216 KiB

NASS - Effect of rotation

- Introduction

- System Description and Analysis

- Integral Force Feedback

- Integral Force Feedback with an High Pass Filter

- IFF with a stiffness in parallel with the force sensor

- Relative Damping Control

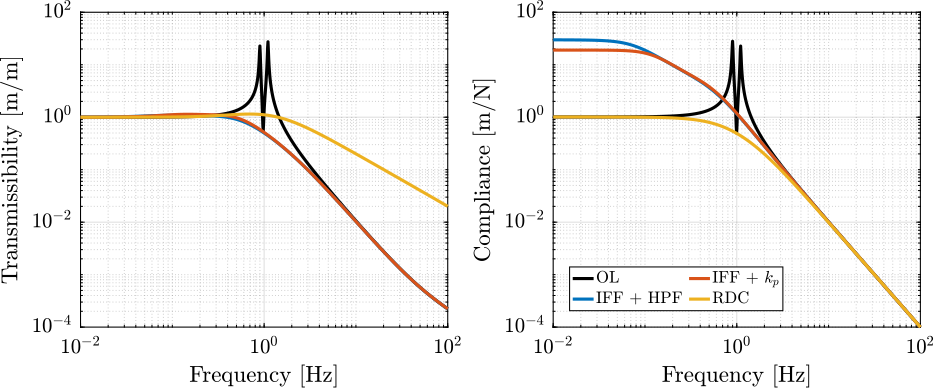

- Comparison of Active Damping Techniques

- Rotating Nano-Hexapod

- Nano-Active-Stabilization-System with rotation

- Conclusion

- Bibliography

This report is also available as a pdf.

Introduction ignore

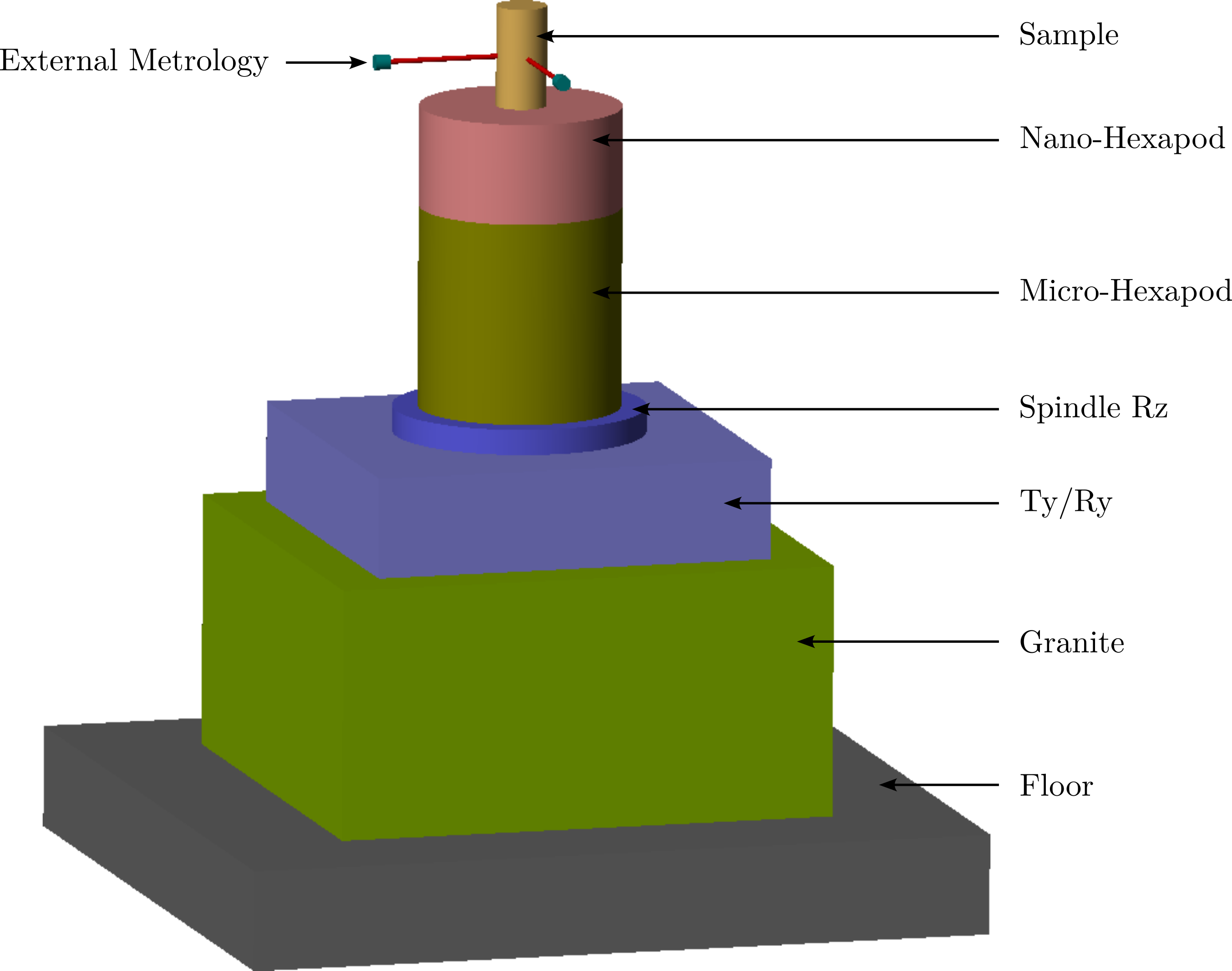

An important aspect of the Nano Active Stabilization System (NASS) is that the nano-hexapod is continuously rotating around a vertical axis while the external metrology is not. Such rotation induces gyroscopic effects that may impact the system dynamics and obtained performances.

In this report, this rotating aspect of the NASS is studied. It is structured in several sections:

- Section ref:sec:rotating_system_description: a simple model of a rotating suspended platform that will be used throughout this study is presented. The effect of the rotation velocity on the system dynamics is shown.

- Section ref:sec:rotating_iff_pure_int: Integral Force Feedback (IFF) is applied to the rotating platform, and it is shown that the unconditional stability of IFF is lost due to Gyroscopic effects induced by the rotation.

- Section ref:sec:rotating_iff_pseudo_int: A first modification of the IFF control law is proposed such that damping can be added to the suspension modes in a robust way. This modification consists of adding an high pass filter to the IFF controller. Optimal high pass filter cut-off frequency is computed.

- Section ref:sec:rotating_iff_parallel_stiffness: A second modification is proposed to regain the unconditional stability of IFF. This modification consists of adding stiffness in parallel to the force sensors. Optimal parallel stiffness is computed.

- Section ref:sec:rotating_relative_damp_control: Relative damping control is applied to the rotating system.

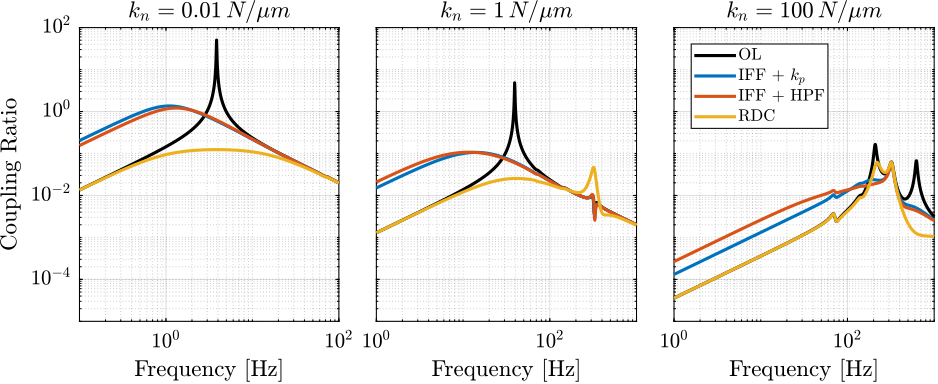

- Section ref:sec:rotating_comp_act_damp: Once the optimal control parameters for the three tested active damping techniques are obtained, they are compared in terms of achievable damping, obtained damped plant and closed-loop compliance and transmissibility.

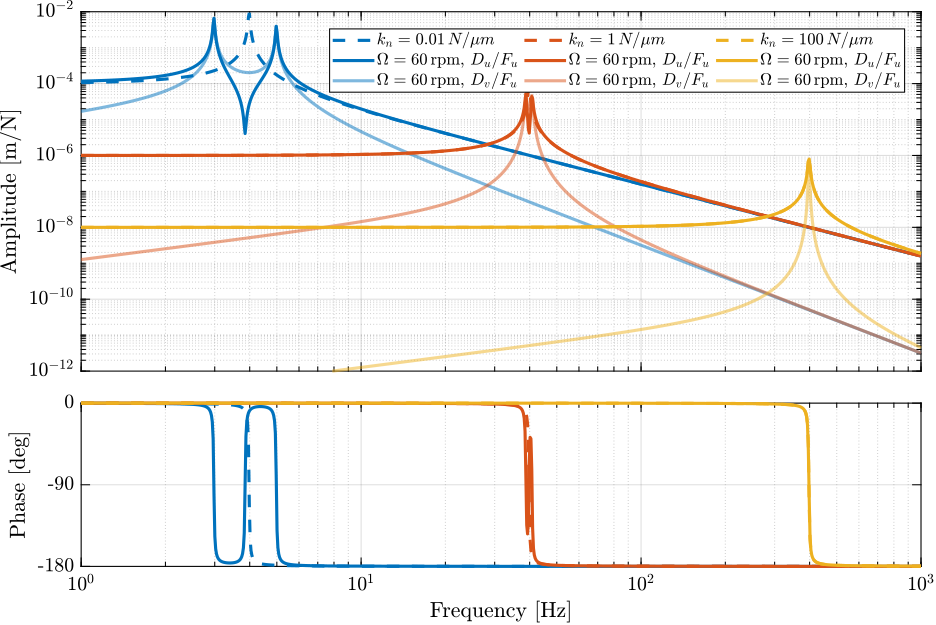

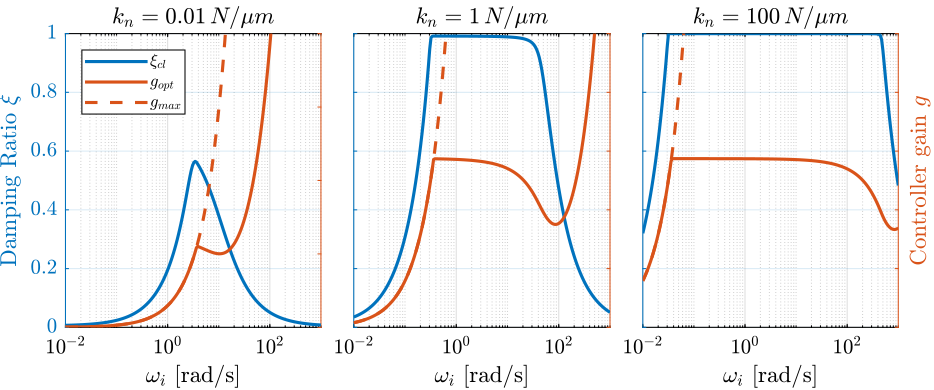

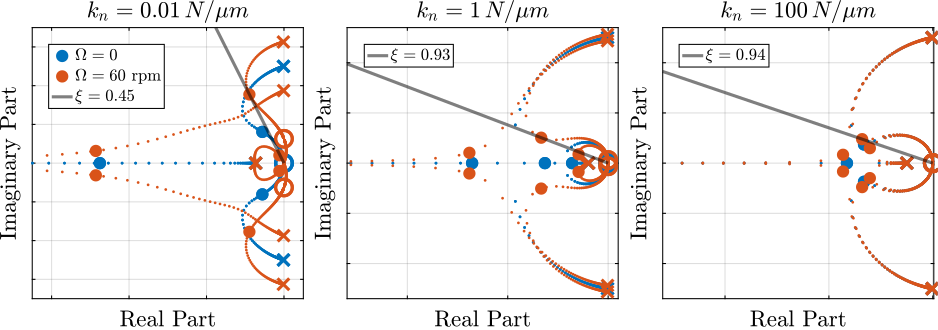

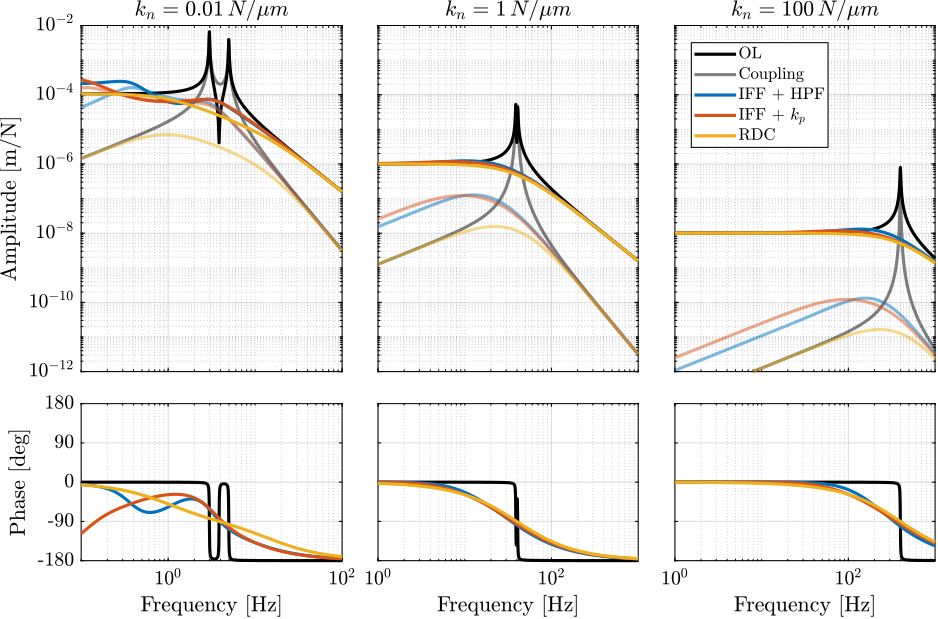

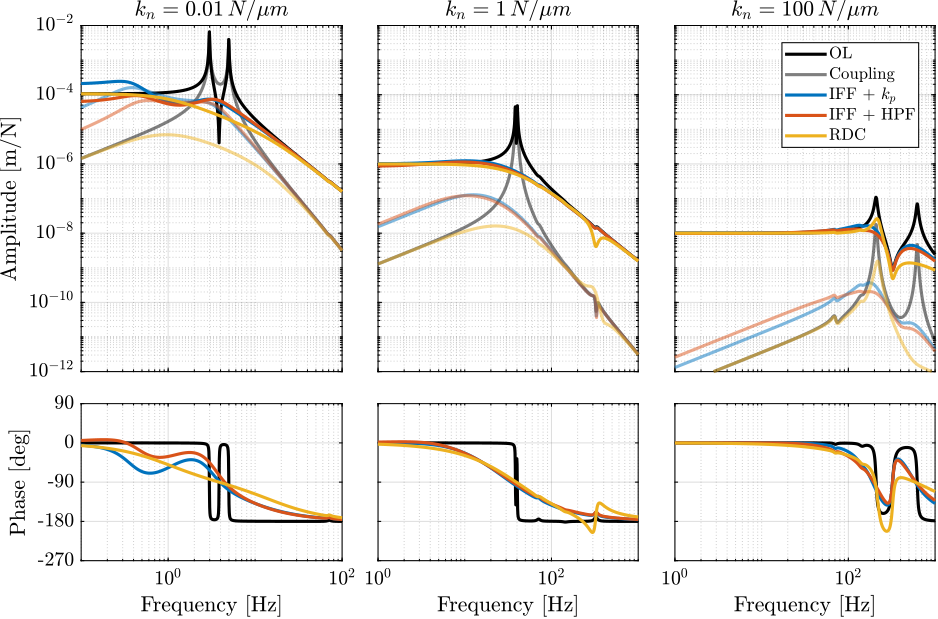

- Section ref:sec:rotating_nano_hexapod: the previous analysis is applied on three nano-hexapod stiffnesses and optimal active damping controller are obtained.

- Section ref:sec:rotating_nass: up until this section, the study was performed on a very simplistic model that just captures the rotation aspect and the model parameters were not tuned to corresponds to the NASS. In this last section, a model of the micro-station is added below the suspended platform (i.e. the nano-hexapod) with a rotating spindle and parameters tuned to match the NASS dynamics. The goal is to determine if the rotation imposes performance limitation for the NASS.

To run the Matlab code, go in the matlab directory and run the Matlab files corresponding to each section (see Table ref:tab:section_matlab_code).

| Sections | Matlab File |

|---|---|

| Section ref:sec:rotating_system_description | rotating_1_system_description.m |

| Section ref:sec:rotating_iff_pure_int | rotating_2_iff_pure_int.m |

| Section ref:sec:rotating_iff_pseudo_int | rotating_3_iff_hpf.m |

| Section ref:sec:rotating_iff_parallel_stiffness | rotating_4_iff_kp.m |

| Section ref:sec:rotating_relative_damp_control | rotating_5_rdc.m |

| Section ref:sec:rotating_comp_act_damp | rotating_5_act_damp_comparison.m |

| Section ref:sec:rotating_nano_hexapod | rotating_6_nano_hexapod.m |

| Section ref:sec:rotating_nass | rotating_6_nass.m |

System Description and Analysis

<<sec:rotating_system_description>>

Introduction ignore

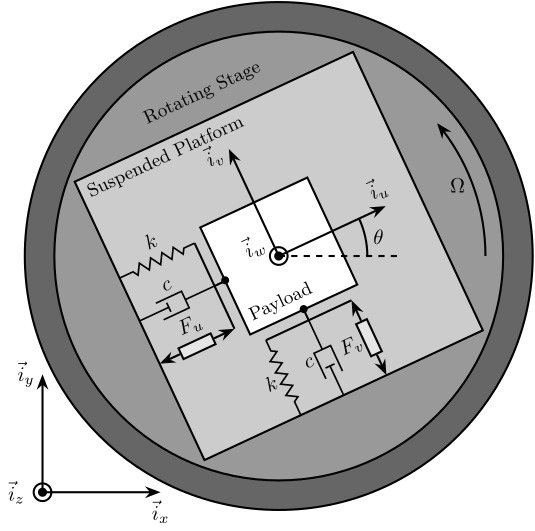

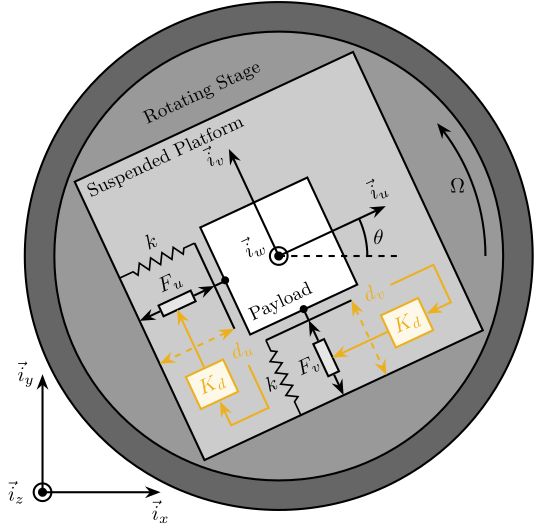

The studied system consists of a 2 degree of freedom translation stage on top of a rotating stage (Figure ref:fig:rotating_3dof_model_schematic).

