237 KiB

Control Optimization

- Introduction

- Multiple Sensor Control

- Decoupling

- Closed-Loop Shaping using Complementary Filters

- Conclusion

- Bibliography

- Footnotes

Introduction ignore

When controlling a MIMO system (specifically parallel manipulator such as the Stewart platform?)

-

Should the quick review of Stewart platform control be here? In that case it should be possible to highlight three areas:

- use of multiple sensors

- decoupling strategy

- control optimization

Several considerations:

- Section ref:sec:detail_control_sensor: How to most effectively use/combine multiple sensors

- Section ref:sec:detail_control_decoupling: How to decouple a system

- Section ref:sec:detail_control_cf: How to design the controller

Multiple Sensor Control

<<sec:detail_control_sensor>>

Introduction ignore

The literature review of Stewart platforms revealed a wide diversity of designs with various sensor and actuator configurations. Control objectives (such as active damping, vibration isolation, or precise positioning) dictate specific sensor configurations. The selection between inertial sensors, force sensors, or relative position sensors is primarily determined by the system's control requirements.

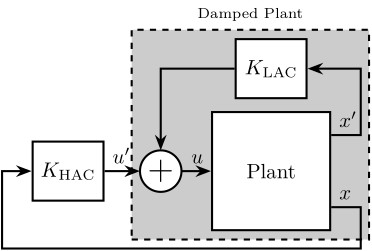

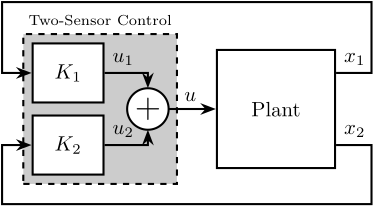

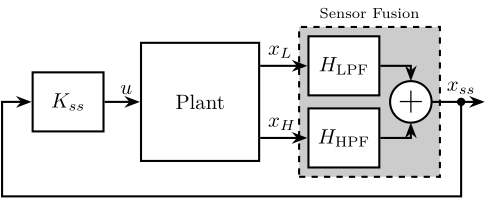

In cases where multiple control objectives must be achieved simultaneously, as is the case for the Nano Active Stabilization System (NASS) where the Stewart platform must both position the sample and provide isolation from micro-station vibrations, combining multiple sensors within the control architecture has been demonstrated to yield significant performance benefits. From the literature, three principal approaches for combining sensors have been identified: High Authority Control-Low Authority Control (HAC-LAC), sensor fusion, and two-sensor control architectures.

\begin{tikzpicture}

% Blocs

\node[block={2.0cm}{2.0cm}] (P) {Plant};

\coordinate[] (input) at ($(P.south west)!0.5!(P.north west)$);

\coordinate[] (outputH) at ($(P.south east)!0.2!(P.north east)$);

\coordinate[] (outputL) at ($(P.south east)!0.8!(P.north east)$);

\node[block, above=0.2 of P] (Klac) {$K_\text{LAC}$};

\node[addb, left=0.5 of input] (addF) {};

\node[block, left=0.6 of addF] (Khac) {$K_\text{HAC}$};

% \node[addb={+}{}{}{}{-}, left=0.5 of Khac] (subr) {};

% Connections and labels

\draw[->] (outputL) -- ++(0.5, 0) coordinate(eastlac) |- (Klac.east);

\node[above right] at (outputL){$x^\prime$};

\draw[->] (Klac.west) -| (addF.north);

\draw[->] (addF.east) -- (input) node[above left]{$u$};

% \draw[<-] (subr.west)node[above left]{$r$} -- ++(-0.5, 0);

% \draw[->] (outputH) -- ++(0.5, 0) -- ++(0, -1.0) -| (subr.south);

\draw[->] (outputH) -- ++(0.5, 0) -- ++(0, -0.7) -| ($(Khac.west)+(-0.5, 0)$) -- (Khac.west);

\node[above right] at (outputH){$x$};

% \draw[->] (subr.east) -- (Khac.west) node[above left]{$\epsilon$};

\draw[->] (Khac.east) node[above right]{$u^\prime$} -- (addF.west);

\begin{scope}[on background layer]

\node[fit={(Klac.north-|eastlac) (addF.west|-P.south)}, fill=black!20!white, draw, dashed, inner sep=4pt] (Pi) {};

% \node[anchor={north west}, align=left] at (Pi.north west){\scriptsize{Damped}\\\scriptsize{Plant}};

\node[above=0 of Pi]{\scriptsize{Damped Plant}};

\end{scope}

\end{tikzpicture}\begin{tikzpicture}

% Blocs

\node[block={2.0cm}{2.0cm}] (P) {Plant};

\coordinate[] (input) at ($(P.south west)!0.5!(P.north west)$);

\coordinate[] (outputH) at ($(P.south east)!0.2!(P.north east)$);

\coordinate[] (outputL) at ($(P.south east)!0.8!(P.north east)$);

\coordinate[] (outputSS) at ($(P.south east)!0.5!(P.north east)$);

\node[block, right=0.8 of outputH] (KH) {$H_\text{HPF}$};

\node[block, right=0.8 of outputL] (KL) {$H_\text{LPF}$};

\node[addb={+}{}{}{}{}, right=2.2 of outputSS] (addss) {};

\node[block, left=0.6 of input] (K) {$K_{ss}$};

% Connections and labels

\draw[->] (outputL) -- (KL.west);

\draw[->] (outputH) -- (KH.west);

\node[above right] at (outputL){$x_L$};

\node[above right] at (outputH){$x_H$};

\draw[->] (KL.east) -| (addss.north);

\draw[->] (KH.east) -| (addss.south);

\draw[->] (addss.east) -- ++(0.9, 0);

\draw[->] ($(addss.east) + (0.5, 0)$)node[branch]{}node[above]{$x_{ss}$} -- ++(0, -1.6) -| ($(K.west)+(-0.5, 0)$) -- (K.west);

\draw[->] (K.east) -- (input) node[above left]{$u$};

\begin{scope}[on background layer]

