89 KiB

Test Bench - Amplified Piezoelectric Actuator

- Introduction

- First Basic Measurements

- Dynamical measurements

- APA300ML - 2 Degrees of Freedom Model

- APA300ML - Super Element

- Conclusion

- Bibliography

- Footnotes

This report is also available as a pdf.

Introduction ignore

In this chapter, the goal is to make sure that the received APA300ML (shown in Figure ref:fig:test_apa_received) are complying with the requirements and that dynamical models of the actuator are well representing its dynamics.

In section ref:sec:test_apa_basic_meas, the mechanical tolerances of the APA300ML interfaces are checked together with the electrical properties of the piezoelectric stacks, the achievable stroke. Flexible modes of the APA300ML are computed with a finite element model and compared with measurements.

Using a dedicated test bench, dynamical measurements are performed (Section ref:sec:test_apa_dynamics). The dynamics from the generated DAC voltage (going through the voltage amplifier and then to two actuator stacks) to the induced axial displacement and to the measured voltage across the force sensor stack are estimated. Integral Force Feedback is experimentally applied and the damped plants are estimated for several feedback gains.

Two different models of the APA300ML are then presented. First, in Section ref:sec:test_apa_model_2dof, a two degrees of freedom model is presented, tuned and compared with the measured dynamics. This model is proven to accurately simulate the APA300ML's axial dynamics.

Then, in Section ref:sec:test_apa_model_flexible, a super element of the APA300ML is extracted using a finite element model and imported in Simscape. This more complex model is also shown to well capture the axial dynamics of the APA300ML.

| Sections | Matlab File |

|---|---|

| Section ref:sec:test_apa_basic_meas | test_apa_1_basic_meas.m |

| Section ref:sec:test_apa_dynamics | test_apa_2_dynamics.m |

| Section ref:sec:test_apa_model_2dof | test_apa_3_model_2dof.m |

| Section ref:sec:test_apa_model_flexible | test_apa_4_model_flexible.m |

First Basic Measurements

<<sec:test_apa_basic_meas>>

Introduction ignore

Before measuring the dynamical characteristics of the APA300ML, first simple measurements are performed. First, the tolerances (especially flatness) of the mechanical interfaces are checked in Section ref:ssec:test_apa_geometrical_measurements. Then, the capacitance of the piezoelectric stacks is measured in Section ref:ssec:test_apa_electrical_measurements. The achievable stroke of the APA300ML is measured using a displacement probe in Section ref:ssec:test_apa_stroke_measurements. Finally, in Section ref:ssec:test_apa_spurious_resonances, the flexible modes of the APA are measured and compared with a finite element model.

Geometrical Measurements

<<ssec:test_apa_geometrical_measurements>>

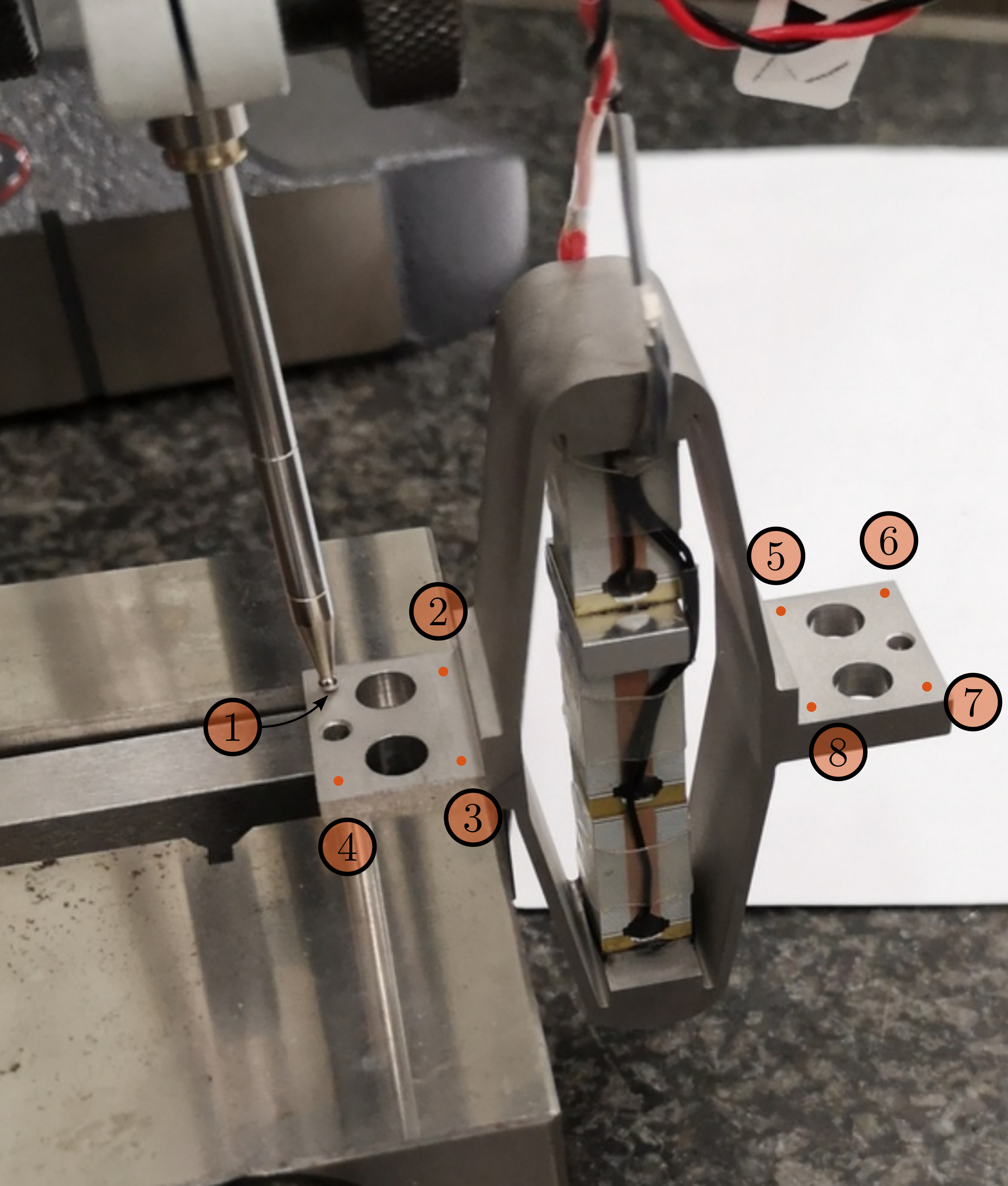

To measure the flatness of the two mechanical interfaces of the APA300ML, a small measurement bench is installed on top of a metrology granite with excellent flatness. As shown in Figure ref:fig:test_apa_flatness_setup, the APA is fixed to a clamp while a measuring probe1 is used to measure the height of 4 points on each of the APA300ML interfaces. From the X-Y-Z coordinates of the measured 8 points, the flatness is estimated by best fitting2 a plane through all the points. The measured flatness, summarized in Table ref:tab:test_apa_flatness_meas, are within the specifications.

%% Measured height for all the APA at the 8 locations

apa1 = 1e-6*[0, -0.5 , 3.5 , 3.5 , 42 , 45.5, 52.5 , 46];

apa2 = 1e-6*[0, -2.5 , -3 , 0 , -1.5 , 1 , -2 , -4];

apa3 = 1e-6*[0, -1.5 , 15 , 17.5 , 6.5 , 6.5 , 21 , 23];

apa4 = 1e-6*[0, 6.5 , 14.5 , 9 , 16 , 22 , 29.5 , 21];

apa5 = 1e-6*[0, -12.5, 16.5 , 28.5 , -43 , -52 , -22.5, -13.5];

apa6 = 1e-6*[0, -8 , -2 , 5 , -57.5, -62 , -55.5, -52.5];

apa7 = 1e-6*[0, 9 , -18.5, -30 , 31 , 46.5, 16.5 , 7.5];

apa = {apa1, apa2, apa3, apa4, apa5, apa6, apa7};

%% X-Y positions of the measurements points

W = 20e-3; % Width [m]

L = 61e-3; % Length [m]

d = 1e-3; % Distance from border [m]

l = 15.5e-3; % [m]

pos = [[-L/2 + d, W/2 - d];

[-L/2 + l - d, W/2 - d];

[-L/2 + l - d, -W/2 + d];

[-L/2 + d, -W/2 + d];

[L/2 - l + d, W/2 - d];

[L/2 - d, W/2 - d];

[L/2 - d, -W/2 + d];

[L/2 - l + d, -W/2 + d]]';

%% Using fminsearch to find the best fitting plane

apa_d = zeros(1, 7); % Measured flatness of the APA

for i = 1:7

fun = @(x)max(abs(([pos; apa{i}]-[0;0;x(1)])'*([x(2:3);1]/norm([x(2:3);1]))));

x0 = [0;0;0];

[x, min_d] = fminsearch(fun,x0);

apa_d(i) = min_d;

end

\hfill

| Flatness $[\mu m]$ | |

|---|---|

| APA 1 | 8.9 |

| APA 2 | 3.1 |

| APA 3 | 9.1 |

| APA 4 | 3.0 |

| APA 5 | 1.9 |

| APA 6 | 7.1 |

| APA 7 | 18.7 |

Electrical Measurements

<<ssec:test_apa_electrical_measurements>>

From the documentation of the APA300ML, the total capacitance of the three stacks should be between $18\,\mu F$ and $26\,\mu F$ with a nominal capacitance of $20\,\mu F$.

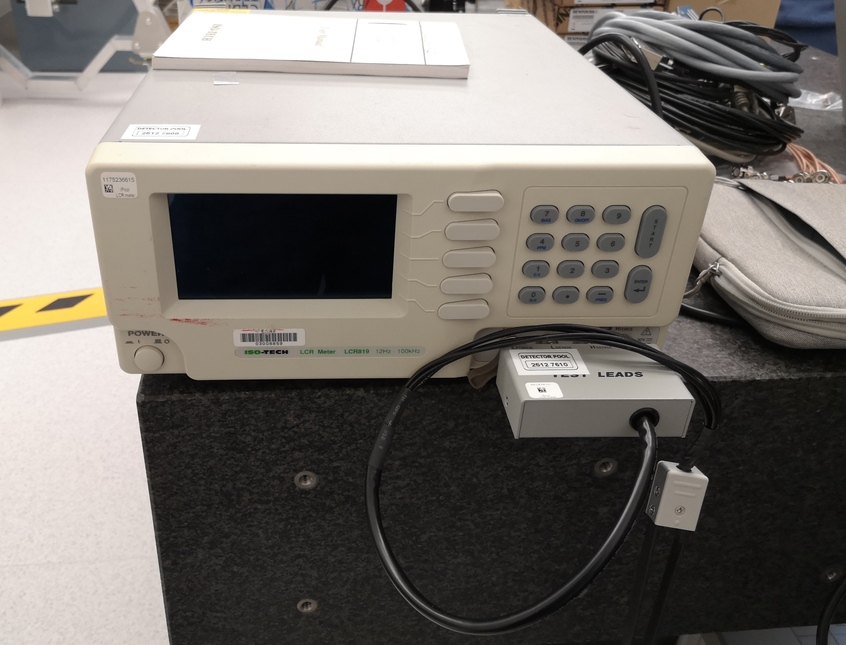

The piezoelectric stacks capacitance of the APA300ML have been measured with the LCR meter3 shown in Figure ref:fig:test_apa_lcr_meter. The two stacks used as an actuator and the stack used as a force sensor are measured separately. The measured capacitance are summarized in Table ref:tab:test_apa_capacitance and the average capacitance of one stack is $\approx 5 \mu F$. However, the measured capacitance of the stacks of "APA 3" is only half of the expected capacitance. This may indicate a manufacturing defect.

The measured capacitance is found to be lower than the specified one. This may be due to the fact that the manufacturer measures the capacitance with large signals ($-20\,V$ to $150\,V$) while it was here measured with small signals cite:&wehrsdorfer95_large_signal_measur_piezoel_stack.