The rotating stage is supposed to be ideal, meaning it induces a perfect rotation $\theta(t) = \Omega t$ where $\Omega$ is the rotational speed in $\si{\radian\per\s}$.

The suspended platform consists of two orthogonal actuators each represented by three elements in parallel: a spring with a stiffness $k$ in $\si{\newton\per\meter}$, a dashpot with a damping coefficient $c$ in $\si{\newton\per(\meter\per\second)}$ and an ideal force source $F_u, F_v$. A payload with a mass $m$ in $\si{\kilo\gram}$, is mounted on the (rotating) suspended platform.

Two reference frames are used: an inertial frame $(\vec{i}_x, \vec{i}_y, \vec{i}_z)$ and a uniform rotating frame $(\vec{i}_u, \vec{i}_v, \vec{i}_w)$ rigidly fixed on top of the rotating stage with $\vec{i}_w$ aligned with the rotation axis. The position of the payload is represented by $(d_u, d_v, 0)$ expressed in the rotating frame.

\begin{tikzpicture}

% Angle

\def\thetau{25}

% Rotational Stage

\draw[fill=black!60!white] (0, 0) circle (4.3);

\draw[fill=black!40!white] (0, 0) circle (3.8);

% Label

\node[anchor=north west, rotate=\thetau] at (-2.5, 2.5) {\small Rotating Stage};

% Rotating Scope

\begin{scope}[rotate=\thetau]

% Rotating Frame

\draw[fill=black!20!white] (-2.6, -2.6) rectangle (2.6, 2.6);

% Label

\node[anchor=north west, rotate=\thetau] at (-2.6, 2.6) {\small Suspended Platform};

% Mass

\draw[fill=white] (-1, -1) rectangle (1, 1);

% Label

\node[anchor=south west, rotate=\thetau] at (-1, -1) {\small Payload};

% Attached Points

\node[] at (-1, 0){$\bullet$};

\draw[] (-1, 0) -- ++(-0.2, 0) coordinate(cu);

\draw[] ($(cu) + (0, -0.8)$) coordinate(actu) -- ($(cu) + (0, 0.8)$) coordinate(ku);

\node[] at (0, -1){$\bullet$};

\draw[] (0, -1) -- ++(0, -0.2) coordinate(cv);

\draw[] ($(cv) + (-0.8, 0)$)coordinate(kv) -- ($(cv) + (0.8, 0)$) coordinate(actv);

% Spring and Actuator for U

\draw[actuator={0.6}{0.2}{black}] (actu) -- node[above=0.1, rotate=\thetau]{$F_u$} (actu-|-2.6,0);

\draw[spring=0.2] (ku) -- node[above=0.1, rotate=\thetau]{$k$} (ku-|-2.6,0);

\draw[damper={black}{8}{8}] (cu) -- node[above left=0.2 and -0.1, rotate=\thetau]{$c$} (cu-|-2.6,0);

\draw[actuator={0.6}{0.2}{black}] (actv) -- node[left, rotate=\thetau]{$F_v$} (actv|-0,-2.6);

\draw[spring=0.2] (kv) -- node[left, rotate=\thetau]{$k$} (kv|-0,-2.6);

\draw[damper={black}{8}{8}] (cv) -- node[left=0.1, rotate=\thetau]{$c$} (cv|-0,-2.6);

\end{scope}

% Inertial Frame

\draw[->] (-4, -4) -- ++(2, 0) node[below]{$\vec{i}_x$};

\draw[->] (-4, -4) -- ++(0, 2) node[left]{$\vec{i}_y$};

\draw[fill, color=black] (-4, -4) circle (0.06);

\node[draw, circle, inner sep=0pt, minimum size=0.3cm, label=left:$\vec{i}_z$] at (-4, -4){};

\draw[->] (0, 0) node[above left, rotate=\thetau]{$\vec{i}_w$} -- ++(\thetau:2) node[above, rotate=\thetau]{$\vec{i}_u$};

\draw[->] (0, 0) -- ++(\thetau+90:2) node[left, rotate=\thetau]{$\vec{i}_v$};

\draw[fill, color=black] (0,0) circle (0.06);

\node[draw, circle, inner sep=0pt, minimum size=0.3cm] at (0, 0){};

\draw[dashed] (0, 0) -- ++(2, 0);

\draw[] (1.5, 0) arc (0:\thetau:1.5) node[midway, right]{$\theta$};

\draw[->] (3.5, 0) arc (0:40:3.5) node[midway, left]{$\Omega$};

\end{tikzpicture}

Equations of motion

To obtain the equations of motion for the system represented in Figure ref:fig:rotating_3dof_model_schematic, the Lagrangian equations are used:

\begin{equation} \frac{d}{dt} \left( \frac{\partial L}{\partial \dot{q}_i} \right) + \frac{\partial D}{\partial \dot{q}_i} - \frac{\partial L}{\partial q_i} = Q_i \end{equation}with $L = T - V$ the Lagrangian, $T$ the kinetic coenergy, $V$ the potential energy, $D$ the dissipation function, and $Q_i$ the generalized force associated with the generalized variable $\begin{bmatrix}q_1 & q_2\end{bmatrix} = \begin{bmatrix}d_u & d_v\end{bmatrix}$. The equation of motion corresponding to the constant rotation along $\vec{i}_w$ is disregarded as this motion is considered to be imposed by the rotation stage.

\begin{equation} \begin{aligned} T &= \frac{1}{2} m \left( ( \dot{d}_u - \Omega d_v )^2 + ( \dot{d}_v + \Omega d_u )^2 \right), \\ V &= \frac{1}{2} k \big( {d_u}^2 + {d_v}^2 \big), \ Q_1 = F_u, \\ D &= \frac{1}{2} c \big( \dot{d}_u{}^2 + \dot{d}_v{}^2 \big), \ Q_2 = F_v \end{aligned} \end{equation}Substituting equations eqref:eq:energy_functions_lagrange into equation eqref:eq:lagrangian_equations for both generalized coordinates gives two coupled differential equations eqref:eq:eom_coupled_1 and eqref:eq:eom_coupled_2.

\begin{subequations} \begin{align} m \ddot{d}_u + c \dot{d}_u + ( k - m \Omega^2 ) d_u &= F_u + 2 m \Omega \dot{d}_v \label{eq:eom_coupled_1} \\ m \ddot{d}_v + c \dot{d}_v + ( k \underbrace{-\,m \Omega^2}_{\text{Centrif.}} ) d_v &= F_v \underbrace{-\,2 m \Omega \dot{d}_u}_{\text{Coriolis}} \label{eq:eom_coupled_2} \end{align} \end{subequations}The uniform rotation of the system induces two gyroscopic effects as shown in equation eqref:eq:eom_coupled:

- Centrifugal forces: that can been seen as an added negative stiffness $- m \Omega^2$ along $\vec{i}_u$ and $\vec{i}_v$

- Coriolis Forces: that adds coupling between the two orthogonal directions.

One can verify that without rotation ($\Omega = 0$) the system becomes equivalent to two uncoupled one degree of freedom mass-spring-damper systems.

Transfer Functions in the Laplace domain

To study the dynamics of the system, the differential equations of motions eqref:eq:eom_coupled are converted into the Laplace domain and the $2 \times 2$ transfer function matrix $\mathbf{G}_d$ from $\begin{bmatrix}F_u & F_v\end{bmatrix}$ to $\begin{bmatrix}d_u & d_v\end{bmatrix}$ in equation eqref:eq:Gd_mimo_tf is obtained. Its elements are shown in equation eqref:eq:Gd_indiv_el.

\begin{equation} \begin{bmatrix} d_u \\ d_v \end{bmatrix} = \mathbf{G}_d \begin{bmatrix} F_u \\ F_v \end{bmatrix} \end{equation} \begin{subequations} \begin{align} \mathbf{G}_{d}(1,1) &= \mathbf{G}_{d}(2,2) = \frac{ms^2 + cs + k - m \Omega^2}{\left( m s^2 + cs + k - m \Omega^2 \right)^2 + \left( 2 m \Omega s \right)^2} \\ \mathbf{G}_{d}(1,2) &= -\mathbf{G}_{d}(2,1) = \frac{2 m \Omega s}{\left( m s^2 + cs + k - m \Omega^2 \right)^2 + \left( 2 m \Omega s \right)^2} \end{align} \end{subequations}To simplify the analysis, the undamped natural frequency $\omega_0$ and the damping ratio $\xi$ are used as in equation eqref:eq:xi_and_omega.

\begin{equation} \omega_0 = \sqrt{\frac{k}{m}} \text{ in } \si{\radian\per\second}, \quad \xi = \frac{c}{2 \sqrt{k m}} \end{equation}The elements of transfer function matrix $\mathbf{G}_d$ are now described by equation eqref:eq:Gd_w0_xi_k.

\begin{subequations} \begin{align} \mathbf{G}_{d}(1,1) &= \frac{\frac{1}{k} \left( \frac{s^2}{{\omega_0}^2} + 2 \xi \frac{s}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \right)}{\left( \frac{s^2}{{\omega_0}^2} + 2 \xi \frac{s}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \right)^2 + \left( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \right)^2} \\ \mathbf{G}_{d}(1,2) &= \frac{\frac{1}{k} \left( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \right)}{\left( \frac{s^2}{{\omega_0}^2} + 2 \xi \frac{s}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \right)^2 + \left( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \right)^2} \end{align} \end{subequations}System Poles: Campbell Diagram

The poles of $\mathbf{G}_d$ are the complex solutions $p$ of equation eqref:eq:poles.

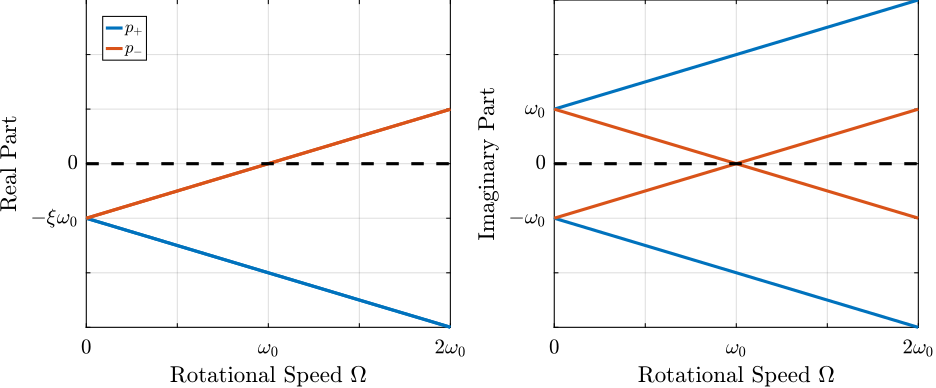

\begin{equation} \left( \frac{p^2}{{\omega_0}^2} + 2 \xi \frac{p}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \right)^2 + \left( 2 \frac{\Omega}{\omega_0} \frac{p}{\omega_0} \right)^2 = 0 \end{equation}Supposing small damping ($\xi \ll 1$), two pairs of complex conjugate poles are obtained as shown in equation eqref:eq:pole_values.

\begin{subequations} \begin{align} p_{+} &= - \xi \omega_0 \left( 1 + \frac{\Omega}{\omega_0} \right) \pm j \omega_0 \left( 1 + \frac{\Omega}{\omega_0} \right) \\ p_{-} &= - \xi \omega_0 \left( 1 - \frac{\Omega}{\omega_0} \right) \pm j \omega_0 \left( 1 - \frac{\Omega}{\omega_0} \right) \end{align} \end{subequations}%% Model parameters for first analysis

kn = 1; % Actuator Stiffness [N/m]

mn = 1; % Payload Mass [kg]

cn = 0.05; % Actuator Damping [N/(m/s)]

xin = cn/(2*sqrt(kn*mn)); % Modal Damping [-]

w0n = sqrt(kn/mn); % Natural Frequency [rad/s]%% Computation of the poles as a function of the rotating velocity

Wzs = linspace(0, 2, 51); % Vector of rotation speeds [rad/s]

p_ws = zeros(4, length(Wzs));

for i = 1:length(Wzs)

Wz = Wzs(i);

pole_G = pole(1/(((s^2)/(w0n^2) + 2*xin*s/w0n + 1 - (Wz^2)/(w0n^2))^2 + (2*Wz*s/(w0n^2))^2));

[~, i_sort] = sort(imag(pole_G));

p_ws(:, i) = pole_G(i_sort);

end

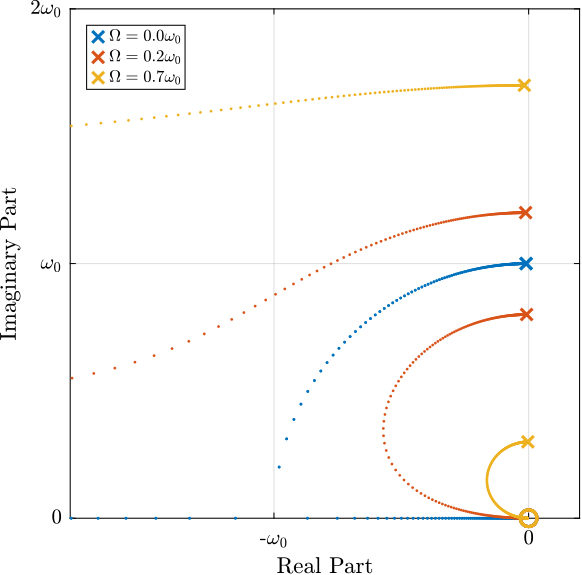

clear pole_G;The real and complex parts of these two pairs of complex conjugate poles are represented in Figure ref:fig:rotating_campbell_diagram as a function of the rotational speed $\Omega$. As the rotational speed increases, $p_{+}$ goes to higher frequencies and $p_{-}$ goes to lower frequencies. The system becomes unstable for $\Omega > \omega_0$ as the real part of $p_{-}$ is positive. Physically, the negative stiffness term $-m\Omega^2$ induced by centrifugal forces exceeds the spring stiffness $k$.

%% Campbell diagram - Real and Imaginary parts of the poles as a function of the rotating velocity

figure;

tiledlayout(1, 2, 'TileSpacing', 'Compact', 'Padding', 'None');

ax1 = nexttile();

hold on;

plot(Wzs, real(p_ws(1, :)), '-', 'color', colors(1,:), 'DisplayName', '$p_{+}$')

plot(Wzs, real(p_ws(4, :)), '-', 'color', colors(1,:), 'HandleVisibility', 'off')

plot(Wzs, real(p_ws(2, :)), '-', 'color', colors(2,:), 'DisplayName', '$p_{-}$')

plot(Wzs, real(p_ws(3, :)), '-', 'color', colors(2,:), 'HandleVisibility', 'off')

plot(Wzs, zeros(size(Wzs)), 'k--', 'HandleVisibility', 'off')

hold off;

xlabel('Rotational Speed $\Omega$'); ylabel('Real Part');

leg = legend('location', 'northwest', 'FontSize', 8);

leg.ItemTokenSize(1) = 8;

xlim([0, 2*w0n]);

xticks([0,w0n/2,w0n,3/2*w0n,2*w0n])

xticklabels({'$0$', '', '$\omega_0$', '', '$2 \omega_0$'})

ylim([-3*xin, 3*xin]);

yticks([-3*xin, -2*xin, -xin, 0, xin, 2*xin, 3*xin])

yticklabels({'', '', '$-\xi\omega_0$', '$0$', ''})

ax2 = nexttile();

hold on;

plot(Wzs, imag(p_ws(1, :)), '-', 'color', colors(1,:))

plot(Wzs, imag(p_ws(4, :)), '-', 'color', colors(1,:))

plot(Wzs, imag(p_ws(2, :)), '-', 'color', colors(2,:))

plot(Wzs, imag(p_ws(3, :)), '-', 'color', colors(2,:))

plot(Wzs, zeros(size(Wzs)), 'k--')

hold off;

xlabel('Rotational Speed $\Omega$'); ylabel('Imaginary Part');

xlim([0, 2*w0n]);

xticks([0,w0n/2,w0n,3/2*w0n,2*w0n])

xticklabels({'$0$', '', '$\omega_0$', '', '$2 \omega_0$'})

ylim([-3*w0n, 3*w0n]);

yticks([-3*w0n, -2*w0n, -w0n, 0, w0n, 2*w0n, 3*w0n])

yticklabels({'', '', '$-\omega_0$', '$0$', '$\omega_0$', '', ''})