\node[fit={(KL.north west) (KH.south-|addss.east)}, fill=black!20!white, draw, dashed, inner sep=4pt] (Pss) {};

\node[above=0 of Pss]{\scriptsize{Sensor Fusion}};

\end{scope}

\end{tikzpicture}\begin{tikzpicture}

% Blocs

\node[block={2.0cm}{2.0cm}] (P) {Plant};

\coordinate[] (input) at ($(P.south west)!0.5!(P.north west)$);

\coordinate[] (output1) at ($(P.south east)!0.8!(P.north east)$);

\coordinate[] (output2) at ($(P.south east)!0.2!(P.north east)$);

\node[addb={+}{}{}{}{}, left=0.8 of input] (addF) {};

\coordinate[left= 1.0 of addF] (Ks);

\node[block] (K1) at (Ks|-output1) {$K_\text{1}$};

\node[block] (K2) at (Ks|-output2) {$K_\text{2}$};

\draw[->] (output1) -| ++(0.6, 1.2) -| ($(K1.west)+(-0.5, 0)$) -- (K1.west);

\draw[->] (output2) -| ++(0.6,-1.0) -| ($(K2.west)+(-0.5, 0)$) -- (K2.west);

\draw[->] (K1.east)node[above right]{$u_1$} -| (addF.north);

\draw[->] (K2.east)node[above right]{$u_2$} -| (addF.south);

\draw[->] (addF.east) -- (input) node[above left=0 and 0.2]{$u$};

\node[above right] at (output1){$x_1$};

\node[above right] at (output2){$x_2$};

\begin{scope}[on background layer]

\node[fit={(K1.north west) (K2.south-|addF.east)}, fill=black!20!white, draw, dashed, inner sep=4pt] (Pss) {};

\node[above=0 of Pss]{\scriptsize{Two-Sensor Control}};

\end{scope}

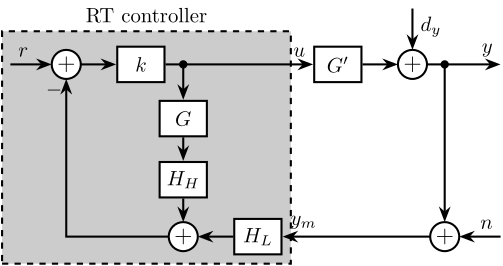

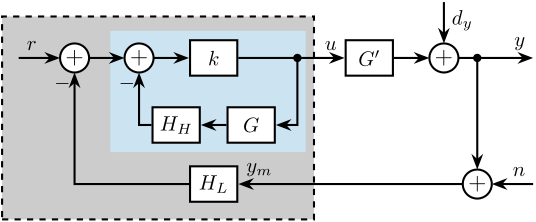

\end{tikzpicture}The HAC-LAC approach, implemented during the conceptual phase, employs a dual-loop control strategy in which two control loops utilize different sensors for distinct purposes (Figure ref:fig:detail_control_sensor_arch_hac_lac). In cite:&li01_simul_vibrat_isolat_point_contr, vibration isolation is provided by accelerometers collocated with the voice coil actuators, while external rotational sensors are utilized to achieve pointing control. In cite:&geng95_intel_contr_system_multip_degree, force sensors collocated with the magnetostrictive actuators are used for active damping using decentralized IFF, and subsequently accelerometers are employed for adaptive vibration isolation. Similarly, in cite:&wang16_inves_activ_vibrat_isolat_stewar, piezoelectric actuators with collocated force sensors are used in a decentralized manner to provide active damping while accelerometers are implemented in an adaptive feedback loop to suppress periodic vibrations. In cite:&xie17_model_contr_hybrid_passiv_activ, force sensors are integrated in the struts for decentralized force feedback while accelerometers fixed to the top platform are employed for centralized control.

The second approach, sensor fusion (illustrated in Figure ref:fig:detail_control_sensor_arch_sensor_fusion), involves filtering signals from two sensors using complementary filters1 and summing them to create an improved sensor signal. In cite:&hauge04_sensor_contr_space_based_six, geophones (used at low frequency) are merged with force sensors (used at high frequency). It is demonstrated that combining both sensors using sensor fusion can improve performance compared to using the individual sensors independently. In cite:&tjepkema12_sensor_fusion_activ_vibrat_isolat_precis_equip, sensor fusion architecture is implemented with an accelerometer and a force sensor. This implementation is shown to simultaneously achieve high damping of structural modes (through the force sensors) while maintaining very low vibration transmissibility (through the accelerometers).

In cite:&beijen14_two_sensor_contr_activ_vibrat, the performance of sensor fusion is compared with the more general case of "two-sensor control" (illustrated in Figure ref:fig:detail_control_sensor_arch_two_sensor_control). It is highlighted that "two-sensor control" provides greater control freedom, potentially enhancing performance. In cite:&thayer02_six_axis_vibrat_isolat_system, the use of force sensors and geophones is compared for vibration isolation purposes. Geophones are shown to provide better isolation performance than load cells but suffer from poor robustness. Conversely, the controller based on force sensors exhibited inferior performance (due to the presence of a pair of low frequency zeros), but demonstrated better robustness properties. A "two-sensor control" approach was proven to perform better than controllers based on individual sensors while maintaining better robustness. A Linear Quadratic Regulator (LQG) was employed to optimize the two-input/one-output controller.

Beyond these three main approaches, other control architectures have been proposed for different purposes. In cite:&yang19_dynam_model_decoup_contr_flexib, a first control loop utilizes force sensors and relative motion sensors to compensate for parasitic stiffness of the flexible joints. Subsequently, the system is decoupled in the modal space (facilitated by the removal of parasitic stiffness) and accelerometers are employed for vibration isolation.

The HAC-LAC architecture was previously investigated during the conceptual phase and successfully implemented to validate the NASS concept, demonstrating excellent performance. At the other end of the spectrum, the two-sensor approach yields greater control design freedom but introduces increased complexity in tuning, and thus was not pursued in this study. This work instead focuses on sensor fusion, which represents a promising middle ground between the proven HAC-LAC approach and the more complex two-sensor control strategy.

