342 KiB

Nano-Hexapod - Test Bench

- Introduction

- Encoders fixed to the Struts - Dynamics

- Introduction

- Identification of the dynamics

- Comparison with the Simscape Model

- Introduction

- Load measured FRF

- Dynamics from Actuator to Force Sensors

- Dynamics from Actuator to Encoder

- Effect of a change in bending damping of the joints

- Effect of a change in damping factor of the APA

- Effect of a change in stiffness damping coef of the APA

- Effect of a change in mass damping coef of the APA

- Using Flexible model

- Flexible model + encoders fixed to the plates

- Integral Force Feedback

- Modal Analysis

- Conclusion

- Encoders fixed to the plates - Dynamics

- Decentralized High Authority Control with Integral Force Feedback

- Functions

- Bibliography

This report is also available as a pdf.

Introduction ignore

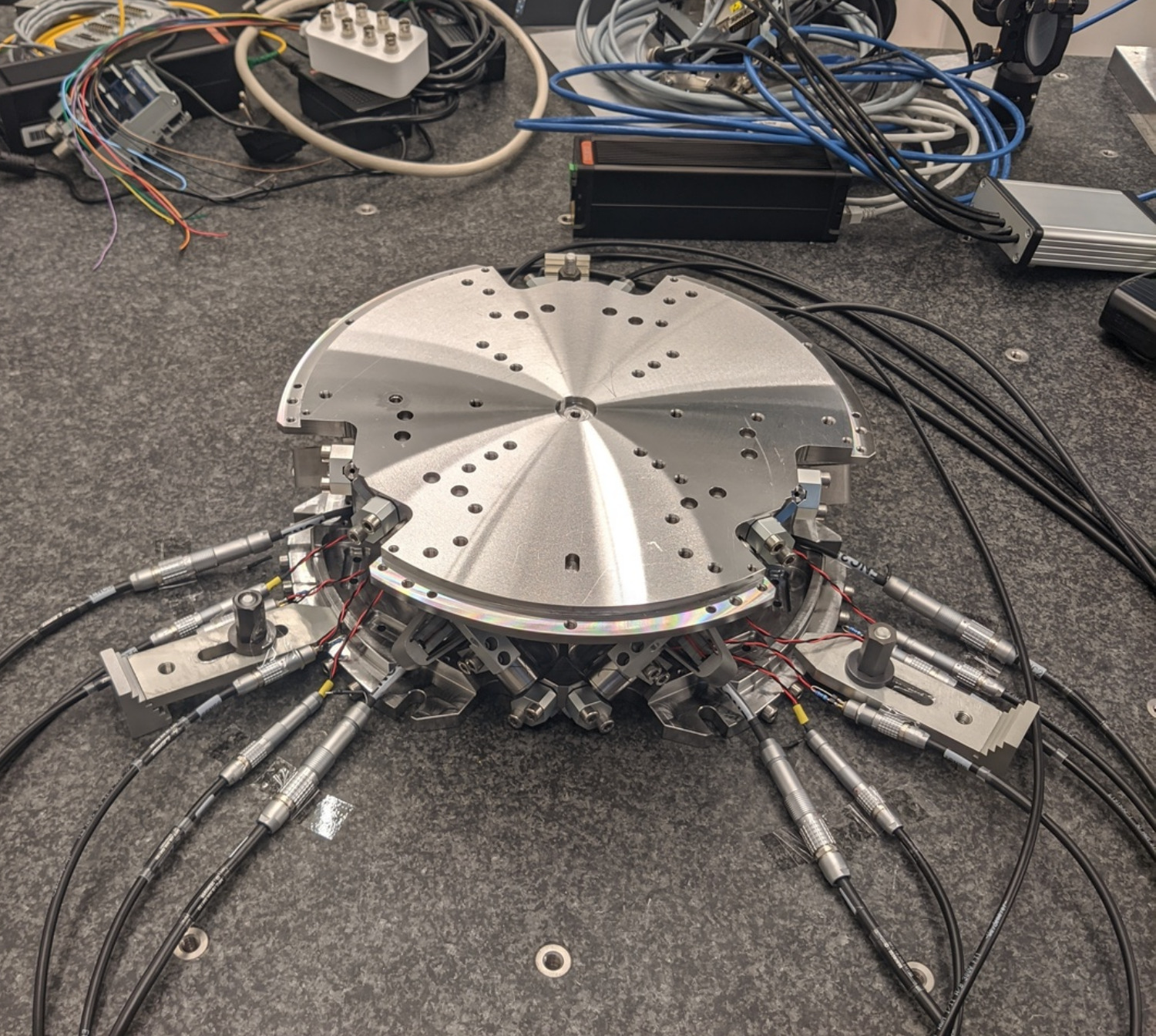

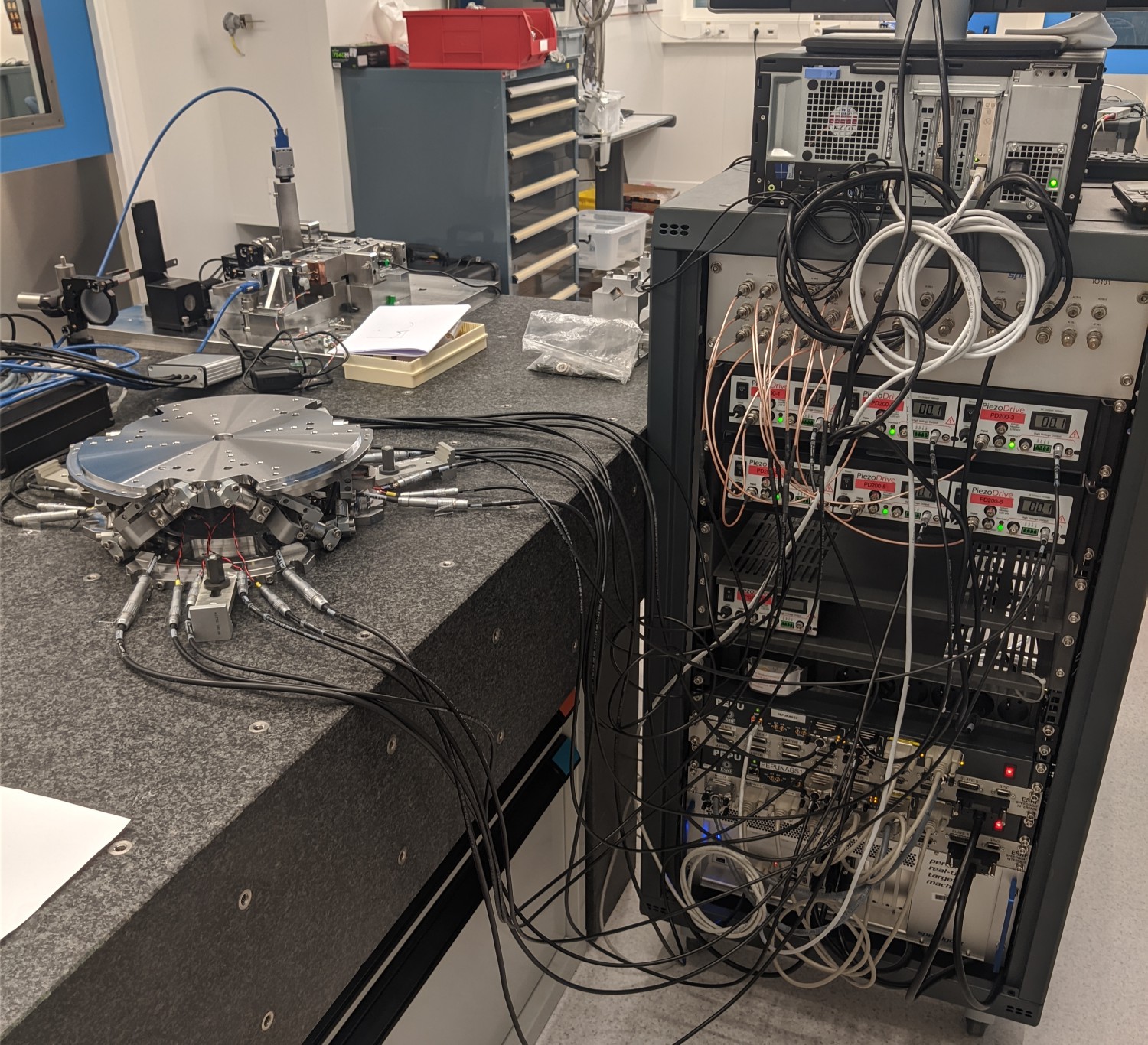

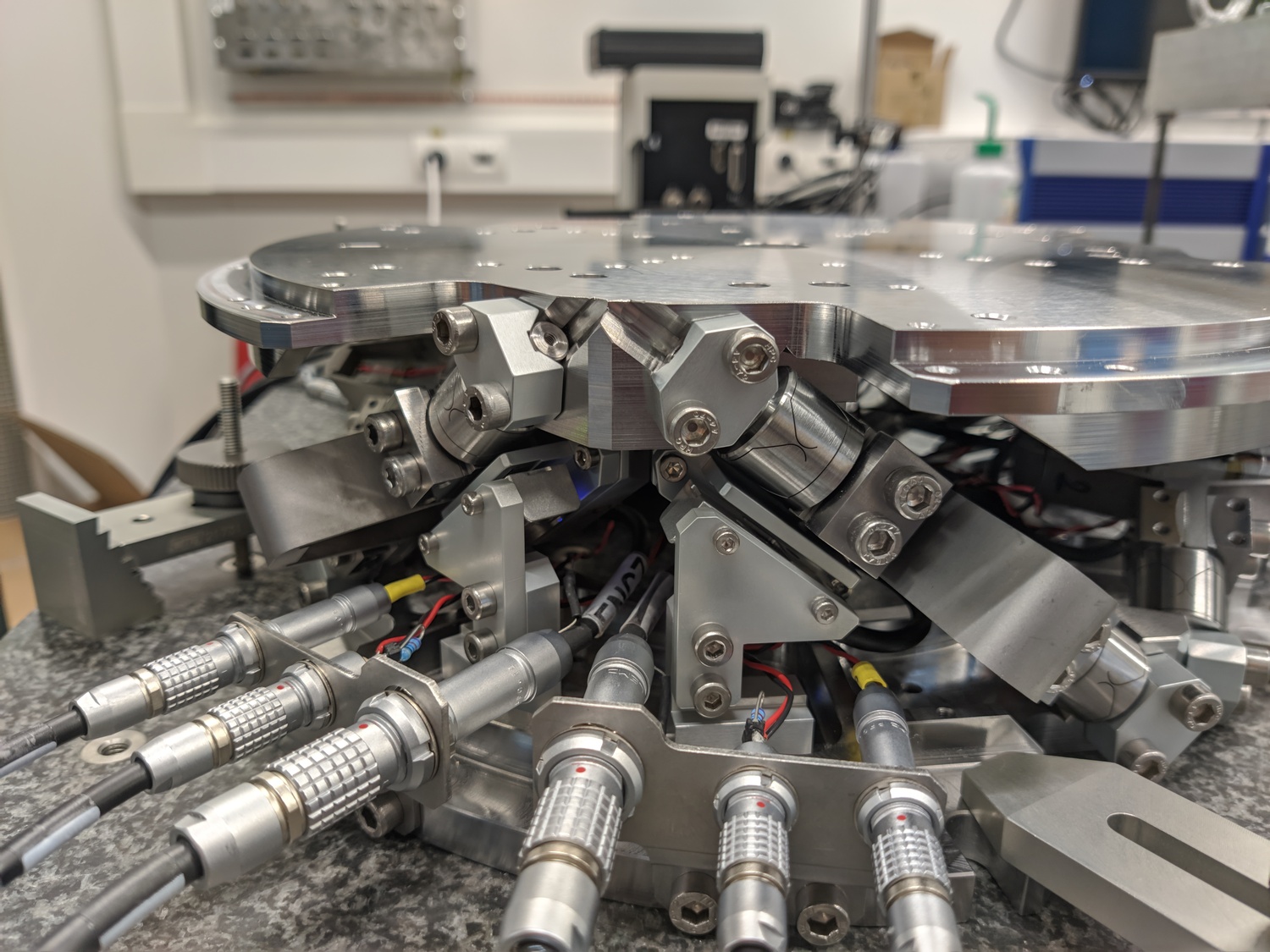

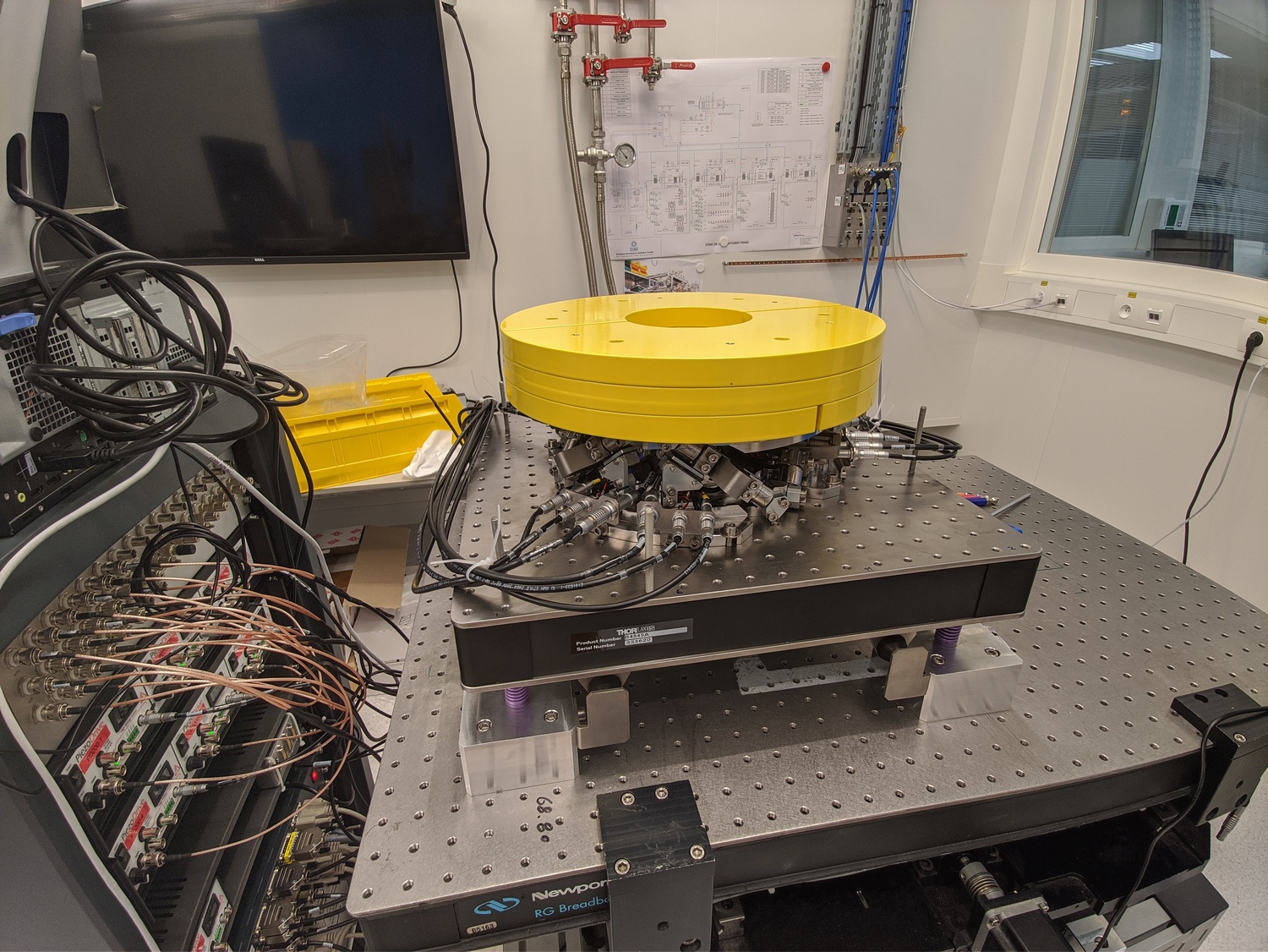

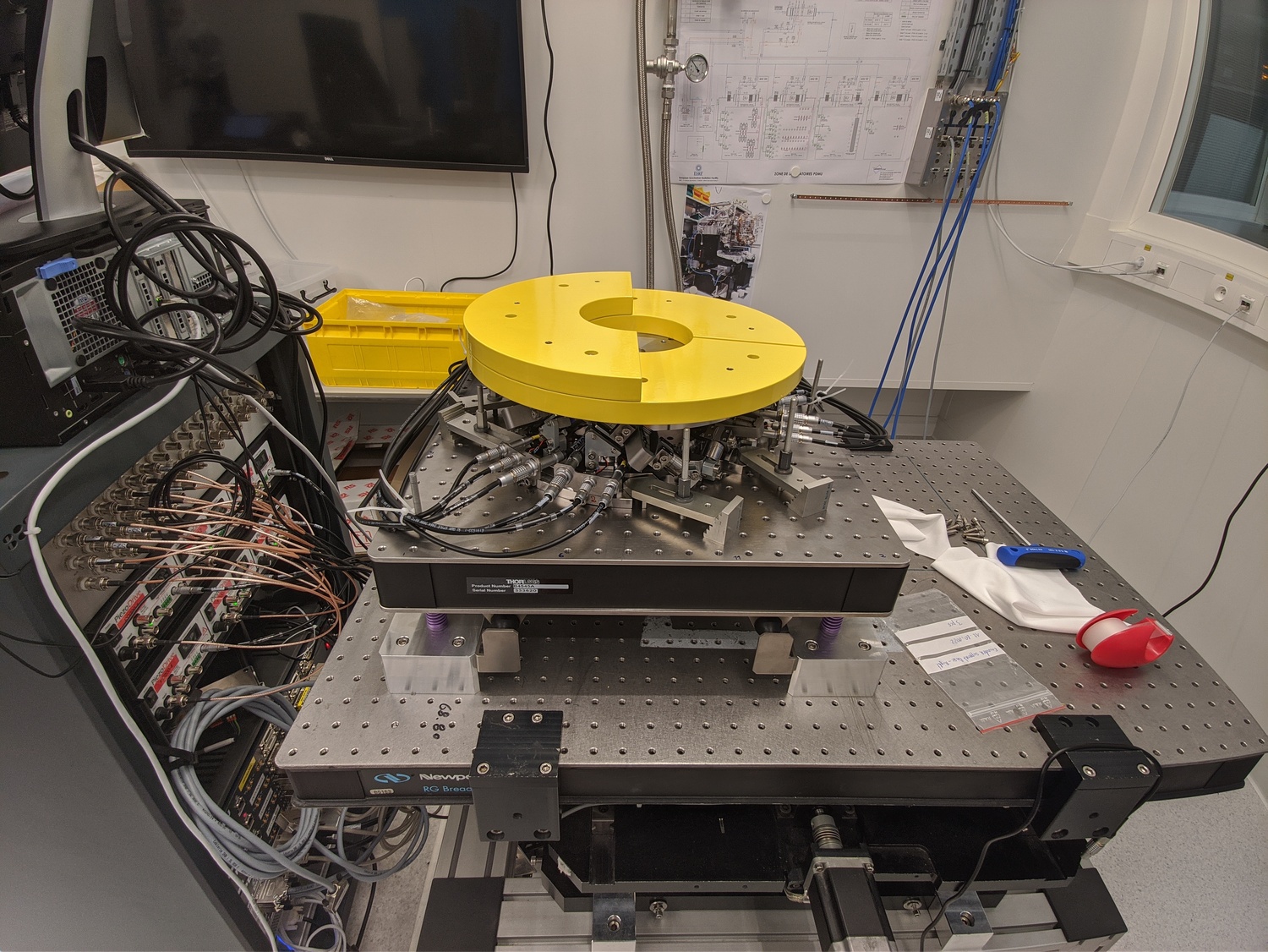

This document is dedicated to the experimental study of the nano-hexapod shown in Figure fig:picture_bench_granite_nano_hexapod.

Here are the documentation of the equipment used for this test bench (lots of them are shwon in Figure fig:picture_bench_granite_overview):

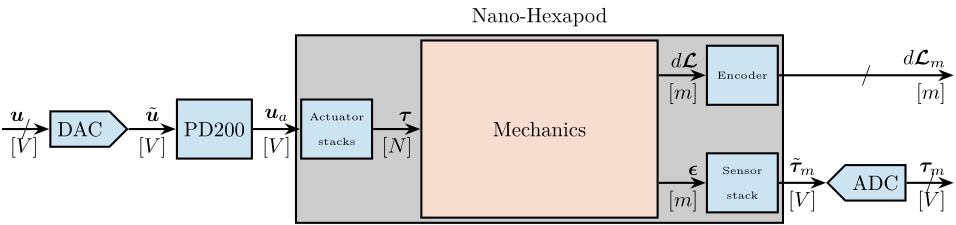

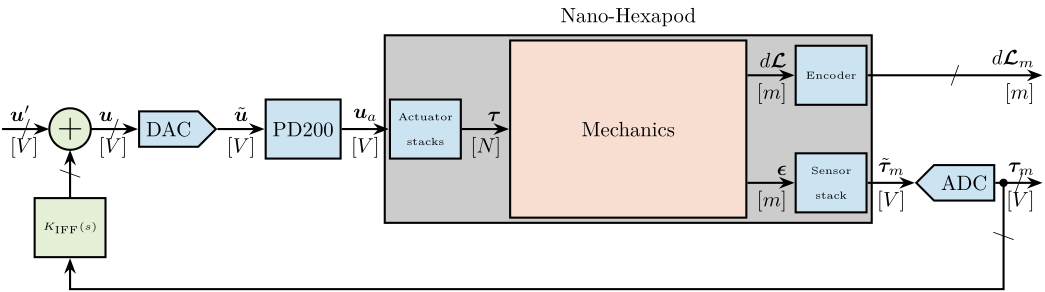

In Figure fig:nano_hexapod_signals is shown a block diagram of the experimental setup. When possible, the notations are consistent with this diagram and summarized in Table tab:list_signals.

\definecolor{instrumentation}{rgb}{0, 0.447, 0.741}

\definecolor{mechanics}{rgb}{0.8500, 0.325, 0.098}

\begin{tikzpicture}

% Blocs

\node[block={4.0cm}{3.0cm}, fill=mechanics!20!white] (nano_hexapod) {Mechanics};

\coordinate[] (inputF) at (nano_hexapod.west);

\coordinate[] (outputL) at ($(nano_hexapod.south east)!0.8!(nano_hexapod.north east)$);

\coordinate[] (outputF) at ($(nano_hexapod.south east)!0.2!(nano_hexapod.north east)$);

\node[block, left= 0.8 of inputF, fill=instrumentation!20!white, align=center] (F_stack) {\tiny Actuator \\ \tiny stacks};

\node[block, left= 0.8 of F_stack, fill=instrumentation!20!white] (PD200) {PD200};

\node[DAC, left= 0.8 of PD200, fill=instrumentation!20!white] (F_DAC) {DAC};

\node[block, right=0.8 of outputF, fill=instrumentation!20!white, align=center] (Fm_stack){\tiny Sensor \\ \tiny stack};

\node[ADC, right=0.8 of Fm_stack,fill=instrumentation!20!white] (Fm_ADC) {ADC};

\node[block, right=0.8 of outputL, fill=instrumentation!20!white] (encoder) {\tiny Encoder};

% Connections and labels

\draw[->] ($(F_DAC.west)+(-0.8,0)$) node[above right]{$\bm{u}$} node[below right]{$[V]$} -- node[sloped]{$/$} (F_DAC.west);

\draw[->] (F_DAC.east) -- node[midway, above]{$\tilde{\bm{u}}$}node[midway, below]{$[V]$} (PD200.west);

\draw[->] (PD200.east) -- node[midway, above]{$\bm{u}_a$}node[midway, below]{$[V]$} (F_stack.west);

\draw[->] (F_stack.east) -- (inputF) node[above left]{$\bm{\tau}$}node[below left]{$[N]$};

\draw[->] (outputF) -- (Fm_stack.west) node[above left]{$\bm{\epsilon}$} node[below left]{$[m]$};

\draw[->] (Fm_stack.east) -- node[midway, above]{$\tilde{\bm{\tau}}_m$}node[midway, below]{$[V]$} (Fm_ADC.west);

\draw[->] (Fm_ADC.east) -- node[sloped]{$/$} ++(0.8, 0)coordinate(end) node[above left]{$\bm{\tau}_m$}node[below left]{$[V]$};

\draw[->] (outputL) -- (encoder.west) node[above left]{$d\bm{\mathcal{L}}$} node[below left]{$[m]$};

\draw[->] (encoder.east) -- node[sloped]{$/$} (encoder-|end) node[above left]{$d\bm{\mathcal{L}}_m$}node[below left]{$[m]$};

% Nano-Hexapod

\begin{scope}[on background layer]

\node[fit={(F_stack.west|-nano_hexapod.south) (Fm_stack.east|-nano_hexapod.north)}, fill=black!20!white, draw, inner sep=2pt] (system) {};

\node[above] at (system.north) {Nano-Hexapod};

\end{scope}

\end{tikzpicture}| Unit | Matlab | Vector | Elements | |

|---|---|---|---|---|

| Control Input (wanted DAC voltage) | [V] |

u |

$\bm{u}$ | $u_i$ |

| DAC Output Voltage | [V] |

u |

$\tilde{\bm{u}}$ | $\tilde{u}_i$ |

| PD200 Output Voltage | [V] |

ua |

$\bm{u}_a$ | $u_{a,i}$ |

| Actuator applied force | [N] |

tau |

$\bm{\tau}$ | $\tau_i$ |

| Strut motion | [m] |

dL |

$d\bm{\mathcal{L}}$ | $d\mathcal{L}_i$ |

| Encoder measured displacement | [m] |

dLm |

$d\bm{\mathcal{L}}_m$ | $d\mathcal{L}_{m,i}$ |

| Force Sensor strain | [m] |

epsilon |

$\bm{\epsilon}$ | $\epsilon_i$ |

| Force Sensor Generated Voltage | [V] |

taum |

$\tilde{\bm{\tau}}_m$ | $\tilde{\tau}_{m,i}$ |

| Measured Generated Voltage | [V] |

taum |

$\bm{\tau}_m$ | $\tau_{m,i}$ |

| Motion of the top platform | [m,rad] |

dX |

$d\bm{\mathcal{X}}$ | $d\mathcal{X}_i$ |

| Metrology measured displacement | [m,rad] |

dXm |

$d\bm{\mathcal{X}}_m$ | $d\mathcal{X}_{m,i}$ |

This document is divided in the following sections:

- Section sec:encoders_struts: the dynamics of the nano-hexapod when the encoders are fixed to the struts is studied.

- Section sec:encoders_plates: the same is done when the encoders are fixed to the plates.