System Dynamics: Effect of rotation

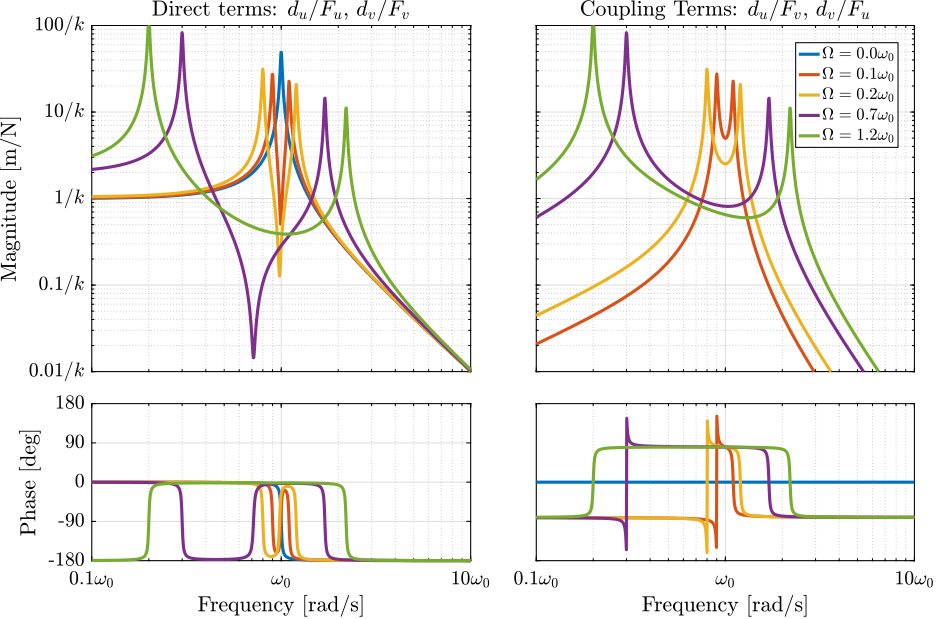

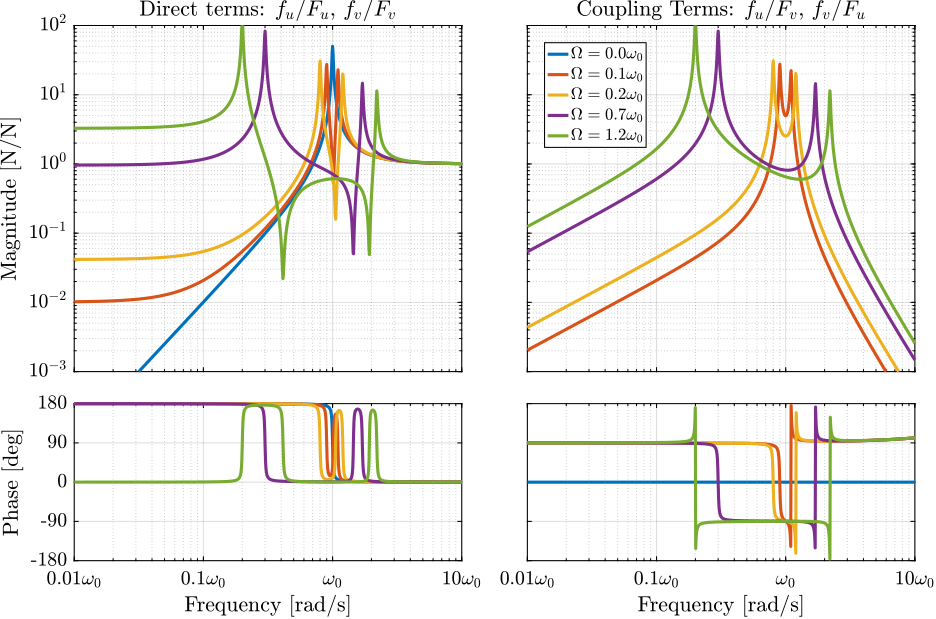

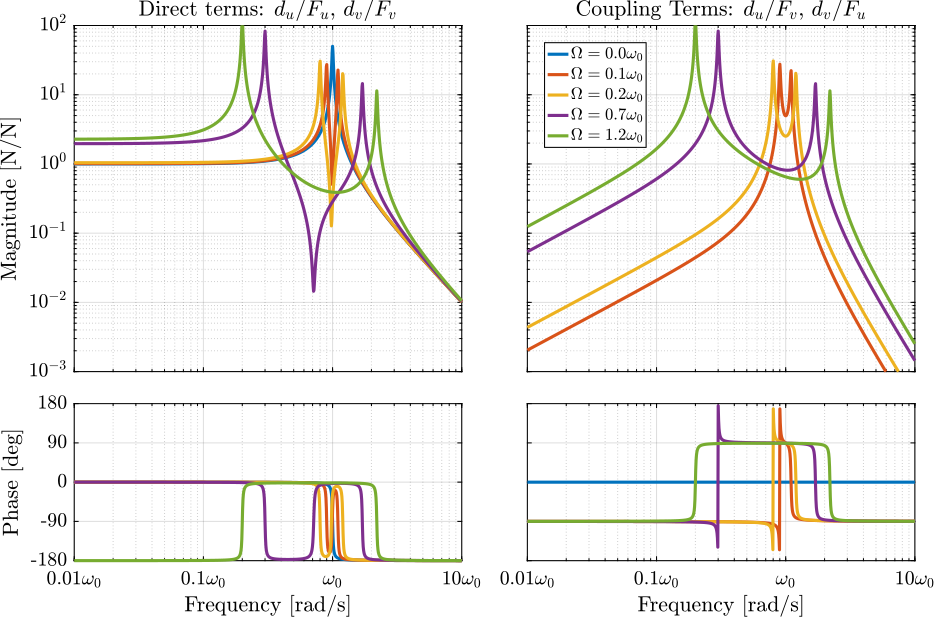

The system dynamics from actuator forces $[F_u, F_v]$ to the relative motion $[d_u, d_v]$ is identified for several rotating velocities.

Looking at the transfer function matrix $\mathbf{G}_d$ in equation eqref:eq:Gd_w0_xi_k, one can see that the two diagonal (direct) terms are equal and that the two off-diagonal (coupling) terms are opposite. The bode plot of these two terms are shown in Figure ref:fig:rotating_direct_coupling_bode_plot for several rotational speeds $\Omega$. These plots confirm the expected behavior: the frequency of the two pairs of complex conjugate poles are further separated as $\Omega$ increases. For $\Omega > \omega_0$, the low frequency pair of complex conjugate poles $p_{-}$ becomes unstable.

%% Bode plot of the direct and coupling terms for several rotating velocities

freqs = logspace(-1, 1, 1000);

figure;

tiledlayout(3, 2, 'TileSpacing', 'Compact', 'Padding', 'None');

% Magnitude

ax1 = nexttile([2, 1]);

hold on;

for i = 1:length(Wzs)

plot(freqs, abs(squeeze(freqresp(Gs{i}('du', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(i,:))

end

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log');

set(gca, 'XTickLabel',[]); ylabel('Magnitude [m/N]');

title('Direct terms: $d_u/F_u$, $d_v/F_v$');

ylim([1e-2, 1e2]);

yticks([1e-2,1e-1,1,1e1,1e2])

yticklabels({'$0.01/k$', '$0.1/k$', '$1/k$', '$10/k$', '$100/k$'})

ax2 = nexttile([2, 1]);

hold on;

for i = 1:length(Wzs)

plot(freqs, abs(squeeze(freqresp(Gs{i}('dv', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(i,:), ...

'DisplayName', sprintf('$\\Omega = %.1f \\omega_0$', Wzs(i)))

end

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log');

set(gca, 'XTickLabel',[]); set(gca, 'YTickLabel',[]);

title('Coupling Terms: $d_u/F_v$, $d_v/F_u$');

ldg = legend('location', 'northeast', 'FontSize', 8, 'NumColumns', 1);

ldg.ItemTokenSize = [10, 1];

ylim([1e-2, 1e2]);

ax3 = nexttile;

hold on;

for i = 1:length(Wzs)

plot(freqs, 180/pi*angle(squeeze(freqresp(Gs{i}('du', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(i,:))

end

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'lin');

xlabel('Frequency [rad/s]'); ylabel('Phase [deg]');

yticks(-180:90:180);

ylim([-180 180]);

xticks([1e-1,1,1e1])

xticklabels({'$0.1 \omega_0$', '$\omega_0$', '$10 \omega_0$'})

ax4 = nexttile;

hold on;

for i = 1:length(Wzs)

plot(freqs, 180/pi*angle(squeeze(freqresp(Gs{i}('dv', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(i,:));

end

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'lin');

xlabel('Frequency [rad/s]'); set(gca, 'YTickLabel',[]);

xticks([1e-1,1,1e1])

xticklabels({'$0.1 \omega_0$', '$\omega_0$', '$10 \omega_0$'})

linkaxes([ax1,ax2,ax3,ax4],'x');

xlim([freqs(1), freqs(end)]);

linkaxes([ax1,ax2],'y');

Integral Force Feedback

<<sec:rotating_iff_pure_int>>

Introduction ignore

In order to further decrease the residual vibrations, active damping can be used for reducing the magnification of the response in the vicinity of the resonances cite:collette11_review_activ_vibrat_isolat_strat.

Many active damping techniques have been developed over the years such as Positive Position Feedback (PPF) cite:lin06_distur_atten_precis_hexap_point,fanson90_posit_posit_feedb_contr_large_space_struc, Integral Force Feedback (IFF) cite:preumont91_activ and Direct Velocity Feedback (DVF) cite:karnopp74_vibrat_contr_using_semi_activ_force_gener,serrand00_multic_feedb_contr_isolat_base_excit_vibrat,preumont02_force_feedb_versus_accel_feedb. \par

In cite:preumont92_activ_dampin_by_local_force, the IFF control scheme has been proposed, where a force sensor, a force actuator and an integral controller are used to directly augment the damping of a mechanical system. When the force sensor is collocated with the actuator, the open-loop transfer function has alternating poles and zeros which facilitate to guarantee the stability of the closed loop system cite:preumont02_force_feedb_versus_accel_feedb. It was latter shown that this property holds for multiple collated actuator/sensor pairs cite:preumont08_trans_zeros_struc_contr_with. \par

The main advantages of IFF over other active damping techniques are the guaranteed stability even in presence of flexible dynamics, good performances and robustness properties cite:preumont02_force_feedb_versus_accel_feedb. \par

Several improvements of the classical IFF have been proposed, such as adding a feed-through term to increase the achievable damping cite:teo15_optim_integ_force_feedb_activ_vibrat_contr or adding an high pass filter to recover the loss of compliance at low frequency cite:chesne16_enhan_dampin_flexib_struc_using_force_feedb. Recently, an $\mathcal{H}_\infty$ optimization criterion has been used to derive optimal gains for the IFF controller cite:zhao19_optim_integ_force_feedb_contr. \par

However, none of these study have been applied to a rotating system. In this section, Integral Force Feedback strategy is applied on the rotating suspended platform, and it is shown that gyroscopic effects alters the system dynamics and that IFF cannot be applied as is.

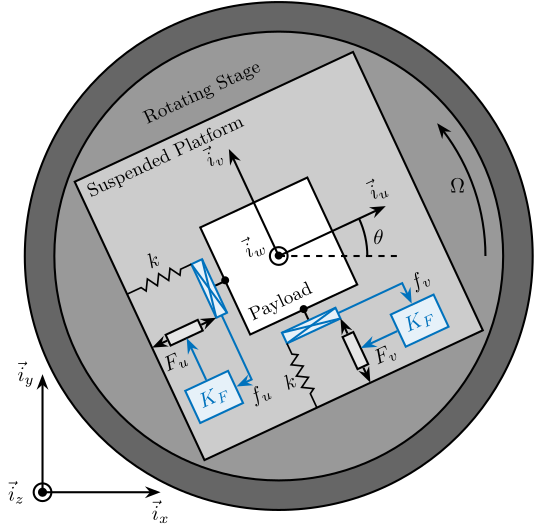

System and Equations of motion

In order to apply Integral Force Feedback, two force sensors are added in series with the actuators (Figure ref:fig:rotating_3dof_model_schematic_iff). Two identical controllers $K_F$ are then used to feedback each of the sensed force to its associated actuator:

\begin{equation} K_{F}(s) = g \cdot \frac{1}{s} \end{equation} \begin{tikzpicture}

% Angle

\def\thetau{25}

% Rotational Stage

\draw[fill=black!60!white] (0, 0) circle (4.3);

\draw[fill=black!40!white] (0, 0) circle (3.8);

% Label

\node[anchor=north west, rotate=\thetau] at (-2.5, 2.5) {\small Rotating Stage};

% Rotating Scope

\begin{scope}[rotate=\thetau]

% Rotating Frame

\draw[fill=black!20!white] (-2.6, -2.6) rectangle (2.6, 2.6);

% Label

\node[anchor=north west, rotate=\thetau] at (-2.6, 2.6) {\small Suspended Platform};

% Mass

\draw[fill=white] (-1, -1) rectangle (1, 1);

% Label

\node[anchor=south west, rotate=\thetau] at (-1, -1) {\small Payload};

% Attached Points

\node[] at (-1, 0){$\bullet$};

\draw[] (-1, 0) -- ++(-0.2, 0) coordinate(au);

\node[] at (0, -1){$\bullet$};

\draw[] (0, -1) -- ++(0, -0.2) coordinate(av);

% Force Sensors

\draw[draw=colorblue, fill=colorblue!10!white] ($(au) + (-0.2, -0.5)$) rectangle ($(au) + (0, 0.5)$);

\draw[draw=colorblue] ($(au) + (-0.2, -0.5)$)coordinate(actu) -- ($(au) + (0, 0.5)$);

\draw[draw=colorblue] ($(au) + (-0.2, 0.5)$)coordinate(ku) -- ($(au) + (0, -0.5)$);

\draw[draw=colorblue, fill=colorblue!10!white] ($(av) + (-0.5, -0.2)$) rectangle ($(av) + (0.5, 0)$);

\draw[draw=colorblue] ($(av) + ( 0.5, -0.2)$)coordinate(actv) -- ($(av) + (-0.5, 0)$);

\draw[draw=colorblue] ($(av) + (-0.5, -0.2)$)coordinate(kv) -- ($(av) + ( 0.5, 0)$);

% Spring and Actuator for U

\draw[actuator={0.6}{0.2}{black}] (actu) -- coordinate[midway](actumid) (actu-|-2.6,0);

\draw[spring=0.2] (ku) -- node[above=0.1, rotate=\thetau]{$k$} (ku-|-2.6,0);

% \draw[actuator={0.6}{0.2}] (actv) -- node[right, rotate=\thetau]{$F_v$} (actv|-0,-2.6);

\draw[actuator={0.6}{0.2}{black}] (actv) -- coordinate[midway](actvmid) (actv|-0,-2.6);

\draw[spring=0.2] (kv) -- node[left, rotate=\thetau]{$k$} (kv|-0,-2.6);

\node[color=colorblue, block={0.8cm}{0.6cm}, fill=colorblue!10!white, rotate=\thetau] (Ku) at ($(actumid) + (0, -1.2)$) {$K_{F}$};

\draw[->, draw=colorblue] ($(au) + (-0.1, -0.5)$) |- (Ku.east) node[below right, rotate=\thetau]{$f_{u}$};

\draw[->, draw=colorblue] (Ku.north) -- ($(actumid) + (0, -0.1)$) node[below left, rotate=\thetau]{$F_u$};

\node[color=colorblue, block={0.8cm}{0.6cm}, fill=colorblue!10!white, rotate=\thetau] (Kv) at ($(actvmid) + (1.2, 0)$) {$K_{F}$};

\draw[->, draw=colorblue] ($(av) + (0.5, -0.1)$) -| (Kv.north) node[above right, rotate=\thetau]{$f_{v}$};

\draw[->, draw=colorblue] (Kv.west) -- ($(actvmid) + (0.1, 0)$) node[below right, rotate=\thetau]{$F_v$};

\end{scope}

% Inertial Frame

\draw[->] (-4, -4) -- ++(2, 0) node[below]{$\vec{i}_x$};

\draw[->] (-4, -4) -- ++(0, 2) node[left]{$\vec{i}_y$};

\draw[fill, color=black] (-4, -4) circle (0.06);

\node[draw, circle, inner sep=0pt, minimum size=0.3cm, label=left:$\vec{i}_z$] at (-4, -4){};

\node[draw, circle, inner sep=0pt, minimum size=0.3cm] at (0, 0){};

\draw[->] (0, 0) node[above left, rotate=\thetau]{$\vec{i}_w$} -- ++(\thetau:2) node[above, rotate=\thetau]{$\vec{i}_u$};

\draw[->] (0, 0) -- ++(\thetau+90:2) node[left, rotate=\thetau]{$\vec{i}_v$};

\draw[dashed] (0, 0) -- ++(2, 0);

\draw[] (1.5, 0) arc (0:\thetau:1.5) node[midway, right]{$\theta$};

\node[] at (0,0) {$\bullet$};

\draw[->] (3.5, 0) arc (0:40:3.5) node[midway, left]{$\Omega$};

\end{tikzpicture}

The forces $\begin{bmatrix}f_u & f_v\end{bmatrix}$ measured by the two force sensors represented in Figure ref:fig:rotating_3dof_model_schematic_iff are described by equation eqref:eq:measured_force.

\begin{equation} \begin{bmatrix} f_{u} \\ f_{v} \end{bmatrix} = \begin{bmatrix} F_u \\ F_v \end{bmatrix} - (c s + k) \begin{bmatrix} d_u \\ d_v \end{bmatrix} \end{equation}The transfer function matrix $\mathbf{G}_{f}$ from actuator forces to measured forces in equation eqref:eq:Gf_mimo_tf can be obtained by inserting equation eqref:eq:Gd_w0_xi_k into equation eqref:eq:measured_force. Its elements are shown in equation eqref:eq:Gf_indiv_el.

\begin{equation} \begin{bmatrix} f_{u} \\ f_{v} \end{bmatrix} = \mathbf{G}_{f} \begin{bmatrix} F_u \\ F_v \end{bmatrix} \end{equation} \begin{subequations} \label{eq:Gf} \begin{align} \mathbf{G}_{f}(1,1) &= \mathbf{G}_{f}(2,2) = \frac{\left( \frac{s^2}{{\omega_0}^2} - \frac{\Omega^2}{{\omega_0}^2} \right) \left( \frac{s^2}{{\omega_0}^2} + 2 \xi \frac{s}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \right) + \left( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \right)^2}{\left( \frac{s^2}{{\omega_0}^2} + 2 \xi \frac{s}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \right)^2 + \left( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \right)^2} \label{eq:Gf_diag_tf} \\ \mathbf{G}_{f}(1,2) &= -\mathbf{G}_{f}(2,1) = \frac{- \left( 2 \xi \frac{s}{\omega_0} + 1 \right) \left( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \right)}{\left( \frac{s^2}{{\omega_0}^2} + 2 \xi \frac{s}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \right)^2 + \left( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \right)^2} \label{eq:Gf_off_diag_tf} \end{align} \end{subequations}The zeros of the diagonal terms of $\mathbf{G}_f$ in equation eqref:eq:Gf_diag_tf are computed, and neglecting the damping for simplicity, two complex conjugated zeros $z_{c}$ are obtained in equation eqref:eq:iff_zero_cc, and two real zeros $z_{r}$ in equation eqref:eq:iff_zero_real.

\begin{subequations} \begin{align} z_c &= \pm j \omega_0 \sqrt{\frac{1}{2} \sqrt{8 \frac{\Omega^2}{{\omega_0}^2} + 1} + \frac{\Omega^2}{{\omega_0}^2} + \frac{1}{2} } \label{eq:iff_zero_cc} \\ z_r &= \pm \omega_0 \sqrt{\frac{1}{2} \sqrt{8 \frac{\Omega^2}{{\omega_0}^2} + 1} - \frac{\Omega^2}{{\omega_0}^2} - \frac{1}{2} } \label{eq:iff_zero_real} \end{align} \end{subequations}It is interesting to see that the frequency of the pair of complex conjugate zeros $z_c$ in equation eqref:eq:iff_zero_cc always lies between the frequency of the two pairs of complex conjugate poles $p_{-}$ and $p_{+}$ in equation eqref:eq:pole_values. This is what usually gives the unconditional stability of IFF when collocated force sensors are used.

