16 KiB

Piezoelectric Force Sensor - Test Bench

- Introduction

- Change of Stiffness due to Sensors stack being open/closed circuit

- Generated Number of Charge / Voltage

Introduction ignore

In this document is studied how a piezoelectric stack can be used to measured the force.

- Section sec:open_closed_circuit: the effect of the input impedance of the electronics connected to the force sensor stack on the stiffness of the stack is studied

- Section sec:charge_voltage_estimation:

Change of Stiffness due to Sensors stack being open/closed circuit

<<sec:open_closed_circuit>>

Introduction ignore

Load Data

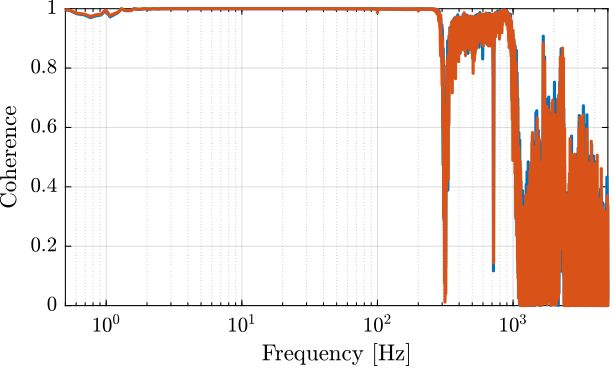

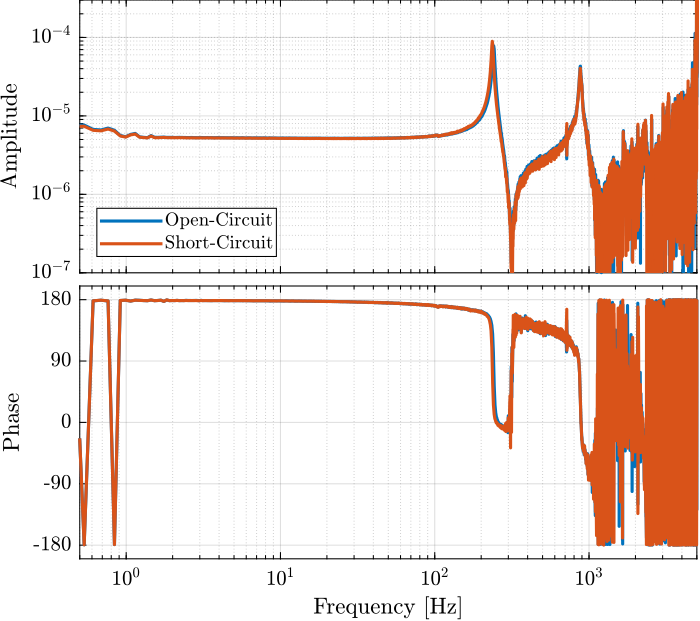

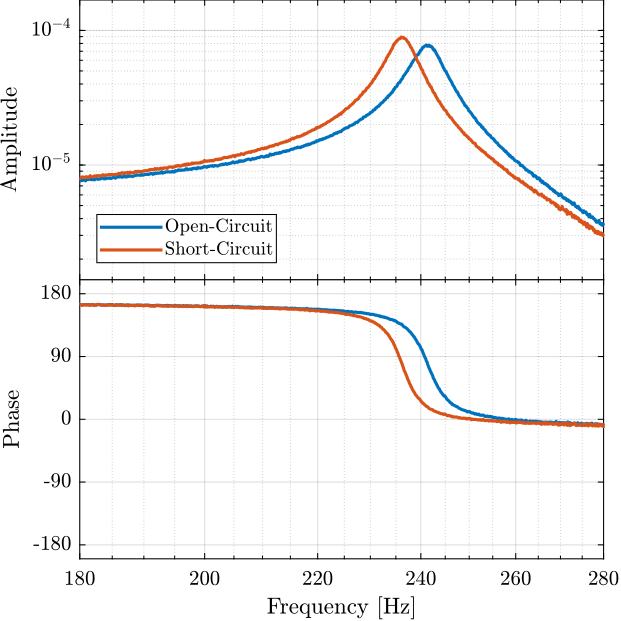

oc = load('identification_open_circuit.mat', 't', 'encoder', 'u');

sc = load('identification_short_circuit.mat', 't', 'encoder', 'u');Transfer Functions

Ts = 1e-4; % Sampling Time [s]

win = hann(ceil(10/Ts)); [tf_oc_est, f] = tfestimate(oc.u, oc.encoder, win, [], [], 1/Ts);

[co_oc_est, ~] = mscohere( oc.u, oc.encoder, win, [], [], 1/Ts);

[tf_sc_est, ~] = tfestimate(sc.u, sc.encoder, win, [], [], 1/Ts);

[co_sc_est, ~] = mscohere( sc.u, sc.encoder, win, [], [], 1/Ts);The change of resonance frequency / stiffness is very small and is not important here.

