75 KiB

Active Damping of Rotating Platforms using Integral Force Feedback - Matlab Computation

- Introduction

- System Description and Analysis

- Problem with pure Integral Force Feedback

- Integral Force Feedback with an High Pass Filter

- IFF with a stiffness in parallel with the force sensor

- Comparison

- Notations

- Bibliography

This report is also available as a pdf.

Introduction ignore

This document gathers the Matlab code used to for the conference paper cite:dehaeze20_activ_dampin_rotat_platf_integ_force_feedb and the journal paper cite:dehaeze21_activ_dampin_rotat_platf_using.

It is structured in several sections:

- Section sec:system_description: presents a simple model of a rotating suspended platform that will be used throughout this study.

- Section sec:iff_pure_int: explains how the unconditional stability of IFF is lost due to Gyroscopic effects induced by the rotation.

- Section sec:iff_pseudo_int: suggests a simple modification of the control law such that damping can be added to the suspension modes in a robust way.

- Section sec:iff_parallel_stiffness: proposes to add springs in parallel with the force sensors to regain the unconditional stability of IFF.

- Section sec:comparison: compares both proposed modifications to the classical IFF in terms of damping authority and closed-loop system behavior.

- Section sec:notations: contains the notations used for both the Matlab code and the paper

The matlab code is accessible on Zonodo and Github cite:dehaeze20_activ_dampin_rotat_posit_platf. It can also be download as a .zip file here.

To run the Matlab code, go in the matlab directory and run the following Matlab files corresponding to each section.

| Sections | Matlab File |

|---|---|

| Section sec:system_description | s1_system_description.m |

| Section sec:iff_pure_int | s2_iff_pure_int.m |

| Section sec:iff_pseudo_int | s3_iff_hpf.m |

| Section sec:iff_parallel_stiffness | s4_iff_kp.m |

| Section sec:comparison | s5_act_damp_comparison.m |

System Description and Analysis

<<sec:system_description>>

System description

The system consists of one 2 degree of freedom translation stage on top of a spindle (figure fig:system).

The control inputs are the forces applied by the actuators of the translation stage ($F_u$ and $F_v$). As the translation stage is rotating around the Z axis due to the spindle, the forces are applied along $\vec{i}_u$ and $\vec{i}_v$.

Equations

Based on the Figure fig:system, the equations of motions are:

Where $\bm{G}_d$ is a $2 \times 2$ transfer function matrix.

\begin{equation} \bm{G}_d = \frac{1}{k} \frac{1}{G_{dp}} \begin{bmatrix} G_{dz} & G_{dc} \\ -G_{dc} & G_{dz} \end{bmatrix} \end{equation}With:

\begin{align} G_{dp} &= \left( \frac{s^2}{{\omega_0}^2} + 2 \xi \frac{s}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \right)^2 + \left( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \right)^2 \\ G_{dz} &= \frac{s^2}{{\omega_0}^2} + 2 \xi \frac{s}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \\ G_{dc} &= 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \end{align}Numerical Values

Let's define initial values for the model.

k = 1; % Actuator Stiffness [N/m]

c = 0.05; % Actuator Damping [N/(m/s)]

m = 1; % Payload mass [kg] xi = c/(2*sqrt(k*m));

w0 = sqrt(k/m); % [rad/s]Campbell Diagram

The Campbell Diagram displays the evolution of the real and imaginary parts of the system as a function of the rotating speed.

It is shown in Figures fig:campbell_diagram_real and fig:campbell_diagram_imag, and one can see that the system becomes unstable for $\Omega > \omega_0$ (the real part of one of the poles becomes positive).

Simscape Model

In order to validate all the equations of motion, a Simscape model of the same system has been developed. The dynamics of the system can be identified from the Simscape model and compare with the analytical model.

The rotating speed for the Simscape Model is defined.

W = 0.1; % Rotation Speed [rad/s] open('rotating_frame.slx');The transfer function from $[F_u, F_v]$ to $[d_u, d_v]$ is identified from the Simscape model.

%% Name of the Simulink File

mdl = 'rotating_frame';

%% Input/Output definition

clear io; io_i = 1;

io(io_i) = linio([mdl, '/K'], 1, 'openinput'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/G'], 2, 'openoutput'); io_i = io_i + 1; G = linearize(mdl, io, 0);

%% Input/Output definition

G.InputName = {'Fu', 'Fv'};

G.OutputName = {'du', 'dv'};The same transfer function from $[F_u, F_v]$ to $[d_u, d_v]$ is written down from the analytical model.