A review of sensor fusion is first presented (Section ref:ssec:detail_control_sensor_review), followed by an examination of the fundamental theoretical concepts (Section ref:ssec:detail_control_sensor_fusion_requirements). In this section, both the robustness of the fusion and the noise characteristics of the resulting "super sensor" are derived and expressed as functions of the complementary filters' norms. A synthesis method for designing complementary filters that allow to shape their norms is proposed (Section ref:ssec:detail_control_sensor_hinf_method). The investigation is then extended beyond the conventional two-sensor scenario, demonstrating how the proposed complementary filter synthesis can be generalized for applications requiring the fusion of three or more sensors (Section ref:ssec:detail_control_sensor_hinf_three_comp_filters).

Review of Sensor Fusion

<<ssec:detail_control_sensor_review>>

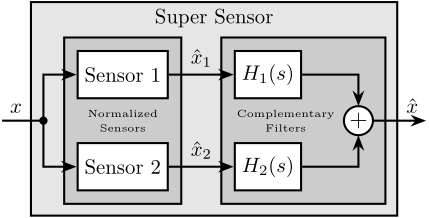

Sensors used to measure physical quantities have two primary limitations: measurement accuracy which is compromised by various noise sources (including electrical noise from conditioning electronics), and limited measurement bandwidth. Sensor fusion offers a solution to these limitations by combining multiple sensors cite:&bendat57_optim_filter_indep_measur_two. By strategically selecting sensors with complementary characteristics, a "super sensor" can be created that combines the advantages of each individual sensor.

Measuring a physical quantity using sensors is always subject to several limitations. First, the accuracy of the measurement is affected by various noise sources, such as electrical noise from the conditioning electronics. Second, the frequency range in which the measurement is relevant is bounded by the bandwidth of the sensor. One way to overcome these limitations is to combine several sensors using a technique called "sensor fusion" cite:&bendat57_optim_filter_indep_measur_two. Fortunately, a wide variety of sensors exists, each with different characteristics. By carefully selecting the sensors to be fused, a "super sensor" is obtained that combines the benefits of the individual sensors.

In some applications, sensor fusion is employed to increase measurement bandwidth cite:&shaw90_bandw_enhan_posit_measur_using_measur_accel;&zimmermann92_high_bandw_orien_measur_contr;&min15_compl_filter_desig_angle_estim. For instance, in cite:&shaw90_bandw_enhan_posit_measur_using_measur_accel, the bandwidth of a position sensor is extended by fusing it with an accelerometer that provides high-frequency motion information. In other applications, sensor fusion is utilized to obtain an estimate of the measured quantity with reduced noise cite:&hua05_low_ligo;&hua04_polyp_fir_compl_filter_contr_system;&plummer06_optim_compl_filter_their_applic_motion_measur;&robert12_introd_random_signal_applied_kalman. More recently, the fusion of sensors measuring different physical quantities has been proposed to enhance control properties cite:&collette15_sensor_fusion_method_high_perfor;&yong16_high_speed_vertic_posit_stage. In cite:&collette15_sensor_fusion_method_high_perfor, an inertial sensor used for active vibration isolation is fused with a sensor collocated with the actuator to improve the stability margins of the feedback controller.

On top of Stewart platforms, practical applications of sensor fusion are numerous. It is widely implemented for attitude estimation in autonomous vehicles such as unmanned aerial vehicles cite:&baerveldt97_low_cost_low_weigh_attit;&corke04_inert_visual_sensin_system_small_auton_helic;&jensen13_basic_uas and underwater vehicles cite:&pascoal99_navig_system_desig_using_time;&batista10_optim_posit_veloc_navig_filter_auton_vehic. Sensor fusion offers significant benefits for high-performance positioning control as demonstrated in cite:&shaw90_bandw_enhan_posit_measur_using_measur_accel;&zimmermann92_high_bandw_orien_measur_contr;&min15_compl_filter_desig_angle_estim;&yong16_high_speed_vertic_posit_stage. It has also been identified as a key technology for improving the performance of active vibration isolation systems cite:&tjepkema12_sensor_fusion_activ_vibrat_isolat_precis_equip. Emblematic examples include the isolation stages of gravitational wave detectors cite:&collette15_sensor_fusion_method_high_perfor;&heijningen18_low such as those employed at LIGO cite:&hua05_low_ligo;&hua04_polyp_fir_compl_filter_contr_system and Virgo cite:&lucia18_low_frequen_optim_perfor_advan.

Two principal methods are employed to perform sensor fusion: using complementary filters cite:&anderson53_instr_approac_system_steer_comput or using Kalman filtering cite:&brown72_integ_navig_system_kalman_filter. For sensor fusion applications, these methods share many relationships cite:&brown72_integ_navig_system_kalman_filter;&higgins75_compar_compl_kalman_filter;&robert12_introd_random_signal_applied_kalman;&fonseca15_compl. However, Kalman filtering requires assumptions about the probabilistic characteristics of sensor noise cite:&robert12_introd_random_signal_applied_kalman, whereas complementary filters do not impose such requirements. Furthermore, complementary filters offer advantages over Kalman filtering for sensor fusion through their general applicability, low computational cost cite:&higgins75_compar_compl_kalman_filter, and intuitive nature, as their effects can be readily interpreted in the frequency domain.

A set of filters is considered complementary if the sum of their transfer functions equals one at all frequencies. In early implementations of complementary filtering, analog circuits were used to physically realize the filters cite:&anderson53_instr_approac_system_steer_comput. While analog complementary filters remain in use today cite:&yong16_high_speed_vertic_posit_stage;&moore19_capac_instr_sensor_fusion_high_bandw_nanop, digital implementation is now more common as it provides greater flexibility.

