44 KiB

Amplifier Piezoelectric Actuator APA300ML - Test Bench

- Introduction

- Model of an Amplified Piezoelectric Actuator and Sensor

- Geometrical Measurements

- Electrical Measurements

- Stiffness measurement

- Test-Bench Description

- Measurement Procedure

- Measurement Results

- Bibliography

This report is also available as a pdf.

Introduction ignore

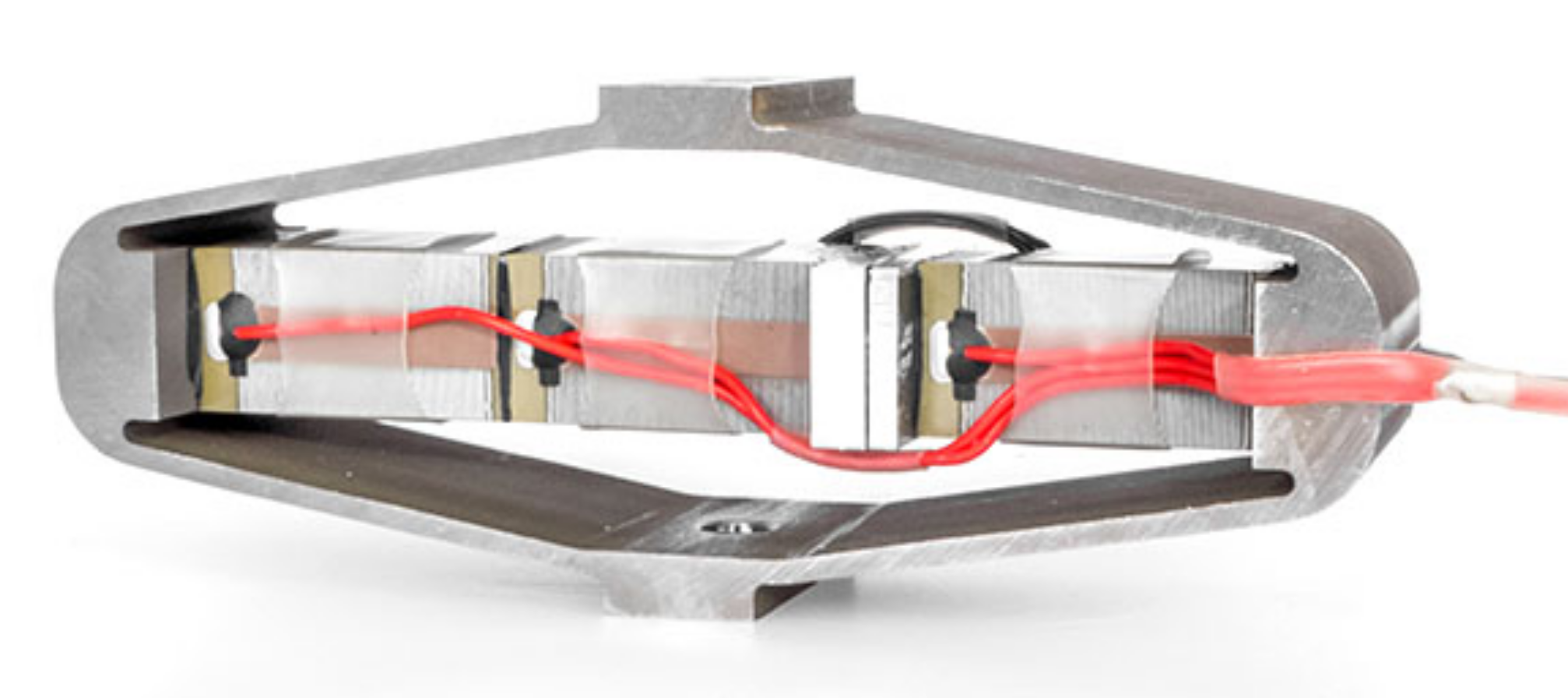

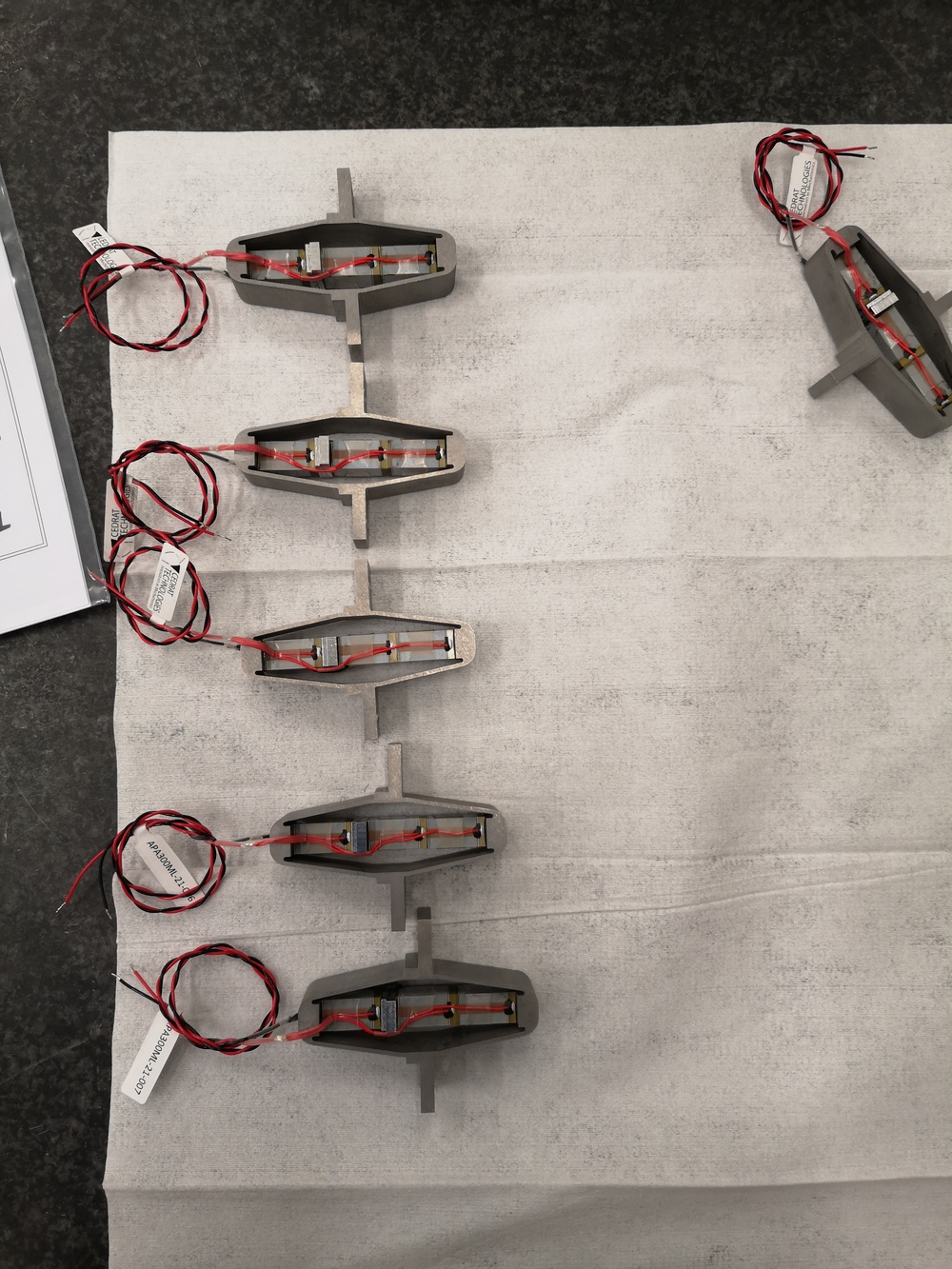

The goal of this test bench is to extract all the important parameters of the Amplified Piezoelectric Actuator APA300ML.