Gth = (1/k)/(((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2))^2 + (2*W*s/(w0^2))^2) * ...

[(s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2), 2*W*s/(w0^2) ; ...

-2*W*s/(w0^2), (s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2)];Both transfer functions are compared in Figure fig:plant_simscape_analytical and are found to perfectly match.

Effect of the rotation speed

The transfer functions from $[F_u, F_v]$ to $[d_u, d_v]$ are identified for the following rotating speeds.

Ws = [0, 0.2, 0.7, 1.1]*w0; % Rotating Speeds [rad/s] Gs = {zeros(2, 2, length(Ws))};

for W_i = 1:length(Ws)

W = Ws(W_i);

Gs(:, :, W_i) = {(1/k)/(((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2))^2 + (2*W*s/(w0^2))^2) * ...

[(s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2), 2*W*s/(w0^2) ; ...

-2*W*s/(w0^2), (s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2)]};

endThey are compared in Figures fig:plant_compare_rotating_speed_direct and fig:plant_compare_rotating_speed_coupling.

Problem with pure Integral Force Feedback

<<sec:iff_pure_int>>

Introduction ignore

Force sensors are added in series with the two actuators (Figure fig:system_iff).

Two identical controllers $K_F$ are used to feedback each of the sensed force to its associated actuator.

Plant Parameters

Let's define initial values for the model.

k = 1; % Actuator Stiffness [N/m]

c = 0.05; % Actuator Damping [N/(m/s)]

m = 1; % Payload mass [kg] xi = c/(2*sqrt(k*m));

w0 = sqrt(k/m); % [rad/s]Equations

The sensed forces are equal to:

\begin{equation} \begin{bmatrix} f_{u} \\ f_{v} \end{bmatrix} = \begin{bmatrix} 1 & 0 \\ 0 & 1 \end{bmatrix} \begin{bmatrix} F_u \\ F_v \end{bmatrix} - (c s + k) \begin{bmatrix} d_u \\ d_v \end{bmatrix} \end{equation}Which then gives:

Comparison of the Analytical Model and the Simscape Model

The rotation speed is set to $\Omega = 0.1 \omega_0$.

W = 0.1*w0; % [rad/s] open('rotating_frame.slx');And the transfer function from $[F_u, F_v]$ to $[f_u, f_v]$ is identified using the Simscape model.

%% Name of the Simulink File

mdl = 'rotating_frame';

%% Input/Output definition

clear io; io_i = 1;

io(io_i) = linio([mdl, '/K'], 1, 'openinput'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/G'], 1, 'openoutput'); io_i = io_i + 1; Giff = linearize(mdl, io, 0);

%% Input/Output definition

Giff.InputName = {'Fu', 'Fv'};

Giff.OutputName = {'fu', 'fv'};The same transfer function from $[F_u, F_v]$ to $[f_u, f_v]$ is written down from the analytical model.

Giff_th = 1/(((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2))^2 + (2*W*s/(w0^2))^2) * ...

[(s^2/w0^2 - W^2/w0^2)*((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2)) + (2*W*s/(w0^2))^2, - (2*xi*s/w0 + 1)*2*W*s/(w0^2) ; ...

(2*xi*s/w0 + 1)*2*W*s/(w0^2), (s^2/w0^2 - W^2/w0^2)*((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2))+ (2*W*s/(w0^2))^2];The two are compared in Figure fig:plant_iff_comp_simscape_analytical and found to perfectly match.

Effect of the rotation speed

The transfer functions from $[F_u, F_v]$ to $[f_u, f_v]$ are identified for the following rotating speeds.

Ws = [0, 0.2, 0.7]*w0; % Rotating Speeds [rad/s] Gsiff = {zeros(2, 2, length(Ws))};

for W_i = 1:length(Ws)

W = Ws(W_i);

Gsiff(:, :, W_i) = {1/(((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2))^2 + (2*W*s/(w0^2))^2) * ...

[(s^2/w0^2 - W^2/w0^2)*((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2)) + (2*W*s/(w0^2))^2, - (2*xi*s/w0 + 1)*2*W*s/(w0^2) ; ...