Various design methods have been developed to optimize complementary filters. The most straightforward approach utilizes analytical formulas. Depending on the application, these formulas may be of first order cite:&corke04_inert_visual_sensin_system_small_auton_helic;&yeh05_model_contr_hydraul_actuat_two;&yong16_high_speed_vertic_posit_stage, second order cite:&baerveldt97_low_cost_low_weigh_attit;&stoten01_fusion_kinet_data_using_compos_filter;&jensen13_basic_uas, or higher orders cite:&shaw90_bandw_enhan_posit_measur_using_measur_accel;&zimmermann92_high_bandw_orien_measur_contr;&stoten01_fusion_kinet_data_using_compos_filter;&collette15_sensor_fusion_method_high_perfor;&matichard15_seism_isolat_advan_ligo.

Since the characteristics of the super sensor depend on the proper design of complementary filters cite:&dehaeze19_compl_filter_shapin_using_synth, several optimization techniques have been developed. Some approaches focus on finding optimal parameters for analytical formulas cite:&jensen13_basic_uas;&min15_compl_filter_desig_angle_estim;&fonseca15_compl, while others employ convex optimization tools cite:&hua04_polyp_fir_compl_filter_contr_system;&hua05_low_ligo such as linear matrix inequalities cite:&pascoal99_navig_system_desig_using_time. As demonstrated in cite:&plummer06_optim_compl_filter_their_applic_motion_measur, complementary filter design can be linked to the standard mixed-sensitivity control problem. Consequently, the powerful tools developed for classical control theory can be applied to complementary filter design. For example, in cite:&jensen13_basic_uas, the two gains of a Proportional Integral (PI) controller are optimized to minimize super sensor noise.

All these complementary filter design methods share the common objective of creating a super sensor with desired characteristics, typically in terms of noise and dynamics. As reported in cite:&zimmermann92_high_bandw_orien_measur_contr;&plummer06_optim_compl_filter_their_applic_motion_measur, phase shifts and magnitude bumps in the super sensor dynamics may occur if complementary filters are poorly designed or if sensors are improperly calibrated. Therefore, the robustness of the fusion must be considered when designing complementary filters. Despite the numerous design methods proposed in the literature, a simple approach that specifies desired super sensor characteristics while ensuring good fusion robustness has been lacking.

Fortunately, both fusion robustness and super sensor characteristics can be linked to complementary filter magnitude cite:&dehaeze19_compl_filter_shapin_using_synth. Based on this relationship, the present work introduces an approach to designing complementary filters using $\mathcal{H}_\infty$ synthesis, which enables intuitive shaping of complementary filter magnitude in a straightforward manner.

Sensor Fusion and Complementary Filters Requirements

<<ssec:detail_control_sensor_fusion_requirements>>

Sensor Fusion Architecture ignore

A general sensor fusion architecture using complementary filters is shown in Figure ref:fig:detail_control_sensor_fusion_overview, where multiple sensors (in this case two) measure the same physical quantity $x$. The sensor output signals $\hat{x}_1$ and $\hat{x}_2$ represent estimates of $x$. These estimates are filtered by complementary filters and combined to form a new estimate $\hat{x}$.

\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[branch] (x) at (0, 0);

\node[block, above right=0.3 and 0.5 of x](sensor1){Sensor 1};

\node[block, below right=0.3 and 0.5 of x](sensor2){Sensor 2};

\node[block, right=1.1 of sensor1](H1){$H_1(s)$};

\node[block, right=1.1 of sensor2](H2){$H_2(s)$};

\node[addb, right=5.0 of x](add){};

\draw[] ($(x)+(-0.7, 0)$) node[above right]{$x$} -- (x.center);

\draw[->] (x.center) |- (sensor1.west);

\draw[->] (x.center) |- (sensor2.west);

\draw[->] (sensor1.east) -- node[midway, above]{$\hat{x}_1$} (H1.west);

\draw[->] (sensor2.east) -- node[midway, above]{$\hat{x}_2$} (H2.west);

\draw[->] (H1) -| (add.north);

\draw[->] (H2) -| (add.south);

\draw[->] (add.east) -- ++(0.9, 0) node[above left]{$\hat{x}$};

\begin{scope}[on background layer]

\node[fit={($(H2.south-|x) + (0, -0.2)$) ($(H1.north-|add.east) + (0.2, 0.6)$)}, fill=black!10!white, draw, inner sep=6pt] (supersensor) {};

\node[below] at (supersensor.north) {Super Sensor};

\node[fit={(sensor2.south west) (sensor1.north east)}, fill=black!20!white, draw, inner sep=6pt] (sensors) {};

\node[align=center] at (sensors.center) {{\tiny Normalized}\\[-0.5em]{\tiny Sensors}};

\node[fit={(H2.south west) (H1.north-|add.east)}, fill=black!20!white, draw, inner sep=6pt] (filters) {};

\node[align=center] at ($(filters.center) + (-0.3, 0)$) {{\tiny Complementary}\\[-0.5em]{\tiny Filters}};

\end{scope}

\end{tikzpicture}The complementary property of filters $H_1(s)$ and $H_2(s)$ requires that the sum of their transfer functions equals one at all frequencies eqref:eq:detail_control_sensor_comp_filter.

\begin{equation}\label{eq:detail_control_sensor_comp_filter} H_1(s) + H_2(s) = 1

\end{equation}

Sensor Models and Sensor Normalization

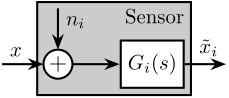

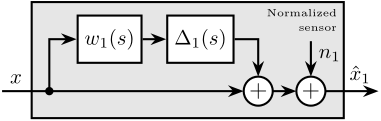

To analyze sensor fusion architectures, appropriate sensor models are required. The model shown in Figure ref:fig:detail_control_sensor_model consists of a linear time invariant (LTI) system $G_i(s)$ representing the sensor dynamics and an input $n_i$ representing sensor noise. The model input $x$ is the measured physical quantity, and its output $\tilde{x}_i$ is the "raw" output of the sensor.

