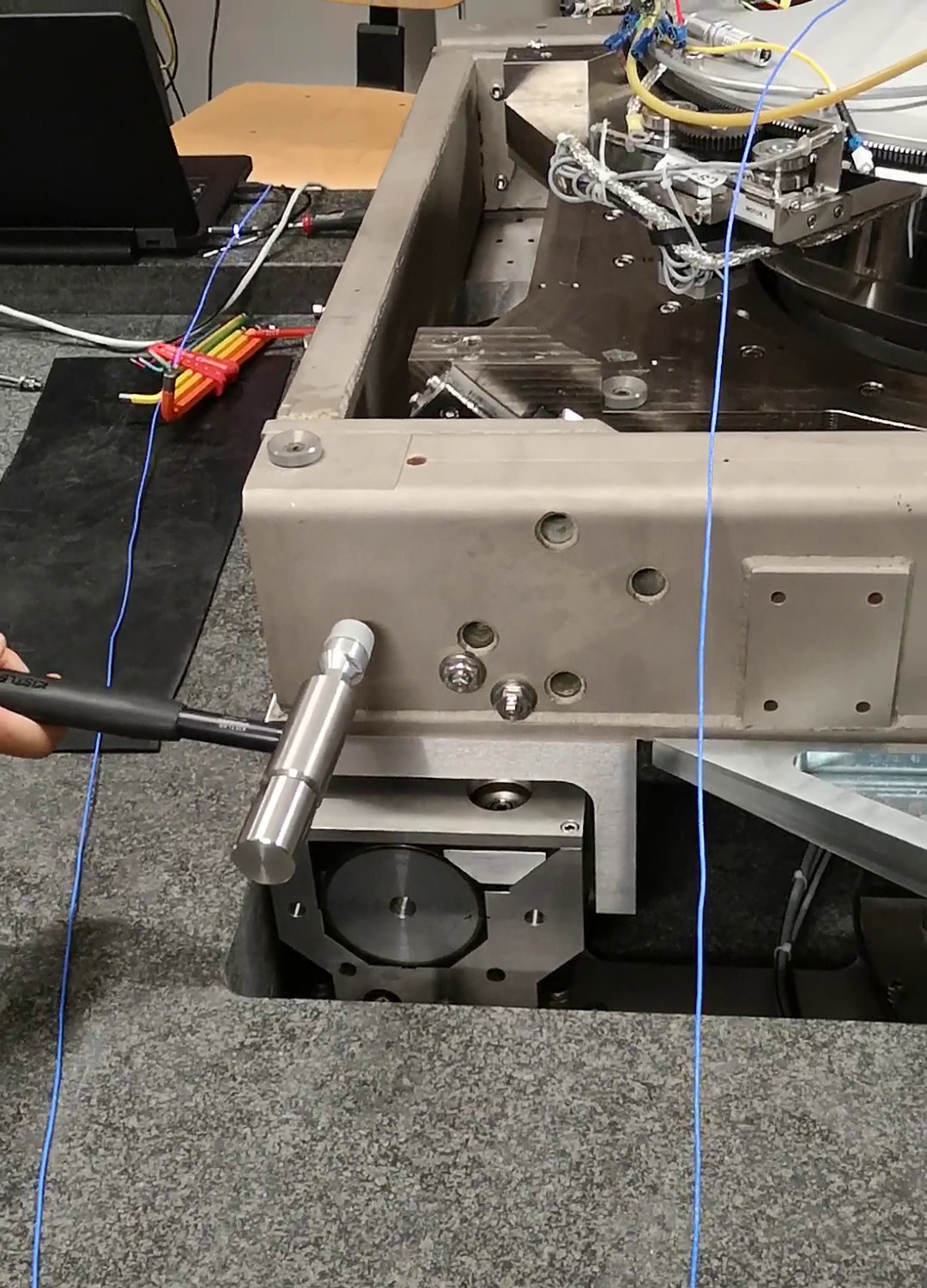

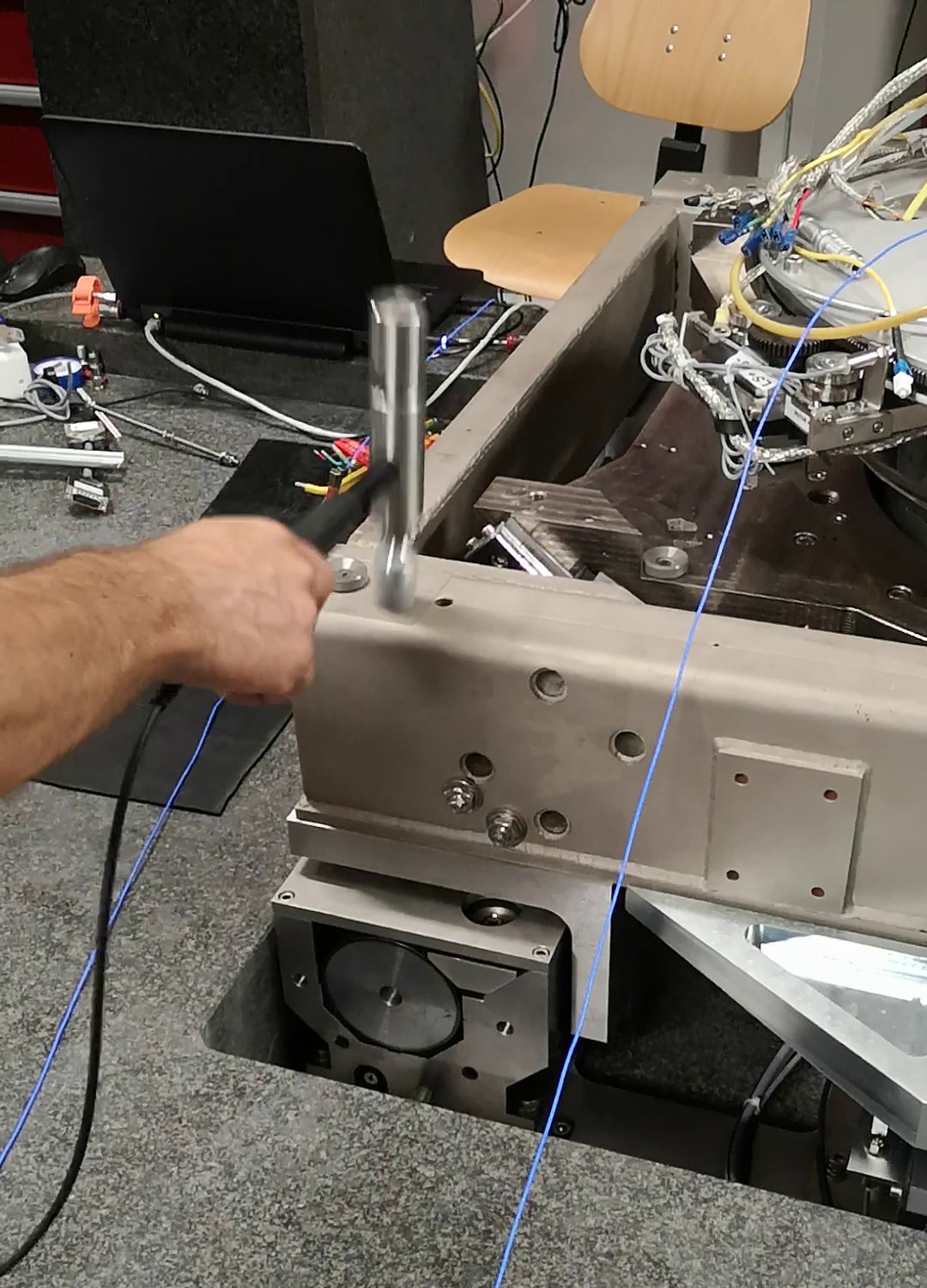

Conceptual design development

The conceptual design phase, detailed in Chapter ref:chap:concept, followed a methodical progression from simplified uniaxial models to more complex multi-body representations. Initial uniaxial analysis (Section ref:sec:uniaxial) provided fundamental insights, particularly regarding the influence of active platform stiffness on performance. The introduction of rotation in a 3-DoF model (Section ref:sec:rotating) allowed investigation of gyroscopic effects, revealing challenges for softer platform designs. Experimental modal analysis of the existing micro-station (Section ref:sec:modal) confirmed its complex dynamics but supported a rigid-body assumption for the different stages, justifying the development of a detailed multi-body model. This model, tuned against experimental data and incorporating measured disturbances, was validated through simulation (Section ref:sec:ustation). The Stewart platform architecture was selected for the active stage, and its kinematics, dynamics, and control were analyzed (Section ref:sec:nhexa). The chapter culminates in Section ref:sec:nass with closed-loop simulations of the integrated NASS concept under realistic conditions, validating its feasibility and providing confidence for proceeding to the detailed design phase. Dynamic error budgeting cite:&monkhorst04_dynam_error_budget;&okyay16_mechat_desig_dynam_contr_metrol was employed throughout this phase to identify performance limitations and guide concept selection.

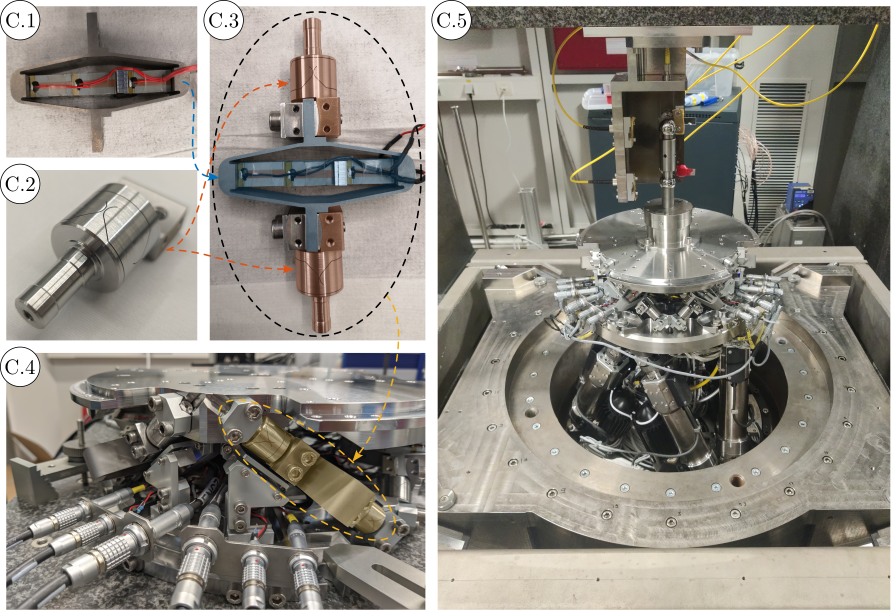

Detailed design

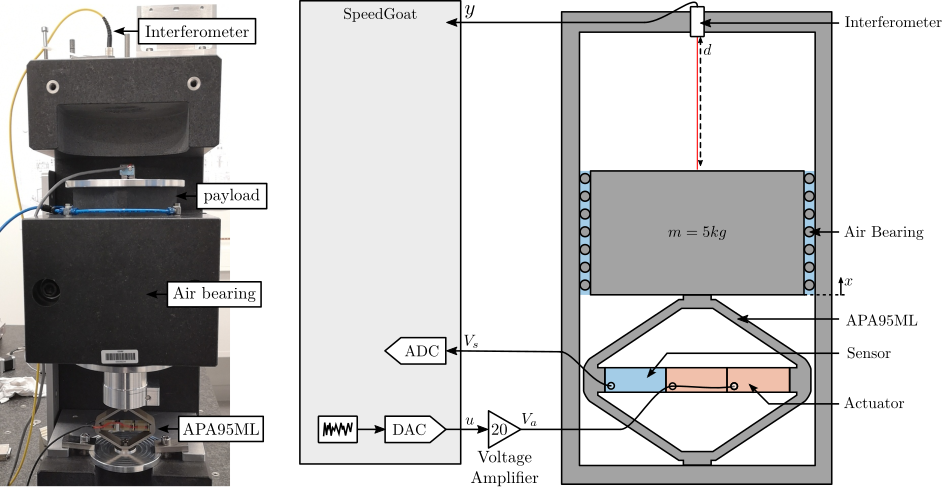

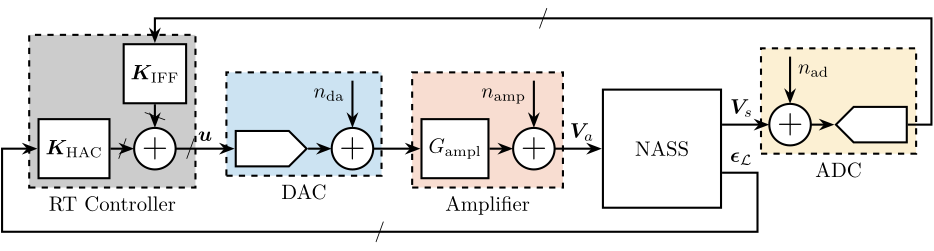

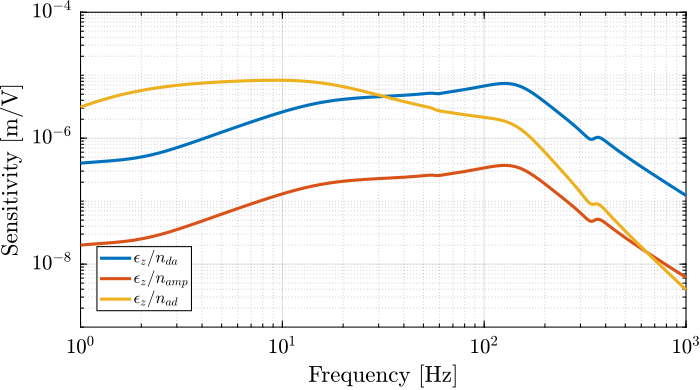

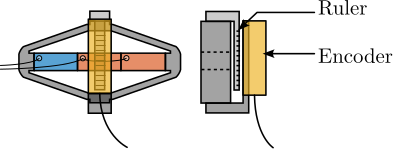

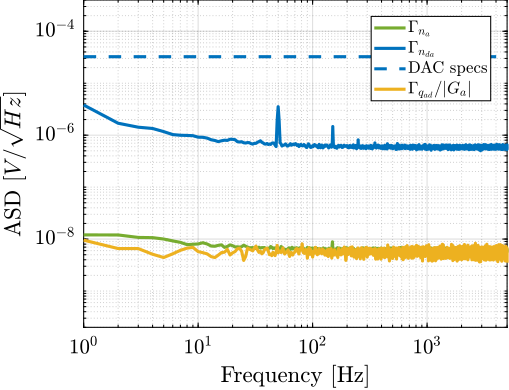

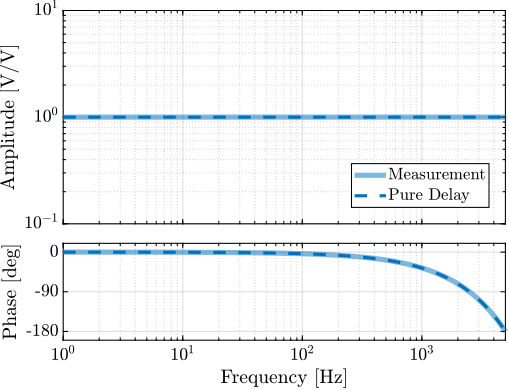

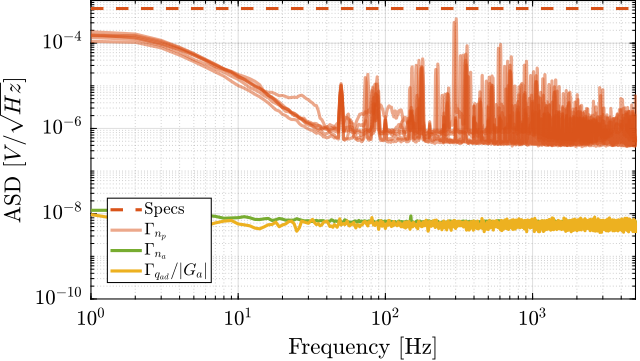

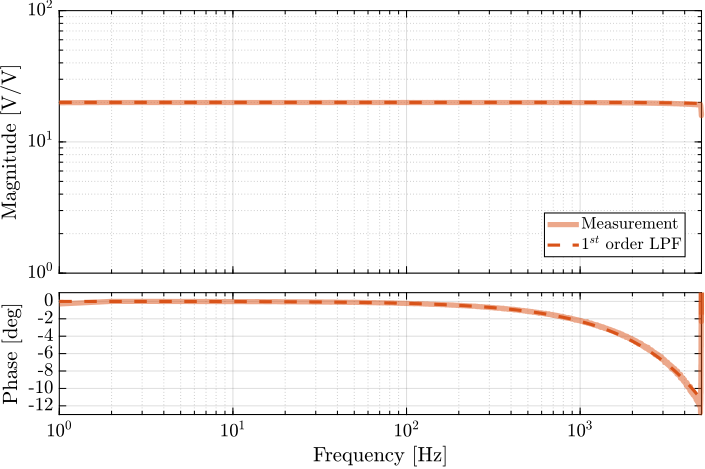

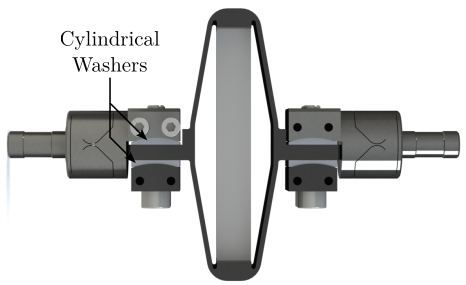

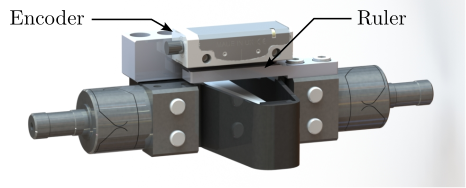

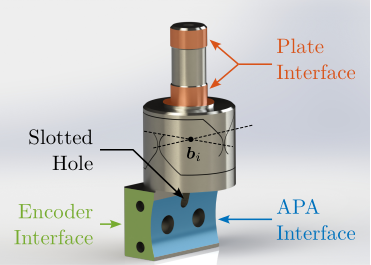

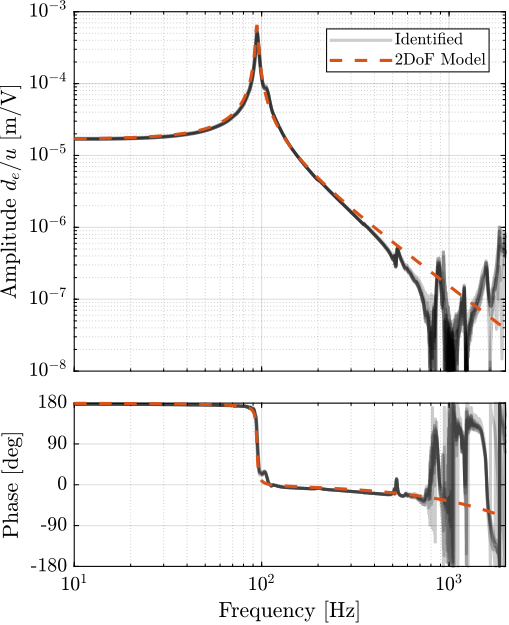

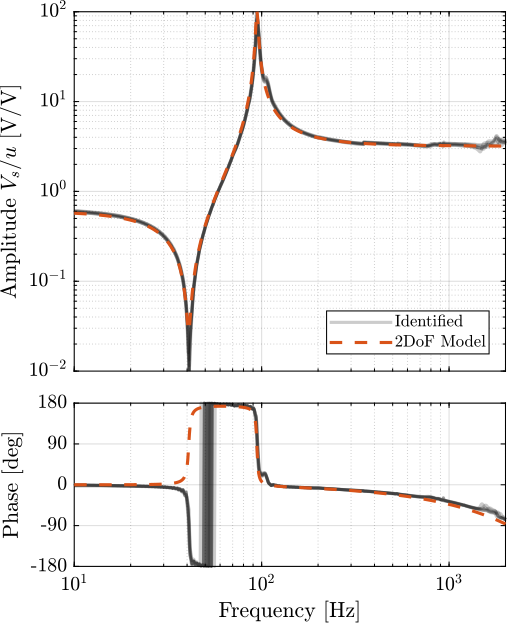

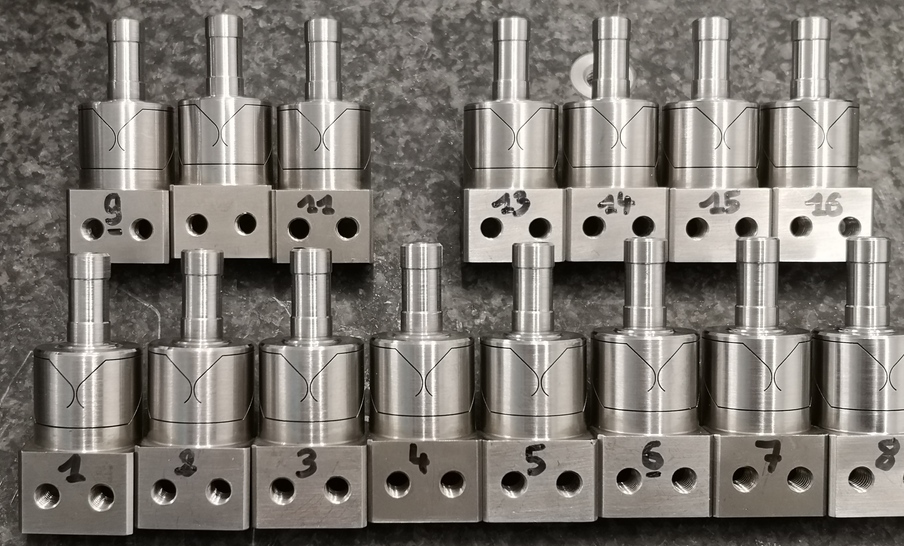

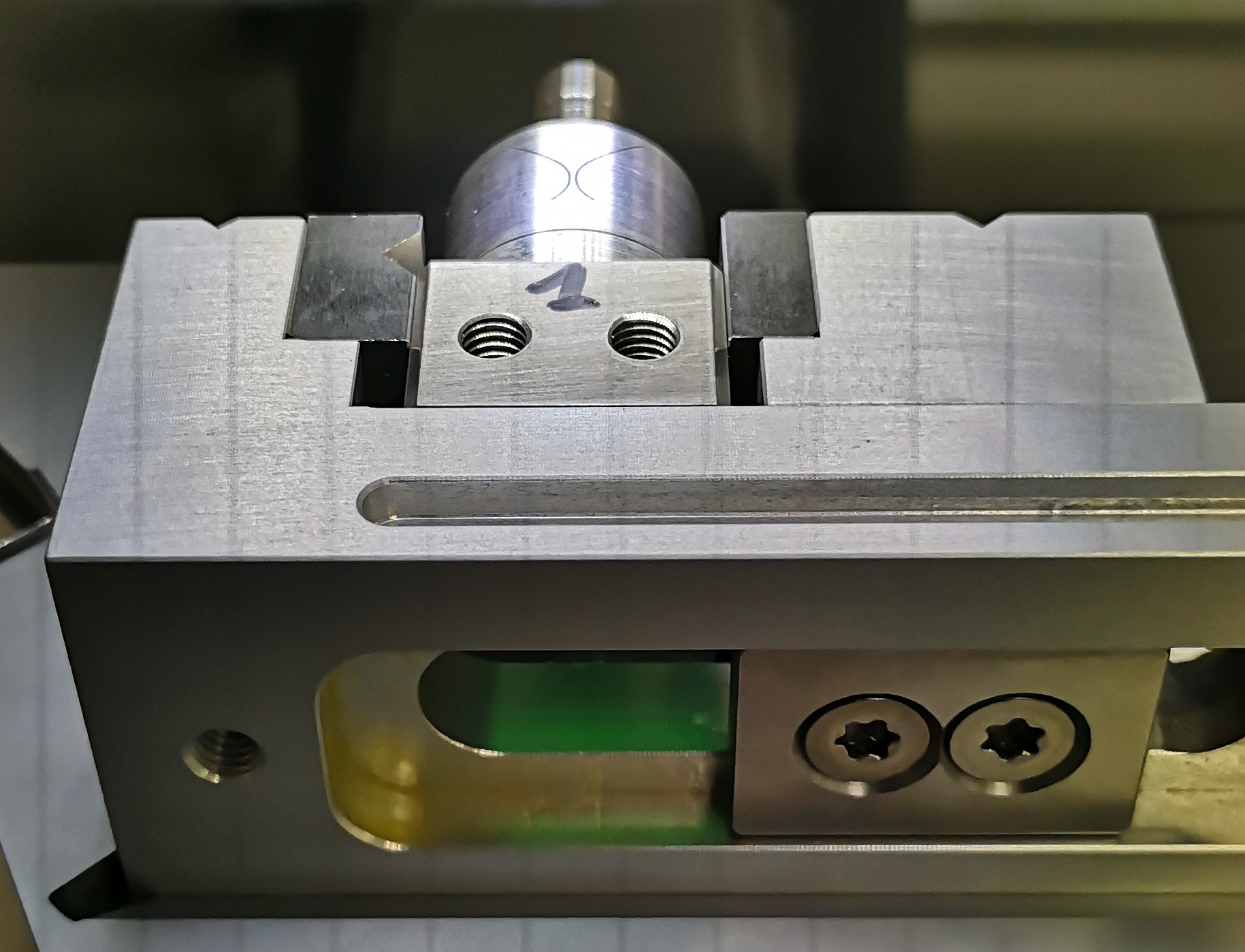

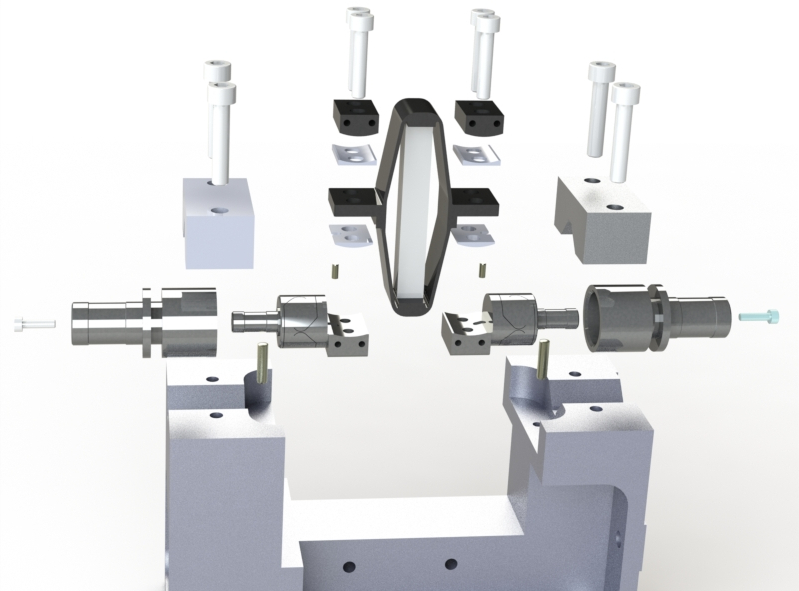

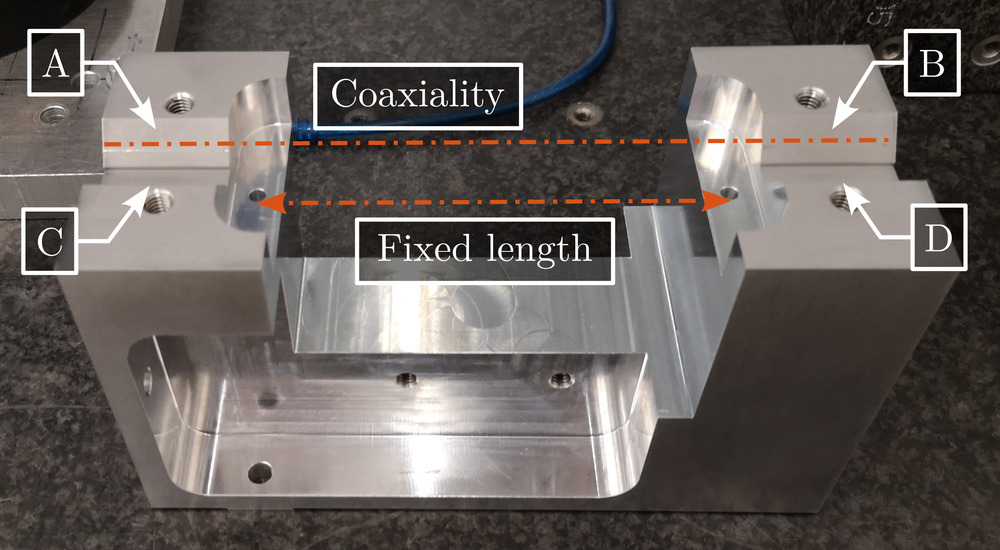

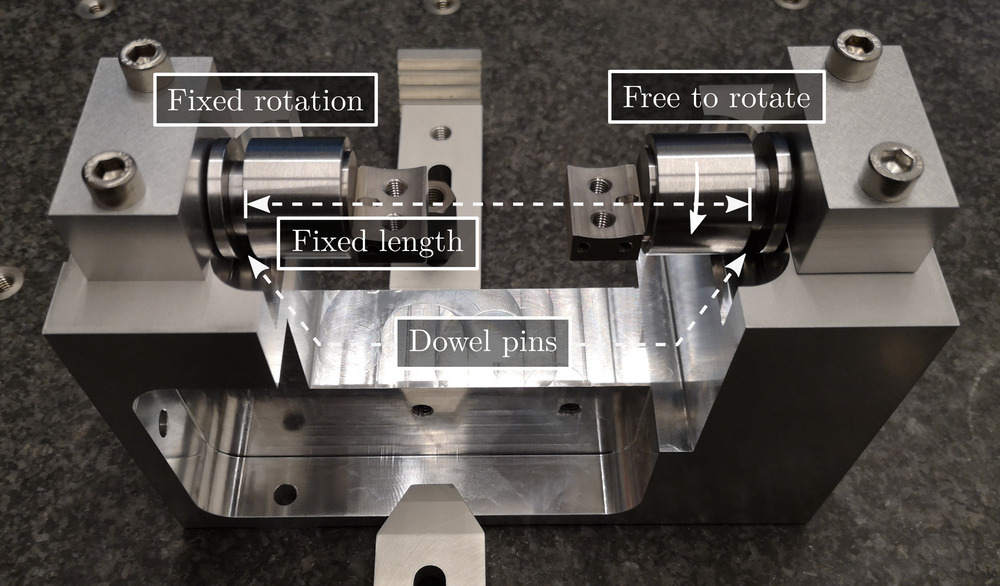

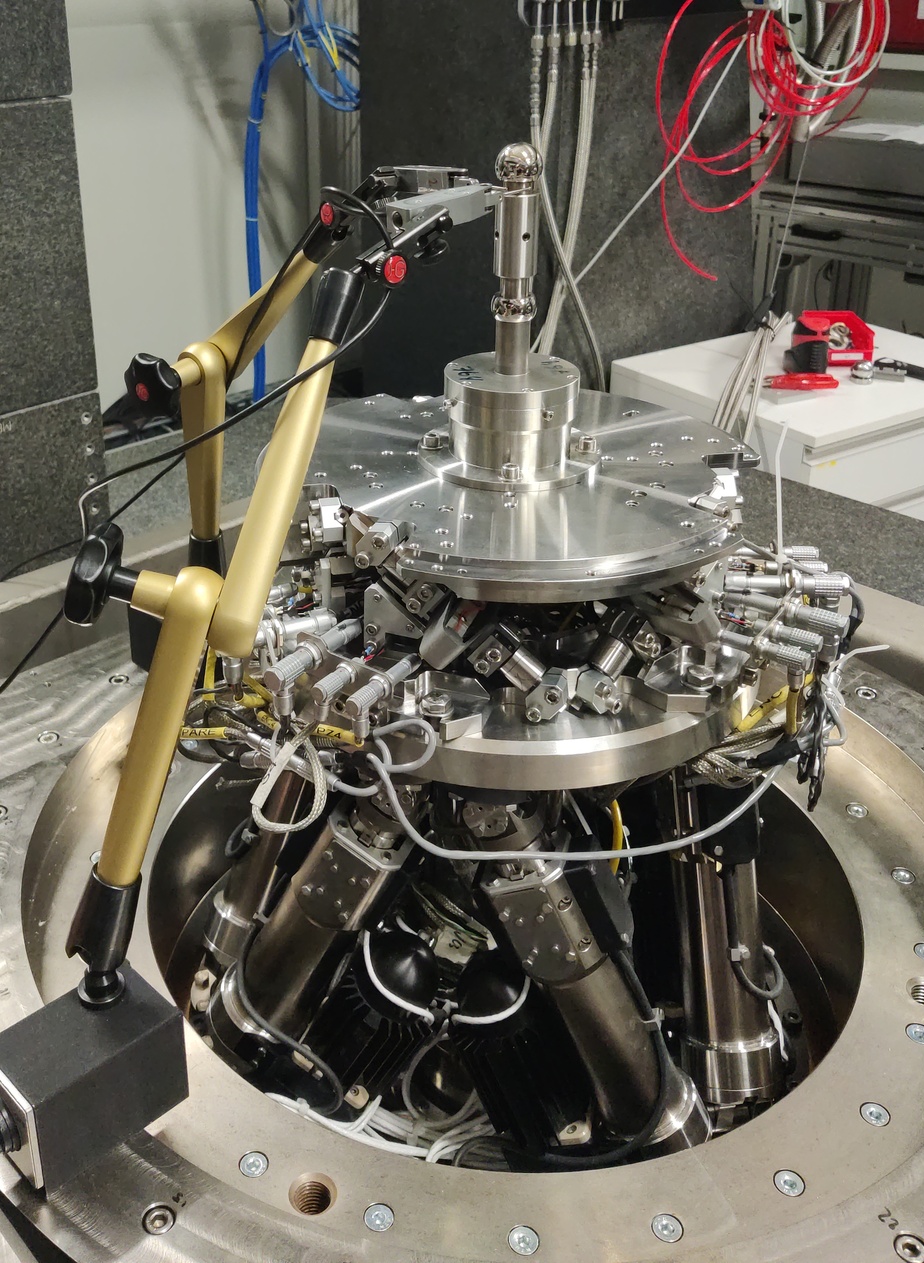

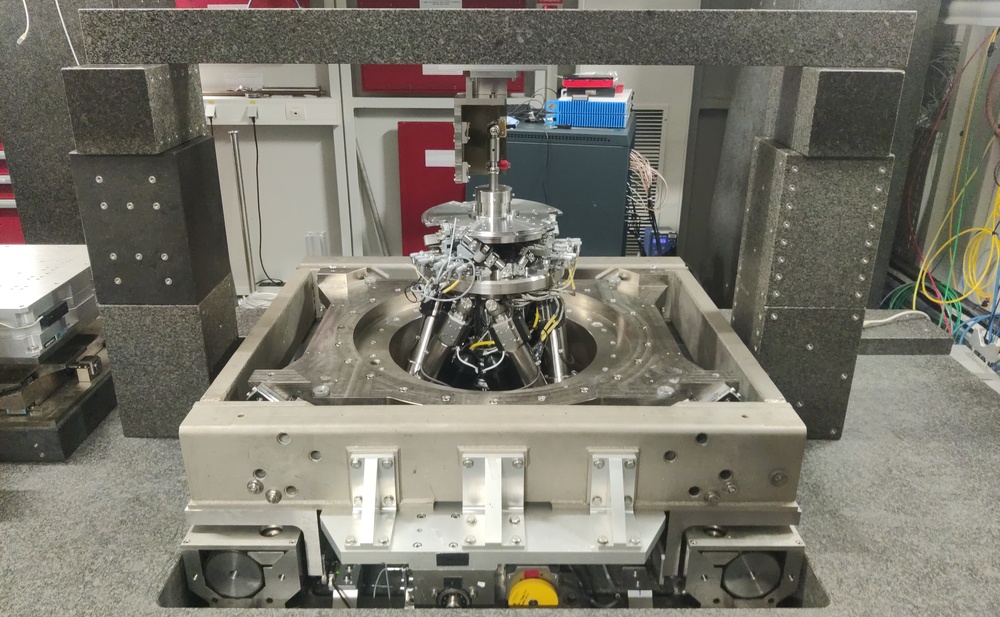

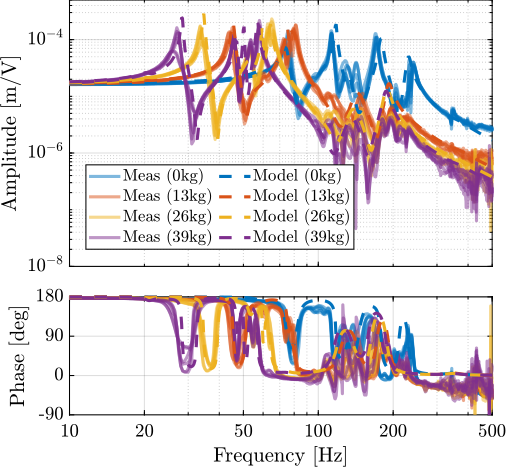

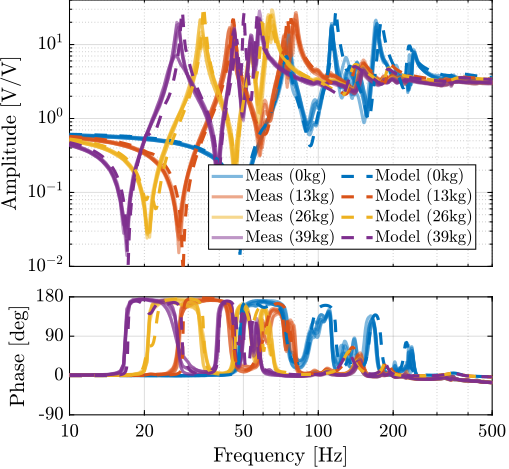

Chapter ref:chap:detail focuses on translating the validated NASS concept into an optimized, implementable design. Building upon the conceptual model which used idealized components, this phase addresses the detailed specification and optimization of each subsystem. It starts with the determination of the optimal active platform geometry (Section ref:sec:detail_kinematics), analyzing the influence of geometric parameters on mobility, stiffness, and dynamics, leading to specific requirements for actuator stroke and joint mobility. A hybrid multi-body/FEA modeling methodology is introduced and experimentally validated (Section ref:sec:detail_fem), then applied to optimize the actuators (Section ref:sec:detail_fem_actuator) and flexible joints (Section ref:sec:detail_fem_joint) while maintaining system-level simulation capability. Control strategy refinement (Section ref:sec:detail_control) involves optimal integration of multiple sensors in the control architecture, evaluating decoupling strategies, and discussing controller optimization for decoupled systems. Instrumentation selection (Section ref:sec:detail_instrumentation) is guided by dynamic error budgeting to establish noise specifications, followed by experimental characterization. The chapter concludes (Section ref:sec:detail_design) by presenting the final, optimized active platform design, ready for procurement and assembly.