This include:

- Stroke

- Stiffness

- Hysteresis

- Gain from the applied voltage $V_a$ to the generated Force $F_a$

- Gain from the sensor stack strain $\delta L$ to the generated voltage $V_s$

- Dynamical behavior

Model of an Amplified Piezoelectric Actuator and Sensor

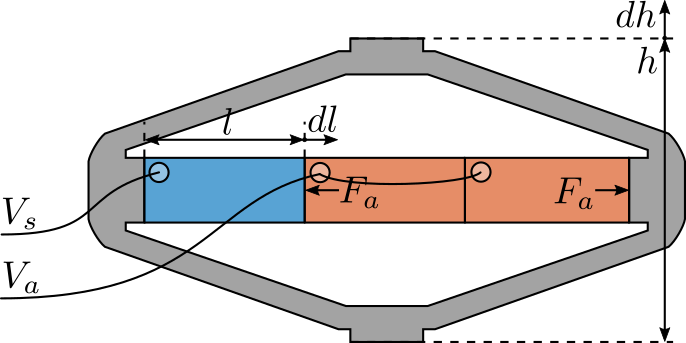

Consider a schematic of the Amplified Piezoelectric Actuator in Figure fig:apa_model_schematic.

A voltage $V_a$ applied to the actuator stacks will induce an actuator force $F_a$:

\begin{equation} F_a = g_a \cdot V_a \end{equation}A change of length $dl$ of the sensor stack will induce a voltage $V_s$:

\begin{equation} V_s = g_s \cdot dl \end{equation}We wish here to experimental measure $g_a$ and $g_s$.

The block-diagram model of the piezoelectric actuator is then as shown in Figure fig:apa-model-simscape-schematic.

\begin{tikzpicture}

\node[block={2.0cm}{2.0cm}, align=center] (model) at (0,0){Simscape\\Model};

\node[block, left=1.0 of model] (ga){$g_a(s)$};

\node[block, right=1.0 of model] (gs){$g_s(s)$};

\draw[<-] (ga.west) -- node[midway, above]{$V_a$} node[midway, below]{$[V]$} ++(-1.0, 0);

\draw[->] (ga.east) --node[midway, above]{$F_a$} node[midway, below]{$[N]$} (model.west);

\draw[->] (model.east) --node[midway, above]{$dl$} node[midway, below]{$[m]$} (gs.west);

\draw[->] (gs.east) -- node[midway, above]{$V_s$} node[midway, below]{$[V]$} ++(1.0, 0);

\end{tikzpicture}

Geometrical Measurements

Introduction ignore

Measurement Setup

Measurement Results

Height (Z) measurements:

apa1 = 1e-6*[0, -0.5 , 3.5 , 3.5 , 42 , 45.5, 52.5 , 46];

apa2 = 1e-6*[0, -2.5 , -3 , 0 , -1.5 , 1 , -2 , -4];

apa3 = 1e-6*[0, -1.5 , 15 , 17.5 , 6.5 , 6.5 , 21 , 23];

apa4 = 1e-6*[0, 6.5 , 14.5 , 9 , 16 , 22 , 29.5 , 21];

apa5 = 1e-6*[0, -12.5, 16.5 , 28.5 , -43 , -52 , -22.5, -13.5];

apa6 = 1e-6*[0, -8 , -2 , 5 , -57.5, -62 , -55.5, -52.5];

apa7 = 1e-6*[0, 19.5 , -8 , -29.5, 75 , 97.5, 70 , 48];

apa7b = 1e-6*[0, 9 , -18.5, -30 , 31 , 46.5, 16.5 , 7.5];

apa = {apa1, apa2, apa3, apa4, apa5, apa6, apa7b};X/Y Positions of the 8 measurement points:

W = 20e-3; % Width [m]

L = 61e-3; % Length [m]

d = 1e-3; % Distance from border [m]

l = 15.5e-3; % [m]

pos = [[-L/2 + d; W/2 - d], [-L/2 + l - d; W/2 - d], [-L/2 + l - d; -W/2 + d], [-L/2 + d; -W/2 + d], [L/2 - l + d; W/2 - d], [L/2 - d; W/2 - d], [L/2 - d; -W/2 + d], [L/2 - l + d; -W/2 + d]];apa_d = zeros(1, 7);

for i = 1:7

fun = @(x)max(abs(([pos; apa{i}]-[0;0;x(1)])'*([x(2:3);1]/norm([x(2:3);1]))));

x0 = [0;0;0];