Prior to filtering the sensor outputs $\tilde{x}_i$ with complementary filters, the sensors are typically normalized to simplify the fusion process. This normalization involves using an estimate $\hat{G}_i(s)$ of the sensor dynamics $G_i(s)$, and filtering the sensor output by the inverse of this estimate $\hat{G}_i^{-1}(s)$, as shown in Figure ref:fig:detail_control_sensor_model_calibrated. It is assumed that the sensor inverse $\hat{G}_i^{-1}(s)$ is proper and stable. This approach ensures that the units of the estimates $\hat{x}_i$ match the units of the physical quantity $x$. The sensor dynamics estimate $\hat{G}_i(s)$ may be a simple gain or a more complex transfer function.

\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[addb](add1){};

\node[block, right=0.8 of add1](G1){$G_i(s)$};

\draw[->] ($(add1.west)+(-0.7, 0)$) node[above right]{$x$} -- (add1.west);

\draw[<-] (add1.north) -- ++(0, 0.7)node[below right](n1){$n_i$};

\draw[->] (add1.east) -- (G1.west);

\draw[->] (G1.east) -- ++(0.7, 0) node[above left]{$\tilde{x}_i$};

\begin{scope}[on background layer]

\node[fit={(add1.west |- G1.south) (n1.north -| G1.east)}, fill=black!20!white, draw, inner sep=3pt] (sensor1) {};

\node[below left] at (sensor1.north east) {Sensor};

\end{scope}

\end{tikzpicture}\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[addb](add1){};

\node[block, right=0.8 of add1](G1){$G_i(s)$};

\node[block, right=0.8 of G1](G1inv){$\hat{G}_i^{-1}(s)$};

\draw[->] ($(add1.west)+(-0.7, 0)$) node[above right]{$x$} -- (add1.west);

\draw[<-] (add1.north) -- ++(0, 0.7)node[below right](n1){$n_i$};

\draw[->] (add1.east) -- (G1.west);

\draw[->] (G1.east) -- (G1inv.west) node[above left]{$\tilde{x}_i$};

\draw[->] (G1inv.east) -- ++(0.8, 0) node[above left]{$\hat{x}_i$};

\begin{scope}[on background layer]

\node[fit={(add1.west |- G1inv.south) (n1.north -| G1inv.east)}, fill=black!10!white, draw, inner sep=6pt] (sensor1cal) {};

\node[below left, align=right] at (sensor1cal.north east) {{\tiny Normalized}\\[-0.5em]{\tiny sensor}};

\node[fit={(add1.west |- G1.south) (n1.north -| G1.east)}, fill=black!20!white, draw, inner sep=3pt] (sensor1) {};

\node[below left] at (sensor1.north east) {Sensor};

\end{scope}

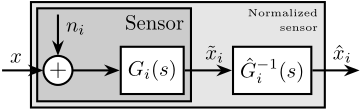

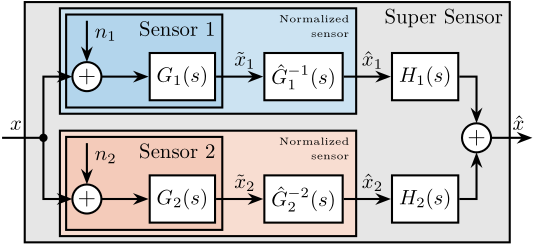

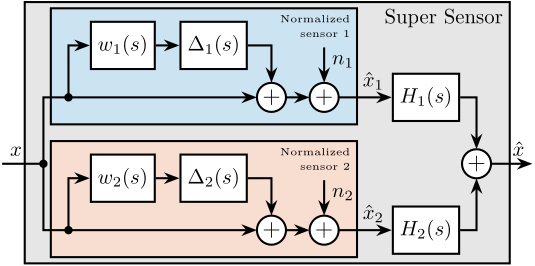

\end{tikzpicture}Two normalized sensors are then combined to form a super sensor as shown in Figure ref:fig:detail_control_sensor_fusion_super_sensor. The two sensors measure the same physical quantity $x$ with dynamics $G_1(s)$ and $G_2(s)$, and with uncorrelated noises $n_1$ and $n_2$. The signals from both normalized sensors are fed into two complementary filters $H_1(s)$ and $H_2(s)$ and then combined to yield an estimate $\hat{x}$ of $x$. The super sensor output $\hat{x}$ is therefore described by eqref:eq:detail_control_sensor_comp_filter_estimate.

\begin{equation}\label{eq:detail_control_sensor_comp_filter_estimate} \hat{x} = \Big( H_1(s) \hat{G}_1-1(s) G_1(s) + H_2(s) \hat{G}_2-1(s) G_2(s) \Big) x + H_1(s) \hat{G}_1-1(s) G_1(s) n_1 + H_2(s) \hat{G}_2-1(s) G_2(s) n_2

\end{equation}

\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[branch] (x) at (0, 0);

\node[addb, above right=0.8 and 0.5 of x](add1){};

\node[addb, below right=0.8 and 0.5 of x](add2){};

\node[block, right=0.8 of add1](G1){$G_1(s)$};

\node[block, right=0.8 of add2](G2){$G_2(s)$};

\node[block, right=0.8 of G1](G1inv){$\hat{G}_1^{-1}(s)$};

\node[block, right=0.8 of G2](G2inv){$\hat{G}_2^{-2}(s)$};

\node[block, right=0.8 of G1inv](H1){$H_1(s)$};

\node[block, right=0.8 of G2inv](H2){$H_2(s)$};

\node[addb, right=7 of x](add){};

\draw[] ($(x)+(-0.7, 0)$) node[above right]{$x$} -- (x.center);

\draw[->] (x.center) |- (add1.west);

\draw[->] (x.center) |- (add2.west);

\draw[<-] (add1.north) -- ++(0, 0.7)node[below right](n1){$n_1$};

\draw[->] (add1.east) -- (G1.west);

\draw[->] (G1.east) -- (G1inv.west) node[above left]{$\tilde{x}_1$};

\draw[->] (G1inv.east) -- (H1.west) node[above left]{$\hat{x}_1$};

\draw[<-] (add2.north) -- ++(0, 0.7)node[below right](n2){$n_2$};

\draw[->] (add2.east) -- (G2.west);

\draw[->] (G2.east) -- (G2inv.west) node[above left]{$\tilde{x}_2$};