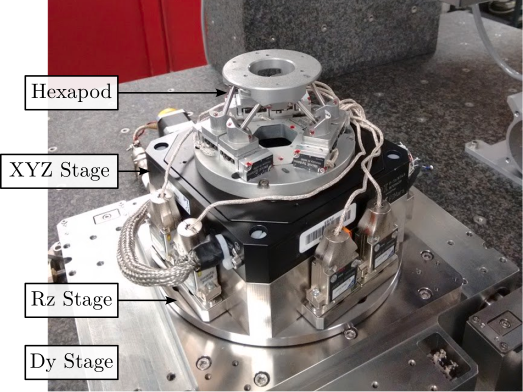

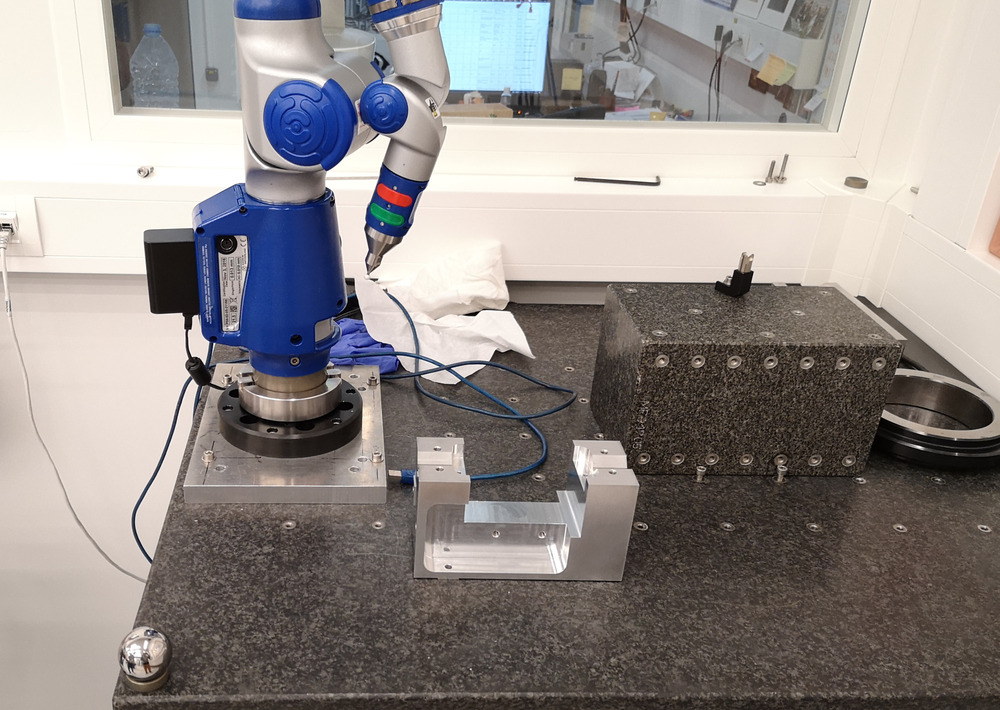

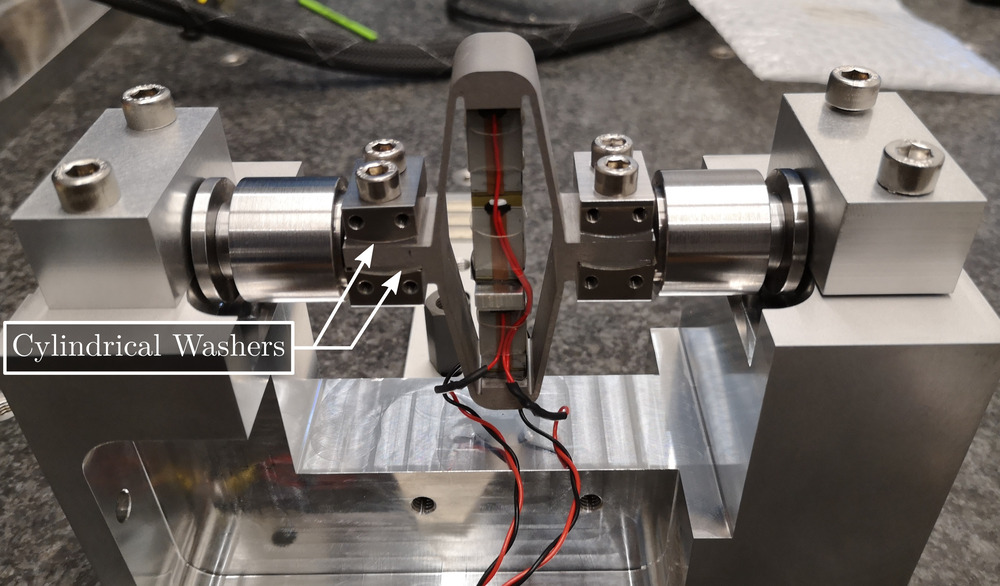

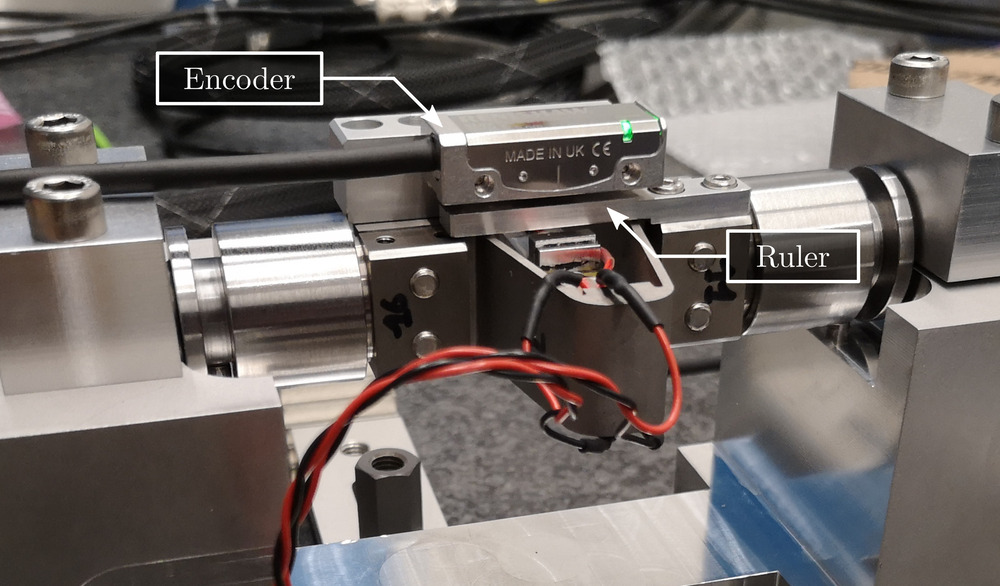

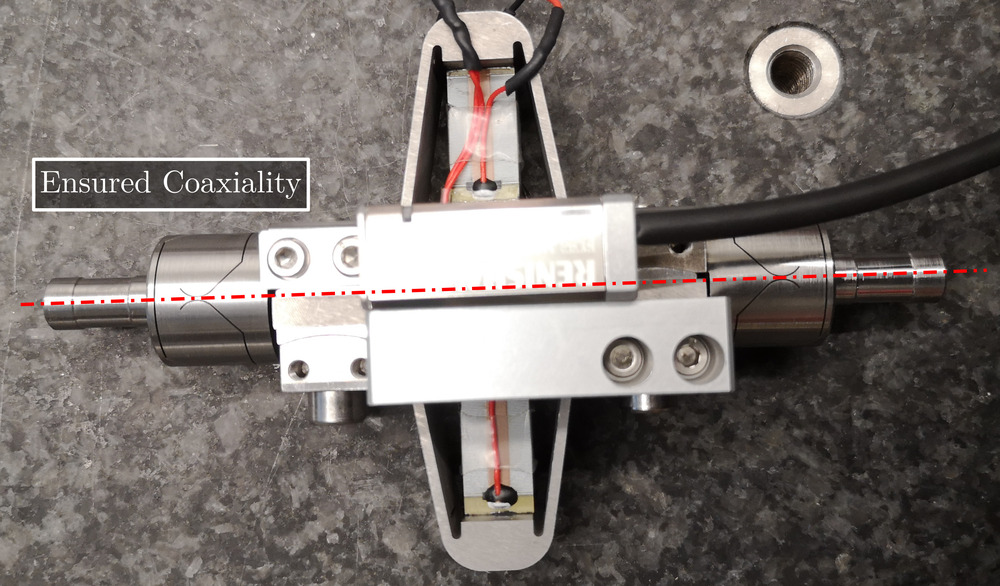

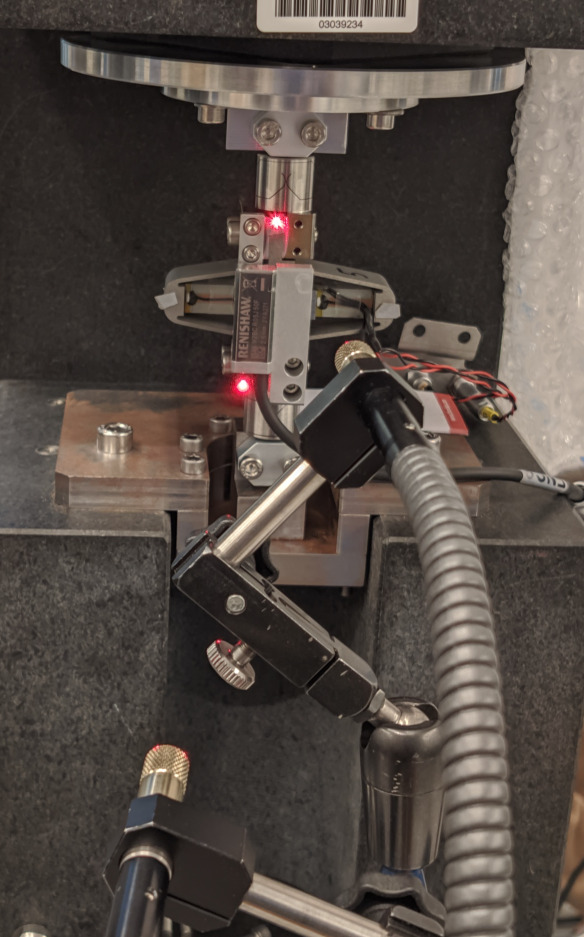

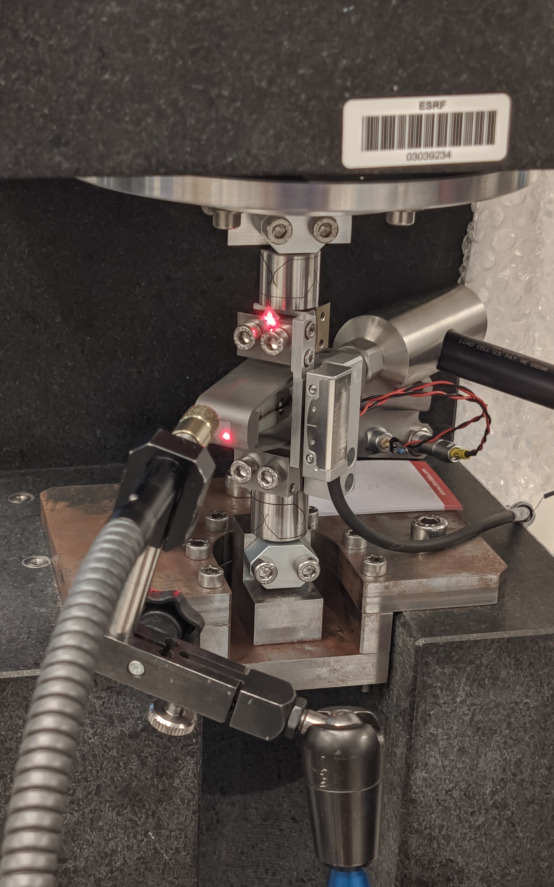

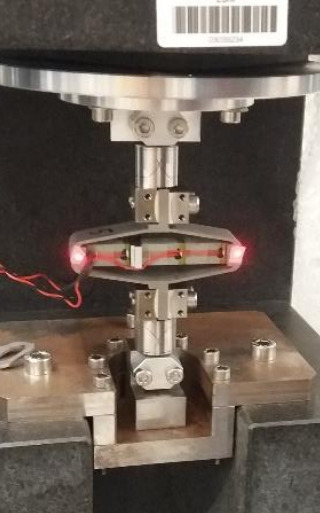

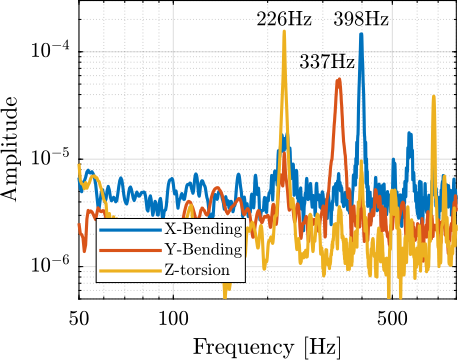

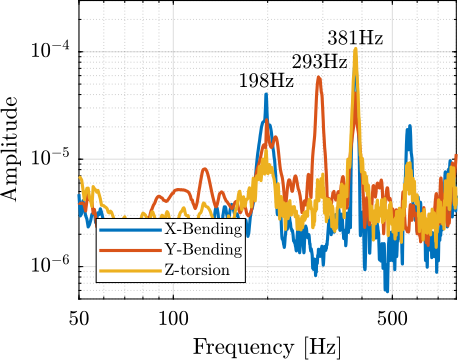

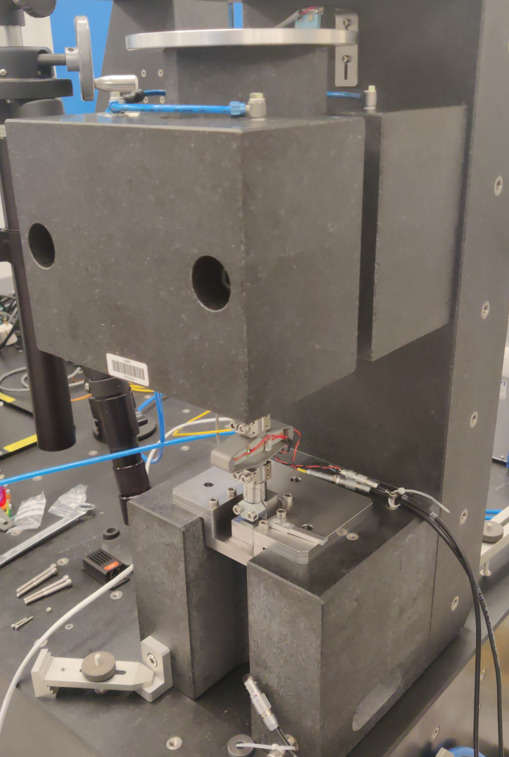

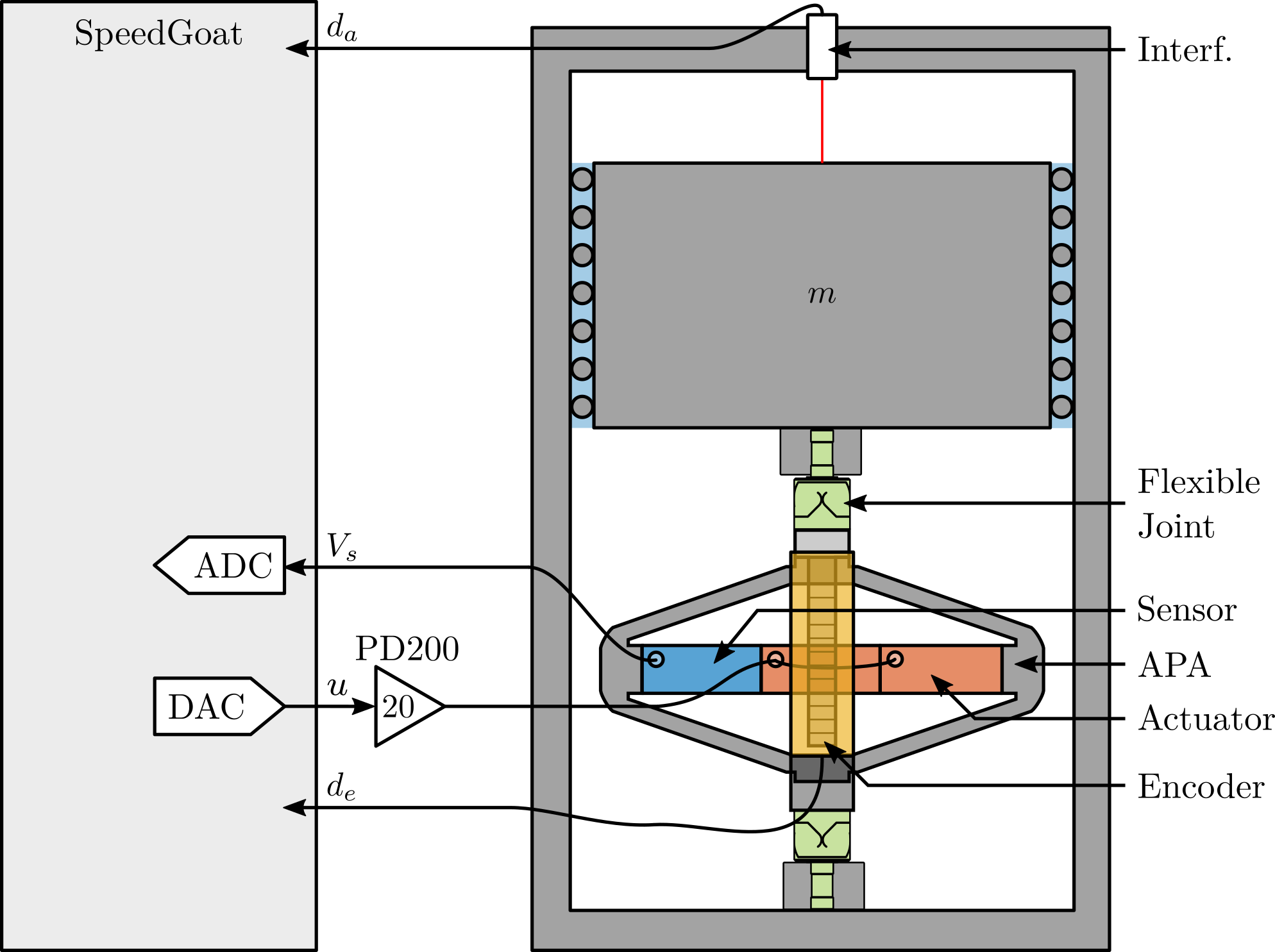

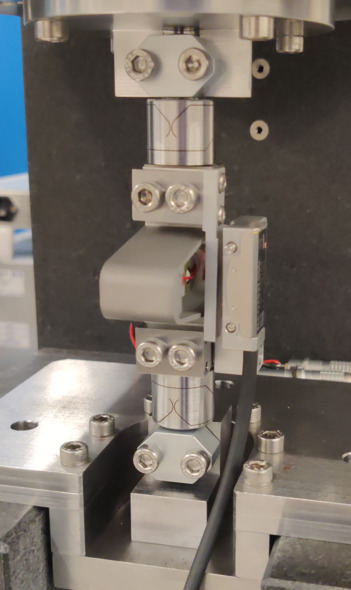

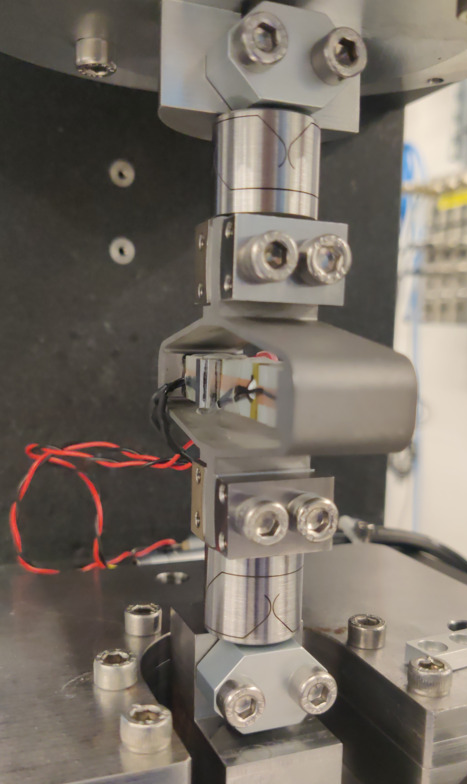

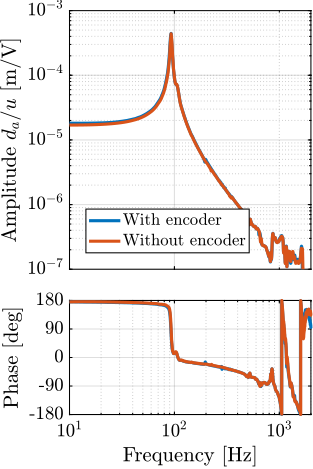

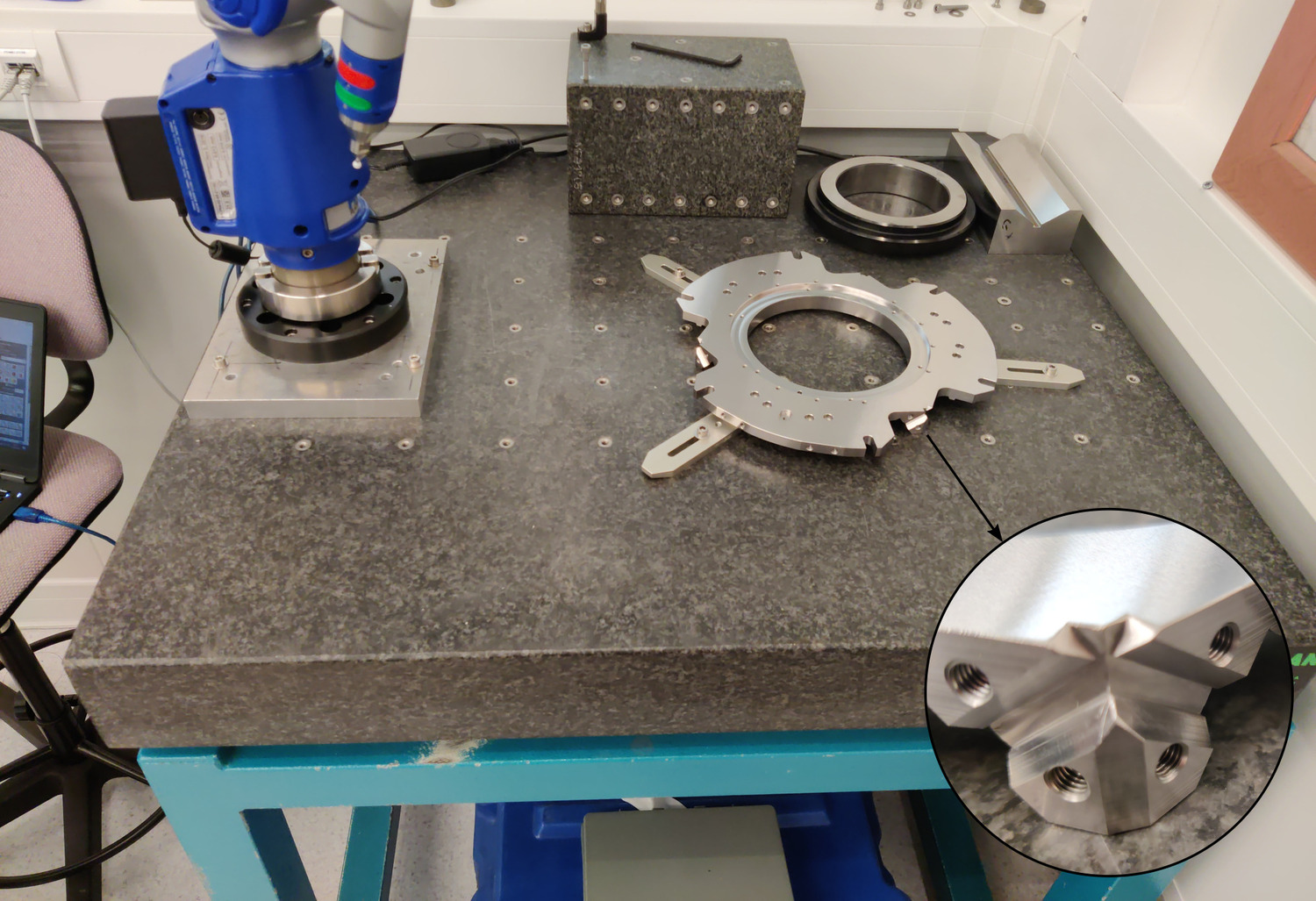

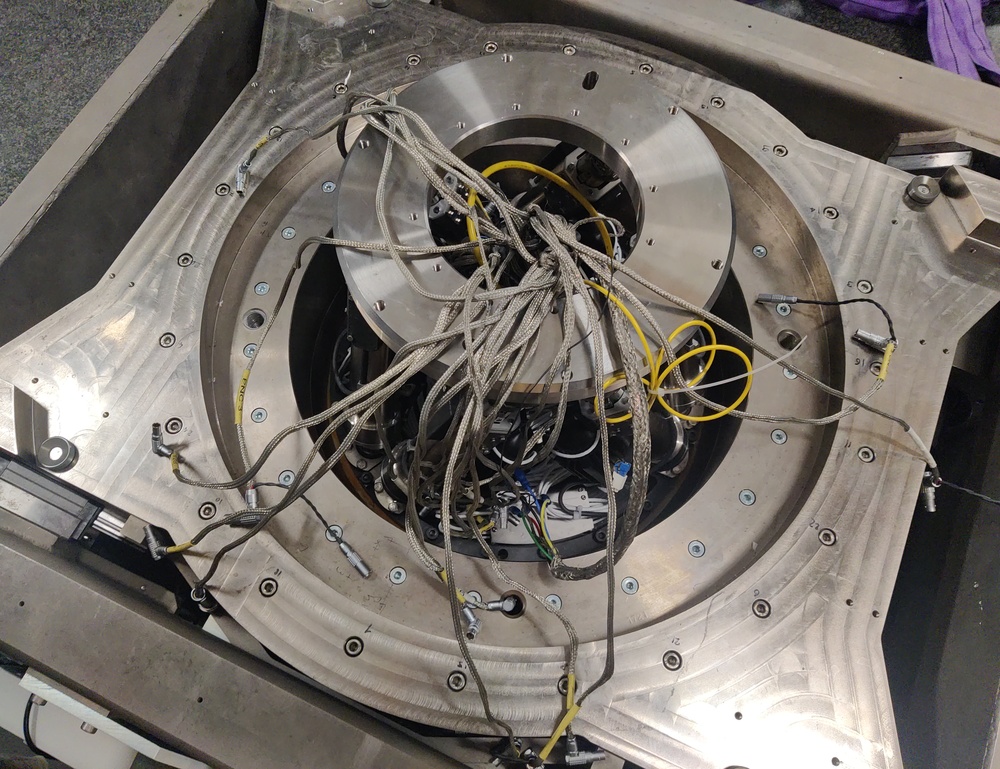

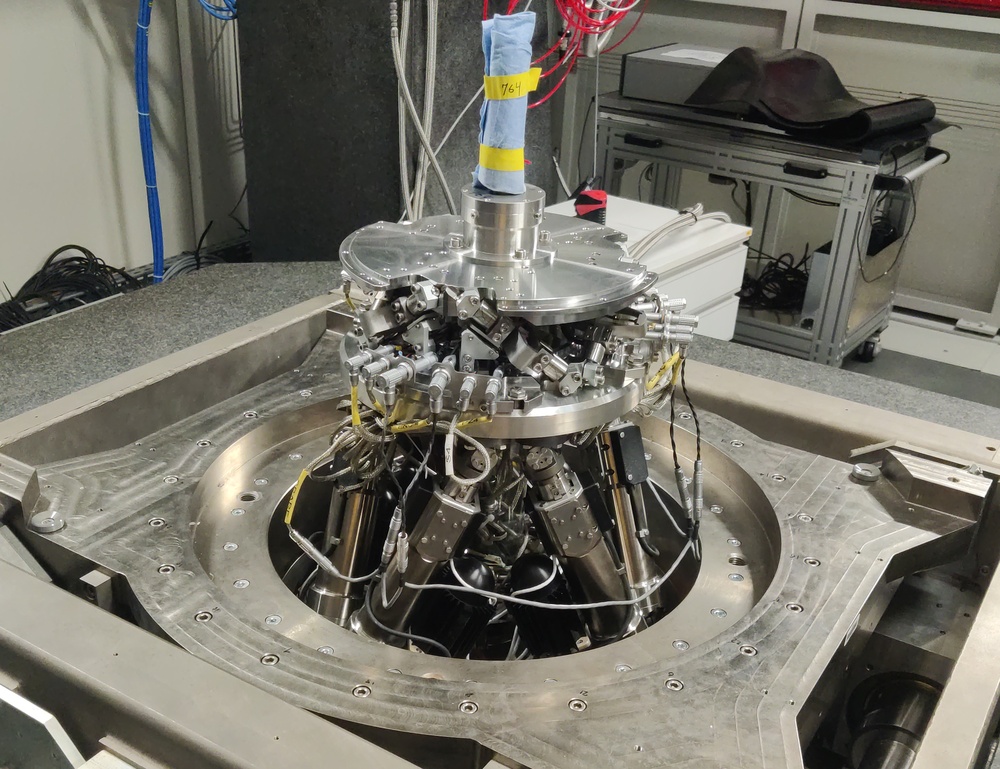

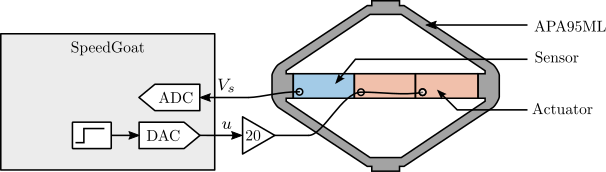

Experimental validation

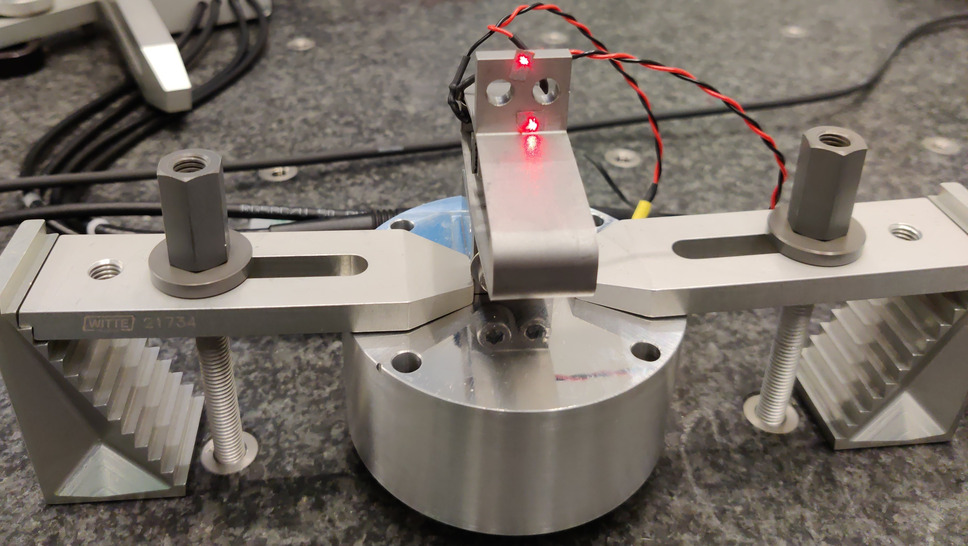

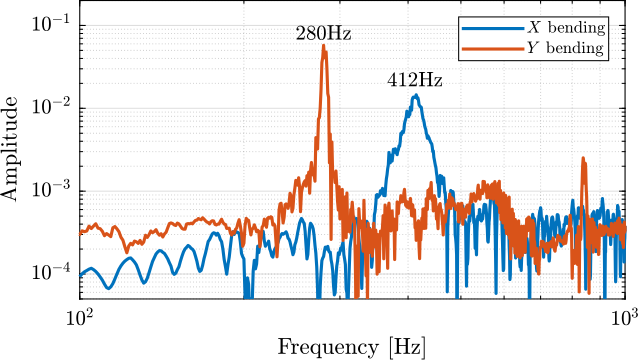

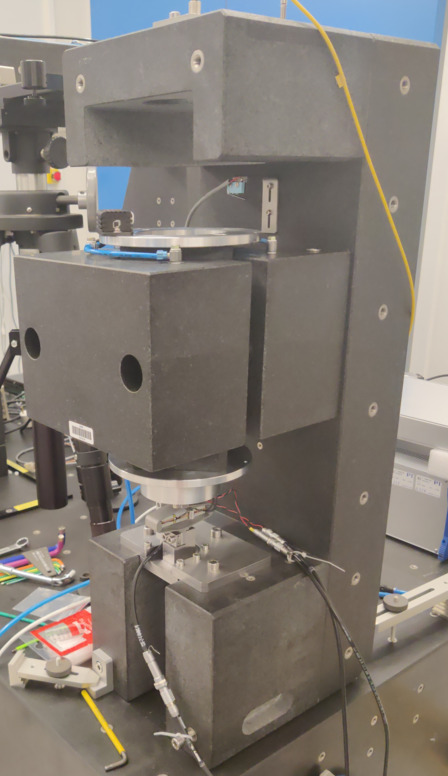

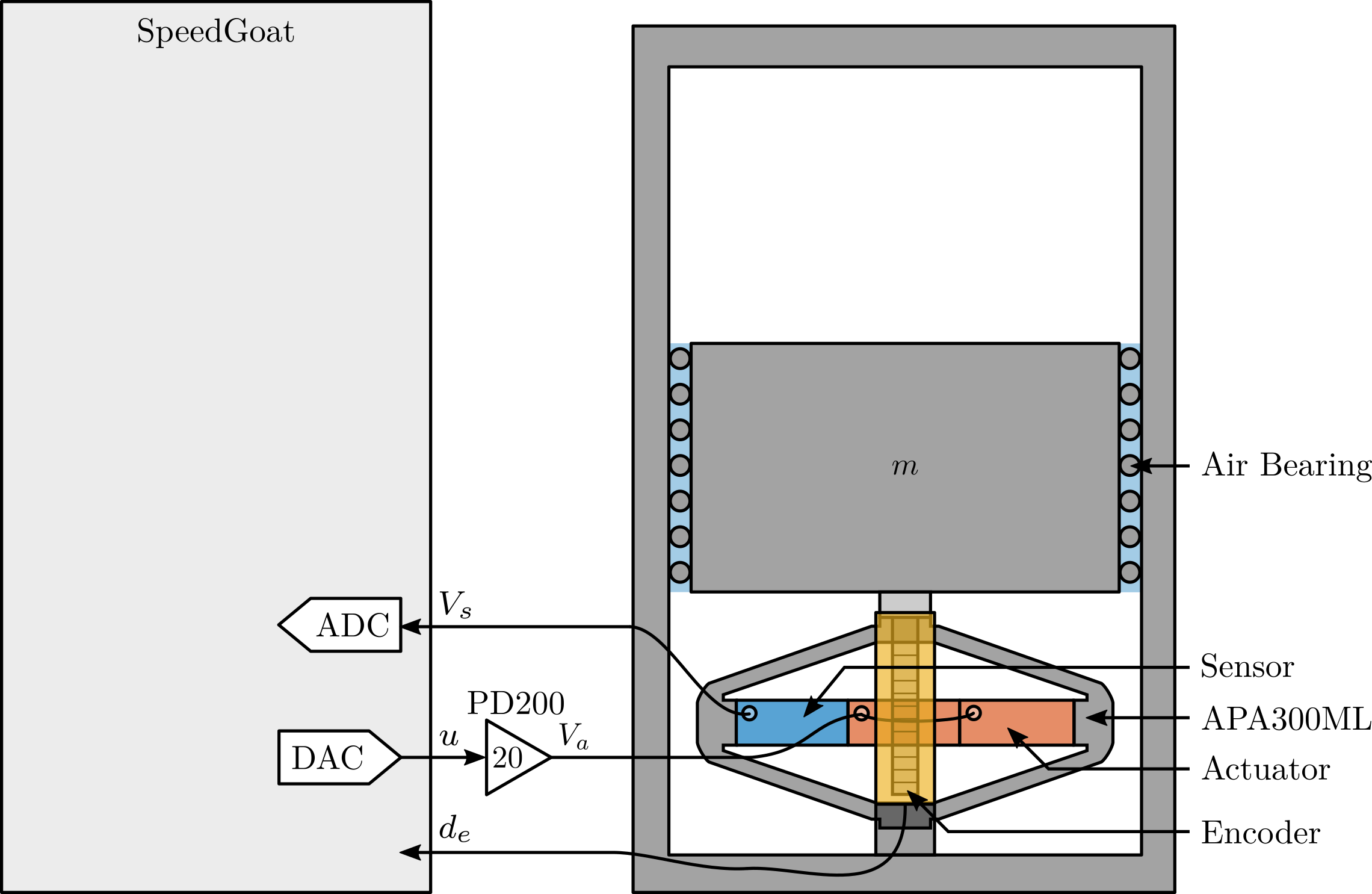

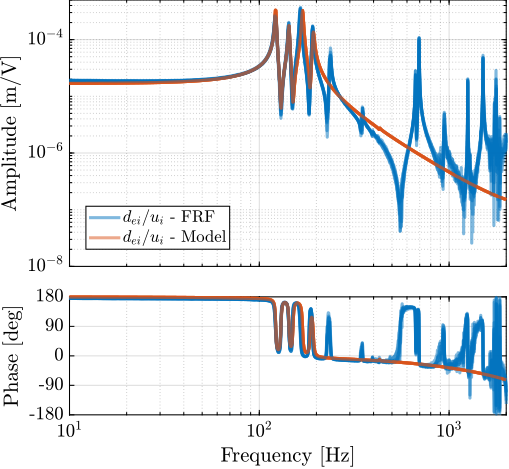

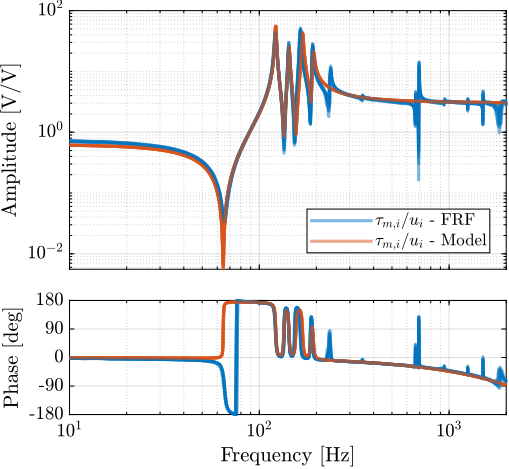

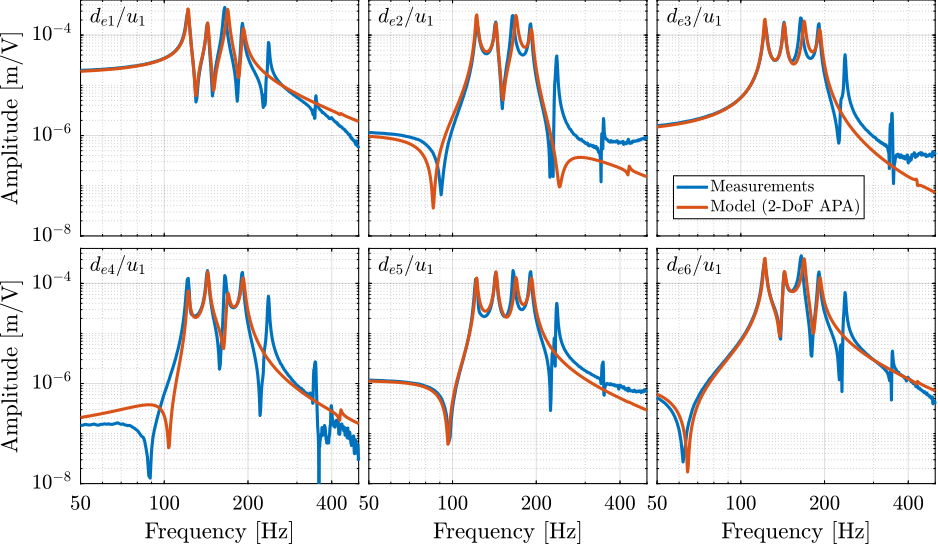

Chapter ref:chap:test details the experimental validation process, proceeding systematically from component-level characterization to full system evaluation on the beamline. Actuators of the active platform were characterized, models validated, and active damping tested (Section ref:sec:test_apa). Flexible joints were tested on a dedicated bench to verify stiffness and stroke specifications (Section ref:sec:test_joints). Assembled struts (actuators + joints) were then characterized to ensure consistency and validate multi-body models (Section ref:sec:test_struts). The complete active platform assembly was tested on an isolated table, allowing accurate dynamic identification and model validation under various payload conditions (Section ref:sec:test_nhexa). Finally, the integrated NASS was validated on the ID31 beamline using a purpose-built short-stroke metrology system (Section ref:sec:test_id31). The implemented control architecture was tested under realistic experimental scenarios, including tomography with heavy payloads, confirming the system's performance and robustness.

Conceptual Design Development

<<chap:concept>> minitoc

Abstract

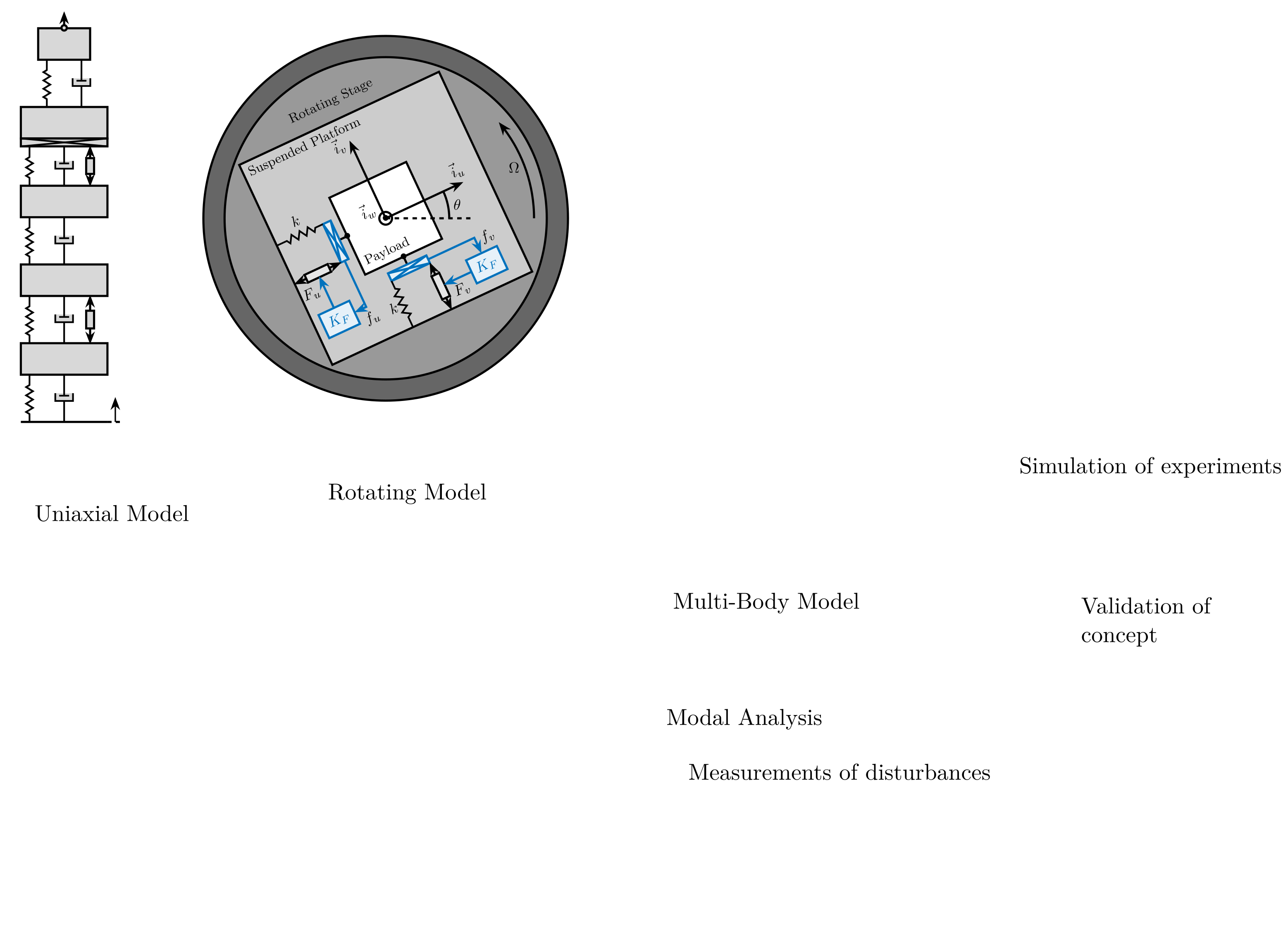

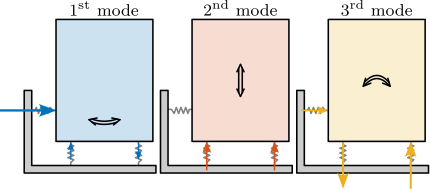

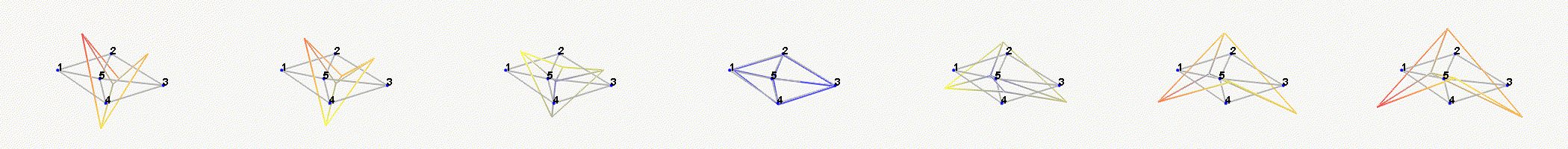

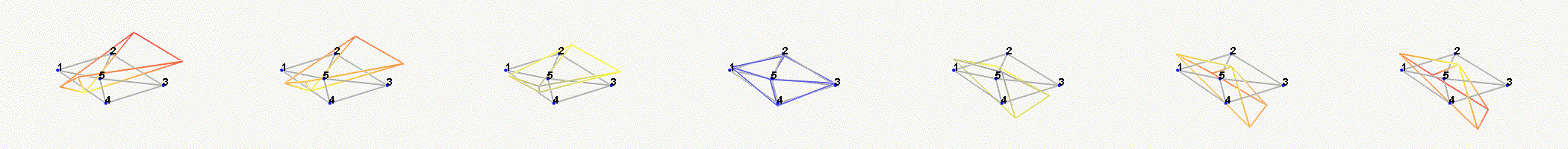

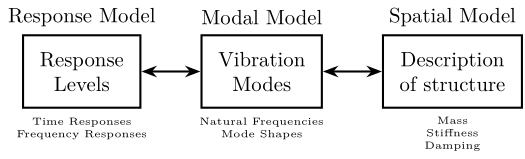

The conceptual design of the Nano Active Stabilization System (NASS) follows a methodical progression from simple to more accurate modeling approaches, as illustrated in Figure ref:fig:chapter1_overview.

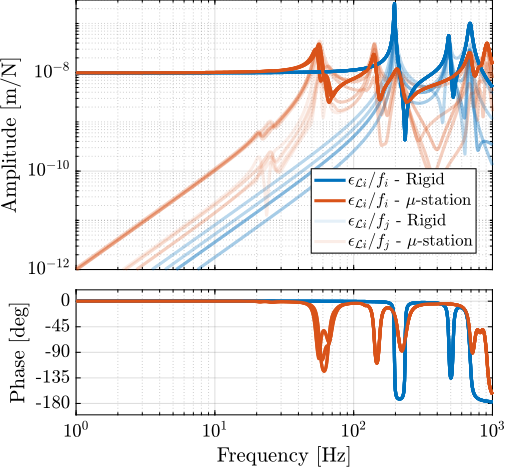

