24 KiB

Nano Hexapod - Optimal Geometry

- Introduction

- Review of Stewart platforms

- Effect of geometry on Stewart platform properties

- The Cubic Architecture

- Conclusion

- Bibliography

Introduction ignore

- In the conceptual design phase, the geometry of the Stewart platform was not optimized

- In the detail design phase, we want to see if the geometry can be optimized to improve the overall performances

- Optimization criteria: mobility, stiffness, dynamical decoupling, more performance / bandwidth

Outline:

- Review of Stewart platform: Section ref:sec:detail_kinematics_stewart_review Geometry, Actuators, Sensors, Joints

- Effect of geometry on the Stewart platform characteristics ref:sec:detail_kinematics_geometry

- Cubic configuration: benefits? ref:sec:detail_kinematics_cubic

Review of Stewart platforms

<<sec:detail_kinematics_stewart_review>>

Introduction ignore

-

as was explained in the conceptual phase, Stewart platform have the following key elements:

- two plates

- flexible joints

- actuators

- sensors

- the geometry

- This results in various designs as shown in Table ref:tab:detail_kinematics_stewart_review

- The focus is here made on Stewart platforms for nano-positioning of vibration control. Not on long stroke stewart platforms.

- All presented Stewart platforms are using flexible joints, as it is a prerequisites for nano-positioning capabilities.

-

Most of stewart platforms are using voice coil actuators or piezoelectric actuators. The actuators used for the Stewart platform will be chosen in the next section.

-

Depending on the application, various sensors are integrated in the struts or on the plates. The choice of sensor for the nano-hexapod will be described in the next section.

- Only keep integrated sensor and not external metrology

- Check for missing information

| Geometry | Actuators | Sensors | Reference | |

|---|---|---|---|---|

| Cubic (6-UPU) | Magnetostrictive | Force (collocated), Accelerometers | cite:&geng93_six_degree_of_freed_activ;&geng94_six_degree_of_freed_activ;&geng95_intel_contr_system_multip_degree | |

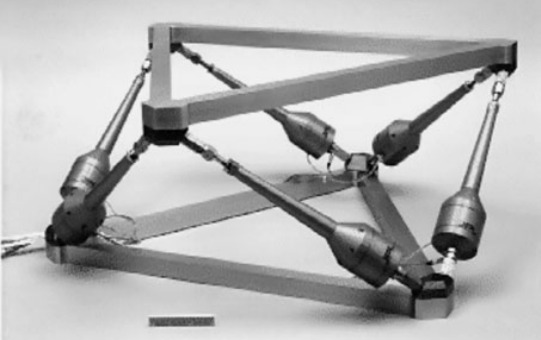

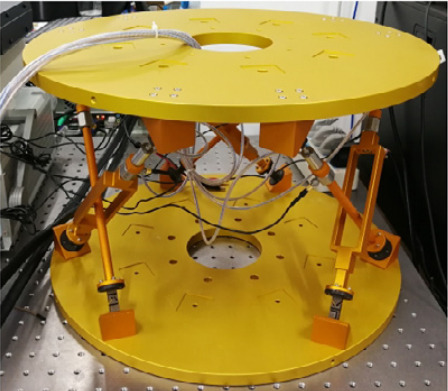

| Figure ref:fig:detail_kinematics_jpl | Cubic | Voice Coil (0.5 mm) | Force (collocated) | cite:&spanos95_soft_activ_vibrat_isolat;&rahman98_multiax |

| Cubic | Voice Coil (10 mm) | Force, LVDT, Geophones | cite:&thayer98_stewar;&thayer02_six_axis_vibrat_isolat_system;&hauge04_sensor_contr_space_based_six | |

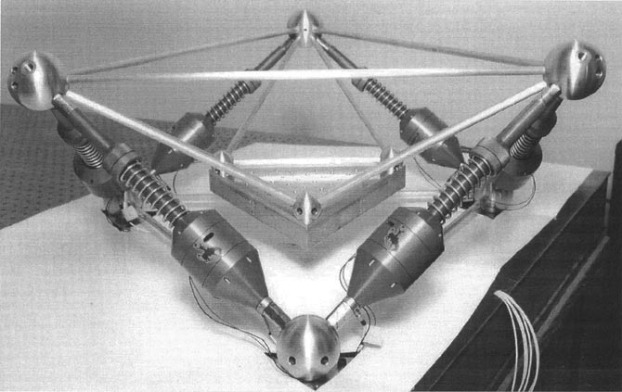

| Figure ref:fig:detail_kinematics_uw_gsp | Cubic (CoM=CoK) | Voice Coil | Force | cite:&mcinroy99_dynam;&mcinroy99_precis_fault_toler_point_using_stewar_platf;&mcinroy00_desig_contr_flexur_joint_hexap;&li01_simul_vibrat_isolat_point_contr;&jafari03_orthog_gough_stewar_platf_microm |