\hfill

| Sensor Stack | Actuator Stacks | |

|---|---|---|

| APA 1 | 5.10 | 10.03 |

| APA 2 | 4.99 | 9.85 |

| APA 3 | 1.72 | 5.18 |

| APA 4 | 4.94 | 9.82 |

| APA 5 | 4.90 | 9.66 |

| APA 6 | 4.99 | 9.91 |

| APA 7 | 4.85 | 9.85 |

Stroke and Hysteresis Measurement

<<ssec:test_apa_stroke_measurements>>

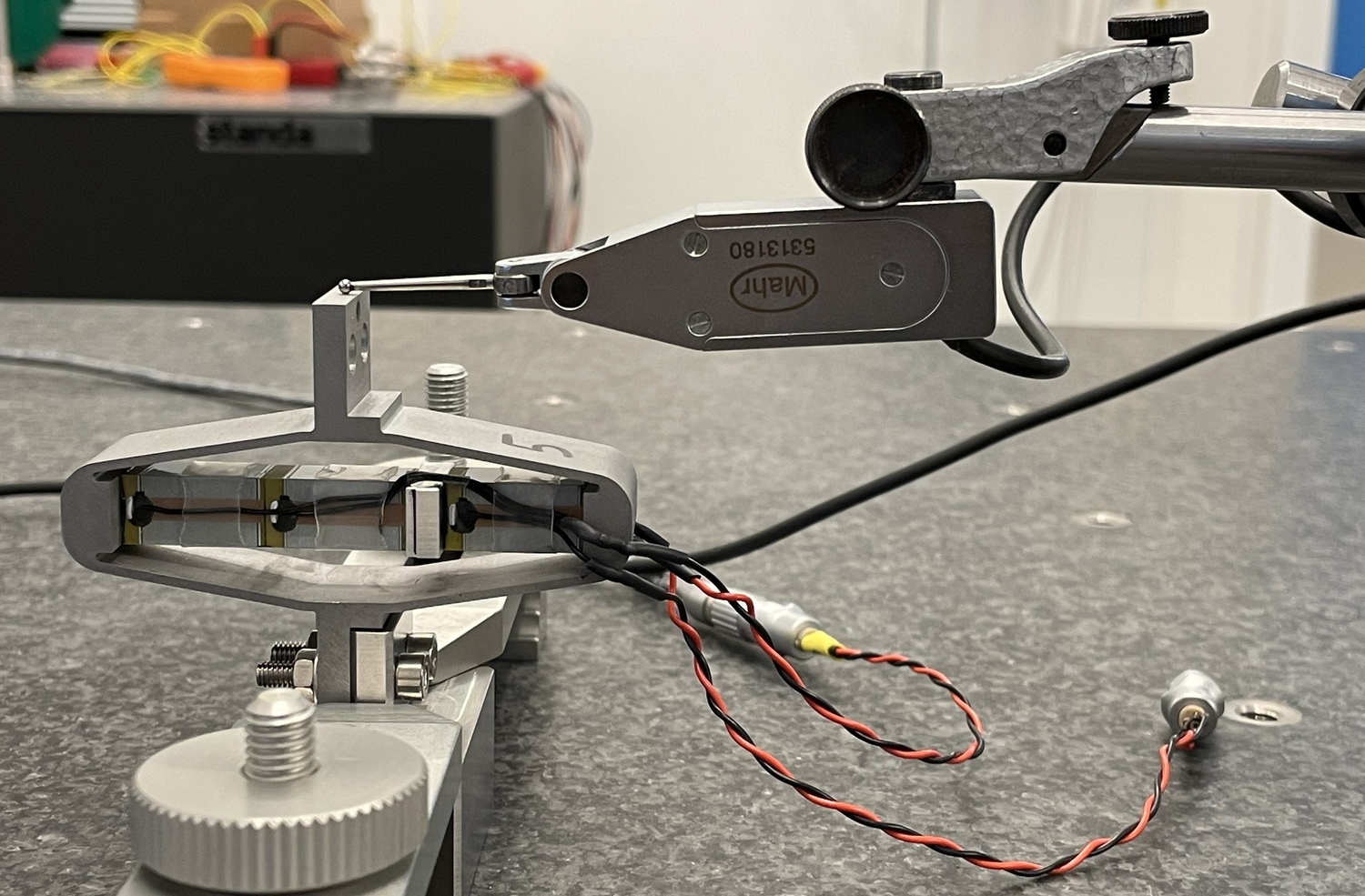

In order to verify that the stroke of the APA300ML is as specified in the datasheet, one side of the APA is fixed to the granite, and a displacement probe4 is located on the other side as shown in Figure ref:fig:test_apa_stroke_bench.

Then, the voltage across the two actuator stacks is varied from $-20\,V$ to $150\,V$ using a DAC and a voltage amplifier. Note that the voltage is here slowly varied as the displacement probe has a very low measurement bandwidth (see Figure ref:fig:test_apa_stroke_voltage).

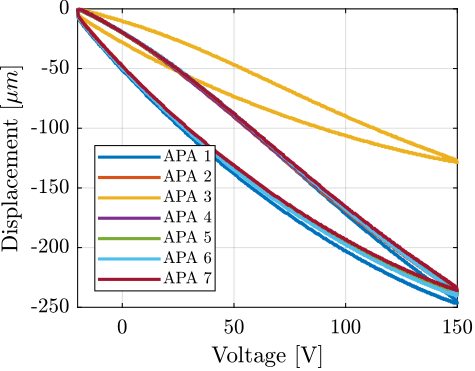

The measured APA displacement is shown as a function of the applied voltage in Figure ref:fig:test_apa_stroke_hysteresis. Typical hysteresis curves for piezoelectric stack actuators can be observed. The measured stroke is approximately $250\,\mu m$ when using only two of the three stacks, which is enough for the current application. This is even above what is specified as the nominal stroke in the data-sheet ($304\,\mu m$, therefore $\approx 200\,\mu m$ if only two stacks are used).

It is clear from Figure ref:fig:test_apa_stroke_hysteresis that "APA 3" has an issue compared to the other units. This confirms the abnormal electrical measurements made in Section ref:ssec:test_apa_electrical_measurements. This unit was send sent back to Cedrat and a new one was shipped back. From now on, only the six APA that behave as expected will be used.

%% Load the measured strokes

load('meas_apa_stroke.mat', 'apa300ml_2s')

Flexible Mode Measurement

<<ssec:test_apa_spurious_resonances>>

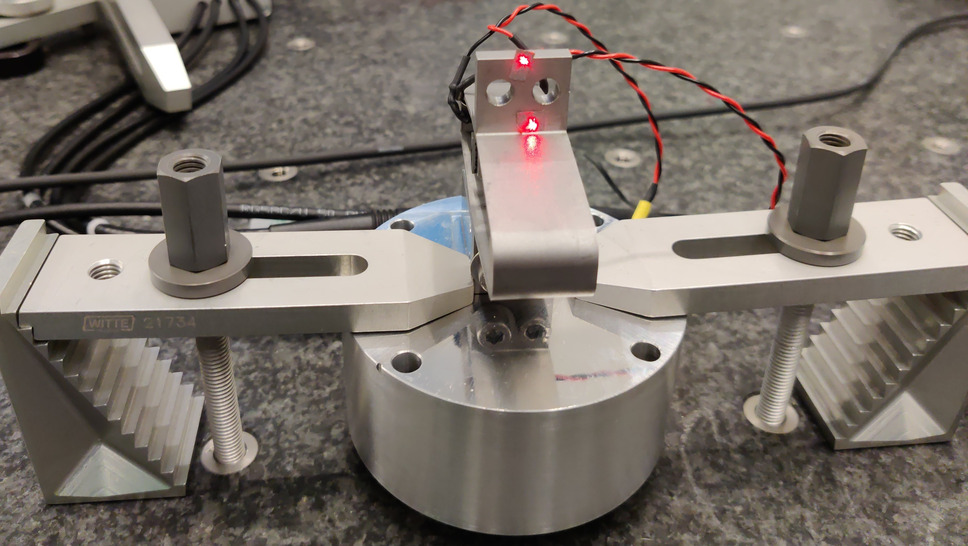

In this section, the flexible modes of the APA300ML are investigated both experimentally and using a Finite Element Model. To experimentally estimate these modes, the APA is fixed on one end (see Figure ref:fig:test_apa_meas_setup_modes). A Laser Doppler Vibrometer5 is used to measure the difference of motion between two "red" points and an instrumented hammer6 is used to excite the flexible modes. Using this setup, the transfer function from the injected force to the measured rotation can be computed in different conditions and the frequency and mode shapes of the flexible modes can be estimated.