The design process begins with a uniaxial model, presented in Section ref:sec:uniaxial, which provides initial insights into fundamental challenges associated with this complex system. This simplified representation focuses exclusively on the vertical direction—having the most stringent requirements—though similar conclusions were drawn from analyses of other axes. Despite its simplicity, this uniaxial model proves valuable for testing initial control strategies and, more importantly, for evaluating how the active platform stiffness affects overall system performance.

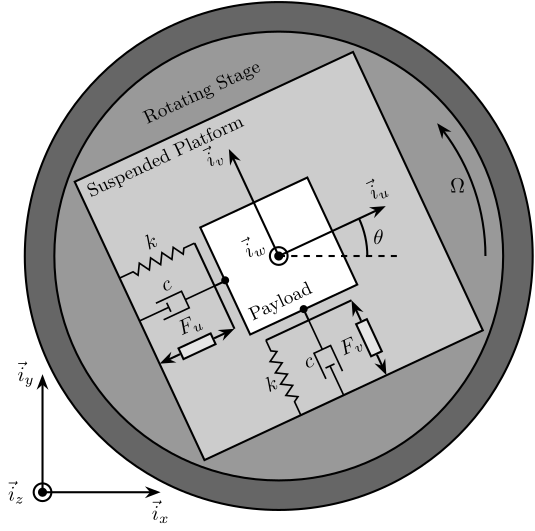

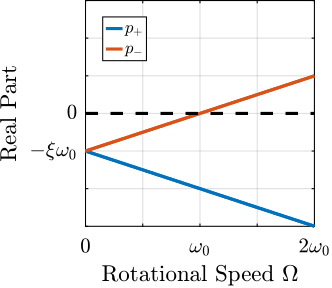

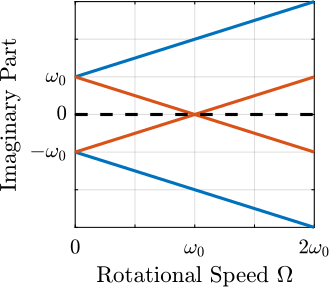

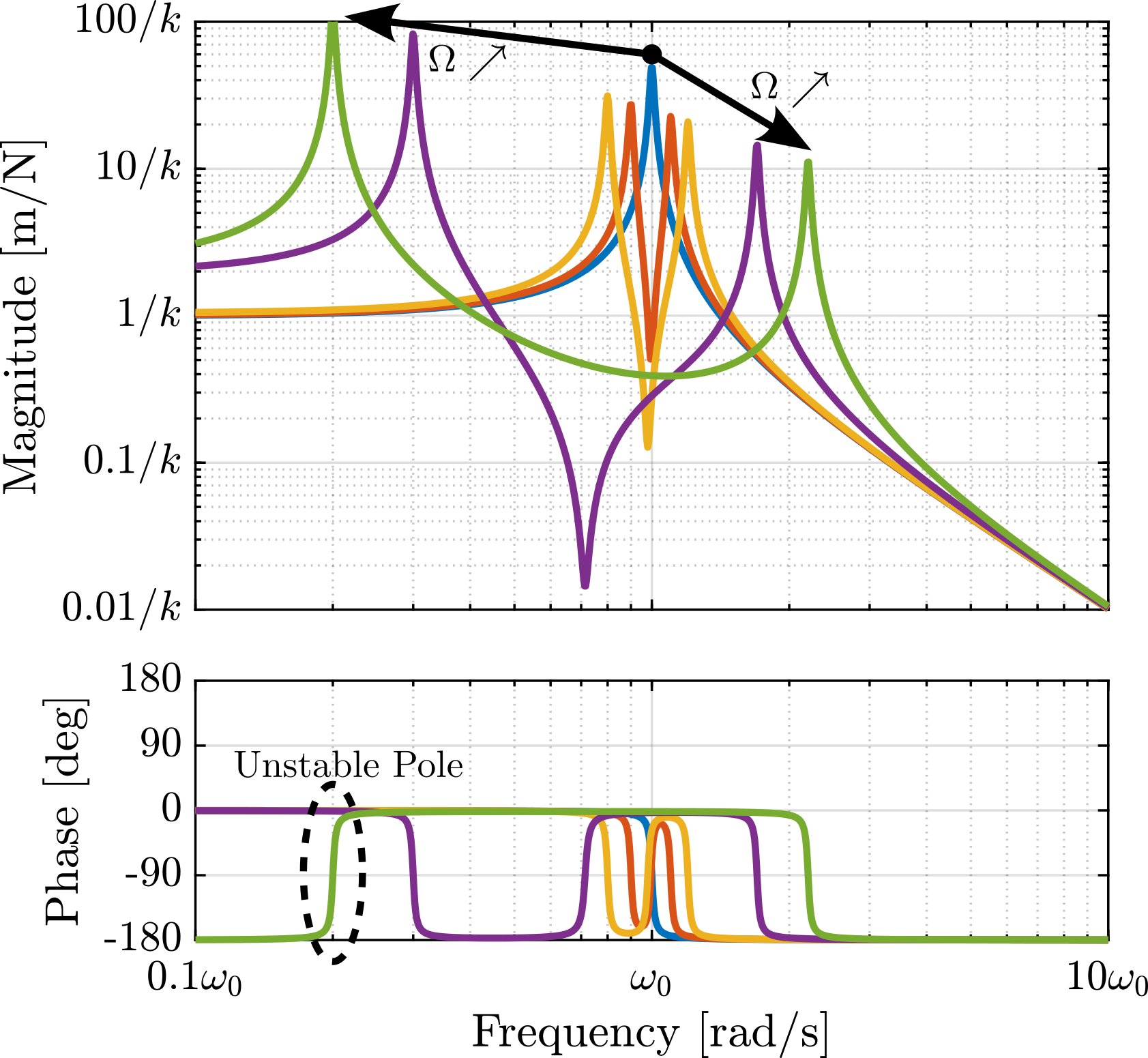

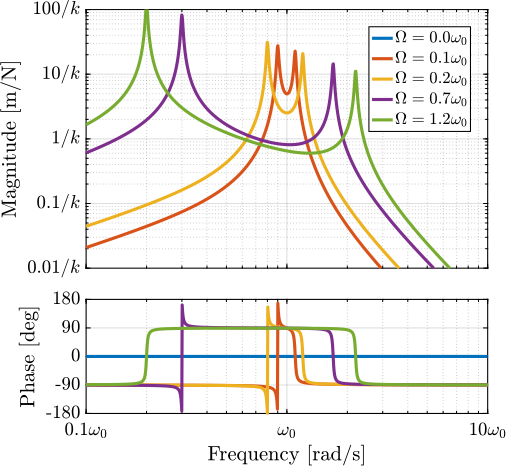

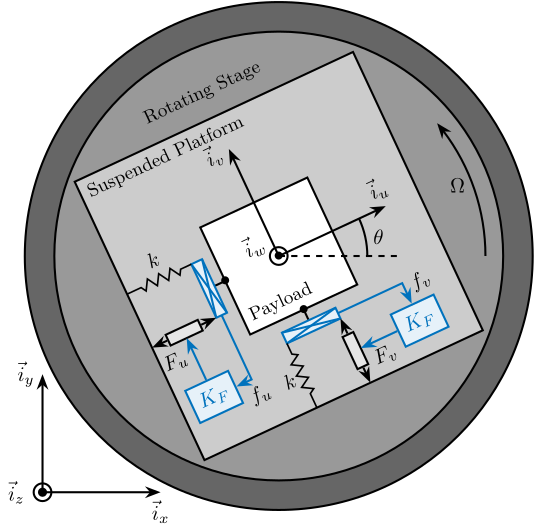

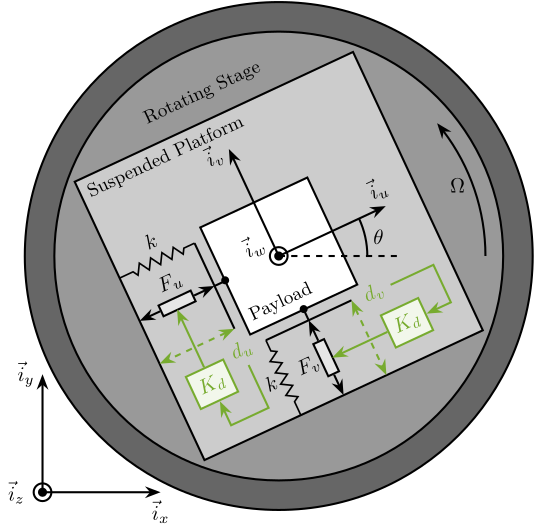

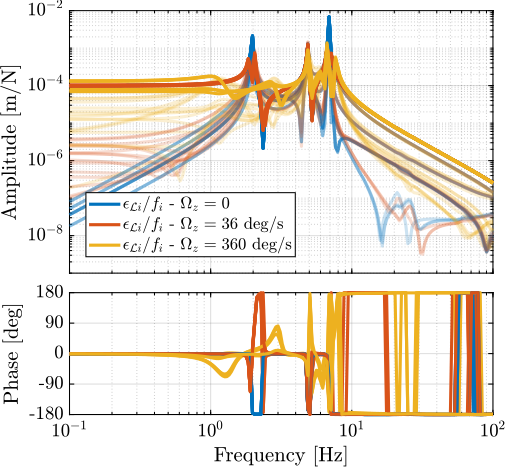

Building upon these findings, Section ref:sec:rotating introduces the rotational aspect through a three-degree-of-freedom model. This new model allows to study the gyroscopic effects induced by the spindle's continuous rotation—a distinctive characteristic of the NASS. The investigation reveals that these gyroscopic effects have more impact on softer active platforms, creating significant challenges for stability and control.

As the investigation progressed, the need for a more accurate representation of the micro-station dynamics became increasingly evident. To construct such a model, a comprehensive modal analysis was conducted, as detailed in Section ref:sec:modal. This experimental modal analysis confirmed the complex nature of the micro-station dynamics while validating that each stage behaves predominantly as a rigid body within the frequency range of interest—thus supporting the subsequent development of a multi-body model.

Section ref:sec:ustation presents the development of this multi-body model for the micro-station. Parameters were meticulously tuned to match measured compliance characteristics, and disturbance sources were carefully modelled based on experimental data. This refined model was then validated through simulations of scientific experiments, demonstrating its accuracy in representing the micro-station behavior under typical operating conditions.

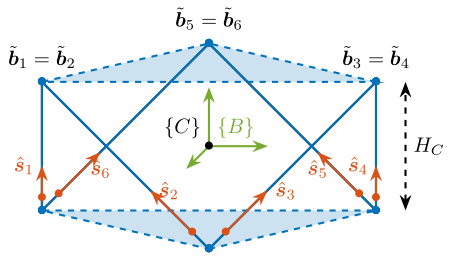

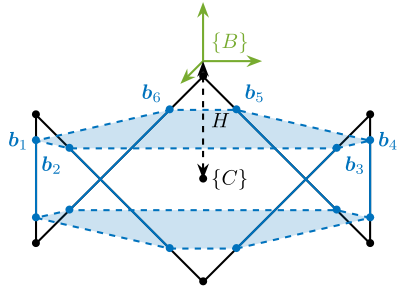

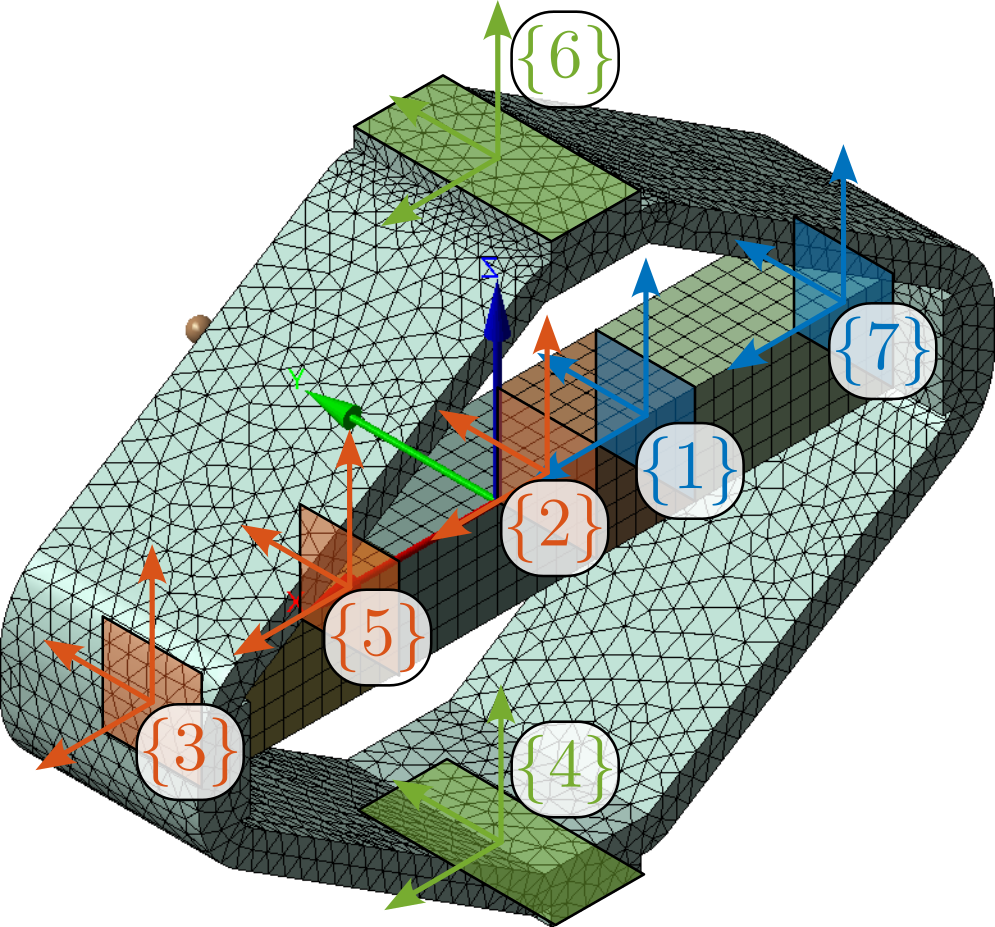

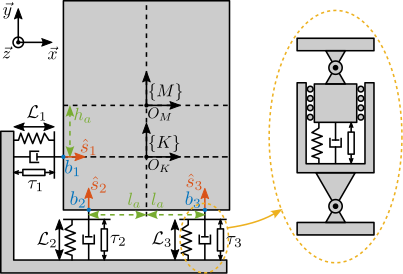

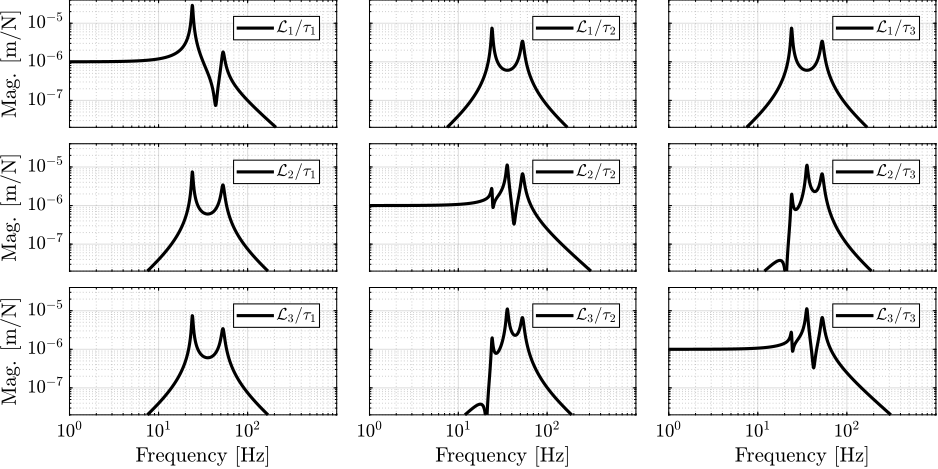

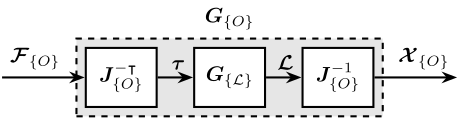

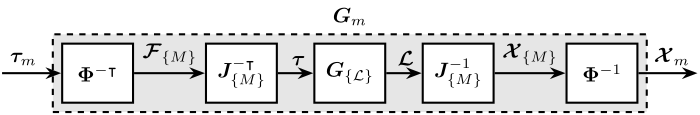

For the active stabilization stage, the Stewart platform architecture was selected after careful evaluation of various options. Section ref:sec:nhexa examines the kinematic and dynamic properties of this parallel manipulator, exploring its control challenges and developing appropriate control strategies for implementation within the NASS. The multi-body modeling approach facilitated the seamless integration of the active platform with the micro-station model.