| Cubic | Piezoelectric ($25\,\mu m$) | Piezo force sensors | cite:&defendini00_techn | |

| Figure ref:fig:detail_kinematics_ulb_pz | Cubic | APA ($50\,\mu m$) | Force sensor | cite:&abu02_stiff_soft_stewar_platf_activ |

| Figure ref:fig:detail_kinematics_pph | Non-Cubic | Voice Coil | Accelerometers | cite:&chen03_payload_point_activ_vibrat_isolat |

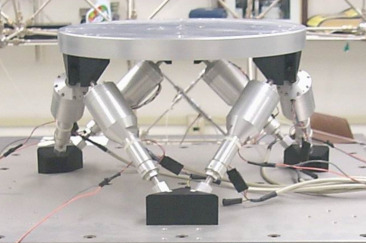

| Cubic | Voice Coil | Force | cite:&hanieh03_activ_stewar;&preumont07_six_axis_singl_stage_activ | |

| Figure ref:fig:detail_kinematics_uqp | Cubic | Piezoelectric ($50\,\mu m$) | Geophone aligned with the strut | cite:&agrawal04_algor_activ_vibrat_isolat_spacec |

| Non-Cubic | Piezoelectric ($16\,\mu m$) | Eddy Current | cite:&furutani04_nanom_cuttin_machin_using_stewar | |

| Cubic | Piezoelectric ($120\,\mu m$) | External capacitive | cite:&ting06_desig_stewar_nanos_platf;&ting13_compos_contr_desig_stewar_nanos_platf | |

| Non-Cubic | Piezoelectric ($160\,\mu m$) | External capacitive (LION) | cite:&ting07_measur_calib_stewar_microm_system | |

| Figure ref:fig:detail_kinematics_zhang11 | Non-cubic | Magnetostrictive | Inertial | cite:&zhang11_six_dof |

| 6-SPS (Optimized) | Piezoelectric | Strain Gauge | cite:&du14_piezo_actuat_high_precis_flexib | |

| Cubic | Voice Coil | Accelerometer in each leg | cite:&chi15_desig_exper_study_vcm_based;&tang18_decen_vibrat_contr_voice_coil;&jiao18_dynam_model_exper_analy_stewar | |

| Cubic | Piezoelectric | Force Sensor + Accelerometer | cite:&wang16_inves_activ_vibrat_isolat_stewar | |

| Almost cubic | Voice Coil | Force Sensor + Accelerometer | cite:&beijen18_self_tunin_mimo_distur_feedf;&tjepkema12_activ_ph | |

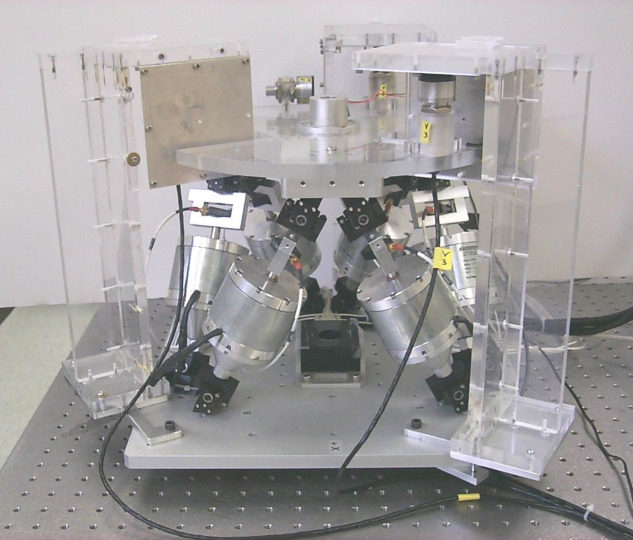

| Figure ref:fig:detail_kinematics_yang19 | 6-UPS (Cubic?) | Piezoelectric | Force, Position | cite:&yang19_dynam_model_decoup_contr_flexib |