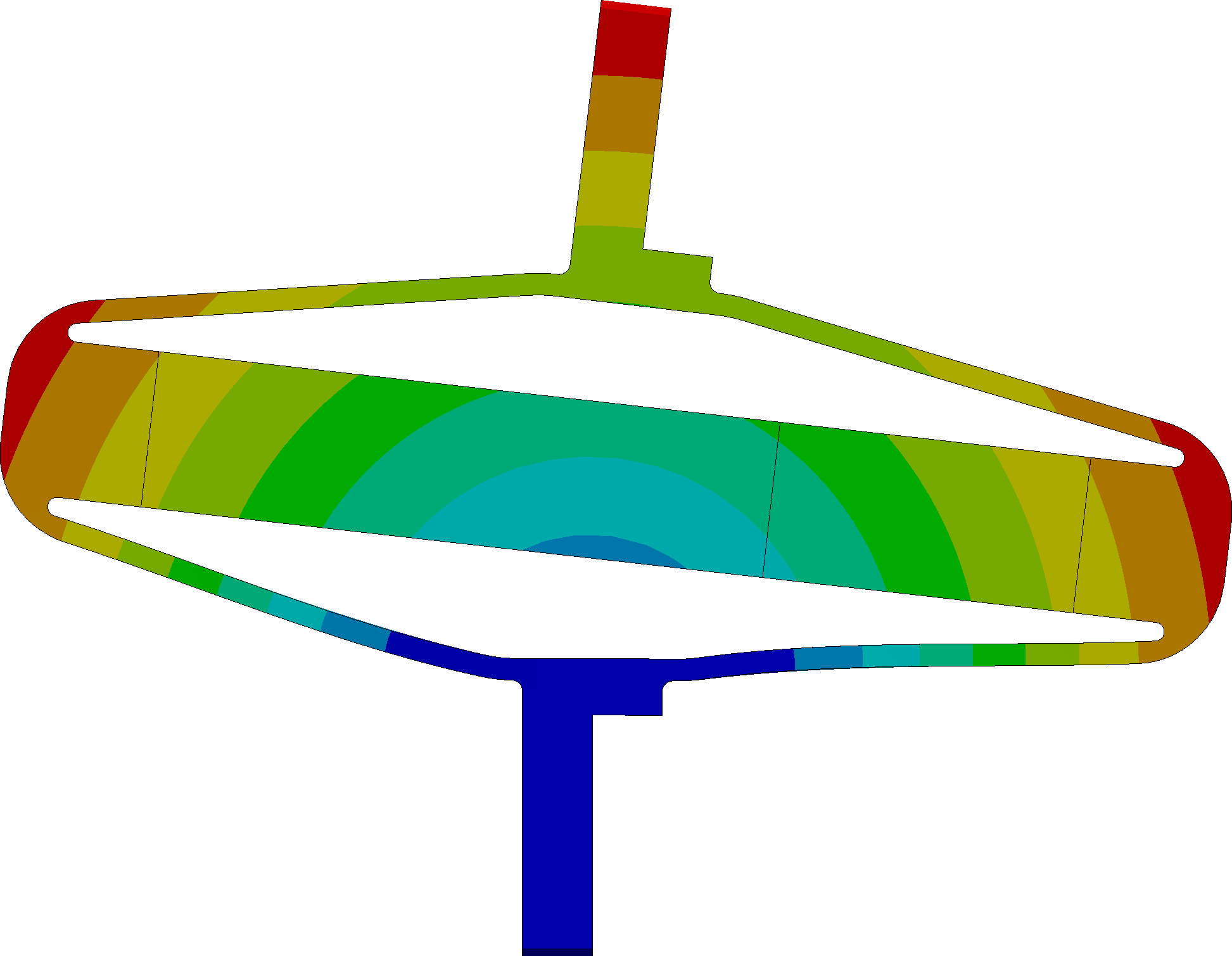

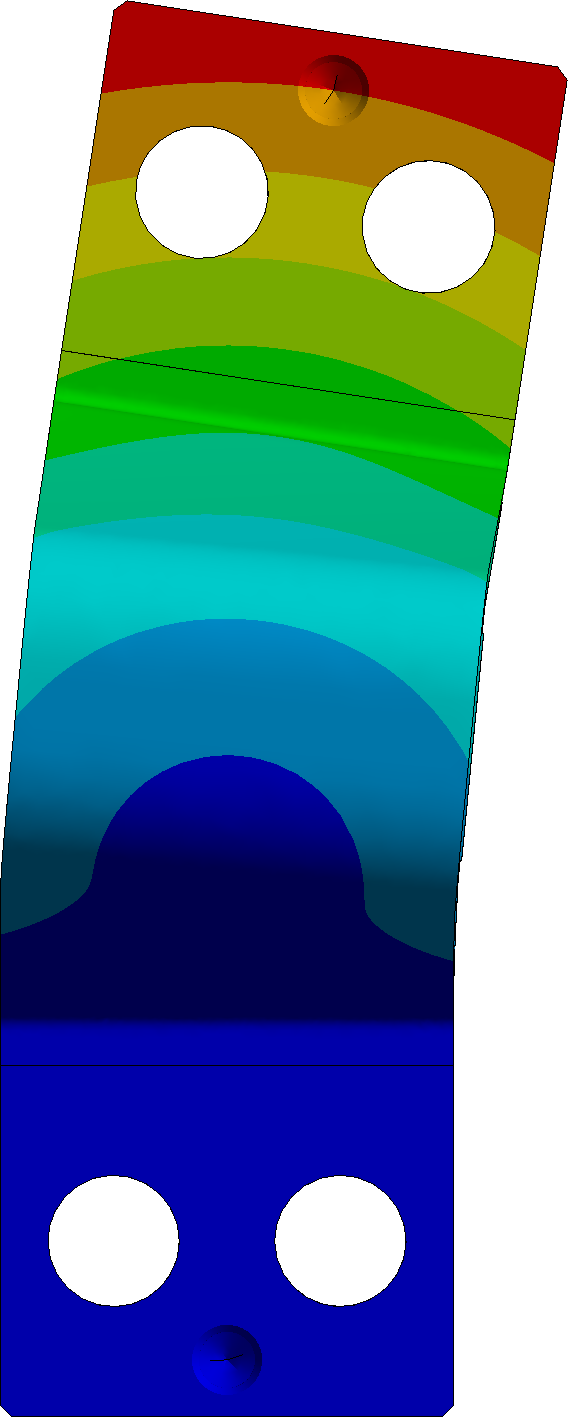

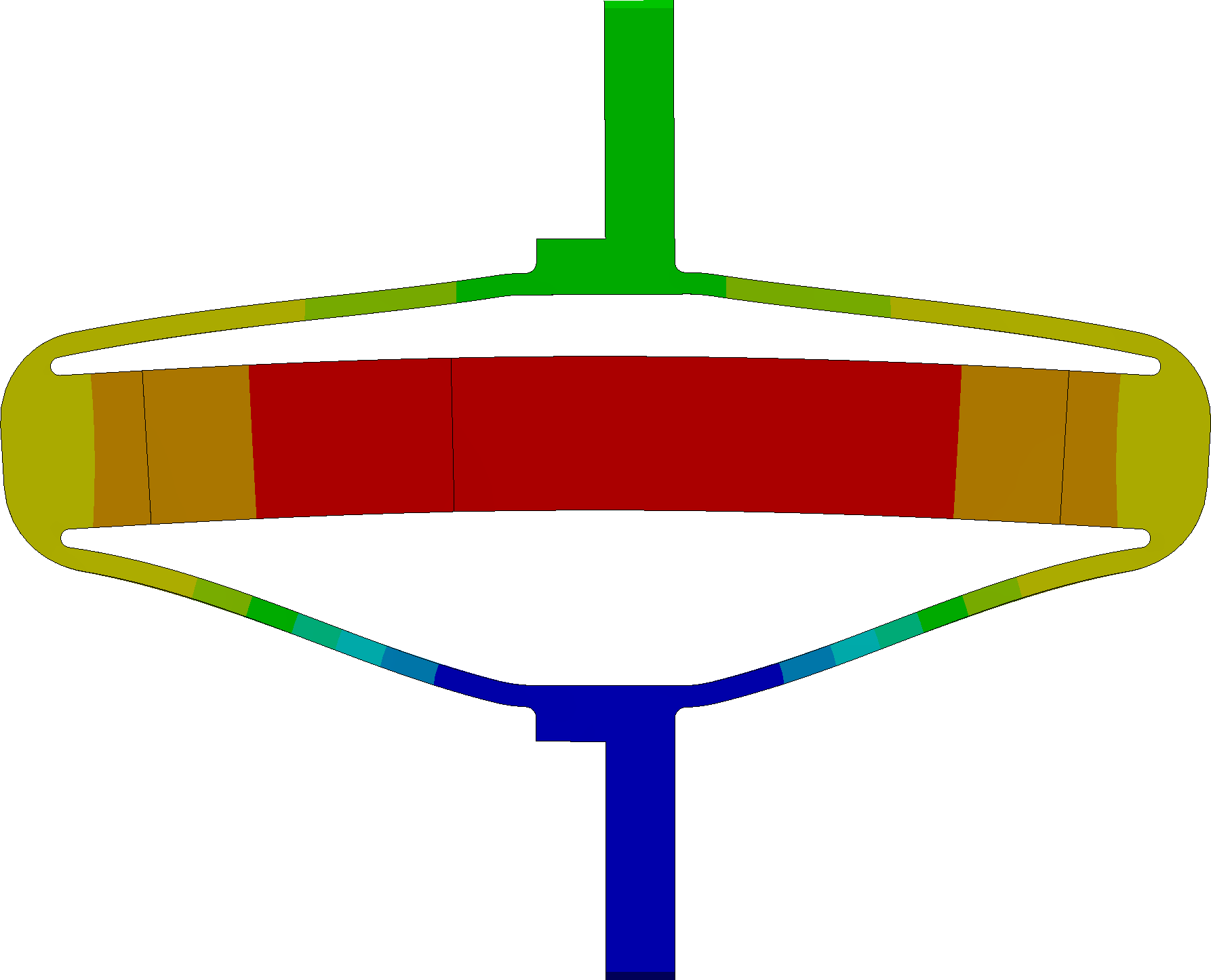

The flexible modes for the same condition (i.e. one mechanical interface of the APA300ML fixed) are estimated using a finite element software and the results are shown in Figure ref:fig:test_apa_mode_shapes.

%% X-Bending Identification

% Load Data

bending_X = load('apa300ml_bending_X_top.mat');

% Spectral Analysis setup

Ts = bending_X.Track1_X_Resolution; % Sampling Time [s]

Nfft = floor(1/Ts);

win = hanning(Nfft);

Noverlap = floor(Nfft/2);

% Compute the transfer function from applied force to measured rotation

[G_bending_X, f] = tfestimate(bending_X.Track1, bending_X.Track2, win, Noverlap, Nfft, 1/Ts);

%% Y-Bending identification

% Load Data

bending_Y = load('apa300ml_bending_Y_top.mat');

% Compute the transfer function

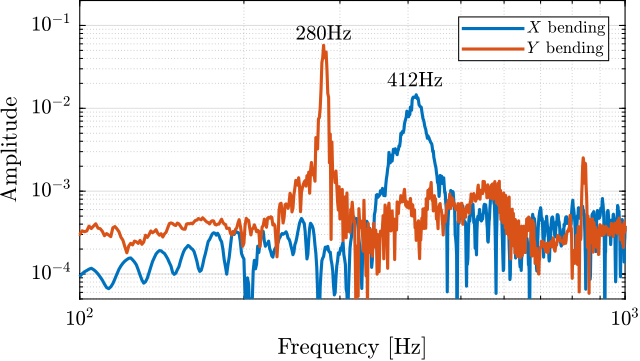

[G_bending_Y, ~] = tfestimate(bending_Y.Track1, bending_Y.Track2, win, Noverlap, Nfft, 1/Ts);The measured frequency response functions computed from the experimental setups of figures ref:fig:test_apa_meas_setup_X_bending and ref:fig:test_apa_meas_setup_Y_bending are shown in Figure ref:fig:test_apa_meas_freq_compare. The $y$ bending mode is observed at $280\,\text{Hz}$ and the $x$ bending mode is at $412\,\text{Hz}$. These modes are measured at higher frequencies than the estimated frequencies from the Finite Element Model (see frequencies in Figure ref:fig:test_apa_meas_setup_modes). This is opposite to what is usually observed (i.e. having lower resonance frequencies in practice than the estimation from a finite element model). This could be explained by underestimation of the Young's modulus of the steel used for the shell (190 GPa was used for the model, but steel with Young's modulus of 210 GPa could have been used). Another explanation is the shape difference between the manufactured APA300ML and the 3D model, for instance thicker blades.