Finally, Section ref:sec:nass validates the NASS concept through acrfull:cl simulations of tomography experiments. These simulations incorporate realistic disturbance sources, confirming the viability of the proposed design approach and control strategies.

This progressive approach, beginning with easily comprehensible simplified models, proved instrumental in developing a thorough understanding of the physical phenomena at play. By methodically increasing model complexity only as needed, the design process converged efficiently toward a concept capable of delivering the required performance levels. The confidence gained through this systematic investigation provides a solid foundation for transitioning to the detailed design phase, which will be addressed in the following chapter.

Uni-axial Model

<<sec:uniaxial>>

Introduction

In this report, a uniaxial model of the acrfull:nass is developed and used to obtain a first idea of the challenges involved in this complex system. Note that in this study, only the vertical direction is considered (which is the most stiff), but other directions were considered as well, leading to similar conclusions.

To have a relevant model, the micro-station dynamics is first identified and its model is tuned to match the measurements (Section ref:sec:uniaxial_micro_station_model). Then, a model of the active platform is added on top of the micro-station. With the added sample and sensors, this gives a uniaxial dynamical model of the acrshort:nass that will be used for further analysis (Section ref:sec:uniaxial_nano_station_model).

The disturbances affecting position stability are identified experimentally (Section ref:sec:uniaxial_disturbances) and included in the model for dynamical error budgeting (Section ref:sec:uniaxial_noise_budgeting). In all the following analysis, three active platform stiffnesses are considered to better understand the trade-offs and to find the most adequate active platform design. Three sample masses are also considered to verify the robustness of the applied control strategies with respect to a change of sample.

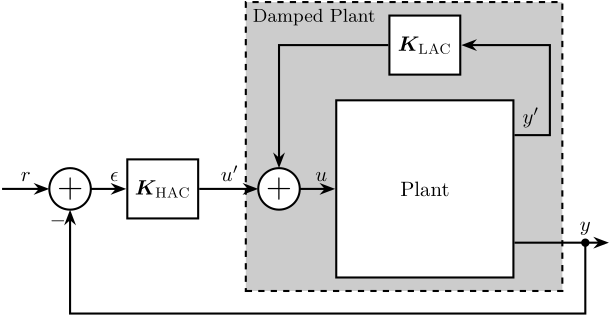

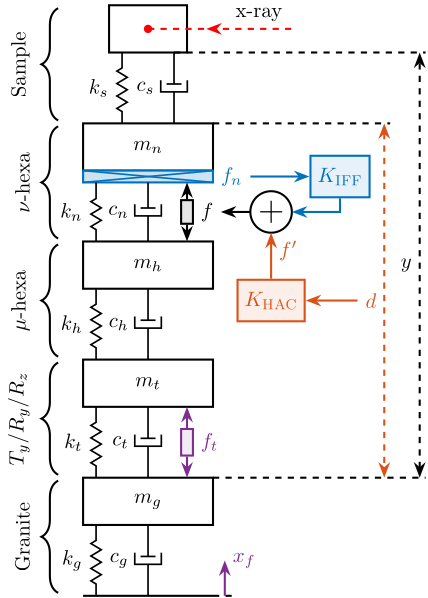

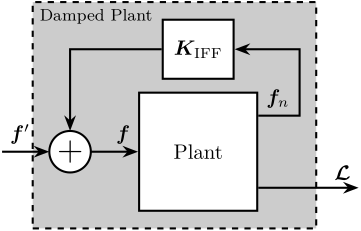

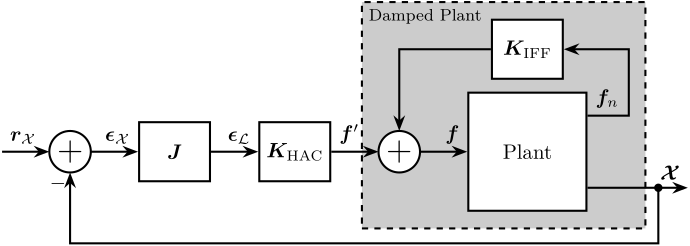

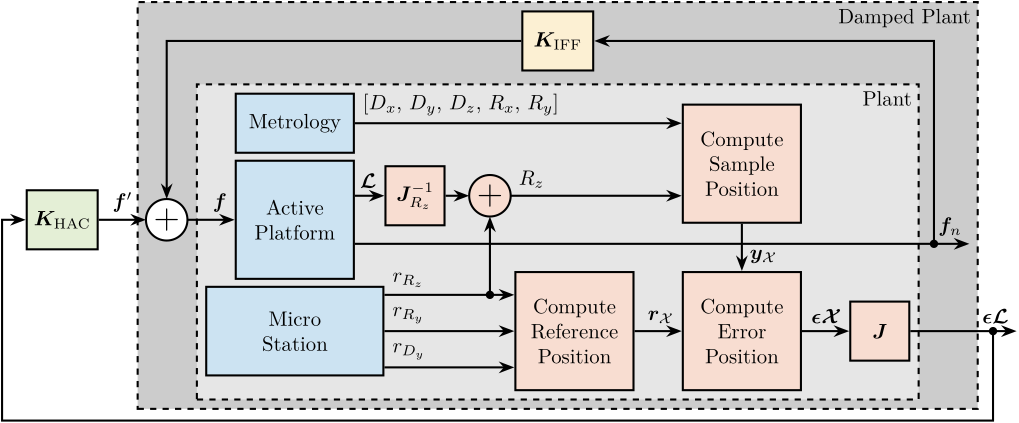

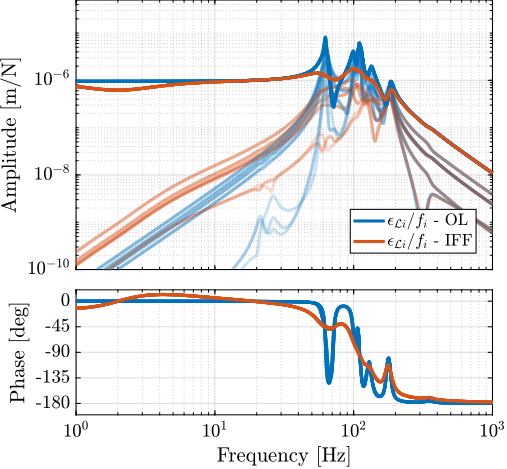

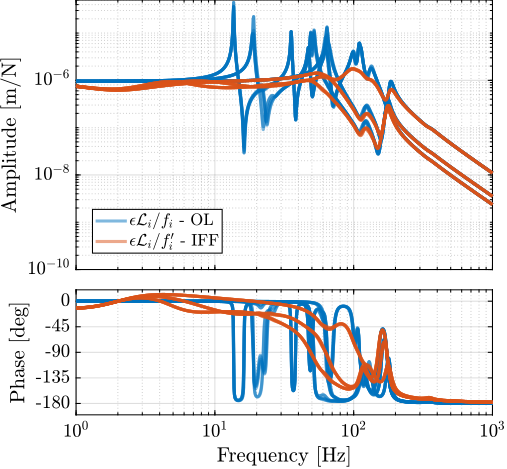

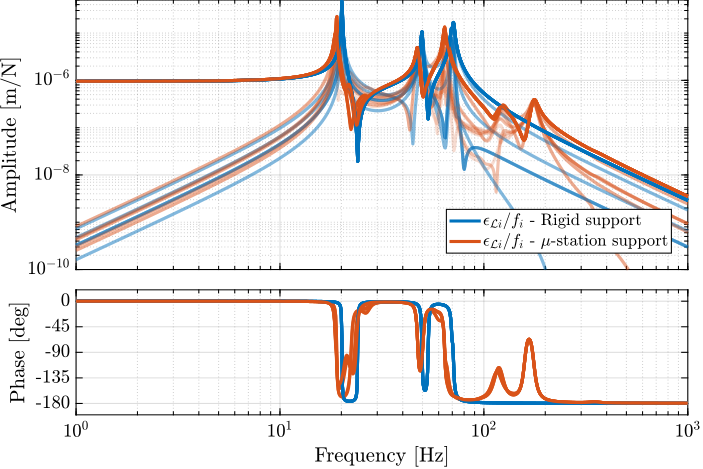

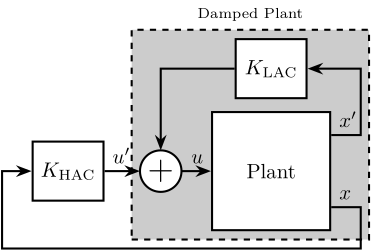

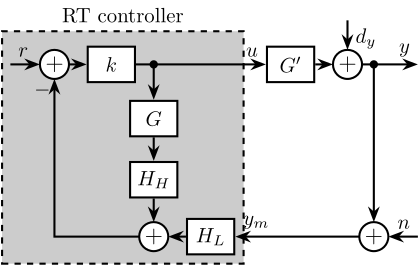

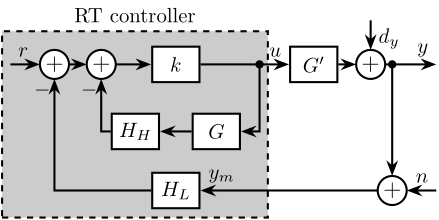

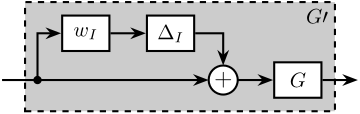

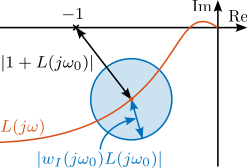

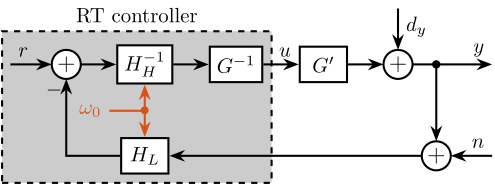

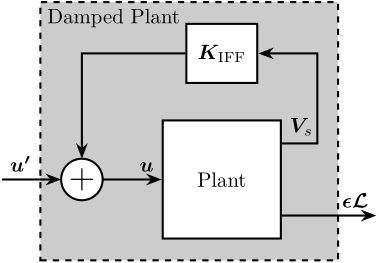

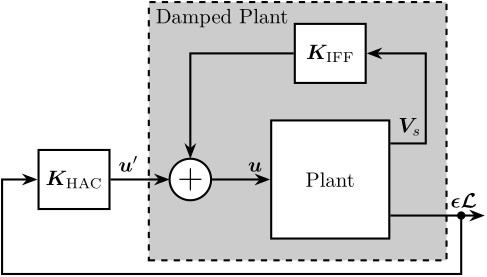

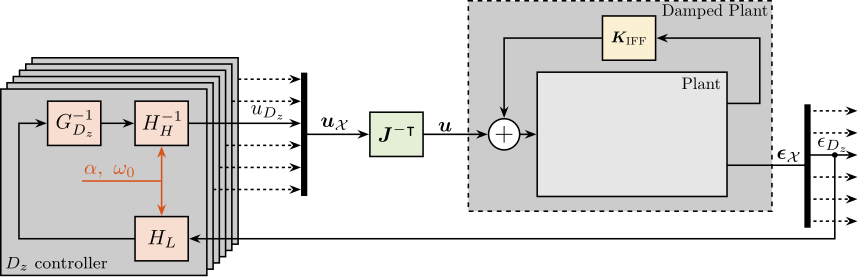

To improve the position stability of the sample, an acrfull:haclac strategy is applied. It consists of first actively damping the plant (the acrshort:lac part), and then applying a position control on the damped plant (the acrshort:hac part).

Three active damping techniques are studied (Section ref:sec:uniaxial_active_damping) which are used to both reduce the effect of disturbances and make the system easier to control afterwards. Once the system is well damped, a feedback position controller is applied and the obtained performance is analyzed (Section ref:sec:uniaxial_position_control).

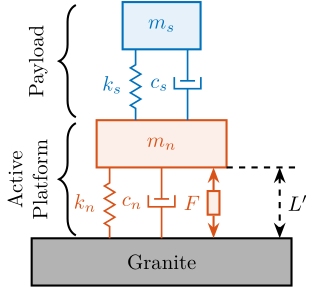

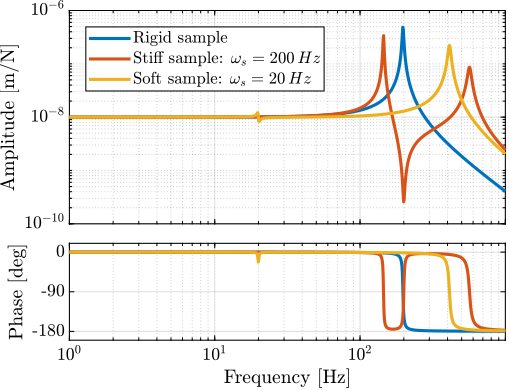

Two key effects that may limit that positioning performances are then considered: the limited micro-station compliance (Section ref:sec:uniaxial_support_compliance) and the presence of dynamics between the active platform and the sample's acrlong:poi (Section ref:sec:uniaxial_payload_dynamics).

Micro Station Model

<<sec:uniaxial_micro_station_model>>

Introduction

In this section, a uniaxial model of the micro-station is tuned to match measurements made on the micro-station.

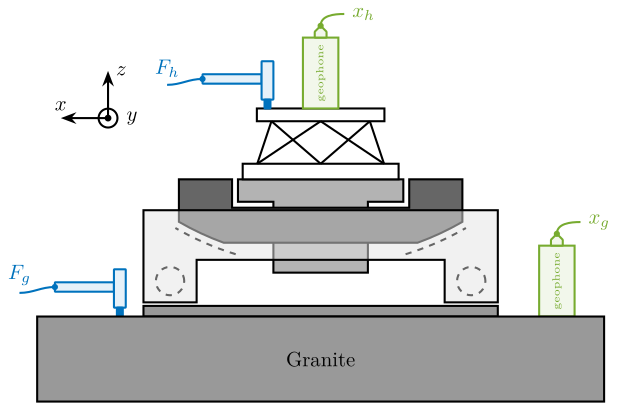

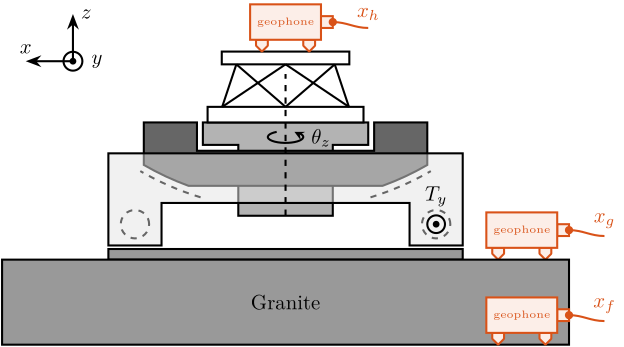

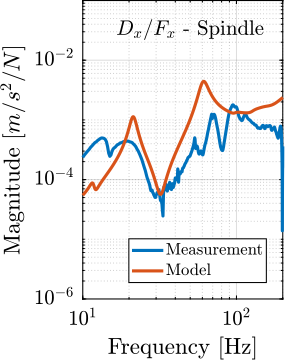

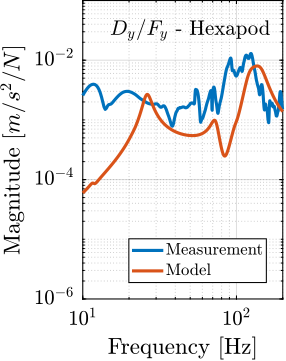

Measured Dynamics

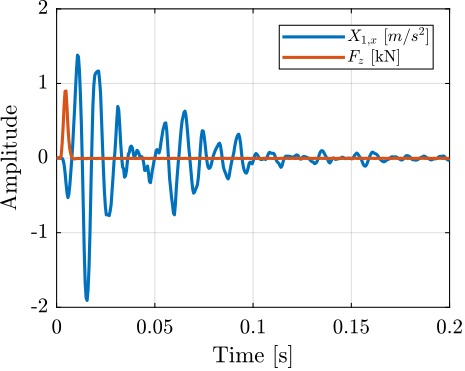

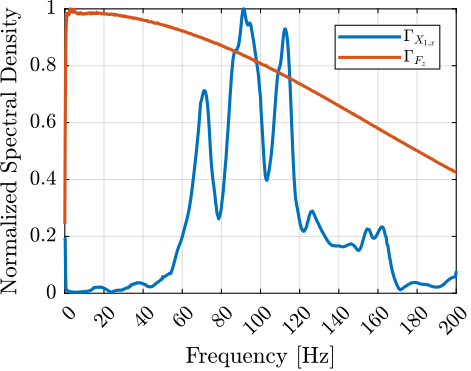

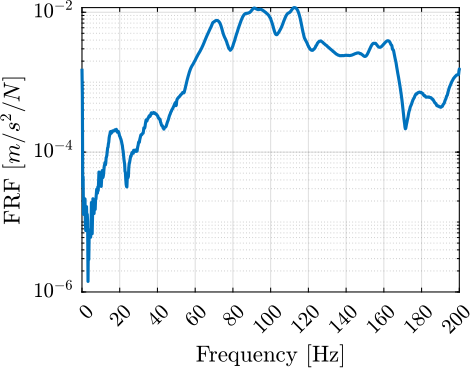

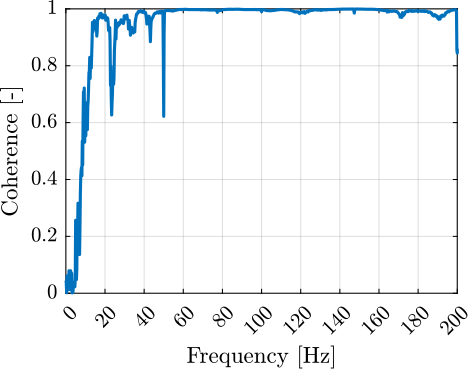

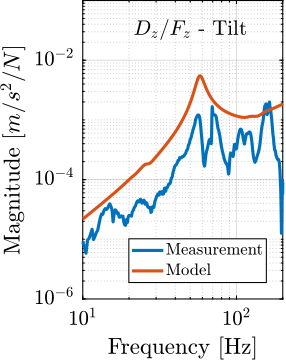

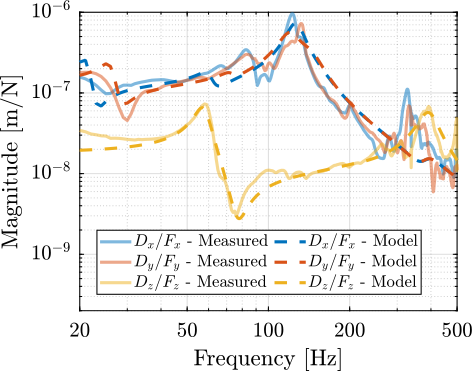

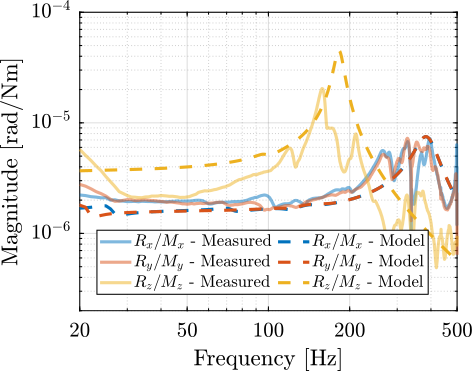

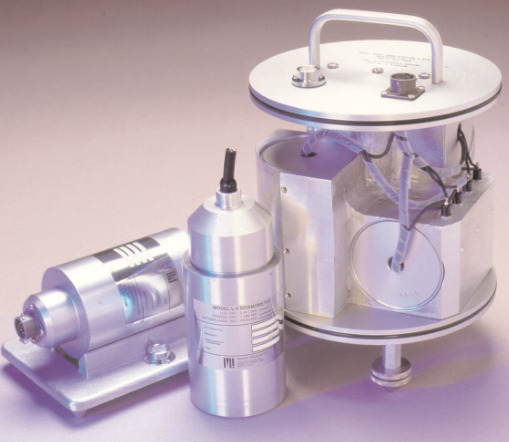

The measurement setup is schematically shown in Figure ref:fig:uniaxial_ustation_meas_dynamics_schematic where two vertical hammer hits are performed, one on the Granite (force $F_{g}$) and the other on the positioning hexapod's top platform (force $F_{h}$). The vertical inertial motion of the granite $x_{g}$ and the top platform of the positioning hexapod $x_{h}$ are measured using geophones1. Three acrfullpl:frf were computed: one from $F_{h}$ to $x_{h}$ (i.e., the compliance of the micro-station), one from $F_{g}$ to $x_{h}$ (or from $F_{h}$ to $x_{g}$) and one from $F_{g}$ to $x_{g}$.

Due to the poor coherence2 at low frequencies, these acrlongpl:frf will only be shown between 20 and $200\,\text{Hz}$ (solid lines in Figure ref:fig:uniaxial_comp_frf_meas_model).

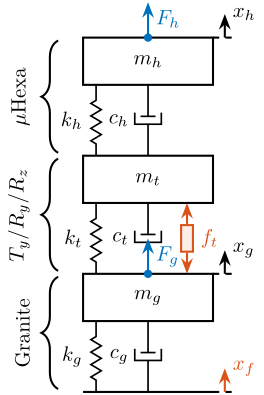

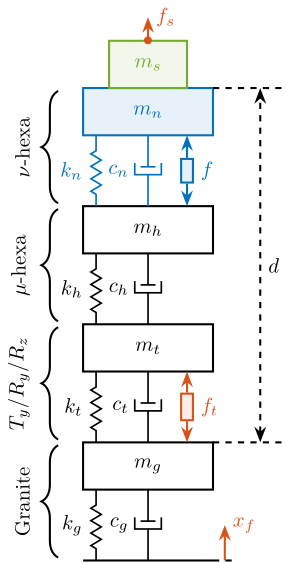

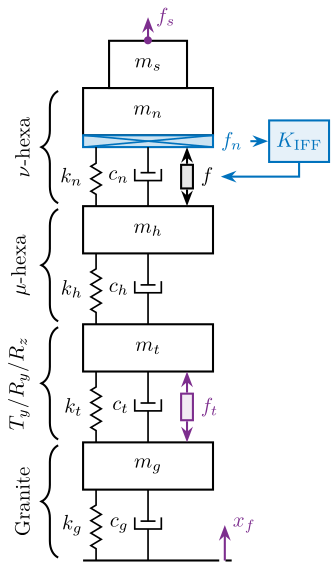

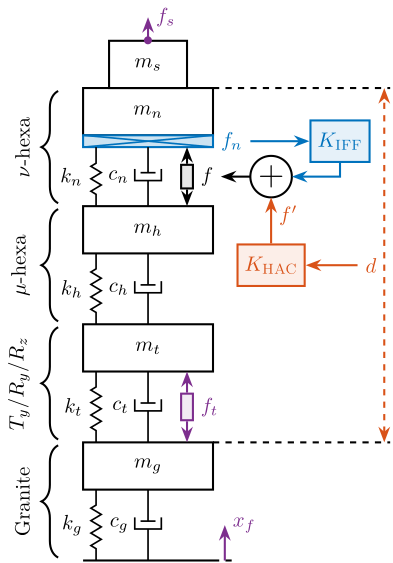

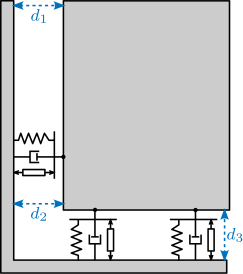

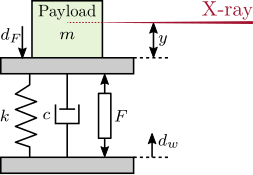

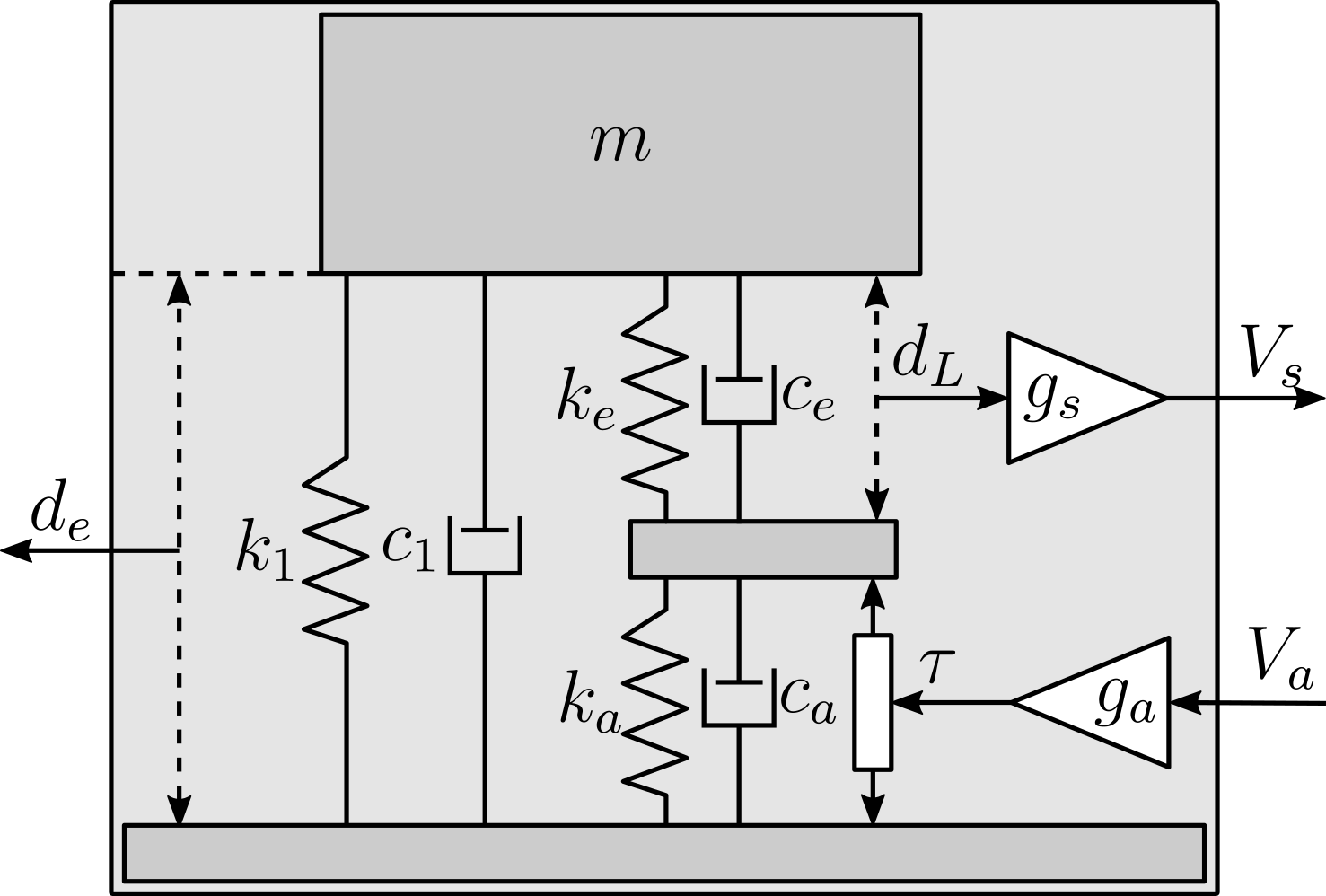

Uniaxial Model

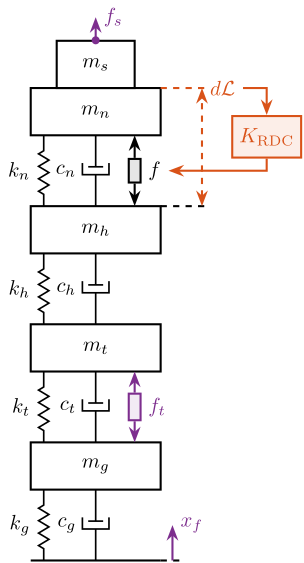

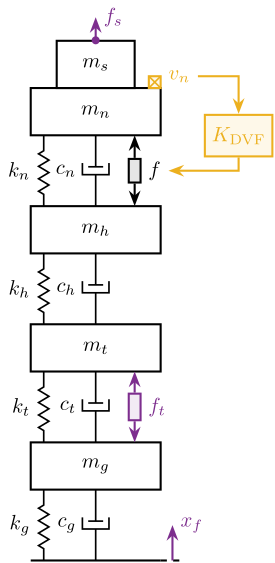

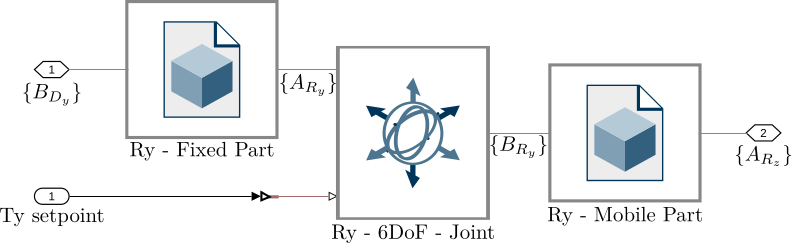

The uniaxial model of the micro-station is shown in Figure ref:fig:uniaxial_model_micro_station. It consists of a mass spring damper system with three degrees of freedom. A mass-spring-damper system represents the granite (with mass $m_g$, stiffness $k_g$ and damping $c_g$). Another mass-spring-damper system represents the different micro-station stages (the $T_y$ stage, the $R_y$ stage and the $R_z$ stage) with mass $m_t$, damping $c_t$ and stiffness $k_t$. Finally, a third mass-spring-damper system represents the positioning hexapod with mass $m_h$, damping $c_h$ and stiffness $k_h$.

The masses of the different stages are computed from the 3D model, while the stiffness values are taken from the manufacturers' datasheets for the various guiding elements used. The damping coefficients were tuned to match the damping identified from the measurements. The parameters obtained are summarized in Table ref:tab:uniaxial_ustation_parameters.

| Stage | Mass | Stiffness | Damping |

|---|---|---|---|

| Hexapod | $m_h = 15\,\text{kg}$ | $k_h = 61\,\text{N}/\upmu\text{m}$ | $c_h = 3\,\frac{\text{kN}}{\text{m/s}}$ |

| $T_y$, $R_y$, $R_z$ | $m_t = 1200\,\text{kg}$ | $k_t = 520\,\text{N}/\upmu\text{m}$ | $c_t = 80\,\frac{\text{kN}}{\text{m/s}}$ |

| Granite | $m_g = 2500\,\text{kg}$ | $k_g = 950\,\text{N}/\upmu\text{m}$ | $c_g = 250\,\frac{\text{kN}}{\text{m/s}}$ |

Two disturbances are considered which are shown in red: the floor motion $x_f$ and the stage vibrations represented by $f_t$. The hammer impacts $F_{h}, F_{g}$ are shown in blue, whereas the measured inertial motions $x_{h}, x_{g}$ are shown in black.

Comparison of Model and Measurements

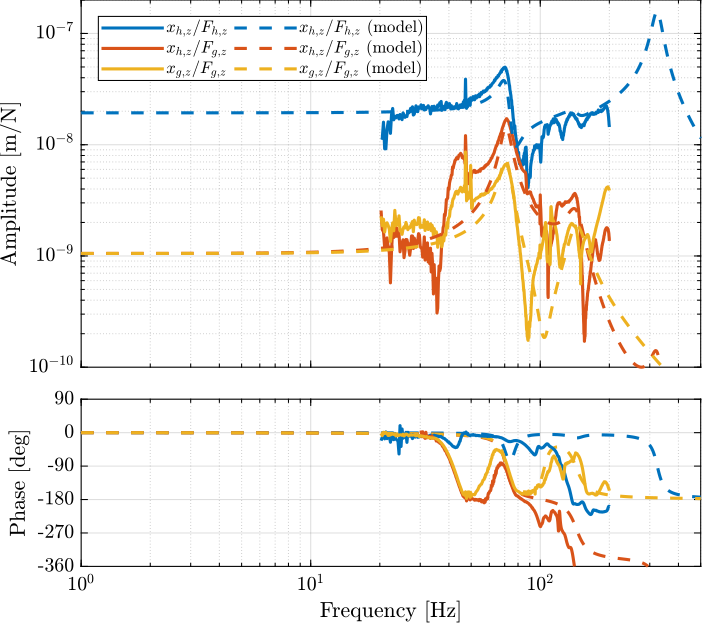

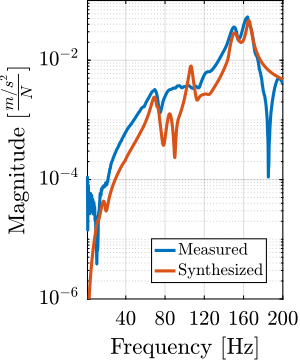

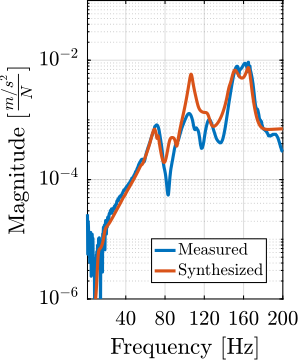

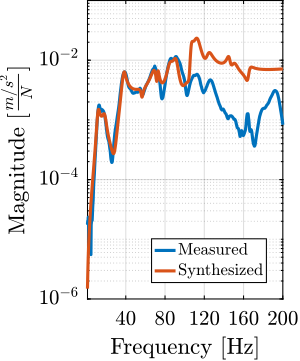

The transfer functions from the forces injected by the hammers to the measured inertial motion of the positioning hexapod and granite are extracted from the uniaxial model and compared to the measurements in Figure ref:fig:uniaxial_comp_frf_meas_model.