- Section sec:decentralized_hac_iff: a decentralized HAC-LAC strategy is studied and implemented.

Encoders fixed to the Struts - Dynamics

<<sec:encoders_struts>>

Introduction ignore

In this section, the encoders are fixed to the struts.

It is divided in the following sections:

- Section sec:enc_struts_plant_id: the transfer function matrix from the actuators to the force sensors and to the encoders is experimentally identified.

- Section sec:enc_struts_comp_simscape: the obtained FRF matrix is compared with the dynamics of the simscape model

- Section sec:enc_struts_iff: decentralized Integral Force Feedback (IFF) is applied and its performances are evaluated.

- Section sec:enc_struts_modal_analysis: a modal analysis of the nano-hexapod is performed

Identification of the dynamics

<<sec:enc_struts_plant_id>>

Introduction ignore

Load Measurement Data

%% Load Identification Data

meas_data_lf = {};

for i = 1:6

meas_data_lf(i) = {load(sprintf('mat/frf_data_exc_strut_%i_noise_lf.mat', i), 't', 'Va', 'Vs', 'de')};

meas_data_hf(i) = {load(sprintf('mat/frf_data_exc_strut_%i_noise_hf.mat', i), 't', 'Va', 'Vs', 'de')};

endSpectral Analysis - Setup

%% Setup useful variables

% Sampling Time [s]

Ts = (meas_data_lf{1}.t(end) - (meas_data_lf{1}.t(1)))/(length(meas_data_lf{1}.t)-1);

% Sampling Frequency [Hz]

Fs = 1/Ts;

% Hannning Windows

win = hanning(ceil(1*Fs));

% And we get the frequency vector

[~, f] = tfestimate(meas_data_lf{1}.Va, meas_data_lf{1}.de, win, [], [], 1/Ts);

i_lf = f < 250; % Points for low frequency excitation

i_hf = f > 250; % Points for high frequency excitationTransfer function from Actuator to Encoder

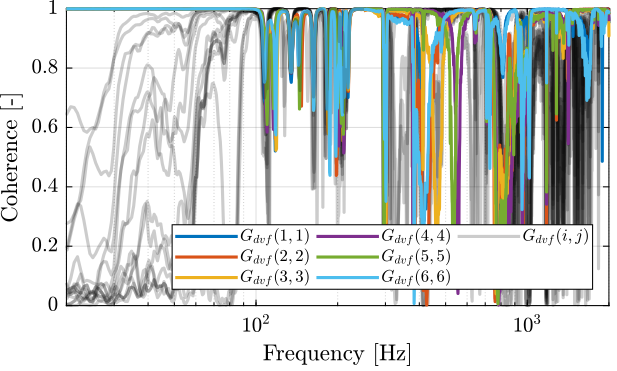

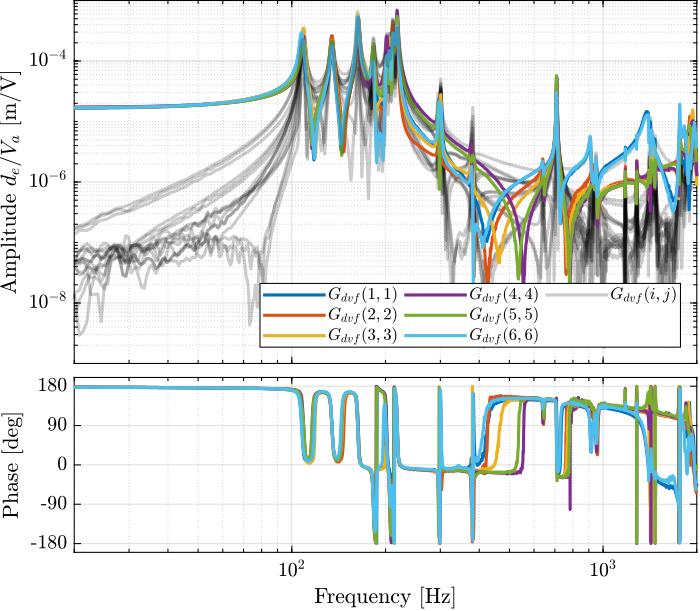

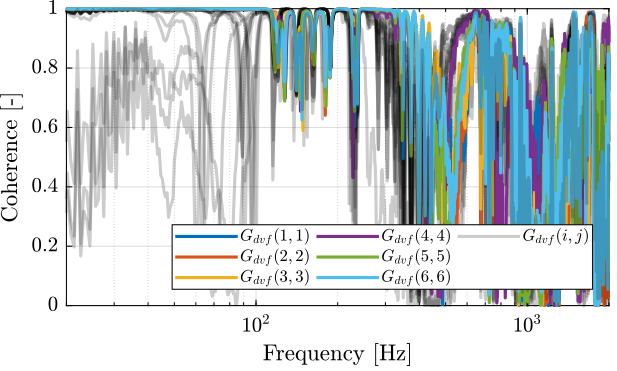

First, let's compute the coherence from the excitation voltage and the displacement as measured by the encoders (Figure fig:enc_struts_dvf_coh).

%% Coherence

coh_dvf = zeros(length(f), 6, 6);

for i = 1:6

coh_dvf_lf = mscohere(meas_data_lf{i}.Va, meas_data_lf{i}.de, win, [], [], 1/Ts);

coh_dvf_hf = mscohere(meas_data_hf{i}.Va, meas_data_hf{i}.de, win, [], [], 1/Ts);

coh_dvf(:,:,i) = [coh_dvf_lf(i_lf, :); coh_dvf_hf(i_hf, :)];

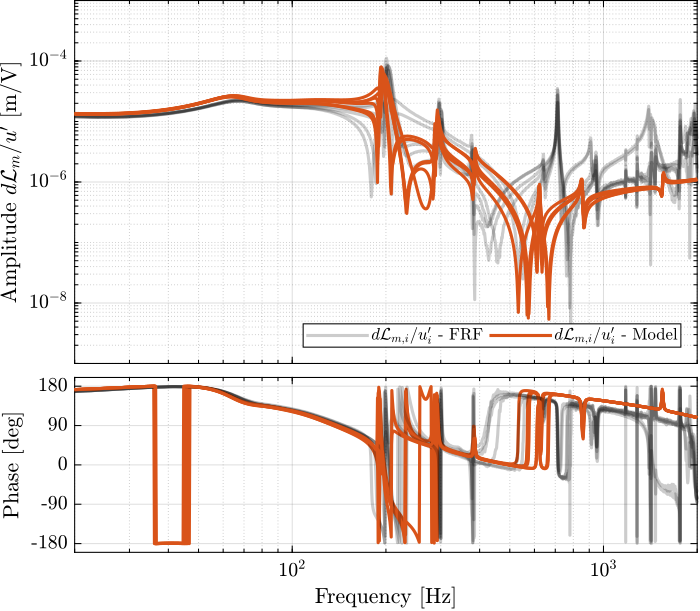

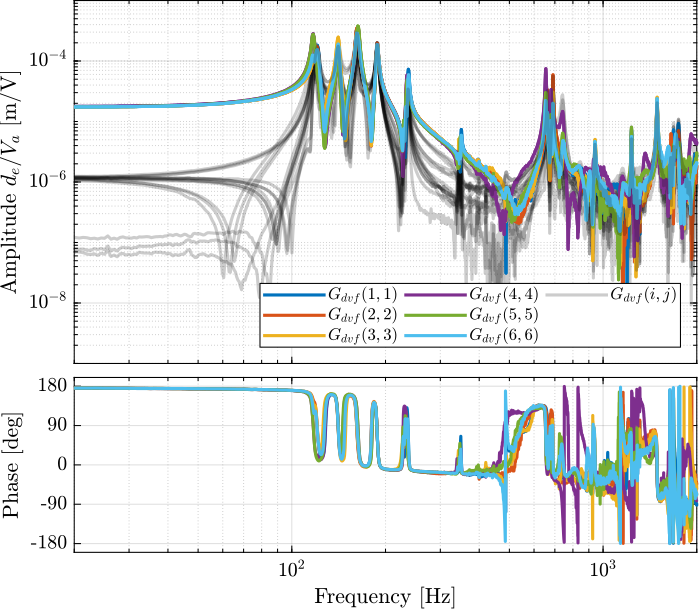

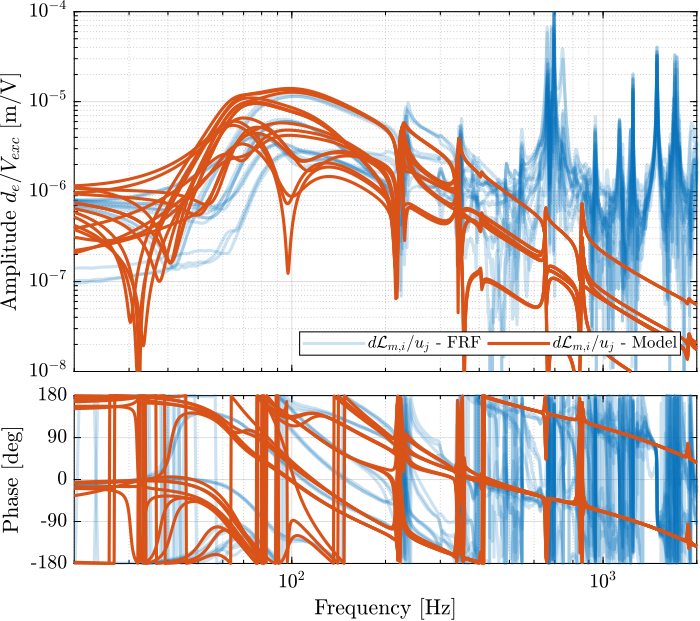

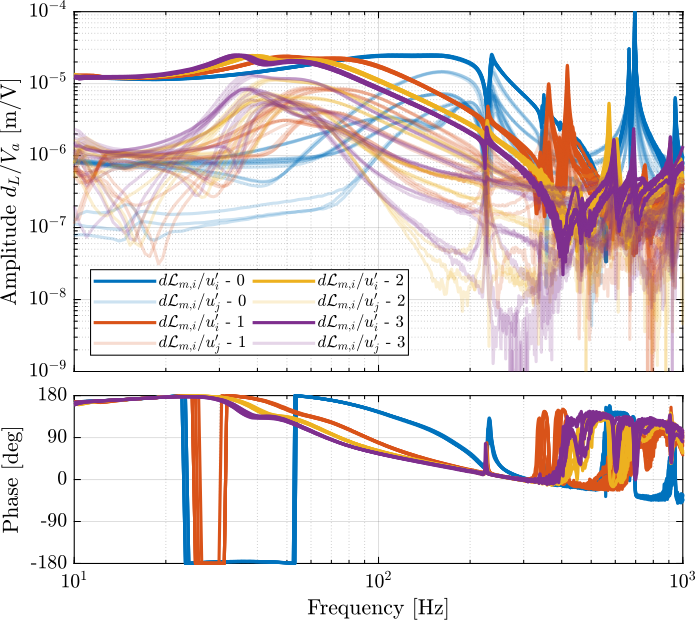

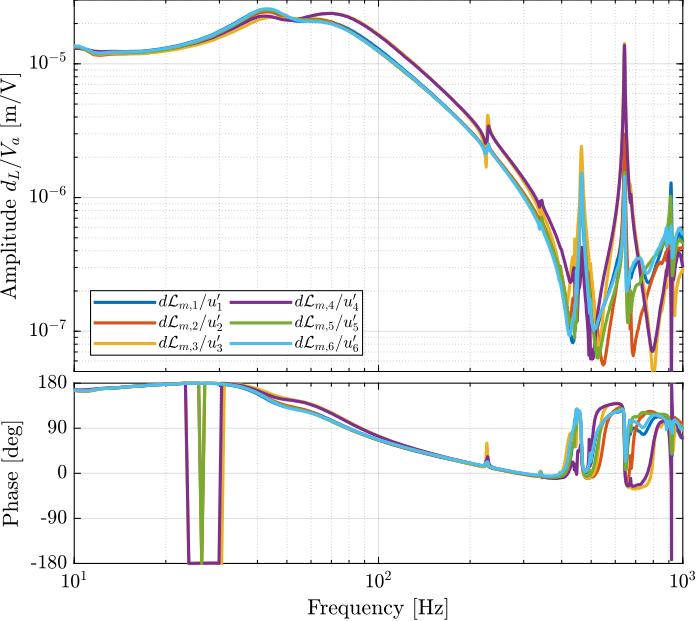

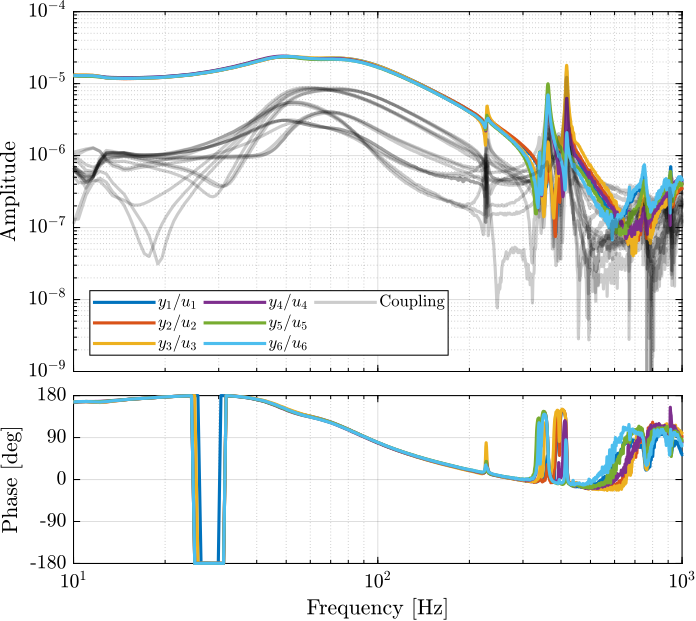

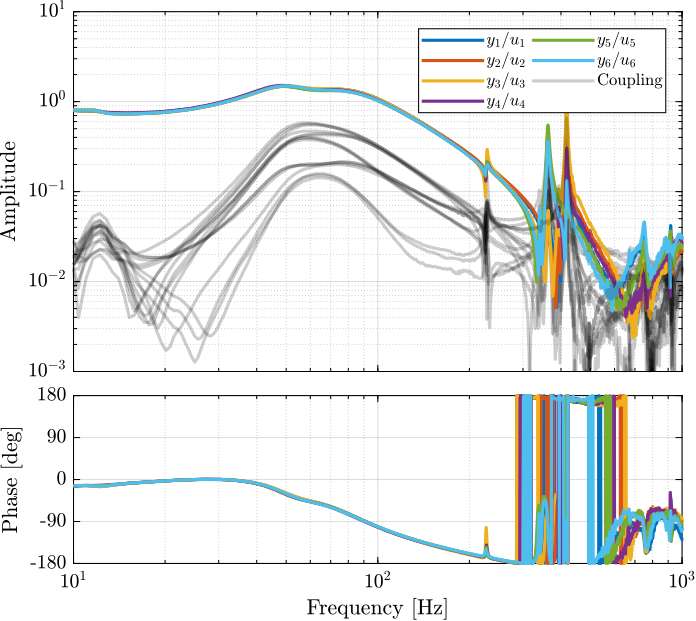

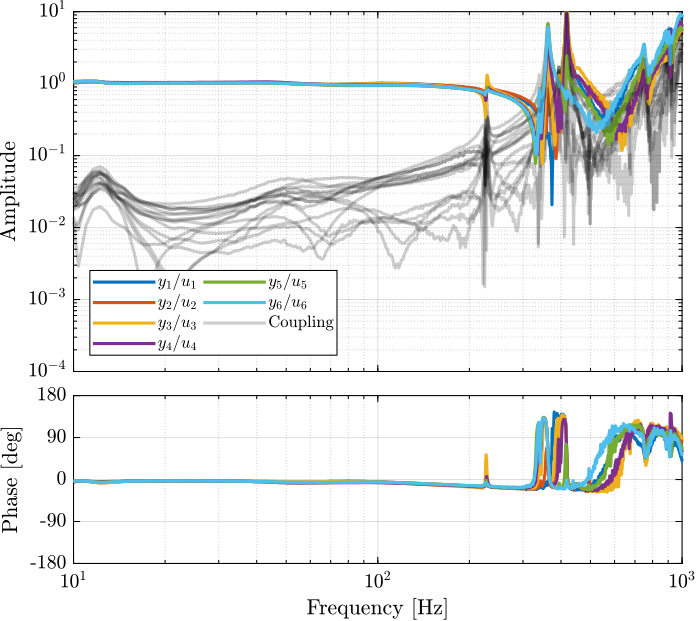

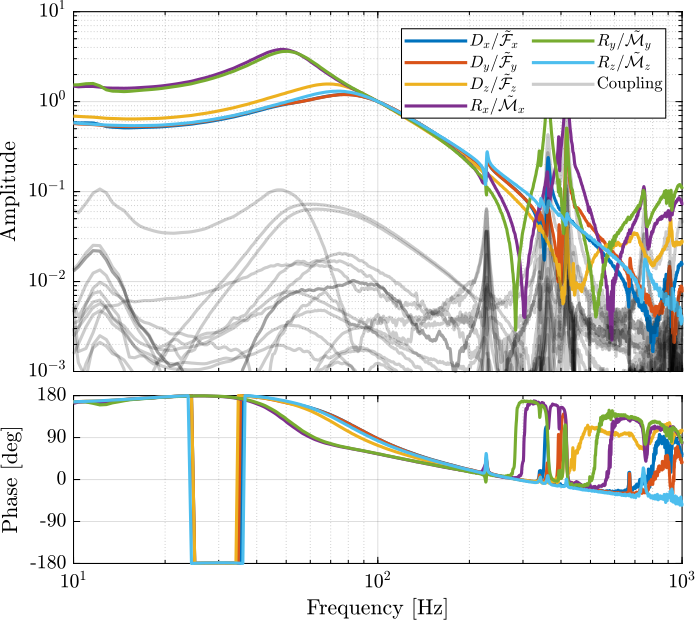

endThen the 6x6 transfer function matrix is estimated (Figure fig:enc_struts_dvf_frf).

%% DVF Plant (transfer function from u to dLm)

G_dvf = zeros(length(f), 6, 6);

for i = 1:6

G_dvf_lf = tfestimate(meas_data_lf{i}.Va, meas_data_lf{i}.de, win, [], [], 1/Ts);

G_dvf_hf = tfestimate(meas_data_hf{i}.Va, meas_data_hf{i}.de, win, [], [], 1/Ts);

G_dvf(:,:,i) = [G_dvf_lf(i_lf, :); G_dvf_hf(i_hf, :)];

endTransfer function from Actuator to Force Sensor

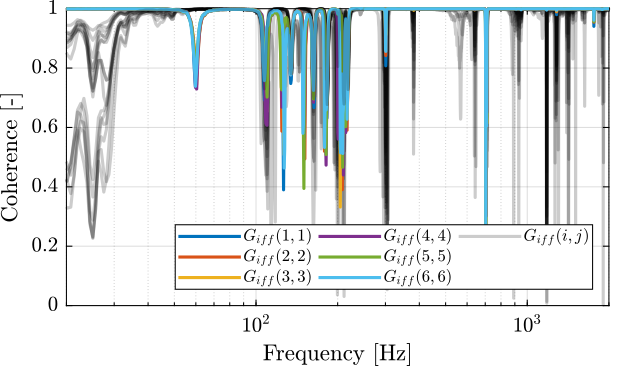

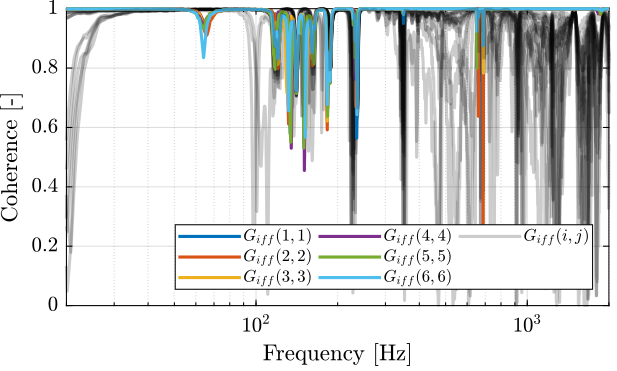

First, let's compute the coherence from the excitation voltage and the displacement as measured by the encoders (Figure fig:enc_struts_iff_coh).

%% Coherence for the IFF plant

coh_iff = zeros(length(f), 6, 6);

for i = 1:6

coh_iff_lf = mscohere(meas_data_lf{i}.Va, meas_data_lf{i}.Vs, win, [], [], 1/Ts);

coh_iff_hf = mscohere(meas_data_hf{i}.Va, meas_data_hf{i}.Vs, win, [], [], 1/Ts);

coh_iff(:,:,i) = [coh_iff_lf(i_lf, :); coh_iff_hf(i_hf, :)];

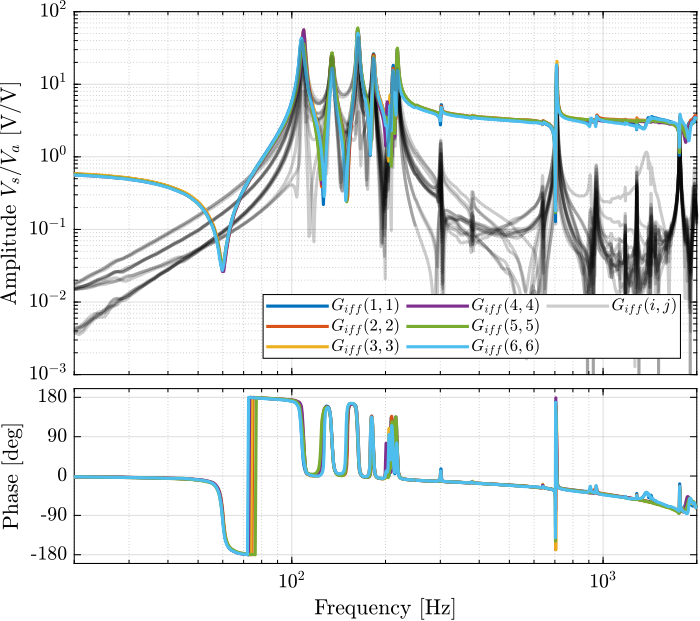

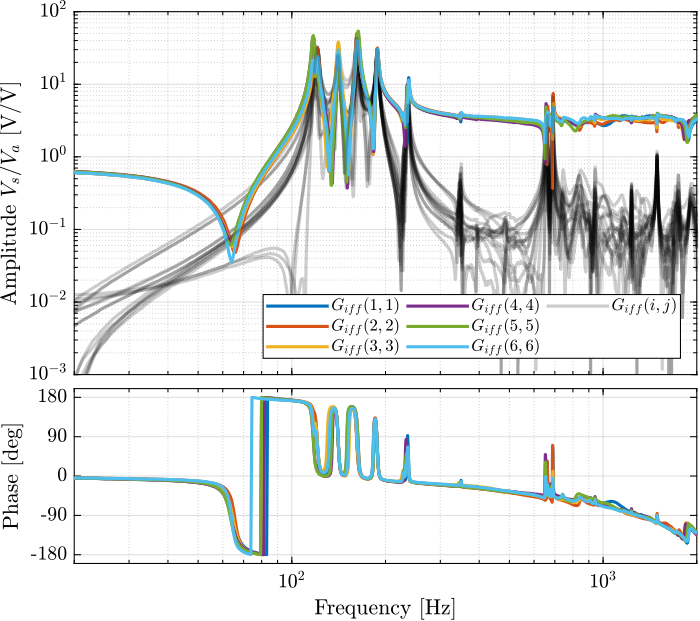

endThen the 6x6 transfer function matrix is estimated (Figure fig:enc_struts_iff_frf).

%% IFF Plant

G_iff = zeros(length(f), 6, 6);

for i = 1:6

G_iff_lf = tfestimate(meas_data_lf{i}.Va, meas_data_lf{i}.Vs, win, [], [], 1/Ts);

G_iff_hf = tfestimate(meas_data_hf{i}.Va, meas_data_hf{i}.Vs, win, [], [], 1/Ts);

G_iff(:,:,i) = [G_iff_lf(i_lf, :); G_iff_hf(i_hf, :)];

endSave Identified Plants

save('matlab/mat/identified_plants_enc_struts.mat', 'f', 'Ts', 'G_iff', 'G_dvf')Comparison with the Simscape Model

<<sec:enc_struts_comp_simscape>>

Introduction ignore

In this section, the measured dynamics is compared with the dynamics estimated from the Simscape model.