[x, min_d] = fminsearch(fun,x0);

apa_d(i) = min_d;

end| Flatness [um] |

|---|

| 8.9 |

| 3.1 |

| 9.1 |

| 3.0 |

| 1.9 |

| 7.1 |

| 18.7 |

Electrical Measurements

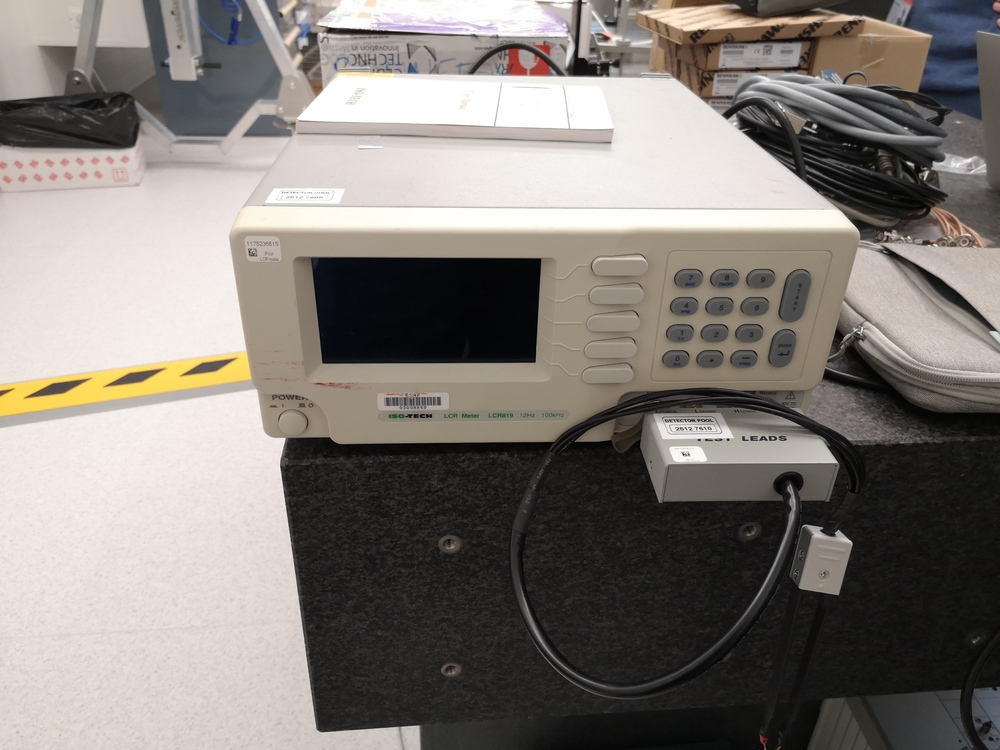

The capacitance of the stacks is measure with the LCR-800 Meter (doc)

The excitation frequency is set to be 1kHz.

| APA Number | Sensor Stack | Actuator Stacks |

|---|---|---|

| 1 | 5.10 | 10.03 |

| 2 | 4.99 | 9.85 |

| 3 | 1.72 | 5.18 |

| 4 | 4.94 | 9.82 |

| 5 | 4.90 | 9.66 |

| 6 | 4.99 | 9.91 |

| 7 | 4.85 | 9.85 |

There is clearly a problem with APA300ML number 3

Stiffness measurement

APA test

load('meas_stiff_apa_1_x.mat', 't', 'F', 'd');figure;

plot(t, F)%% Automatic Zero of the force

F = F - mean(F(t > 0.1 & t < 0.3));

%% Start measurement at t = 0.2 s

d = d(t > 0.2);

F = F(t > 0.2);

t = t(t > 0.2); t = t - t(1);i_l_start = find(F > 0.3, 1, 'first');