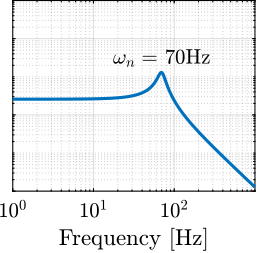

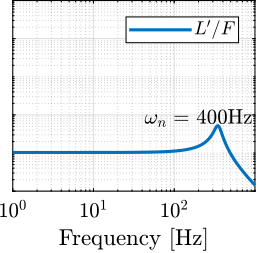

Because the uniaxial model has three degrees of freedom, only three modes with frequencies at $70\,\text{Hz}$, $140\,\text{Hz}$ and $320\,\text{Hz}$ are modelled. Many more modes can be observed in the measurements (see Figure ref:fig:uniaxial_comp_frf_meas_model). However, the goal is not to have a perfect match with the measurement (this would require a much more complex model), but to have a first approximation. More accurate models will be used later on.

Active Platform Model

<<sec:uniaxial_nano_station_model>>

Introduction

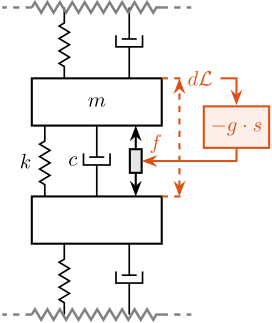

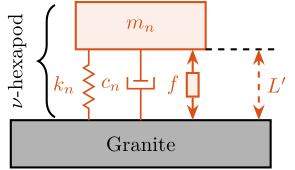

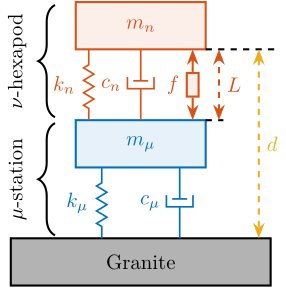

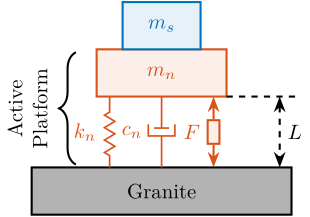

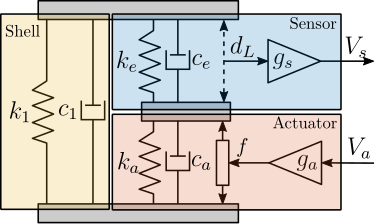

A model of the active platform and sample is now added on top of the uniaxial model of the micro-station (Figure ref:fig:uniaxial_model_micro_station_nass). Disturbances (shown in red) are $f_s$ the direct forces applied to the sample (for example cable forces), $f_t$ representing the vibrations induced when scanning the different stages and $x_f$ the floor motion. The control signal is the force applied by the active platform $f$ and the measurement is the relative motion between the sample and the granite $d$. The sample is here considered as a rigid body and rigidly fixed to the active platform. The effect of resonances between the sample's acrshort:poi and the active platform actuator will be considered in Section ref:sec:uniaxial_payload_dynamics.

Active Platform Parameters

The active platform is represented by a mass spring damper system (shown in blue in Figure ref:fig:uniaxial_model_micro_station_nass). Its mass $m_n$ is set to $15\,\text{kg}$ while its stiffness $k_n$ can vary depending on the chosen architecture/technology. The sample is represented by a mass $m_s$ that can vary from $1\,\text{kg}$ up to $50\,\text{kg}$.

As a first example, the active platform stiffness of is set at $k_n = 10\,\text{N}/\upmu\text{m}$ and the sample mass is chosen at $m_s = 10\,\text{kg}$.

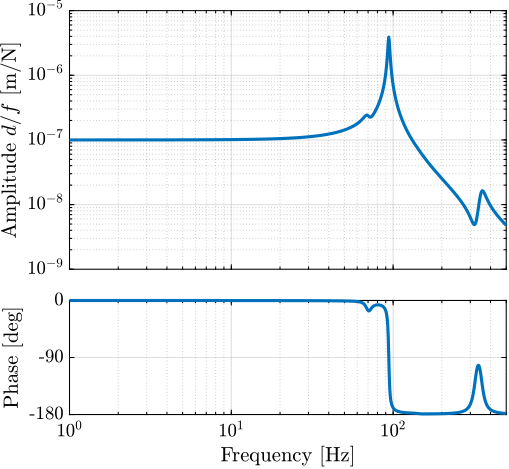

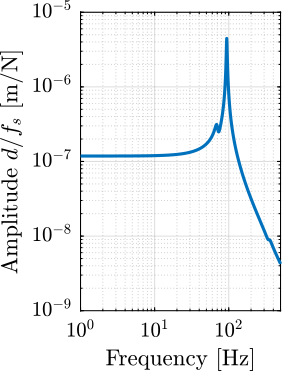

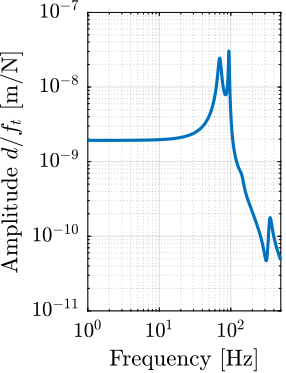

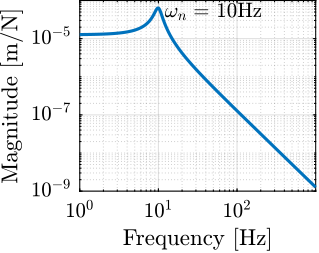

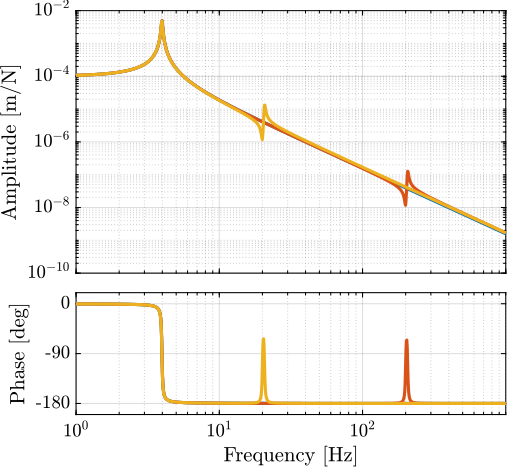

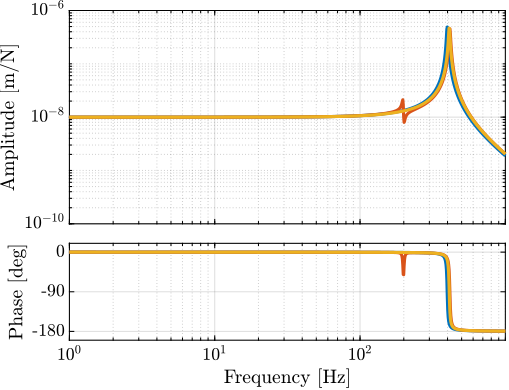

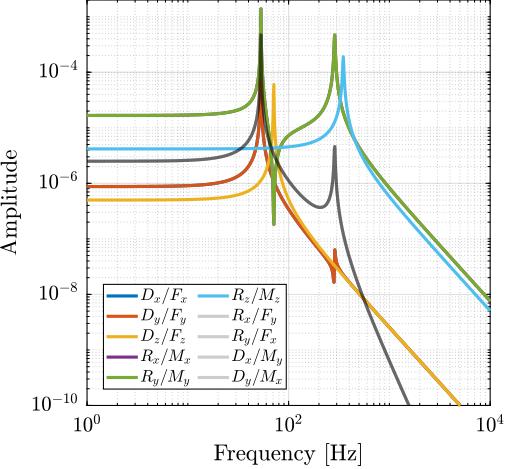

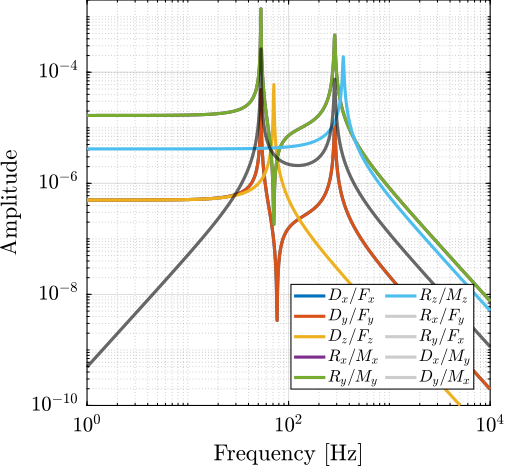

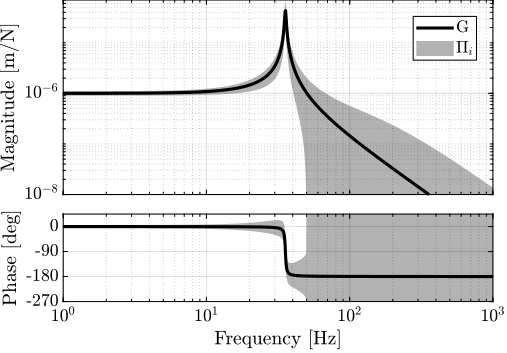

Obtained Dynamic Response

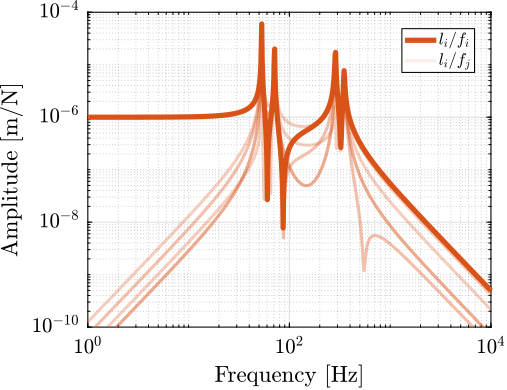

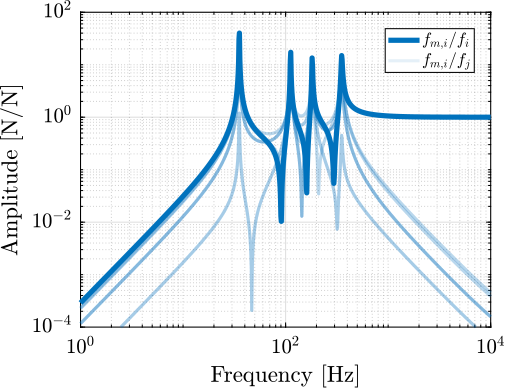

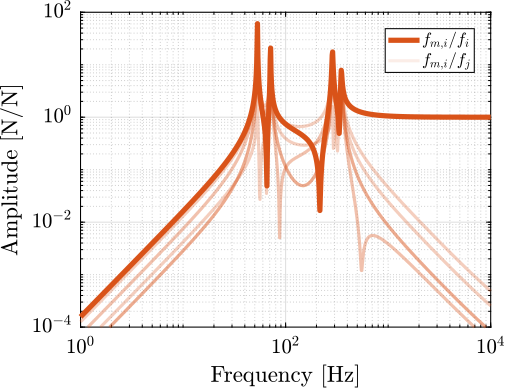

The sensitivity to disturbances (i.e., the transfer functions from $x_f,f_t,f_s$ to $d$) can be extracted from the uniaxial model of Figure ref:fig:uniaxial_model_micro_station_nass and are shown in Figure ref:fig:uniaxial_sensitivity_dist_first_params. The plant (i.e., the transfer function from actuator force $f$ to displacement $d$) is shown in Figure ref:fig:uniaxial_plant_first_params.

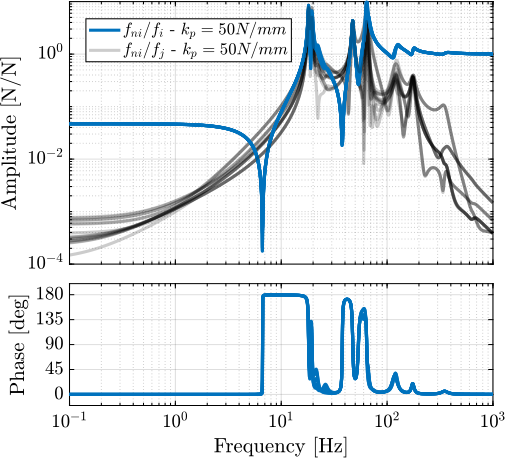

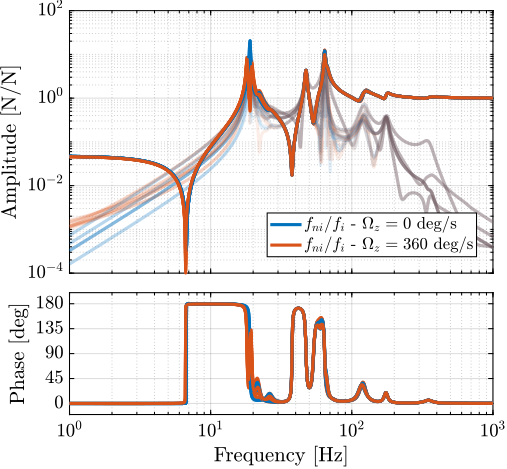

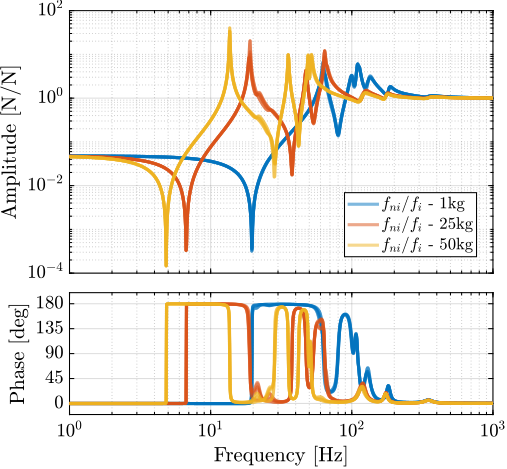

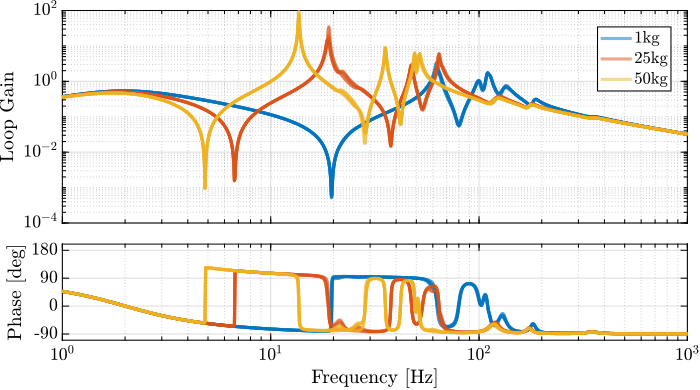

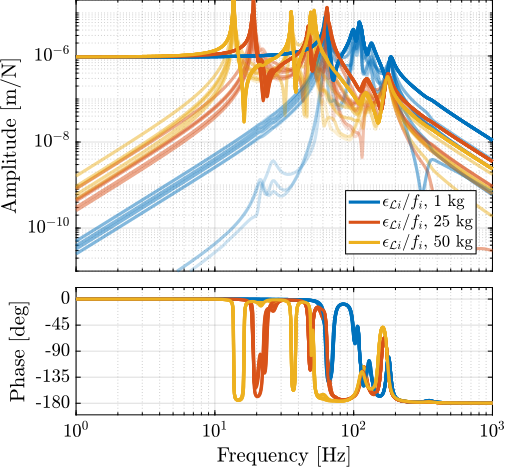

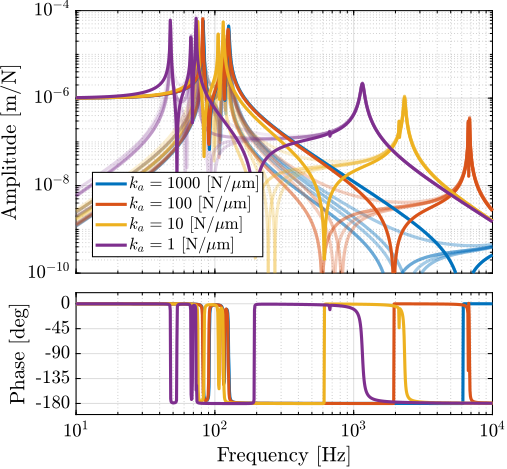

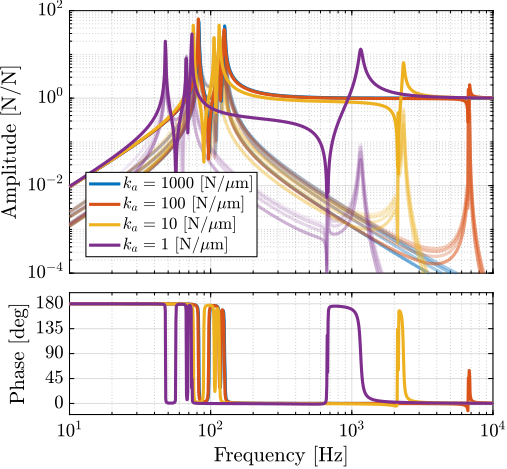

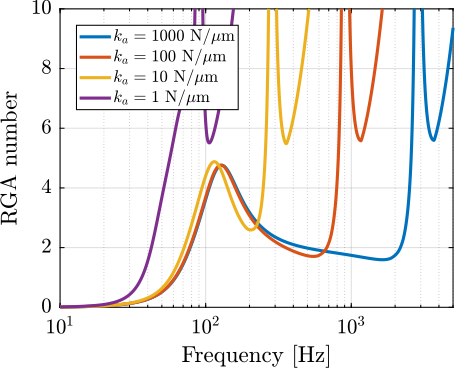

For further analysis, 9 "configurations" of the uniaxial NASS model of Figure ref:fig:uniaxial_model_micro_station_nass will be considered: three active platform stiffnesses ($k_n = 0.01\,\text{N}/\upmu\text{m}$, $k_n = 1\,\text{N}/\upmu\text{m}$ and $k_n = 100\,\text{N}/\upmu\text{m}$) combined with three sample's masses ($m_s = 1\,\text{kg}$, $m_s = 25\,\text{kg}$ and $m_s = 50\,\text{kg}$).

Identification of Disturbances

<<sec:uniaxial_disturbances>>

Introduction

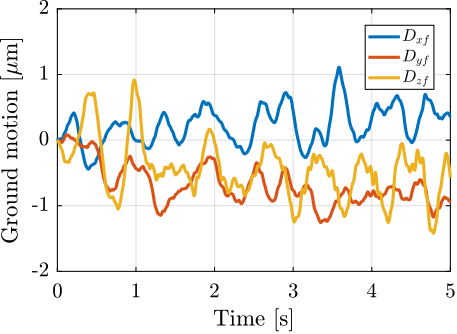

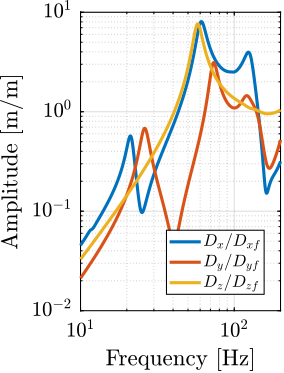

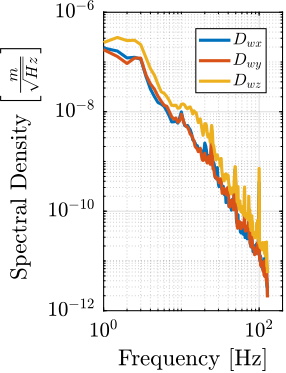

To quantify disturbances (red signals in Figure ref:fig:uniaxial_model_micro_station_nass), three geophones3 are used. One is located on the floor, another one on the granite, and the last one on the positioning hexapod's top platform (see Figure ref:fig:uniaxial_ustation_meas_disturbances). The geophone located on the floor was used to measure the floor motion $x_f$ while the other two geophones were used to measure vibrations introduced by scanning of the $T_y$ stage and $R_z$ stage (see Figure ref:fig:uniaxial_ustation_dynamical_id_setup).

Ground Motion

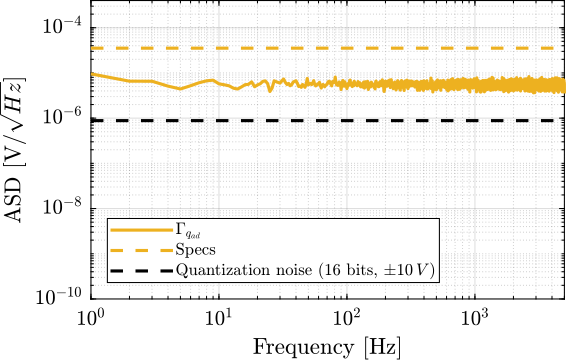

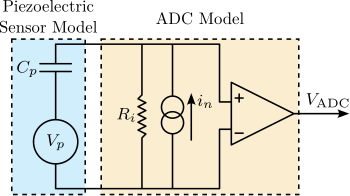

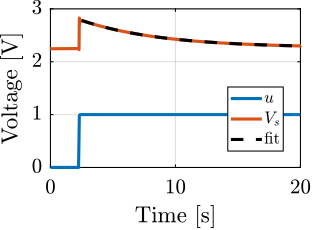

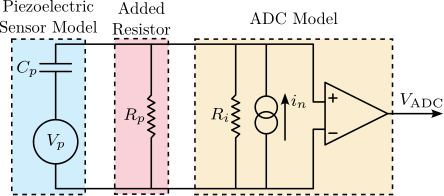

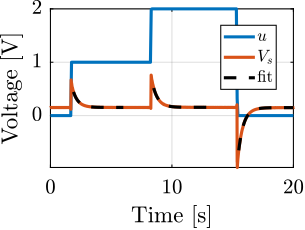

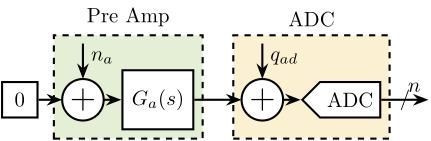

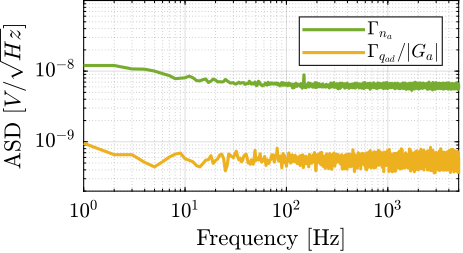

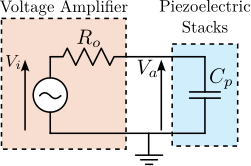

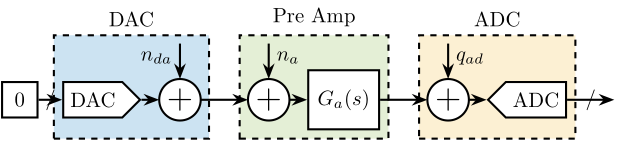

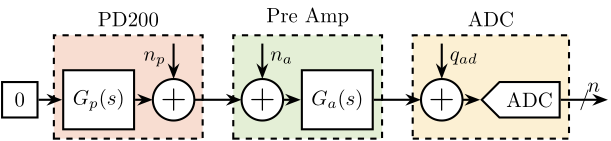

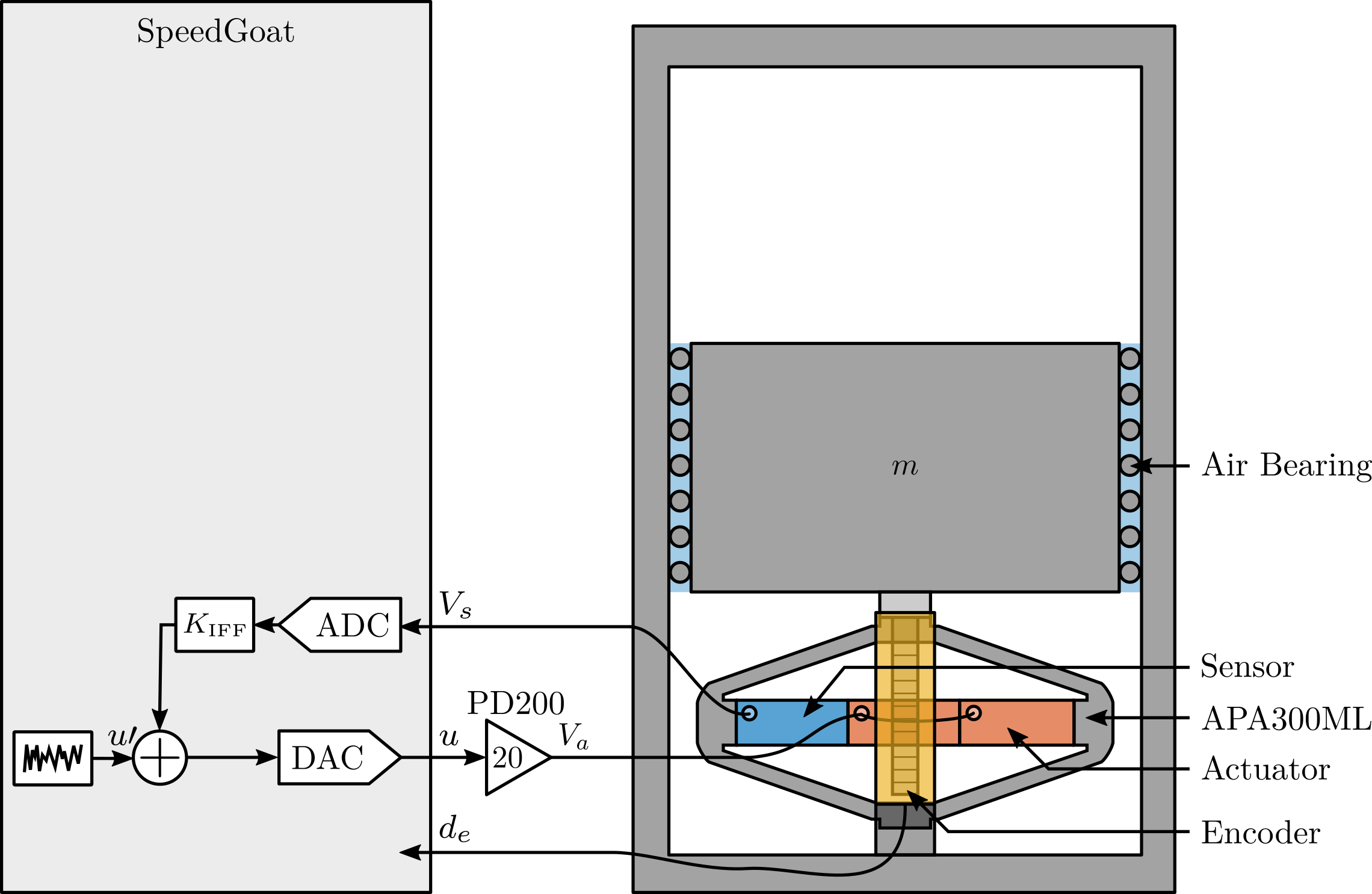

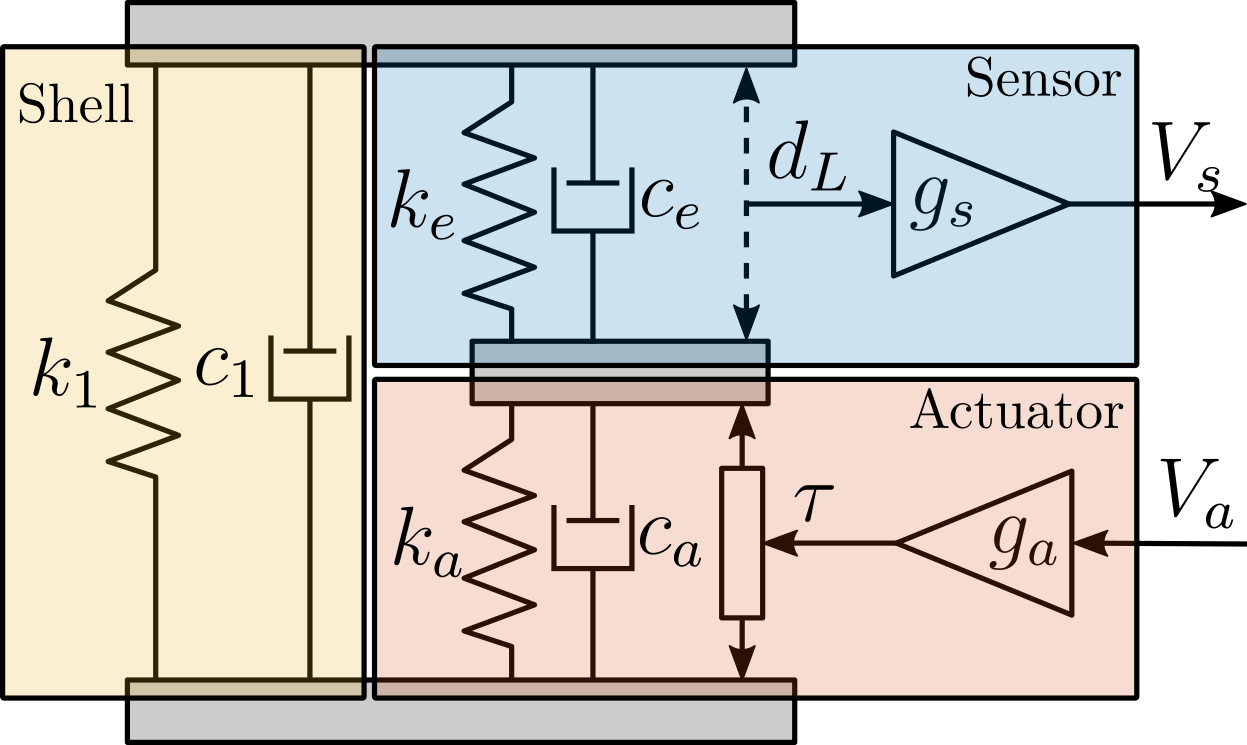

To acquire the geophone signals, the measurement setup shown in Figure ref:fig:uniaxial_geophone_meas_chain is used. The voltage generated by the geophone is amplified using a low noise voltage amplifier4 with a gain of $60\,\text{dB}$ before going to the acrfull:adc. This is done to improve the signal-to-noise ratio.

To reconstruct the displacement $x_f$ from the measured voltage $\hat{V}_{x_f}$, the transfer function of the measurement chain from $x_f$ to $\hat{V}_{x_f}$ needs to be estimated. First, the transfer function $G_{geo}$ from the floor motion $x_{f}$ to the generated geophone voltage $V_{x_f}$ is shown in eqref:eq:uniaxial_geophone_tf, with $T_g = 88\,\frac{V}{\text{m/s}}$ the sensitivity of the geophone, $f_0 = \frac{\omega_0}{2\pi} = 2\,\text{Hz}$ its resonance frequency and $\xi = 0.7$ its damping ratio. This model of the geophone was taken from cite:&collette12_review. The gain of the voltage amplifier is $V^{\prime}_{x_f}/V_{x_f} = g_0 = 1000$.

\begin{equation}\label{eq:uniaxial_geophone_tf} Ggeo(s) = \frac{Vx_f}{x_f}(s) = Tg ⋅ s ⋅ \frac{s^2}{s^2 + 2 ξ ω_0 s + ω_0^2} \quad ≤ft[ \text{V/m} \right]

\end{equation}

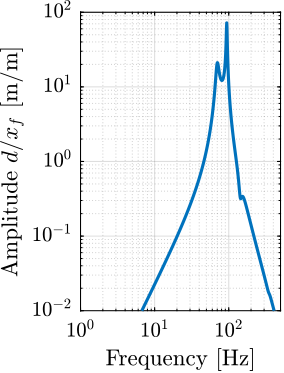

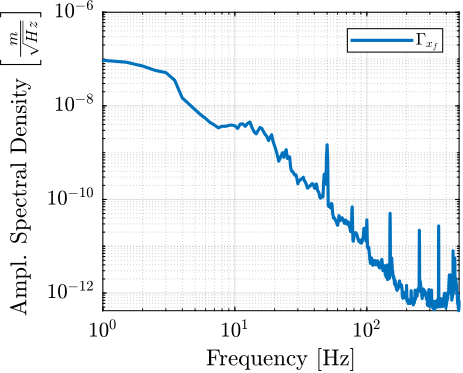

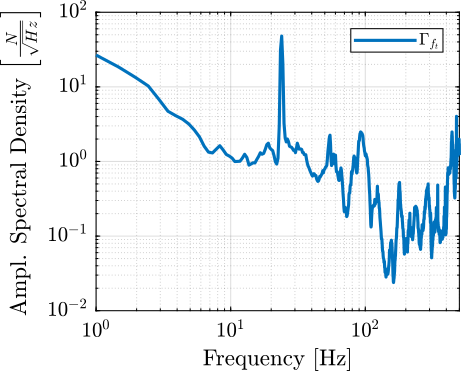

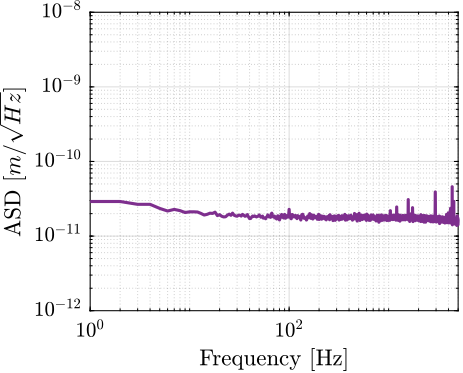

The acrfull:asd of the floor motion $\Gamma_{x_f}$ can be computed from the acrlong:asd of measured voltage $\Gamma_{\hat{V}_{x_f}}$ using eqref:eq:uniaxial_asd_floor_motion. The estimated acrshort:asd $\Gamma_{x_f}$ of the floor motion $x_f$ is shown in Figure ref:fig:uniaxial_asd_floor_motion_id31.

\begin{equation}\label{eq:uniaxial_asd_floor_motion} Γx_f(ω) = \frac{Γ_{\hat{V}x_f}(ω)}{|Ggeo(jω)| ⋅ g_0} \quad ≤ft[ m/\sqrt{\text{Hz}} \right]

\end{equation}

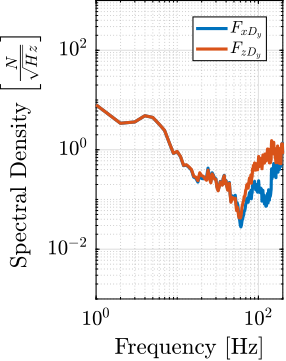

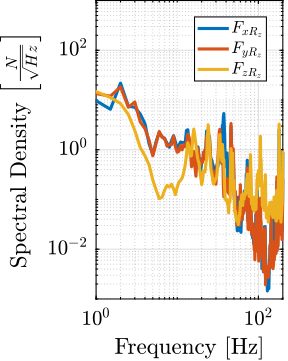

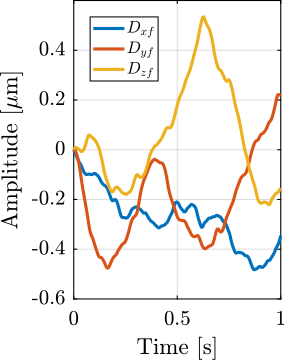

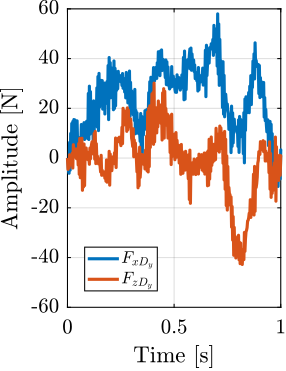

Stage Vibration

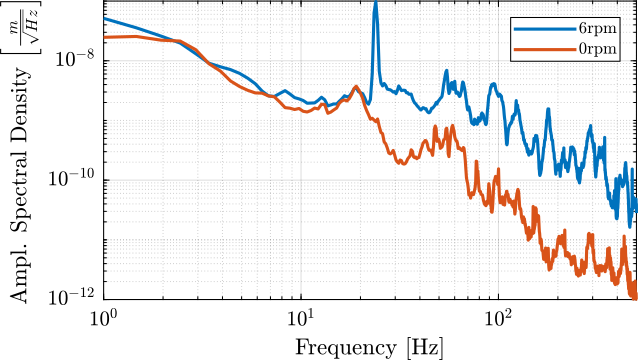

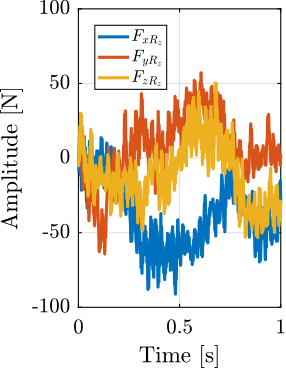

To estimate the vibrations induced by scanning the micro-station stages, two geophones are used, as shown in Figure ref:fig:uniaxial_ustation_dynamical_id_setup. The vertical relative velocity between the top platform of the positioning hexapod and the granite is estimated in two cases: without moving the micro-station stages, and then during a Spindle rotation at 6 acrfull:rpm. The vibrations induced by the $T_y$ stage are not considered here because they have less amplitude than the vibrations induced by the $R_z$ stage and because the $T_y$ stage can be scanned at lower velocities if the induced vibrations are found to be an issue.