Load measured FRF

%% Load data

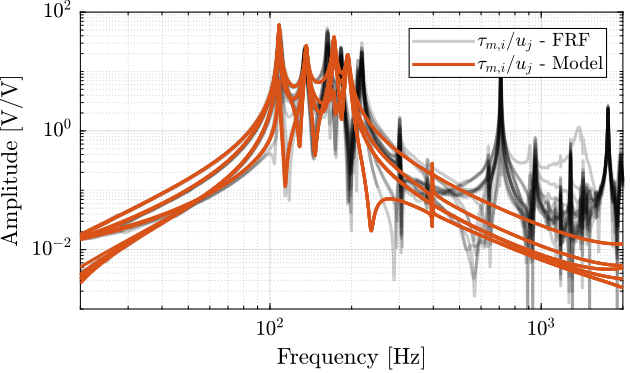

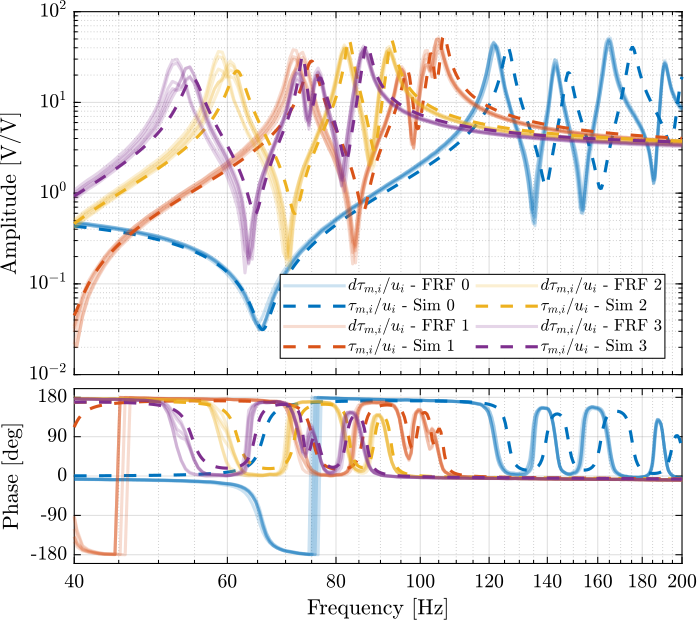

load('identified_plants_enc_struts.mat', 'f', 'Ts', 'G_iff', 'G_dvf')Dynamics from Actuator to Force Sensors

%% Initialize Nano-Hexapod

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', '2dof');%% Identify the IFF Plant (transfer function from u to taum)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/dum'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors

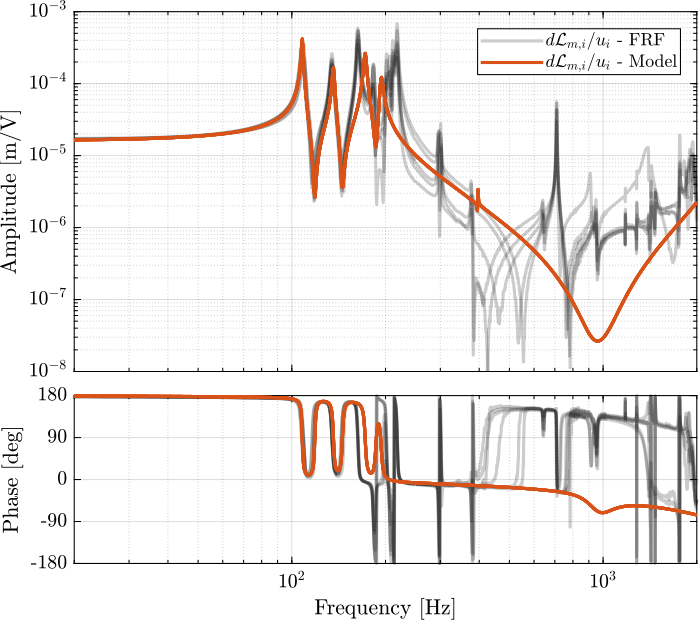

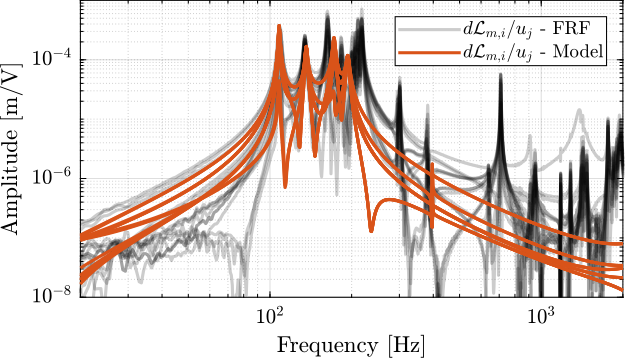

Giff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);Dynamics from Actuator to Encoder

%% Initialization of the Nano-Hexapod

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', 'flexible');%% Identify the DVF Plant (transfer function from u to dLm)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Encoders

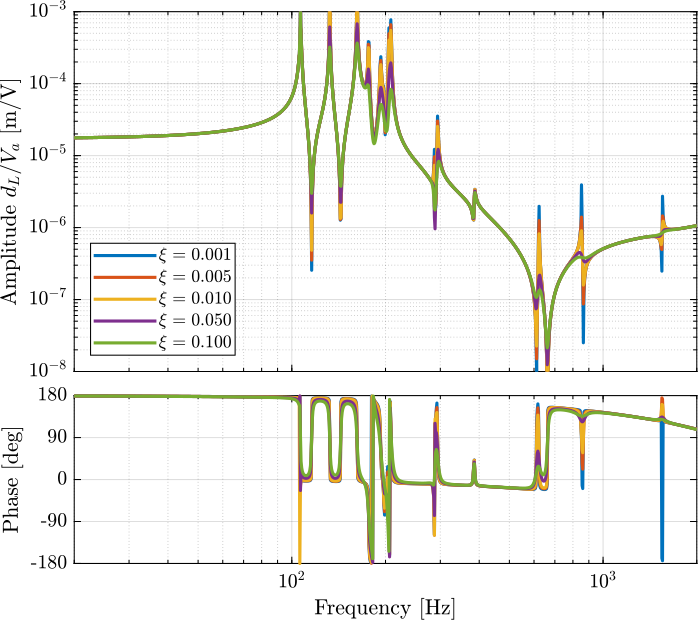

Gdvf = exp(-s*Ts)*linearize(mdl, io, 0.0, options);Effect of a change in bending damping of the joints

%% Tested bending dampings [Nm/(rad/s)]

cRs = [1e-3, 5e-3, 1e-2, 5e-2, 1e-1];%% Identify the DVF Plant (transfer function from u to dLm)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % EncodersThen the identification is performed for all the values of the bending damping.

%% Idenfity the transfer function from actuator to encoder for all bending dampins

Gs = {zeros(length(cRs), 1)};

for i = 1:length(cRs)

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', 'flexible', ...

'flex_bot_cRx', cRs(i), ...

'flex_bot_cRy', cRs(i), ...

'flex_top_cRx', cRs(i), ...

'flex_top_cRy', cRs(i));

G = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

G.InputName = {'Va1', 'Va2', 'Va3', 'Va4', 'Va5', 'Va6'};

G.OutputName = {'dL1', 'dL2', 'dL3', 'dL4', 'dL5', 'dL6'};

Gs(i) = {G};

end- Could be nice

- Actual damping is very small

Effect of a change in damping factor of the APA

%% Tested bending dampings [Nm/(rad/s)]

xis = [1e-3, 5e-3, 1e-2, 5e-2, 1e-1];%% Identify the DVF Plant (transfer function from u to dLm)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Encoders%% Idenfity the transfer function from actuator to encoder for all bending dampins

Gs = {zeros(length(xis), 1)};

for i = 1:length(xis)

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', 'flexible', ...

'actuator_xi', xis(i));

G = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

G.InputName = {'Va1', 'Va2', 'Va3', 'Va4', 'Va5', 'Va6'};

G.OutputName = {'dL1', 'dL2', 'dL3', 'dL4', 'dL5', 'dL6'};

Gs(i) = {G};

endDamping factor $\xi$ has a large impact on the damping of the "spurious resonances" at 200Hz and 300Hz.

Why is the damping factor does not change the damping of the first peak?

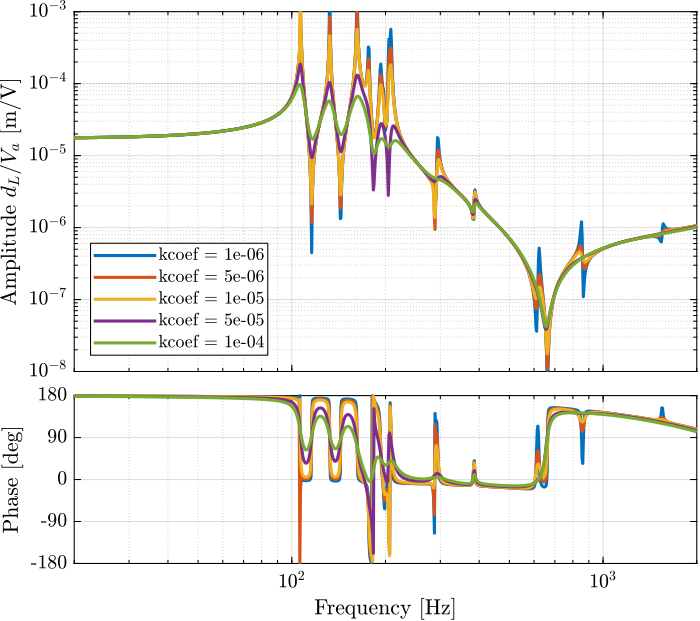

Effect of a change in stiffness damping coef of the APA

m_coef = 1e1;%% Tested bending dampings [Nm/(rad/s)]

k_coefs = [1e-6, 5e-6, 1e-5, 5e-5, 1e-4];%% Identify the DVF Plant (transfer function from u to dLm)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Encoders%% Idenfity the transfer function from actuator to encoder for all bending dampins

Gs = {zeros(length(k_coefs), 1)};

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', 'flexible');

for i = 1:length(k_coefs)

k_coef = k_coefs(i);

G = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

G.InputName = {'Va1', 'Va2', 'Va3', 'Va4', 'Va5', 'Va6'};

G.OutputName = {'dL1', 'dL2', 'dL3', 'dL4', 'dL5', 'dL6'};

Gs(i) = {G};

endEffect of a change in mass damping coef of the APA

k_coef = 1e-6;%% Tested bending dampings [Nm/(rad/s)]

m_coefs = [1e1, 5e1, 1e2, 5e2, 1e3];%% Identify the DVF Plant (transfer function from u to dLm)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Encoders%% Idenfity the transfer function from actuator to encoder for all bending dampins

Gs = {zeros(length(m_coefs), 1)};

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', 'flexible');

for i = 1:length(m_coefs)

m_coef = m_coefs(i);

G = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

G.InputName = {'Va1', 'Va2', 'Va3', 'Va4', 'Va5', 'Va6'};

G.OutputName = {'dL1', 'dL2', 'dL3', 'dL4', 'dL5', 'dL6'};

Gs(i) = {G};

endTODO Using Flexible model

d_aligns = [[-0.05, -0.3, 0];

[ 0, 0.5, 0];

[-0.1, -0.3, 0];

[ 0, 0.3, 0];

[-0.05, 0.05, 0];

[0, 0, 0]]*1e-3;d_aligns = zeros(6,3);

% d_aligns(1,:) = [-0.05, -0.3, 0]*1e-3;

d_aligns(2,:) = [ 0, 0.3, 0]*1e-3;%% Initialize Nano-Hexapod

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', 'flexible', ...

'actuator_d_align', d_aligns);Why do we have smaller resonances when using flexible APA? On the test bench we have the same resonance as the 2DoF model. Could it be due to the compliance in other dof of the flexible model?

%% Identify the DVF Plant (transfer function from u to dLm)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Encoders

Gdvf = exp(-s*Ts)*linearize(mdl, io, 0.0, options);%% Identify the IFF Plant (transfer function from u to taum)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/dum'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors

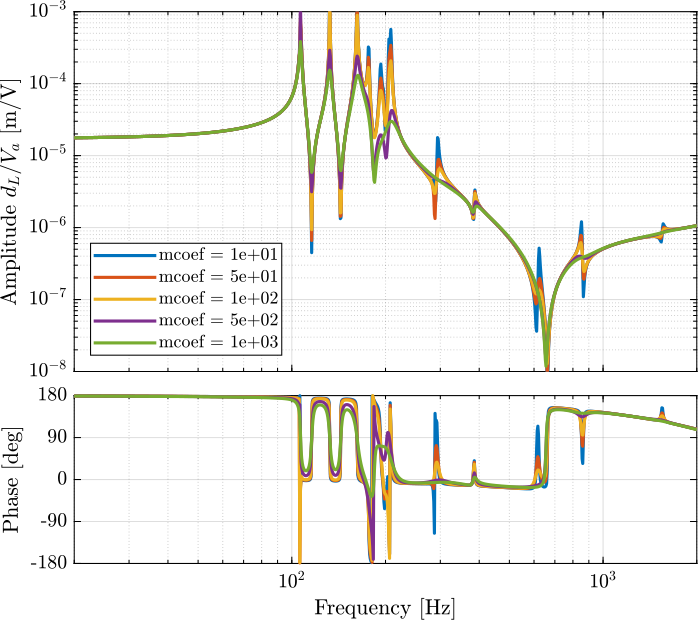

Giff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);Flexible model + encoders fixed to the plates

%% Identify the IFF Plant (transfer function from u to taum)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensorsd_aligns = [[-0.05, -0.3, 0];

[ 0, 0.5, 0];

[-0.1, -0.3, 0];

[ 0, 0.3, 0];

[-0.05, 0.05, 0];

[0, 0, 0]]*1e-3;%% Initialize Nano-Hexapod

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', 'flexible', ...

'actuator_d_align', d_aligns);Gdvf_struts = exp(-s*Ts)*linearize(mdl, io, 0.0, options);%% Initialize Nano-Hexapod

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'plates', ...

'actuator_type', 'flexible', ...

'actuator_d_align', d_aligns);Gdvf_plates = exp(-s*Ts)*linearize(mdl, io, 0.0, options);Integral Force Feedback

<<sec:enc_struts_iff>>

Introduction ignore

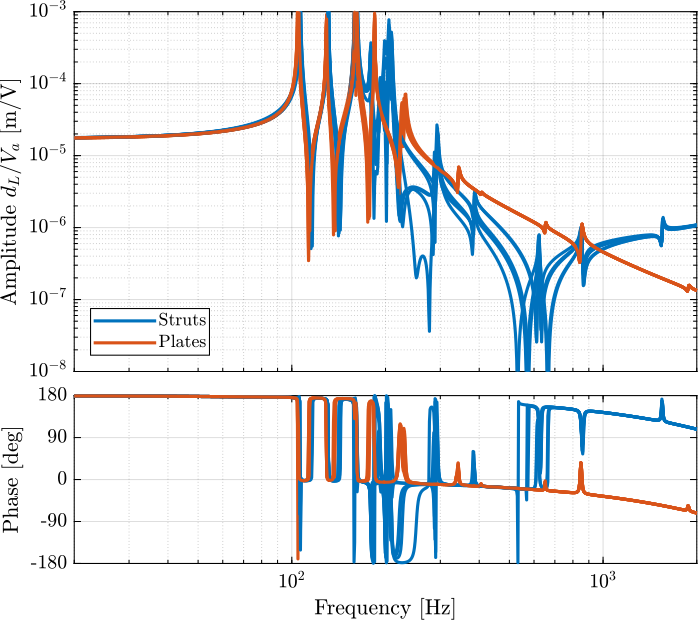

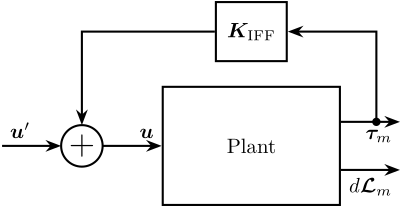

In this section, the Integral Force Feedback (IFF) control strategy is applied to the nano-hexapod. The main goal of this to add damping to the nano-hexapod's modes.

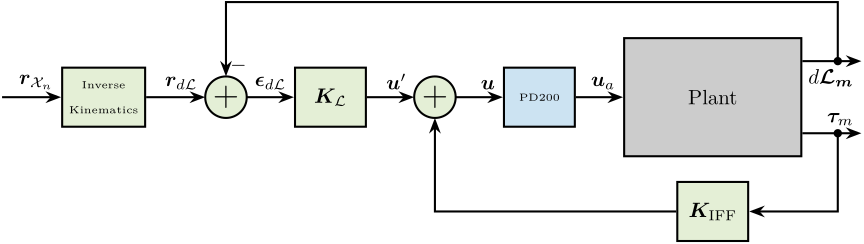

The control architecture is shown in Figure fig:control_architecture_iff_struts where $\bm{K}_\text{IFF}$ is a diagonal $6 \times 6$ controller.

The system as then a new input $\bm{u}^\prime$, and the transfer function from $\bm{u}^\prime$ to $d\bm{\mathcal{L}}_m$ should be easier to control than the initial transfer function from $\bm{u}$ to $d\bm{\mathcal{L}}_m$.

\begin{tikzpicture}

% Blocs

\node[block={3.0cm}{2.0cm}] (P) {Plant};

\coordinate[] (inputF) at ($(P.south west)!0.5!(P.north west)$);

\coordinate[] (outputF) at ($(P.south east)!0.7!(P.north east)$);

\coordinate[] (outputL) at ($(P.south east)!0.3!(P.north east)$);

\node[block, above=0.4 of P] (Kiff) {$\bm{K}_\text{IFF}$};

\node[addb, left= of inputF] (addF) {};

% Connections and labels

\draw[->] (outputF) -- ++(1, 0) node[below left]{$\bm{\tau}_m$};

\draw[->] (outputL) -- ++(1, 0) node[below left]{$d\bm{\mathcal{L}}_m$};

\draw[->] ($(outputF) + (0.6, 0)$)node[branch]{} |- (Kiff.east);

\draw[->] (Kiff.west) -| (addF.north);

\draw[->] (addF.east) -- (inputF) node[above left]{$\bm{u}$};

\draw[<-] (addF.west) -- ++(-1, 0) node[above right]{$\bm{u}^\prime$};

\end{tikzpicture}This section is structured as follow:

- Section sec:iff_struts_plant_id: Using the Simscape model (APA taken as 2DoF model), the transfer function from $\bm{u}$ to $\bm{\tau}_m$ is identified. Based on the obtained dynamics, the control law is developed and the optimal gain is estimated using the Root Locus.

- Section sec:iff_struts_effect_plant: Still using the Simscape model, the effect of the IFF gain on the the transfer function from $\bm{u}^\prime$ to $d\bm{\mathcal{L}}_m$ is studied.

- Section sec:iff_struts_effect_plant_exp: The same is performed experimentally: several IFF gains are used and the damped plant is identified each time.

- Section sec:iff_struts_opt_gain: The damped model and the identified damped system are compared for the optimal IFF gain. It is found that IFF indeed adds a lot of damping into the system. However it is not efficient in damping the spurious struts modes.

- Section sec:iff_struts_comp_flex_model: Finally, a "flexible" model of the APA is used in the Simscape model and the optimally damped model is compared with the measurements.

IFF Control Law and Optimal Gain

<<sec:iff_struts_plant_id>>

Let's use a model of the Nano-Hexapod with the encoders fixed to the struts and the APA taken as 2DoF model.

%% Initialize Nano-Hexapod

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', '2dof');The transfer function from $\bm{u}$ to $\bm{\tau}_m$ is identified.

%% Identify the IFF Plant (transfer function from u to taum)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/dum'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors

Giff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);The IFF controller is defined as shown below:

%% IFF Controller

Kiff_g1 = -(1/(s + 2*pi*40))*... % LPF: provides integral action above 40Hz

(s/(s + 2*pi*30))*... % HPF: limit low frequency gain

(1/(1 + s/2/pi/500))*... % LPF: more robust to high frequency resonances

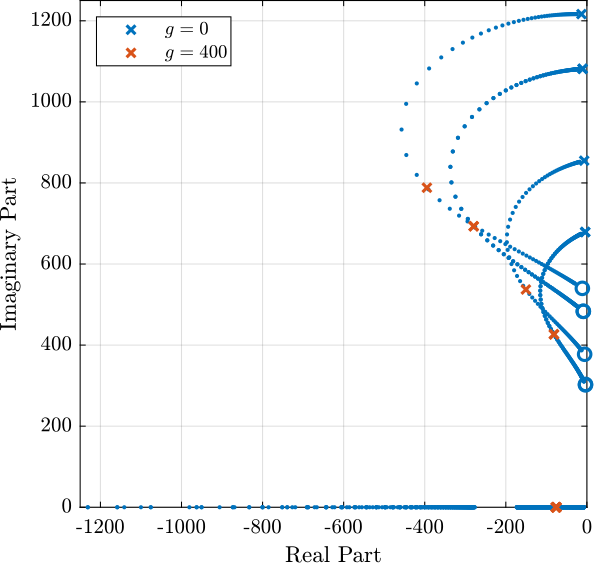

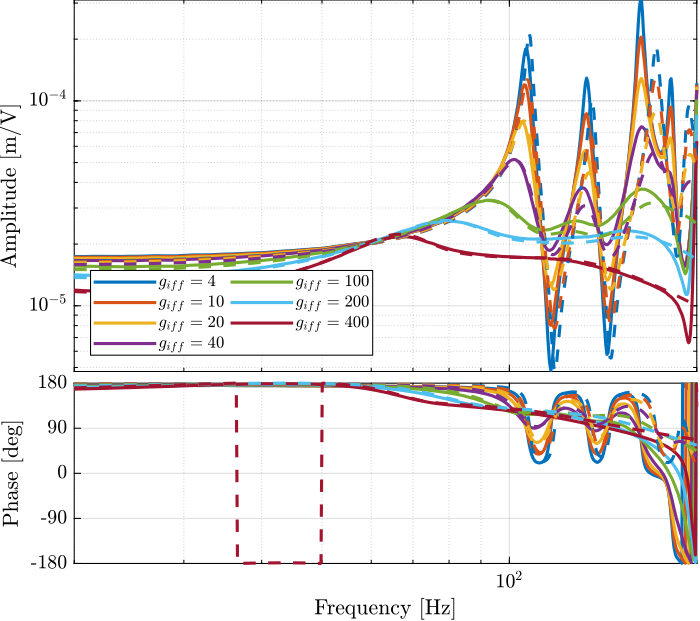

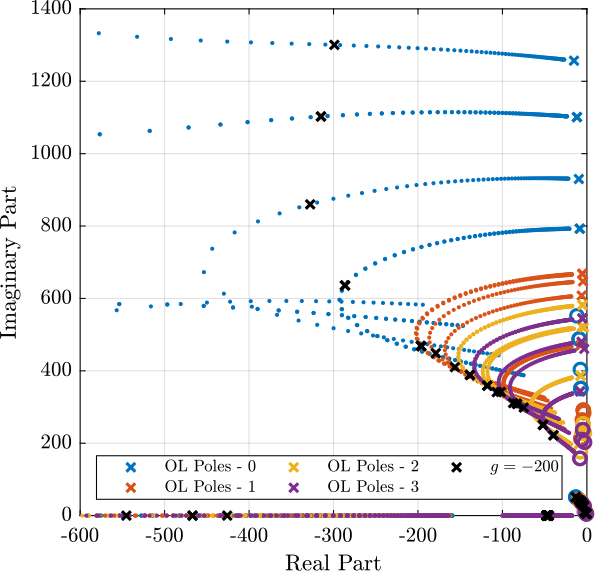

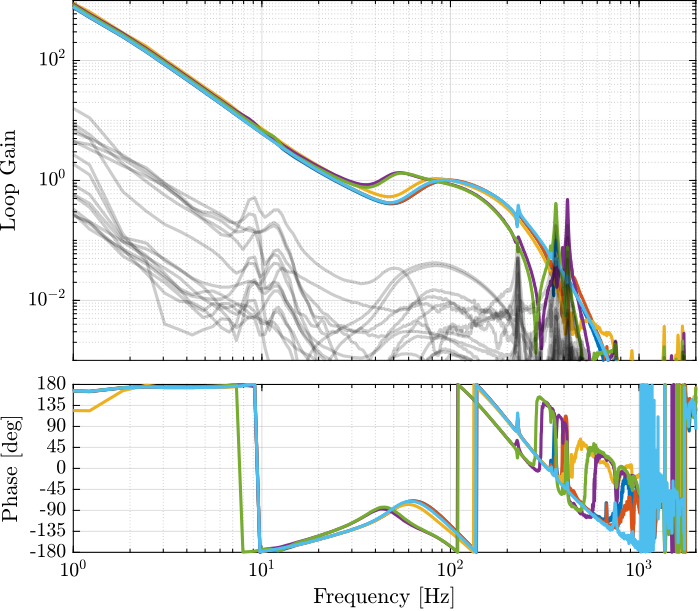

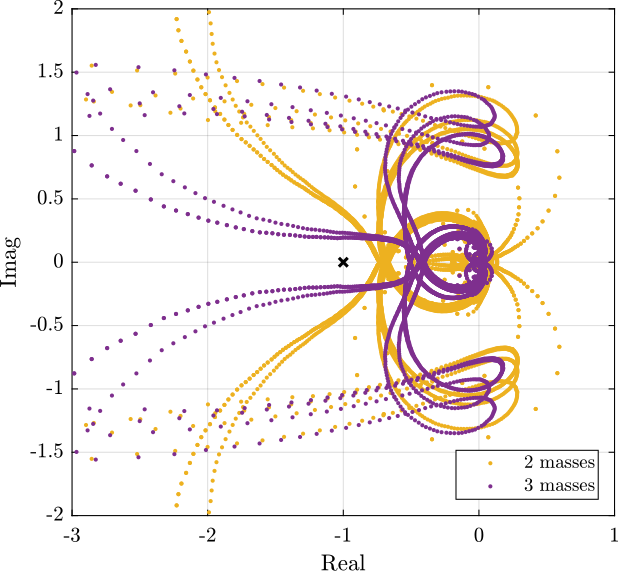

eye(6); % Diagonal 6x6 controllerThen, the poles of the system are shown in the complex plane as a function of the controller gain (i.e. Root Locus plot) in Figure fig:enc_struts_iff_root_locus. A gain of $400$ is chosen as the "optimal" gain as it visually seems to be the gain that adds the maximum damping to all the suspension modes simultaneously.

Then the "optimal" IFF controller is:

%% IFF controller with Optimal gain

Kiff = 400*Kiff_g1;And it is saved for further use.

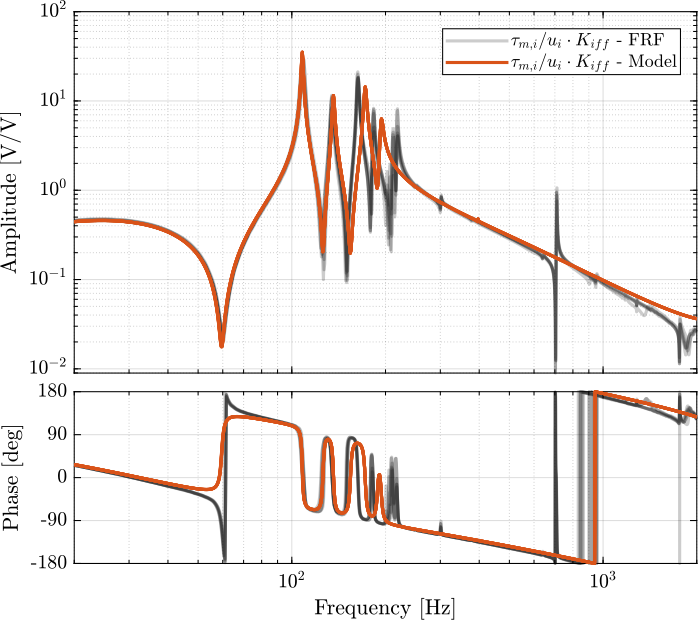

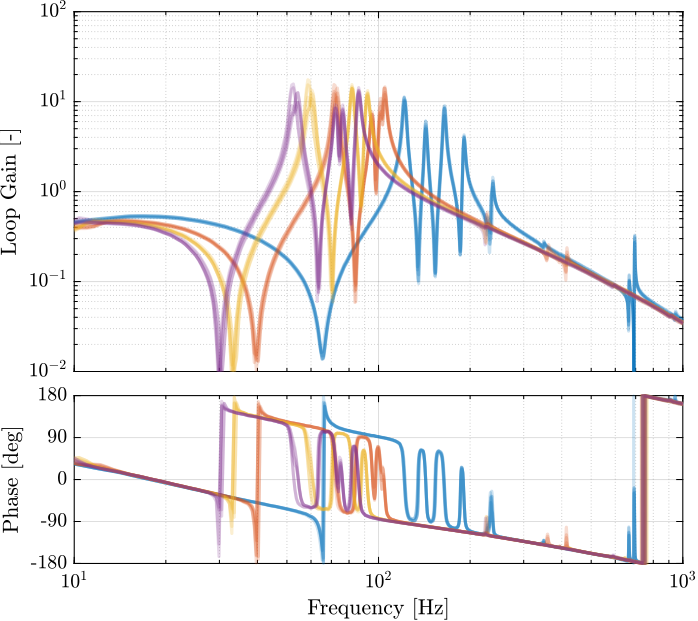

save('mat/Kiff.mat', 'Kiff')The bode plots of the "diagonal" elements of the loop gain are shown in Figure fig:enc_struts_iff_opt_loop_gain. It is shown that the phase and gain margins are quite high and the loop gain is large arround the resonances.