Generated Number of Charge / Voltage

<<sec:charge_voltage_estimation>>

Introduction ignore

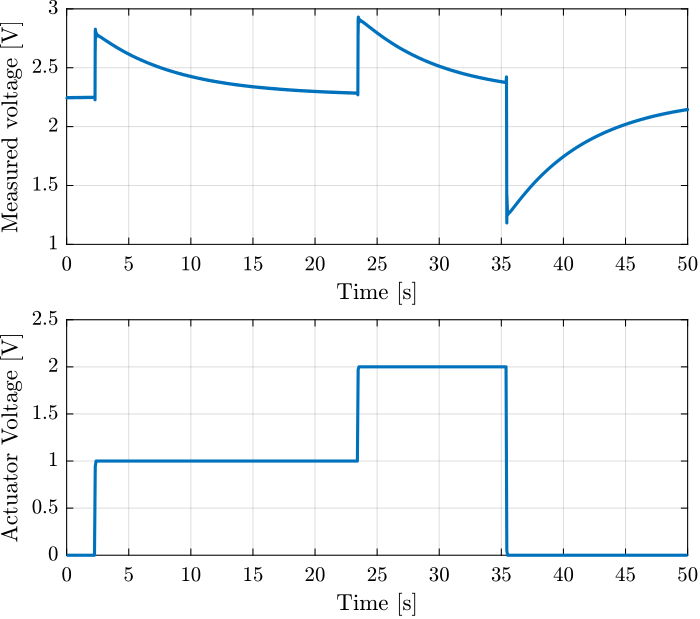

Two stacks are used as actuator (in parallel) and one stack is used as sensor.

The amplifier gain is 20V/V (Cedrat LA75B).

Steps

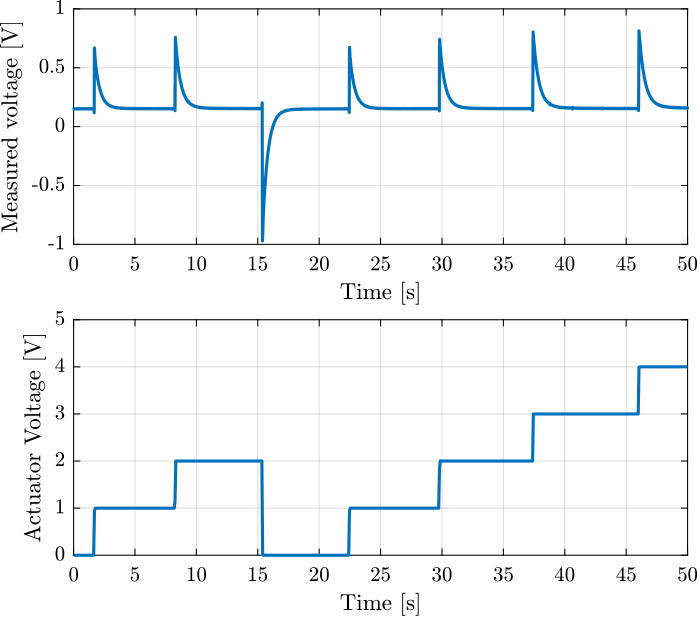

load('force_sensor_steps.mat', 't', 'encoder', 'u', 'v'); figure;

tiledlayout(2, 1, 'TileSpacing', 'None', 'Padding', 'None');

nexttile;

plot(t, v);

xlabel('Time [s]'); ylabel('Measured voltage [V]');

nexttile;

plot(t, u);

xlabel('Time [s]'); ylabel('Actuator Voltage [V]');Three steps are performed at the following time intervals:

t_s = [ 2.5, 23;

23.8, 35;

35.8, 50];Fit function:

f = @(b,x) b(1).*exp(b(2).*x) + b(3);

We are interested by the b(2) term, which is the time constant of the exponential.

tau = zeros(size(t_s, 1),1);

V0 = zeros(size(t_s, 1),1); for t_i = 1:size(t_s, 1)

t_cur = t(t_s(t_i, 1) < t & t < t_s(t_i, 2));

t_cur = t_cur - t_cur(1);

y_cur = v(t_s(t_i, 1) < t & t < t_s(t_i, 2));

nrmrsd = @(b) norm(y_cur - f(b,t_cur)); % Residual Norm Cost Function

B0 = [0.5, -0.15, 2.2]; % Choose Appropriate Initial Estimates

[B,rnrm] = fminsearch(nrmrsd, B0); % Estimate Parameters ‘B’

tau(t_i) = 1/B(2);

V0(t_i) = B(3);

end| $tau$ [s] | $V_0$ [V] |

|---|---|

| 6.47 | 2.26 |

| 6.76 | 2.26 |

| 6.49 | 2.25 |

With the capacitance being $C = 4.4 \mu F$, the internal impedance of the Speedgoat ADC can be computed as follows:

Cp = 4.4e-6; % [F]

Rin = abs(mean(tau))/Cp;1494100.0

The input impedance of the Speedgoat's ADC should then be close to $1.5\,M\Omega$ (specified at $1\,M\Omega$).