The amplitude spectral density of the relative motion with and without the Spindle rotation are compared in Figure ref:fig:uniaxial_asd_vibration_spindle_rotation. It is shown that the spindle rotation increases the vibrations above $20\,\text{Hz}$. The sharp peak observed at $24\,\text{Hz}$ is believed to be induced by electromagnetic interference between the currents in the spindle motor phases and the geophone cable because this peak is not observed when rotating the spindle "by hand".

To compute the equivalent disturbance force $f_t$ (Figure ref:fig:uniaxial_model_micro_station) that induces such motion, the transfer function $G_{f_t}(s)$ from $f_t$ to the relative motion between the positioning hexapod's top platform and the granite $(x_{h} - x_{g})$ is extracted from the model. The amplitude spectral density $\Gamma_{f_{t}}$ of the disturbance force is them computed from eqref:eq:uniaxial_ft_asd and is shown in Figure ref:fig:uniaxial_asd_disturbance_force.

\begin{equation}\label{eq:uniaxial_ft_asd} Γ_{ft}(ω) = \frac{Γ_{Rz}(ω)}{|Gf_t(jω)|}

\end{equation}

Open-Loop Dynamic Error Budgeting

<<sec:uniaxial_noise_budgeting>>

Introduction

Now that a model of the acrshort:nass has been obtained (see section ref:sec:uniaxial_nano_station_model) and that the disturbances have been estimated (see section ref:sec:uniaxial_disturbances), it is possible to perform an open-loop dynamic error budgeting.

To perform such error budget, the disturbances need to be modelled by their spectral densities (done in section ref:sec:uniaxial_disturbances). Then, the transfer functions from disturbances to the performance metric (here the distance $d$) are computed. Finally, these two types of information are combined to estimate the corresponding spectral density of the performance metric. This is very useful to identify what is limiting the performance of the system, and to compare the achievable performance with different system parameters.

Sensitivity to Disturbances

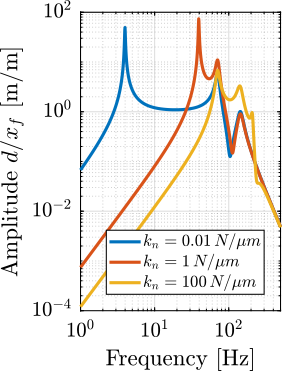

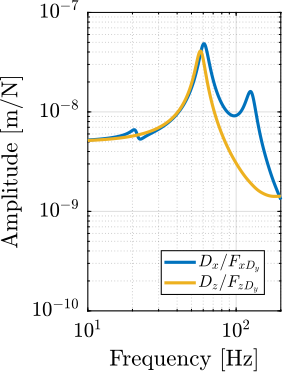

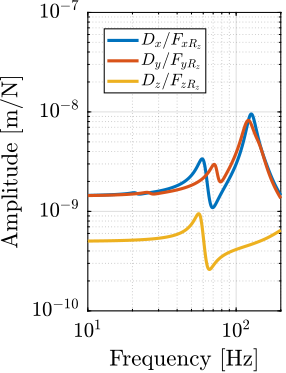

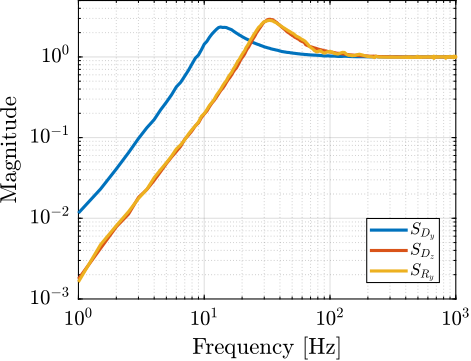

From the uniaxial model of the acrshort:nass (Figure ref:fig:uniaxial_model_micro_station_nass), the transfer function from the disturbances ($f_s$, $x_f$ and $f_t$) to the displacement $d$ are computed.

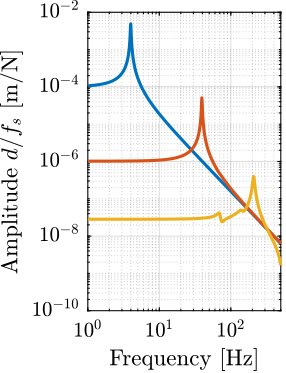

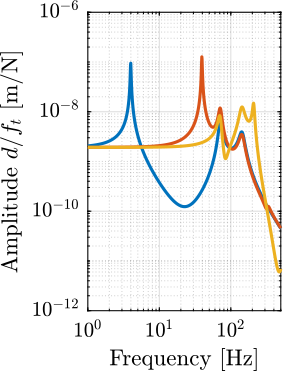

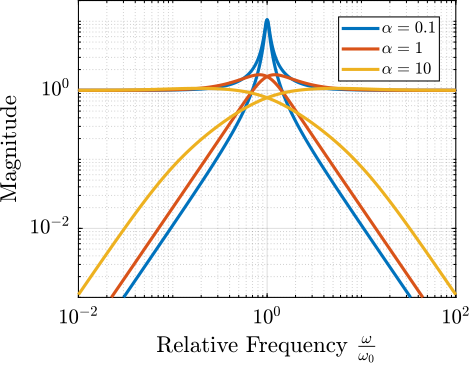

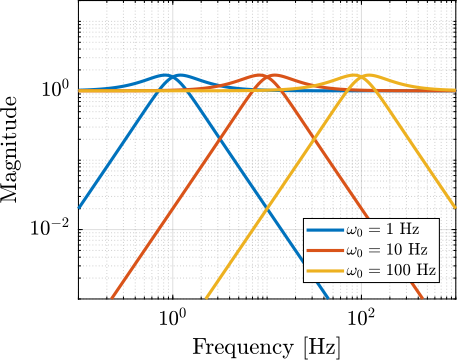

This is done for two extreme sample masses $m_s = 1\,\text{kg}$ and $m_s = 50\,\text{kg}$ and three active platform stiffnesses:

- $k_n = 0.01\,\text{N}/\upmu\text{m}$ that represents a voice coil actuator with soft flexible guiding

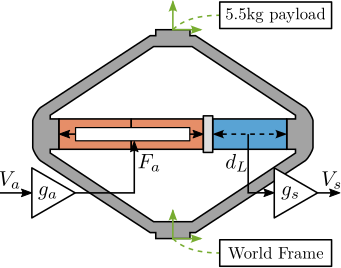

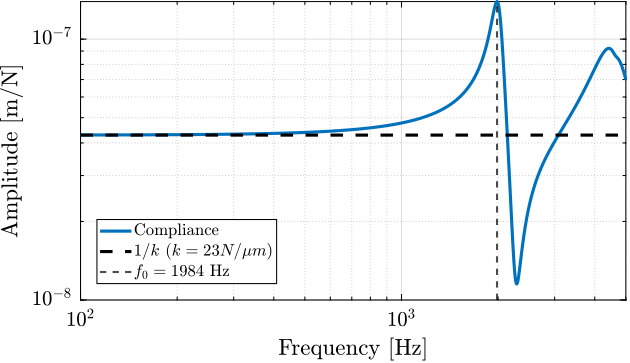

- $k_n = 1\,\text{N}/\upmu\text{m}$ that represents a voice coil actuator with a stiff flexible guiding or a mechanically amplified piezoelectric actuator

- $k_n = 100\,\text{N}/\upmu\text{m}$ that represents a stiff piezoelectric stack actuator

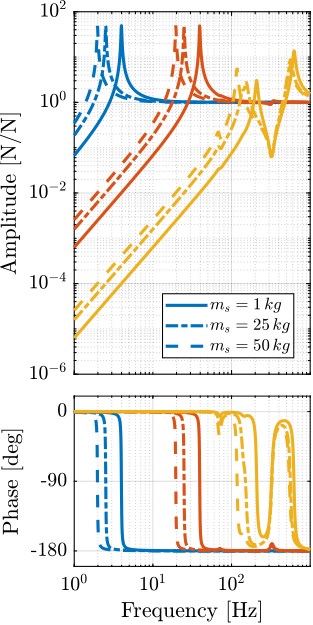

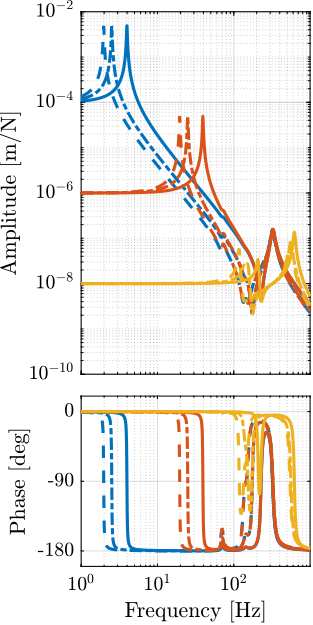

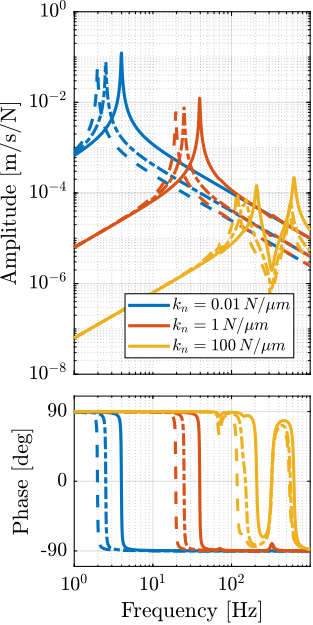

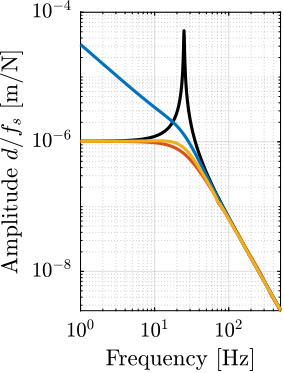

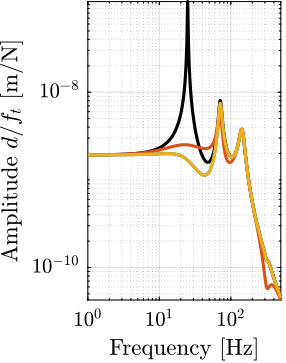

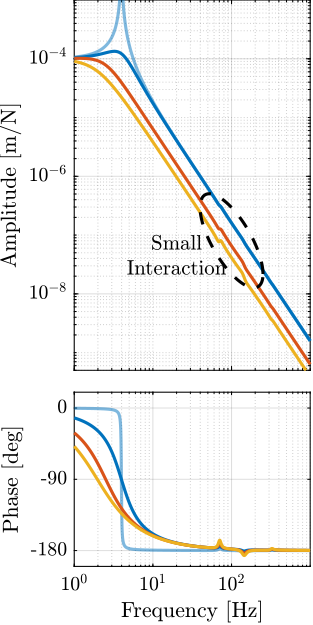

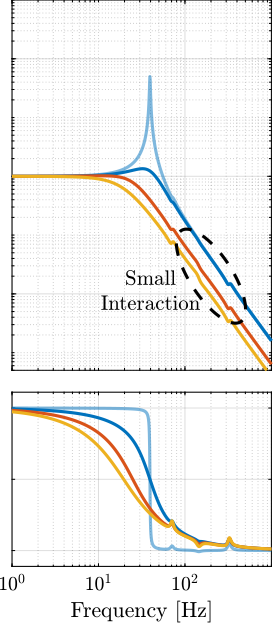

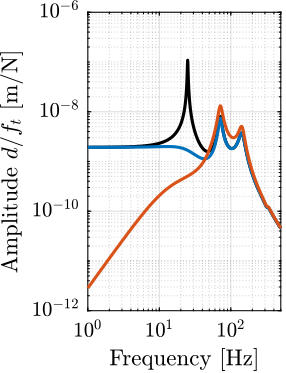

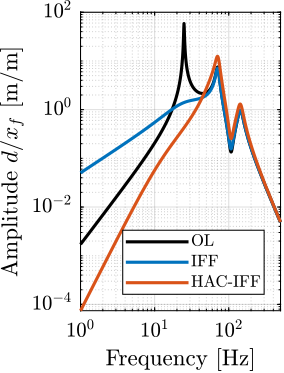

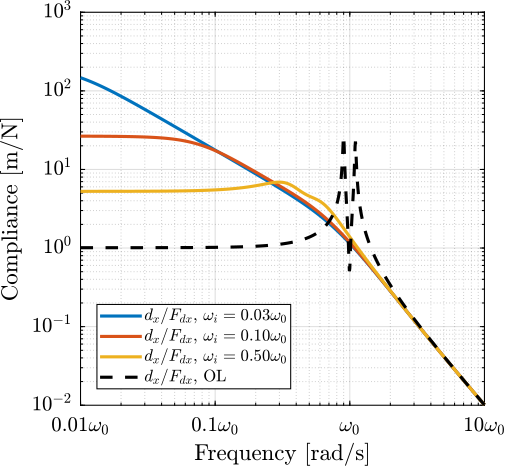

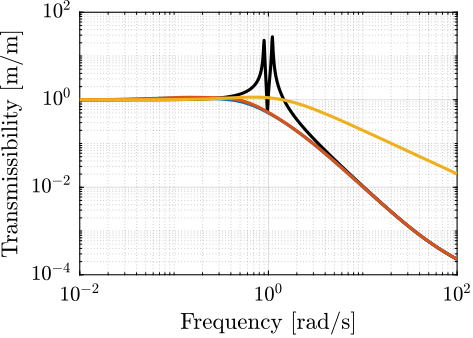

The obtained sensitivity to disturbances for the three active platform stiffnesses are shown in Figure ref:fig:uniaxial_sensitivity_disturbances_nano_hexapod_stiffnesses for the sample mass $m_s = 1\,\text{kg}$ (the same conclusions can be drawn with $m_s = 50\,\text{kg}$):

- The soft active platform is more sensitive to forces applied on the sample (cable forces for instance), which is expected due to its lower stiffness (Figure ref:fig:uniaxial_sensitivity_disturbances_nano_hexapod_stiffnesses_fs)

- Between the suspension mode5 of the active platform (here at $5\,\text{Hz}$) and the first mode of the micro-station (here at $70\,\text{Hz}$), the disturbances induced by the stage vibrations are filtered out (Figure ref:fig:uniaxial_sensitivity_disturbances_nano_hexapod_stiffnesses_ft)

- Above the suspension mode of the active platform, the sample's inertial motion is unaffected by the floor motion; therefore, the sensitivity to floor motion is close to $1$ (Figure ref:fig:uniaxial_sensitivity_disturbances_nano_hexapod_stiffnesses_xf)

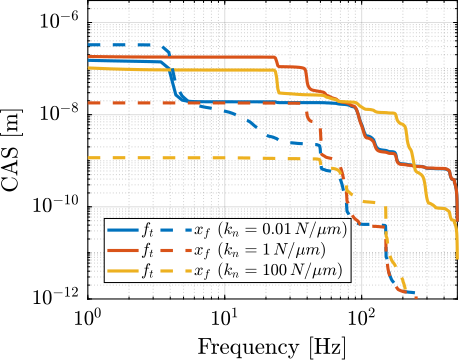

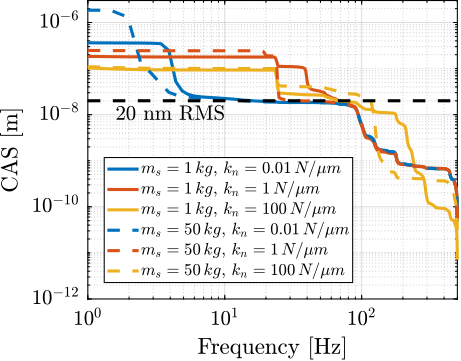

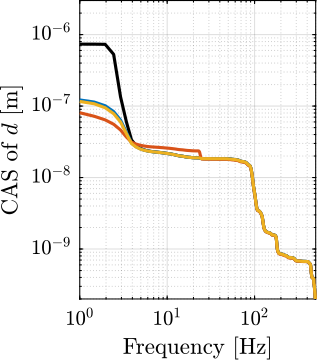

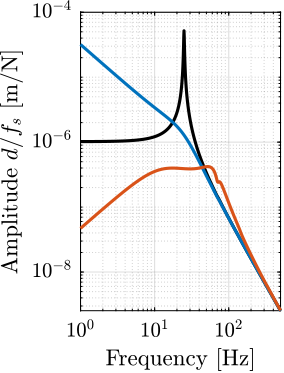

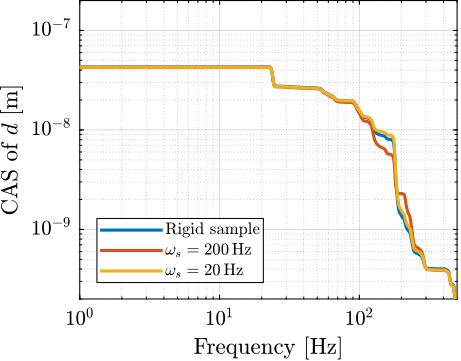

Open-Loop Dynamic Error Budgeting

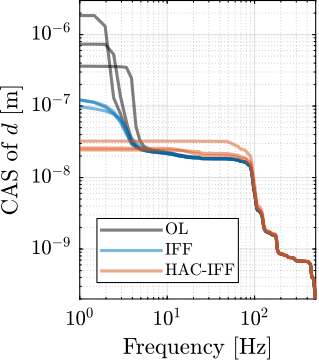

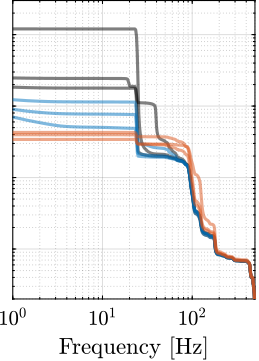

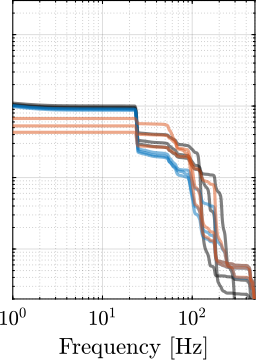

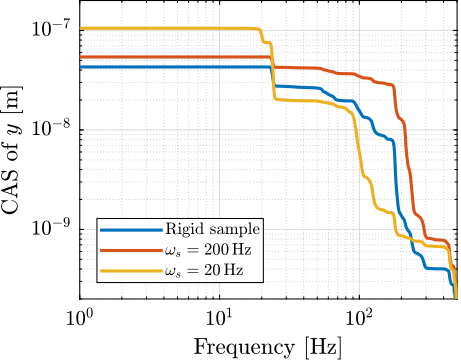

Now, the amplitude spectral densities of the disturbances are considered to estimate the residual motion $d$ for each active platform and sample configuration. The acrfull:cas of the relative motion $d$ due to both floor motion $x_f$ and stage vibrations $f_t$ are shown in Figure ref:fig:uniaxial_cas_d_disturbances_stiffnesses for the three active platform stiffnesses. It is shown that the effect of floor motion is much less than that of stage vibrations, except for the soft active platform below $5\,\text{Hz}$.

The total cumulative amplitude spectrum of $d$ for the three active platform stiffnesses and for the two samples masses are shown in Figure ref:fig:uniaxial_cas_d_disturbances_payload_masses. The conclusion is that the sample mass has little effect on the cumulative amplitude spectrum of the relative motion $d$.

Conclusion

The open-loop residual vibrations of $d$ can be estimated from the low-frequency value of the cumulative amplitude spectrum in Figure ref:fig:uniaxial_cas_d_disturbances_payload_masses. This residual vibration of $d$ is found to be in the order of $100\,\text{nm RMS}$ for the stiff active platform ($k_n = 100\,\text{N}/\upmu\text{m}$), $200\,\text{nm RMS}$ for the relatively stiff active platform ($k_n = 1\,\text{N}/\upmu\text{m}$) and $1\,\upmu\text{m}\,\text{RMS}$ for the soft active platform ($k_n = 0.01\,\text{N}/\upmu\text{m}$). From this analysis, it may be concluded that the stiffer the active platform the better.

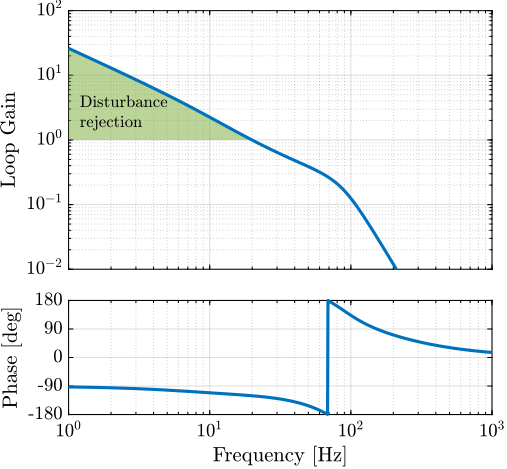

However, what is more important is the closed-loop residual vibration of $d$ (i.e., while the feedback controller is used). The goal is to obtain a closed-loop residual vibration $\epsilon_d \approx 20\,\text{nm RMS}$ (represented by an horizontal dashed black line in Figure ref:fig:uniaxial_cas_d_disturbances_payload_masses). The bandwidth of the feedback controller leading to a closed-loop residual vibration of $20\,\text{nm RMS}$ can be estimated as the frequency at which the cumulative amplitude spectrum crosses the black dashed line in Figure ref:fig:uniaxial_cas_d_disturbances_payload_masses.

This is why, in this document, cumulative amplitude spectra are computed by integrating from high to low frequency. Another important point is that cumulative &litude\ spectra are plotted instead of cumulative \power\ spectra, despite the warnings discussed in cite:&schmidt20_desig_high_perfor_mechat_third_revis_edition Chapt. 8.1.5. This choice comes at the cost of losing the straightforward interpretation of the relative importance of different frequencies, but it makes the plots easier to read and simplifies the estimation of the bandwidth required to achieve a desired residual RMS value.

A closed loop bandwidth of $\approx 10\,\text{Hz}$ is found for the soft active platform ($k_n = 0.01\,\text{N}/\upmu\text{m}$), $\approx 50\,\text{Hz}$ for the relatively stiff active platform ($k_n = 1\,\text{N}/\upmu\text{m}$), and $\approx 100\,\text{Hz}$ for the stiff active platform ($k_n = 100\,\text{N}/\upmu\text{m}$). Therefore, while the open-loop vibration is the lowest for the stiff active platform, it requires the largest feedback bandwidth to meet the specifications.

The advantage of the soft active platform can be explained by its natural isolation from the micro-station vibration above its suspension mode, as shown in Figure ref:fig:uniaxial_sensitivity_disturbances_nano_hexapod_stiffnesses_ft.

Active Damping

<<sec:uniaxial_active_damping>>

Introduction

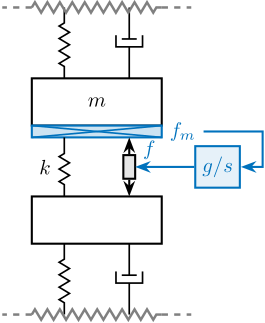

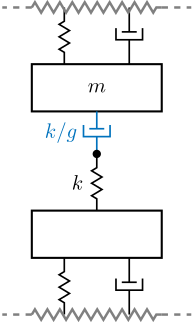

In this section, three active damping techniques are applied to the active platform (see Figure ref:fig:uniaxial_active_damping_strategies): Integral Force Feedback (IFF) cite:&preumont91_activ, Relative Damping Control (RDC) cite:&preumont18_vibrat_contr_activ_struc_fourt_edition Chapt. 7.2 and Direct Velocity Feedback (DVF) cite:&karnopp74_vibrat_contr_using_semi_activ_force_gener;&serrand00_multic_feedb_contr_isolat_base_excit_vibrat;&preumont02_force_feedb_versus_accel_feedb.

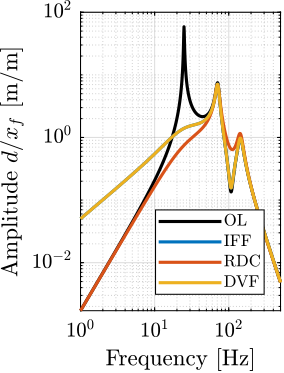

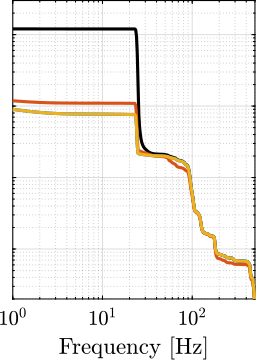

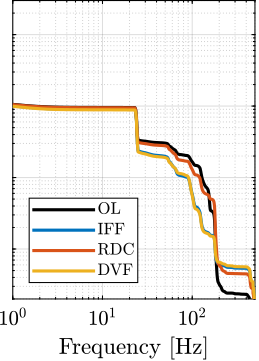

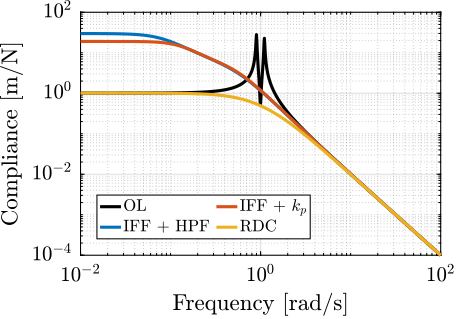

These damping strategies are first described and are then compared in terms of achievable damping of the active platform mode, reduction of the effect of disturbances (i.e., $x_f$, $f_t$ and $f_s$) on the displacement $d$.

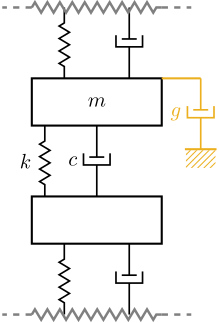

Integral Force Feedback (IFF)

The Integral Force Feedback strategy consists of using a force sensor in series with the actuator (see Figure ref:fig:uniaxial_active_damping_iff_schematic) and applying an "integral" feedback controller eqref:eq:uniaxial_iff_controller.

\begin{equation}\label{eq:uniaxial_iff_controller} \boxed{K_{\text{IFF}}(s) = \frac{g}{s}}

\end{equation}

The mechanical equivalent of this acrshort:iff strategy is a dashpot in series with the actuator stiffness with a damping coefficient equal to the stiffness of the actuator divided by the controller gain $k/g$ (see Figure ref:fig:uniaxial_active_damping_iff_equiv).

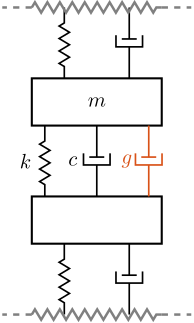

Relative Damping Control (RDC)

For the Relative Damping Control strategy, a relative motion sensor that measures the motion of the actuator is used (see Figure ref:fig:uniaxial_active_damping_rdc_schematic) and a "derivative" feedback controller is used eqref:eq:uniaxial_rdc_controller.

\begin{equation}\label{eq:uniaxial_rdc_controller} \boxed{K_{\text{RDC}}(s) = - g ⋅ s}

\end{equation}

The mechanical equivalent of acrshort:rdc is a dashpot in parallel with the actuator with a damping coefficient equal to the controller gain $g$ (see Figure ref:fig:uniaxial_active_damping_rdc_equiv).

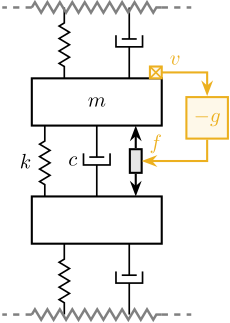

Direct Velocity Feedback (DVF)

Finally, the direct velocity feedback strategy consists of using an inertial sensor (usually a geophone) that measures the "absolute" velocity of the body fixed on top of the actuator (see Figure ref:fig:uniaxial_active_damping_dvf_schematic). This velocity is fed back to the actuator with a "proportional" controller eqref:eq:uniaxial_dvf_controller.

\begin{equation}\label{eq:uniaxial_dvf_controller} \boxed{K_{\text{DVF}}(s) = - g}

\end{equation}

This is equivalent to a dashpot (with a damping coefficient equal to the controller gain $g$) between the body (on which the inertial sensor is fixed) and an inertial reference frame (see Figure ref:fig:uniaxial_active_damping_dvf_equiv). This is usually referred to as "sky hook damper".