Effect of IFF on the plant - Simulations

<<sec:iff_struts_effect_plant>>

Still using the Simscape model with encoders fixed to the struts and 2DoF APA, the IFF strategy is tested.

%% Initialize the Simscape model in closed loop

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', '2dof', ...

'controller_type', 'iff');The following IFF gains are tried:

%% Tested IFF gains

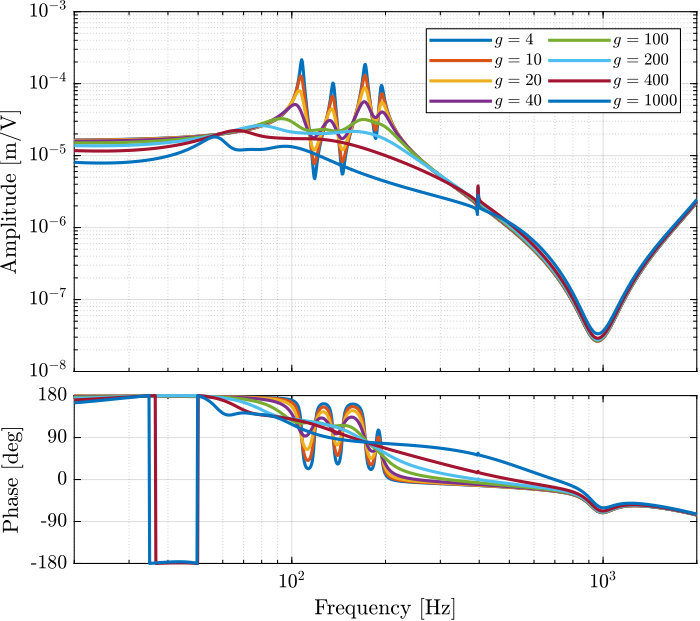

iff_gains = [4, 10, 20, 40, 100, 200, 400];And the transfer functions from $\bm{u}^\prime$ to $d\bm{\mathcal{L}}_m$ are identified for all the IFF gains.

%% Identify the (damped) transfer function from u to dLm for different values of the IFF gain

Gd_iff = {zeros(1, length(iff_gains))};

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Strut Displacement (encoder)

for i = 1:length(iff_gains)

Kiff = iff_gains(i)*Kiff_g1*eye(6); % IFF Controller

Gd_iff(i) = {exp(-s*Ts)*linearize(mdl, io, 0.0, options)};

isstable(Gd_iff{i})

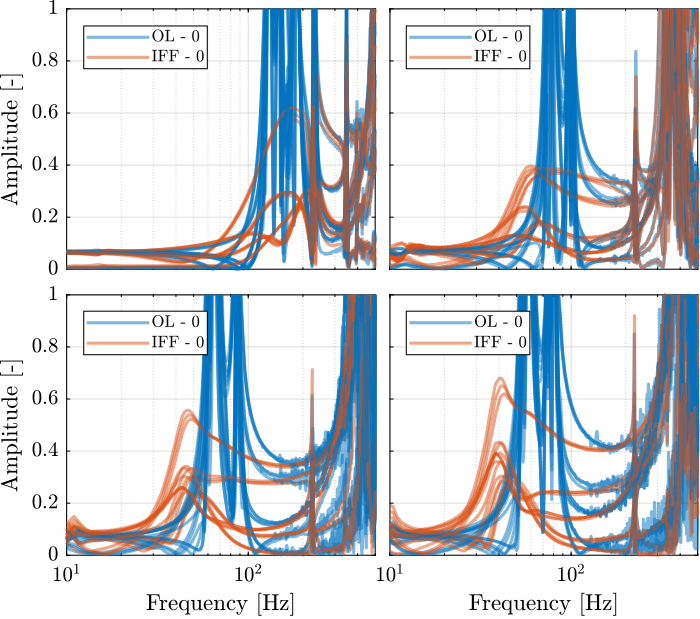

endThe obtained dynamics are shown in Figure fig:enc_struts_iff_gains_effect_dvf_plant.

Effect of IFF on the plant - Experimental Results

<<sec:iff_struts_effect_plant_exp>>

Introduction ignore

The IFF strategy is applied experimentally and the transfer function from $\bm{u}^\prime$ to $d\bm{\mathcal{L}}_m$ is identified for all the defined values of the gain.

Load Data

First load the identification data.

%% Load Identification Data

meas_iff_gains = {};

for i = 1:length(iff_gains)

meas_iff_gains(i) = {load(sprintf('mat/iff_strut_1_noise_g_%i.mat', iff_gains(i)), 't', 'Vexc', 'Vs', 'de', 'u')};

endSpectral Analysis - Setup

And define the useful variables that will be used for the identification using the tfestimate function.

%% Setup useful variables

% Sampling Time [s]

Ts = (meas_iff_gains{1}.t(end) - (meas_iff_gains{1}.t(1)))/(length(meas_iff_gains{1}.t)-1);

% Sampling Frequency [Hz]

Fs = 1/Ts;

% Hannning Windows

win = hanning(ceil(1*Fs));

% And we get the frequency vector

[~, f] = tfestimate(meas_iff_gains{1}.Vexc, meas_iff_gains{1}.de, win, [], [], 1/Ts);DVF Plant

The transfer functions are estimated for all the values of the gain.

%% DVF Plant (transfer function from u to dLm)

G_iff_gains = {};

for i = 1:length(iff_gains)

G_iff_gains{i} = tfestimate(meas_iff_gains{i}.Vexc, meas_iff_gains{i}.de(:,1), win, [], [], 1/Ts);

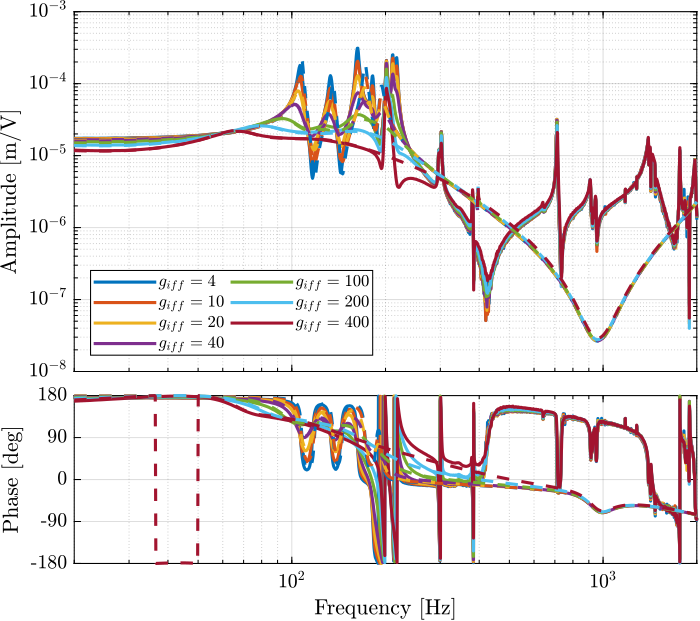

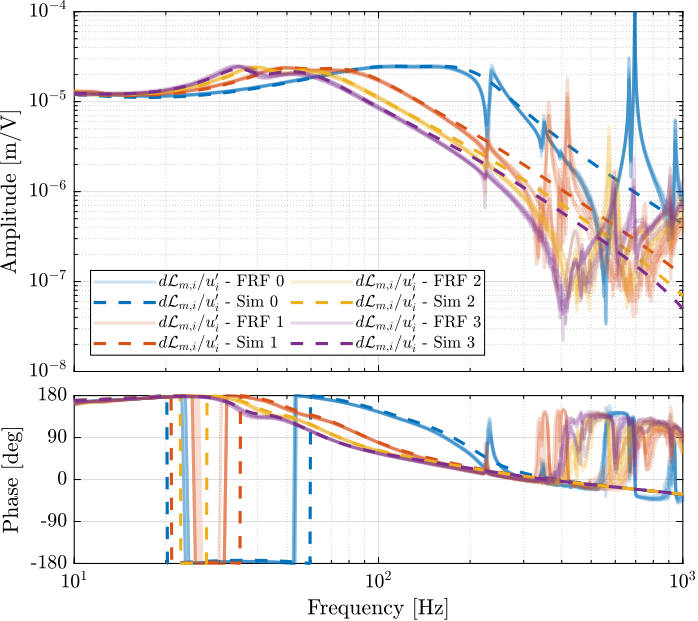

endThe obtained dynamics as shown in the bode plot in Figure fig:comp_iff_gains_dvf_plant. The dashed curves are the results obtained using the model, and the solid curves the results from the experimental identification.

The bode plot is then zoomed on the suspension modes of the nano-hexapod in Figure fig:comp_iff_gains_dvf_plant_zoom.

The IFF control strategy is very effective for the damping of the suspension modes. It however does not damp the modes at 200Hz, 300Hz and 400Hz (flexible modes of the APA).

Also, the experimental results and the models obtained from the Simscape model are in agreement concerning the damped system (up to the flexible modes).

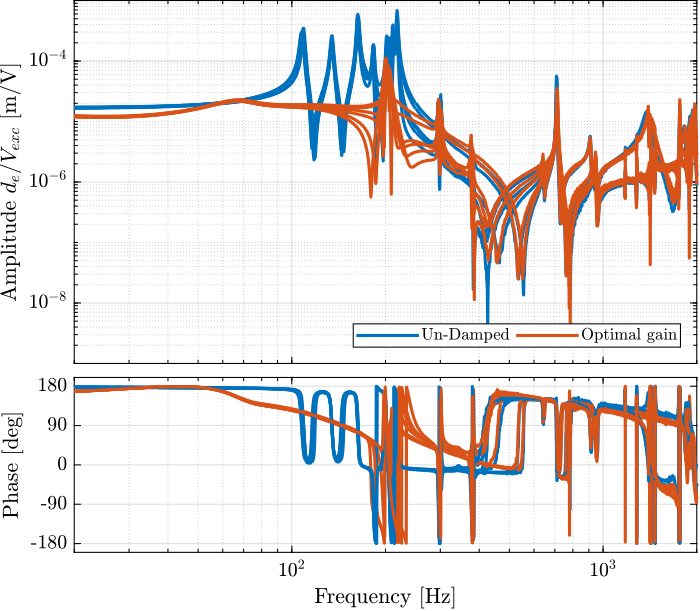

Experimental Results - Comparison of the un-damped and fully damped system

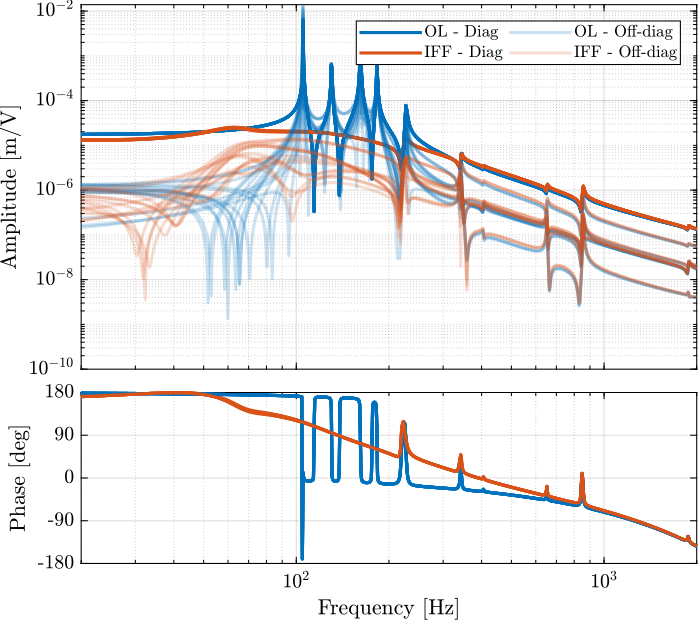

The un-damped and damped experimental plants are compared in Figure fig:comp_undamped_opt_iff_gain_diagonal (diagonal terms).

It is very clear that all the suspension modes are very well damped thanks to IFF. However, there is little to no effect on the flexible modes of the struts and of the plate.

Experimental Results - Damped Plant with Optimal gain

<<sec:iff_struts_opt_gain>>

Introduction ignore

Let's now look at the $6 \times 6$ damped plant with the optimal gain $g = 400$.

Load Data

The experimental data are loaded.

%% Load Identification Data

meas_iff_struts = {};

for i = 1:6

meas_iff_struts(i) = {load(sprintf('mat/iff_strut_%i_noise_g_400.mat', i), 't', 'Vexc', 'Vs', 'de', 'u')};

endSpectral Analysis - Setup

And the parameters useful for the spectral analysis are defined.

%% Setup useful variables

% Sampling Time [s]

Ts = (meas_iff_struts{1}.t(end) - (meas_iff_struts{1}.t(1)))/(length(meas_iff_struts{1}.t)-1);

% Sampling Frequency [Hz]

Fs = 1/Ts;

% Hannning Windows

win = hanning(ceil(1*Fs));

% And we get the frequency vector

[~, f] = tfestimate(meas_iff_struts{1}.Vexc, meas_iff_struts{1}.de, win, [], [], 1/Ts);DVF Plant

Finally, the $6 \times 6$ plant is identified using the tfestimate function.

%% DVF Plant (transfer function from u to dLm)

G_iff_opt = {};

for i = 1:6

G_iff_opt{i} = tfestimate(meas_iff_struts{i}.Vexc, meas_iff_struts{i}.de, win, [], [], 1/Ts);

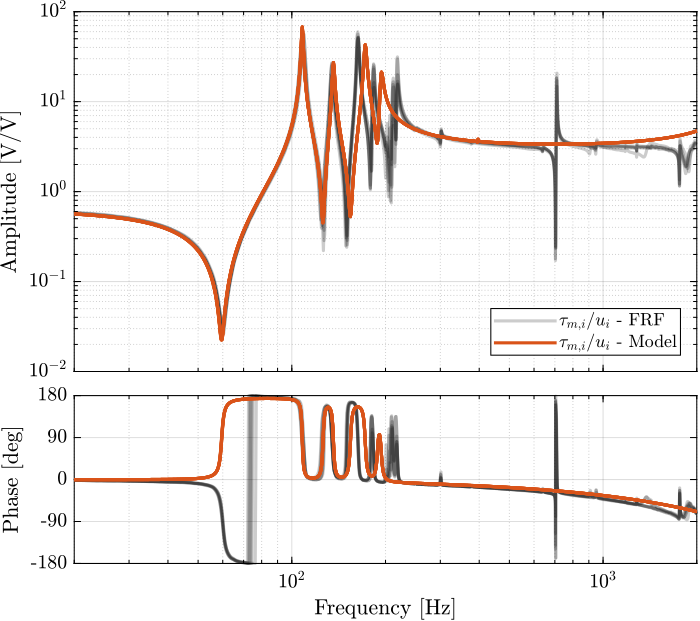

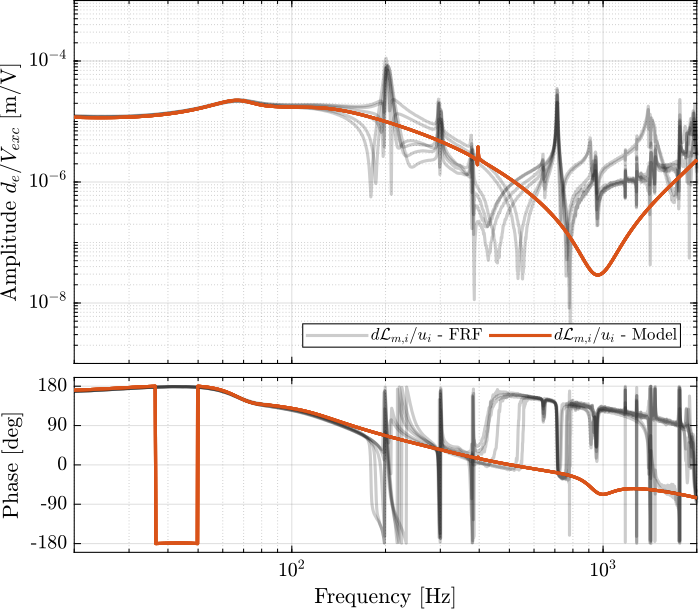

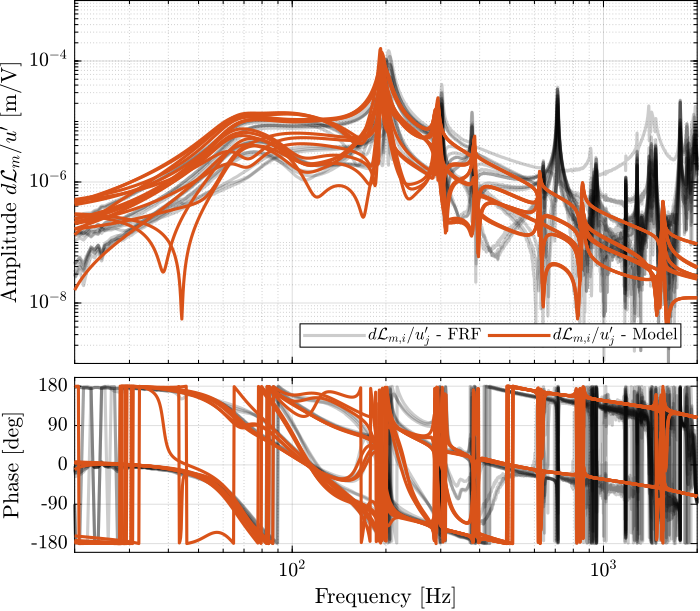

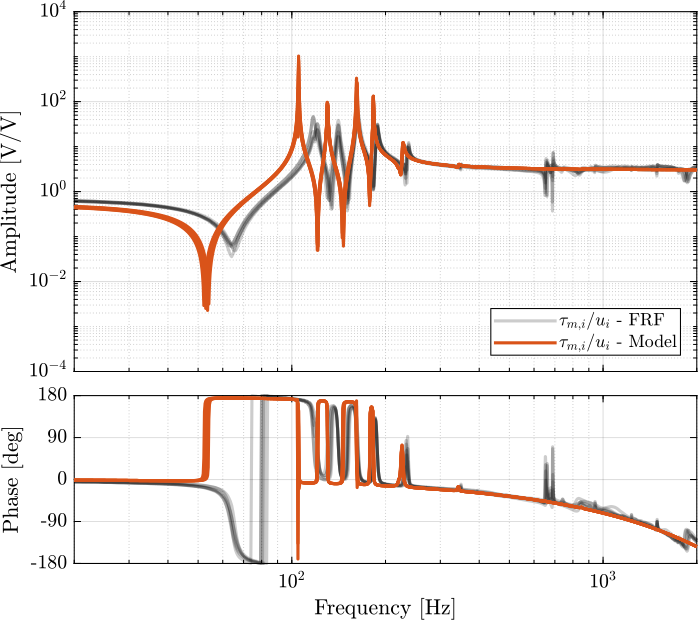

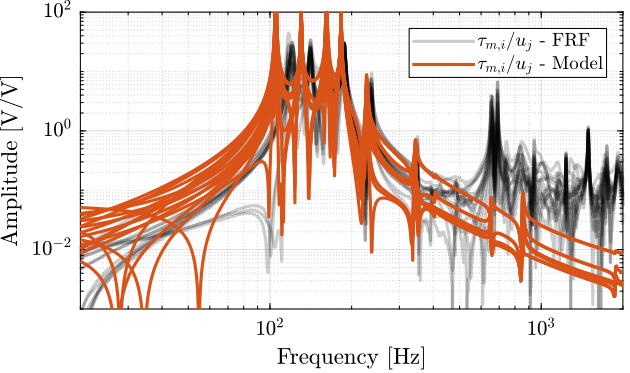

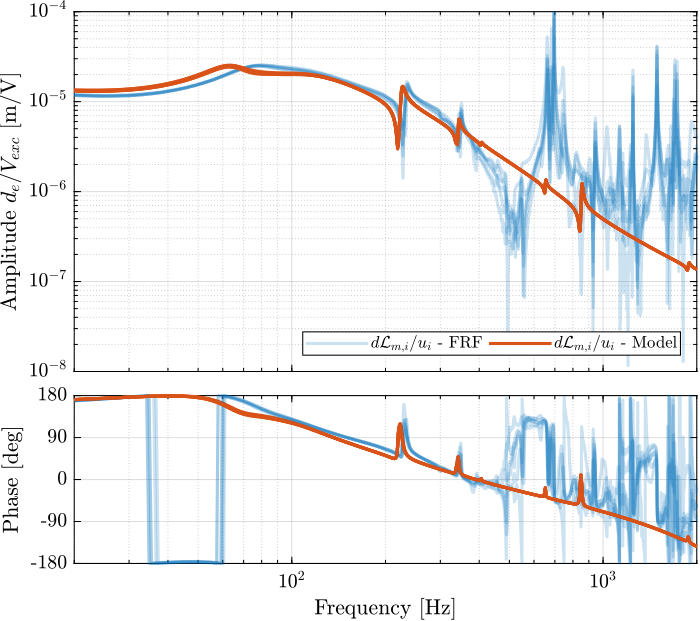

endThe obtained diagonal elements are compared with the model in Figure fig:damped_iff_plant_comp_diagonal.

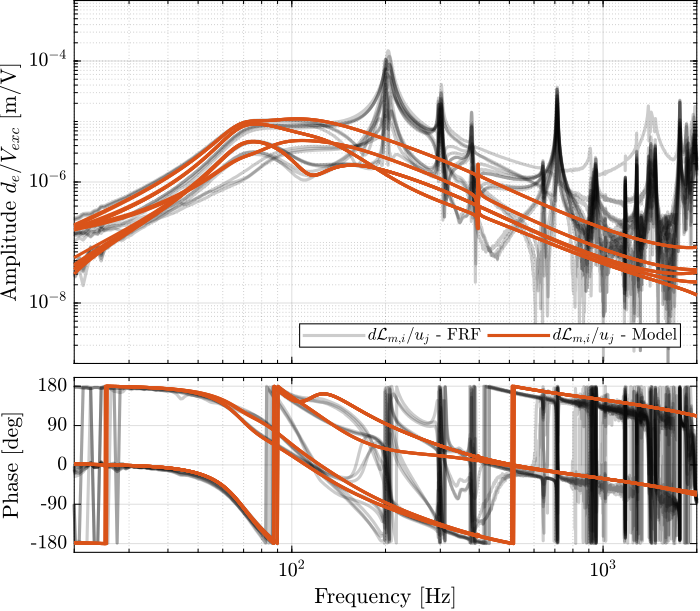

And all the off-diagonal elements are compared with the model in Figure fig:damped_iff_plant_comp_off_diagonal.

With the IFF control strategy applied and the optimal gain used, the suspension modes are very well damped. Remains the un-damped flexible modes of the APA (200Hz, 300Hz, 400Hz), and the modes of the plates (700Hz).

The Simscape model and the experimental results are in very good agreement.

Comparison with the Flexible model

<<sec:iff_struts_comp_flex_model>>

When using the 2-DoF model for the APA, the flexible modes of the struts were not modelled, and it was the main limitation of the model. Now, let's use a flexible model for the APA, and see if the obtained damped plant using the model is similar to the measured dynamics.

First, the nano-hexapod is initialized.

%% Estimated misalignement of the struts

d_aligns = [[-0.05, -0.3, 0];

[ 0, 0.5, 0];

[-0.1, -0.3, 0];

[ 0, 0.3, 0];

[-0.05, 0.05, 0];

[0, 0, 0]]*1e-3;

%% Initialize Nano-Hexapod

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', 'flexible', ...

'actuator_d_align', d_aligns, ...

'controller_type', 'iff');And the "optimal" controller is loaded.

%% Optimal IFF controller

load('Kiff.mat', 'Kiff');The transfer function from $\bm{u}^\prime$ to $d\bm{\mathcal{L}}_m$ is identified using the Simscape model.

%% Linearized inputs/outputs

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Strut Displacement (encoder)

%% Identification of the plant

Gd_iff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);The obtained diagonal elements are shown in Figure fig:enc_struts_iff_opt_damp_comp_flex_model_diag while the off-diagonal elements are shown in Figure fig:enc_struts_iff_opt_damp_comp_flex_model_off_diag.

Using flexible models for the APA, the agreement between the Simscape model of the nano-hexapod and the measured FRF is very good.

Only the flexible mode of the top-plate is not appearing in the model which is very logical as the top plate is taken as a solid body.

Conclusion

The decentralized Integral Force Feedback strategy applied on the nano-hexapod is very effective in damping all the suspension modes.

The Simscape model (especially when using a flexible model for the APA) is shown to be very accurate, even when IFF is applied.