Dynamical measurements

<<sec:test_apa_dynamics>>

Introduction ignore

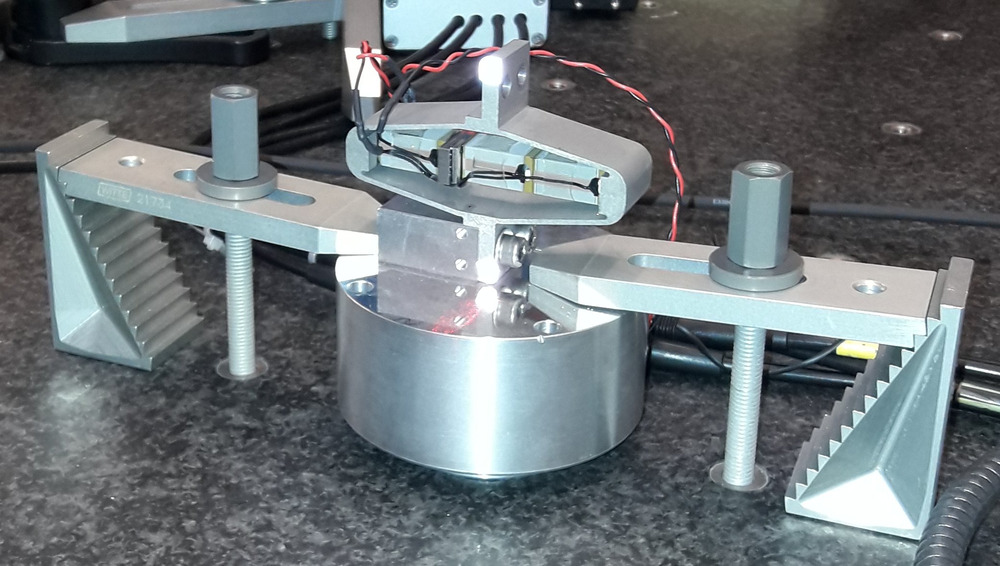

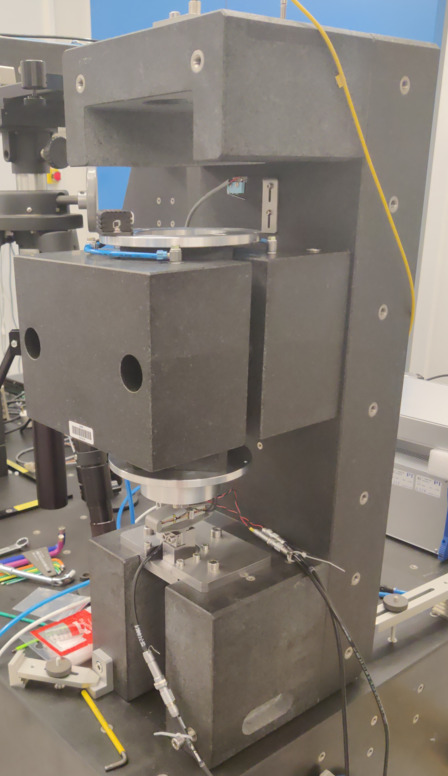

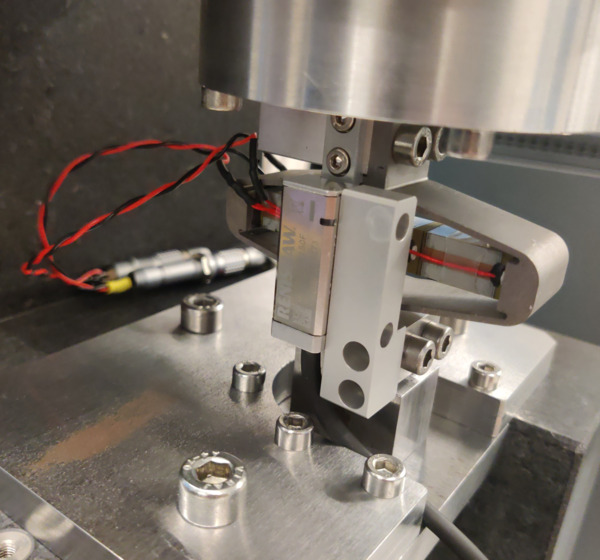

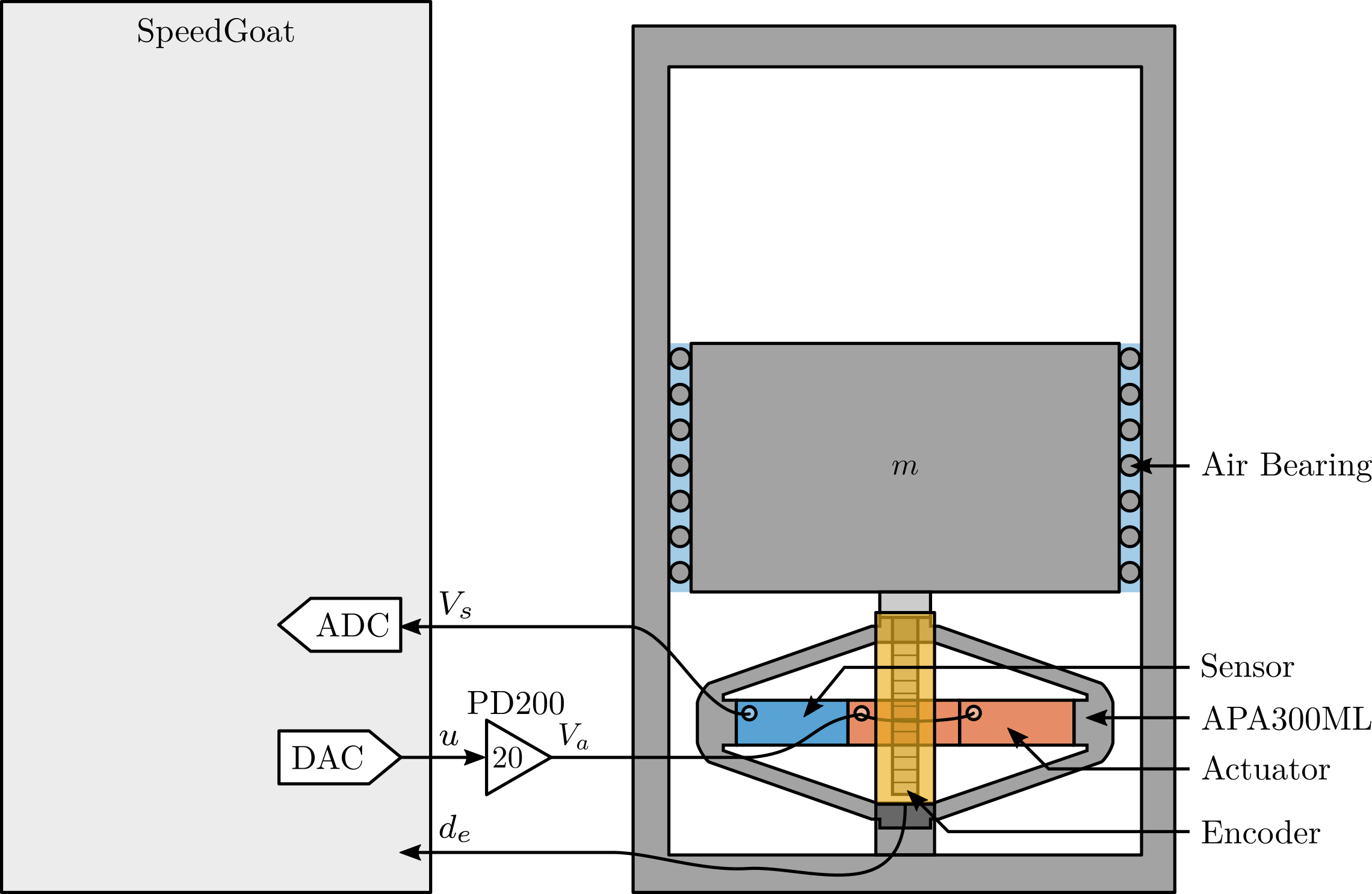

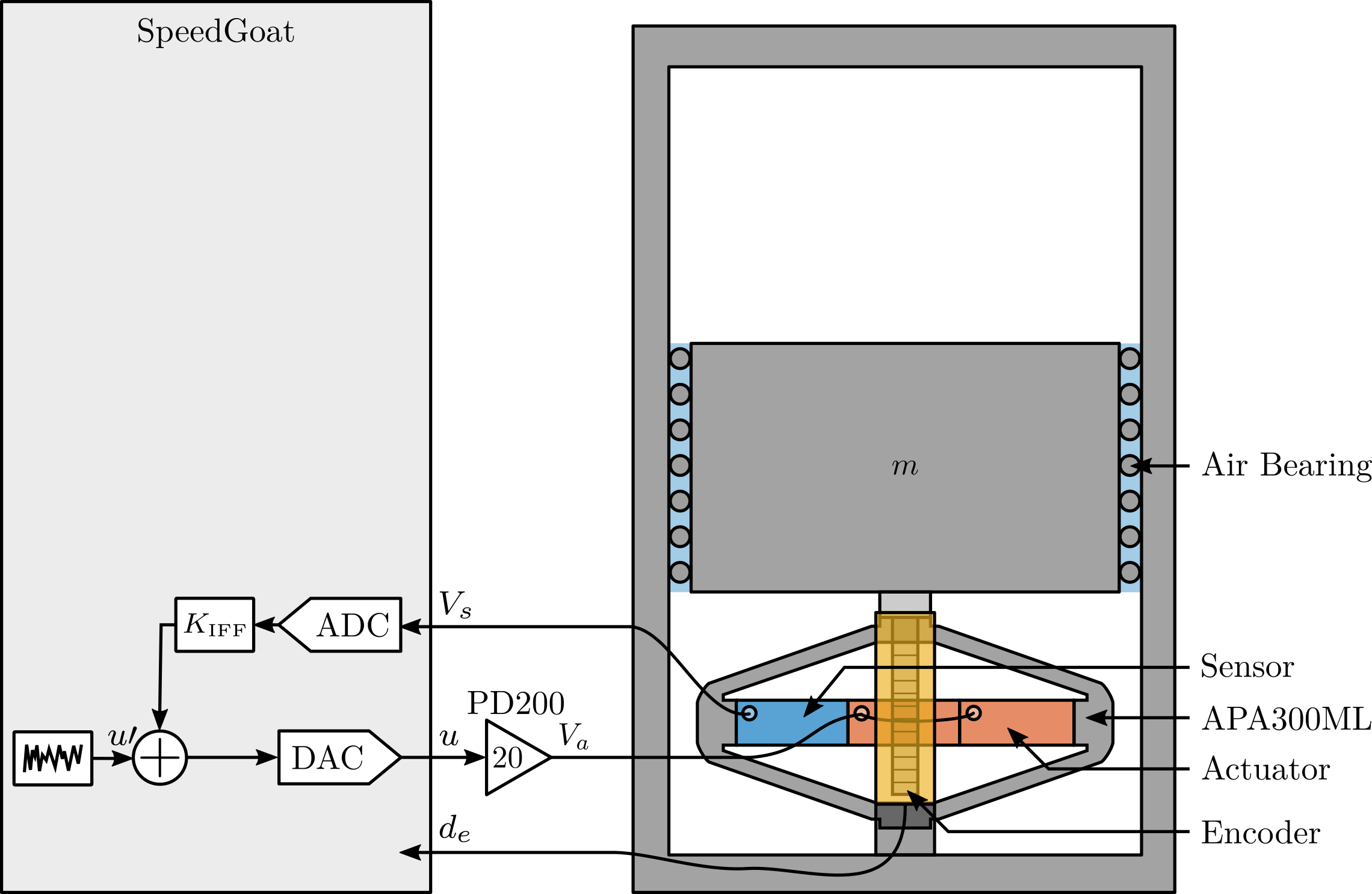

After the basic measurements on the APA were performed in Section ref:sec:test_apa_basic_meas, a new test bench is used to better characterize the dynamics of the APA300ML. This test bench, depicted in Figure ref:fig:test_bench_apa, comprises the APA300ML fixed at one end to a stationary granite block, and at the other end to a 5kg granite block that is vertically guided by an air bearing. That way, there is no friction when actuating the APA300ML, and it will be easier to characterize its behavior independently of other factors. An encoder7 is utilized to measure the relative movement between the two granite blocks, thereby measuring the axial displacement of the APA.

The bench is schematically shown in Figure ref:fig:test_apa_schematic with all the associated signals. It will be first used to estimate the hysteresis from the piezoelectric stack (Section ref:ssec:test_apa_hysteresis) as well as the axial stiffness of the APA300ML (Section ref:ssec:test_apa_stiffness). Then, the frequency response functions from the DAC voltage $u$ to the displacement $d_e$ and to the voltage $V_s$ are measured in Section ref:ssec:test_apa_meas_dynamics. The presence of a non minimum phase zero found on the transfer function from $u$ to $V_s$ is investigated in Section ref:ssec:test_apa_non_minimum_phase. In order to limit the low frequency gain of the transfer function from $u$ to $V_s$, a resistor is added across the force sensor stack (Section ref:ssec:test_apa_resistance_sensor_stack). Finally, the Integral Force Feedback is implemented, and the amount of damping added is experimentally estimated in Section ref:ssec:test_apa_iff_locus.

Hysteresis

<<ssec:test_apa_hysteresis>>

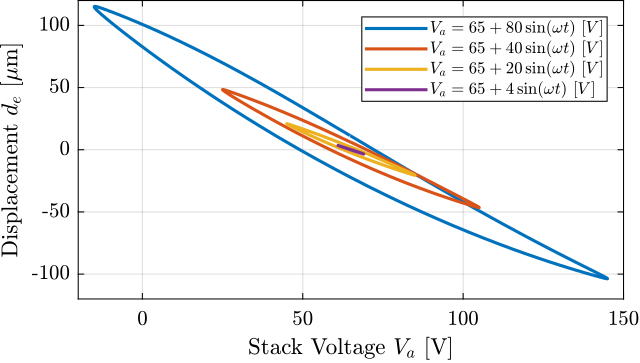

As the payload is vertically guided without friction, the hysteresis of the APA can be estimated from the motion of the payload. Do to so, a quasi static8 sinusoidal excitation $V_a$ with an offset of $65\,V$ (halfway between $-20\,V$ and $150\,V$) and with an amplitude varying from $4\,V$ up to $80\,V$ is generated using the DAC. For each excitation amplitude, the vertical displacement $d_e$ of the mass is measured and displayed as a function of the applied voltage in Figure ref:fig:test_apa_meas_hysteresis. This is the typical behavior expected from a PZT stack actuator where the hysteresis increases as a function of the applied voltage amplitude cite:&fleming14_desig_model_contr_nanop_system chap. 1.4.

%% Load measured data - hysteresis

apa_hyst = load('frf_data_1_hysteresis.mat', 't', 'u', 'de');

% Initial time set to zero

apa_hyst.t = apa_hyst.t - apa_hyst.t(1);

ampls = [0.1, 0.2, 0.4, 1, 2, 4]; % Excitation voltage amplitudes

Axial stiffness

<<ssec:test_apa_stiffness>>

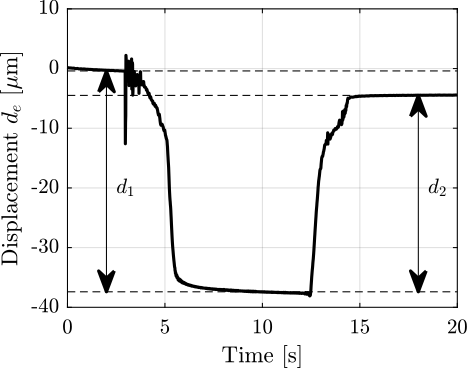

In order to estimate the stiffness of the APA, a weight with known mass $m_a = 6.4\,\text{kg}$ is added on top of the suspended granite and the deflection $d_e$ is measured using the encoder. The APA stiffness can then be estimated from equation eqref:eq:test_apa_stiffness.

\begin{equation} \label{eq:test_apa_stiffness} k_{\text{apa}} = \frac{m_a g}{Δ d_e}

\end{equation}

%% Load data for stiffness measurement

apa_nums = [1 2 4 5 6 8];

apa_mass = {};

for i = 1:length(apa_nums)

apa_mass(i) = {load(sprintf('frf_data_%i_add_mass_closed_circuit.mat', apa_nums(i)), 't', 'de')};

% The initial displacement is set to zero

apa_mass{i}.de = apa_mass{i}.de - mean(apa_mass{i}.de(apa_mass{i}.t<11));

end

added_mass = 6.4; % Added mass [kg]The measured displacement $d_e$ as a function of time is shown in Figure ref:fig:test_apa_meas_stiffness_time. It can be seen that there are some drifts in the measured displacement (probably due to piezoelectric creep) and the that displacement does not come back to the initial position after the mass is removed (probably due to piezoelectric hysteresis). These two effects induce some uncertainties in the measured stiffness.

The stiffnesses are computed for all the APA from the two displacements $d_1$ and $d_2$ (see Figure ref:fig:test_apa_meas_stiffness_time) leading to two stiffness estimations $k_1$ and $k_2$. These estimated stiffnesses are summarized in Table ref:tab:test_apa_measured_stiffnesses and are found to be close to the specified nominal stiffness of the APA300ML $k = 1.8\,N/\mu m$.

\hfill

| APA | $k_1$ | $k_2$ |

|---|---|---|

| 1 | 1.68 | 1.9 |

| 2 | 1.69 | 1.9 |

| 4 | 1.7 | 1.91 |

| 5 | 1.7 | 1.93 |

| 6 | 1.7 | 1.92 |

| 8 | 1.73 | 1.98 |

The stiffness can also be computed using equation eqref:eq:test_apa_res_freq by knowing the main vertical resonance frequency $\omega_z \approx 95\,\text{Hz}$ (estimated by the dynamical measurements shown in section ref:ssec:test_apa_meas_dynamics) and the suspended mass $m_{\text{sus}} = 5.7\,\text{kg}$.

\begin{equation} \label{eq:test_apa_res_freq} ω_z = \sqrt{\frac{k}{m_{\text{sus}}}}

\end{equation}

The obtain stiffness is $k \approx 2\,N/\mu m$ which is close to the values found in the documentation and by the "static deflection" method.

It is important to note that changes to the electrical impedance connected to the piezoelectric stacks impacts the mechanical compliance (or stiffness) of the piezoelectric stack cite:&reza06_piezoel_trans_vibrat_contr_dampin chap. 2.

To estimate this effect for the APA300ML, its stiffness is estimated using the "static deflection" method in two cases:

- $k_{\text{os}}$: piezoelectric stacks left unconnected (or connect to the high impedance ADC)

- $k_{\text{sc}}$: piezoelectric stacks short circuited (or connected to the voltage amplifier with small output impedance)

It is found that the open-circuit stiffness is estimated at $k_{\text{oc}} \approx 2.3\,N/\mu m$ while the the closed-circuit stiffness $k_{\text{sc}} \approx 1.7\,N/\mu m$.