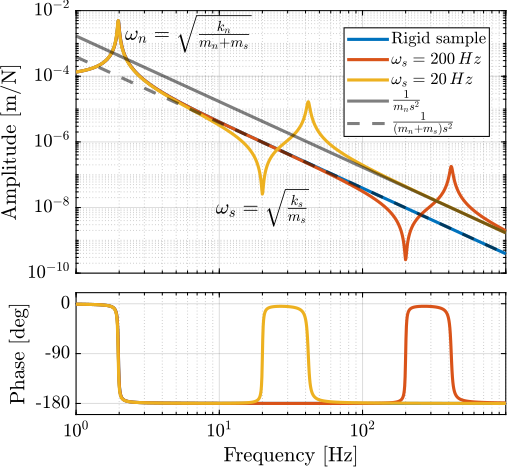

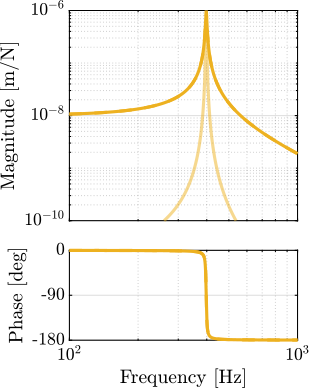

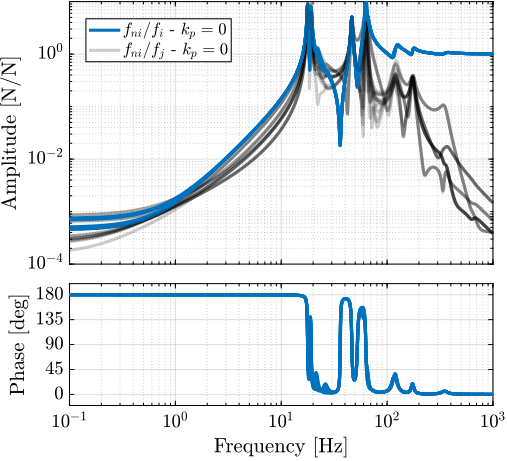

Plant Dynamics for Active Damping

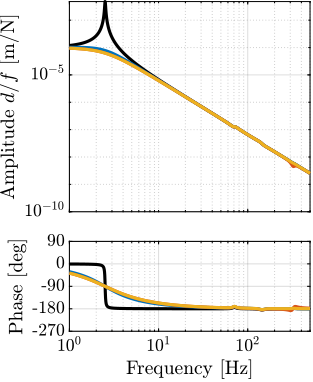

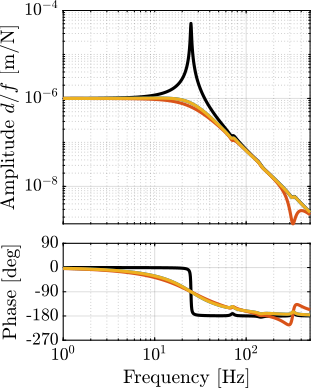

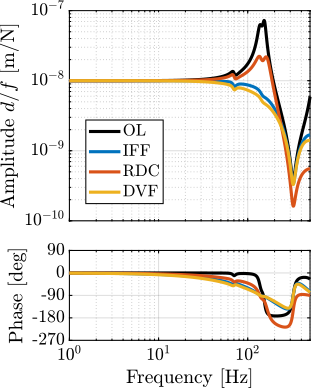

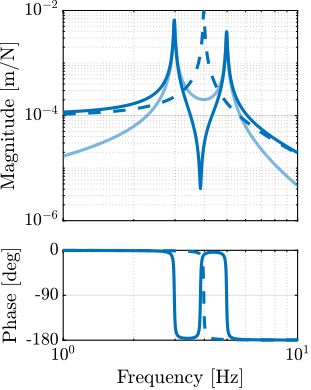

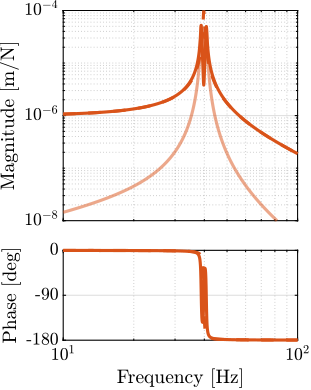

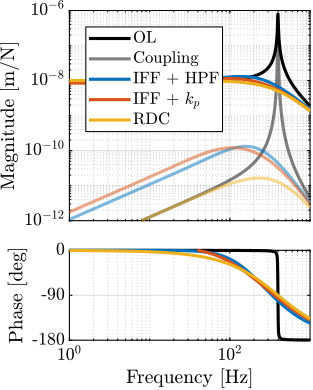

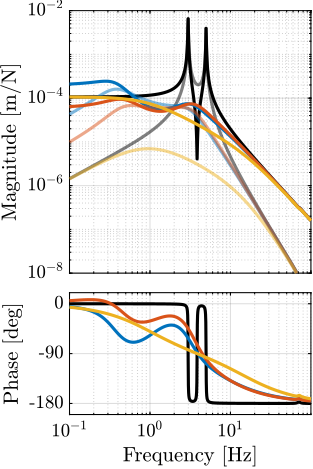

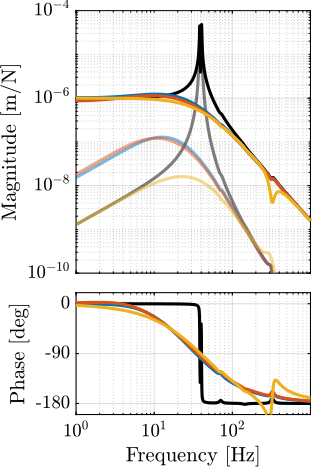

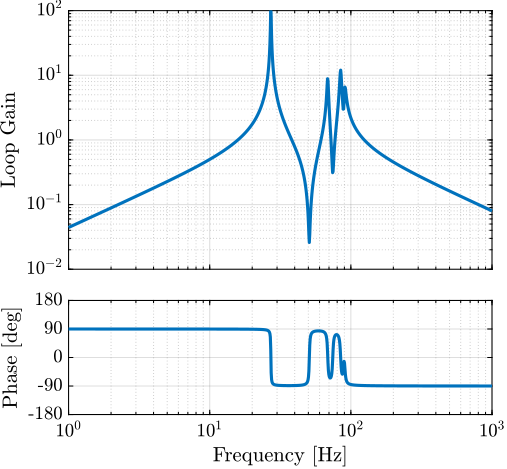

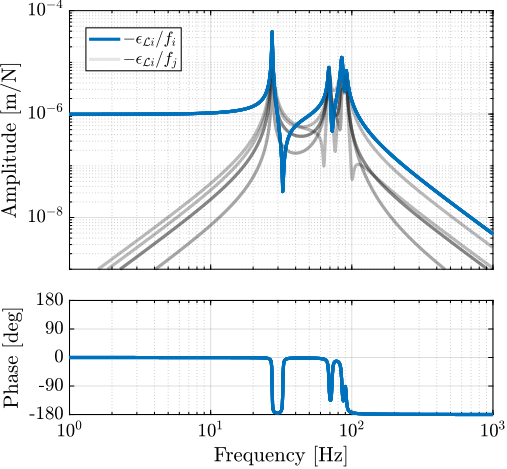

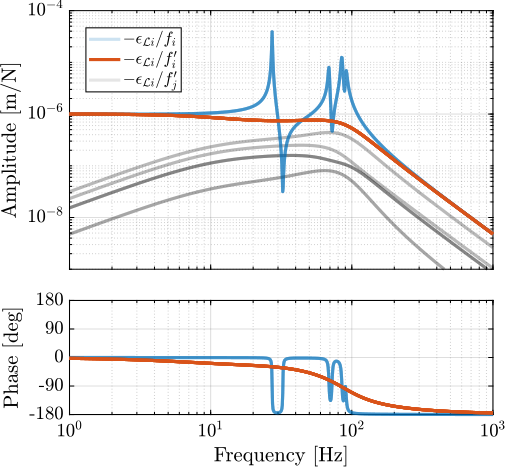

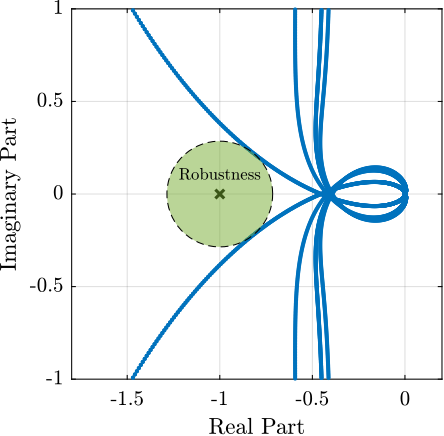

The plant dynamics for all three active damping techniques are shown in Figure ref:fig:uniaxial_plant_active_damping_techniques. All have alternating poles and zeros meaning that the phase does not vary by more than $180\,\text{deg}$ which makes the design of a robust damping controller very easy.

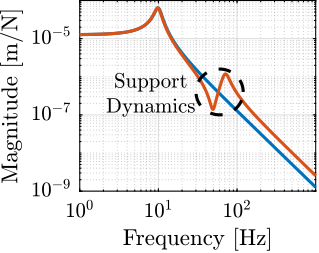

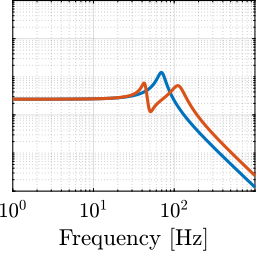

This alternating poles and zeros property is guaranteed for the IFF and acrshort:rdc cases because the sensors are collocated with the actuator cite:&preumont18_vibrat_contr_activ_struc_fourt_edition Chapt. 7. For the acrshort:dvf controller, this property is not guaranteed, and may be lost if some flexibility between the active platform and the sample is considered cite:&preumont18_vibrat_contr_activ_struc_fourt_edition Chapt. 8.4.

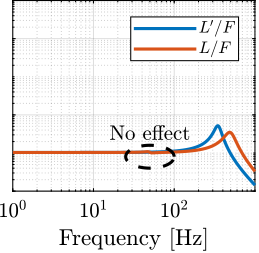

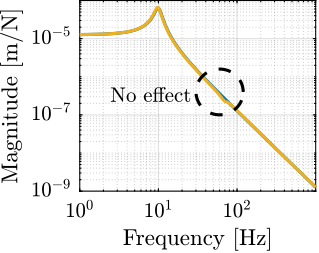

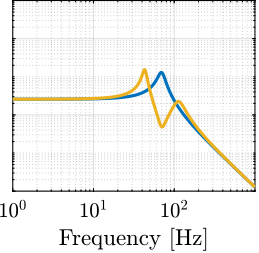

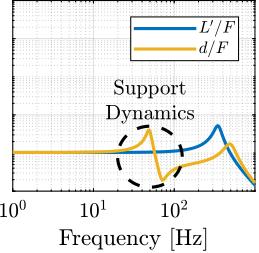

When the active platform's suspension modes are at frequencies lower than the resonances of the micro-station (blue and red curves in Figure ref:fig:uniaxial_plant_active_damping_techniques), the resonances of the micro-stations have little impact on the IFF and acrshort:dvf transfer functions. For the stiff active platform (yellow curves), the micro-station dynamics can be seen on the transfer functions in Figure ref:fig:uniaxial_plant_active_damping_techniques. Therefore, it is expected that the micro-station dynamics might impact the achievable damping if a stiff active platform is used.

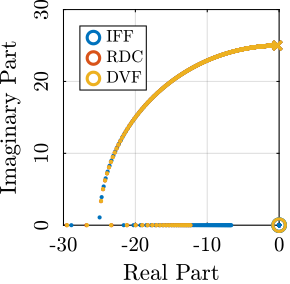

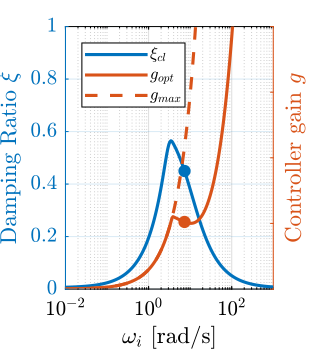

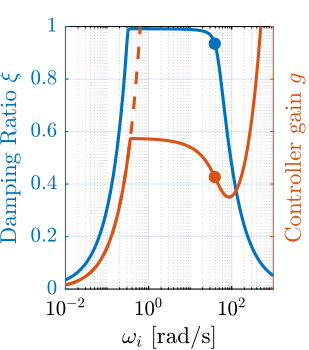

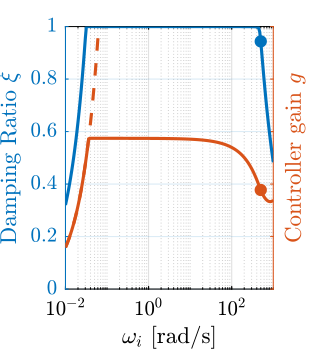

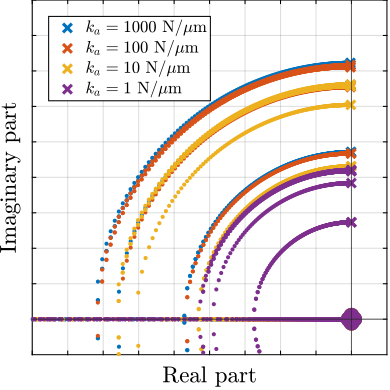

Achievable Damping and Damped Plants

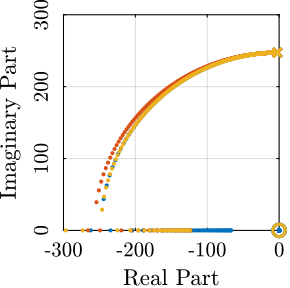

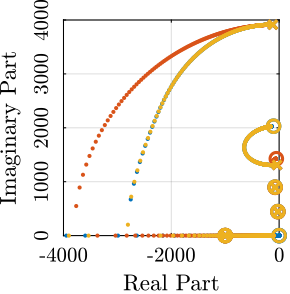

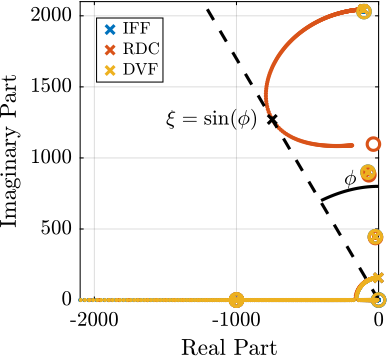

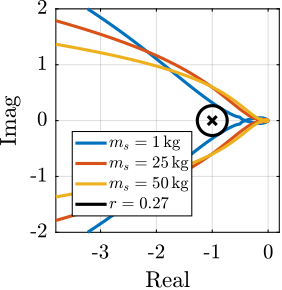

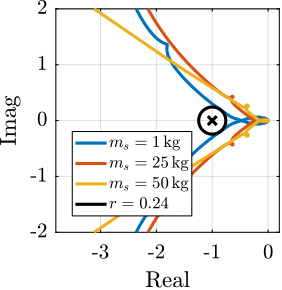

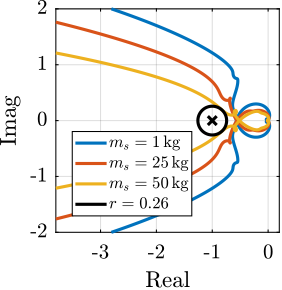

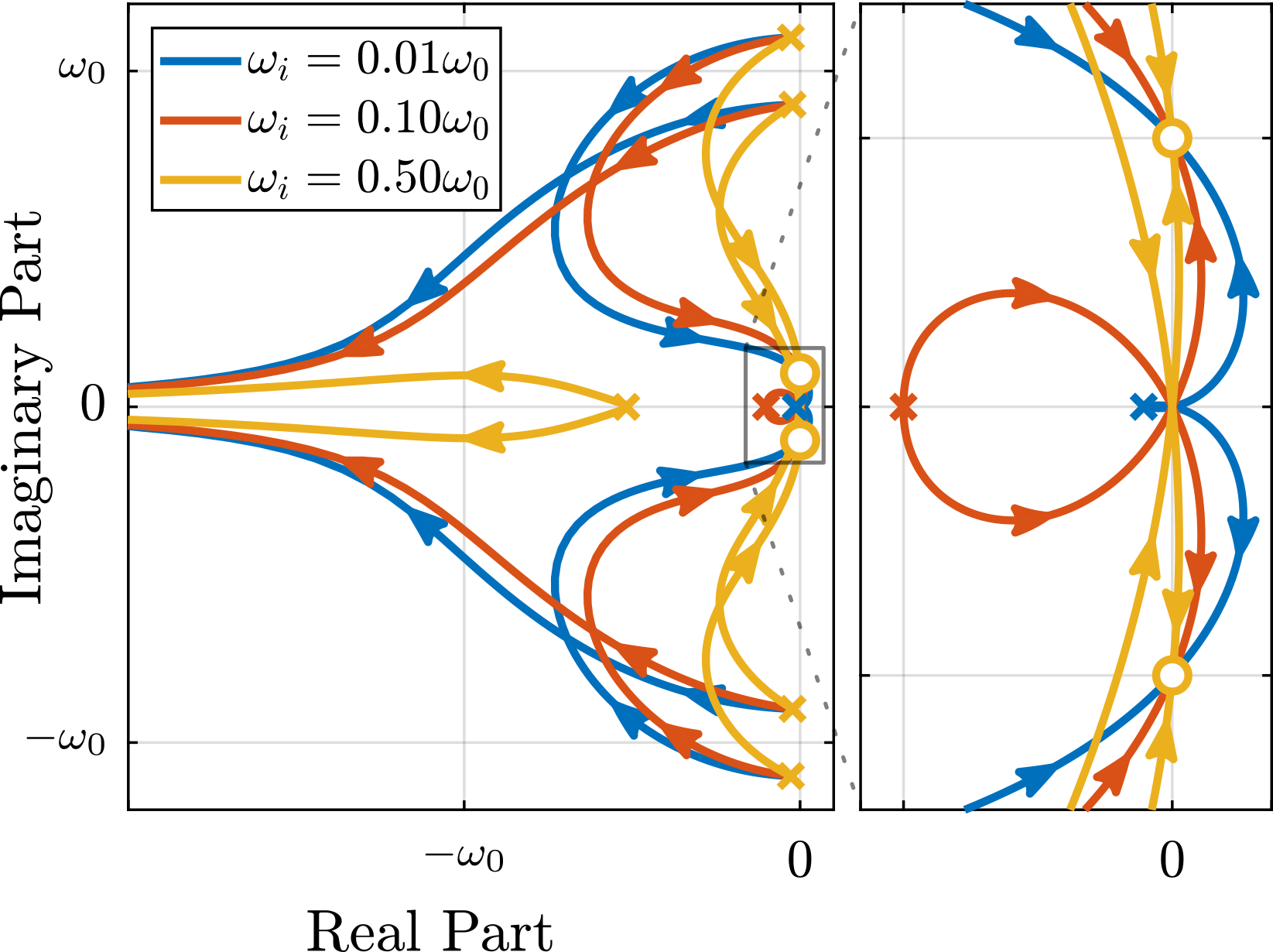

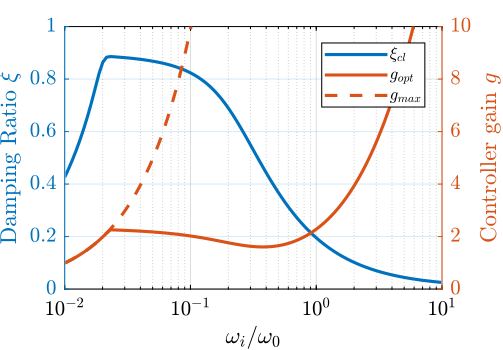

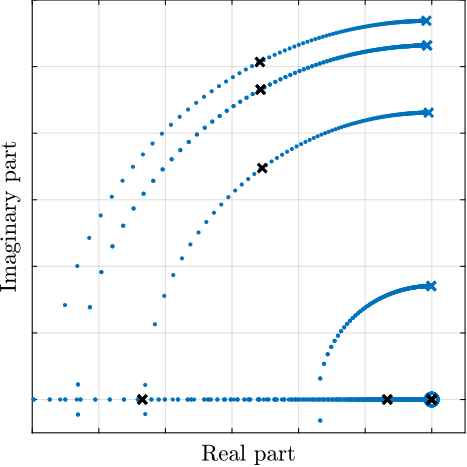

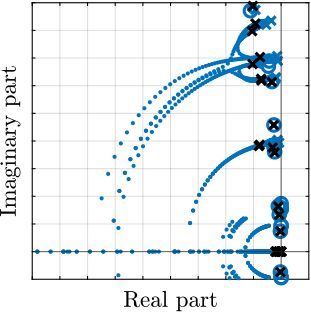

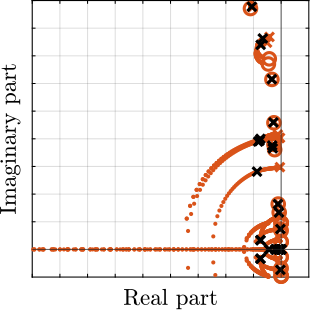

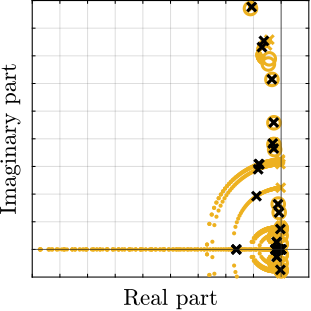

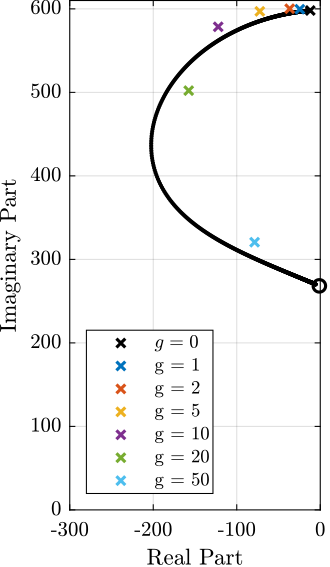

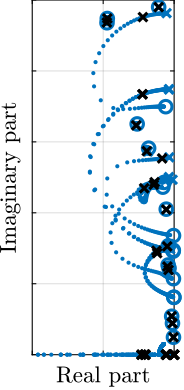

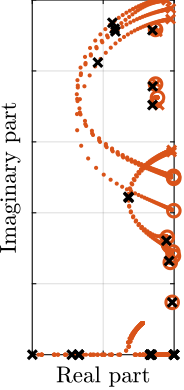

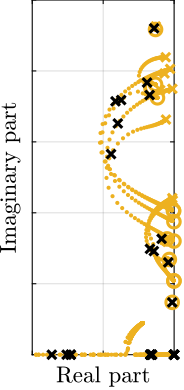

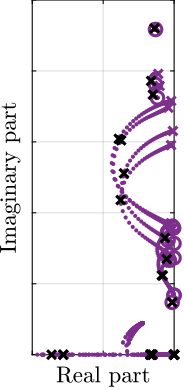

To compare the added damping using the three considered active damping strategies, the root locus plot is used. Indeed, the damping ratio $\xi$ of a pole in the complex plane can be estimated from the angle $\phi$ it makes with the imaginary axis eqref:eq:uniaxial_damping_ratio_angle. Increasing the angle with the imaginary axis therefore means that more damping is added to the considered resonance. This is illustrated in Figure ref:fig:uniaxial_root_locus_damping_techniques_micro_station_mode by the dashed black line indicating the maximum achievable damping.

\begin{equation}\label{eq:uniaxial_damping_ratio_angle} ξ = sin(ɸ)

\end{equation}

The root locus for the three active platform stiffnesses and the three active damping techniques are shown in Figure ref:fig:uniaxial_root_locus_damping_techniques. All three active damping approaches can lead to critical damping of the active platform suspension mode (angle $\phi$ can be increased up to 90 degrees). There is even some damping authority on micro-station modes in the following cases:

- IFF with a stiff active platform (Figure ref:fig:uniaxial_root_locus_damping_techniques_stiff)

- This can be understood from the mechanical equivalent of IFF shown in Figure ref:fig:uniaxial_active_damping_iff_equiv considering an high stiffness $k$. The micro-station top platform is connected to an inertial mass (the active platform) through a damper, which dampens the micro-station suspension mode.

- DVF with a stiff active platform (Figure ref:fig:uniaxial_root_locus_damping_techniques_stiff)

- In that case, the "sky hook damper" (see mechanical equivalent of acrshort:dvf in Figure ref:fig:uniaxial_active_damping_dvf_equiv) is connected to the micro-station top platform through the stiff active platform.

- RDC with a soft active platform (Figure ref:fig:uniaxial_root_locus_damping_techniques_micro_station_mode)

- At the frequency of the micro-station mode, the active platform top mass behaves as an inertial reference because the suspension mode of the soft active platform is at much lower frequency. The micro-station and the active platform masses are connected through a large damper induced by acrshort:rdc (see mechanical equivalent in Figure ref:fig:uniaxial_active_damping_rdc_equiv) which allows some damping of the micro-station.

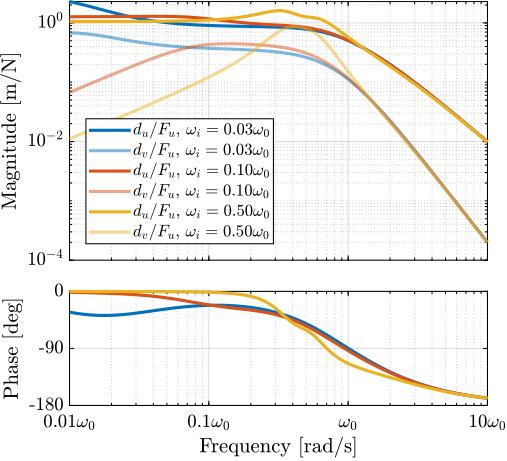

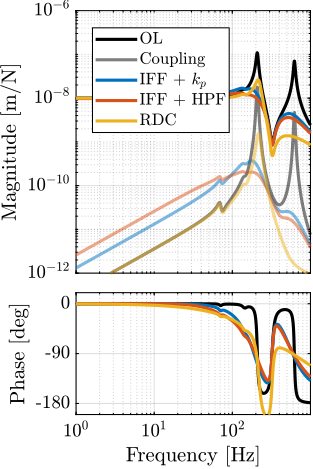

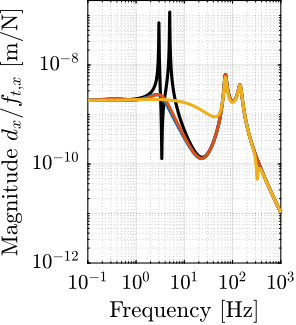

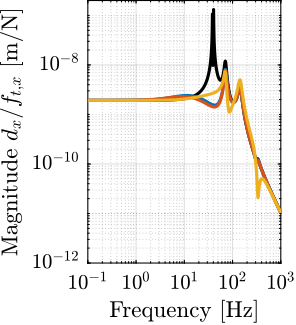

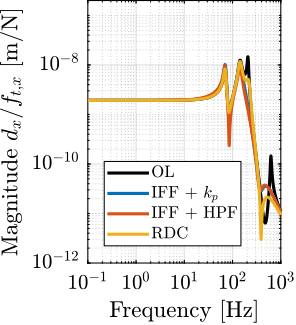

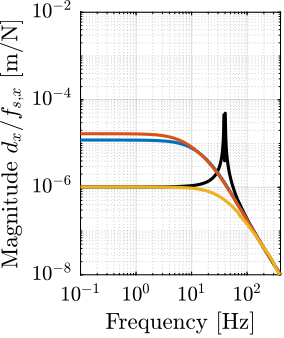

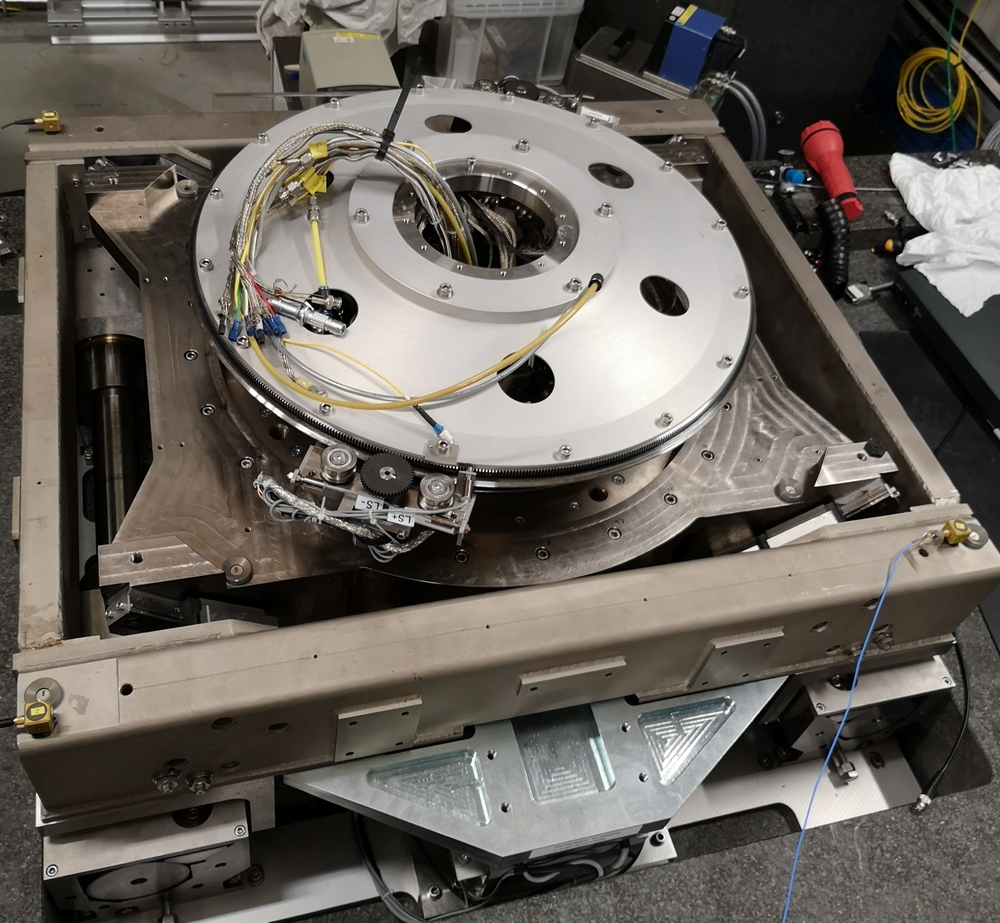

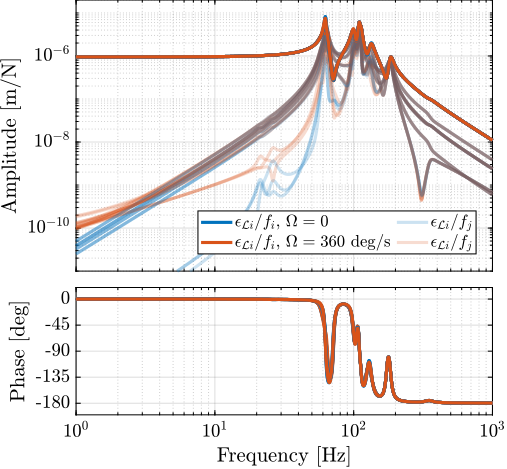

The transfer functions from the plant input $f$ to the relative displacement $d$ while active damping is implemented are shown in Figure ref:fig:uniaxial_damped_plant_three_active_damping_techniques. All three active damping techniques yielded similar damped plants.