(2*xi*s/w0 + 1)*2*W*s/(w0^2), (s^2/w0^2 - W^2/w0^2)*((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2))+ (2*W*s/(w0^2))^2]};

endThe obtained transfer functions are shown in Figure fig:plant_iff_compare_rotating_speed.

Decentralized Integral Force Feedback

The decentralized IFF controller consists of pure integrators:

\begin{equation} \bm{K}_{\text{IFF}}(s) = \frac{g}{s} \begin{bmatrix} 1 & 0 \\ 0 & 1 \end{bmatrix} \end{equation}The Root Locus (evolution of the poles of the closed loop system in the complex plane as a function of $g$) is shown in Figure fig:root_locus_pure_iff. It is shown that for non-null rotating speed, one pole is bound to the right-half plane, and thus the closed loop system is unstable.

Integral Force Feedback with an High Pass Filter

<<sec:iff_pseudo_int>>

Plant Parameters

Let's define initial values for the model.

k = 1; % Actuator Stiffness [N/m]

c = 0.05; % Actuator Damping [N/(m/s)]

m = 1; % Payload mass [kg] xi = c/(2*sqrt(k*m));

w0 = sqrt(k/m); % [rad/s]Modified Integral Force Feedback Controller

Let's modify the initial Integral Force Feedback Controller ; instead of using pure integrators, pseudo integrators (i.e. low pass filters) are used:

\begin{equation} K_{\text{IFF}}(s) = g\frac{1}{\omega_i + s} \begin{bmatrix} 1 & 0 \\ 0 & 1 \end{bmatrix} \end{equation}where $\omega_i$ characterize down to which frequency the signal is integrated.

Let's arbitrary choose the following control parameters:

g = 2;

wi = 0.1*w0;And the following rotating speed.

Giff = 1/(((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2))^2 + (2*W*s/(w0^2))^2) * ...

[(s^2/w0^2 - W^2/w0^2)*((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2)) + (2*W*s/(w0^2))^2, - (2*xi*s/w0 + 1)*2*W*s/(w0^2) ; ...

(2*xi*s/w0 + 1)*2*W*s/(w0^2), (s^2/w0^2 - W^2/w0^2)*((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2))+ (2*W*s/(w0^2))^2];The obtained Loop Gain is shown in Figure fig:loop_gain_modified_iff.

Root Locus

As shown in the Root Locus plot (Figure fig:root_locus_modified_iff), for some value of the gain, the system remains stable.

What is the optimal $\omega_i$ and $g$?

In order to visualize the effect of $\omega_i$ on the attainable damping, the Root Locus is displayed in Figure fig:root_locus_wi_modified_iff for the following $\omega_i$:

wis = [0.01, 0.1, 0.5, 1]*w0; % [rad/s]

For the controller

\begin{equation} K_{\text{IFF}}(s) = g\frac{1}{\omega_i + s} \begin{bmatrix} 1 & 0 \\ 0 & 1 \end{bmatrix} \end{equation}The gain at which the system becomes unstable is

\begin{equation} g_\text{max} = \omega_i \left( \frac{{\omega_0}^2}{\Omega^2} - 1 \right) \label{eq:iff_gmax} \end{equation}While it seems that small $\omega_i$ do allow more damping to be added to the system (Figure fig:root_locus_wi_modified_iff), the control gains may be limited to small values due to eqref:eq:iff_gmax thus reducing the attainable damping.

There must be an optimum for $\omega_i$. To find the optimum, the gain that maximize the simultaneous damping of the mode is identified for a wide range of $\omega_i$ (Figure fig:mod_iff_damping_wi).

wis = logspace(-2, 1, 100)*w0; % [rad/s]

opt_xi = zeros(1, length(wis)); % Optimal simultaneous damping

opt_gain = zeros(1, length(wis)); % Corresponding optimal gain

for wi_i = 1:length(wis)

wi = wis(wi_i);

Kiff = 1/(s + wi)*eye(2);

fun = @(g)computeSimultaneousDamping(g, Giff, Kiff);

[g_opt, xi_opt] = fminsearch(fun, 0.5*wi*((w0/W)^2 - 1));

opt_xi(wi_i) = 1/xi_opt;

opt_gain(wi_i) = g_opt;

end

IFF with a stiffness in parallel with the force sensor

<<sec:iff_parallel_stiffness>>

Schematic

In this section additional springs in parallel with the force sensors are added to counteract the negative stiffness induced by the rotation.