Modal Analysis

<<sec:enc_struts_modal_analysis>>

Introduction ignore

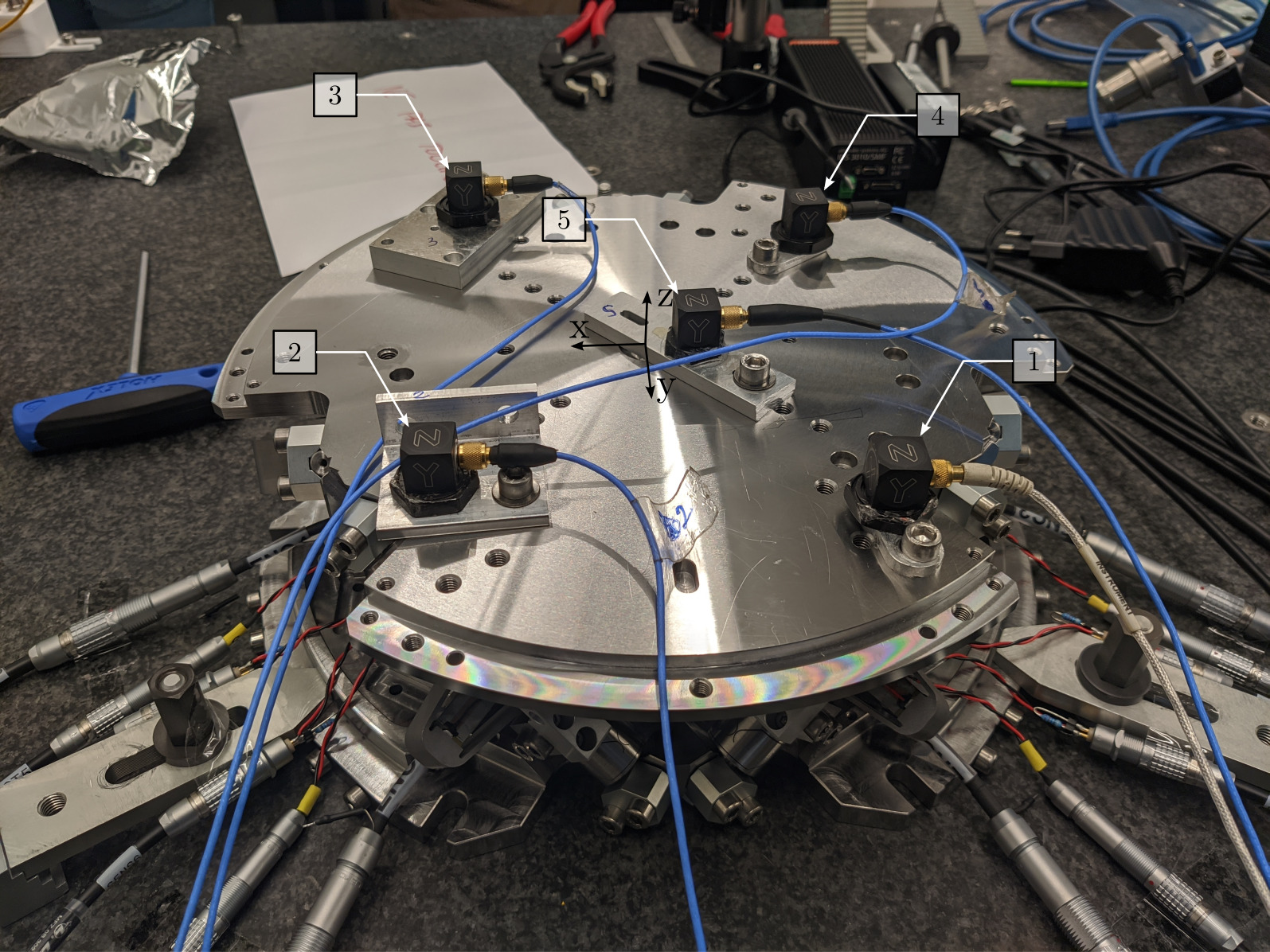

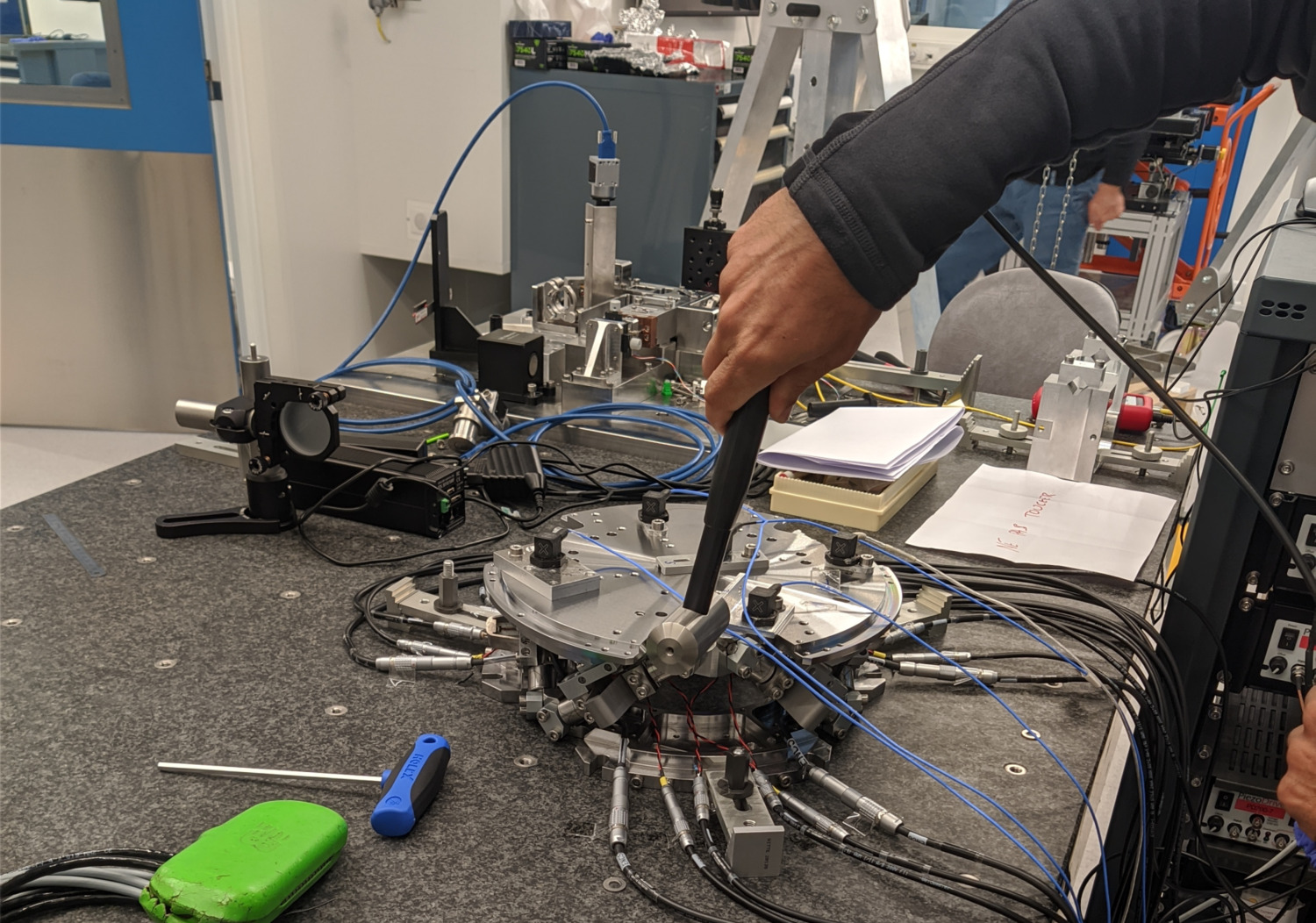

Several 3-axis accelerometers are fixed on the top platform of the nano-hexapod as shown in Figure fig:compliance_vertical_comp_iff.

The top platform is then excited using an instrumented hammer as shown in Figure fig:hammer_excitation_compliance_meas.

From this experiment, the resonance frequencies and the associated mode shapes can be computed (Section sec:modal_analysis_mode_shapes). Then, in Section sec:compliance_effect_iff, the vertical compliance of the nano-hexapod is experimentally estimated. Finally, in Section sec:compliance_effect_iff_comp_model, the measured compliance is compare with the estimated one from the Simscape model.

Obtained Mode Shapes

<<sec:modal_analysis_mode_shapes>>

We can observe the mode shapes of the first 6 modes that are the suspension modes (the plate is behaving as a solid body) in Figure fig:mode_shapes_annotated.

Then, there is a mode at 692Hz which corresponds to a flexible mode of the top plate (Figure fig:mode_shapes_flexible_annotated).

The obtained modes are summarized in Table tab:description_modes.

| Mode | Freq. [Hz] | Description |

|---|---|---|

| 1 | 105 | Suspension Mode: Y-translation |

| 2 | 107 | Suspension Mode: X-translation |

| 3 | 131 | Suspension Mode: Z-translation |

| 4 | 161 | Suspension Mode: Y-tilt |

| 5 | 162 | Suspension Mode: X-tilt |

| 6 | 180 | Suspension Mode: Z-rotation |

| 7 | 692 | (flexible) Membrane mode of the top platform |

Nano-Hexapod Compliance - Effect of IFF

<<sec:compliance_effect_iff>>

In this section, we wish to estimated the effectiveness of the IFF strategy concerning the compliance.

The top plate is excited vertically using the instrumented hammer two times:

- no control loop is used

- decentralized IFF is used

The data is loaded.

frf_ol = load('Measurement_Z_axis.mat'); % Open-Loop

frf_iff = load('Measurement_Z_axis_damped.mat'); % IFFThe mean vertical motion of the top platform is computed by averaging all 5 accelerometers.

%% Multiply by 10 (gain in m/s^2/V) and divide by 5 (number of accelerometers)

d_frf_ol = 10/5*(frf_ol.FFT1_H1_4_1_RMS_Y_Mod + frf_ol.FFT1_H1_7_1_RMS_Y_Mod + frf_ol.FFT1_H1_10_1_RMS_Y_Mod + frf_ol.FFT1_H1_13_1_RMS_Y_Mod + frf_ol.FFT1_H1_16_1_RMS_Y_Mod)./(2*pi*frf_ol.FFT1_H1_16_1_RMS_X_Val).^2;

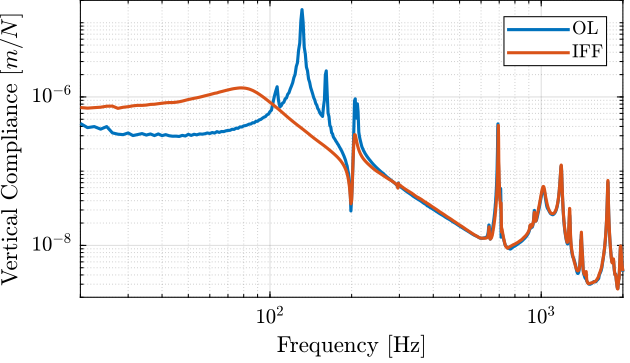

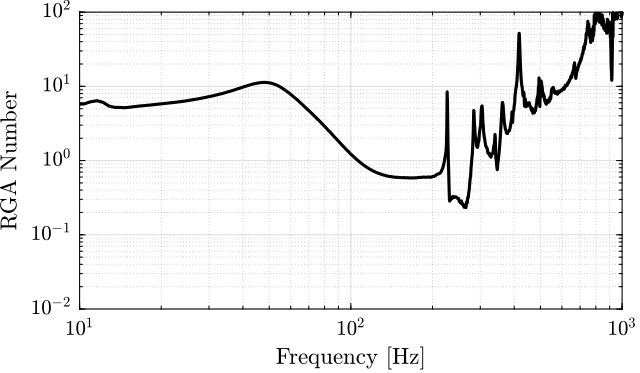

d_frf_iff = 10/5*(frf_iff.FFT1_H1_4_1_RMS_Y_Mod + frf_iff.FFT1_H1_7_1_RMS_Y_Mod + frf_iff.FFT1_H1_10_1_RMS_Y_Mod + frf_iff.FFT1_H1_13_1_RMS_Y_Mod + frf_iff.FFT1_H1_16_1_RMS_Y_Mod)./(2*pi*frf_iff.FFT1_H1_16_1_RMS_X_Val).^2;The vertical compliance (magnitude of the transfer function from a vertical force applied on the top plate to the vertical motion of the top plate) is shown in Figure fig:compliance_vertical_comp_iff.

From Figure fig:compliance_vertical_comp_iff, it is clear that the IFF control strategy is very effective in damping the suspensions modes of the nano-hexapod. It also has the effect of (slightly) degrading the vertical compliance at low frequency.

It also seems some damping can be added to the modes at around 205Hz which are flexible modes of the struts.

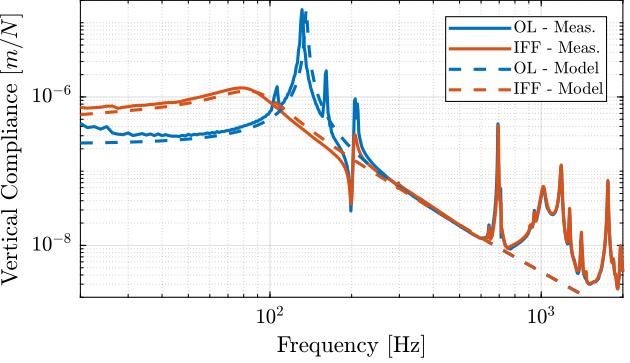

Comparison with the Simscape Model

<<sec:compliance_effect_iff_comp_model>>

Let's now compare the measured vertical compliance with the vertical compliance as estimated from the Simscape model.

The transfer function from a vertical external force to the absolute motion of the top platform is identified (with and without IFF) using the Simscape model.

The comparison is done in Figure fig:compliance_vertical_comp_model_iff. Again, the model is quite accurate!

Conclusion

From the previous analysis, several conclusions can be drawn:

- Decentralized IFF is very effective in damping the "suspension" modes of the nano-hexapod (Figure fig:comp_undamped_opt_iff_gain_diagonal)

- Decentralized IFF does not damp the "spurious" modes of the struts nor the flexible modes of the top plate (Figure fig:comp_undamped_opt_iff_gain_diagonal)

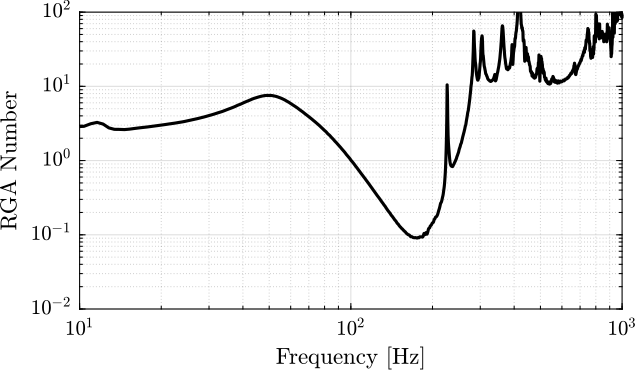

- Even though the Simscape model and the experimentally measured FRF are in good agreement (Figures fig:enc_struts_iff_opt_damp_comp_flex_model_diag and fig:enc_struts_iff_opt_damp_comp_flex_model_off_diag), the obtain dynamics from the control inputs $\bm{u}$ and the encoders $d\bm{\mathcal{L}}_m$ is very difficult to control

Therefore, in the following sections, the encoders will be fixed to the plates. The goal is to be less sensitive to the flexible modes of the struts.

Encoders fixed to the plates - Dynamics

<<sec:encoders_plates>>

Introduction ignore

In this section, the encoders are fixed to the plates rather than to the struts as shown in Figure fig:enc_fixed_to_struts.

It is structured as follow:

- Section sec:enc_plates_plant_id: The dynamics of the nano-hexapod is identified.

- Section sec:enc_plates_comp_simscape: The identified dynamics is compared with the Simscape model.

- Section sec:enc_plates_iff: The Integral Force Feedback (IFF) control strategy is applied and the dynamics of the damped nano-hexapod is identified and compare with the Simscape model.

Identification of the dynamics

<<sec:enc_plates_plant_id>>

Introduction ignore

In this section, the dynamics of the nano-hexapod with the encoders fixed to the plates is identified.

First, the measurement data are loaded in Section sec:enc_plates_plant_id_setup, then the transfer function matrix from the actuators to the encoders are estimated in Section sec:enc_plates_plant_id_dvf. Finally, the transfer function matrix from the actuators to the force sensors is estimated in Section sec:enc_plates_plant_id_iff.

Data Loading and Spectral Analysis Setup

<<sec:enc_plates_plant_id_setup>>

The actuators are excited one by one using a low pass filtered white noise. For each excitation, the 6 force sensors and 6 encoders are measured and saved.

%% Load Identification Data

meas_data_lf = {};

for i = 1:6

meas_data_lf(i) = {load(sprintf('mat/frf_exc_strut_%i_enc_plates_noise.mat', i), 't', 'Va', 'Vs', 'de')};

endTransfer function from Actuator to Encoder

<<sec:enc_plates_plant_id_dvf>>

Let's compute the coherence from the excitation voltage $\bm{u}$ and the displacement $d\bm{\mathcal{L}}_m$ as measured by the encoders.

%% Coherence

coh_dvf = zeros(length(f), 6, 6);

for i = 1:6

coh_dvf(:, :, i) = mscohere(meas_data_lf{i}.Va, meas_data_lf{i}.de, win, [], [], 1/Ts);

endThe obtained coherence shown in Figure fig:enc_plates_dvf_coh is quite good up to 400Hz.

Then the 6x6 transfer function matrix is estimated.

%% DVF Plant (transfer function from u to dLm)

G_dvf = zeros(length(f), 6, 6);

for i = 1:6

G_dvf(:,:,i) = tfestimate(meas_data_lf{i}.Va, meas_data_lf{i}.de, win, [], [], 1/Ts);

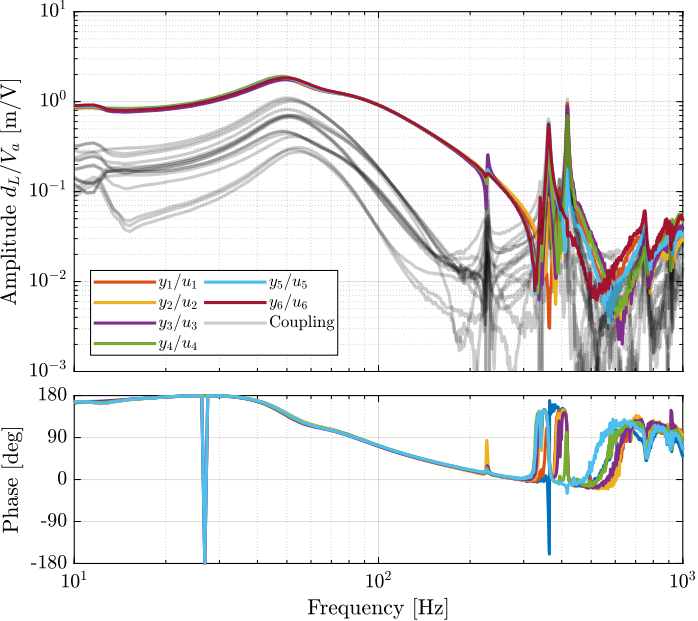

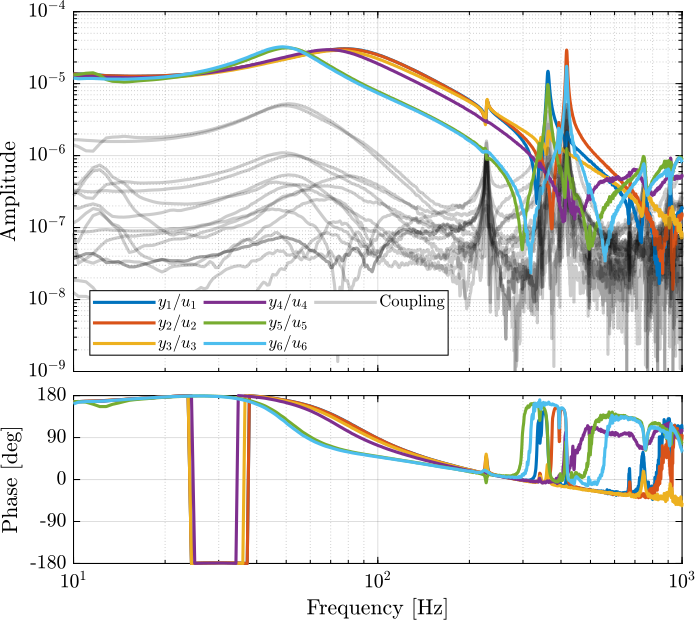

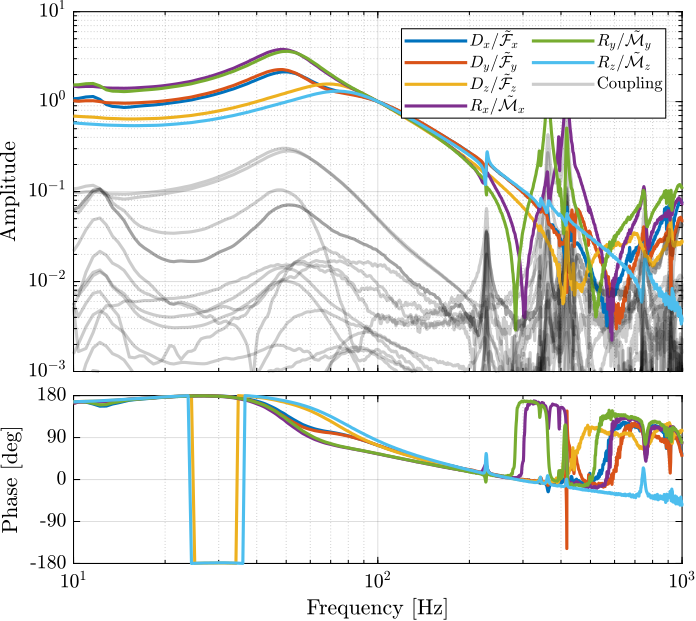

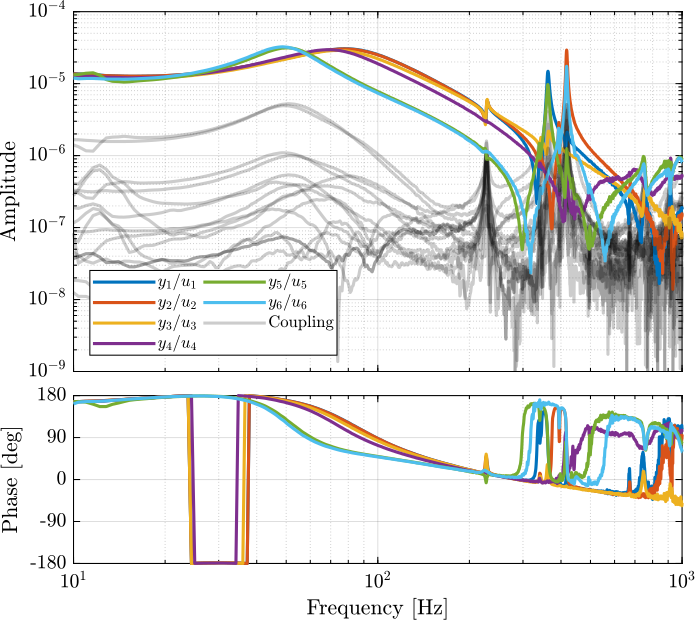

endThe diagonal and off-diagonal terms of this transfer function matrix are shown in Figure fig:enc_plates_dvf_frf.

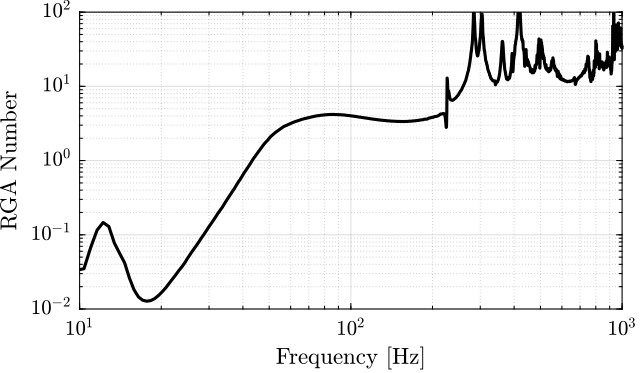

From Figure fig:enc_plates_dvf_frf, we can draw few conclusions on the transfer functions from $\bm{u}$ to $d\bm{\mathcal{L}}_m$ when the encoders are fixed to the plates:

- the decoupling is rather good at low frequency (below the first suspension mode). The low frequency gain is constant for the off diagonal terms, whereas when the encoders where fixed to the struts, the low frequency gain of the off-diagonal terms were going to zero (Figure fig:enc_struts_dvf_frf).

- the flexible modes of the struts at 226Hz and 337Hz are indeed shown in the transfer functions, but their amplitudes are rather low.

- the diagonal terms have alternating poles and zeros up to at least 600Hz: the flexible modes of the struts are not affecting the alternating pole/zero pattern. This what not the case when the encoders were fixed to the struts (Figure fig:enc_struts_dvf_frf).

Transfer function from Actuator to Force Sensor

<<sec:enc_plates_plant_id_iff>>

Let's now compute the coherence from the excitation voltage $\bm{u}$ and the voltage $\bm{\tau}_m$ generated by the Force senors.

%% Coherence for the IFF plant

coh_iff = zeros(length(f), 6, 6);

for i = 1:6

coh_iff(:,:,i) = mscohere(meas_data_lf{i}.Va, meas_data_lf{i}.Vs, win, [], [], 1/Ts);

endThe coherence is shown in Figure fig:enc_plates_iff_coh, and is very good for from 10Hz up to 2kHz.

Then the 6x6 transfer function matrix is estimated.

%% IFF Plant

G_iff = zeros(length(f), 6, 6);

for i = 1:6

G_iff(:,:,i) = tfestimate(meas_data_lf{i}.Va, meas_data_lf{i}.Vs, win, [], [], 1/Ts);

endThe bode plot of the diagonal and off-diagonal terms are shown in Figure fig:enc_plates_iff_frf.

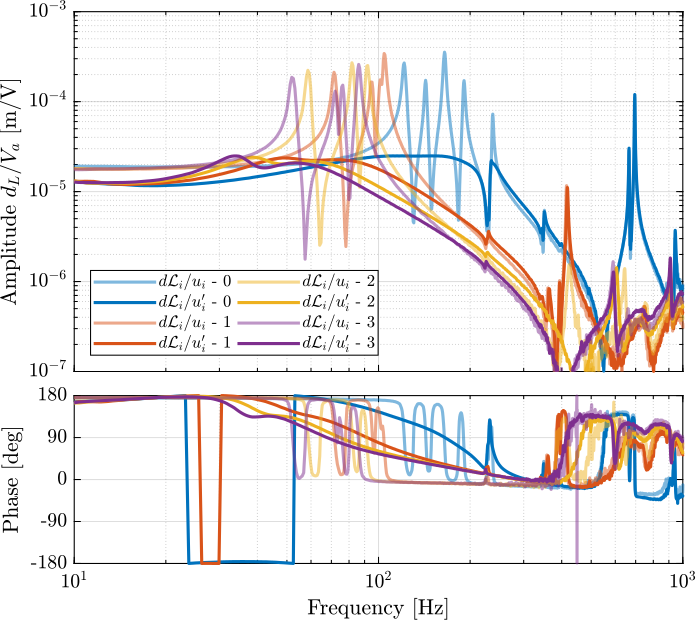

It is shown in Figure fig:enc_plates_iff_comp_simscape_all that:

- The IFF plant has alternating poles and zeros

- The first flexible mode of the struts as 235Hz is appearing, and therefore is should be possible to add some damping to this mode using IFF

- The decoupling is quite good at low frequency (below the first model) as well as high frequency (above the last suspension mode, except near the flexible modes of the top plate)

Save Identified Plants

The identified dynamics is saved for further use.

save('mat/identified_plants_enc_plates.mat', 'f', 'Ts', 'G_iff', 'G_dvf')Comparison with the Simscape Model

<<sec:enc_plates_comp_simscape>>

Introduction ignore

In this section, the measured dynamics done in Section sec:enc_plates_plant_id is compared with the dynamics estimated from the Simscape model.

Identification Setup

The nano-hexapod is initialized with the APA taken as flexible models.

%% Initialize Nano-Hexapod

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'plates', ...