However, for non-null rotational speeds, the two real zeros $z_r$ in equation eqref:eq:iff_zero_real are inducing a non-minimum phase behavior. This can be seen in the Bode plot of the diagonal terms (Figure ref:fig:rotating_iff_bode_plot_effect_rot) where the low frequency gain is no longer zero while the phase stays at $\SI{180}{\degree}$.

The low frequency gain of $\mathbf{G}_f$ increases with the rotational speed $\Omega$ as shown in equation eqref:eq:low_freq_gain_iff_plan.

\begin{equation} \lim_{\omega \to 0} \left| \mathbf{G}_f (j\omega) \right| = \begin{bmatrix} \frac{\Omega^2}{{\omega_0}^2 - \Omega^2} & 0 \\ 0 & \frac{\Omega^2}{{\omega_0}^2 - \Omega^2} \end{bmatrix} \end{equation}This can be explained as follows: a constant actuator force $F_u$ induces a small displacement of the mass $d_u = \frac{F_u}{k - m\Omega^2}$ (Hooke's law taking into account the negative stiffness induced by the rotation). This small displacement then increases the centrifugal force $m\Omega^2d_u = \frac{\Omega^2}{{\omega_0}^2 - \Omega^2} F_u$ which is then measured by the force sensors.

Effect of the rotation speed on the IFF plant dynamics

The transfer functions from actuator forces $[F_u,\ F_v]$ to the measured force sensors $[f_u,\ f_v]$ are identified for several rotating velocities and shown in Figure ref:fig:rotating_iff_bode_plot_effect_rot.

As was expected from the derived equations of motion:

- when $0 < \Omega < \omega_0$: the low frequency gain is no longer zero and two (non-minimum phase) real zero appears at low frequency. The low frequency gain increases with $\Omega$. A pair of (minimum phase) complex conjugate zeros appears between the two complex conjugate poles that are split further apart as $\Omega$ increases.

- when $\omega_0 < \Omega$: the low frequency pole becomes unstable.

%% Bode plot of the direct and coupling term for Integral Force Feedback - Effect of rotation

figure;

freqs = logspace(-2, 1, 1000);

figure;

tiledlayout(3, 2, 'TileSpacing', 'Compact', 'Padding', 'None');

% Magnitude

ax1 = nexttile([2, 1]);

hold on;

for i = 1:length(Wzs)

plot(freqs, abs(squeeze(freqresp(Gs{i}('fu', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(i,:))

end

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log');

set(gca, 'XTickLabel',[]); ylabel('Magnitude [N/N]');

title('Direct terms: $f_u/F_u$, $f_v/F_v$');

ylim([1e-3, 1e2]);

ax2 = nexttile([2, 1]);

hold on;

for i = 1:length(Wzs)

plot(freqs, abs(squeeze(freqresp(Gs{i}('fv', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(i,:), ...

'DisplayName', sprintf('$\\Omega = %.1f \\omega_0$', Wzs(i)))

end

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log');

set(gca, 'XTickLabel',[]); set(gca, 'YTickLabel',[]);

title('Coupling Terms: $f_u/F_v$, $f_v/F_u$');

ldg = legend('location', 'northwest', 'FontSize', 8, 'NumColumns', 1);

ldg.ItemTokenSize = [10, 1];

ylim([1e-3, 1e2]);

ax3 = nexttile;

hold on;

for i = 1:length(Wzs)

plot(freqs, 180/pi*angle(squeeze(freqresp(Gs{i}('fu', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(i,:))

end

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'lin');

xlabel('Frequency [rad/s]'); ylabel('Phase [deg]');

yticks(-180:90:180);

ylim([-180 180]);

xticks([1e-2,1e-1,1,1e1])

xticklabels({'$0.01 \omega_0$', '$0.1 \omega_0$', '$\omega_0$', '$10 \omega_0$'})

ax4 = nexttile;

hold on;

for i = 1:length(Wzs)

plot(freqs, 180/pi*angle(squeeze(freqresp(Gs{i}('fv', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(i,:));

end

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'lin');

xlabel('Frequency [rad/s]'); set(gca, 'YTickLabel',[]);

yticks(-180:90:180);

ylim([-180 180]);

xticks([1e-2,1e-1,1,1e1])

xticklabels({'$0.01 \omega_0$', '$0.1 \omega_0$', '$\omega_0$', '$10 \omega_0$'})

linkaxes([ax1,ax2,ax3,ax4],'x');

xlim([freqs(1), freqs(end)]);

linkaxes([ax1,ax2],'y');

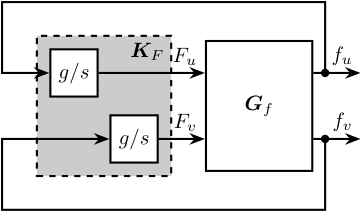

Decentralized Integral Force Feedback

The control diagram for decentralized Integral Force Feedback is shown in Figure ref:fig:rotating_iff_diagram.

\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[block={1.8cm}{2.2cm}] (G) {$\bm{G}_f$};

% Inputs of the controllers

\coordinate[] (output1) at ($(G.south east)!0.75!(G.north east)$);

\coordinate[] (output2) at ($(G.south east)!0.25!(G.north east)$);

\coordinate[] (input1) at ($(G.south west)!0.75!(G.north west)$);

\coordinate[] (input2) at ($(G.south west)!0.25!(G.north west)$);

\node[block, left=1.8 of input1] (K1) {$g/s$};

\node[block] (K2) at ($(K1.east|-input2)+(0.6, 0)$) {$g/s$};

% Connections and labels

\draw[->] (K1.east) -- (input1)node[above left]{$F_u$};

\draw[->] (K2.east) -- (input2)node[above left]{$F_v$};

\draw[->] (output1) -- ++(0.8, 0) node[above left]{$f_u$};

\draw[->] (output2) -- ++(0.8, 0) node[above left]{$f_v$};

\draw[->] ($(output1)+(0.2, 0)$)node[branch]{} -- ++(0, 1.2) -| ($(K1.west) + (-0.8, 0)$)coordinate(start) -- (K1.west);

\draw[->] ($(output2)+(0.2, 0)$)node[branch]{} -- ++(0, -1.2) -| (start|-K2) -- (K2.west);

\begin{scope}[on background layer]

\node[fit={(K1.north west) (K2.south east)}, inner sep=6pt, draw, dashed, fill=black!20!white] (K) {};

\node[below left] at (K.north east) {$\bm{K}_F$};

\end{scope}

\end{tikzpicture}

The decentralized IFF controller $\bm{K}_F$ corresponds to a diagonal controller with integrators:

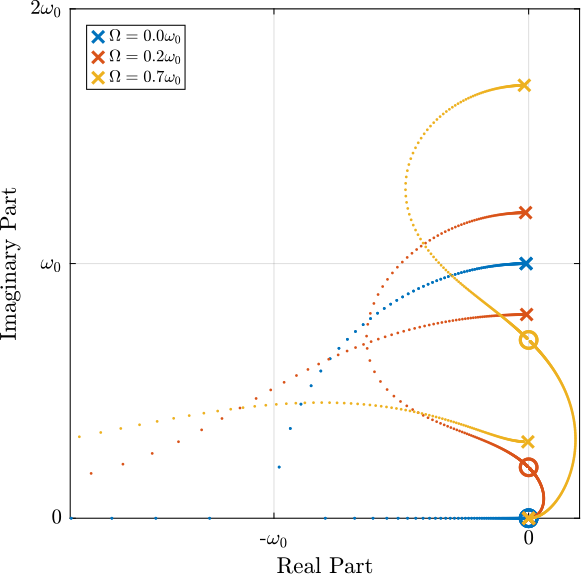

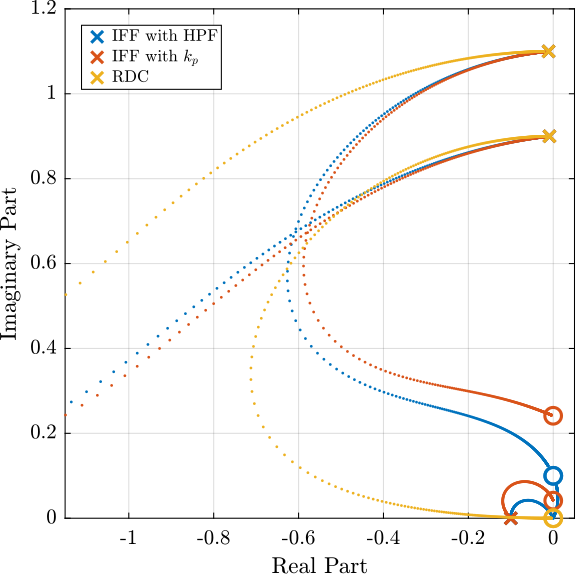

\begin{equation} \begin{aligned} \mathbf{K}_{F}(s) &= \begin{bmatrix} K_{F}(s) & 0 \\ 0 & K_{F}(s) \end{bmatrix} \\ K_{F}(s) &= g \cdot \frac{1}{s} \end{aligned} \end{equation}In order to see how the IFF controller affects the poles of the closed loop system, a Root Locus plot (Figure ref:fig:rotating_root_locus_iff_pure_int) is constructed as follows: the poles of the closed-loop system are drawn in the complex plane as the controller gain $g$ varies from $0$ to $\infty$ for the two controllers $K_{F}$ simultaneously. As explained in cite:preumont08_trans_zeros_struc_contr_with,skogestad07_multiv_feedb_contr, the closed-loop poles start at the open-loop poles (shown by $\tikz[baseline=-0.6ex] \node[cross out, draw=black, minimum size=1ex, line width=2pt, inner sep=0pt, outer sep=0pt] at (0, 0){};$) for $g = 0$ and coincide with the transmission zeros (shown by $\tikz[baseline=-0.6ex] \draw[line width=2pt, inner sep=0pt, outer sep=0pt] (0,0) circle[radius=3pt];$) as $g \to \infty$.

Whereas collocated IFF is usually associated with unconditional stability cite:preumont91_activ, this property is lost due to gyroscopic effects as soon as the rotation velocity in non-null. This can be seen in the Root Locus plot (Figure ref:fig:rotating_root_locus_iff_pure_int) where poles corresponding to the controller are bound to the right half plane implying closed-loop system instability.

Physically, this can be explained like so: at low frequency, the loop gain is very large due to the pure integrator in $K_{F}$ and the finite gain of the plant (Figure ref:fig:rotating_iff_bode_plot_effect_rot). The control system is thus canceling the spring forces which makes the suspended platform no able to hold the payload against centrifugal forces, hence the instability.

%% Root Locus for the Decentralized Integral Force Feedback controller

figure;

Kiff = 1/s*eye(2);

gains = logspace(-2, 4, 300);

Wz_i = [1,3,4];

hold on;

for i = 1:length(Wz_i)

plot(real(pole(Gs{Wz_i(i)}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), imag(pole(Gs{Wz_i(i)}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), 'x', 'color', colors(i,:), ...

'DisplayName', sprintf('$\\Omega = %.1f \\omega_0 $', Wzs(Wz_i(i))),'MarkerSize',8);

plot(real(tzero(Gs{Wz_i(i)}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), imag(tzero(Gs{Wz_i(i)}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), 'o', 'color', colors(i,:), ...

'HandleVisibility', 'off','MarkerSize',8);

for g = gains

cl_poles = pole(feedback(Gs{Wz_i(i)}({'fu', 'fv'}, {'Fu', 'Fv'}), g*Kiff, -1));

plot(real(cl_poles), imag(cl_poles), '.', 'color', colors(i,:), ...

'HandleVisibility', 'off','MarkerSize',4);

end

end

hold off;

axis square;

xlim([-1.8, 0.2]); ylim([0, 2]);

xticks([-1, 0])

xticklabels({'-$\omega_0$', '$0$'})

yticks([0, 1, 2])

yticklabels({'$0$', '$\omega_0$', '$2 \omega_0$'})

xlabel('Real Part'); ylabel('Imaginary Part');

leg = legend('location', 'northwest', 'FontSize', 8);

leg.ItemTokenSize(1) = 8;

Integral Force Feedback with an High Pass Filter

<<sec:rotating_iff_pseudo_int>>

Introduction ignore

As was explained in the previous section, the instability of the IFF controller applied on the rotating system comes in part from the high gain at low frequency caused by the pure integrators.

In order to limit the low frequency controller gain, an High Pass Filter (HPF) can be added to the controller as shown in equation eqref:eq:iff_lhf.

\begin{equation} \boxed{K_{F}(s) = g \cdot \frac{1}{s} \cdot \underbrace{\frac{s/\omega_i}{1 + s/\omega_i}}_{\text{HPF}} = g \cdot \frac{1}{s + \omega_i}} \end{equation}This is equivalent as to slightly shifting the controller pole to the left along the real axis.

This modification of the IFF controller is typically done to avoid saturation associated with the pure integrator cite:preumont91_activ,marneffe07_activ_passiv_vibrat_isolat_dampin_shunt_trans. This is however not why this high pass filter is added here.

Modified Integral Force Feedback Controller

The Integral Force Feedback Controller is modified such that instead of using pure integrators, pseudo integrators (i.e. low pass filters) are used:

\begin{equation} K_{\text{IFF}}(s) = g\frac{1}{\omega_i + s} \begin{bmatrix} 1 & 0 \\ 0 & 1 \end{bmatrix} \end{equation}where $\omega_i$ characterize down to which frequency the signal is integrated.

Let's arbitrary choose the following control parameters:

%% Modified IFF - parameters

g = 2; % Controller gain

wi = 0.1; % HPF Cut-Off frequency [rad/s]

Kiff = (g/s)*eye(2); % Pure IFF

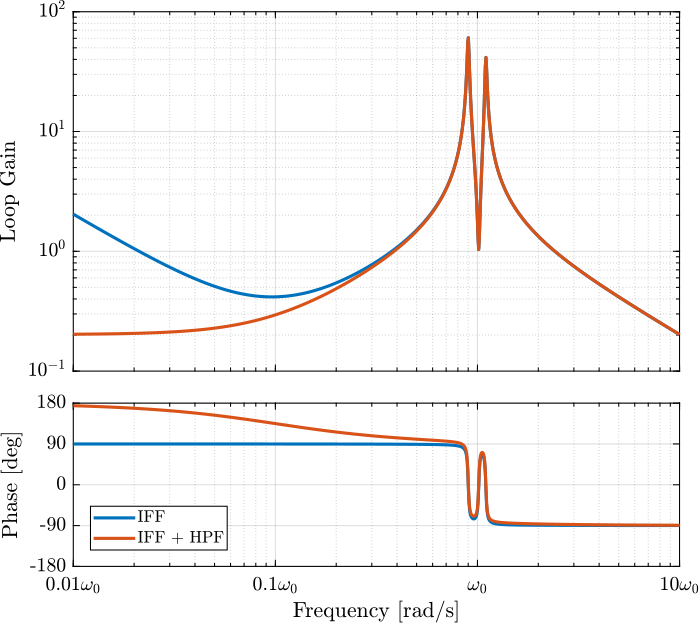

Kiff_hpf = (g/(wi+s))*eye(2); % IFF with added HPFThe loop gains ($K_F(s)$ times the direct dynamics $f_u/F_u$) with and without the added HPF are shown in Figure ref:fig:rotating_iff_modified_loop_gain. The effect of the added HPF limits the low frequency gain to finite values as expected.

%% Loop gain for the IFF with pure integrator and modified IFF with added high pass filter

freqs = logspace(-2, 1, 1000);

Wz_i = 2;

figure;

tiledlayout(3, 1, 'TileSpacing', 'Compact', 'Padding', 'None');

% Magnitude

ax1 = nexttile([2, 1]);

hold on;

plot(freqs, abs(squeeze(freqresp(Gs{Wz_i}('fu', 'Fu')*Kiff(1,1), freqs, 'rad/s'))))

plot(freqs, abs(squeeze(freqresp(Gs{Wz_i}('fu', 'Fu')*Kiff_hpf(1,1), freqs, 'rad/s'))))

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log');

set(gca, 'XTickLabel',[]); ylabel('Loop Gain');

% Phase

ax2 = nexttile;

hold on;

plot(freqs, 180/pi*angle(squeeze(freqresp(Gs{Wz_i}('fu', 'Fu')*Kiff(1,1), freqs, 'rad/s'))), 'DisplayName', 'IFF')

plot(freqs, 180/pi*angle(squeeze(freqresp(Gs{Wz_i}('fu', 'Fu')*Kiff_hpf(1,1), freqs, 'rad/s'))), 'DisplayName', 'IFF + HPF')

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'lin');

xlabel('Frequency [rad/s]'); ylabel('Phase [deg]');

yticks(-180:90:180);

ylim([-180 180]);

xticks([1e-2,1e-1,1,1e1])

xticklabels({'$0.01 \omega_0$', '$0.1 \omega_0$', '$\omega_0$', '$10 \omega_0$'})

leg = legend('location', 'southwest', 'FontSize', 8);

leg.ItemTokenSize(1) = 20;

linkaxes([ax1,ax2],'x');

xlim([freqs(1), freqs(end)]);

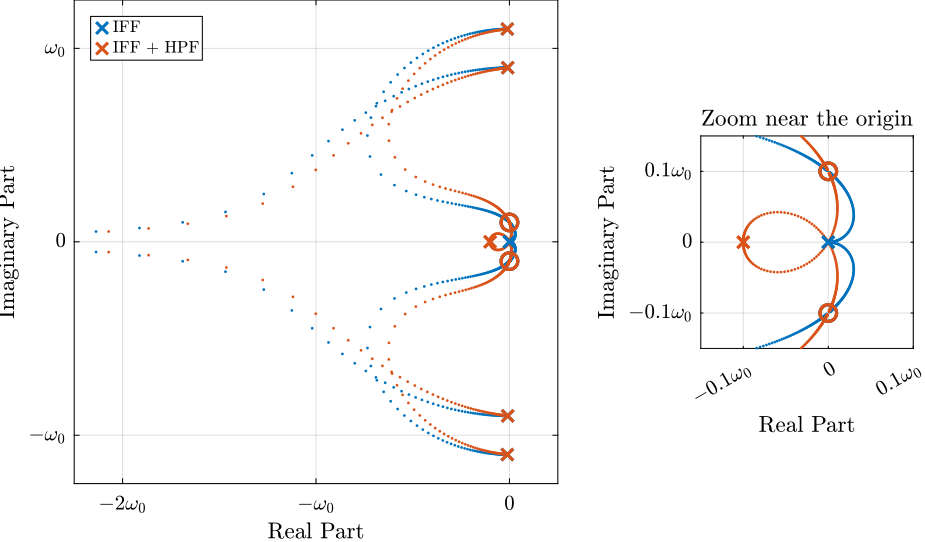

The Root Locus plots for the decentralized IFF with and without the HPF are displayed in Figure ref:fig:rotating_iff_root_locus_hpf. With the added HPF, the poles of the closed loop system are shown to be stable up to some value of the gain $g_\text{max}$ given by equation eqref:eq:gmax_iff_hpf.

\begin{equation} \boxed{g_{\text{max}} = \omega_i \left( \frac{{\omega_0}^2}{\Omega^2} - 1 \right)} \end{equation}It is interesting to note that $g_{\text{max}}$ also corresponds to the controller gain at which the low frequency loop gain (Figure ref:fig:rotating_iff_modified_loop_gain) reaches one.