%% Load Data

add_mass_oc = load('frf_data_1_add_mass_open_circuit.mat', 't', 'de');

add_mass_cc = load('frf_data_1_add_mass_closed_circuit.mat', 't', 'de');

%% Zero displacement at initial time

add_mass_oc.de = add_mass_oc.de - mean(add_mass_oc.de(add_mass_oc.t<11));

add_mass_cc.de = add_mass_cc.de - mean(add_mass_cc.de(add_mass_cc.t<11));

%% Estimation of the stiffness in Open Circuit and Closed-Circuit

apa_k_oc = 9.8 * added_mass / (mean(add_mass_oc.de(add_mass_oc.t > 12 & add_mass_oc.t < 12.5)) - mean(add_mass_oc.de(add_mass_oc.t > 20 & add_mass_oc.t < 20.5)));

apa_k_sc = 9.8 * added_mass / (mean(add_mass_cc.de(add_mass_cc.t > 12 & add_mass_cc.t < 12.5)) - mean(add_mass_cc.de(add_mass_cc.t > 20 & add_mass_cc.t < 20.5)));Dynamics

<<ssec:test_apa_meas_dynamics>>

%% Identification using sweep sine (low frequency)

load('frf_data_sweep.mat');

load('frf_data_noise_hf.mat');

%% Sampling Frequency

Ts = 1e-4; % Sampling Time [s]

Fs = 1/Ts; % Sampling Frequency [Hz]

%% "Hanning" windows used for the spectral analysis:

Nfft = floor(2/Ts);

win = hanning(Nfft);

Noverlap = floor(Nfft/2);

%% Separation of frequencies: low freqs using sweep sine, and high freq using noise

% Only used to have the frequency vector "f"

[~, f] = tfestimate(apa_sweep{1}.u, apa_sweep{1}.de, win, Noverlap, Nfft, 1/Ts);

i_lf = f <= 350;

i_hf = f > 350;

%% FRF estimation of the transfer function from u to de

enc_frf = zeros(length(f), length(apa_nums));

for i = 1:length(apa_nums)

[frf_lf, ~] = tfestimate(apa_sweep{i}.u, apa_sweep{i}.de, win, Noverlap, Nfft, 1/Ts);

[frf_hf, ~] = tfestimate(apa_noise_hf{i}.u, apa_noise_hf{i}.de, win, Noverlap, Nfft, 1/Ts);

enc_frf(:, i) = [frf_lf(i_lf); frf_hf(i_hf)];

end

%% FRF estimation of the transfer function from u to Vs

iff_frf = zeros(length(f), length(apa_nums));

for i = 1:length(apa_nums)

[frf_lf, ~] = tfestimate(apa_sweep{i}.u, apa_sweep{i}.Vs, win, Noverlap, Nfft, 1/Ts);

[frf_hf, ~] = tfestimate(apa_noise_hf{i}.u, apa_noise_hf{i}.Vs, win, Noverlap, Nfft, 1/Ts);

iff_frf(:, i) = [frf_lf(i_lf); frf_hf(i_hf)];

end%% Save the identified dynamics for further analysis

save('mat/meas_apa_frf.mat', 'f', 'Ts', 'enc_frf', 'iff_frf', 'apa_nums');In this section, the dynamics from the excitation voltage $u$ to the encoder measured displacement $d_e$ and to the force sensor voltage $V_s$ is identified.

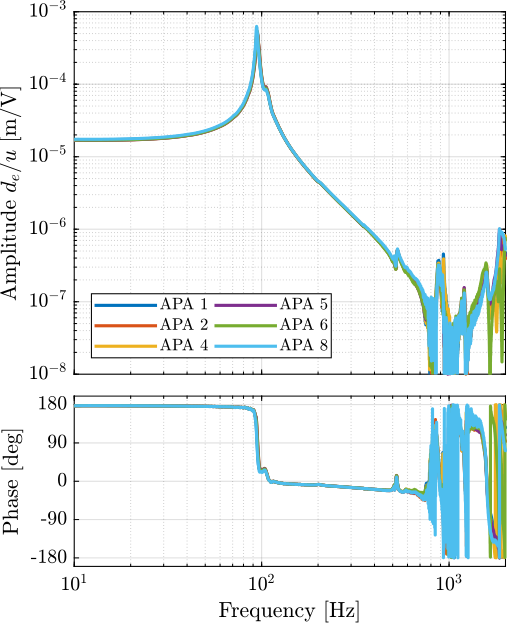

First, the dynamics from $u$ to $d_e$ for the six APA300ML are compared in Figure ref:fig:test_apa_frf_encoder. The obtained frequency response functions are similar to that of a (second order) mass-spring-damper system with:

- A "stiffness line" indicating a static gain equal to $\approx -17\,\mu m/V$. The minus sign comes from the fact that an increase in voltage stretches the piezoelectric stack which reduces the height of the APA

- A lightly damped resonance at $95\,\text{Hz}$

- A "mass line" up to $\approx 800\,\text{Hz}$, above which additional resonances appear. These additional resonances might be coming from the limited stiffness of the encoder support or from the limited compliance of the APA support. Flexible modes studied in section ref:ssec:test_apa_spurious_resonances seems not to impact the measured axial motion of the actuator.

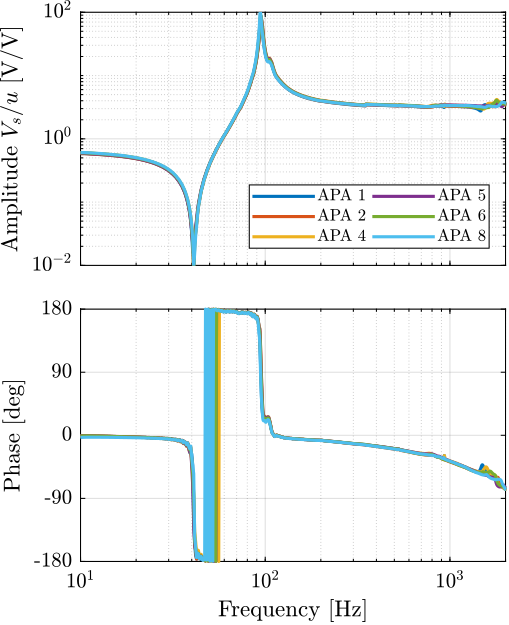

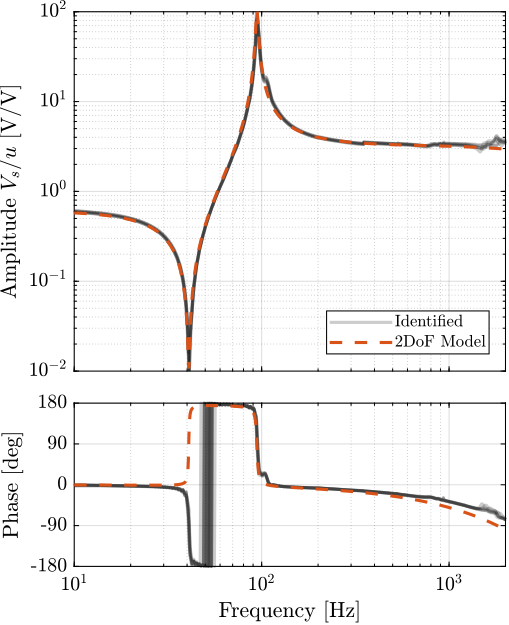

The dynamics from $u$ to the measured voltage across the sensor stack $V_s$ for the six APA300ML are compared in Figure ref:fig:test_apa_frf_force.

A lightly damped resonance (pole) is observed at $95\,\text{Hz}$ and a lightly damped anti-resonance (zero) at $41\,\text{Hz}$. No additional resonances is present up to at least $2\,\text{kHz}$ indicating that Integral Force Feedback can be applied without stability issues from high frequency flexible modes. The zero at $41\,\text{Hz}$ seems to be non-minimum phase (the phase decreases by 180 degrees whereas it should have increased by 180 degrees for a minimum phase zero). This is investigated in Section ref:ssec:test_apa_non_minimum_phase.

As illustrated by the Root Locus, the poles of the closed-loop system converges to the zeros of the open-loop plant as the feedback gain increases. The significance of this behavior varies on the type of sensor used as explained in cite:&preumont18_vibrat_contr_activ_struc_fourt_edition chap. 7.6. Considering the transfer function from $u$ to $V_s$, if a controller with a very high gain is applied such that the sensor stack voltage $V_s$ is kept at zero, the sensor (and by extension, the actuator stacks since they are in series) experiences negligible stress and strain. Consequently, the closed-loop system would virtually corresponds to one where the piezoelectric stacks are absent, leaving only the mechanical shell. From this analysis, it can be inferred that the axial stiffness of the shell is $k_{\text{shell}} = m \omega_0^2 = 5.7 \cdot (2\pi \cdot 41)^2 = 0.38\,N/\mu m$ (which is close to what is found using a finite element model).

All the identified dynamics of the six APA300ML (both when looking at the encoder in Figure ref:fig:test_apa_frf_encoder and at the force sensor in Figure ref:fig:test_apa_frf_force) are almost identical, indicating good manufacturing repeatability for the piezoelectric stacks and the mechanical shell.

Non Minimum Phase Zero?

<<ssec:test_apa_non_minimum_phase>>

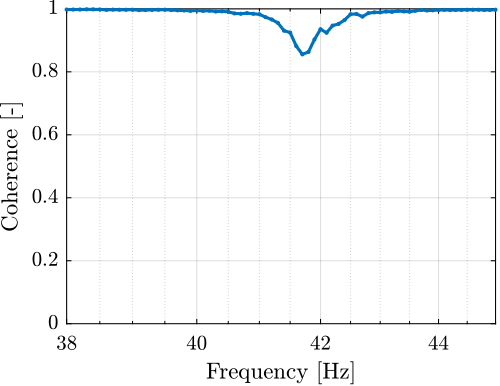

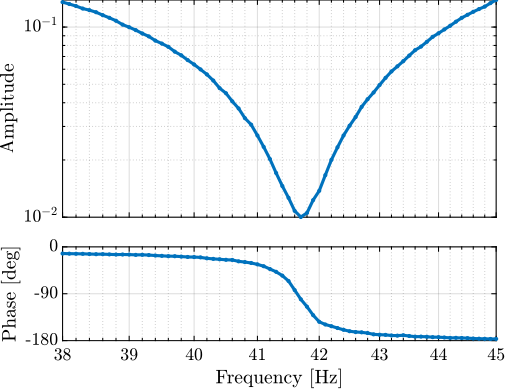

It was surprising to observe a non-minimum phase behavior for the zero on the transfer function from $u$ to $V_s$ (Figure ref:fig:test_apa_frf_force). It was initially thought that this non-minimum phase behavior is an artifact coming from the measurement. A longer measurement was performed with different excitation signals (noise, slow sine sweep, etc.) to see it the phase behavior of the zero changes. Results of one long measurement is shown in Figure ref:fig:test_apa_non_minimum_phase. The coherence (Figure ref:fig:test_apa_non_minimum_phase_coherence) is good even in the vicinity of the lightly damped zero, and the phase (Figure ref:fig:test_apa_non_minimum_phase_zoom) clearly indicates non-minimum phase behavior.

Such non-minimum phase zero when using load cells has also been observed on other mechanical systems cite:&spanos95_soft_activ_vibrat_isolat;&thayer02_six_axis_vibrat_isolat_system;&hauge04_sensor_contr_space_based_six. It could be induced to small non-linearity in the system, but the reason of this non-minimum phase for the APA300ML is not yet clear.

However, this is not so important here as the zero is lightly damped (i.e. very close to the imaginary axis), and the closed loop poles (see the Root Locus plot in Figure ref:fig:test_apa_iff_root_locus) should not be unstable except for very large controller gains that will never be applied in practice.

%% Long measurement

long_noise = load('frf_struts_align_3_noise_long.mat', 't', 'u', 'Vs');

% Long window for fine frequency axis

Ts = 1e-4; % Sampling Time [s]

Nfft = floor(10/Ts);

win = hanning(Nfft);

Noverlap = floor(Nfft/2);

% Transfer function estimation

[frf_noise, f] = tfestimate(long_noise.u, long_noise.Vs, win, Noverlap, Nfft, 1/Ts);

[coh_noise, ~] = mscohere(long_noise.u, long_noise.Vs, win, Noverlap, Nfft, 1/Ts);

Effect of the resistor on the IFF Plant

<<ssec:test_apa_resistance_sensor_stack>>

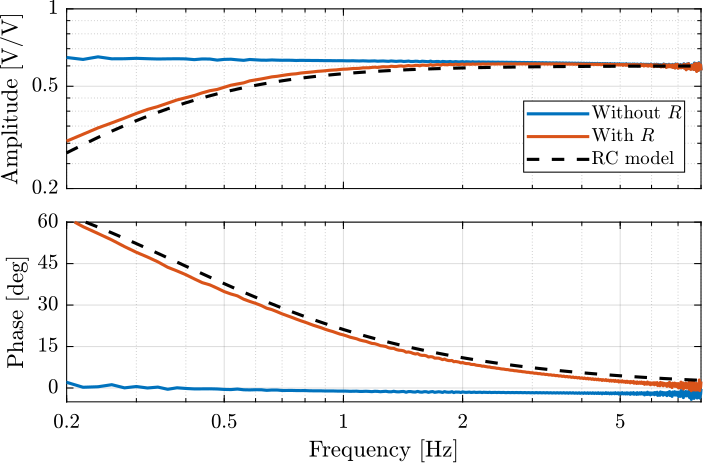

A resistor $R \approx 80.6\,k\Omega$ is added in parallel with the sensor stack which has the effect to form a high pass filter with the capacitance of the piezoelectric stack (capacitance estimated at $\approx 5\,\mu F$).

As explain before, this is done to limit the voltage offset due to the input bias current of the ADC as well as to limit the low frequency gain.

The (low frequency) transfer function from $u$ to $V_s$ with and without this resistor have been measured and are compared in Figure ref:fig:test_apa_effect_resistance. It is confirmed that the added resistor as the effect of adding an high pass filter with a cut-off frequency of $\approx 0.39\,\text{Hz}$.