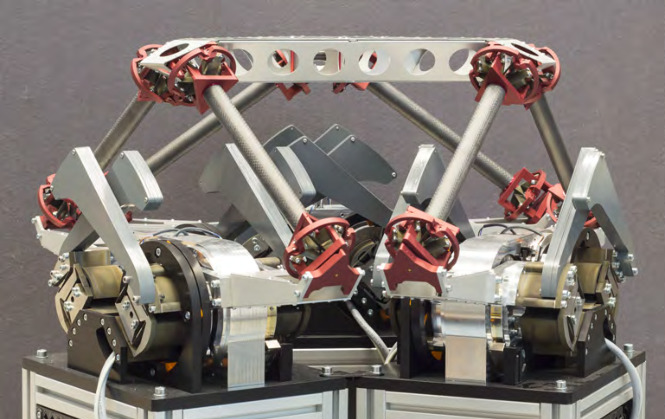

| Figure ref:fig:detail_kinematics_naves | Non-Cubic | 3-phase rotary motor | Rotary Encoders | cite:&naves20_desig;&naves20_t_flex |

- https://research.tdehaeze.xyz/stewart-simscape/docs/bibliography.html

- Joints and actuators are optimized in the next section

Effect of geometry on Stewart platform properties

<<sec:detail_kinematics_geometry>>

Introduction ignore

- Remind that the choice of frames (independently of the physical geometry) impacts the obtained stiffness matrix (as it is defined as forces/motion evaluated at the chosen frame)

- Important: bi (join position w.r.t top platform) and si (orientation of struts)

For the nano-hexapod:

- Size requirements: Maximum height, maximum radius

Stiffness

-

Give some examples:

- struts further apart: higher angular stiffness, same linear stiffness

- orientation: more vertical => increase vertical stiffness, decrease horizontal stiffness

Mobility and required joint and actuator stroke

- Comparison of the XYZ mobility (fixed orientation) for two geometry (or maybe only in the XY or YZ plane to see more clearly the differences)

- Estimated required actuator stroke from specified platform mobility Will be useful to choose the actuators

- Estimation of the Joint required Stroke Will be useful to design the flexible joints

Conclusion

- Table that summarize the findings Optimal Nano-Hexapod Geometry

The Cubic Architecture

<<sec:detail_kinematics_cubic>>

Introduction ignore

Cubic configuration file:~/Cloud/work-projects/ID31-NASS/matlab/stewart-simscape/org/cubic-configuration.org

The Cubic Architecture

From cite:&geng94_six_degree_of_freed_activ, 7 properties of cubic configuration:

- Uniformity in control capability in all directions

- Uniformity in stiffness in all directions

- Minimum cross coupling force effect among actuators

- Facilitate collocated sensor-actuator control system design

- Simple kinematics relationships

- Simple dynamic analysis

- Simple mechanical design

- Principle

- Examples of Stewart platform with Cubic architecture

- Different options? Center of the cube above the top platform? Where to mention that ? With examples

Static Properties

Explain that we get diagonal K matrix => static decoupling in the cartesian frame. Uniform mobility in X,Y,Z directions

Dynamical Properties?

cite:&mcinroy00_desig_contr_flexur_joint_hexap

cite:&afzali-far16_vibrat_dynam_isotr_hexap_analy_studies:

- proposes an architecture where the CoM can be above the top platform

- "Dynamic isotropy, leading to equal eigenfrequencies, is a powerful optimization measure."

- Show examples where the dynamics can indeed be decoupled in the cartesian frame (i.e. decoupled K and M matrices)

- Better decoupling between the struts? not sure… Compute the coupling between the struts for a cubic and non-cubic architecture

- Same resonance frequencies for suspension modes? Maybe in one case: sphere at the CoM? Could be nice to show that. Say that this can be nice for optimal damping for instance (link to paper explaining that)

Conclusion

<<sec:detail_kinematics_conclusion>>

Inertia used for experiments will be very broad => difficult to optimize the dynamics Specific geometry is not found to have a huge impact on performances. Practical implementation is important.

Geometry impacts the static and dynamical characteristics of the Stewart platform. Considering the design constrains, the slight change of geometry will not significantly impact the obtained results.