%% Root Locus for the initial IFF and the modified IFF

gains = logspace(-2, 4, 200);

figure;

tiledlayout(1, 3, 'TileSpacing', 'Compact', 'Padding', 'None');

ax1 = nexttile([1,2]);

hold on;

for g = gains

clpoles = pole(feedback(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'}), g*Kiff));

plot(real(clpoles), imag(clpoles), '.', 'color', colors(1,:), 'HandleVisibility', 'off','MarkerSize',4);

end

for g = gains

clpoles = pole(feedback(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'}), g*Kiff_hpf));

plot(real(clpoles), imag(clpoles), '.', 'color', colors(2,:), 'HandleVisibility', 'off','MarkerSize',4);

end

% Pure Integrator

plot(real(pole(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

imag(pole(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

'x', 'color', colors(1,:), 'DisplayName', 'IFF','MarkerSize',8);

plot(real(tzero(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

imag(tzero(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

'o', 'color', colors(1,:), 'HandleVisibility', 'off','MarkerSize',8);

% Modified IFF

plot(real(pole(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff_hpf)), ...

imag(pole(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff_hpf)), ...

'x', 'color', colors(2,:), 'DisplayName', 'IFF + HPF','MarkerSize',8);

plot(real(tzero(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff_hpf)), ...

imag(tzero(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff_hpf)), ...

'o', 'color', colors(2,:), 'HandleVisibility', 'off','MarkerSize',8);

hold off;

axis square;

leg = legend('location', 'northwest', 'FontSize', 8);

leg.ItemTokenSize(1) = 8;

xlabel('Real Part'); ylabel('Imaginary Part');

xlim([-2.25, 0.25]); ylim([-1.25, 1.25]);

xticks([-2, -1, 0])

xticklabels({'$-2\omega_0$', '$-\omega_0$', '$0$'})

yticks([-1, 0, 1])

yticklabels({'$-\omega_0$', '$0$', '$\omega_0$'})

ax2 = nexttile();

hold on;

for g = gains

clpoles = pole(feedback(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'}), g*Kiff));

plot(real(clpoles), imag(clpoles), '.', 'color', colors(1,:),'MarkerSize',4);

end

for g = gains

clpoles = pole(feedback(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'}), g*Kiff_hpf));

plot(real(clpoles), imag(clpoles), '.', 'color', colors(2,:),'MarkerSize',4);

end

% Pure Integrator

plot(real(pole(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

imag(pole(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

'x', 'color', colors(1,:),'MarkerSize',8);

plot(real(tzero(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

imag(tzero(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

'o', 'color', colors(1,:),'MarkerSize',8);

% Modified IFF

plot(real(pole(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff_hpf)), ...

imag(pole(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff_hpf)), ...

'x', 'color', colors(2,:),'MarkerSize',8);

plot(real(tzero(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff_hpf)), ...

imag(tzero(Gs{Wz_i}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff_hpf)), ...

'o', 'color', colors(2,:),'MarkerSize',8);

hold off;

axis square;

xlabel('Real Part'); ylabel('Imaginary Part');

title('Zoom near the origin');

xlim([-0.15, 0.1]); ylim([-0.15, 0.15]);

xticks([-0.1, 0, 0.1])

xticklabels({'$-0.1\omega_0$', '$0$', '$0.1\omega_0$'})

yticks([-0.1, 0, 0.1])

yticklabels({'$-0.1\omega_0$', '$0$', '$0.1\omega_0$'})

Optimal IFF with HPF parameters $\omega_i$ and $g$

Two parameters can be tuned for the modified controller in equation eqref:eq:iff_lhf: the gain $g$ and the pole's location $\omega_i$. The optimal values of $\omega_i$ and $g$ are here considered as the values for which the damping of all the closed-loop poles are simultaneously maximized.

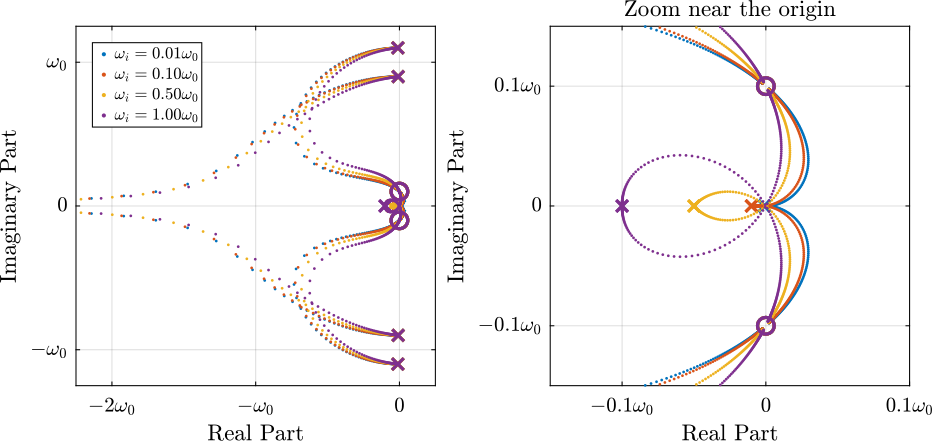

In order to visualize how $\omega_i$ does affect the attainable damping, the Root Locus plots for several $\omega_i$ are displayed in Figure ref:fig:rotating_root_locus_iff_modified_effect_wi. It is shown that even though small $\omega_i$ seem to allow more damping to be added to the suspension modes, the control gain $g$ may be limited to small values due to equation eqref:eq:gmax_iff_hpf.

%% High Pass Filter Cut-Off Frequency

wis = [0.01, 0.1, 0.5, 1]*Wzs(2); % [rad/s]%% Root Locus for the initial IFF and the modified IFF

gains = logspace(-2, 4, 200);

figure;

tiledlayout(1, 2, 'TileSpacing', 'Compact', 'Padding', 'None');

ax1 = nexttile();

hold on;

for wi_i = 1:length(wis)

wi = wis(wi_i);

Kiff = (1/(wi+s))*eye(2);

L(wi_i) = plot(nan, nan, '.', 'color', colors(wi_i,:), 'DisplayName', sprintf('$\\omega_i = %.2f \\omega_0$', wi./Wzs(2)));

for g = gains

clpoles = pole(feedback(Gs{2}({'fu', 'fv'}, {'Fu', 'Fv'}), g*Kiff));

plot(real(clpoles), imag(clpoles), '.', 'color', colors(wi_i,:),'MarkerSize',4);

end

plot(real(pole(Gs{2}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

imag(pole(Gs{2}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

'x', 'color', colors(wi_i,:),'MarkerSize',8);

plot(real(tzero(Gs{2}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

imag(tzero(Gs{2}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

'o', 'color', colors(wi_i,:),'MarkerSize',8);

end

hold off;

axis square;

xlim([-2.3, 0.1]); ylim([-1.2, 1.2]);

xticks([-2:1:2]); yticks([-2:1:2]);

leg = legend(L, 'location', 'northwest', 'FontSize', 8);

leg.ItemTokenSize(1) = 8;

xlabel('Real Part'); ylabel('Imaginary Part');

clear L

xlim([-2.25, 0.25]); ylim([-1.25, 1.25]);

xticks([-2, -1, 0])

xticklabels({'$-2\omega_0$', '$-\omega_0$', '$0$'})

yticks([-1, 0, 1])

yticklabels({'$-\omega_0$', '$0$', '$\omega_0$'})

ax2 = nexttile();

hold on;

for wi_i = 1:length(wis)

wi = wis(wi_i);

Kiff = (1/(wi+s))*eye(2);

L(wi_i) = plot(nan, nan, '.', 'color', colors(wi_i,:));

for g = gains

clpoles = pole(feedback(Gs{2}({'fu', 'fv'}, {'Fu', 'Fv'}), g*Kiff));

plot(real(clpoles), imag(clpoles), '.', 'color', colors(wi_i,:),'MarkerSize',4);

end

plot(real(pole(Gs{2}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

imag(pole(Gs{2}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

'x', 'color', colors(wi_i,:),'MarkerSize',8);

plot(real(tzero(Gs{2}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

imag(tzero(Gs{2}({'fu', 'fv'}, {'Fu', 'Fv'})*Kiff)), ...

'o', 'color', colors(wi_i,:),'MarkerSize',8);

end

hold off;

axis square;

xlim([-2.3, 0.1]); ylim([-1.2, 1.2]);

xticks([-2:1:2]); yticks([-2:1:2]);

xlabel('Real Part'); ylabel('Imaginary Part');

title('Zoom near the origin');

clear L

xlim([-0.15, 0.1]); ylim([-0.15, 0.15]);

xticks([-0.1, 0, 0.1])

xticklabels({'$-0.1\omega_0$', '$0$', '$0.1\omega_0$'})

yticks([-0.1, 0, 0.1])

yticklabels({'$-0.1\omega_0$', '$0$', '$0.1\omega_0$'})

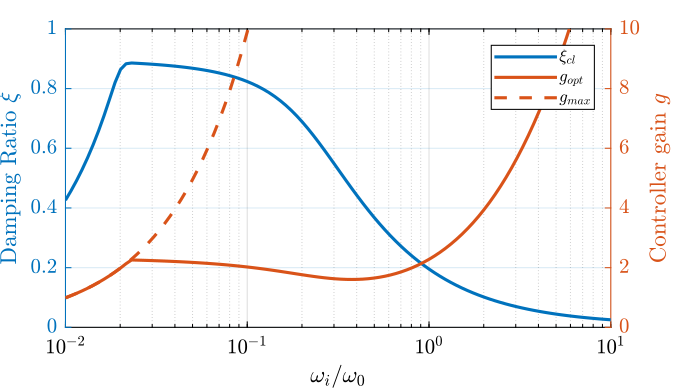

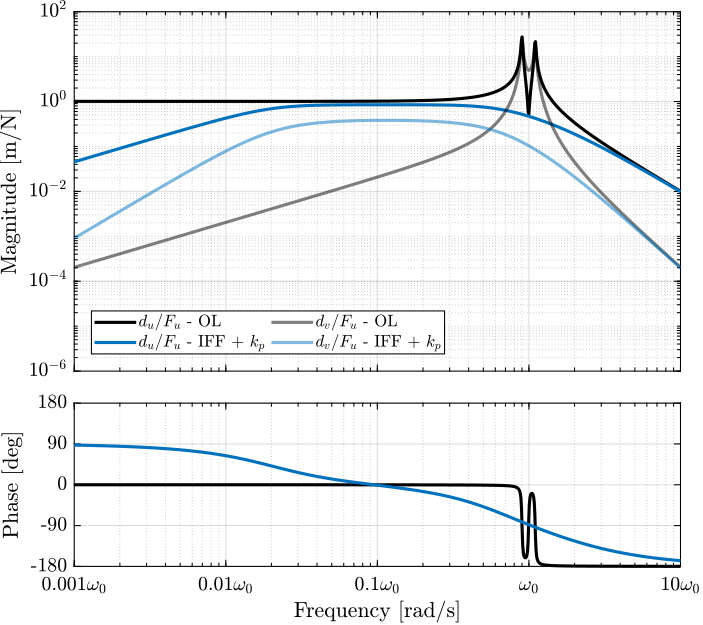

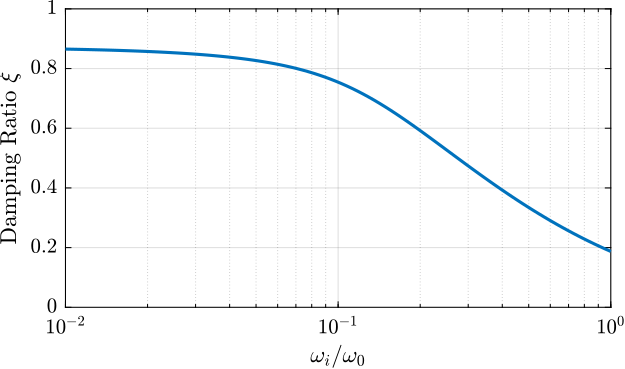

In order to study this trade off, the attainable closed-loop damping ratio $\xi_{\text{cl}}$ is computed as a function of $\omega_i/\omega_0$. The gain $g_{\text{opt}}$ at which this maximum damping is obtained is also displayed and compared with the gain $g_{\text{max}}$ at which the system becomes unstable (Figure ref:fig:rotating_iff_hpf_optimal_gain).

Three regions can be observed:

- $\omega_i/\omega_0 < 0.02$: the added damping is limited by the maximum allowed control gain $g_{\text{max}}$

- $0.02 < \omega_i/\omega_0 < 0.2$: the attainable damping ratio is maximized and is reached for $g \approx 2$

- $0.2 < \omega_i/\omega_0$: the added damping decreases as $\omega_i/\omega_0$ increases.

%% Compute the optimal control gain

wis = logspace(-2, 1, 100); % [rad/s]

opt_xi = zeros(1, length(wis)); % Optimal simultaneous damping

opt_gain = zeros(1, length(wis)); % Corresponding optimal gain

for wi_i = 1:length(wis)

wi = wis(wi_i);

Kiff = 1/(s + wi)*eye(2);

fun = @(g)computeSimultaneousDamping(g, Gs{2}({'fu', 'fv'}, {'Fu', 'Fv'}), Kiff);

[g_opt, xi_opt] = fminsearch(fun, 0.5*wi*((1/Wzs(2))^2 - 1));

opt_xi(wi_i) = 1/xi_opt;

opt_gain(wi_i) = g_opt;

end%% Attainable damping ratio as a function of wi/w0. Corresponding control gain g_opt and g_max are also shown

figure;

yyaxis left

plot(wis, opt_xi, '-', 'DisplayName', '$\xi_{cl}$');

set(gca, 'YScale', 'lin');

ylim([0,1]);

ylabel('Damping Ratio $\xi$');

yyaxis right

hold on;

plot(wis, opt_gain, '-', 'DisplayName', '$g_{opt}$');

plot(wis, wis*((1/Wzs(2))^2 - 1), '--', 'DisplayName', '$g_{max}$');

set(gca, 'YScale', 'lin');

ylim([0,10]);

ylabel('Controller gain $g$');

xlabel('$\omega_i/\omega_0$');

set(gca, 'XScale', 'log');

legend('location', 'northeast', 'FontSize', 8);