%% Load the data

wi_k = load('frf_data_1_sweep_lf_with_R.mat', 't', 'Vs', 'u'); % With the resistor

wo_k = load('frf_data_1_sweep_lf.mat', 't', 'Vs', 'u'); % Without the resistor

%% Large Hanning window for good low frequency estimate

Nfft = floor(50/Ts);

win = hanning(Nfft);

Noverlap = floor(Nfft/2);

%% Compute the transfer functions from u to Vs

[frf_wo_k, f] = tfestimate(wo_k.u, wo_k.Vs, win, Noverlap, Nfft, 1/Ts);

[frf_wi_k, ~] = tfestimate(wi_k.u, wi_k.Vs, win, Noverlap, Nfft, 1/Ts);

%% Model for the high pass filter

C = 5.1e-6; % Sensor Stack capacitance [F]

R = 80.6e3; % Parallel Resistor [Ohm]

f0 = 1/(2*pi*R*C); % Crossover frequency of RC HPF [Hz]

G_hpf = 0.6*(s/(2*pi*f0))/(1 + s/(2*pi*f0));

Integral Force Feedback

<<ssec:test_apa_iff_locus>>

%% Load identification Data

data = load("2023-03-17_11-28_iff_plant.mat");

%% Spectral Analysis setup

Ts = 1e-4; % Sampling Time [s]

Nfft = floor(5/Ts);

win = hanning(Nfft);

Noverlap = floor(Nfft/2);

%% Compute the transfer function from applied force to measured rotation

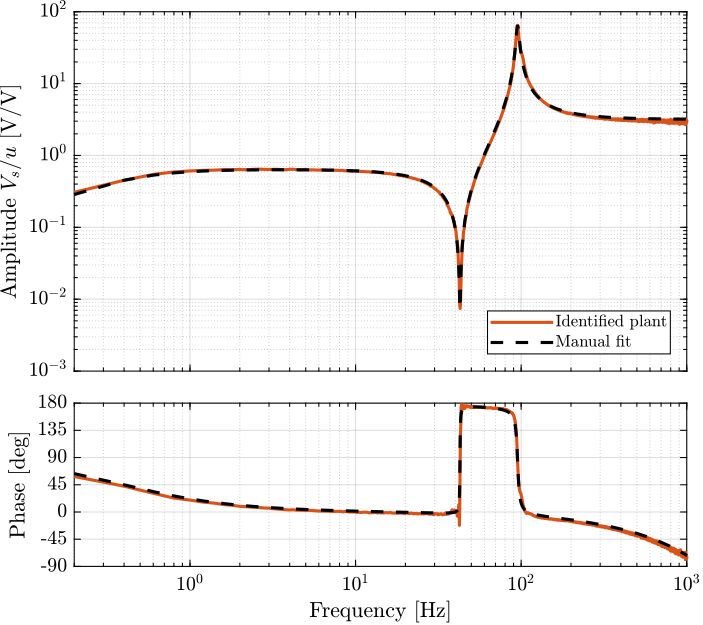

[G_iff, f] = tfestimate(data.id_plant, data.Vs, win, Noverlap, Nfft, 1/Ts);In order to implement the Integral Force Feedback strategy, the measured frequency response function from $u$ to $V_s$ (Figure ref:fig:test_apa_frf_force) is fitted using the transfer function shown in equation eqref:eq:test_apa_iff_manual_fit. The parameters are manually tuned, and the obtained values are $\omega_{\textsc{hpf}} = 0.4\, \text{Hz}$, $\omega_{z} = 42.7\, \text{Hz}$, $\xi_{z} = 0.4\,\%$, $\omega_{p} = 95.2\, \text{Hz}$, $\xi_{p} = 2\,\%$ and $g_0 = 0.64$.

\begin{equation} \label{eq:test_apa_iff_manual_fit} G_{\textsc{iff},m}(s) = g_0 ⋅ \frac{1 + 2 ξ_z \frac{s}{ω_z} + \frac{s^2}{ω_z^2}}{1 + 2 ξ_p \frac{s}{ω_p} + \frac{s^2}{ω_p^2}} ⋅ \frac{s}{ω_{\textsc{hpf}} + s}

\end{equation}

The comparison between the identified plant and the manually tuned transfer function is done in Figure ref:fig:test_apa_iff_plant_comp_manual_fit.

%% Basic manually tuned model

w0z = 2*pi*42.7; % Zero frequency

xiz = 0.004; % Zero damping

w0p = 2*pi*95.2; % Pole frequency

xip = 0.02; % Pole damping

G_iff_model = exp(-2*s*Ts)*0.64*(1 + 2*xiz/w0z*s + s^2/w0z^2)/(1 + 2*xip/w0p*s + s^2/w0p^2)*(s/(s+2*pi*0.4));

The implemented Integral Force Feedback Controller transfer function is shown in equation eqref:eq:test_apa_Kiff_formula. It contains an high pass filter (cut-off frequency of $2\,\text{Hz}$) to limit the low frequency gain, a low pass filter to add integral action above $20\,\text{Hz}$, a second low pass filter to add robustness to high frequency resonances and a tunable gain $g$.

\begin{equation} \label{eq:test_apa_Kiff_formula} K_{\textsc{iff}}(s) = -10 ⋅ g ⋅ \frac{s}{s + 2π ⋅ 2} ⋅ \frac{1}{1 + 2π ⋅ 20} ⋅ \frac{1}{s + 2π⋅ 2000}

\end{equation}

%% Integral Force Feedback Controller

K_iff = -10*(1/(s + 2*pi*20)) * ... % LPF: provides integral action above 20Hz

(s/(s + 2*pi*2)) * ... % HPF: limit low frequency gain

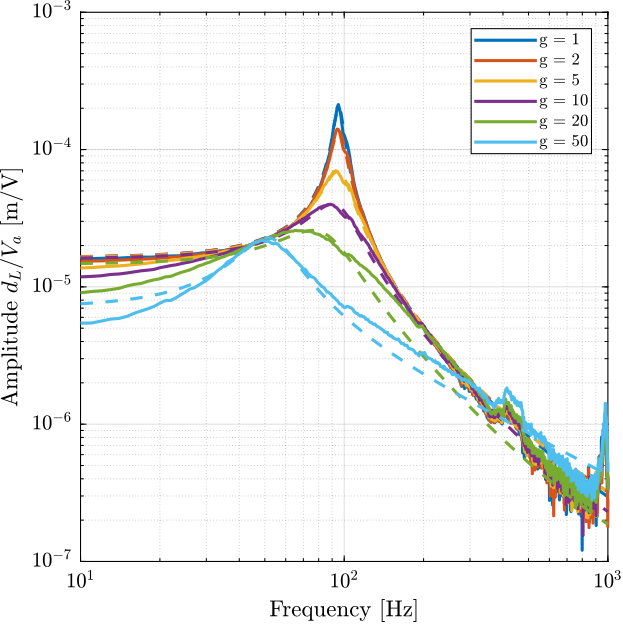

(1/(1 + s/2/pi/2e3)); % LPF: more robust to high frequency resonancesTo estimate how the dynamics of the APA changes when the Integral Force Feedback controller is implemented, the test bench shown in Figure ref:fig:test_apa_iff_schematic is used. The transfer function from the "damped" plant input $u\prime$ to the encoder displacement $d_e$ is identified for several IFF controller gains $g$.

%% Load Data

data = load("2023-03-17_14-10_damped_plants_new.mat");

%% Spectral Analysis setup

Ts = 1e-4; % Sampling Time [s]

Nfft = floor(1/Ts);

win = hanning(Nfft);

Noverlap = floor(Nfft/2);

%% Get the frequency vector

[~, f] = tfestimate(data.data(1).id_plant(1:end), data.data(1).dL(1:end), win, Noverlap, Nfft, 1/Ts);

%% Gains used for analysis are between 1 and 50

i_kept = [5:10];

%% Identify the damped plant from u' to de for different IFF gains

G_dL_frf = {zeros(1,length(i_kept))};

for i = 1:length(i_kept)

[G_dL, ~] = tfestimate(data.data(i_kept(i)).id_plant(1:end), data.data(i_kept(i)).dL(1:end), win, Noverlap, Nfft, 1/Ts);

G_dL_frf(i) = {G_dL};

endThe identified dynamics are then fitted by second order transfer functions9. The comparison between the identified damped dynamics and the fitted second order transfer functions is done in Figure ref:fig:test_apa_identified_damped_plants for different gains $g$. It is clear that large amount of damping is added when the gain is increased and that the frequency of the pole is shifted to lower frequencies.

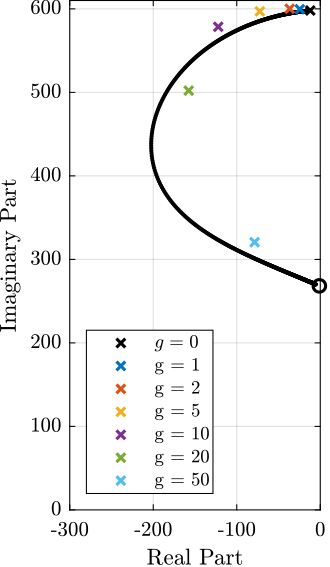

The evolution of the pole in the complex plane as a function of the controller gain $g$ (i.e. the "root locus") is computed both using the IFF plant model eqref:eq:test_apa_iff_manual_fit and the implemented controller eqref:eq:test_apa_Kiff_formula and from the fitted transfer functions of the damped plants experimentally identified for several controller gains. The two obtained root loci are compared in Figure ref:fig:test_apa_iff_root_locus and are in good agreement considering that the damped plants were only fitted using a second order transfer function.

%% Fit the data with 2nd order transfer function using vectfit3

opts = struct();

opts.stable = 1; % Enforce stable poles

opts.asymp = 1; % Force D matrix to be null

opts.relax = 1; % Use vector fitting with relaxed non-triviality constraint

opts.skip_pole = 0; % Do NOT skip pole identification

opts.skip_res = 0; % Do NOT skip identification of residues (C,D,E)

opts.cmplx_ss = 0; % Create real state space model with block diagonal A

opts.spy1 = 0; % No plotting for first stage of vector fitting

opts.spy2 = 0; % Create magnitude plot for fitting of f(s)

Niter = 100; % Number of iteration.

N = 2; % Order of approximation

poles = [-25 - 1i*60, -25 + 1i*60]; % First get for the pole location

G_dL_id = {zeros(1,length(i_kept))};

% Identification just between two frequencies

f_keep = (f>5 & f<200);

for i = 1:length(i_kept)

%% Estimate resonance frequency and damping

for iter = 1:Niter

[G_est, poles, ~, frf_est] = vectfit3(G_dL_frf{i}(f_keep).', 1i*2*pi*f(f_keep)', poles, ones(size(f(f_keep)))', opts);

end

G_dL_id(i) = {ss(G_est.A, G_est.B, G_est.C, G_est.D)};

end

APA300ML - 2 Degrees of Freedom Model

<<sec:test_apa_model_2dof>>

Introduction ignore

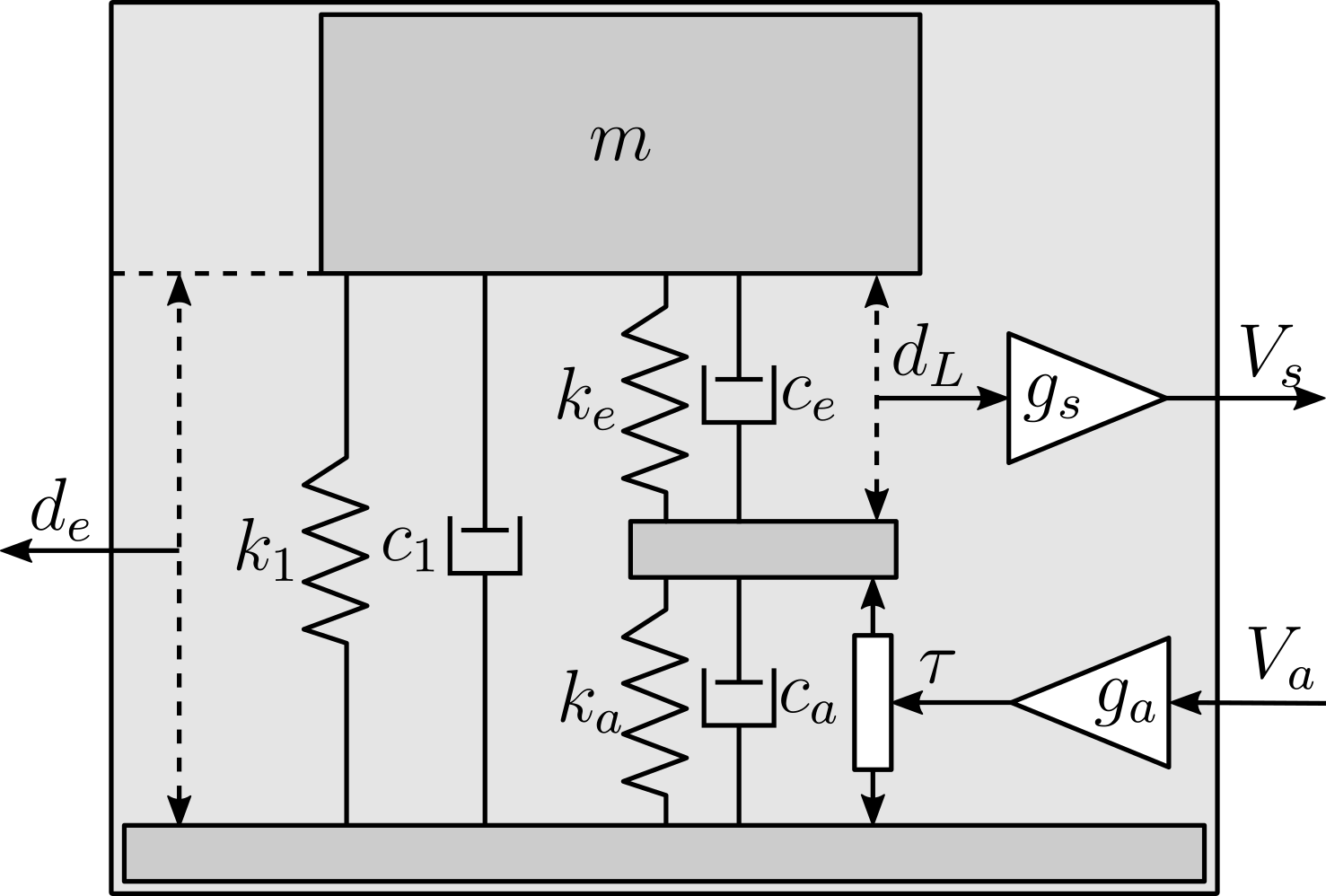

In this section, a simscape model (Figure ref:fig:test_apa_bench_model) of the measurement bench is used to compare the model of the APA with the measured frequency response functions.