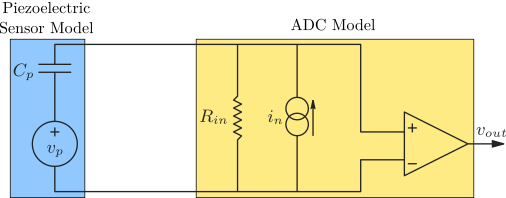

How can we explain the voltage offset?

As shown in Figure fig:force_sensor_model_electronics_without_R (taken from cite:reza06_piezoel_trans_vibrat_contr_dampin), an input voltage offset is due to the input bias current $i_n$.

The estimated input bias current is then:

in = mean(V0)/Rin;1.5119e-06

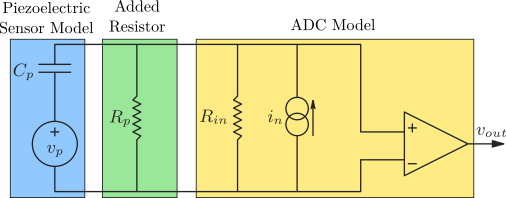

An additional resistor in parallel with $R_{in}$ would have two effects:

- reduce the input voltage offset \[ V_{off} = \frac{R_a R_{in}}{R_a + R_{in}} i_n \]

- increase the high pass corner frequency $f_c$ \[ C_p \frac{R_{in}R_a}{R_{in} + R_a} = \tau_c = \frac{1}{f_c} \] \[ R_a = \frac{R_i}{f_c C_p R_i - 1} \]

If we allow the high pass corner frequency to be equals to 3Hz:

fc = 3;

Ra = Rin/(fc*Cp*Rin - 1);79804

With this parallel resistance value, the voltage offset would be:

V_offset = Ra*Rin/(Ra + Rin) * in;0.11454

Which is much more acceptable.

Add Parallel Resistor

A resistor $R_p \approx 100\,k\Omega$ is added in parallel with the force sensor as shown in Figure fig:force_sensor_model_electronics.

load('force_sensor_steps_R_82k7.mat', 't', 'encoder', 'u', 'v'); figure;

tiledlayout(2, 1, 'TileSpacing', 'None', 'Padding', 'None');

nexttile;

plot(t, v);

xlabel('Time [s]'); ylabel('Measured voltage [V]');

nexttile;

plot(t, u);

xlabel('Time [s]'); ylabel('Actuator Voltage [V]');Three steps are performed at the following time intervals:

t_s = [1.9, 6;

8.5, 13;

15.5, 21;

22.6, 26;

30.0, 36;

37.5, 41;

46.2, 49.5]Fit function:

f = @(b,x) b(1).*exp(b(2).*x) + b(3);

We are interested by the b(2) term, which is the time constant of the exponential.

tau = zeros(size(t_s, 1),1);

V0 = zeros(size(t_s, 1),1); for t_i = 1:size(t_s, 1)

t_cur = t(t_s(t_i, 1) < t & t < t_s(t_i, 2));

t_cur = t_cur - t_cur(1);

y_cur = v(t_s(t_i, 1) < t & t < t_s(t_i, 2));

nrmrsd = @(b) norm(y_cur - f(b,t_cur)); % Residual Norm Cost Function

B0 = [0.5, -0.2, 0.2]; % Choose Appropriate Initial Estimates

[B,rnrm] = fminsearch(nrmrsd, B0); % Estimate Parameters ‘B’

tau(t_i) = 1/B(2);

V0(t_i) = B(3);

endAnd indeed, we obtain a much smaller offset voltage and a much faster time constant.

| $tau$ [s] | $V_0$ [V] |

|---|---|

| 0.43 | 0.15 |

| 0.45 | 0.16 |

| 0.43 | 0.15 |

| 0.43 | 0.15 |

| 0.45 | 0.15 |

| 0.46 | 0.16 |

| 0.48 | 0.16 |

Knowing the capacitance value, we can estimate the value of the added resistor (neglecting the input impedance of $\approx 1\,M\Omega$):

Cp = 4.4e-6; % [F]

Rin = abs(mean(tau))/Cp;101200.0

And we can verify that the bias current estimation stays the same:

in = mean(V0)/Rin;1.5305e-06

This validates the model of the ADC and the effectiveness of the added resistor.