In order to keep the overall stiffness $k = k_a + k_p$ constant, a scalar parameter $\alpha$ ($0 \le \alpha < 1$) is defined to describe the fraction of the total stiffness in parallel with the actuator and force sensor

\begin{equation} k_p = \alpha k, \quad k_a = (1 - \alpha) k \end{equation}Equations

With:

\begin{align} G_{kp} &= \left( \frac{s^2}{{\omega_0}^2} + 2\xi \frac{s}{{\omega_0}^2} + 1 - \frac{\Omega^2}{{\omega_0}^2} \right)^2 + \left( 2 \frac{\Omega}{\omega_0}\frac{s}{\omega_0} \right)^2 \\ G_{kz} &= \left( \frac{s^2}{{\omega_0}^2} - \frac{\Omega^2}{{\omega_0}^2} + \alpha \right) \left( \frac{s^2}{{\omega_0}^2} + 2\xi \frac{s}{{\omega_0}^2} + 1 - \frac{\Omega^2}{{\omega_0}^2} \right) + \left( 2 \frac{\Omega}{\omega_0}\frac{s}{\omega_0} \right)^2 \\ G_{kc} &= \left( 2 \xi \frac{s}{\omega_0} + 1 - \alpha \right) \left( 2 \frac{\Omega}{\omega_0}\frac{s}{\omega_0} \right) \end{align}If we compare $G_{kz}$ and $G_{fz}$, we see that the spring in parallel adds a term $\alpha$. In order to have two complex conjugate zeros (instead of real zeros):

\begin{equation} \alpha > \frac{\Omega^2}{{\omega_0}^2} \quad \Leftrightarrow \quad k_p > m \Omega^2 \end{equation}Plant Parameters

Let's define initial values for the model.

k = 1; % Actuator Stiffness [N/m]

c = 0.05; % Actuator Damping [N/(m/s)]

m = 1; % Payload mass [kg] xi = c/(2*sqrt(k*m));

w0 = sqrt(k/m); % [rad/s]Comparison of the Analytical Model and the Simscape Model

The same transfer function from $[F_u, F_v]$ to $[f_u, f_v]$ is written down from the analytical model.

W = 0.1*w0; % [rad/s]

kp = 1.5*m*W^2;

cp = 0; open('rotating_frame.slx'); %% Name of the Simulink File

mdl = 'rotating_frame';

%% Input/Output definition

clear io; io_i = 1;

io(io_i) = linio([mdl, '/K'], 1, 'openinput'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/G'], 1, 'openoutput'); io_i = io_i + 1;

Giff = linearize(mdl, io, 0);

%% Input/Output definition

Giff.InputName = {'Fu', 'Fv'};

Giff.OutputName = {'fu', 'fv'}; w0p = sqrt((k + kp)/m);

xip = c/(2*sqrt((k+kp)*m));

Giff_th = 1/( (s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2)^2 + (2*(s/w0p)*(W/w0p))^2 ) * [ ...

(s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2, -(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p));

(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p)), (s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2 ];

Giff_th.InputName = {'Fu', 'Fv'};

Giff_th.OutputName = {'fu', 'fv'};

Effect of the parallel stiffness on the IFF plant

The rotation speed is set to $\Omega = 0.1 \omega_0$.

W = 0.1*w0; % [rad/s]And the IFF plant (transfer function from $[F_u, F_v]$ to $[f_u, f_v]$) is identified in three different cases:

- without parallel stiffness

- with a small parallel stiffness $k_p < m \Omega^2$

- with a large parallel stiffness $k_p > m \Omega^2$

The results are shown in Figure fig:plant_iff_kp.

One can see that for $k_p > m \Omega^2$, the systems shows alternating complex conjugate poles and zeros.

kp = 0;

w0p = sqrt((k + kp)/m);

xip = c/(2*sqrt((k+kp)*m));

Giff = 1/( (s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2)^2 + (2*(s/w0p)*(W/w0p))^2 ) * [ ...

(s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2, -(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p));

(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p)), (s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2]; kp = 0.5*m*W^2;

k = 1 - kp;

w0p = sqrt((k + kp)/m);

xip = c/(2*sqrt((k+kp)*m));

Giff_s = 1/( (s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2)^2 + (2*(s/w0p)*(W/w0p))^2 ) * [ ...