A 2 degrees of freedom model is used to model the APA300ML. This model is presented in Section ref:ssec:test_apa_2dof_model and the procedure to tuned the model is described in Section ref:ssec:test_apa_2dof_model_tuning. The obtained model dynamics is compared with the measurements in Section ref:ssec:test_apa_2dof_model_result.

Two Degrees of Freedom APA Model

<<ssec:test_apa_2dof_model>>

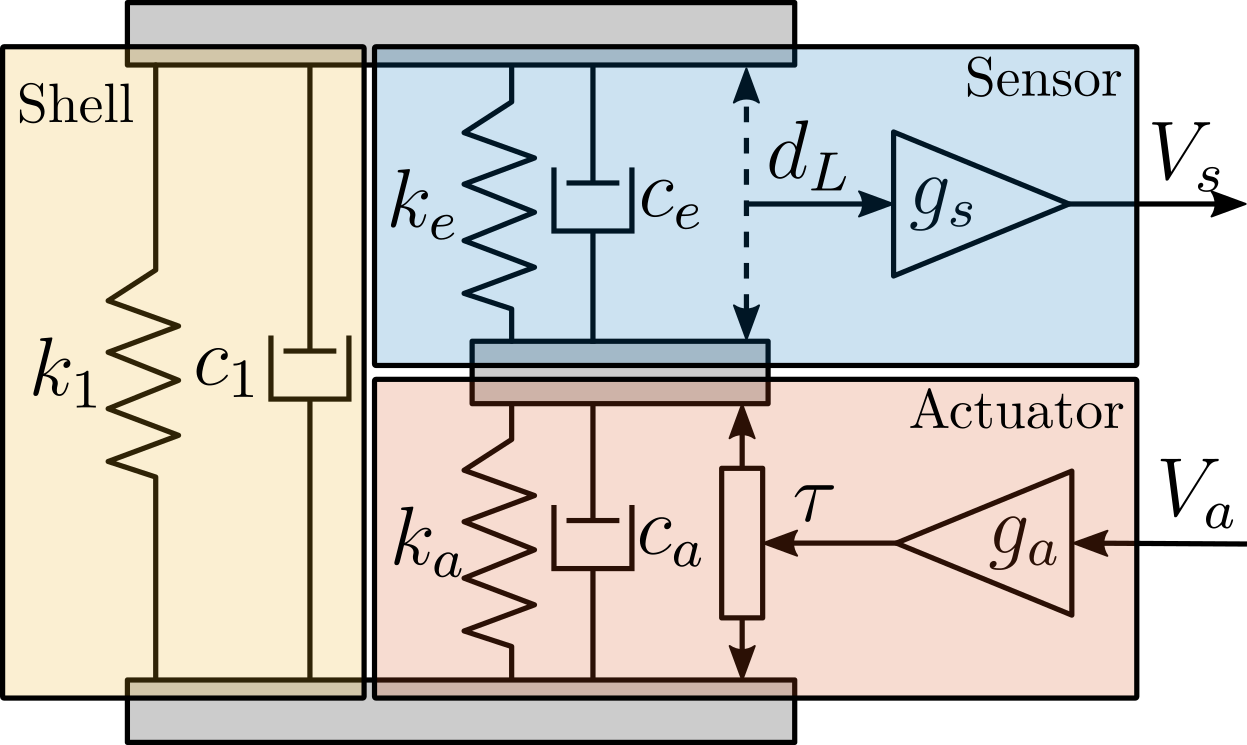

The model of the amplified piezoelectric actuator is shown in Figure ref:fig:test_apa_2dof_model. It can be decomposed into three components:

- the shell whose axial properties are represented by $k_1$ and $c_1$

- the actuator stacks whose contribution in the axial stiffness is represented by $k_a$ and $c_a$. A force source $\tau$ represents the axial force induced by the force sensor stacks. The gain $g_a$ (in $N/m$) is used to convert the applied voltage $V_a$ to the axial force $\tau$

- the sensor stack whose contribution in the axial stiffness is represented by $k_e$ and $c_e$. A sensor measures the stack strain $d_L$ which is then converted to a voltage $V_s$ using a gain $g_s$ (in $V/m$)

Such simple model has some limitations:

- it only represents the axial characteristics of the APA as it is modelled as infinitely rigid in the other directions

- some physical insights are lost such as the amplification factor, the real stress and strain in the piezoelectric stacks

- it is fully linear and therefore the creep and hysteresis of the piezoelectric stacks are not modelled

Tuning of the APA model

<<ssec:test_apa_2dof_model_tuning>>

9 parameters ($m$, $k_1$, $c_1$, $k_e$, $c_e$, $k_a$, $c_a$, $g_s$ and $g_a$) have to be tuned such that the dynamics of the model (Figure ref:fig:test_apa_2dof_model_simscape) well represents the identified dynamics in Section ref:sec:test_apa_dynamics.

%% Stiffness values for the 2DoF APA model

k1 = 0.38e6; % Estimated Shell Stiffness [N/m]

w0 = 2*pi*95; % Resonance frequency [rad/s]

m = 5.7; % Suspended mass [kg]

ktot = m*(w0)^2; % Total Axial Stiffness to have to wanted resonance frequency [N/m]

ka = 1.5*(ktot-k1); % Stiffness of the (two) actuator stacks [N/m]

ke = 2*ka; % Stiffness of the Sensor stack [N/m]

%% Damping values for the 2DoF APA model

c1 = 20; % Damping for the Shell [N/(m/s)]

ca = 100; % Damping of the actuators stacks [N/(m/s)]

ce = 2*ca; % Damping of the sensor stack [N/(m/s)]%% Estimation ot the sensor and actuator gains

% Initialize the structure with unitary sensor and actuator "gains"

n_hexapod = struct();

n_hexapod.actuator = initializeAPA(...

'type', '2dof', ...

'k', k1, ...

'ka', ka, ...

'ke', ke, ...

'c', c1, ...

'ca', ca, ...

'ce', ce, ...

'Ga', 1, ... % Actuator constant [N/V]

'Gs', 1 ... % Sensor constant [V/m]

);

c_granite = 0; % Do not take into account damping added by the air bearing

% Run the linearization

G_norm = linearize(mdl, io, 0.0, opts);

G_norm.InputName = {'u'};

G_norm.OutputName = {'Vs', 'de'};

% Load Identification Data to estimate the two gains

load('meas_apa_frf.mat', 'f', 'Ts', 'enc_frf', 'iff_frf', 'apa_nums');

% Estimation ot the Actuator Gain

fa = 10; % Frequency where the two FRF should match [Hz]

[~, i_f] = min(abs(f - fa));

ga = -abs(enc_frf(i_f,1))./abs(evalfr(G_norm('de', 'u'), 1i*2*pi*fa));

% Estimation ot the Sensor Gain

fs = 600; % Frequency where the two FRF should match [Hz]

[~, i_f] = min(abs(f - fs));

gs = -abs(iff_frf(i_f,1))./abs(evalfr(G_norm('Vs', 'u'), 1i*2*pi*fs))/ga;First, the mass $m$ supported by the APA300ML can be estimated from the geometry and density of the different parts or by directly measuring it using a precise weighing scale. Both methods leads to an estimated mass of $m = 5.7\,\text{kg}$.

Then, the axial stiffness of the shell was estimated at $k_1 = 0.38\,N/\mu m$ in Section ref:ssec:test_apa_meas_dynamics from the frequency of the anti-resonance seen on Figure ref:fig:test_apa_frf_force. Similarly, $c_1$ can be estimated from the damping ratio of the same anti-resonance and is found to be close to $20\,Ns/m$.

Then, it is reasonable to make the assumption that the sensor stacks and the two actuator stacks have identical mechanical characteristics10. Therefore, we have $k_e = 2 k_a$ and $c_e = 2 c_a$ as the actuator stack is composed of two stacks in series. In that case, the total stiffness of the APA model is described by eqref:eq:test_apa_2dof_stiffness.

\begin{equation}\label{eq:test_apa_2dof_stiffness} k_{\text{tot}} = k_1 + \frac{k_e k_a}{k_e + k_a} = k_1 + \frac{2}{3} k_a

\end{equation}

Knowing from eqref:eq:test_apa_tot_stiffness that the total stiffness is $k_{\text{tot}} = 2\,N/\mu m$, we get from eqref:eq:test_apa_2dof_stiffness that $k_a = 2.5\,N/\mu m$ and $k_e = 5\,N/\mu m$.

\begin{equation}\label{eq:test_apa_tot_stiffness} ω_0 = \frac{k_{\text{tot}}}{m} \Longrightarrow k_{\text{tot}} = m ω_0^2 = 2\,N/μ m \quad \text{with}\ m = 5.7\,\text{kg}\ \text{and}\ ω_0 = 2π ⋅ 95\, \text{rad}/s

\end{equation}

Then, $c_a$ (and therefore $c_e = 2 c_a$) can be tuned to match the damping ratio of the identified resonance. $c_a = 100\,Ns/m$ and $c_e = 200\,Ns/m$ are obtained.

Finally, the two gains $g_s$ and $g_a$ can be tuned to match the gain of the identified transfer functions.

The obtained parameters of the model shown in Figure ref:fig:test_apa_2dof_model_simscape are summarized in Table ref:tab:test_apa_2dof_parameters.

| Parameter | Value |

|---|---|

| $m$ | $5.7\,\text{kg}$ |

| $k_1$ | $0.38\,N/\mu m$ |

| $k_e$ | $5.0\, N/\mu m$ |

| $k_a$ | $2.5\,N/\mu m$ |

| $c_1$ | $20\,Ns/m$ |

| $c_e$ | $200\,Ns/m$ |

| $c_a$ | $100\,Ns/m$ |

| $g_a$ | $-2.58\,N/V$ |

| $g_s$ | $0.46\,V/\mu m$ |

Obtained Dynamics

<<ssec:test_apa_2dof_model_result>>

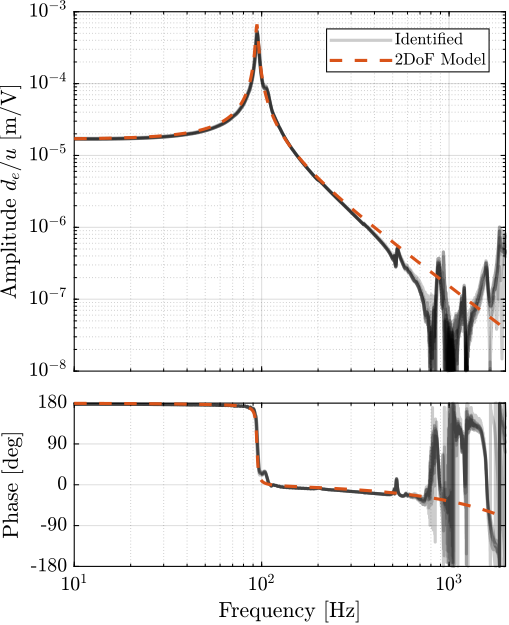

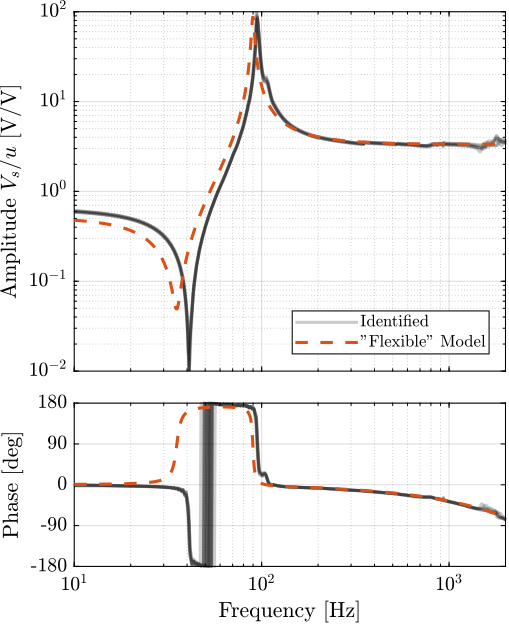

The dynamics of the two degrees of freedom model of the APA300ML is now extracted using optimized parameters (listed in Table ref:tab:test_apa_2dof_parameters) from the Simscape model. It is compared with the experimental data in Figure ref:fig:test_apa_2dof_comp_frf. A good match can be observed between the model and the experimental data, both for the encoder (Figure ref:fig:test_apa_2dof_comp_frf_enc) and for the force sensor (Figure ref:fig:test_apa_2dof_comp_frf_force). This indicates that this model represents well the axial dynamics of the APA300ML.

%% 2DoF APA300ML with optimized parameters

n_hexapod = struct();

n_hexapod.actuator = initializeAPA( ...

'type', '2dof', ...

'k', k1, ...