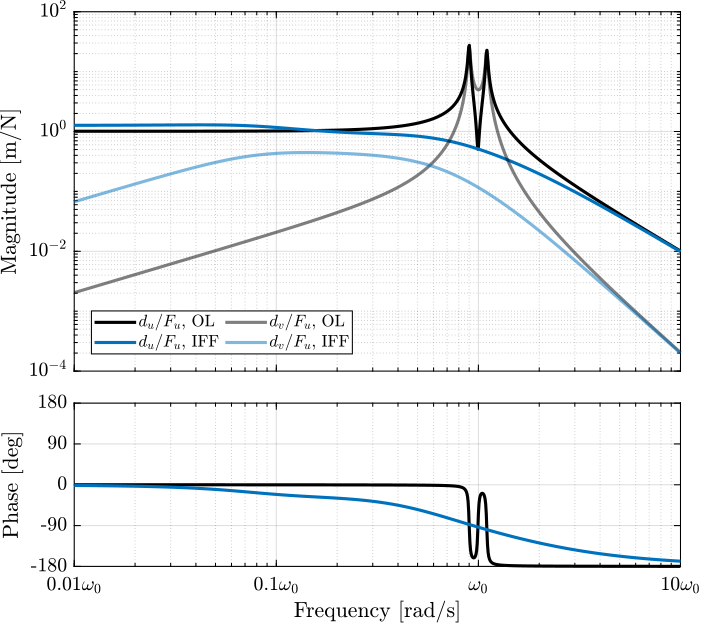

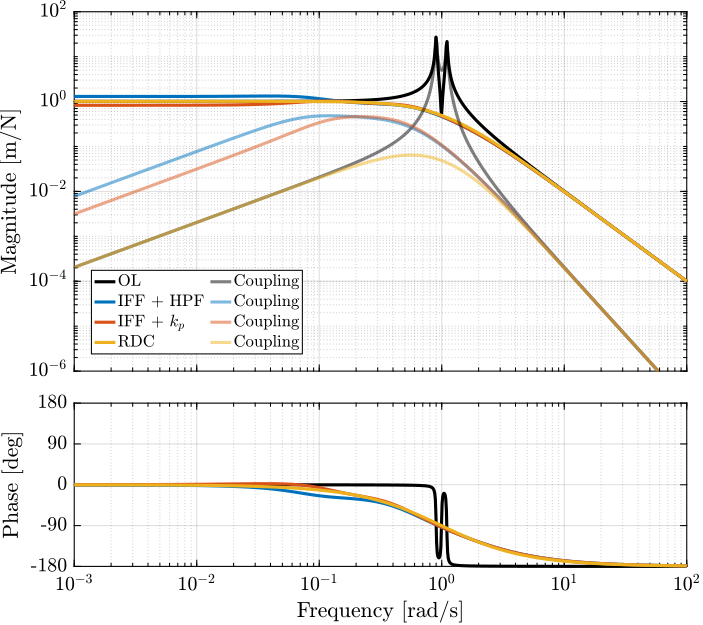

Obtained Damped Plant

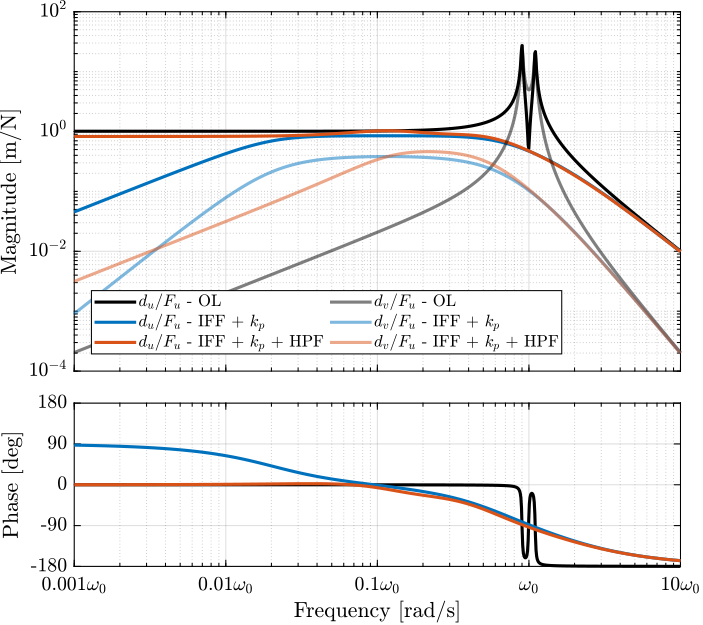

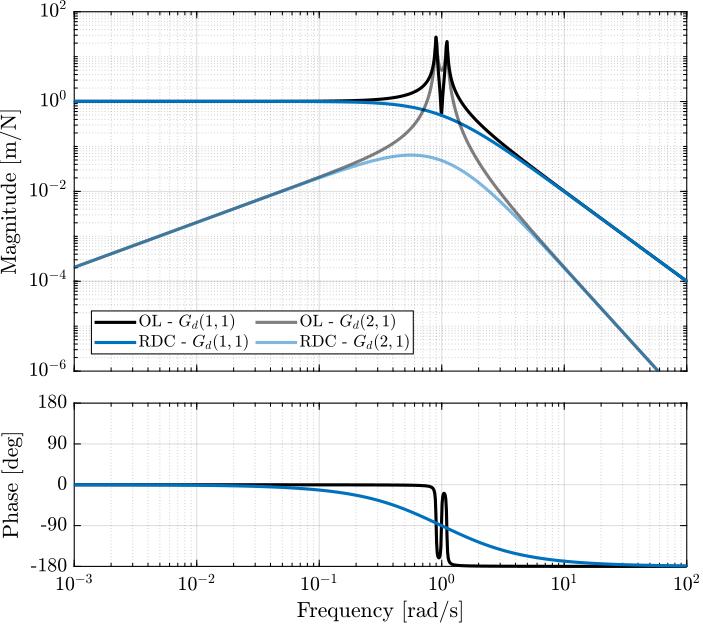

Let's choose $\omega_i = 0.1 \cdot \omega_0$ and compute the damped plant. The undamped and damped plants are compared in Figure ref:fig:rotating_iff_hpf_damped_plant in blue and red respectively. A well damped plant is indeed obtained.

However, the magnitude of the coupling term ($d_v/F_u$) is larger then IFF is applied.

%% Compute damped plant

wi = 0.1; % [rad/s]

g = 2; % Gain

Kiff_hpf = (g/(wi+s))*eye(2); % IFF with added HPF

Kiff_hpf.InputName = {'fu', 'fv'};

Kiff_hpf.OutputName = {'Fu', 'Fv'};

G_iff_hpf = feedback(Gs{2}, Kiff_hpf, 'name');

isstable(G_iff_hpf) % Verify stability%% Damped plant with IFF and added HPF - Transfer function from $F_u$ to $d_u$

freqs = logspace(-2, 1, 1000);

figure;

tiledlayout(3, 1, 'TileSpacing', 'Compact', 'Padding', 'None');

% Magnitude

ax1 = nexttile([2, 1]);

hold on;

plot(freqs, abs(squeeze(freqresp(Gs{2}('Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', [zeros(1,3)], ...

'DisplayName', '$d_u/F_u$, OL')

plot(freqs, abs(squeeze(freqresp(G_iff_hpf('Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', [colors(1,:)], ...

'DisplayName', '$d_u/F_u$, IFF')

plot(freqs, abs(squeeze(freqresp(Gs{2}('Dv', 'Fu'), freqs, 'rad/s'))), '-', 'color', [zeros(1,3), 0.5], ...

'DisplayName', '$d_v/F_u$, OL')

plot(freqs, abs(squeeze(freqresp(G_iff_hpf('Dv', 'Fu'), freqs, 'rad/s'))), '-', 'color', [colors(1,:), 0.5], ...

'DisplayName', '$d_v/F_u$, IFF')

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log');

set(gca, 'XTickLabel',[]); ylabel('Magnitude [m/N]');

leg = legend('location', 'southwest', 'FontSize', 8, 'NumColumns', 2);

leg.ItemTokenSize(1) = 20;

ax2 = nexttile;

hold on;

plot(freqs, 180/pi*angle(squeeze(freqresp(Gs{2}('Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', zeros(1,3))

plot(freqs, 180/pi*angle(squeeze(freqresp(G_iff_hpf('Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(1,:))

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'lin');

xlabel('Frequency [rad/s]'); ylabel('Phase [deg]');

yticks(-180:90:180);

ylim([-180 180]);

xticks([1e-2,1e-1,1,1e1])

xticklabels({'$0.01 \omega_0$', '$0.1 \omega_0$', '$\omega_0$', '$10 \omega_0$'})

linkaxes([ax1,ax2],'x');

xlim([freqs(1), freqs(end)]);

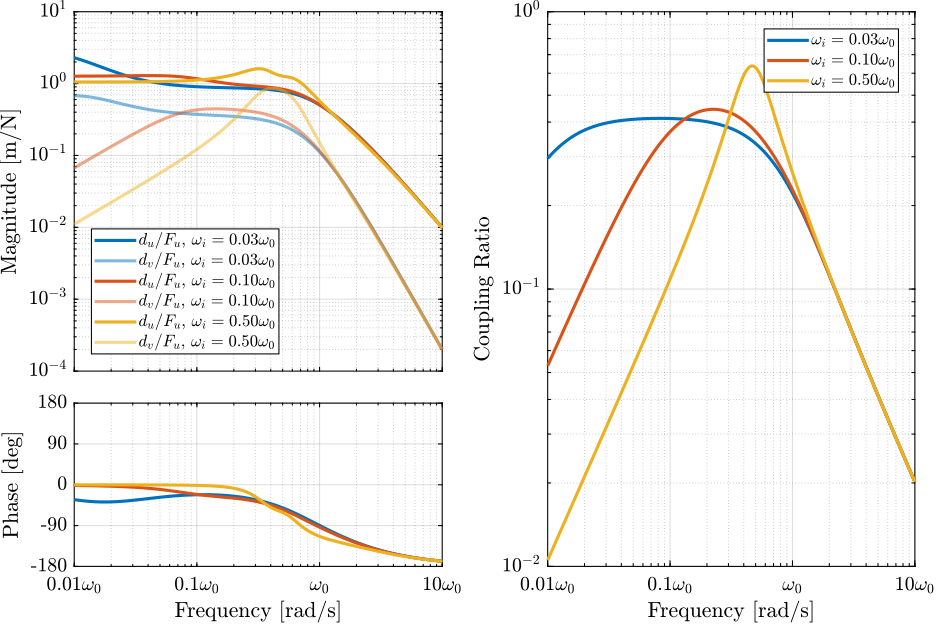

In order to study how $\omega_i$ affects the coupling of the damped plant, the closed-loop plant is identified for several $\omega_i$. The direct and coupling terms of the plants are shown in Figure ref:fig:rotating_iff_hpf_damped_plant_effect_wi_coupling (left) and the ratio between the two (i.e. the coupling ratio) is shown in Figure ref:fig:rotating_iff_hpf_damped_plant_effect_wi_coupling (right).

The coupling ratio is decreasing as $\omega_i$ increases. There is therefore a trade-off between achievable damping and coupling ratio for the choice of $\omega_i$. The same trade-off can be seen between achievable damping and loss of compliance at low frequency (see Figure ref:fig:rotating_iff_hpf_effect_wi_compliance).

%% Compute damped plant

wis = [0.03, 0.1, 0.5]; % [rad/s]

g = 2; % Gain

Gs_iff_hpf = {};

for i = 1:length(wis)

Kiff_hpf = (g/(wis(i)+s))*eye(2); % IFF with added HPF

Kiff_hpf.InputName = {'fu', 'fv'};

Kiff_hpf.OutputName = {'Fu', 'Fv'};

Gs_iff_hpf(i) = {feedback(Gs{2}, Kiff_hpf, 'name')};

end

IFF with a stiffness in parallel with the force sensor

<<sec:rotating_iff_parallel_stiffness>>

Introduction ignore

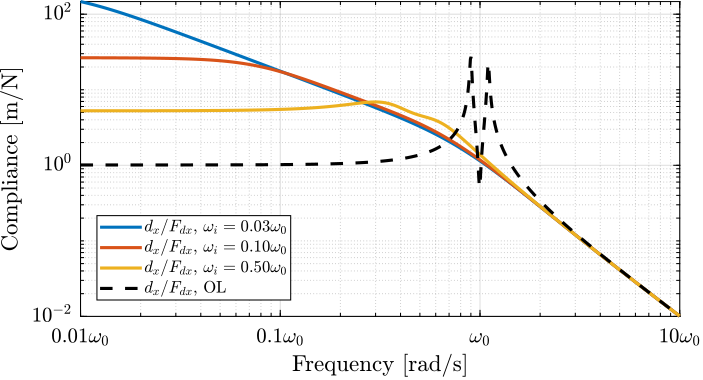

In this section it is proposed to add springs in parallel with the force sensors to counteract the negative stiffness induced by the gyroscopic effects.

Such springs are schematically shown in Figure ref:fig:rotating_3dof_model_schematic_iff_parallel_springs where $k_a$ is the stiffness of the actuator and $k_p$ the added stiffness in parallel with the actuator and force sensor.

\begin{tikzpicture}

% Angle

\def\thetau{25}

% Rotational Stage

\draw[fill=black!60!white] (0, 0) circle (4.3);

\draw[fill=black!40!white] (0, 0) circle (3.8);

% Label

\node[anchor=north west, rotate=\thetau] at (-2.5, 2.5) {\small Rotating Stage};

% Rotating Scope

\begin{scope}[rotate=\thetau]

% Rotating Frame

\draw[fill=black!20!white] (-2.6, -2.6) rectangle (2.6, 2.6);

% Label

\node[anchor=north west, rotate=\thetau] at (-2.6, 2.6) {\small Suspended Platform};

% Mass

\draw[fill=white] (-1, -1) rectangle (1, 1);

% Label

\node[anchor=south west, rotate=\thetau] at (-1, -1) {\small Payload};

% Attached Points

\draw[] (-1, 0) -- ++(-0.2, 0) coordinate(au);

\draw[] (0, -1) -- ++(0, -0.2) coordinate(av);

% Force Sensors

\draw[fill=white] ($(au) + (-0.2, -0.5)$) rectangle ($(au) + (0, 0.5)$);

\draw[] ($(au) + (-0.2, -0.5)$)coordinate(actu) -- ($(au) + (0, 0.5)$);

\draw[] ($(au) + (-0.2, 0.5)$)coordinate(ku) -- ($(au) + (0, -0.5)$);

\node[below=0.1, rotate=\thetau] at ($(au) + (-0.1, -0.5)$) {$f_{u}$};

\draw[fill=white] ($(av) + (-0.5, -0.2)$) rectangle ($(av) + (0.5, 0)$);

\draw[] ($(av) + ( 0.5, -0.2)$)coordinate(actv) -- ($(av) + (-0.5, 0)$);

\draw[] ($(av) + (-0.5, -0.2)$)coordinate(kv) -- ($(av) + ( 0.5, 0)$);

\node[right=0.1, rotate=\thetau] at ($(av) + (0.5, -0.1)$) {$f_{v}$};

% Spring and Actuator for U

\draw[actuator={0.6}{0.2}{black}] (actu) -- node[below=0.1, rotate=\thetau]{$F_u$} (actu-|-2.6,0);

\draw[spring=0.2] (ku) -- node[below=0.1, rotate=\thetau]{$k_a$} (ku-|-2.6,0);

\draw[spring=0.2,draw=colorred] (-1, 0.8) -- node[above=0.1, rotate=\thetau, color=colorred]{$k_p$} (-1, 0.8-|-2.6,0);

\draw[actuator={0.6}{0.2}{black}] (actv) -- node[right=0.1, rotate=\thetau]{$F_v$} (actv|-0,-2.6);

\draw[spring=0.2] (kv) -- node[right=0.1, rotate=\thetau]{$k_a$} (kv|-0,-2.6);

\draw[spring=0.2, draw=colorred] (-0.8, -1) -- node[left=0.1, rotate=\thetau, color=colorred]{$k_p$} (-0.8, -1|-0,-2.6);

\end{scope}

% Inertial Frame

\draw[->] (-4, -4) -- ++(2, 0) node[below]{$\vec{i}_x$};

\draw[->] (-4, -4) -- ++(0, 2) node[left]{$\vec{i}_y$};

\draw[fill, color=black] (-4, -4) circle (0.06);

\node[draw, circle, inner sep=0pt, minimum size=0.3cm, label=left:$\vec{i}_z$] at (-4, -4){};

\node[draw, circle, inner sep=0pt, minimum size=0.3cm] at (0, 0){};

\draw[->] (0, 0) node[above left, rotate=\thetau]{$\vec{i}_w$} -- ++(\thetau:2) node[above, rotate=\thetau]{$\vec{i}_u$};

\draw[->] (0, 0) -- ++(\thetau+90:2) node[left, rotate=\thetau]{$\vec{i}_v$};

\draw[dashed] (0, 0) -- ++(2, 0);

\draw[] (1.5, 0) arc (0:\thetau:1.5) node[midway, right]{$\theta$};

\node[] at (0,0) {$\bullet$};

\draw[->] (3.5, 0) arc (0:40:3.5) node[midway, left]{$\Omega$};

\end{tikzpicture}

Equations

The forces measured by the two force sensors represented in Figure ref:fig:rotating_3dof_model_schematic_iff_parallel_springs are described by Eq. eqref:eq:measured_force_kp.

\begin{equation} \begin{bmatrix} f_{u} \\ f_{v} \end{bmatrix} = \begin{bmatrix} F_u \\ F_v \end{bmatrix} - (c s + k_a) \begin{bmatrix} d_u \\ d_v \end{bmatrix} \end{equation}In order to keep the overall stiffness $k = k_a + k_p$ constant, thus not modifying the open-loop poles as $k_p$ is changed, a scalar parameter $\alpha$ ($0 \le \alpha < 1$) is defined to describe the fraction of the total stiffness in parallel with the actuator and force sensor as in Eq. eqref:eq:kp_alpha.

\begin{equation} k_p = \alpha k, \quad k_a = (1 - \alpha) k \end{equation}After the equations of motion derived and transformed in the Laplace domain, the transfer function matrix $\mathbf{G}_k$ in Eq. eqref:eq:Gk_mimo_tf is computed. Its elements are shown in Eq. eqref:eq:Gk_diag and eqref:eq:Gk_off_diag.

\begin{equation} \begin{bmatrix} f_u \\ f_v \end{bmatrix} = \mathbf{G}_k \begin{bmatrix} F_u \\ F_v \end{bmatrix} \end{equation} \begin{subequations} \begin{align} \mathbf{G}_{k}(1,1) &= \mathbf{G}_{k}(2,2) = \frac{\big( \frac{s^2}{{\omega_0}^2} - \frac{\Omega^2}{{\omega_0}^2} + \alpha \big) \big( \frac{s^2}{{\omega_0}^2} + 2 \xi \frac{s}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \big) + \big( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \big)^2}{\big( \frac{s^2}{{\omega_0}^2} + 2 \xi \frac{s}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \big)^2 + \big( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \big)^2} \label{eq:Gk_diag} \\ \mathbf{G}_{k}(1,2) &= -\mathbf{G}_{k}(2,1) = \frac{- \left( 2 \xi \frac{s}{\omega_0} + 1 - \alpha \right) \left( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \right)}{\left( \frac{s^2}{{\omega_0}^2} + 2 \xi \frac{s}{\omega_0} + 1 - \frac{{\Omega}^2}{{\omega_0}^2} \right)^2 + \left( 2 \frac{\Omega}{\omega_0} \frac{s}{\omega_0} \right)^2} \label{eq:Gk_off_diag} \end{align} \end{subequations}Comparing $\mathbf{G}_k$ in Eq. eqref:eq:Gk with $\mathbf{G}_f$ in Eq. eqref:eq:Gf shows that while the poles of the system are kept the same, the zeros of the diagonal terms have changed. The two real zeros $z_r$ in Eq. eqref:eq:iff_zero_real that were inducing a non-minimum phase behavior are transformed into two complex conjugate zeros if the condition in Eq. eqref:eq:kp_cond_cc_zeros holds.

\begin{equation} \boxed{\alpha > \frac{\Omega^2}{{\omega_0}^2} \quad \Leftrightarrow \quad k_p > m \Omega^2} \end{equation}Thus, if the added parallel stiffness $k_p$ is higher than the negative stiffness induced by centrifugal forces $m \Omega^2$, the dynamics from actuator to its collocated force sensor will show minimum phase behavior.