'actuator_type', 'flexible');Dynamics from Actuator to Force Sensors

Then the transfer function from $\bm{u}$ to $\bm{\tau}_m$ is identified using the Simscape model.

%% Identify the IFF Plant (transfer function from u to taum)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/Fm'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors

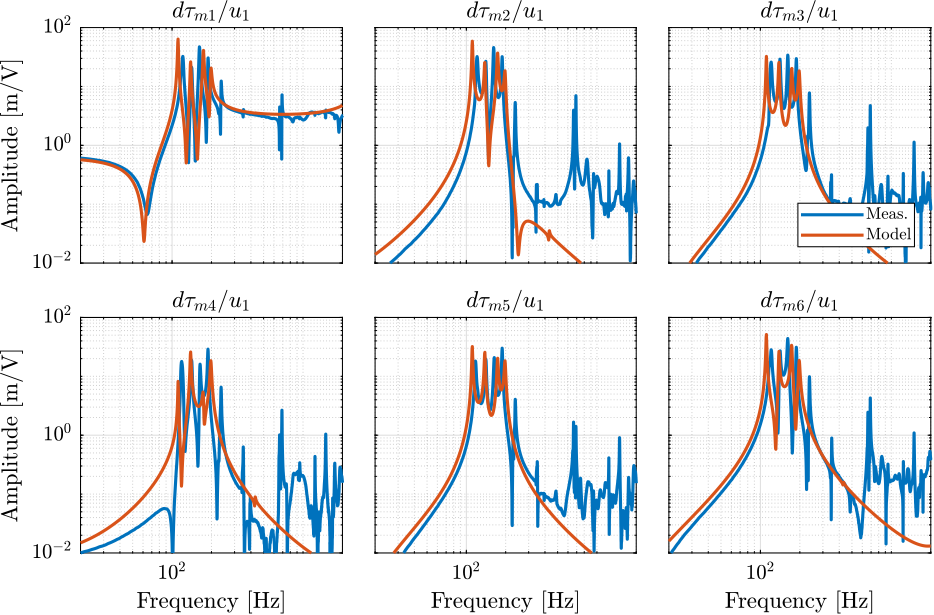

Giff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);The identified dynamics is compared with the measured FRF:

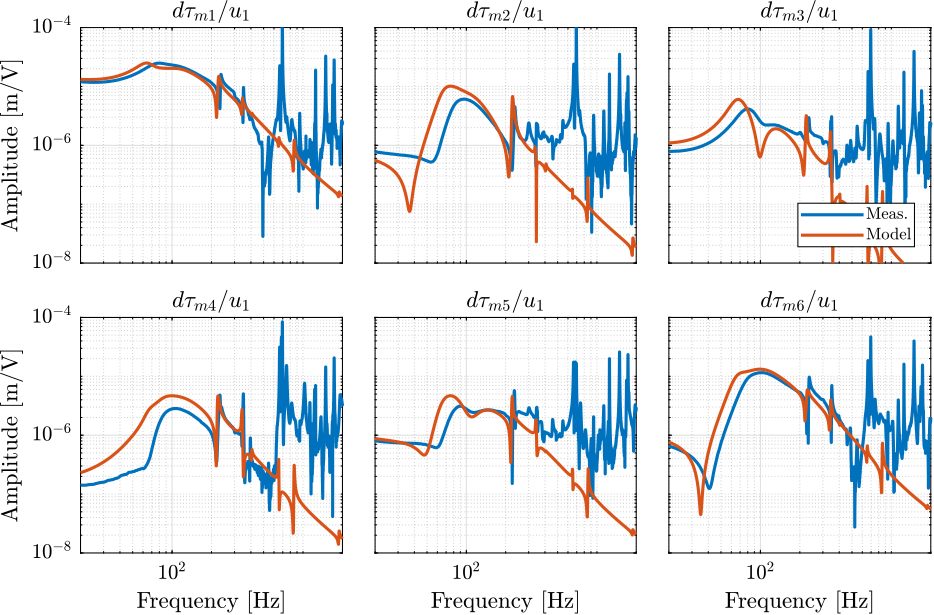

- Figure fig:enc_plates_iff_comp_simscape_all: the individual transfer function from $u_1$ (the DAC voltage for the first actuator) to the force sensors of all 6 struts are compared

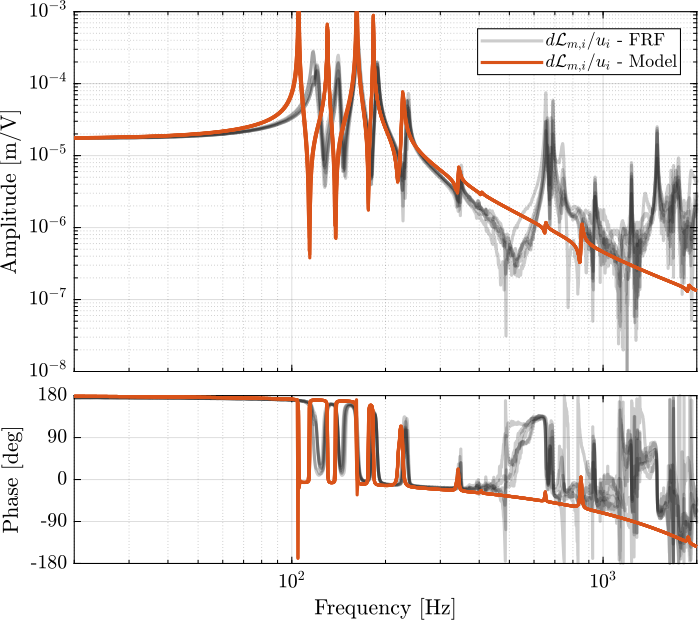

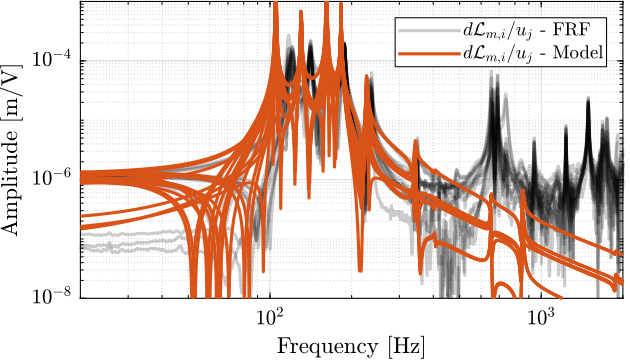

- Figure fig:enc_plates_iff_comp_simscape: all the diagonal elements are compared

- Figure fig:enc_plates_iff_comp_offdiag_simscape: all the off-diagonal elements are compared

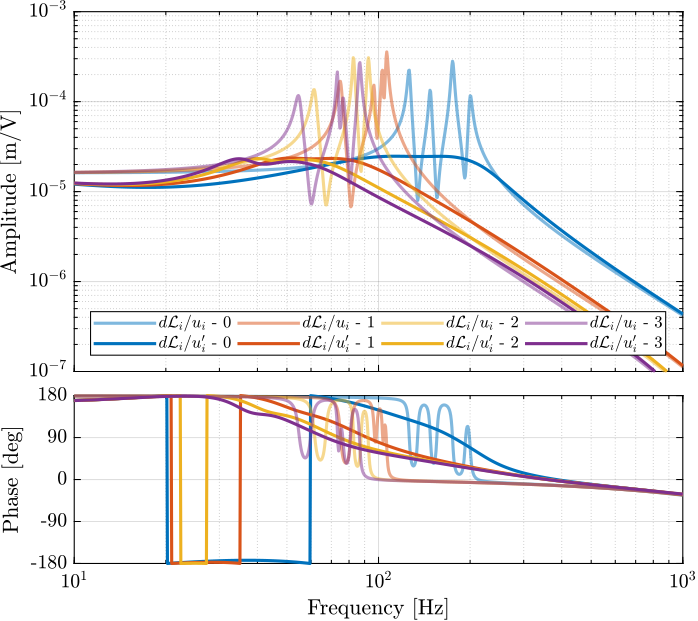

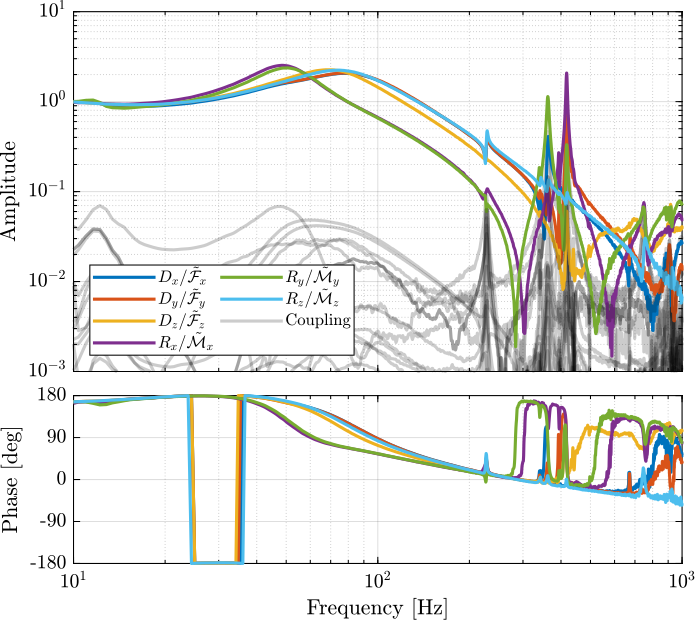

Dynamics from Actuator to Encoder

Now, the dynamics from the DAC voltage $\bm{u}$ to the encoders $d\bm{\mathcal{L}}_m$ is estimated using the Simscape model.

%% Identify the DVF Plant (transfer function from u to dLm)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Encoders

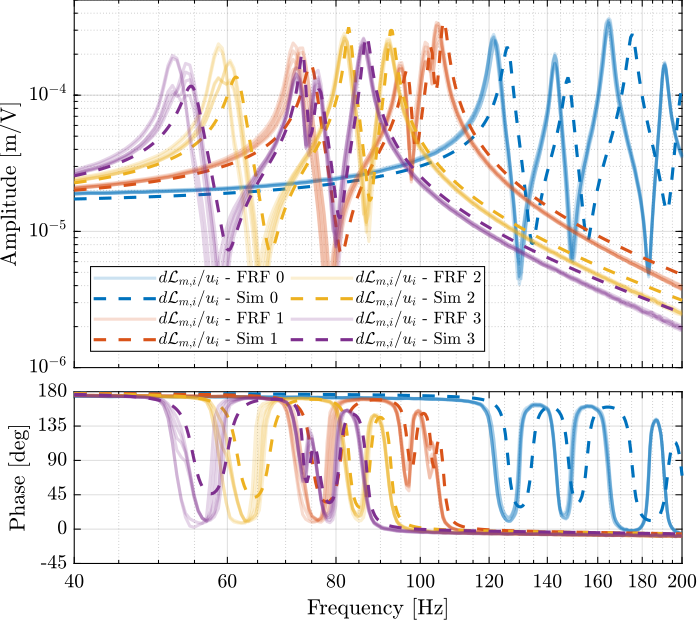

Gdvf = exp(-s*Ts)*linearize(mdl, io, 0.0, options);The identified dynamics is compared with the measured FRF:

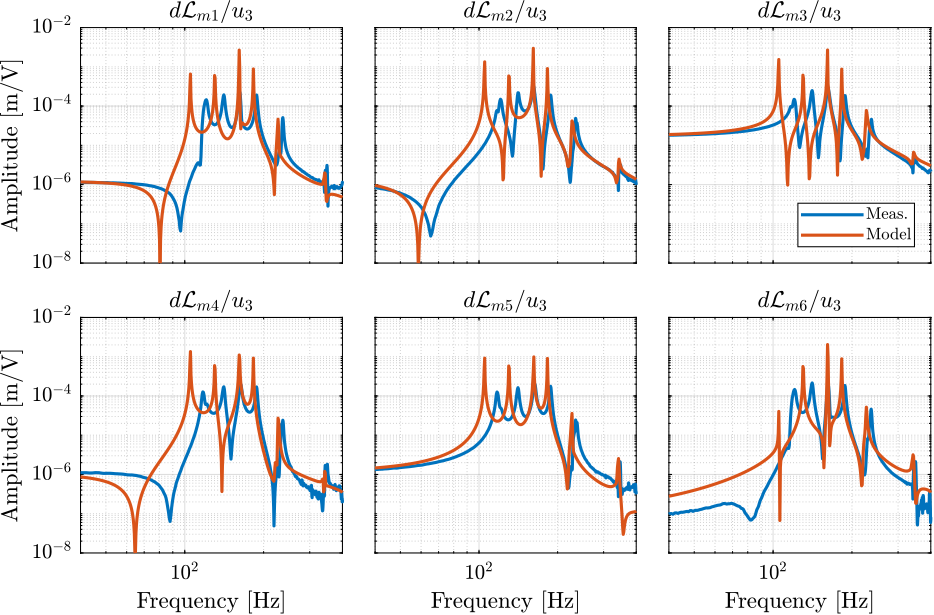

- Figure fig:enc_plates_dvf_comp_simscape_all: the individual transfer function from $u_3$ (the DAC voltage for the actuator number 3) to the six encoders

- Figure fig:enc_plates_dvf_comp_simscape: all the diagonal elements are compared

- Figure fig:enc_plates_dvf_comp_offdiag_simscape: all the off-diagonal elements are compared

TODO Flexible Top Plate

%% Initialize Nano-Hexapod

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '2dof', ...

'flex_top_type', '3dof', ...

'motion_sensor_type', 'struts', ...

'actuator_type', '2dof', ...

'top_plate_type', 'rigid');%% Identify the DVF Plant (transfer function from u to dLm)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Encoders

Gdvf = linearize(mdl, io, 0.0, options);size(Gdvf)

isstable(Gdvf)[sys,g] = balreal(Gdvf); % Compute balanced realization

elim = (g<1e-4); % Small entries of g are negligible states

rsys = modred(sys,elim); % Remove negligible states

size(rsys)%% Identify the IFF Plant (transfer function from u to taum)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/Fm'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors

Giff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);Conclusion

The Simscape model is quite accurate for the transfer function matrices from $\bm{u}$ to $\bm{\tau}_m$ and from $\bm{u}$ to $d\bm{\mathcal{L}}_m$ except at frequencies of the flexible modes of the top-plate. The Simscape model can therefore be used to develop the control strategies.

Integral Force Feedback

<<sec:enc_plates_iff>>

Introduction ignore

In this section, the Integral Force Feedback (IFF) control strategy is applied to the nano-hexapod in order to add damping to the suspension modes.

The control architecture is shown in Figure fig:control_architecture_iff:

- $\bm{\tau}_m$ is the measured voltage of the 6 force sensors

- $\bm{K}_{\text{IFF}}$ is the $6 \times 6$ diagonal controller

- $\bm{u}$ is the plant input (voltage generated by the 6 DACs)

- $\bm{u}^\prime$ is the new plant inputs with added damping

\begin{tikzpicture}

% Blocs

\node[block={3.0cm}{2.0cm}] (P) {Plant};

\coordinate[] (inputF) at ($(P.south west)!0.5!(P.north west)$);

\coordinate[] (outputF) at ($(P.south east)!0.7!(P.north east)$);

\coordinate[] (outputL) at ($(P.south east)!0.3!(P.north east)$);

\node[block, above=0.4 of P] (Kiff) {$\bm{K}_\text{IFF}$};

\node[addb, left= of inputF] (addF) {};

% Connections and labels

\draw[->] (outputF) -- ++(1, 0) node[below left]{$\bm{\tau}_m$};

\draw[->] (outputL) -- ++(1, 0) node[below left]{$d\bm{\mathcal{L}}_m$};

\draw[->] ($(outputF) + (0.6, 0)$)node[branch]{} |- (Kiff.east);

\draw[->] (Kiff.west) -| (addF.north);

\draw[->] (addF.east) -- (inputF) node[above left]{$\bm{u}$};

\draw[<-] (addF.west) -- ++(-1, 0) node[above right]{$\bm{u}^\prime$};

\end{tikzpicture}- Section sec:enc_struts_effect_iff_plant

Effect of IFF on the plant - Simscape Model

<<sec:enc_struts_effect_iff_plant>>

The nano-hexapod is initialized with flexible APA and the encoders fixed to the struts.

%% Initialize the Simscape model in closed loop

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'plates', ...

'actuator_type', 'flexible');The same controller as the one developed when the encoder were fixed to the struts is used.

%% Optimal IFF controller

load('Kiff.mat', 'Kiff')The transfer function from $\bm{u}^\prime$ to $d\bm{\mathcal{L}}_m$ is identified.

%% Identify the (damped) transfer function from u to dLm for different values of the IFF gain

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Plate Displacement (encoder)First in Open-Loop:

%% Transfer function from u to dL (open-loop)

Gd_ol = exp(-s*Ts)*linearize(mdl, io, 0.0, options);And then with the IFF controller:

%% Initialize the Simscape model in closed loop

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'plates', ...

'actuator_type', 'flexible', ...

'controller_type', 'iff');

%% Transfer function from u to dL (IFF)

Gd_iff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);It is first verified that the system is stable:

isstable(Gd_iff)1

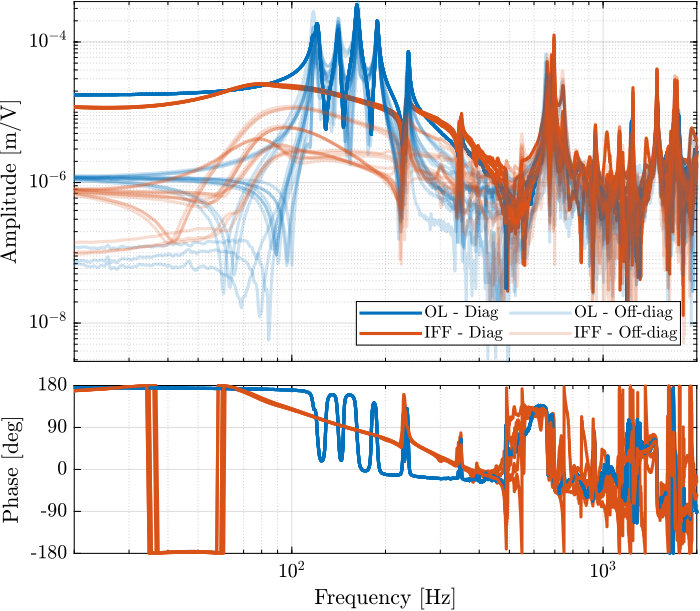

The diagonal and off-diagonal terms of the $6 \times 6$ transfer function matrices identified are compared in Figure fig:enc_plates_iff_gains_effect_dvf_plant. It is shown, as was the case when the encoders were fixed to the struts, that the IFF control strategy is very effective in damping the suspension modes of the nano-hexapod.

Effect of IFF on the plant - FRF

The IFF control strategy is experimentally implemented. The (damped) transfer function from $\bm{u}^\prime$ to $d\bm{\mathcal{L}}_m$ is experimentally identified.

The identification data are loaded:

%% Load Identification Data

meas_iff_plates = {};

for i = 1:6

meas_iff_plates(i) = {load(sprintf('mat/frf_exc_iff_strut_%i_enc_plates_noise.mat', i), 't', 'Va', 'Vs', 'de', 'u')};

endAnd the parameters used for the transfer function estimation are defined below.

% Sampling Time [s]

Ts = (meas_iff_plates{1}.t(end) - (meas_iff_plates{1}.t(1)))/(length(meas_iff_plates{1}.t)-1);

% Hannning Windows

win = hanning(ceil(1/Ts));

% And we get the frequency vector

[~, f] = tfestimate(meas_iff_plates{1}.Va, meas_iff_plates{1}.de, win, [], [], 1/Ts);

The estimation is performed using the tfestimate command.

%% Estimation of the transfer function matrix from u to dL when IFF is applied

G_enc_iff_opt = zeros(length(f), 6, 6);

for i = 1:6

G_enc_iff_opt(:,:,i) = tfestimate(meas_iff_plates{i}.Va, meas_iff_plates{i}.de, win, [], [], 1/Ts);

endThe obtained diagonal and off-diagonal elements of the transfer function from $\bm{u}^\prime$ to $d\bm{\mathcal{L}}_m$ are shown in Figure fig:enc_plant_plates_effect_iff both without and with IFF.

As was predicted with the Simscape model, the IFF control strategy is very effective in damping the suspension modes of the nano-hexapod. Little damping is also applied on the first flexible mode of the strut at 235Hz. However, no damping is applied on other modes, such as the flexible modes of the top plate.

Comparison of the measured FRF and the Simscape model

Let's now compare the obtained damped plants obtained experimentally with the one extracted from Simscape:

- Figure fig:enc_plates_opt_iff_comp_simscape_all: the individual transfer function from $u_1^\prime$ to the six encoders are comapred

- Figure fig:damped_iff_plates_plant_comp_diagonal: all the diagonal elements are compared

- Figure fig:damped_iff_plates_plant_comp_off_diagonal: all the off-diagonal elements are compared

From Figures fig:damped_iff_plates_plant_comp_diagonal and fig:damped_iff_plates_plant_comp_off_diagonal, it is clear that the Simscape model very well represents the dynamics of the nano-hexapod. This is true to around 400Hz, then the dynamics depends on the flexible modes of the top plate which are not modelled.

Save Damped Plant

The experimentally identified plant is saved for further use.

save('matlab/mat/damped_plant_enc_plates.mat', 'f', 'Ts', 'G_enc_iff_opt')save('mat/damped_plant_enc_plates.mat', 'f', 'Ts', 'G_enc_iff_opt')Effect of Payload mass - Robust IFF

<<sec:added_mass>>

Introduction ignore

In this section, the encoders are fixed to the plates, and we identify the dynamics for several payloads. The added payload are half cylinders, and three layers can be added for a total of around 40kg (Figure fig:picture_added_3_masses).

First the dynamics from $\bm{u}$ to $d\mathcal{L}_m$ and $\bm{\tau}_m$ is identified. Then, the Integral Force Feedback controller is developed and applied as shown in Figure fig:nano_hexapod_signals_iff. Finally, the dynamics from $\bm{u}^\prime$ to $d\mathcal{L}_m$ is identified and the added damping can be estimated.

\definecolor{instrumentation}{rgb}{0, 0.447, 0.741}

\definecolor{mechanics}{rgb}{0.8500, 0.325, 0.098}

\definecolor{control}{rgb}{0.4660, 0.6740, 0.1880}

\begin{tikzpicture}

% Blocs

\node[block={4.0cm}{3.0cm}, fill=mechanics!20!white] (nano_hexapod) {Mechanics};

\coordinate[] (inputF) at (nano_hexapod.west);

\coordinate[] (outputL) at ($(nano_hexapod.south east)!0.8!(nano_hexapod.north east)$);

\coordinate[] (outputF) at ($(nano_hexapod.south east)!0.2!(nano_hexapod.north east)$);

\node[block, left= 0.8 of inputF, fill=instrumentation!20!white, align=center] (F_stack) {\tiny Actuator \\ \tiny stacks};

\node[block, left= 0.8 of F_stack, fill=instrumentation!20!white] (PD200) {PD200};

\node[DAC, left= 0.8 of PD200, fill=instrumentation!20!white] (F_DAC) {DAC};

\node[block, right=0.8 of outputF, fill=instrumentation!20!white, align=center] (Fm_stack){\tiny Sensor \\ \tiny stack};

\node[ADC, right=0.8 of Fm_stack,fill=instrumentation!20!white] (Fm_ADC) {ADC};

\node[block, right=0.8 of outputL, fill=instrumentation!20!white] (encoder) {\tiny Encoder};

\node[addb, left= 0.8 of F_DAC, fill=control!20!white] (add_iff) {};

\node[block, below=0.8 of add_iff, fill=control!20!white] (Kiff) {\tiny $K_{\text{IFF}}(s)$};

% Connections and labels

\draw[->] (add_iff.east) node[above right]{$\bm{u}$} node[below right]{$[V]$} -- node[sloped]{$/$} (F_DAC.west);

\draw[->] (F_DAC.east) -- node[midway, above]{$\tilde{\bm{u}}$}node[midway, below]{$[V]$} (PD200.west);

\draw[->] (PD200.east) -- node[midway, above]{$\bm{u}_a$}node[midway, below]{$[V]$} (F_stack.west);

\draw[->] (F_stack.east) -- (inputF) node[above left]{$\bm{\tau}$}node[below left]{$[N]$};

\draw[->] (outputF) -- (Fm_stack.west) node[above left]{$\bm{\epsilon}$} node[below left]{$[m]$};

\draw[->] (Fm_stack.east) -- node[midway, above]{$\tilde{\bm{\tau}}_m$}node[midway, below]{$[V]$} (Fm_ADC.west);

\draw[->] (Fm_ADC.east) -- node[sloped]{$/$} ++(0.8, 0)coordinate(end) node[above left]{$\bm{\tau}_m$}node[below left]{$[V]$};

\draw[->] (outputL) -- (encoder.west) node[above left]{$d\bm{\mathcal{L}}$} node[below left]{$[m]$};

\draw[->] (encoder.east) -- node[sloped]{$/$} (encoder-|end) node[above left]{$d\bm{\mathcal{L}}_m$}node[below left]{$[m]$};

\draw[->] ($(Fm_ADC.east)+(0.14,0)$) node[branch]{} -- node[sloped]{$/$} ++(0, -1.8) -| (Kiff.south);

\draw[->] (Kiff.north) -- node[sloped]{$/$} (add_iff.south);

\draw[->] ($(add_iff.west)+(-0.8,0)$) node[above right]{$\bm{u}^\prime$} node[below right]{$[V]$} -- node[sloped]{$/$} (add_iff.west);

% Nano-Hexapod

\begin{scope}[on background layer]

\node[fit={(F_stack.west|-nano_hexapod.south) (Fm_stack.east|-nano_hexapod.north)}, fill=black!20!white, draw, inner sep=2pt] (system) {};

\node[above] at (system.north) {Nano-Hexapod};

\end{scope}

\end{tikzpicture}Measured Frequency Response Functions

Introduction ignore

Compute FRF in open-loop

The identification is performed without added mass, and with one, two and three layers of added cylinders.

i_masses = 0:3;The following data are loaded:

Va: the excitation voltage (corresponding to $u_i$)Vs: the generated voltage by the 6 force sensors (corresponding to $\bm{\tau}_m$)de: the measured motion by the 6 encoders (corresponding to $d\bm{\mathcal{L}}_m$)

%% Load Identification Data

meas_added_mass = {};

for i_mass = i_masses

for i_strut = 1:6

meas_added_mass(i_strut, i_mass+1) = {load(sprintf('frf_data_exc_strut_%i_realigned_vib_table_%im.mat', i_strut, i_mass), 't', 'Va', 'Vs', 'de')};

end

end

The window win and the frequency vector f are defined.