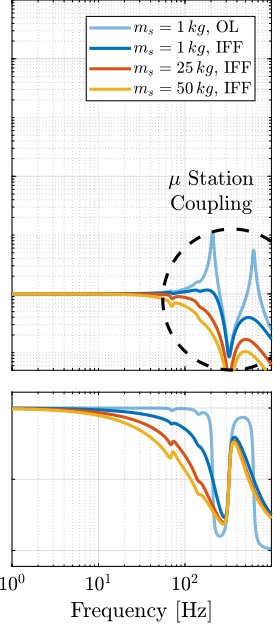

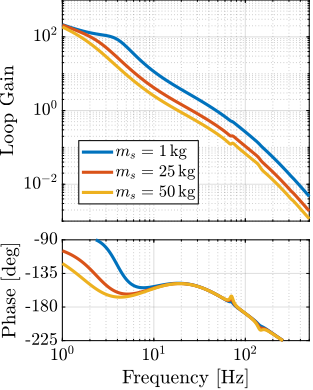

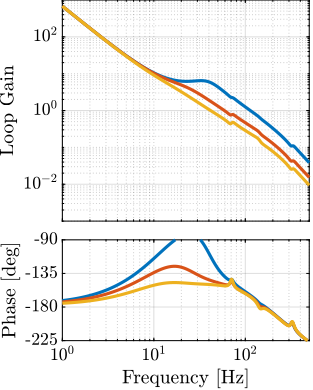

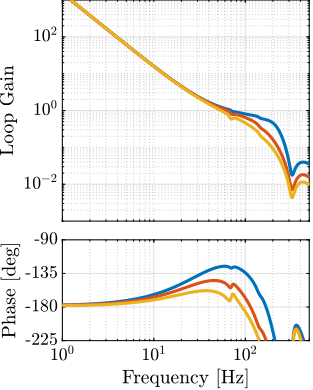

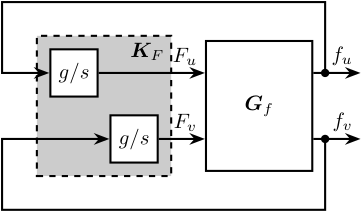

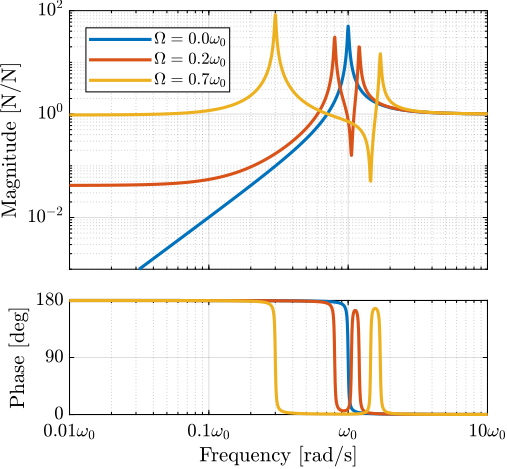

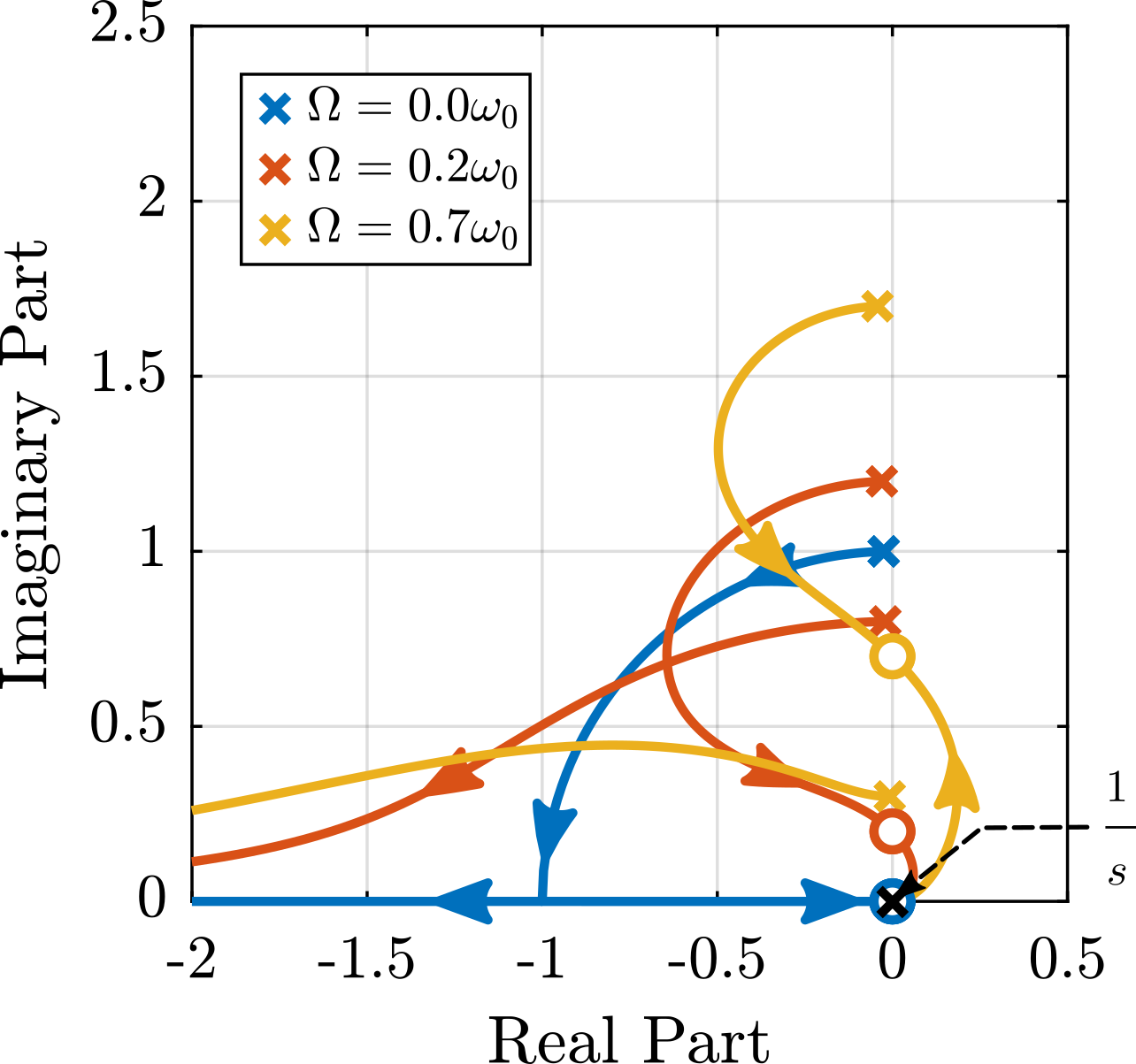

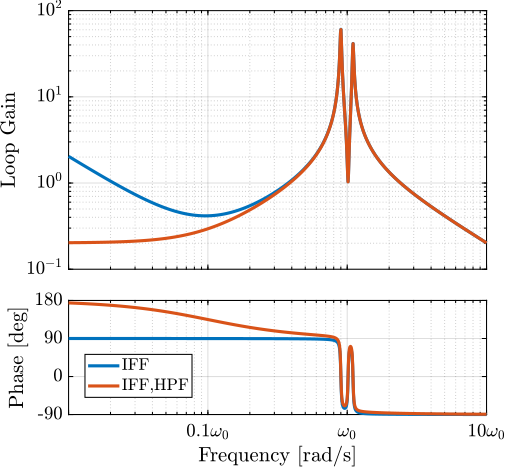

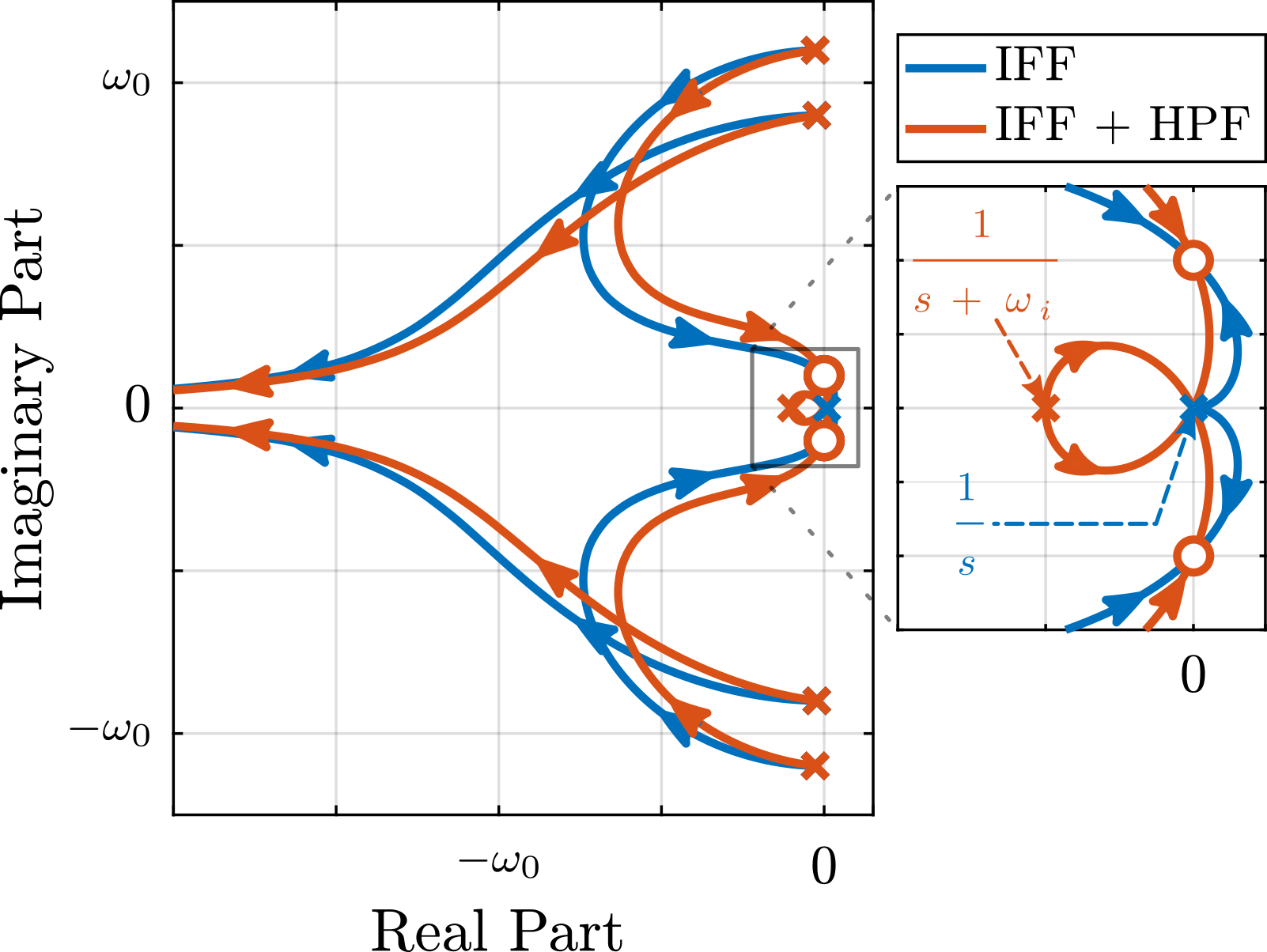

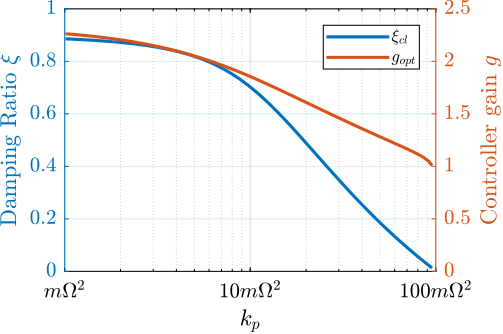

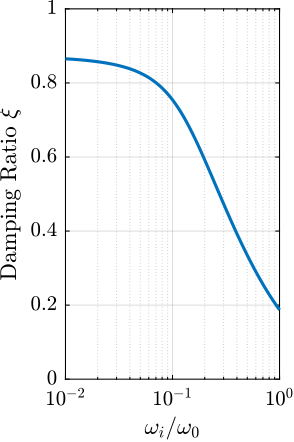

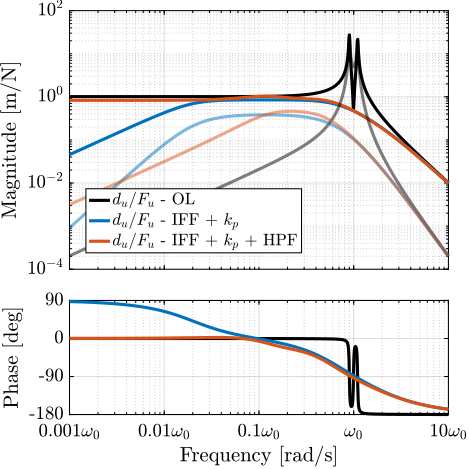

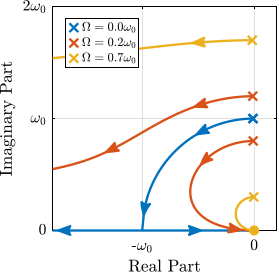

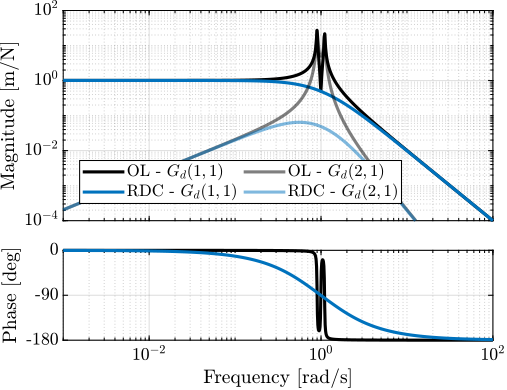

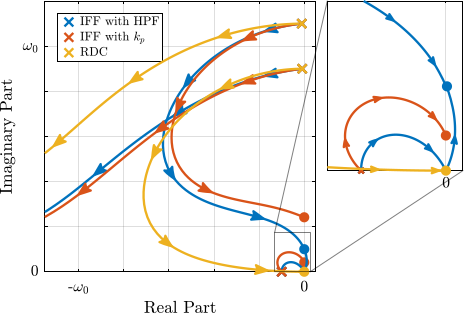

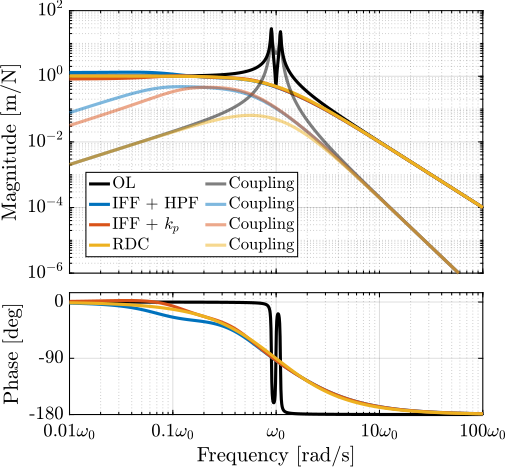

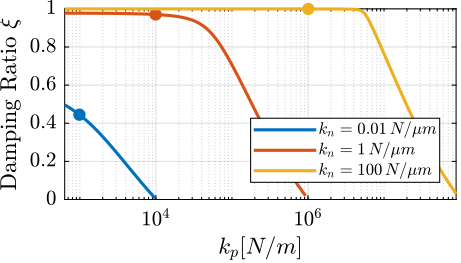

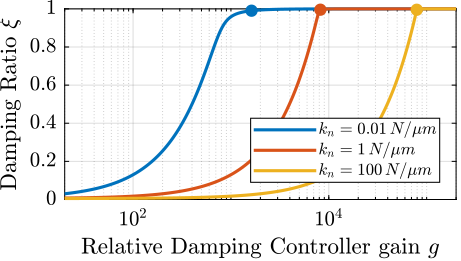

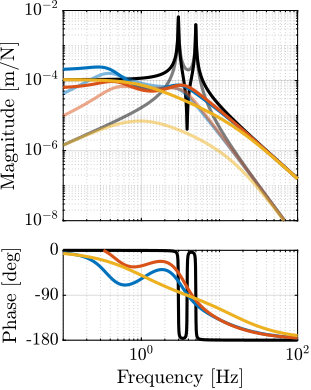

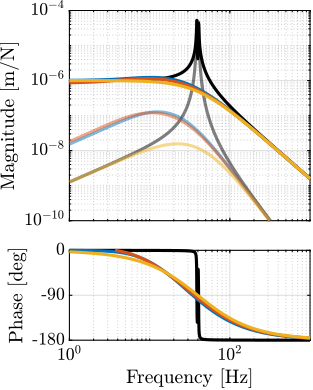

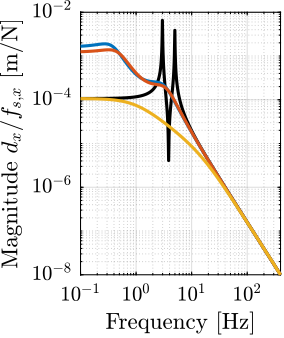

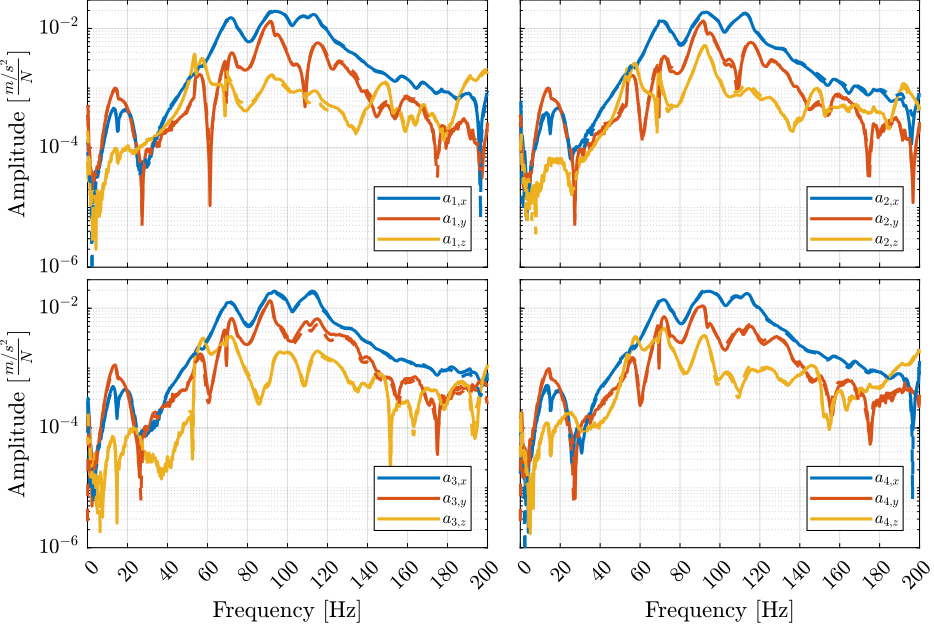

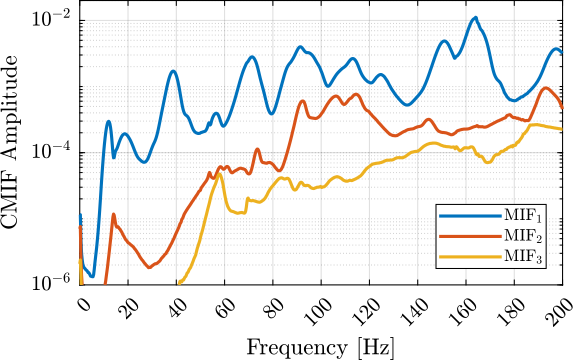

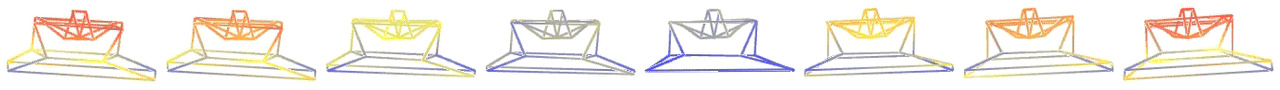

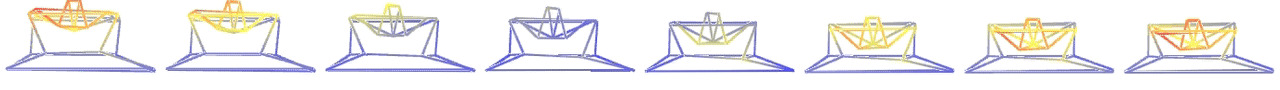

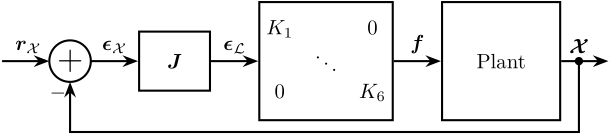

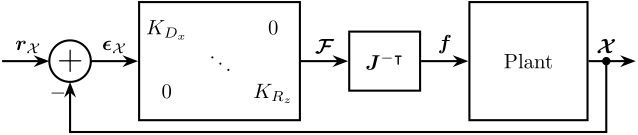

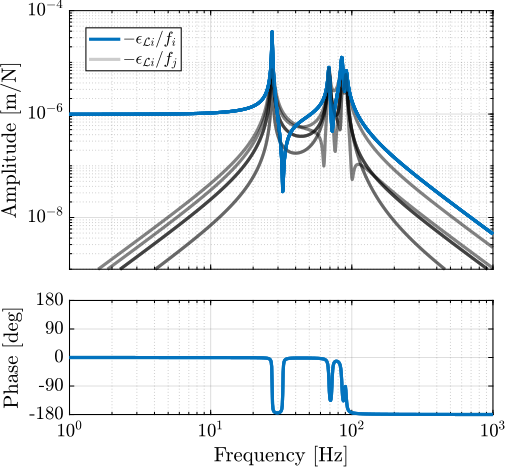

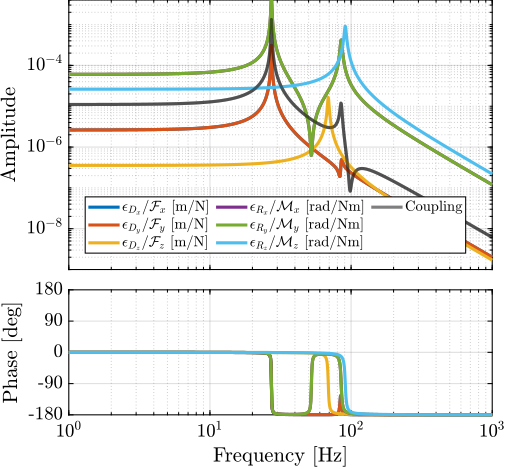

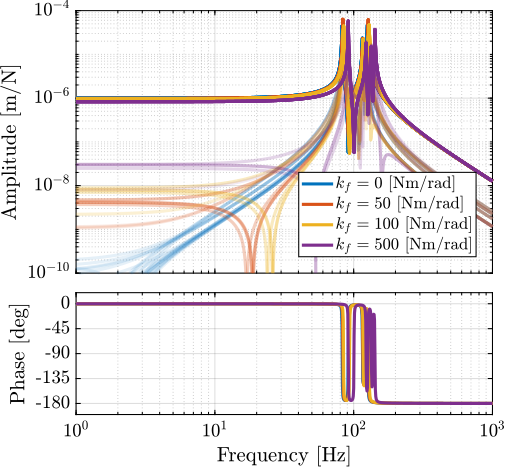

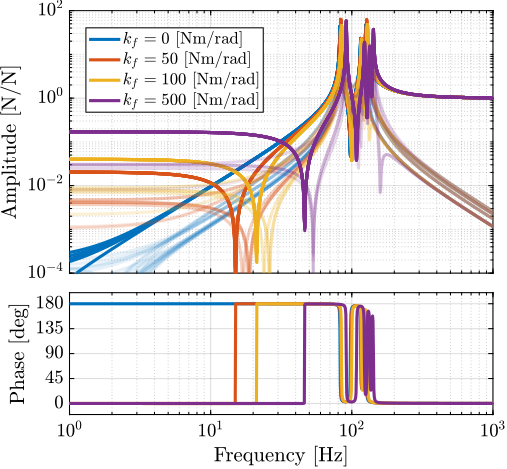

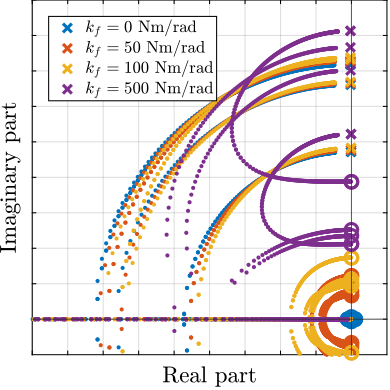

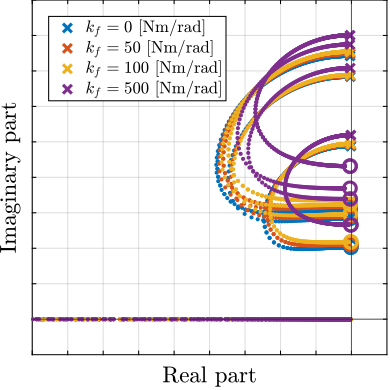

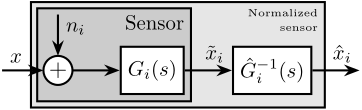

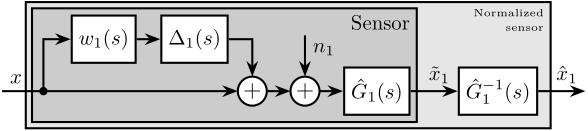

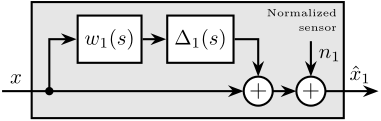

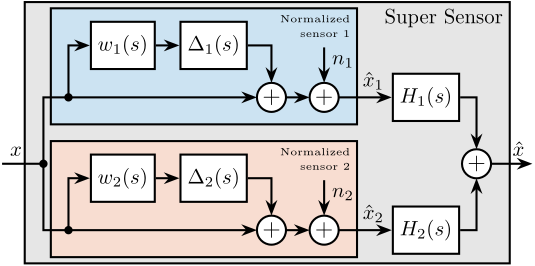

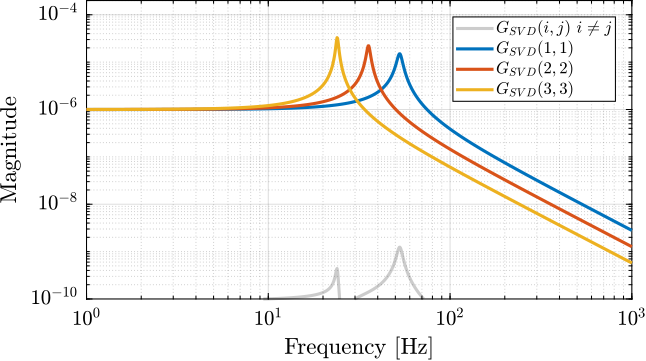

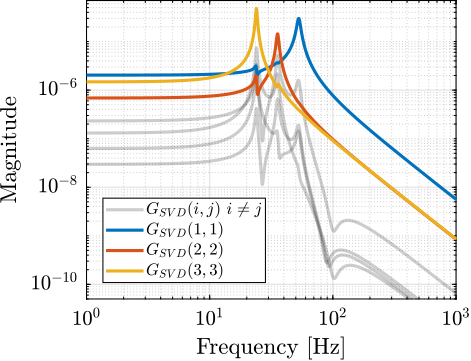

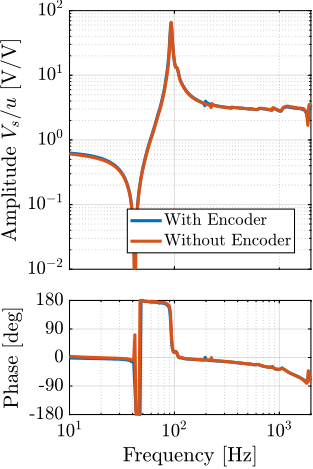

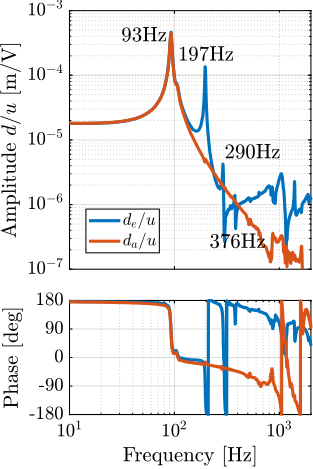

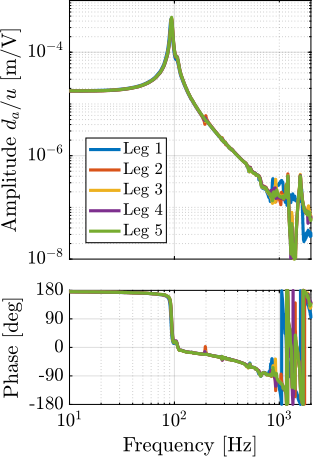

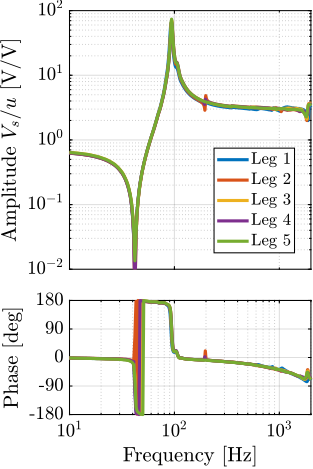

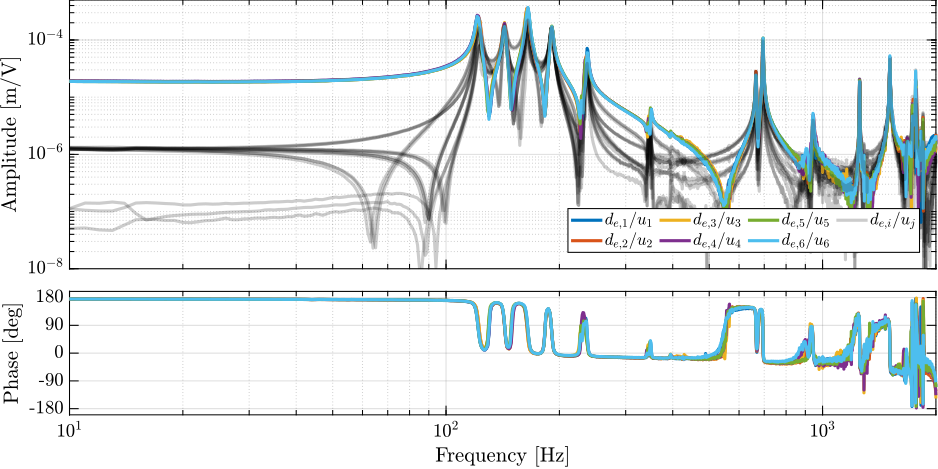

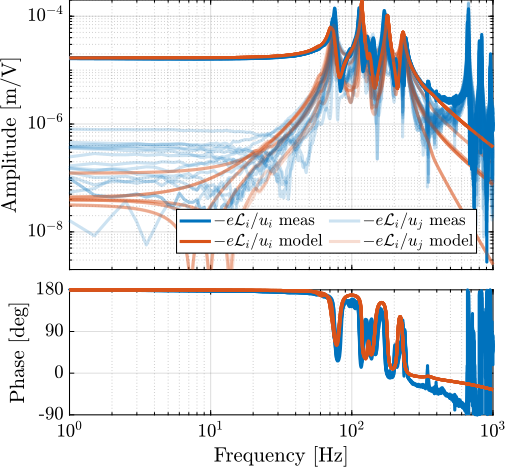

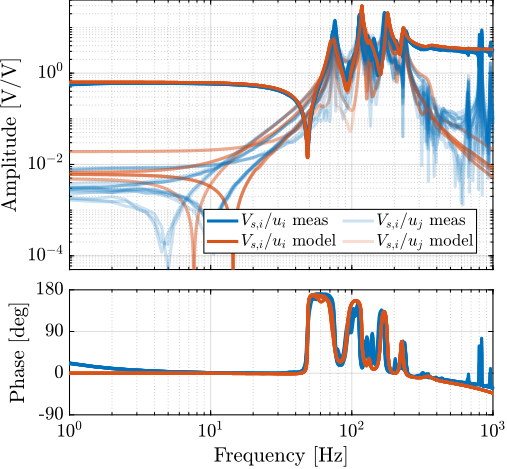

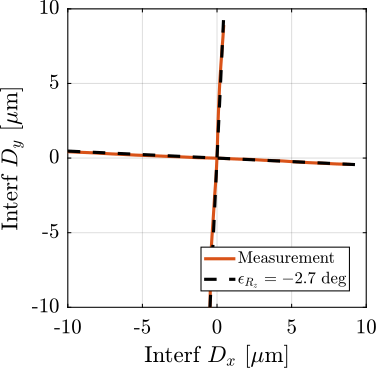

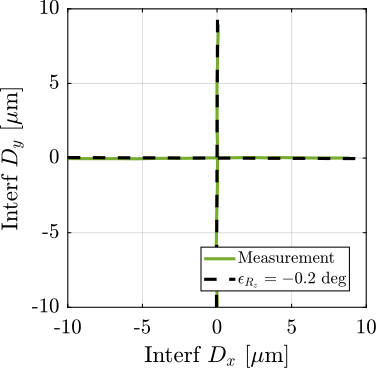

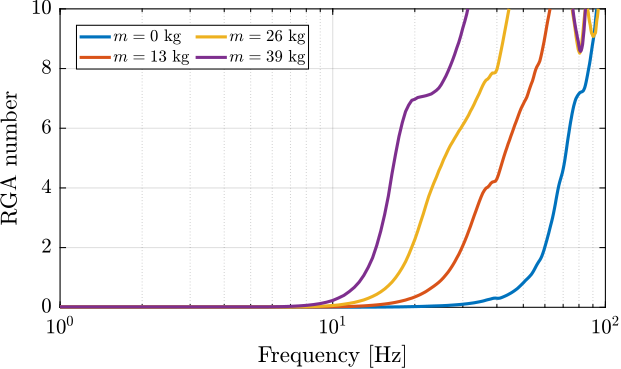

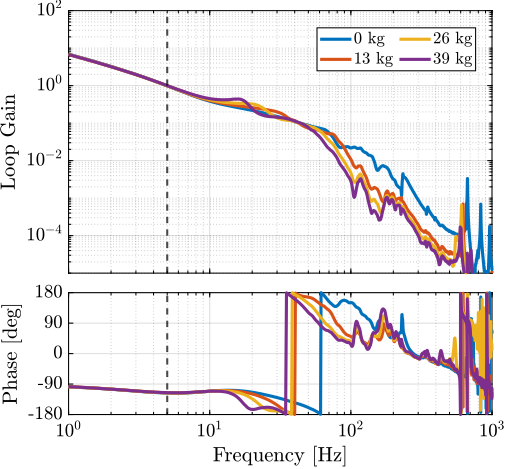

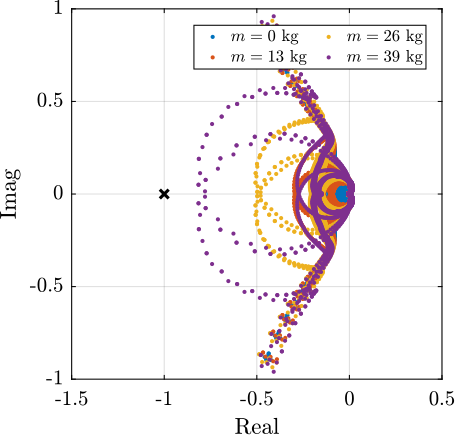

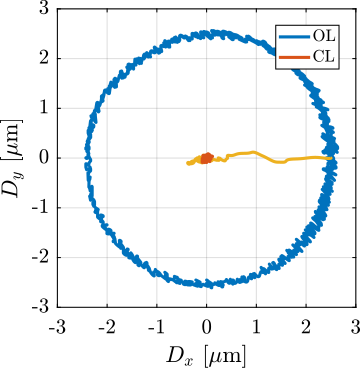

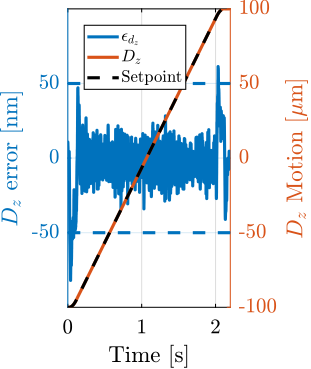

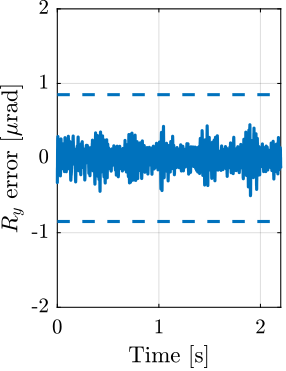

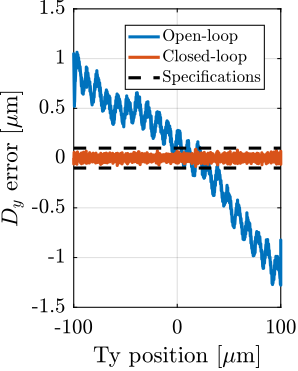

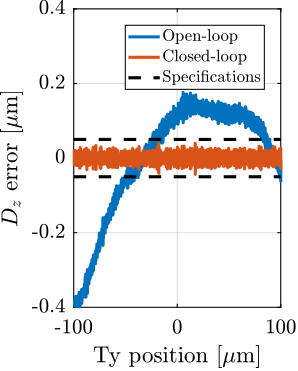

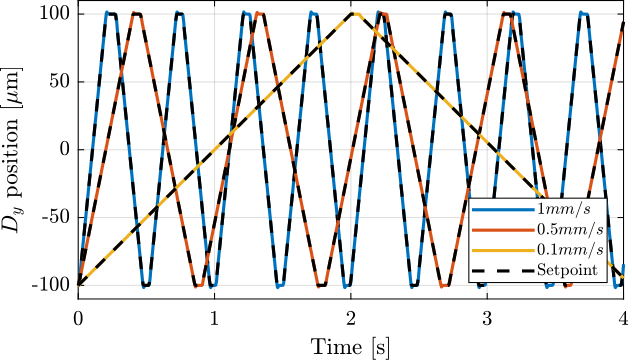

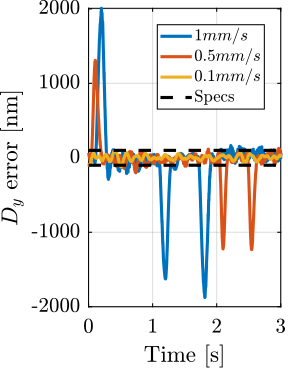

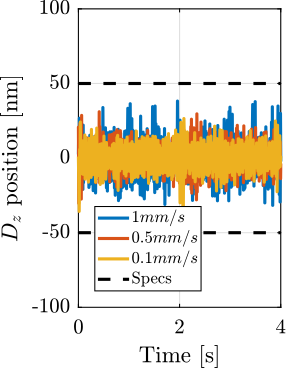

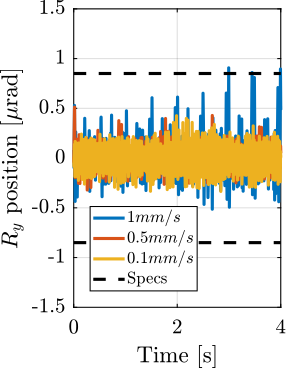

Sensitivity to Disturbances and Error Budget