[~, i_l_stop] = max(F);F_l = F(i_l_start:i_l_stop);

d_l = d(i_l_start:i_l_stop);fit_l = polyfit(F_l, d_l, 1);

% %% Reset displacement based on fit

% d = d - fit_l(2);

% fit_s(2) = fit_s(2) - fit_l(2);

% fit_l(2) = 0;

% %% Estimated Stroke

% F_max = fit_s(2)/(fit_l(1) - fit_s(1));

% d_max = fit_l(1)*F_max;h^2/fit_l(1)figure;

hold on;

plot(F,d,'k')

plot(F_l, d_l)

plot(F_l, F_l*fit_l(1) + fit_l(2), '--')Test-Bench Description

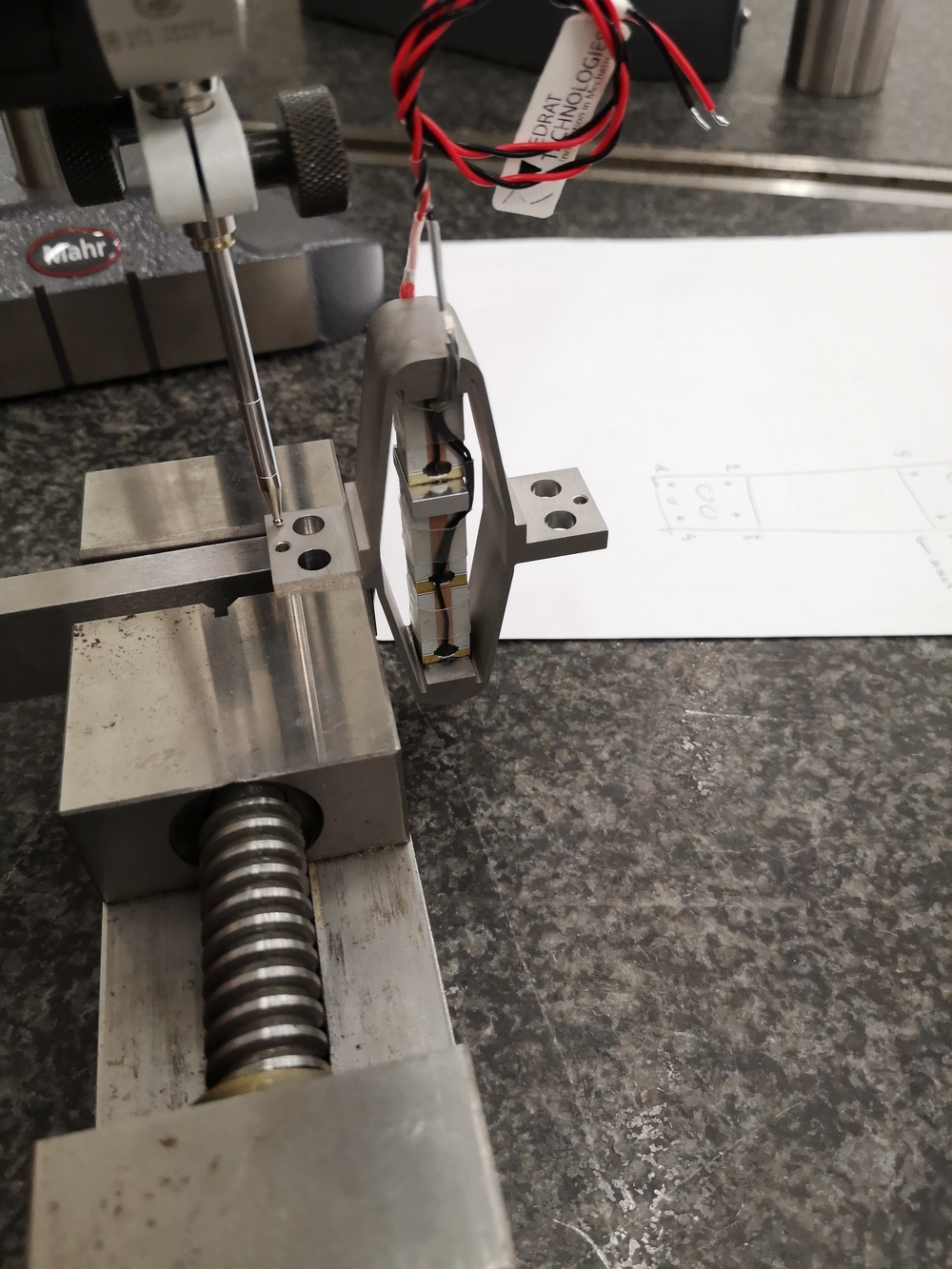

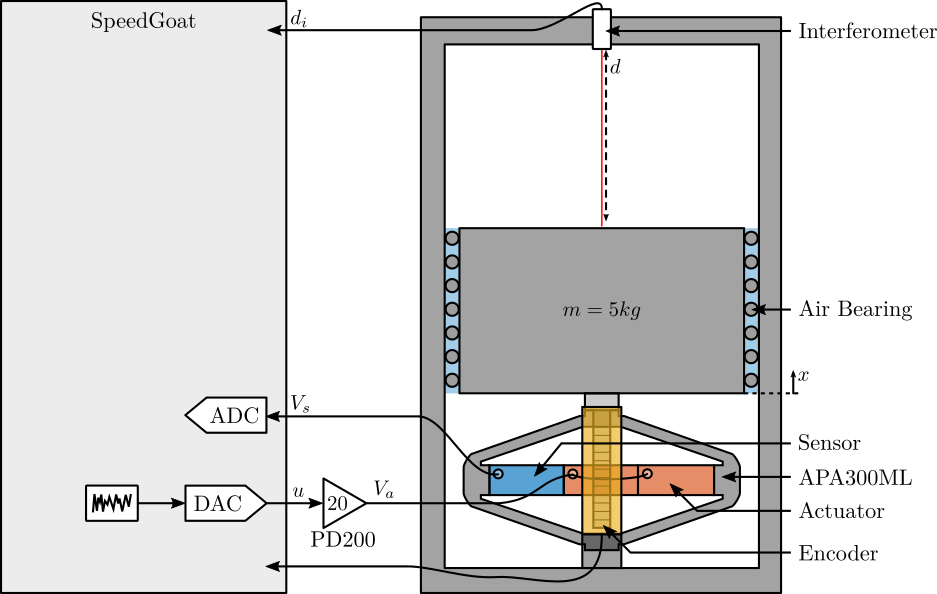

Here are the documentation of the equipment used for this test bench:

- Voltage Amplifier: PD200

- Amplified Piezoelectric Actuator: APA300ML

- DAC/ADC: Speedgoat IO313

- Encoder: Renishaw Vionic and used Ruler

- Interferometer: Attocube IDS3010

Measurement Procedure

Introduction ignore

Stroke Measurement

Using the PD200 amplifier, output a voltage: \[ V_a = 65 + 85 \sin(2\pi \cdot t) \] To have a quasi-static excitation between -20 and 150V.

As the gain of the PD200 amplifier is 20, the DAC output voltage should be: \[ V_{dac}(t) = 3.25 + 4.25\sin(2\pi \cdot t) \]

Verify that the voltage offset of the PD200 is zero!

Measure the output vertical displacement $d$ using the interferometer.

Then, plot $d$ as a function of $V_a$, and perform a linear regression. Conclude on the obtained stroke.

Stiffness Measurement

Add some (known) weight $\delta m g$ on the suspended mass and measure the deflection $\delta d$. This can be tested when the piezoelectric stacks are open-circuit.

As the stiffness will be around $k \approx 10^6 N/m$, an added mass of $m \approx 100g$ will induce a static deflection of $\approx 1\mu m$ which should be large enough for a precise measurement using the interferometer.