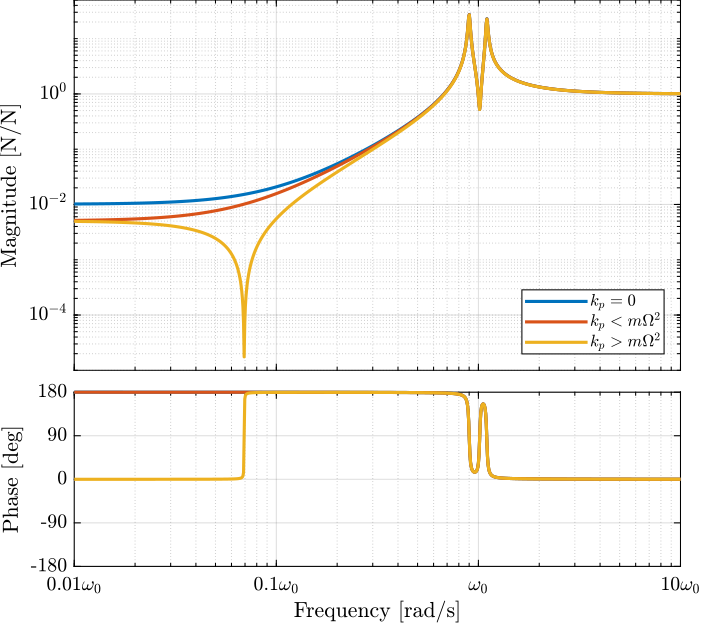

Effect of the parallel stiffness on the IFF plant

The IFF plant (transfer function from $[F_u, F_v]$ to $[f_u, f_v]$) is identified in three different cases:

- without parallel stiffness $k_p = 0$

- with a small parallel stiffness $k_p < m \Omega^2$

- with a large parallel stiffness $k_p > m \Omega^2$

Wz = 0.1; % The rotation speed [rad/s]

%% No parallel Stiffness

kp = 0; % Parallel Stiffness [N/m]

cp = 0.001*2*sqrt(kp*(mn+ms)); % Small parallel damping [N/(m/s)]

kn = 1 - kp; % Stiffness [N/m]

cn = 0.01*2*sqrt(kn*(mn+ms)); % Damping [N/(m/s)]

G_no_kp = linearize(mdl, io, 0);

G_no_kp.InputName = {'Fu', 'Fv', 'Fdx', 'Fdy'};

G_no_kp.OutputName = {'fu', 'fv', 'Du', 'Dv', 'Dx', 'Dy'};

%% Small parallel Stiffness

kp = 0.5*(mn+ms)*Wz^2; % Parallel Stiffness [N/m]

cp = 0.001*2*sqrt(kp*(mn+ms)); % Small parallel damping [N/(m/s)]

kn = 1 - kp; % Stiffness [N/m]

cn = 0.01*2*sqrt(kn*(mn+ms)); % Damping [N/(m/s)]

G_low_kp = linearize(mdl, io, 0);

G_low_kp.InputName = {'Fu', 'Fv', 'Fdx', 'Fdy'};

G_low_kp.OutputName = {'fu', 'fv', 'Du', 'Dv', 'Dx', 'Dy'};

%% Large parallel Stiffness

kp = 1.5*(mn+ms)*Wz^2; % Parallel Stiffness [N/m]

cp = 0.001*2*sqrt(kp*(mn+ms)); % Small parallel damping [N/(m/s)]

kn = 1 - kp; % Stiffness [N/m]

cn = 0.01*2*sqrt(kn*(mn+ms)); % Damping [N/(m/s)]

G_high_kp = linearize(mdl, io, 0);

G_high_kp.InputName = {'Fu', 'Fv', 'Fdx', 'Fdy'};

G_high_kp.OutputName = {'fu', 'fv', 'Du', 'Dv', 'Dx', 'Dy'};The Bode plots of the obtained dynamics are shown in Figure ref:fig:rotating_iff_effect_kp. One can see that for $k_p > m \Omega^2$, the two real zeros with $k_p < m \Omega^2$ are transformed into two complex conjugate zeros and the systems shows alternating complex conjugate poles and zeros.

%% Effect of the parallel stiffness on the IFF plant

freqs = logspace(-2, 1, 1000);

figure;

tiledlayout(3, 1, 'TileSpacing', 'Compact', 'Padding', 'None');

% Magnitude

ax1 = nexttile([2, 1]);

hold on;

plot(freqs, abs(squeeze(freqresp(G_no_kp( 'fu', 'Fu'), freqs, 'rad/s'))), '-', ...

'DisplayName', '$k_p = 0$')

plot(freqs, abs(squeeze(freqresp(G_low_kp( 'fu', 'Fu'), freqs, 'rad/s'))), '-', ...

'DisplayName', '$k_p < m\Omega^2$')

plot(freqs, abs(squeeze(freqresp(G_high_kp('fu', 'Fu'), freqs, 'rad/s'))), '-', ...

'DisplayName', '$k_p > m\Omega^2$')

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log');

set(gca, 'XTickLabel',[]); ylabel('Magnitude [N/N]');

ylim([1e-5, 5e1]);

legend('location', 'southeast', 'FontSize', 8);

% Phase

ax2 = nexttile;

hold on;

plot(freqs, 180/pi*angle(squeeze(freqresp(G_no_kp( 'fu', 'Fu'), freqs, 'rad/s'))), '-')

plot(freqs, 180/pi*angle(squeeze(freqresp(G_low_kp( 'fu', 'Fu'), freqs, 'rad/s'))), '-')

plot(freqs, 180/pi*angle(squeeze(freqresp(G_high_kp('fu', 'Fu'), freqs, 'rad/s'))), '-')

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'lin');

xlabel('Frequency [rad/s]'); ylabel('Phase [deg]');

yticks(-180:90:180);

ylim([-180 180]);

hold off;

xticks([1e-2,1e-1,1,1e1])

xticklabels({'$0.01 \omega_0$', '$0.1 \omega_0$', '$\omega_0$', '$10 \omega_0$'})

linkaxes([ax1,ax2],'x');

xlim([freqs(1), freqs(end)]);

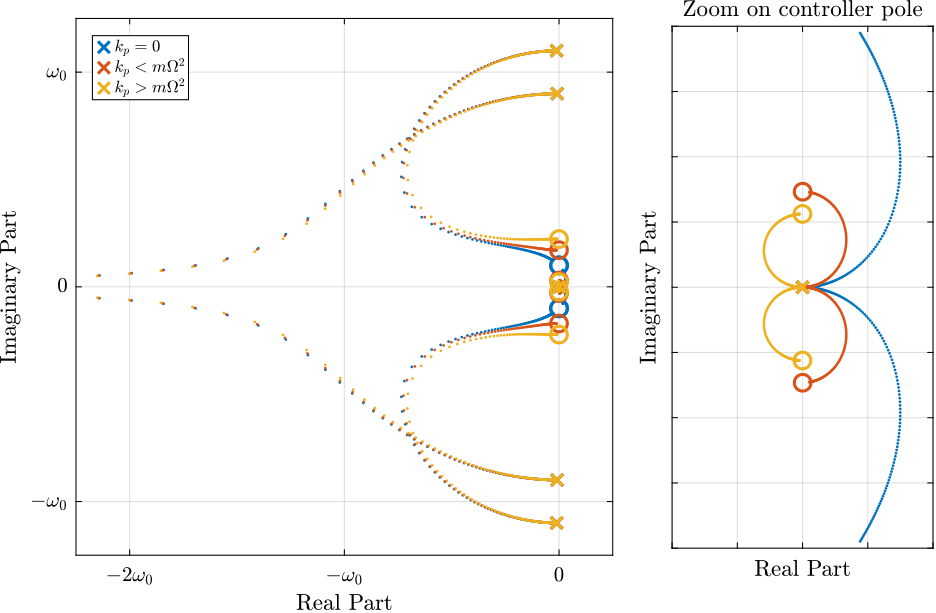

Figure ref:fig:rotating_iff_kp_root_locus shows the Root Locus plots for $k_p = 0$, $k_p < m \Omega^2$ and $k_p > m \Omega^2$ when $K_F$ is a pure integrator as in Eq. eqref:eq:Kf_pure_int. It is shown that if the added stiffness is higher than the maximum negative stiffness, the poles of the closed-loop system are bounded on the (stable) left half-plane, and hence the unconditional stability of IFF is recovered.

%% Root Locus for IFF without parallel spring, with small parallel spring and with large parallel spring

gains = logspace(-2, 2, 200);

figure;

tiledlayout(1, 3, 'TileSpacing', 'Compact', 'Padding', 'None');

ax1 = nexttile([1,2]);

hold on;

plot(real(pole(G_no_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), imag(pole(G_no_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), 'x', 'color', colors(1,:), ...

'DisplayName', '$k_p = 0$','MarkerSize',8);

plot(real(tzero(G_no_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), imag(tzero(G_no_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), 'o', 'color', colors(1,:), ...

'HandleVisibility', 'off','MarkerSize',8);

for g = gains

cl_poles = pole(feedback(G_no_kp({'fu','fv'},{'Fu','Fv'}), (g/s)*eye(2)));

plot(real(cl_poles), imag(cl_poles), '.', 'color', colors(1,:), ...

'HandleVisibility', 'off','MarkerSize',4);

end

plot(real(pole(G_low_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), imag(pole(G_low_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), 'x', 'color', colors(2,:), ...

'DisplayName', '$k_p < m\Omega^2$','MarkerSize',8);

plot(real(tzero(G_low_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), imag(tzero(G_low_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), 'o', 'color', colors(2,:), ...

'HandleVisibility', 'off','MarkerSize',8);

for g = gains

cl_poles = pole(feedback(G_low_kp({'fu','fv'},{'Fu','Fv'}), (g/s)*eye(2)));

plot(real(cl_poles), imag(cl_poles), '.', 'color', colors(2,:), ...

'HandleVisibility', 'off','MarkerSize',4);

end

plot(real(pole(G_high_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), imag(pole(G_high_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), 'x', 'color', colors(3,:), ...

'DisplayName', '$k_p > m\Omega^2$','MarkerSize',8);

plot(real(tzero(G_high_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), imag(tzero(G_high_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), 'o', 'color', colors(3,:), ...

'HandleVisibility', 'off','MarkerSize',8);

for g = gains

cl_poles = pole(feedback(G_high_kp({'fu','fv'},{'Fu','Fv'}), (g/s)*eye(2)));

plot(real(cl_poles), imag(cl_poles), '.', 'color', colors(3,:), ...

'HandleVisibility', 'off','MarkerSize',4);

end

hold off;

axis square;

xlim([-2.25, 0.25]); ylim([-1.25, 1.25]);

xticks([-2, -1, 0])

xticklabels({'$-2\omega_0$', '$-\omega_0$', '$0$'})

yticks([-1, 0, 1])

yticklabels({'$-\omega_0$', '$0$', '$\omega_0$'})

xlabel('Real Part'); ylabel('Imaginary Part');

leg = legend('location', 'northwest', 'FontSize', 8);

leg.ItemTokenSize(1) = 8;

ax2 = nexttile();

hold on;

plot(real(pole(G_no_kp( {'fu','fv'},{'Fu','Fv'})*(1/s))), imag(pole(G_no_kp( {'fu','fv'},{'Fu','Fv'})*(1/s))), 'x', 'color', colors(1,:), 'MarkerSize',8);

plot(real(tzero(G_no_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), imag(tzero(G_no_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), 'o', 'color', colors(1,:), 'MarkerSize',8);

for g = gains

cl_poles = pole(feedback(G_no_kp({'fu','fv'},{'Fu','Fv'}), (g/s)*eye(2)));

plot(real(cl_poles), imag(cl_poles), '.', 'color', colors(1,:), 'MarkerSize', 4);

end

plot(real(pole(G_low_kp( {'fu','fv'},{'Fu','Fv'})*(1/s))), imag(pole(G_low_kp( {'fu','fv'},{'Fu','Fv'})*(1/s))), 'x', 'color', colors(2,:), 'MarkerSize',8);

plot(real(tzero(G_low_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), imag(tzero(G_low_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), 'o', 'color', colors(2,:), 'MarkerSize',8);

for g = gains

cl_poles = pole(feedback(G_low_kp({'fu','fv'},{'Fu','Fv'}), (g/s)*eye(2)));

plot(real(cl_poles), imag(cl_poles), '.', 'color', colors(2,:), 'MarkerSize', 4);

end

plot(real(pole(G_high_kp( {'fu','fv'},{'Fu','Fv'})*(1/s))), imag(pole(G_high_kp( {'fu','fv'},{'Fu','Fv'})*(1/s))), 'x', 'color', colors(3,:), 'MarkerSize',8);

plot(real(tzero(G_high_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), imag(tzero(G_high_kp({'fu','fv'},{'Fu','Fv'})*(1/s))), 'o', 'color', colors(3,:), 'MarkerSize',8);

for g = gains

cl_poles = pole(feedback(G_high_kp({'fu','fv'},{'Fu','Fv'}), (g/s)*eye(2)));

plot(real(cl_poles), imag(cl_poles), '.', 'color', colors(3,:), 'MarkerSize',4);

end

hold off;

axis equal;

xlim([-0.04, 0.04]); ylim([-0.08, 0.08]);

set(gca, 'XTickLabel',[]); set(gca, 'YTickLabel',[]);

xlabel('Real Part'); ylabel('Imaginary Part');

title('Zoom on controller pole')

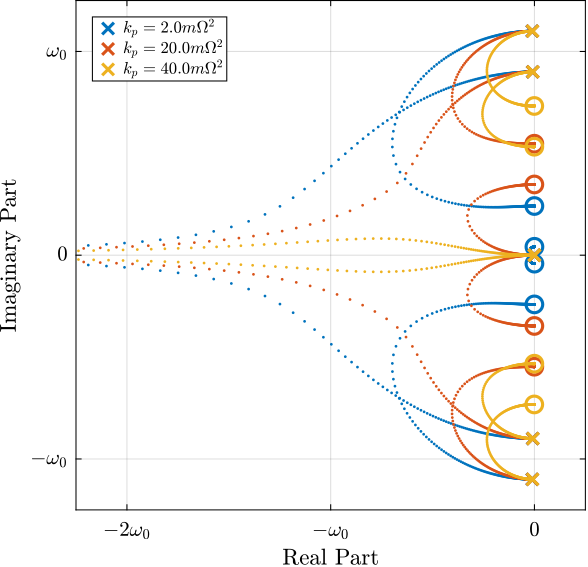

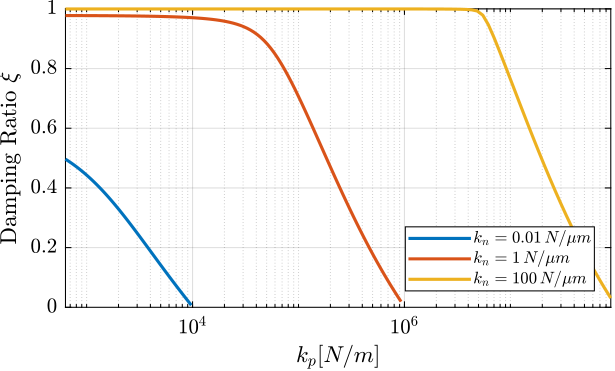

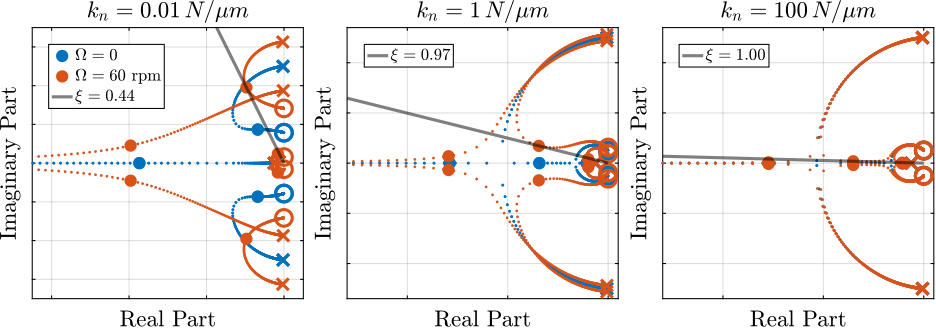

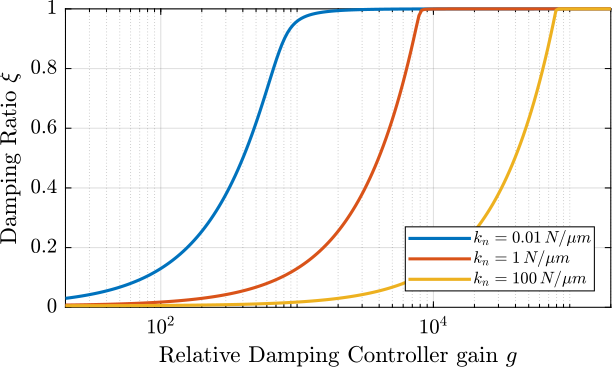

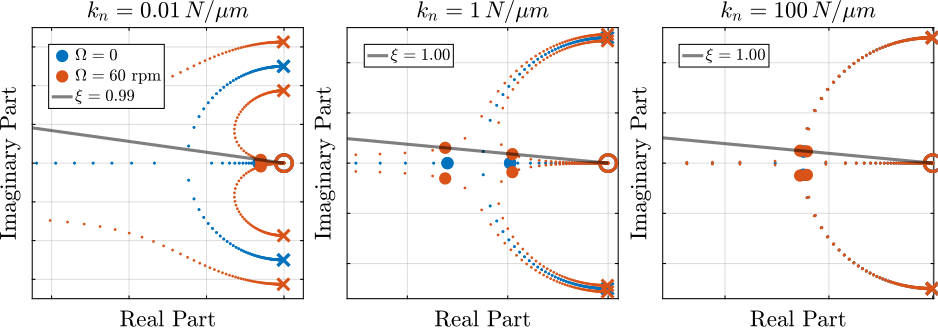

Effect of $k_p$ on the attainable damping

Even though the parallel stiffness $k_p$ has no impact on the open-loop poles (as the overall stiffness $k$ is kept constant), it has a large impact on the transmission zeros. Moreover, as the attainable damping is generally proportional to the distance between poles and zeros cite:preumont18_vibrat_contr_activ_struc_fourt_edition, the parallel stiffness $k_p$ is foreseen to have some impact on the attainable damping.