\draw[->] (G2inv.east) -- (H2.west) node[above left]{$\hat{x}_2$};

\draw[->] (H1) -| (add.north);

\draw[->] (H2) -| (add.south);

\draw[->] (add.east) -- ++(0.7, 0) node[above left]{$\hat{x}$};

\begin{scope}[on background layer]

\node[fit={(G2.south-|x) (n1.north-|add.east)}, fill=black!10!white, draw, inner sep=9pt] (supersensor) {};

\node[below left] at (supersensor.north east) {Super Sensor};

\node[fit={(add1.west |- G1inv.south) (n1.north -| G1inv.east)}, fill=colorblue!20!white, draw, inner sep=6pt] (sensor1cal) {};

\node[below left, align=right] at (sensor1cal.north east) {{\tiny Normalized}\\[-0.5em]{\tiny sensor}};

\node[fit={(add1.west |- G1.south) (n1.north -| G1.east)}, fill=colorblue!30!white, draw, inner sep=3pt] (sensor1) {};

\node[below left] at (sensor1.north east) {Sensor 1};

\node[fit={(add2.west |- G2inv.south) (n2.north -| G2inv.east)}, fill=colorred!20!white, draw, inner sep=6pt] (sensor2cal) {};

\node[below left, align=right] at (sensor2cal.north east) {{\tiny Normalized}\\[-0.5em]{\tiny sensor}};

\node[fit={(add2.west |- G2.south) (n2.north -| G2.east)}, fill=colorred!30!white, draw, inner sep=3pt] (sensor2) {};

\node[below left] at (sensor2.north east) {Sensor 2};

\end{scope}

\end{tikzpicture}Noise Sensor Filtering

First, consider the case where all sensors are perfectly normalized eqref:eq:detail_control_sensor_perfect_dynamics. The effects of imperfect normalization will be addressed subsequently.

\begin{equation}\label{eq:detail_control_sensor_perfect_dynamics} \frac{\hat{x}_i}{x} = \hat{G}_i(s) G_i(s) = 1

\end{equation}

In that case, the super sensor output $\hat{x}$ equals $x$ plus the filtered noise from both sensors eqref:eq:detail_control_sensor_estimate_perfect_dyn. From this equation, it is evident that the complementary filters $H_1(s)$ and $H_2(s)$ operate solely on the sensor noise. Thus, this sensor fusion architecture allows filtering of sensor noise without introducing distortion in the measured physical quantity. This fundamental property necessitates that the two filters must be complementary.

\begin{equation}\label{eq:detail_control_sensor_estimate_perfect_dyn} \hat{x} = x + H_1(s) n_1 + H_2(s) n_2

\end{equation}

The estimation error $\epsilon_x$, defined as the difference between the sensor output $\hat{x}$ and the measured quantity $x$, is computed for the super sensor eqref:eq:detail_control_sensor_estimate_error.

\begin{equation}\label{eq:detail_control_sensor_estimate_error} ε_x ≜ \hat{x} - x = H_1(s) n_1 + H_2(s) n_2

\end{equation}

As shown in eqref:eq:detail_control_sensor_noise_filtering_psd, the Power Spectral Density (PSD) of the estimation error $\Phi_{\epsilon_x}$ depends both on the norm of the two complementary filters and on the PSD of the noise sources $\Phi_{n_1}$ and $\Phi_{n_2}$.

\begin{equation}\label{eq:detail_control_sensor_noise_filtering_psd} Φε_x(ω) = ≤ft|H_1(jω)\right|^2 Φn_1(ω) + ≤ft|H_2(jω)\right|^2 Φn_2(ω)

\end{equation}

If the two sensors have identical noise characteristics ($\Phi_{n_1}(\omega) = \Phi_{n_2}(\omega)$), simple averaging ($H_1(s) = H_2(s) = 0.5$) would minimize the super sensor noise. This represents the simplest form of sensor fusion using complementary filters.

However, sensors typically exhibit high noise levels in different frequency regions. In such cases, to reduce the noise of the super sensor, the norm $|H_1(j\omega)|$ should be minimized when $\Phi_{n_1}(\omega)$ exceeds $\Phi_{n_2}(\omega)$, and the norm $|H_2(j\omega)|$ should be minimized when $\Phi_{n_2}(\omega)$ exceeds $\Phi_{n_1}(\omega)$. Therefore, by appropriately shaping the norm of the complementary filters, the noise of the super sensor can be minimized.

Sensor Fusion Robustness

In practical systems, sensor normalization is rarely perfect, and condition eqref:eq:detail_control_sensor_perfect_dynamics is not fully satisfied.

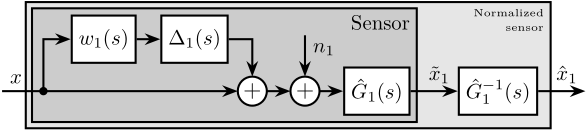

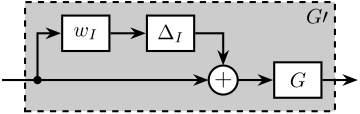

To analyze such imperfections, a multiplicative input uncertainty is incorporated into the sensor dynamics (Figure ref:fig:detail_control_sensor_model_uncertainty). The nominal model is the estimated model used for normalization $\hat{G}_i(s)$, $\Delta_i(s)$ is any stable transfer function satisfying $|\Delta_i(j\omega)| \le 1,\ \forall\omega$, and $w_i(s)$ is a weighting transfer function representing the magnitude of uncertainty. The weight $w_i(s)$ is selected such that the actual sensor dynamics $G_i(j\omega)$ remains within the uncertain region represented by a circle in the complex plane, centered on $1$ with a radius equal to $|w_i(j\omega)|$.

Since the nominal sensor dynamics is taken as the normalized filter, the normalized sensor model can be further simplified as shown in Figure ref:fig:detail_control_sensor_model_uncertainty_simplified.