% Sampling Time [s]

Ts = (meas_added_mass{1,1}.t(end) - (meas_added_mass{1,1}.t(1)))/(length(meas_added_mass{1,1}.t)-1);

% Hannning Windows

win = hanning(ceil(1/Ts));

% And we get the frequency vector

[~, f] = tfestimate(meas_added_mass{1,1}.Va, meas_added_mass{1,1}.de, win, [], [], 1/Ts);Finally the $6 \times 6$ transfer function matrices from $\bm{u}$ to $d\bm{\mathcal{L}}_m$ and from $\bm{u}$ to $\bm{\tau}_m$ are identified:

%% DVF Plant (transfer function from u to dLm)

G_dL = {};

for i_mass = i_masses

G_dL(i_mass+1) = {zeros(length(f), 6, 6)};

for i_strut = 1:6

G_dL{i_mass+1}(:,:,i_strut) = tfestimate(meas_added_mass{i_strut, i_mass+1}.Va, meas_added_mass{i_strut, i_mass+1}.de, win, [], [], 1/Ts);

end

end

%% IFF Plant (transfer function from u to taum)

G_tau = {};

for i_mass = i_masses

G_tau(i_mass+1) = {zeros(length(f), 6, 6)};

for i_strut = 1:6

G_tau{i_mass+1}(:,:,i_strut) = tfestimate(meas_added_mass{i_strut, i_mass+1}.Va, meas_added_mass{i_strut, i_mass+1}.Vs, win, [], [], 1/Ts);

end

endThe identified dynamics are then saved for further use.

save('mat/frf_vib_table_m.mat', 'f', 'Ts', 'G_tau', 'G_dL')Transfer function from $\bm{u}$ to $d\bm{\mathcal{L}}_m$

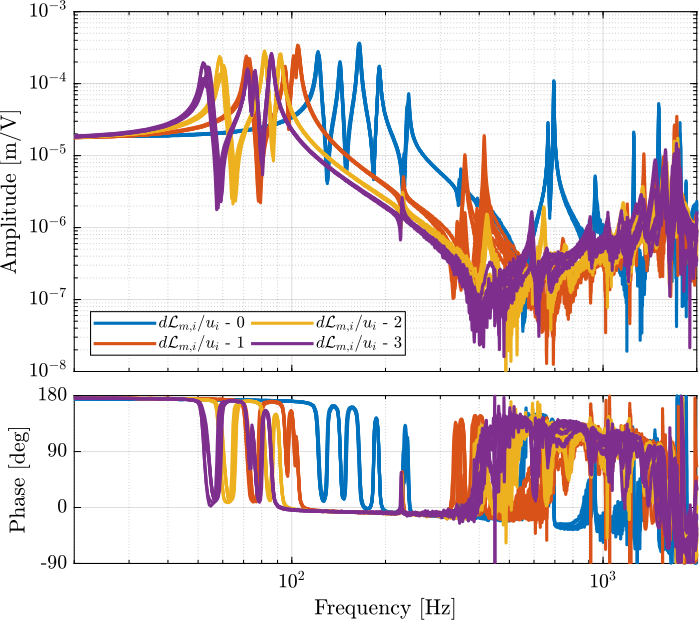

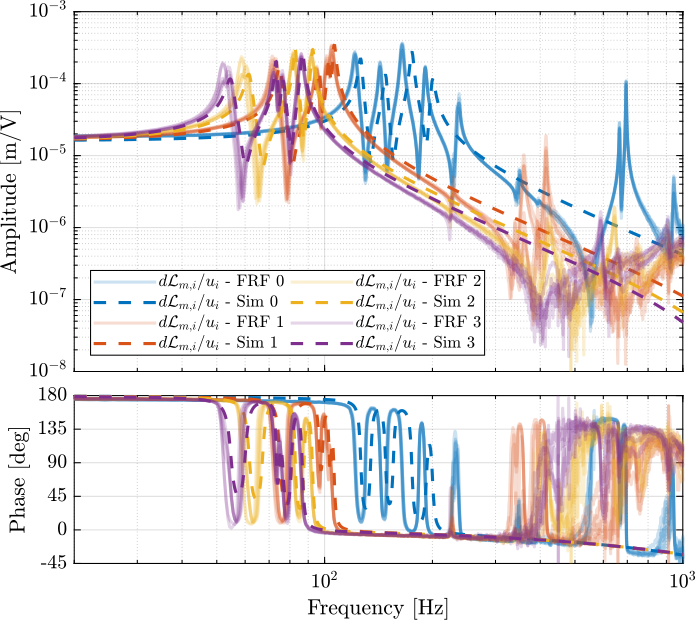

The transfer functions from $u_i$ to $d\mathcal{L}_{m,i}$ are shown in Figure fig:comp_plant_payloads_dvf.

From Figure fig:comp_plant_payloads_dvf, we can observe few things:

- The obtained dynamics is changing a lot between the case without mass and when there is at least one added mass.

- Between 1, 2 and 3 added masses, the dynamics is not much different, and it would be easier to design a controller only for these cases.

- The flexible modes of the top plate is first decreased a lot when the first mass is added (from 700Hz to 400Hz). This is due to the fact that the added mass is composed of two half cylinders which are not fixed together. Therefore is adds a lot of mass to the top plate without adding a lot of rigidity in one direction. When more than 1 mass layer is added, the half cylinders are added with some angles such that rigidity are added in all directions (see Figure fig:picture_added_3_masses). In that case, the frequency of these flexible modes are increased. In practice, the payload should be one solid body, and we should not see a massive decrease of the frequency of this flexible mode.

- Flexible modes of the top plate are becoming less problematic as masses are added.

- First flexible mode of the strut at 230Hz is not much decreased when mass is added. However, its apparent amplitude is much decreased.

Transfer function from $\bm{u}$ to $\bm{\tau}_m$

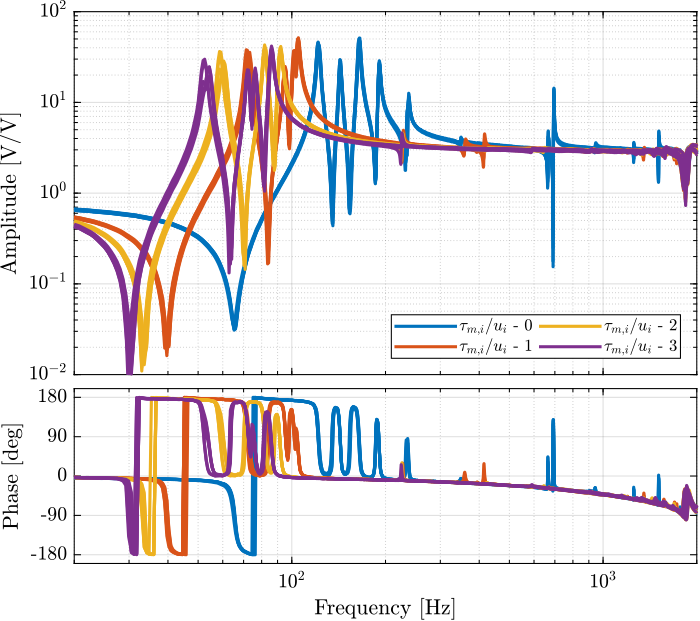

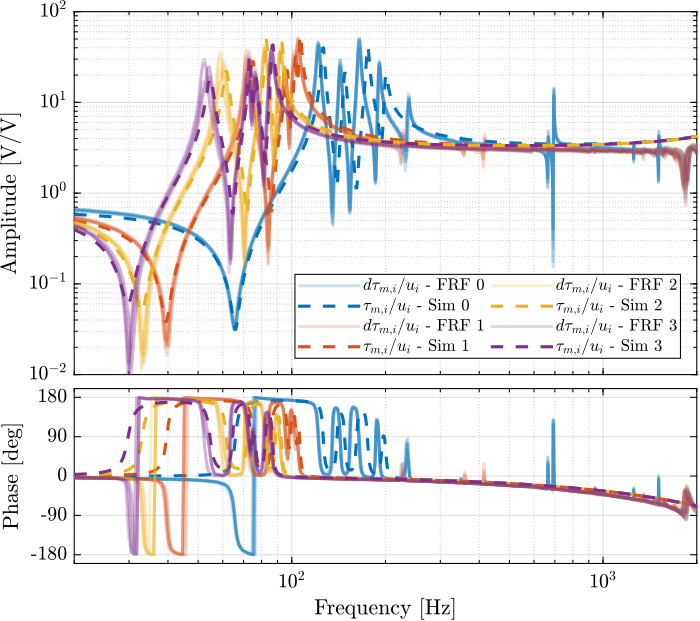

The transfer functions from $u_i$ to $\tau_{m,i}$ are shown in Figure fig:comp_plant_payloads_iff.

From Figure fig:comp_plant_payloads_iff, we can see that for all added payloads, the transfer function from $u_i$ to $\tau_{m,i}$ always has alternating poles and zeros.

Comparison with the Simscape model

Introduction ignore

System Identification

Let's initialize the simscape model with the nano-hexapod fixed on top of the vibration table.

support.type = 1; % On top of vibration tableThe model of the nano-hexapod is defined as shown bellow:

%% Initialize Nano-Hexapod

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '2dof', ...

'flex_top_type', '3dof', ...

'motion_sensor_type', 'plates', ...

'actuator_type', '2dof');And finally, we add the same payloads as during the experiments:

payload.type = 1; % Payload / 1 "mass layer"First perform the identification for the transfer functions from $\bm{u}$ to $d\bm{\mathcal{L}}_m$:

%% Identify the DVF Plant (transfer function from u to dLm)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Encoders

%% Identification for all the added payloads

G_dL = {};

for i = i_masses

fprintf('i = %i\n', i)

payload.type = i;

G_dL(i+1) = {exp(-s*frf_ol.Ts)*linearize(mdl, io, 0.0, options)};

end%% Identify the IFF Plant (transfer function from u to taum)

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/Fm'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors

%% Identification for all the added payloads

G_tau = {};

for i = 0:3

fprintf('i = %i\n', i)

payload.type = i;

G_tau(i+1) = {exp(-s*frf_ol.Ts)*linearize(mdl, io, 0.0, options)};

endThe identified dynamics are then saved for further use.

save('mat/sim_vib_table_m.mat', 'G_tau', 'G_dL')Transfer function from $\bm{u}$ to $d\bm{\mathcal{L}}_m$

The measured FRF and the identified dynamics from $u_i$ to $d\mathcal{L}_{m,i}$ are compared in Figure fig:comp_masses_model_exp_dvf. A zoom near the "suspension" modes is shown in Figure fig:comp_masses_model_exp_dvf_zoom.

The Simscape model is very accurately representing the measured dynamics up. Only the flexible modes of the struts and of the top plate are not represented here as these elements are modelled as rigid bodies.

Transfer function from $\bm{u}$ to $\bm{\tau}_m$

The measured FRF and the identified dynamics from $u_i$ to $\tau_{m,i}$ are compared in Figure fig:comp_masses_model_exp_iff. A zoom near the "suspension" modes is shown in Figure fig:comp_masses_model_exp_iff_zoom.

Integral Force Feedback Controller

Introduction ignore

Robust IFF Controller

Based on the measured FRF from $u_i$ to $\tau_{m,i}$, the following IFF controller is developed:

%% IFF Controller

Kiff_g1 = (1/(s + 2*pi*20))*... % LPF: provides integral action above 20[Hz]

(s/(s + 2*pi*20))*... % HPF: limit low frequency gain

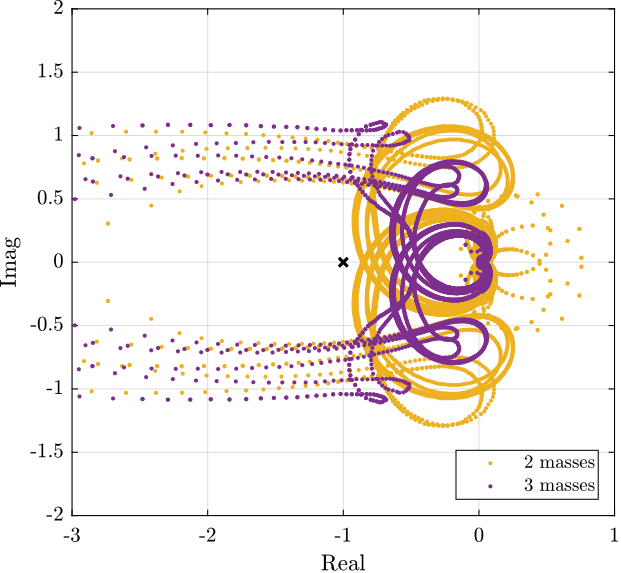

(1/(1 + s/2/pi/400)); % LPF: more robust to high frequency resonancesThen, the Root Locus plot of Figure fig:iff_root_locus_masses is used to estimate the optimal gain. This Root Locus plot is computed from the Simscape model.

The found optimal IFF controller is:

%% Optimal controller

g_opt = -2e2;

Kiff = g_opt*Kiff_g1*eye(6);It is saved for further use.

save('mat/Kiff_opt.mat', 'Kiff')The corresponding experimental loop gains are shown in Figure fig:iff_loop_gain_masses.

Based on the above analysis:

- The same IFF controller can be used to damp the suspension modes for all payload conditions

- The IFF controller should be robust

Estimated Damped Plant from the Simscape model

Let's initialize the simscape model with the nano-hexapod fixed on top of the vibration table.

support.type = 1; % On top of vibration tableThe model of the nano-hexapod is defined as shown bellow:

%% Initialize the Simscape model in closed loop

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '2dof', ...

'flex_top_type', '3dof', ...

'motion_sensor_type', 'plates', ...

'actuator_type', '2dof', ...

'controller_type', 'iff');And finally, we add the same payloads as during the experiments:

payload.type = 1; % Payload / 1 "mass layer"%% Identify the (damped) transfer function from u to dLm

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Plate Displacement (encoder)

%% Identify for all add masses

G_dL = {};

for i = i_masses

payload.type = i;

G_dL(i+1) = {exp(-s*frf_ol.Ts)*linearize(mdl, io, 0.0, options)};

endThe identified dynamics are then saved for further use.

save('mat/sim_iff_vib_table_m.mat', 'G_dL');sim_iff = load('sim_iff_vib_table_m.mat', 'G_dL');Compute the identified FRF with IFF

The identification is performed without added mass, and with one, two and three layers of added cylinders.

i_masses = 0:3;The following data are loaded:

Va: the excitation voltage for the damped plant (corresponding to $u^\prime_i$)de: the measured motion by the 6 encoders (corresponding to $d\bm{\mathcal{L}}_m$)

%% Load Identification Data

meas_added_mass = {};

for i_mass = i_masses

for i_strut = 1:6

meas_iff_mass(i_strut, i_mass+1) = {load(sprintf('frf_data_exc_strut_%i_iff_vib_table_%im.mat', i_strut, i_mass), 't', 'Va', 'de')};

end

end

The window win and the frequency vector f are defined.

% Sampling Time [s]

Ts = (meas_iff_mass{1,1}.t(end) - (meas_iff_mass{1,1}.t(1)))/(length(meas_iff_mass{1,1}.t)-1);

% Hannning Windows

win = hanning(ceil(1/Ts));

% And we get the frequency vector

[~, f] = tfestimate(meas_iff_mass{1,1}.Va, meas_iff_mass{1,1}.de, win, [], [], 1/Ts);Finally the $6 \times 6$ transfer function matrix from $\bm{u}^\prime$ to $d\bm{\mathcal{L}}_m$ is estimated:

%% DVF Plant (transfer function from u to dLm)

G_dL = {};

for i_mass = i_masses

G_dL(i_mass+1) = {zeros(length(f), 6, 6)};

for i_strut = 1:6

G_dL{i_mass+1}(:,:,i_strut) = tfestimate(meas_iff_mass{i_strut, i_mass+1}.Va, meas_iff_mass{i_strut, i_mass+1}.de, win, [], [], 1/Ts);

end

endThe identified dynamics are then saved for further use.

save('mat/frf_iff_vib_table_m.mat', 'f', 'Ts', 'G_dL');Comparison of the measured FRF and the Simscape model

The following figures are computed:

- Figure fig:damped_iff_plant_meas_frf: the measured damped FRF are displayed

- Figure fig:comp_undamped_damped_plant_meas_frf: the open-loop and damped FRF are compared (diagonal elements)

- Figure fig:comp_iff_plant_frf_sim: the obtained damped FRF is compared with the identified damped from using the Simscape model

The IFF control strategy effectively damps all the suspensions modes of the nano-hexapod whatever the payload is. The obtained plant is easier to control (provided the flexible modes of the top platform are well damped).

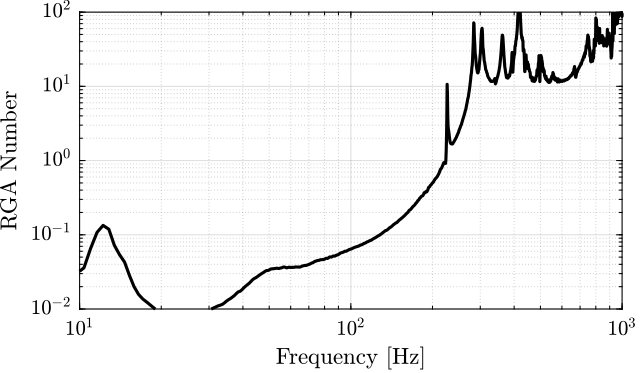

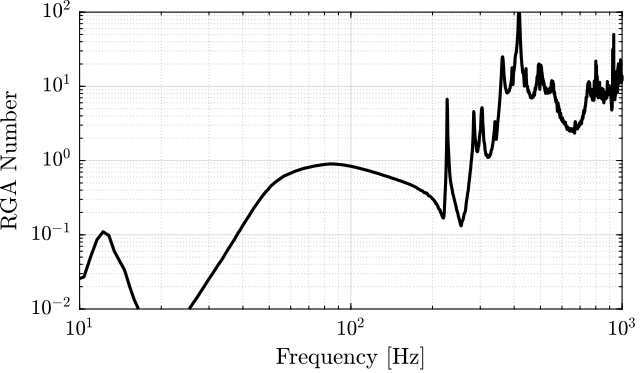

Change of coupling with IFF

The added damping using IFF reduces the coupling in the system near the suspensions modes that are damped. It can be estimated by taking the ratio of the diagonal-term and the off-diagonal term.

This is shown in Figure fig:reduced_coupling_iff_masses.

Un-Balanced mass

Compute the identified FRF with IFF

The following data are loaded:

Va: the excitation voltage for the damped plant (corresponding to $u^\prime_i$)de: the measured motion by the 6 encoders (corresponding to $d\bm{\mathcal{L}}_m$)

%% Load Identification Data

meas_added_mass = {zeros(6,1)};

for i_strut = 1:6

meas_iff_mass(i_strut) = {load(sprintf('frf_data_exc_strut_%i_iff_vib_table_1m_unbalanced.mat', i_strut), 't', 'Va', 'de')};

end

The window win and the frequency vector f are defined.

% Sampling Time [s]

Ts = (meas_iff_mass{1}.t(end) - (meas_iff_mass{1}.t(1)))/(length(meas_iff_mass{1}.t)-1);

% Hannning Windows

win = hanning(ceil(1/Ts));

% And we get the frequency vector

[~, f] = tfestimate(meas_iff_mass{1}.Va, meas_iff_mass{1}.de, win, [], [], 1/Ts);Finally the $6 \times 6$ transfer function matrix from $\bm{u}^\prime$ to $d\bm{\mathcal{L}}_m$ is estimated:

%% DVF Plant (transfer function from u to dLm)

G_dL = zeros(length(f), 6, 6);

for i_strut = 1:6

G_dL(:,:,i_strut) = tfestimate(meas_iff_mass{i_strut}.Va, meas_iff_mass{i_strut}.de, win, [], [], 1/Ts);

endThe identified dynamics are then saved for further use.

save('mat/frf_iff_unbalanced_vib_table_m.mat', 'f', 'Ts', 'G_dL');Effect of an unbalanced payload

The transfer functions from $u_i$ to $d\mathcal{L}_i$ are shown in Figure fig:frf_damp_unbalanced_mass. Due to the unbalanced payload, the system is not symmetrical anymore, and therefore each of the diagonal elements are not equal. This is due to the fact that each strut is not affected by the same inertia.

Conclusion

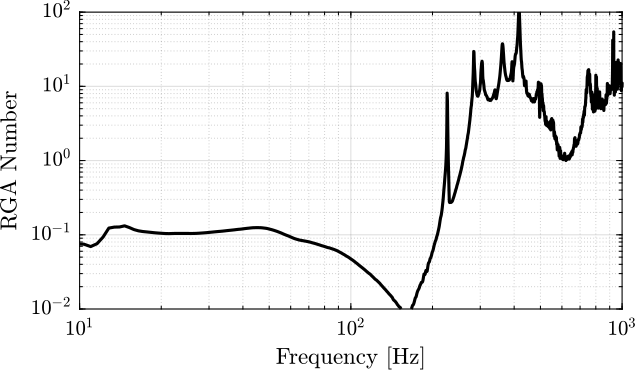

In this section, the dynamics of the nano-hexapod with the encoders fixed to the plates is studied.

It has been found that:

- The measured dynamics is in agreement with the dynamics of the simscape model, up to the flexible modes of the top plate. See figures fig:enc_plates_iff_comp_simscape and fig:enc_plates_iff_comp_offdiag_simscape for the transfer function to the force sensors and Figures fig:enc_plates_dvf_comp_simscape and fig:enc_plates_dvf_comp_offdiag_simscapefor the transfer functions to the encoders

- The Integral Force Feedback strategy is very effective in damping the suspension modes of the nano-hexapod (Figure fig:enc_plant_plates_effect_iff).

- The transfer function from $\bm{u}^\prime$ to $d\bm{\mathcal{L}}_m$ show nice dynamical properties and is a much better candidate for the high-authority-control than when the encoders were fixed to the struts. At least up to the flexible modes of the top plate, the diagonal elements of the transfer function matrix have alternating poles and zeros, and the phase is moving smoothly. Only the flexible modes of the top plates seems to be problematic for control.

Decentralized High Authority Control with Integral Force Feedback

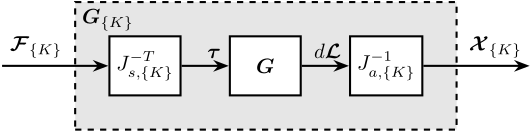

<<sec:decentralized_hac_iff>>

Introduction ignore

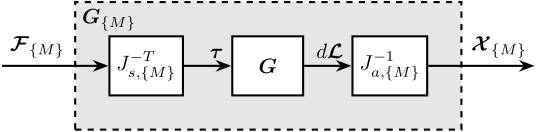

In this section is studied the HAC-IFF architecture for the Nano-Hexapod. More precisely:

- The LAC control is a decentralized integral force feedback as studied in Section sec:enc_plates_iff

- The HAC control is a decentralized controller working in the frame of the struts

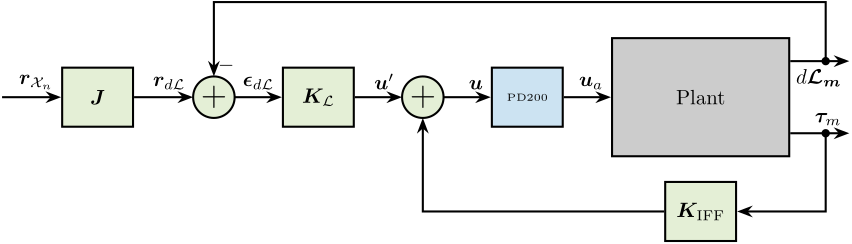

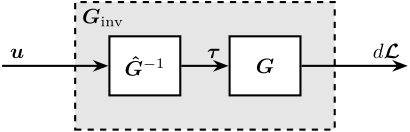

The corresponding control architecture is shown in Figure fig:control_architecture_hac_iff_struts with:

- $\bm{r}_{\mathcal{X}_n}$: the $6 \times 1$ reference signal in the cartesian frame

- $\bm{r}_{d\mathcal{L}}$: the $6 \times 1$ reference signal transformed in the frame of the struts thanks to the inverse kinematic

- $\bm{\epsilon}_{d\mathcal{L}}$: the $6 \times 1$ length error of the 6 struts

- $\bm{u}^\prime$: input of the damped plant

- $\bm{u}$: generated DAC voltages

- $\bm{\tau}_m$: measured force sensors

- $d\bm{\mathcal{L}}_m$: measured displacement of the struts by the encoders

\definecolor{instrumentation}{rgb}{0, 0.447, 0.741}

\definecolor{mechanics}{rgb}{0.8500, 0.325, 0.098}

\definecolor{control}{rgb}{0.4660, 0.6740, 0.1880}

\begin{tikzpicture}

% Blocs

\node[block={3.0cm}{2.0cm}, fill=black!20!white] (P) {Plant};

\coordinate[] (inputF) at ($(P.south west)!0.5!(P.north west)$);

\coordinate[] (outputF) at ($(P.south east)!0.2!(P.north east)$);

\coordinate[] (outputL) at ($(P.south east)!0.8!(P.north east)$);

\node[block, below=0.4 of P, fill=control!20!white] (Kiff) {$\bm{K}_\text{IFF}$};

\node[block, left=0.8 of inputF, fill=instrumentation!20!white] (pd200) {\tiny PD200};

\node[addb, left=0.8 of pd200, fill=control!20!white] (addF) {};

\node[block, left=0.8 of addF, fill=control!20!white] (K) {$\bm{K}_\mathcal{L}$};

\node[addb={+}{}{-}{}{}, left=0.8 of K, fill=control!20!white] (subr) {};

\node[block, align=center, left= of subr, fill=control!20!white] (J) {\tiny Inverse\\\tiny Kinematics};

% Connections and labels

\draw[->] (outputF) -- ++(1.0, 0) node[above left]{$\bm{\tau}_m$};

\draw[->] ($(outputF) + (0.6, 0)$)node[branch]{} |- (Kiff.east);

\draw[->] (Kiff.west) -| (addF.south);

\draw[->] (addF.east) -- (pd200.west) node[above left]{$\bm{u}$};

\draw[->] (pd200.east) -- (inputF) node[above left]{$\bm{u}_a$};

\draw[->] (outputL) -- ++(1.0, 0) node[below left]{$d\bm{\mathcal{L}_m}$};

\draw[->] ($(outputL) + (0.6, 0)$)node[branch]{} -- ++(0, 1) -| (subr.north);

\draw[->] (subr.east) -- (K.west) node[above left]{$\bm{\epsilon}_{d\mathcal{L}}$};

\draw[->] (K.east) -- (addF.west) node[above left]{$\bm{u}^\prime$};

\draw[->] (J.east) -- (subr.west) node[above left]{$\bm{r}_{d\mathcal{L}}$};

\draw[<-] (J.west)node[above left]{$\bm{r}_{\mathcal{X}_n}$} -- ++(-1, 0);

\end{tikzpicture}This part is structured as follow:

- Section sec:hac_iff_struts_ref_track: some reference tracking tests are performed

- Section sec:hac_iff_struts_controller: the decentralized high authority controller is tuned using the Simscape model and is implemented and tested experimentally

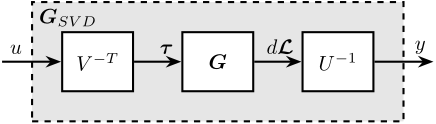

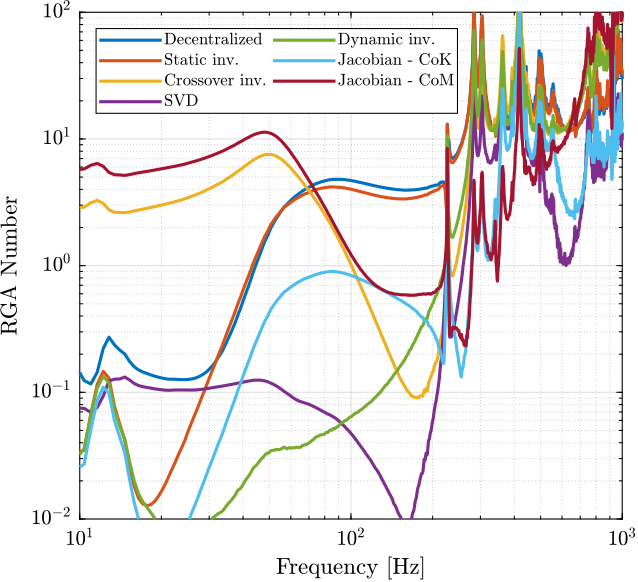

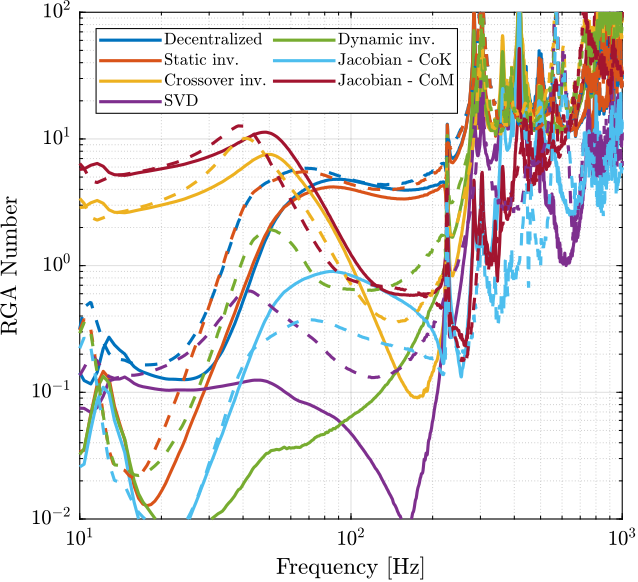

- Section sec:interaction_analysis: an interaction analysis is performed, from which the best decoupling strategy can be determined

- Section sec:robust_hac_design: Robust High Authority Controller are designed

Reference Tracking - Trajectories

<<sec:hac_iff_struts_ref_track>>

Introduction ignore

In this section, several trajectories representing the wanted pose (position and orientation) of the top platform with respect to the bottom platform are defined.