'ka', ka, ...

'ke', ke, ...

'c', c1, ...

'ca', ca, ...

'ce', ce, ...

'Ga', ga, ...

'Gs', gs ...

);

%% Identification of the APA300ML with optimized parameters

G_2dof = exp(-s*Ts)*linearize(mdl, io, 0.0, opts);

G_2dof.InputName = {'u'};

G_2dof.OutputName = {'Vs', 'de'};

APA300ML - Super Element

<<sec:test_apa_model_flexible>>

Introduction ignore

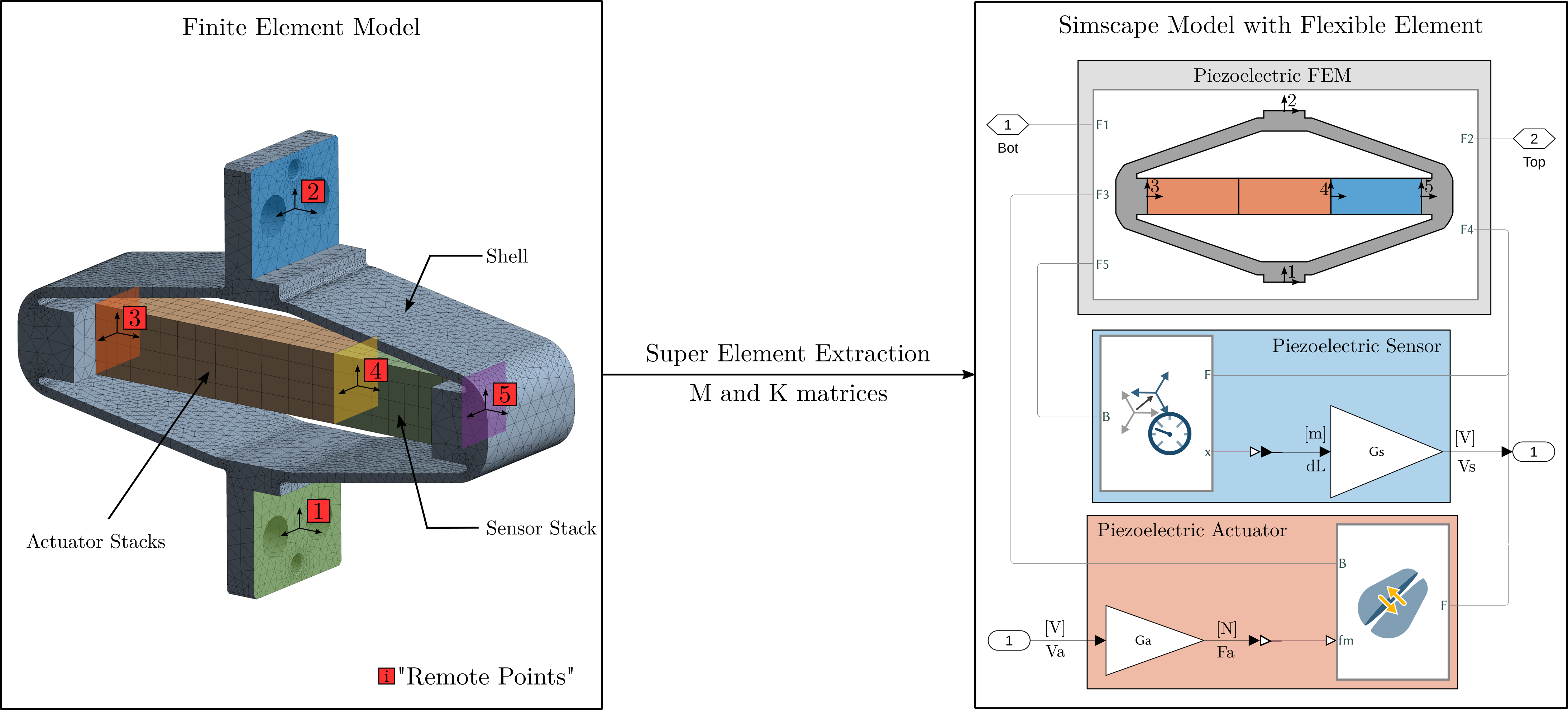

In this section, a super element of the APA300ML is computed using a finite element software11.

It is then imported in Simscape (in the form of a stiffness matrix and a mass matrix) and included in the same model that was used in ref:sec:test_apa_model_2dof.

This procedure is illustrated in Figure ref:fig:test_apa_super_element_simscape.

Several remote points are defined in the finite element model (here illustrated by colorful planes and numbers from 1 to 5) and are then make accessible in the Simscape model as shown at the right by the "frames" F1 to F5.

For the APA300ML super element, 5 remote points are defined.

Two remote points (1 and 2) are fixed to the top and bottom mechanical interfaces of the APA300ML and will be used for connecting the APA300ML with other mechanical elements.

Two remote points (3 and 4) are located across two piezoelectric stacks and will be used to apply internal forces representing the actuator stacks.

Finally, two remote points (4 and 4) are located across the third piezoelectric stack.

It will be used to measure the strain experience by this stack, and model the sensor stack.

Identification of the Actuator and Sensor constants

<<ssec:test_apa_flexible_ga_gs>>

Once the APA300ML super element is included in the Simscape model, the transfer function from $F_a$ to $d_L$ and $d_e$ can be extracted. The gains $g_a$ and $g_s$ are then be tuned such that the gain of the transfer functions are matching the identified ones. By doing so, $g_s = 4.9\,V/\mu m$ and $g_a = 23.2\,N/V$ are obtained.

%% Identification of the actuator and sensor "constants"

% Initialize the APA as a flexible body with unity "constants"

n_hexapod.actuator = initializeAPA(...

'type', 'flexible', ...

'ga', 1, ...

'gs', 1);

c_granite = 100; % Rought estimation of the damping added by the air bearing

% Identify the dynamics

G_norm = linearize(mdl, io, 0.0, opts);

G_norm.InputName = {'u'};

G_norm.OutputName = {'Vs', 'de'};

% Load Identification Data to estimate the two gains

load('meas_apa_frf.mat', 'f', 'Ts', 'enc_frf', 'iff_frf', 'apa_nums');

% Actuator Constant in [N/V]

ga = -mean(abs(enc_frf(f>10 & f<20)))./dcgain(G_norm('de', 'u'));

% Sensor Constant in [V/m]

gs = -mean(abs(iff_frf(f>400 & f<500)))./(ga*abs(squeeze(freqresp(G_norm('Vs', 'u'), 1e3, 'Hz'))));To make sure these "gains" are physically valid, it is possible to estimate them from physical properties of the piezoelectric stack material.

From cite:&fleming14_desig_model_contr_nanop_system p. 123, the relation between relative displacement $d_L$ of the sensor stack and generated voltage $V_s$ is given by eqref:eq:test_apa_piezo_strain_to_voltage and from cite:&fleming10_integ_strain_force_feedb_high the relation between the force $F_a$ and the applied voltage $V_a$ is given by eqref:eq:test_apa_piezo_voltage_to_force.

\begin{subequations} \begin{align} V_s &= \underbrace{\frac{d_{33}}{\epsilon^T s^D n}}_{g_s} d_L \label{eq:test_apa_piezo_strain_to_voltage} \\ F_a &= \underbrace{d_{33} n k_a}_{g_a} \cdot V_a, \quad k_a = \frac{c^{E} A}{L} \label{eq:test_apa_piezo_voltage_to_force} \end{align} \end{subequations}Unfortunately, the manufacturer of the stack was not willing to share the piezoelectric material properties of the stack used in the APA300ML. However, based on available properties of the APA300ML stacks in the data-sheet, the soft Lead Zirconate Titanate "THP5H" from Thorlabs seemed to match quite well the observed properties. The properties of this "THP5H" material used to compute $g_a$ and $g_s$ are listed in Table ref:tab:test_apa_piezo_properties.

From these parameters, $g_s = 5.1\,V/\mu m$ and $g_a = 26\,N/V$ were obtained which are close to the identified constants using the experimentally identified transfer functions.

| Parameter | Value | Description |

|---|---|---|

| $d_{33}$ | $680 \cdot 10^{-12}\,m/V$ | Piezoelectric constant |

| $\epsilon^{T}$ | $4.0 \cdot 10^{-8}\,F/m$ | Permittivity under constant stress |

| $s^{D}$ | $21 \cdot 10^{-12}\,m^2/N$ | Elastic compliance understand constant electric displacement |

| $c^{E}$ | $48 \cdot 10^{9}\,N/m^2$ | Young's modulus of elasticity |

| $L$ | $20\,mm$ per stack | Length of the stack |

| $A$ | $10^{-4}\,m^2$ | Area of the piezoelectric stack |

| $n$ | $160$ per stack | Number of layers in the piezoelectric stack |

%% Estimate "Sensor Constant" - (THP5H)

d33 = 680e-12; % Strain constant [m/V]

n = 160; % Number of layers per stack

eT = 4500*8.854e-12; % Permittivity under constant stress [F/m]

sD = 21e-12; % Compliance under constant electric displacement [m2/N]

gs_th = d33/(eT*sD*n); % Sensor Constant [V/m]

%% Estimate "Actuator Constant" - (THP5H)

d33 = 680e-12; % Strain constant [m/V]

n = 320; % Number of layers

cE = 1/sD; % Youngs modulus [N/m^2]

A = (10e-3)^2; % Area of the stacks [m^2]

L = 40e-3; % Length of the two stacks [m]

ka = cE*A/L; % Stiffness of the two stacks [N/m]

ga_th = d33*n*ka; % Actuator Constant [N/V]Comparison of the obtained dynamics

<<ssec:test_apa_flexible_comp_frf>>

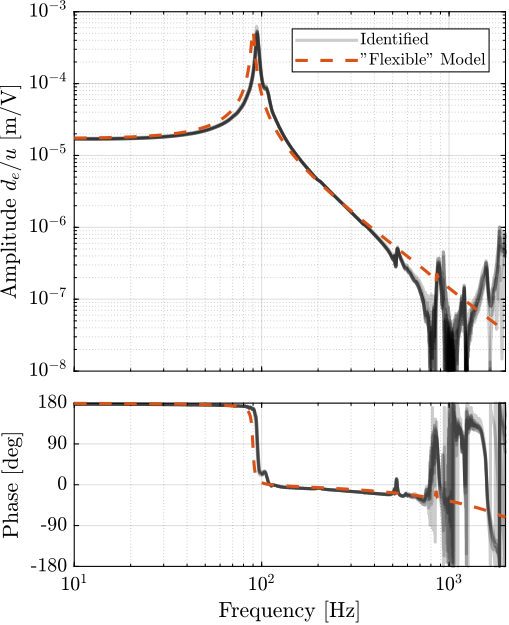

The obtained dynamics using the super element with the tuned "sensor gain" and "actuator gain" are compared with the experimentally identified frequency response functions in Figure ref:fig:test_apa_super_element_comp_frf. A good match between the model and the experimental results is observed. It is however a bit surprising that the model is a bit "softer" than the measured system as finite element models are usually overestimating the stiffness.

Using this simple test bench, it can be concluded that the super element model of the APA300ML well captures the axial dynamics of the actuator (the actuator stacks, the force sensor stack as well as the shell used as a mechanical lever).

%% Idenfify the dynamics of the Simscape model with correct actuator and sensor "constants"

% Initialize the APA

n_hexapod.actuator = initializeAPA(...

'type', 'flexible', ...

'ga', 23.2, ... % Actuator gain [N/V]

'gs', -4.9e6); % Sensor gain [V/m]

% Identify with updated constants

G_flex = exp(-Ts*s)*linearize(mdl, io, 0.0, opts);

G_flex.InputName = {'u'};

G_flex.OutputName = {'Vs', 'de'};

Conclusion

<<sec:test_apa_conclusion>>

The main characteristics of the APA300ML such as hysteresis and axial stiffness have been measured and were found to comply with the specifications.

The dynamics of the received APA were measured and found to all be identical (Figure ref:fig:test_apa_frf_dynamics). Even tough a non-minimum zero was observed on the transfer function from $u$ to $V_s$ (Figure ref:fig:test_apa_non_minimum_phase), it was not found to be problematic as large amount of damping could be added using the integral force feedback strategy (Figure ref:fig:test_apa_iff).

- Compare 2DoF and FEM models (usefulness of the two)

- Good match between all the APA: will simplify the modeling and control of the nano-hexapod

- No advantage of the FEM model here (as only uniaxial behavior is checked), but may be useful later

Bibliography ignore

Footnotes

11Ansys\textsuperscript{\textregistered} was used

9The transfer function fitting was computed using the vectfit3 routine, see cite:&gustavsen99_ration_approx_frequen_domain_respon

8Frequency of the sinusoidal wave is $1\,\text{Hz}$

7Renishaw Vionic, resolution of $2.5\,nm$

6Kistler 9722A

5Polytec controller 3001 with sensor heads OFV512

10Note that this is not fully correct as it was shown in Section ref:ssec:test_apa_stiffness that the electrical boundaries of the piezoelectric stack impacts its stiffness and that the sensor stack is almost open-circuited while the actuator stacks are almost short-circuited.

2The Matlab fminsearch command is used to fit the plane

1Heidenhain MT25, specified accuracy of $\pm 0.5\,\mu m$

4Millimar 1318 probe, specified linearity better than $1\,\mu m$

3LCR-819 from Gwinstek, specified accuracy of $0.05\%$, measured frequency is set at $1\,\text{kHz}$