\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[branch] (input) at (0,0) {};

\node[block, above right= 0.4 and 0.4 of input](W1){$w_1(s)$};

\node[block, right=0.4 of W1](delta1){$\Delta_1(s)$};

\node[addb] (addu) at ($(delta1.east|-input) + (0.4, 0)$) {};

\node[addb, right=0.4 of addu] (addn) {};

\node[block, right=0.4 of addn] (G1) {$\hat{G}_1(s)$};

\node[block, right=0.8 of G1](G1inv){$\hat{G}_1^{-1}(s)$};

\draw[->] ($(input)+(-0.7, 0)$) node[above right]{$x$} -- (addu);

\draw[->] (input.center) |- (W1.west);

\draw[->] (W1.east) -- (delta1.west);

\draw[->] (delta1.east) -| (addu.north);

\draw[->] (addu.east) -- (addn.west);

\draw[->] (addn.east) -- (G1.west);

\draw[<-] (addn.north) -- ++(0, 0.7)node[below right](n1){$n_1$};

\draw[->] (G1.east) -- (G1inv.west) node[above left]{$\tilde{x}_1$};

\draw[->] (G1inv.east) -- ++(0.8, 0) node[above left]{$\hat{x}_1$};

\begin{scope}[on background layer]

\node[fit={(input.west |- G1inv.south) (delta1.north -| G1inv.east)}, fill=black!10!white, draw, inner sep=6pt] (sensor1cal) {};

\node[below left, align=right] at (sensor1cal.north east) {{\tiny Normalized}\\[-0.5em]{\tiny sensor}};

\node[fit={(input.west |- G1.south) (delta1.north -| G1.east)}, fill=black!20!white, draw, inner sep=3pt] (sensor1) {};

\node[below left] at (sensor1.north east) {Sensor};

\end{scope}

\end{tikzpicture}\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[branch] (input) at (0,0) {};

\node[block, above right= 0.4 and 0.4 of input](W1){$w_1(s)$};

\node[block, right=0.4 of W1](delta1){$\Delta_1(s)$};

\node[addb] (addu) at ($(delta1.east|-input) + (0.4, 0)$) {};

\node[addb, right=0.4 of addu] (addn) {};

\draw[->] ($(input)+(-0.8, 0)$) node[above right]{$x$} -- (addu);

\draw[->] (input.center) |- (W1.west);

\draw[->] (W1.east) -- (delta1.west);

\draw[->] (delta1.east) -| (addu.north);

\draw[->] (addu.east) -- (addn.west);

\draw[<-] (addn.north) -- ++(0, 0.6)node[below right](n1){$n_1$};

\draw[->] (addn.east) -- ++(0.9, 0) node[above left]{$\hat{x}_1$};

\begin{scope}[on background layer]

\node[fit={(input.west |- addu.south) ($(delta1.north -| addn.east) + (0.1, 0)$)}, fill=black!10!white, draw, inner sep=6pt] (sensor1cal) {};

\node[below left, align=right] at (sensor1cal.north east) {{\tiny Normalized}\\[-0.5em]{\tiny sensor}};

\end{scope}

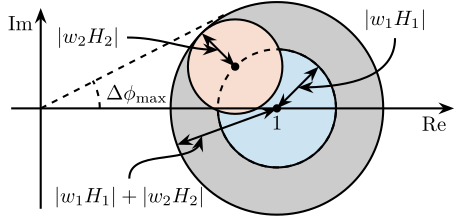

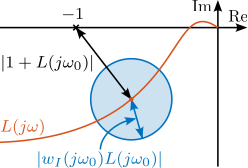

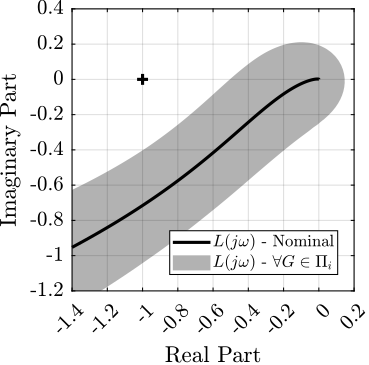

\end{tikzpicture}The sensor fusion architecture incorporating sensor models with dynamical uncertainty is illustrated in Figure ref:fig:detail_control_sensor_fusion_dynamic_uncertainty. The super sensor dynamics eqref:eq:detail_control_sensor_super_sensor_dyn_uncertainty is no longer unity but depends on the sensor dynamical uncertainty weights $w_i(s)$ and the complementary filters $H_i(s)$. The dynamical uncertainty of the super sensor can be graphically represented in the complex plane by a circle centered on $1$ with a radius equal to $|w_1(j\omega) H_1(j\omega)| + |w_2(j\omega) H_2(j\omega)|$ (Figure ref:fig:detail_control_sensor_uncertainty_set_super_sensor).

The sensor fusion architecture with the sensor models including dynamical uncertainty is shown in Figure ref:fig:detail_control_sensor_fusion_dynamic_uncertainty. The super sensor dynamics eqref:eq:detail_control_sensor_super_sensor_dyn_uncertainty is no longer equal to $1$ and now depends on the sensor dynamical uncertainty weights $w_i(s)$ as well as on the complementary filters $H_i(s)$. The dynamical uncertainty of the super sensor can be graphically represented in the complex plane by a circle centered on $1$ with a radius equal to $|w_1(j\omega) H_1(j\omega)| + |w_2(j\omega) H_2(j\omega)|$ (Figure ref:fig:detail_control_sensor_uncertainty_set_super_sensor).

\begin{equation}\label{eq:detail_control_sensor_super_sensor_dyn_uncertainty} \frac{\hat{x}}{x} = 1 + w_1(s) H_1(s) Δ_1(s) + w_2(s) H_2(s) Δ_2(s)

\end{equation}

\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[branch] (x) at (0, 0);

\node[branch, above right=1.0 and 0.3 of x] (input1) {};

\node[branch, below right=1.0 and 0.3 of x] (input2) {};

\node[block, above right= 0.4 and 0.3 of input1](W1){$w_1(s)$};

\node[block, above right= 0.4 and 0.3 of input2](W2){$w_2(s)$};

\node[block, right=0.4 of W1](delta1){$\Delta_1(s)$};