These trajectories will be used to test the HAC-LAC architecture.

In order to transform the wanted pose to the wanted displacement of the 6 struts, the inverse kinematic is required. As a first approximation, the Jacobian matrix $\bm{J}$ can be used instead of using the full inverse kinematic equations.

Therefore, the control architecture with the input trajectory $\bm{r}_{\mathcal{X}_n}$ is shown in Figure fig:control_architecture_hac_iff_L.

\definecolor{instrumentation}{rgb}{0, 0.447, 0.741}

\definecolor{mechanics}{rgb}{0.8500, 0.325, 0.098}

\definecolor{control}{rgb}{0.4660, 0.6740, 0.1880}

\begin{tikzpicture}

% Blocs

\node[block={3.0cm}{2.0cm}, fill=black!20!white] (P) {Plant};

\coordinate[] (inputF) at ($(P.south west)!0.5!(P.north west)$);

\coordinate[] (outputF) at ($(P.south east)!0.2!(P.north east)$);

\coordinate[] (outputL) at ($(P.south east)!0.8!(P.north east)$);

\node[block, below=0.4 of P, fill=control!20!white] (Kiff) {$\bm{K}_\text{IFF}$};

\node[block, left=0.8 of inputF, fill=instrumentation!20!white] (pd200) {\tiny PD200};

\node[addb, left=0.8 of pd200, fill=control!20!white] (addF) {};

\node[block, left=0.8 of addF, fill=control!20!white] (K) {$\bm{K}_\mathcal{L}$};

\node[addb={+}{}{-}{}{}, left=0.8 of K, fill=control!20!white] (subr) {};

\node[block, align=center, left= of subr, fill=control!20!white] (J) {$\bm{J}$};

% Connections and labels

\draw[->] (outputF) -- ++(1.0, 0) node[above left]{$\bm{\tau}_m$};

\draw[->] ($(outputF) + (0.6, 0)$)node[branch]{} |- (Kiff.east);

\draw[->] (Kiff.west) -| (addF.south);

\draw[->] (addF.east) -- (pd200.west) node[above left]{$\bm{u}$};

\draw[->] (pd200.east) -- (inputF) node[above left]{$\bm{u}_a$};

\draw[->] (outputL) -- ++(1.0, 0) node[below left]{$d\bm{\mathcal{L}_m}$};

\draw[->] ($(outputL) + (0.6, 0)$)node[branch]{} -- ++(0, 1) -| (subr.north);

\draw[->] (subr.east) -- (K.west) node[above left]{$\bm{\epsilon}_{d\mathcal{L}}$};

\draw[->] (K.east) -- (addF.west) node[above left]{$\bm{u}^\prime$};

\draw[->] (J.east) -- (subr.west) node[above left]{$\bm{r}_{d\mathcal{L}}$};

\draw[<-] (J.west)node[above left]{$\bm{r}_{\mathcal{X}_n}$} -- ++(-1, 0);

\end{tikzpicture}In the following sections, several reference trajectories are defined:

- Section sec:yz_scans: simple scans in the Y-Z plane

- Section sec:tilt_scans: scans in tilt are performed

- Section sec:nass_scans: scans with X-Y-Z translations in order to draw the word "NASS"

Y-Z Scans

<<sec:yz_scans>>

A function generateYZScanTrajectory has been developed (accessible here) in order to easily generate scans in the Y-Z plane.

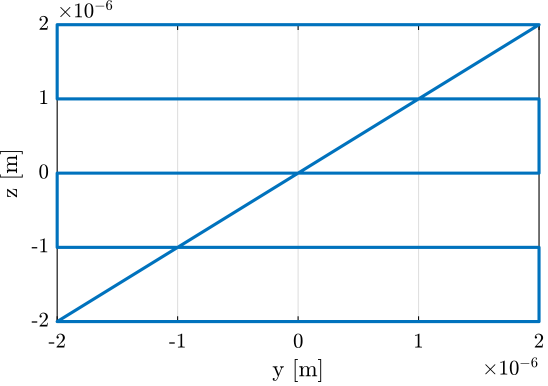

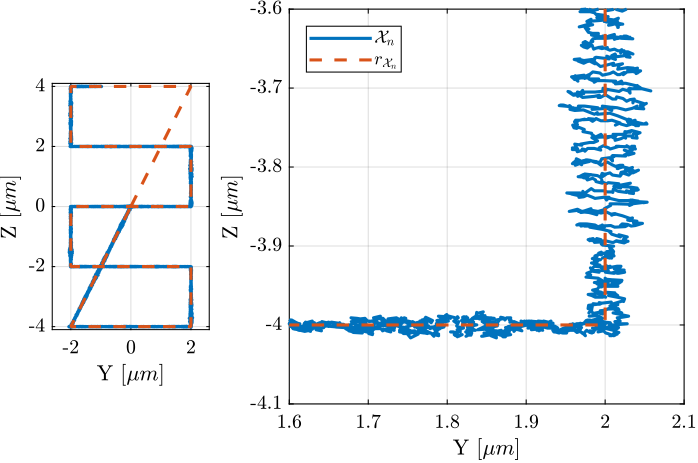

For instance, the following generated trajectory is represented in Figure fig:yz_scan_example_trajectory_yz_plane.

%% Generate the Y-Z trajectory scan

Rx_yz = generateYZScanTrajectory(...

'y_tot', 4e-6, ... % Length of Y scans [m]

'z_tot', 4e-6, ... % Total Z distance [m]

'n', 5, ... % Number of Y scans

'Ts', 1e-3, ... % Sampling Time [s]

'ti', 1, ... % Time to go to initial position [s]

'tw', 0, ... % Waiting time between each points [s]

'ty', 0.6, ... % Time for a scan in Y [s]

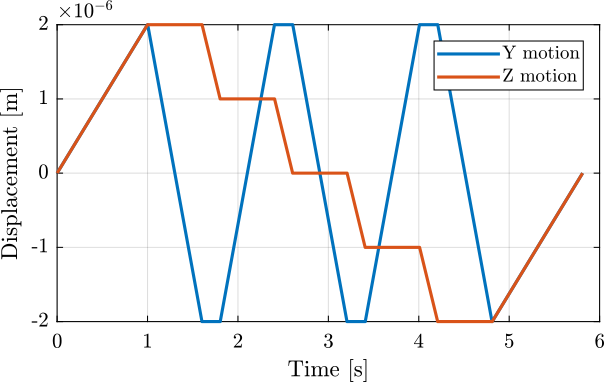

'tz', 0.2); % Time for a scan in Z [s]The Y and Z positions as a function of time are shown in Figure fig:yz_scan_example_trajectory.

Using the Jacobian matrix, it is possible to compute the wanted struts lengths as a function of time:

\begin{equation} \bm{r}_{d\mathcal{L}} = \bm{J} \bm{r}_{\mathcal{X}_n} \end{equation}%% Compute the reference in the frame of the legs

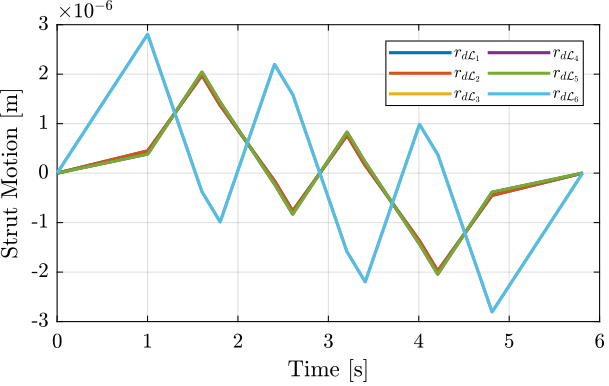

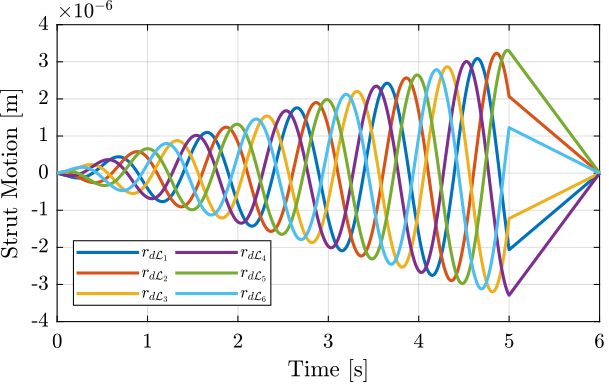

dL_ref = [J*Rx_yz(:, 2:7)']';The reference signal for the strut length is shown in Figure fig:yz_scan_example_trajectory_struts.

Tilt Scans

<<sec:tilt_scans>>

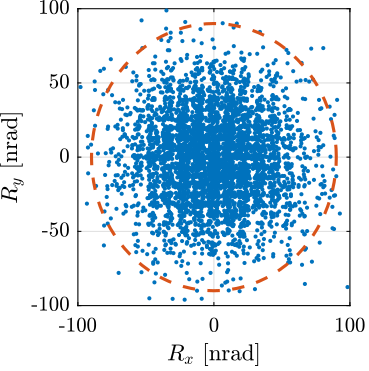

A function generalSpiralAngleTrajectory has been developed in order to easily generate $R_x,R_y$ tilt scans.

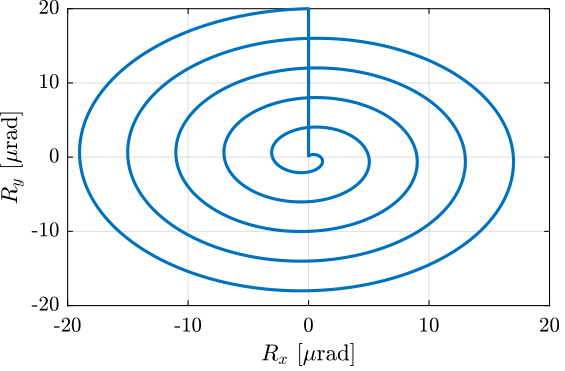

For instance, the following generated trajectory is represented in Figure fig:tilt_scan_example_trajectory.

%% Generate the "tilt-spiral" trajectory scan

R_tilt = generateSpiralAngleTrajectory(...

'R_tot', 20e-6, ... % Total Tilt [ad]

'n_turn', 5, ... % Number of scans

'Ts', 1e-3, ... % Sampling Time [s]

't_turn', 1, ... % Turn time [s]

't_end', 1); % End time to go back to zero [s]The reference signal for the strut length is shown in Figure fig:tilt_scan_example_trajectory_struts.

"NASS" reference path

<<sec:nass_scans>> In this section, a reference path that "draws" the work "NASS" is developed.

First, a series of points representing each letter are defined. Between each letter, a negative Z motion is performed.

%% List of points that draws "NASS"

ref_path = [ ...

0, 0,0; % Initial Position

0,0,1; 0,4,1; 3,0,1; 3,4,1; % N

3,4,0; 4,0,0; % Transition

4,0,1; 4,3,1; 5,4,1; 6,4,1; 7,3,1; 7,2,1; 4,2,1; 4,3,1; 5,4,1; 6,4,1; 7,3,1; 7,0,1; % A

7,0,0; 8,0,0; % Transition

8,0,1; 11,0,1; 11,2,1; 8,2,1; 8,4,1; 11,4,1; % S

11,4,0; 12,0,0; % Transition

12,0,1; 15,0,1; 15,2,1; 12,2,1; 12,4,1; 15,4,1; % S

15,4,0;

];

%% Center the trajectory arround zero

ref_path = ref_path - (max(ref_path) - min(ref_path))/2;

%% Define the X-Y-Z cuboid dimensions containing the trajectory

X_max = 10e-6;

Y_max = 4e-6;

Z_max = 2e-6;

ref_path = ([X_max, Y_max, Z_max]./max(ref_path)).*ref_path; % [m]

Then, using the generateXYZTrajectory function, the $6 \times 1$ trajectory signal is computed.

%% Generating the trajectory

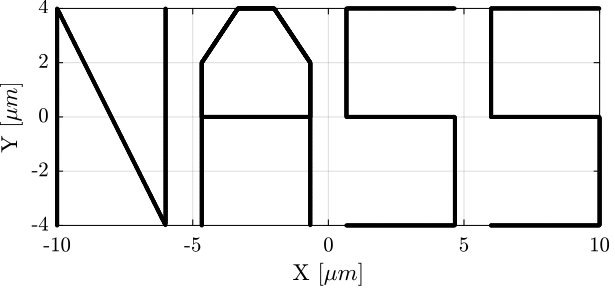

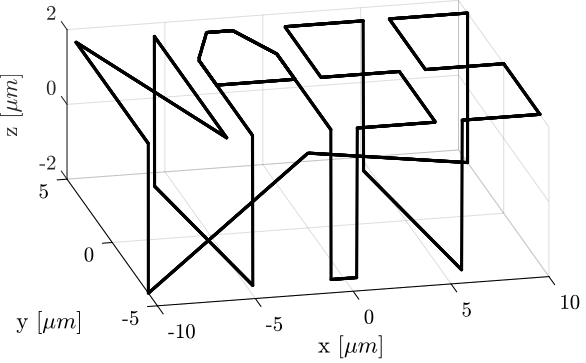

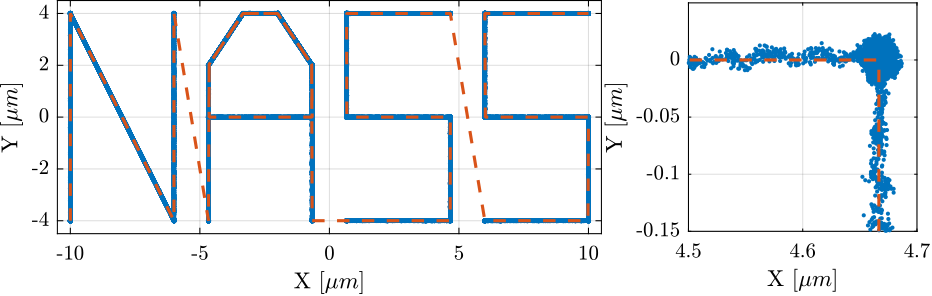

Rx_nass = generateXYZTrajectory('points', ref_path);The trajectory in the X-Y plane is shown in Figure fig:ref_track_test_nass (the transitions between the letters are removed).

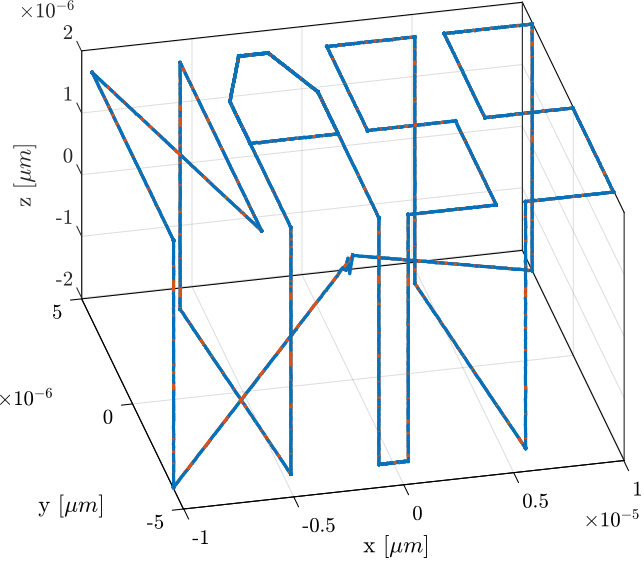

It can also be better viewed in a 3D representation as in Figure fig:ref_track_test_nass_3d.

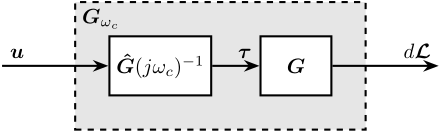

First Basic High Authority Controller

<<sec:hac_iff_struts_controller>>

Introduction ignore

In this section, a simple decentralized high authority controller $\bm{K}_{\mathcal{L}}$ is developed to work without any payload.

The diagonal controller is tuned using classical Loop Shaping in Section sec:hac_iff_no_payload_tuning. The stability is verified in Section sec:hac_iff_no_payload_stability using the Simscape model.

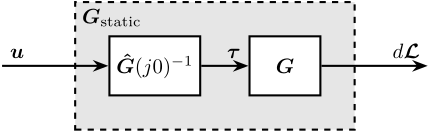

HAC Controller

<<sec:hac_iff_no_payload_tuning>>

Let's first try to design a first decentralized controller with:

- a bandwidth of 100Hz

- sufficient phase margin

- simple and understandable components

After some very basic and manual loop shaping, A diagonal controller is developed. Each diagonal terms are identical and are composed of:

- A lead around 100Hz

- A first order low pass filter starting at 200Hz to add some robustness to high frequency modes

- A notch at 700Hz to cancel the flexible modes of the top plate

- A pure integrator

%% Lead to increase phase margin

a = 2; % Amount of phase lead / width of the phase lead / high frequency gain

wc = 2*pi*100; % Frequency with the maximum phase lead [rad/s]

H_lead = (1 + s/(wc/sqrt(a)))/(1 + s/(wc*sqrt(a)));

%% Low Pass filter to increase robustness

H_lpf = 1/(1 + s/2/pi/200);

%% Notch at the top-plate resonance

gm = 0.02;

xi = 0.3;

wn = 2*pi*700;

H_notch = (s^2 + 2*gm*xi*wn*s + wn^2)/(s^2 + 2*xi*wn*s + wn^2);

%% Decentralized HAC

Khac_iff_struts = -(1/(2.87e-5)) * ... % Gain

H_lead * ... % Lead

H_notch * ... % Notch

(2*pi*100/s) * ... % Integrator

eye(6); % 6x6 DiagonalThis controller is saved for further use.

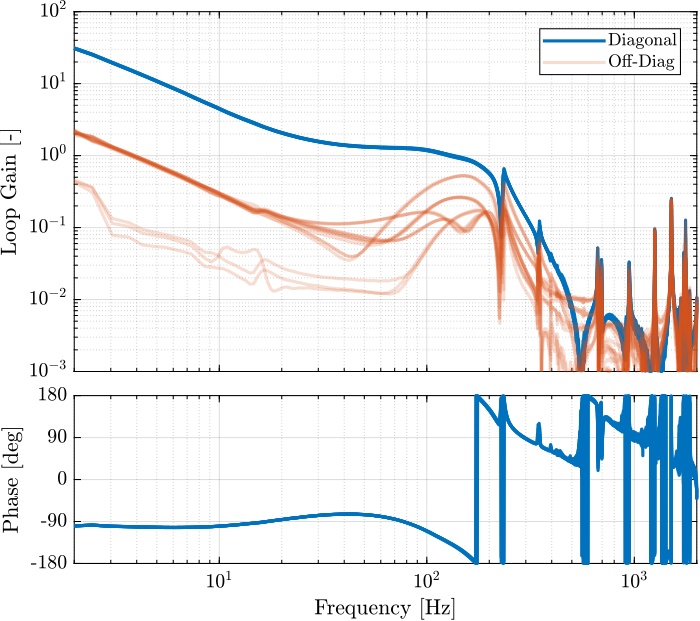

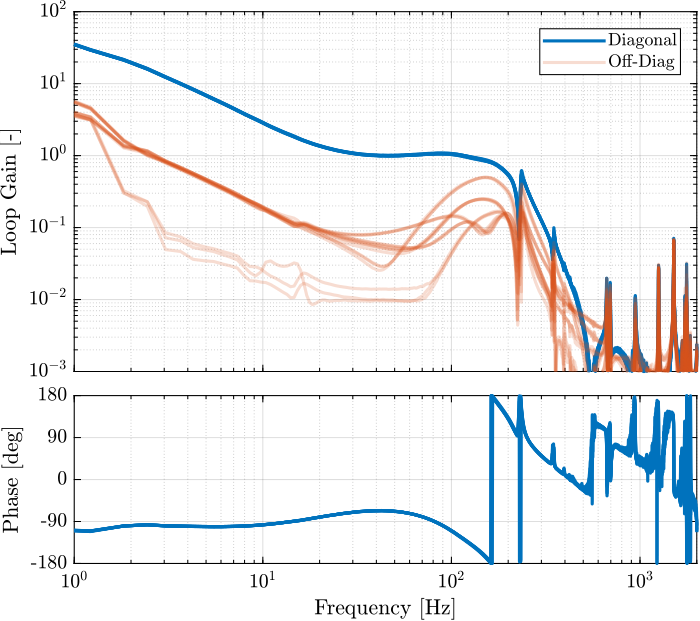

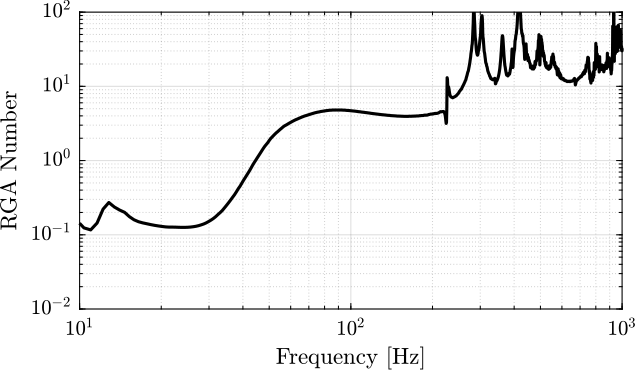

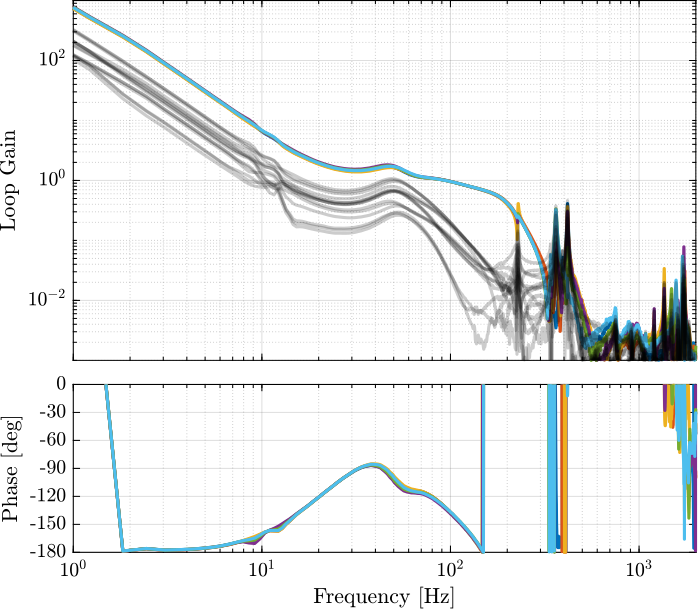

save('mat/Khac_iff_struts.mat', 'Khac_iff_struts')The experimental loop gain is computed and shown in Figure fig:loop_gain_hac_iff_struts.

L_hac_iff_struts = pagemtimes(permute(frf_iff.G_dL{1}, [2 3 1]), squeeze(freqresp(Khac_iff_struts, frf_iff.f, 'Hz')));Verification of the Stability using the Simscape model

<<sec:hac_iff_no_payload_stability>>

The HAC-IFF control strategy is implemented using Simscape.

%% Initialize the Simscape model in closed loop

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ...

'flex_top_type', '4dof', ...

'motion_sensor_type', 'plates', ...

'actuator_type', 'flexible', ...

'controller_type', 'hac-iff-struts');%% Identify the (damped) transfer function from u to dLm

clear io; io_i = 1;

io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs

io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Plate Displacement (encoder)We identify the closed-loop system.

%% Identification

Gd_iff_hac_opt = linearize(mdl, io, 0.0, options);And verify that it is indeed stable.

%% Verify the stability