(s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2, -(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p));

(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p)), (s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2]; kp = 1.5*m*W^2;

k = 1 - kp;

w0p = sqrt((k + kp)/m);

xip = c/(2*sqrt((k+kp)*m));

Giff_l = 1/( (s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2)^2 + (2*(s/w0p)*(W/w0p))^2 ) * [ ...

(s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2, -(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p));

(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p)), (s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2];

IFF when adding a spring in parallel

In Figure fig:root_locus_iff_kp is displayed the Root Locus in the three considered cases with

\begin{equation} K_{\text{IFF}} = \frac{g}{s} \begin{bmatrix} 1 & 0 \\ 0 & 1 \end{bmatrix} \end{equation}One can see that for $k_p > m \Omega^2$, the root locus stays in the left half of the complex plane and thus the control system is unconditionally stable.

Thus, decentralized IFF controller with pure integrators can be used if:

\begin{equation} k_{p} > m \Omega^2 \end{equation}

Effect of $k_p$ on the attainable damping

However, having large values of $k_p$ may decrease the attainable damping.

To study the second point, Root Locus plots for the following values of $k_p$ are shown in Figure fig:root_locus_iff_kps.

kps = [2, 20, 40]*m*W^2;It is shown that large values of $k_p$ decreases the attainable damping.

alphas = logspace(-2, 0, 100);

opt_xi = zeros(1, length(alphas)); % Optimal simultaneous damping

opt_gain = zeros(1, length(alphas)); % Corresponding optimal gain

Kiff = 1/s*eye(2);

for alpha_i = 1:length(alphas)

kp = alphas(alpha_i);

k = 1 - alphas(alpha_i);

w0p = sqrt((k + kp)/m);

xip = c/(2*sqrt((k+kp)*m));

Giff = 1/( (s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2)^2 + (2*(s/w0p)*(W/w0p))^2 ) * [ ...

(s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2, -(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p));

(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p)), (s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2];

fun = @(g)computeSimultaneousDamping(g, Giff, Kiff);

[g_opt, xi_opt] = fminsearch(fun, 2);

opt_xi(alpha_i) = 1/xi_opt;

opt_gain(alpha_i) = g_opt;

end

Comparison

<<sec:comparison>>

Introduction ignore

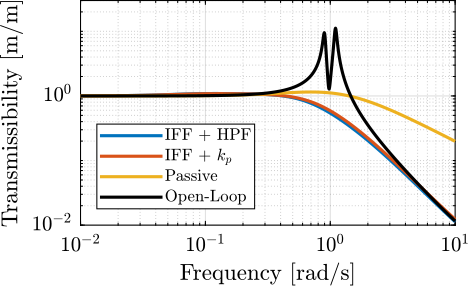

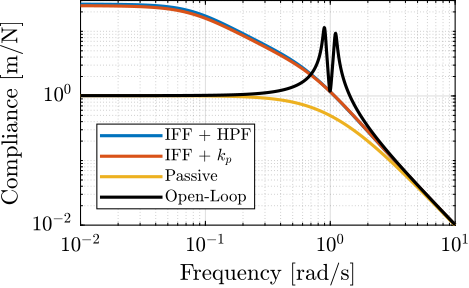

Two modifications to adapt the IFF control strategy to rotating platforms have been proposed. These two methods are now compared in terms of added damping, closed-loop compliance and transmissibility.

Plant Parameters

Let's define initial values for the model.

k = 1; % Actuator Stiffness [N/m]

c = 0.05; % Actuator Damping [N/(m/s)]

m = 1; % Payload mass [kg] xi = c/(2*sqrt(k*m));

w0 = sqrt(k/m); % [rad/s]The rotating speed is set to $\Omega = 0.1 \omega_0$.

W = 0.1*w0;Root Locus

IFF with High Pass Filter

wi = 0.1*w0; % [rad/s]

Giff = 1/(((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2))^2 + (2*W*s/(w0^2))^2) * ...

[(s^2/w0^2 - W^2/w0^2)*((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2)) + (2*W*s/(w0^2))^2, - (2*xi*s/w0 + 1)*2*W*s/(w0^2) ; ...