Sinus

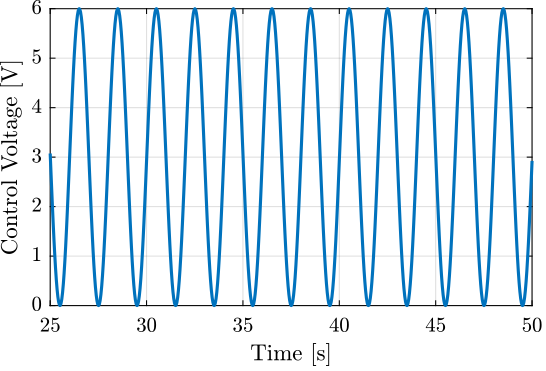

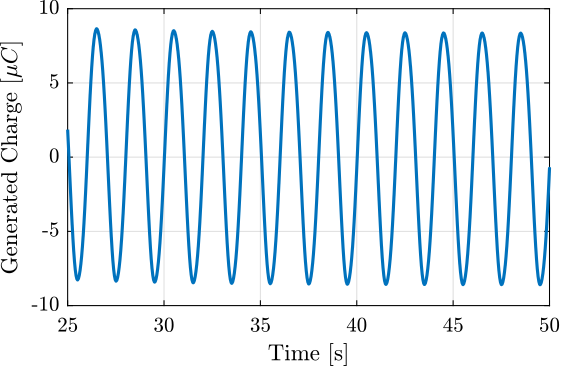

load('force_sensor_sin.mat', 't', 'encoder', 'u', 'v');

u = u(t>25);

v = v(t>25);

encoder = encoder(t>25) - mean(encoder(t>25));

t = t(t>25);The driving voltage is a sinus at 0.5Hz centered on 3V and with an amplitude of 3V (Figure fig:force_sensor_sin_u).

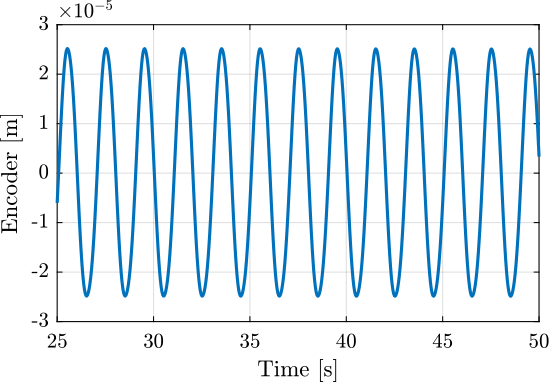

The full stroke as measured by the encoder is:

max(encoder)-min(encoder)5.005e-05

Its signal is shown in Figure fig:force_sensor_sin_encoder.

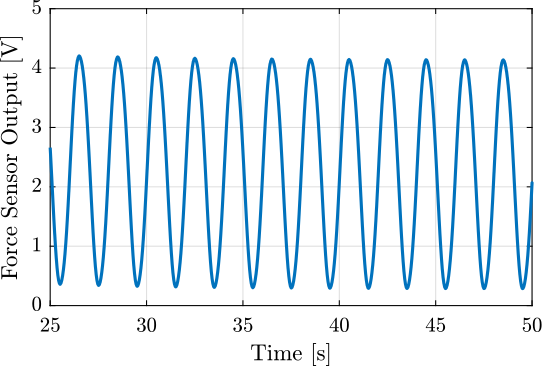

The generated voltage by the stack is shown in Figure

The capacitance of the stack is

Cp = 4.4e-6; % [F]The corresponding generated charge is then shown in Figure fig:force_sensor_sin_charge.

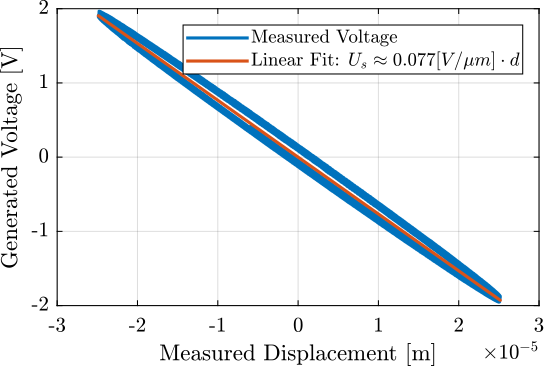

The relation between the generated voltage and the measured displacement is almost linear as shown in Figure fig:force_sensor_linear_relation.

b1 = encoder\(v-mean(v));With a 16bits ADC, the resolution will then be equals to (in [nm]):

abs((20/2^16)/(b1/1e9))3.9838