Then the obtained stiffness is:

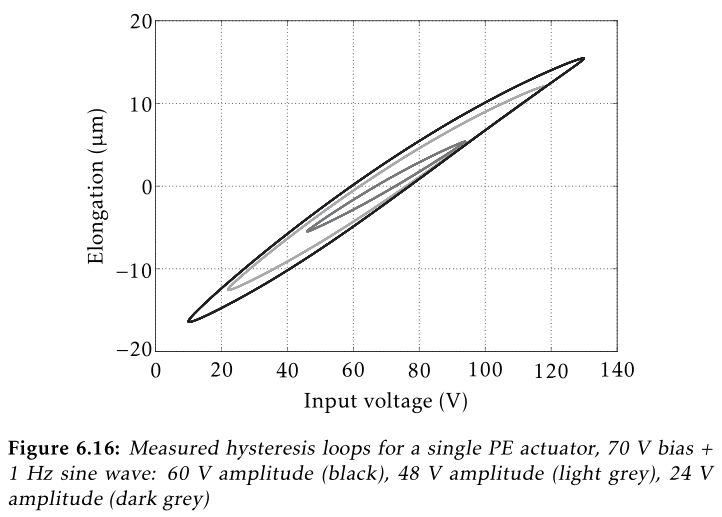

\begin{equation} k = \frac{\delta m g}{\delta d} \end{equation}Hysteresis measurement

Supply a quasi static sinusoidal excitation $V_a$ at different voltages.

The offset should be 65V, and the sin amplitude can range from 1V up to 85V.

For each excitation amplitude, the vertical displacement $d$ of the mass is measured.

Then, $d$ is plotted as a function of $V_a$ for all the amplitudes.

Piezoelectric Actuator Constant

Using the measurement test-bench, it is rather easy the determine the static gain between the applied voltage $V_a$ to the induced displacement $d$. Use a quasi static (1Hz) excitation signal $V_a$ on the piezoelectric stack and measure the vertical displacement $d$. Perform a linear regression to obtain:

\begin{equation} d = g_{d/V_a} \cdot V_a \end{equation}Using the Simscape model of the APA, it is possible to determine the static gain between the actuator force $F_a$ to the induced displacement $d$:

\begin{equation} d = g_{d/F_a} \cdot F_a \end{equation}From the two gains, it is then easy to determine $g_a$:

\begin{equation} g_a = \frac{F_a}{V_a} = \frac{F_a}{d} \cdot \frac{d}{V_a} = \frac{g_{d/V_a}}{g_{d/F_a}} \end{equation}Piezoelectric Sensor Constant

From a quasi static excitation of the piezoelectric stack, measure the gain from $V_a$ to $V_s$:

\begin{equation} V_s = g_{V_s/V_a} V_a \end{equation}Note here that there is an high pass filter formed by the piezo capacitor and parallel resistor. The excitation frequency should then be in between the cut-off frequency of this high pass filter and the first resonance.

Alternatively, the gain can be computed from the dynamical identification and taking the gain at the wanted frequency.

Using the simscape model, compute the static gain from the actuator force $F_a$ to the strain of the sensor stack $dl$:

\begin{equation} dl = g_{dl/F_a} F_a \end{equation}Then, the static gain from the sensor stack strain $dl$ to the general voltage $V_s$ is:

\begin{equation} g_s = \frac{V_s}{dl} = \frac{V_s}{V_a} \cdot \frac{V_a}{F_a} \cdot \frac{F_a}{dl} = \frac{g_{V_s/V_a}}{g_a \cdot g_{dl/F_a}} \end{equation}Alternatively, we could impose an external force to add strain in the APA that should be equally present in all the 3 stacks and equal to 1/5 of the vertical strain. This external force can be some weight added, or a piezo in parallel.

Capacitance Measurement

Measure the capacitance of the 3 stacks individually using a precise multi-meter.

Dynamical Behavior

Perform a system identification from $V_a$ to the measured displacement $d$ by the interferometer and by the encoder, and to the generated voltage $V_s$.

This can be performed using different excitation signals.

This can also be performed with and without the encoder fixed to the APA.

Compare the results obtained for all 7 APA300ML

Compare all the obtained parameters for all the test APA.