(2*xi*s/w0 + 1)*2*W*s/(w0^2), (s^2/w0^2 - W^2/w0^2)*((s^2)/(w0^2) + 2*xi*s/w0 + 1 - (W^2)/(w0^2))+ (2*W*s/(w0^2))^2];IFF With parallel Stiffness

kp = 5*m*W^2;

k = k - kp;

w0p = sqrt((k + kp)/m);

xip = c/(2*sqrt((k+kp)*m));

Giff_kp = 1/( (s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2)^2 + (2*(s/w0p)*(W/w0p))^2 ) * [ ...

(s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2, -(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p));

(2*xip*s/w0p + k/(k + kp))*(2*(s/w0p)*(W/w0p)), (s^2/w0p^2 + kp/(k + kp) - W^2/w0p^2)*(s^2/w0p^2 + 2*xip*s/w0p + 1 - W^2/w0p^2) + (2*(s/w0p)*(W/w0p))^2 ];

k = k + kp;

Controllers - Optimal Gains

In order to compare to three considered Active Damping techniques, gains that yield maximum damping of all the modes are computed for each case.

The obtained damping ratio and control are shown below.

| Obtained $\xi$ | Control Gain | |

|---|---|---|

| Modified IFF | 0.83 | 1.99 |

| IFF with $k_p$ | 0.83 | 2.02 |

Passive Damping - Critical Damping

Critical Damping corresponds to to $\xi = 1$, and thus:

\begin{equation} c_{\text{crit}} = 2 \sqrt{km} \end{equation} c_opt = 2*sqrt(k*m);Transmissibility And Compliance

<<sec:comp_transmissibilty>>

open('rotating_frame.slx'); %% Name of the Simulink File

mdl = 'rotating_frame';

%% Input/Output definition

clear io; io_i = 1;

io(io_i) = linio([mdl, '/dw'], 1, 'input'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/fd'], 1, 'input'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/Meas'], 1, 'output'); io_i = io_i + 1;Open Loop ignore

G_ol = linearize(mdl, io, 0);

%% Input/Output definition

G_ol.InputName = {'Dwx', 'Dwy', 'Fdx', 'Fdy'};

G_ol.OutputName = {'Dx', 'Dy'};Passive Damping

kp = 0;

cp = 0; c_old = c;

c = c_opt; G_pas = linearize(mdl, io, 0);

%% Input/Output definition

G_pas.InputName = {'Dwx', 'Dwy', 'Fdx', 'Fdy'};

G_pas.OutputName = {'Dx', 'Dy'}; c = c_old;Pseudo Integrator IFF ignore

Kiff = opt_gain_iff/(wi + s)*tf(eye(2)); G_iff = linearize(mdl, io, 0);

%% Input/Output definition

G_iff.InputName = {'Dwx', 'Dwy', 'Fdx', 'Fdy'};

G_iff.OutputName = {'Dx', 'Dy'};IFF With parallel Stiffness ignore

kp = 5*m*W^2;

cp = 0.01; Kiff = opt_gain_kp/s*tf(eye(2)); G_kp = linearize(mdl, io, 0);

%% Input/Output definition

G_kp.InputName = {'Dwx', 'Dwy', 'Fdx', 'Fdy'};

G_kp.OutputName = {'Dx', 'Dy'};Transmissibility ignore

Compliance ignore

Notations

<<sec:notations>>

| Mathematical Notation | Matlab | Unit | |

|---|---|---|---|

| Actuator Stiffness | $k$ | k |

N/m |

| Actuator Damping | $c$ | c |

N/(m/s) |

| Payload Mass | $m$ | m |

kg |

| Damping Ratio | $\xi = \frac{c}{2\sqrt{km}}$ | xi |

|

| Actuator Force | $\bm{F}, F_u, F_v$ | F Fu Fv |

N |

| Force Sensor signal | $\bm{f}, f_u, f_v$ | f fu fv |

N |

| Relative Displacement | $\bm{d}, d_u, d_v$ | d du dv |

m |

| Resonance freq. when $\Omega = 0$ | $\omega_0$ | w0 |

rad/s |

| Rotation Speed | $\Omega = \dot{\theta}$ | W |

rad/s |

| Low Pass Filter corner frequency | $\omega_i$ | wi |

rad/s |

| Mathematical Notation | Matlab | Unit | |

|---|---|---|---|

| Laplace variable | $s$ | s |

|

| Complex number | $j$ | j |

|

| Frequency | $\omega$ | w |

[rad/s] |

Bibliography ignore

bibliography:ref.bib