To study this effect, Root Locus plots for several parallel stiffnesses $k_p > m \Omega^2$ are shown in Figure ref:fig:rotating_iff_kp_root_locus_effect_kp. The frequencies of the transmission zeros of the system are increasing with an increase of the parallel stiffness $k_p$ (thus getting closer to the poles) and the associated attainable damping is reduced.

Therefore, even though the parallel stiffness $k_p$ should be larger than $m \Omega^2$ for stability reasons, it should not be taken too large as this would limit the attainable damping.

%% Tested parallel stiffnesses

kps = [2, 20, 40]*(mn + ms)*Wz^2;%% Root Locus: Effect of the parallel stiffness on the attainable damping

figure;

gains = logspace(-2, 4, 500);

hold on;

for kp_i = 1:length(kps)

kp = kps(kp_i); % Parallel Stiffness [N/m]

cp = 0.001*2*sqrt(kp*(mn+ms)); % Small parallel damping [N/(m/s)]

kn = 1 - kp; % Stiffness [N/m]

cn = 0.01*2*sqrt(kn*(mn+ms)); % Damping [N/(m/s)]

% Identify dynamics

G = linearize(mdl, io, 0);

G.InputName = {'Fu', 'Fv', 'Fdx', 'Fdy'};

G.OutputName = {'fu', 'fv', 'Du', 'Dv', 'Dx', 'Dy'};

plot(real(pole(G({'fu', 'fv'}, {'Fu', 'Fv'})*(1/s*eye(2)))), imag(pole(G({'fu', 'fv'}, {'Fu', 'Fv'})*(1/s*eye(2)))), 'x', 'color', colors(kp_i,:), ...

'DisplayName', sprintf('$k_p = %.1f m \\Omega^2$', kp/((mn+ms)*Wz^2)),'MarkerSize',8);

plot(real(tzero(G({'fu', 'fv'}, {'Fu', 'Fv'})*(1/s*eye(2)))), imag(tzero(G({'fu', 'fv'}, {'Fu', 'Fv'})*(1/s*eye(2)))), 'o', 'color', colors(kp_i,:), ...

'HandleVisibility', 'off','MarkerSize',8);

for g = gains

cl_poles = pole(feedback(G({'fu', 'fv'}, {'Fu', 'Fv'}), (g/s)*eye(2)));

plot(real(cl_poles), imag(cl_poles), '.', 'color', colors(kp_i,:),'MarkerSize',4, ...

'HandleVisibility', 'off');

end

end

hold off;

axis square;

% xlim([-1.15, 0.05]); ylim([0, 1.2]);

xlim([-2.25, 0.25]); ylim([-1.25, 1.25]);

xticks([-2, -1, 0])

xticklabels({'$-2\omega_0$', '$-\omega_0$', '$0$'})

yticks([-1, 0, 1])

yticklabels({'$-\omega_0$', '$0$', '$\omega_0$'})

xlabel('Real Part'); ylabel('Imaginary Part');

leg = legend('location', 'northwest', 'FontSize', 8);

leg.ItemTokenSize(1) = 12;

This is confirmed by the Figure ref:fig:rotating_iff_kp_optimal_gain where the attainable closed-loop damping ratio $\xi_{\text{cl}}$ and the associated optimal control gain $g_\text{opt}$ are computed as a function of the parallel stiffness.

%% Computes the optimal parameters and attainable simultaneous damping

alphas = logspace(-2, 0, 100);

alphas(end) = []; % Remove last point

opt_xi = zeros(1, length(alphas)); % Optimal simultaneous damping

opt_gain = zeros(1, length(alphas)); % Corresponding optimal gain

Kiff = 1/s*eye(2);

for alpha_i = 1:length(alphas)

kp = alphas(alpha_i);

cp = 0.001*2*sqrt(kp*(mn+ms)); % Small parallel damping [N/(m/s)]

kn = 1 - kp; % Stiffness [N/m]

cn = 0.01*2*sqrt(kn*(mn+ms)); % Damping [N/(m/s)]

% Identify dynamics

G = linearize(mdl, io, 0);

G.InputName = {'Fu', 'Fv', 'Fdx', 'Fdy'};

G.OutputName = {'fu', 'fv', 'Du', 'Dv', 'Dx', 'Dy'};

fun = @(g)computeSimultaneousDamping(g, G({'fu', 'fv'}, {'Fu', 'Fv'}), Kiff);

[g_opt, xi_opt] = fminsearch(fun, 2);

opt_xi(alpha_i) = 1/xi_opt;

opt_gain(alpha_i) = g_opt;

end%% Attainable damping as a function of the stiffness ratio

figure;

yyaxis left

plot(alphas, opt_xi, '-', 'DisplayName', '$\xi_{cl}$');

set(gca, 'YScale', 'lin');

ylim([0,1]);

ylabel('Damping Ratio $\xi$');

yyaxis right

hold on;

plot(alphas, opt_gain, '-', 'DisplayName', '$g_{opt}$');

set(gca, 'YScale', 'lin');

ylim([0,2.5]);

ylabel('Controller gain $g$');

set(gca, 'XScale', 'log');

legend('location', 'northeast', 'FontSize', 8);

xlabel('$k_p$');

xlim([0.01, 1]);

xticks([0.01, 0.1, 1])

xticklabels({'$m\Omega^2$', '$10m\Omega^2$', '$100m\Omega^2$'})

Damped plant

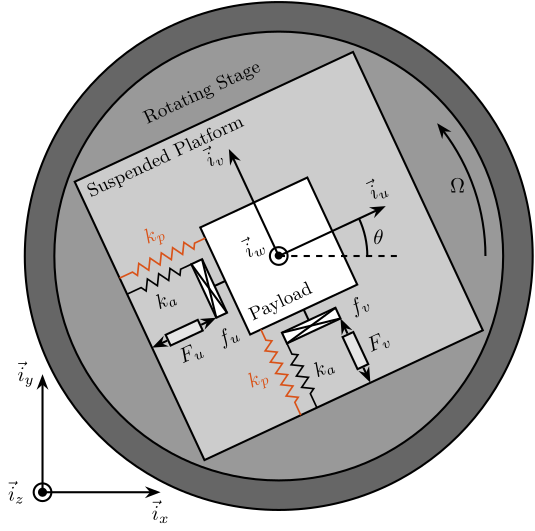

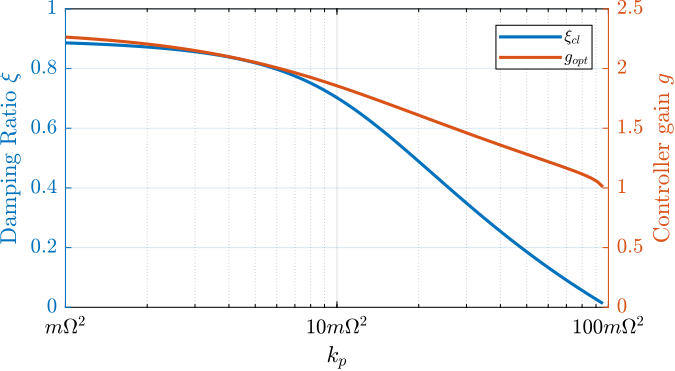

Let's choose a parallel stiffness equal to $k_p = 2 m \Omega^2$ and compute the damped plant. The damped and undamped transfer functions from $F_u$ to $d_u$ are compared in Figure ref:fig:rotating_iff_kp_damped_plant.

Even though the two resonances are well damped, the IFF changes the low frequency behavior of the plant which is usually not wanted. This is due to the fact that "pure" integrators are used, and that the low frequency loop gains becomes large below some frequency.

%% Identify dynamics with parallel stiffness = 2mW^2

Wz = 0.1; % [rad/s]

kp = 2*(mn + ms)*Wz^2; % Parallel Stiffness [N/m]

cp = 0.001*2*sqrt(kp*(mn+ms)); % Small parallel damping [N/(m/s)]

kn = 1 - kp; % Stiffness [N/m]

cn = 0.01*2*sqrt(kn*(mn+ms)); % Damping [N/(m/s)]

% Identify dynamics

G = linearize(mdl, io, 0);

G.InputName = {'Fu', 'Fv', 'Fdx', 'Fdy'};

G.OutputName = {'fu', 'fv', 'Du', 'Dv', 'Dx', 'Dy'};

%% IFF controller with pure integrator

Kiff_kp = (2.2/s)*eye(2);

Kiff_kp.InputName = {'fu', 'fv'};

Kiff_kp.OutputName = {'Fu', 'Fv'};

%% Compute the damped plant

G_cl_iff_kp = feedback(G, Kiff_kp, 'name');%% Damped plant with IFF - Transfer function from $F_u$ to $d_u$

freqs = logspace(-3, 1, 1000);

figure;

tiledlayout(3, 1, 'TileSpacing', 'Compact', 'Padding', 'None');

% Magnitude

ax1 = nexttile([2, 1]);

hold on;

plot(freqs, abs(squeeze(freqresp(G('Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', zeros(1,3), ...

'DisplayName', '$d_u/F_u$ - OL')

plot(freqs, abs(squeeze(freqresp(G_cl_iff_kp('Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(1,:), ...

'DisplayName', '$d_u/F_u$ - IFF + $k_p$')

plot(freqs, abs(squeeze(freqresp(G('Dv', 'Fu'), freqs, 'rad/s'))), '-', 'color', [zeros(1,3), 0.5], ...

'DisplayName', '$d_v/F_u$ - OL')

plot(freqs, abs(squeeze(freqresp(G_cl_iff_kp('Dv', 'Fu'), freqs, 'rad/s'))), '-', 'color', [colors(1,:), 0.5], ...

'DisplayName', '$d_v/F_u$ - IFF + $k_p$')

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log');

set(gca, 'XTickLabel',[]); ylabel('Magnitude [m/N]');

ldg = legend('location', 'southwest', 'FontSize', 8, 'NumColumns', 2);

ldg.ItemTokenSize(1) = 20;

ylim([1e-6, 1e2]);

ax2 = nexttile;

hold on;

plot(freqs, 180/pi*angle(squeeze(freqresp(G('Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', zeros(1,3))

plot(freqs, 180/pi*angle(squeeze(freqresp(G_cl_iff_kp('Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(1,:))

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'lin');

xlabel('Frequency [rad/s]'); ylabel('Phase [deg]');

yticks(-180:90:180);

ylim([-180 180]);

xticks([1e-3,1e-2,1e-1,1,1e1])

xticklabels({'$0.001 \omega_0$', '$0.01 \omega_0$', '$0.1 \omega_0$', '$\omega_0$', '$10 \omega_0$'})

linkaxes([ax1,ax2],'x');

xlim([freqs(1), freqs(end)]);

In order to lower the low frequency gain, an high pass filter is added to the IFF controller (which is equivalent as shifting the controller pole to the left in the complex plane):

\begin{equation} K_{\text{IFF}}(s) = g\frac{1}{\omega_i + s} \begin{bmatrix} 1 & 0 \\ 0 & 1 \end{bmatrix} \end{equation}Let's see how the high pass filter impacts the attainable damping. The controller gain $g$ is kept constant while $\omega_i$ is changed, and the minimum damping ratio of the damped plant is computed. The obtained damping ratio as a function of $\omega_i/\omega_0$ (where $\omega_0$ is the resonance of the system without rotation) is shown in Figure ref:fig:rotating_iff_kp_added_hpf_effect_damping.

w0 = sqrt((kn+kp)/(mn+ms)); % Resonance frequency [rad/s]

wis = w0*logspace(-2, 0, 100); % LPF cut-off [rad/s]%% Computes the obtained damping as a function of the HPF cut-off frequency

opt_xi = zeros(1, length(wis)); % Optimal simultaneous damping

for wi_i = 1:length(wis)

Kiff_kp_hpf = (2.2/(s + wis(wi_i)))*eye(2);

Kiff_kp_hpf.InputName = {'fu', 'fv'};

Kiff_kp_hpf.OutputName = {'Fu', 'Fv'};

[~, xi] = damp(feedback(G, Kiff_kp_hpf, 'name'));

opt_xi(wi_i) = min(xi);

end%% Effect of the high pass filter cut-off frequency on the obtained damping

figure;

plot(wis, opt_xi, '-');

set(gca, 'XScale', 'log');

set(gca, 'YScale', 'lin');

ylim([0,1]);

ylabel('Damping Ratio $\xi$');

xlabel('$\omega_i/\omega_0$');

Let's choose $\omega_i = 0.1 \cdot \omega_0$ and compute the damped plant again. The Bode plots of the undamped, damped with "pure" IFF, and with added high pass filters are shown in Figure ref:fig:rotating_iff_kp_added_hpf_damped_plant. The added high pass filter gives almost the same damping properties while giving acceptable low frequency behavior.

%% Compute the damped plant with added High Pass Filter

Kiff_kp_hpf = (2.2/(s + 0.1*w0))*eye(2);

Kiff_kp_hpf.InputName = {'fu', 'fv'};

Kiff_kp_hpf.OutputName = {'Fu', 'Fv'};

G_cl_iff_hpf_kp = feedback(G, Kiff_kp_hpf, 'name');%% Bode plot of the direct and coupling terms for several rotating velocities

freqs = logspace(-3, 1, 1000);

figure;

tiledlayout(3, 1, 'TileSpacing', 'Compact', 'Padding', 'None');

% Magnitude

ax1 = nexttile([2, 1]);

hold on;

plot(freqs, abs(squeeze(freqresp(G( 'Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', zeros( 1,3), ...

'DisplayName', '$d_u/F_u$ - OL')

plot(freqs, abs(squeeze(freqresp(G_cl_iff_kp( 'Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(1,:), ...

'DisplayName', '$d_u/F_u$ - IFF + $k_p$')

plot(freqs, abs(squeeze(freqresp(G_cl_iff_hpf_kp('Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(2,:), ...

'DisplayName', '$d_u/F_u$ - IFF + $k_p$ + HPF')

plot(freqs, abs(squeeze(freqresp(G( 'Dv', 'Fu'), freqs, 'rad/s'))), '-', 'color', [zeros( 1,3), 0.5], ...

'DisplayName', '$d_v/F_u$ - OL')

plot(freqs, abs(squeeze(freqresp(G_cl_iff_kp( 'Dv', 'Fu'), freqs, 'rad/s'))), '-', 'color', [colors(1,:), 0.5], ...

'DisplayName', '$d_v/F_u$ - IFF + $k_p$')

plot(freqs, abs(squeeze(freqresp(G_cl_iff_hpf_kp('Dv', 'Fu'), freqs, 'rad/s'))), '-', 'color', [colors(2,:), 0.5], ...

'DisplayName', '$d_v/F_u$ - IFF + $k_p$ + HPF')

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'log');

set(gca, 'XTickLabel',[]); ylabel('Magnitude [m/N]');

ldg = legend('location', 'southwest', 'FontSize', 8, 'NumColumns', 2);

ldg.ItemTokenSize(1) = 20;

ax2 = nexttile;

hold on;

plot(freqs, 180/pi*angle(squeeze(freqresp(G( 'Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', zeros( 1,3))

plot(freqs, 180/pi*angle(squeeze(freqresp(G_cl_iff_kp( 'Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(1,:))

plot(freqs, 180/pi*angle(squeeze(freqresp(G_cl_iff_hpf_kp('Du', 'Fu'), freqs, 'rad/s'))), '-', 'color', colors(2,:))

hold off;

set(gca, 'XScale', 'log'); set(gca, 'YScale', 'lin');

xlabel('Frequency [rad/s]'); ylabel('Phase [deg]');

yticks(-180:90:180);

ylim([-180 180]);

xticks([1e-3,1e-2,1e-1,1,1e1])

xticklabels({'$0.001 \omega_0$', '$0.01 \omega_0$', '$0.1 \omega_0$', '$\omega_0$', '$10 \omega_0$'})

linkaxes([ax1,ax2],'x');

xlim([freqs(1), freqs(end)]);

Relative Damping Control

<<sec:rotating_relative_damp_control>>

Introduction ignore

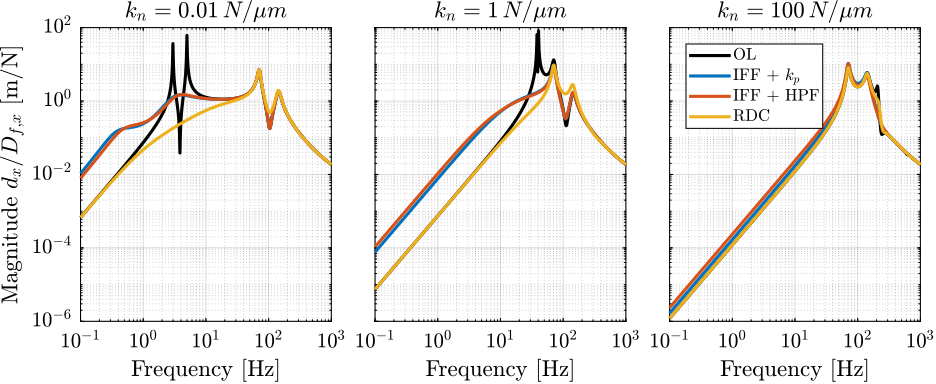

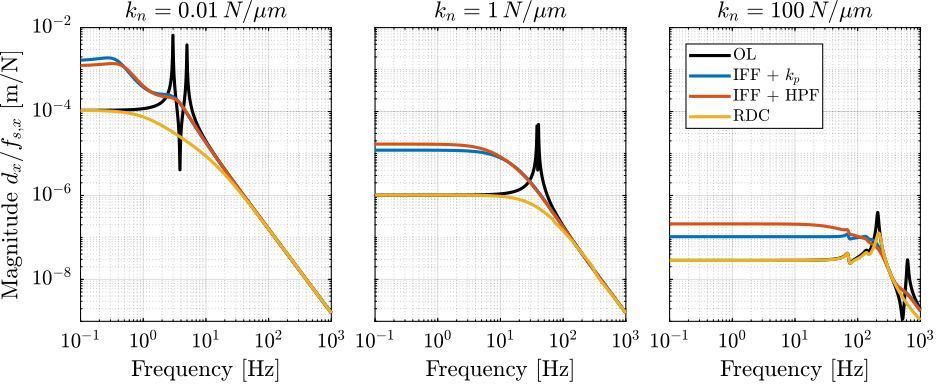

In order to apply a "relative damping control strategy", relative motion sensors are added in parallel with the actuators as shown in Figure ref:fig:rotating_3dof_model_schematic_rdc.