\node[block, right=0.4 of W2](delta2){$\Delta_2(s)$};

\node[addb] (addu1) at ($(delta1.east|-input1) + (0.4, 0)$) {};

\node[addb] (addu2) at ($(delta2.east|-input2) + (0.4, 0)$) {};

\node[addb, right=0.4 of addu1] (addn1) {};

\node[addb, right=0.4 of addu2] (addn2) {};

\node[block, right=0.9 of addn1](H1){$H_1(s)$};

\node[block, right=0.9 of addn2](H2){$H_2(s)$};

\node[addb, right=7 of x](add){};

\draw[] ($(x)+(-0.7, 0)$) node[above right]{$x$} -- (x.center);

\draw[->] (x.center) |- (addu1.west);

\draw[->] (x.center) |- (addu2.west);

\draw[->] (input1.center) |- (W1.west);

\draw[->] (W1.east) -- (delta1.west);

\draw[->] (delta1.east) -| (addu1.north);

\draw[->] (addu1.east) -- (addn1.west);

\draw[<-] (addn1.north) -- ++(0, 0.6)node[below right](n1){$n_1$};

\draw[->] (input2.center) |- (W2.west);

\draw[->] (W2.east) -- (delta2.west);

\draw[->] (delta2.east) -| (addu2.north);

\draw[->] (addu2.east) -- (addn2.west);

\draw[<-] (addn2.north) -- ++(0, 0.6)node[below right](n2){$n_2$};

\draw[->] (addn1.east) -- (H1.west) node[above left]{$\hat{x}_1$};

\draw[->] (addn2.east) -- (H2.west) node[above left]{$\hat{x}_2$};

\draw[->] (H1) -| (add.north);

\draw[->] (H2) -| (add.south);

\draw[->] (add.east) -- ++(0.7, 0) node[above left]{$\hat{x}$};

\begin{scope}[on background layer]

\node[fit={(addn2.south-|x) (delta1.north-|add.east)}, fill=black!10!white, draw, inner sep=9pt] (supersensor) {};

\node[below left] at (supersensor.north east) {Super Sensor};

\node[fit={(input1.west |- addu1.south) ($(delta1.north -| addn1.east) + (0.1, 0.0)$)}, fill=colorblue!20!white, draw, inner sep=6pt] (sensor1cal) {};

\node[below left, align=right] at (sensor1cal.north east) {{\tiny Normalized}\\[-0.5em]{\tiny sensor 1}};

\node[fit={(input2.west |- addu2.south) ($(delta2.north -| addn1.east) + (0.1, 0.0)$)}, fill=colorred!20!white, draw, inner sep=6pt] (sensor2cal) {};

\node[below left, align=right] at (sensor2cal.north east) {{\tiny Normalized}\\[-0.5em]{\tiny sensor 2}};

\end{scope}

\end{tikzpicture}\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\begin{scope}[shift={(4, 0)}]

% Uncertainty Circle

\node[draw, circle, fill=black!20!white, minimum size=3.6cm] (c) at (0, 0) {};

\path[draw, fill=colorblue!20!white] (0, 0) circle [radius=1.0];

\path[draw, fill=colorred!20!white] (135:1.0) circle [radius=0.8];

\path[draw, dashed] (0, 0) circle [radius=1.0];

% Center of Circle

\node[below] at (0, 0){$1$};

\draw[<->] (0, 0) node[branch]{} -- coordinate[midway](r1) ++(45:1.0);

\draw[<->] (135:1.0)node[branch]{} -- coordinate[midway](r2) ++(135:0.8);

\node[] (l1) at (2, 1.5) {$|w_1 H_1|$};

\draw[->, out=-90, in=0] (l1.south) to (r1);

\node[] (l2) at (-3.2, 1.2) {$|w_2 H_2|$};

\draw[->, out=0, in=-180] (l2.east) to (r2);

\draw[<->] (0, 0) -- coordinate[near end](r3) ++(200:1.8);

\node[] (l3) at (-2.5, -1.5) {$|w_1 H_1| + |w_2 H_2|$};

\draw[->, out=90, in=-90] (l3.north) to (r3);

\end{scope}

% Real and Imaginary Axis

\draw[->] (-0.5, 0) -- (7.0, 0) node[below left]{Re};

\draw[->] (0, -1.7) -- (0, 1.7) node[below left]{Im};

\draw[dashed] (0, 0) -- (tangent cs:node=c,point={(0, 0)},solution=2);

\draw[dashed] (1, 0) arc (0:28:1) node[midway, right]{$\Delta \phi_\text{max}$};

\end{tikzpicture}The super sensor dynamical uncertainty, and consequently the robustness of the fusion, clearly depends on the complementary filters' norm. As it is generally desired to limit the dynamical uncertainty of the super sensor, the norm of the complementary filter $|H_i(j\omega)|$ should be made small when $|w_i(j\omega)|$ is large, i.e., at frequencies where the sensor dynamics is uncertain.

Complementary Filters Shaping

<<ssec:detail_control_sensor_hinf_method>>

Introduction ignore

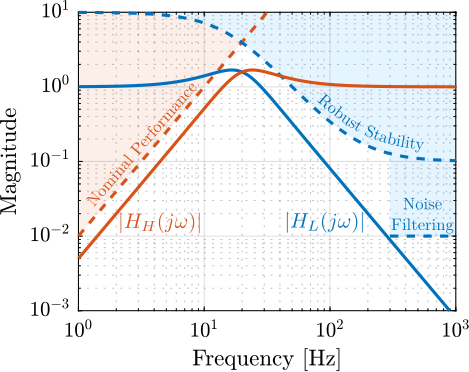

As established in Section ref:ssec:detail_control_sensor_fusion_requirements, the super sensor's noise characteristics and robustness are directly dependent on the complementary filters' norm. A synthesis method enabling precise shaping of these norms would therefore offer substantial practical benefits. This section develops such an approach by formulating the design objective as a standard $\mathcal{H}_\infty$ optimization problem. The methodology for designing appropriate weighting functions (which specify desired complementary filter shapes during synthesis) is examined in detail, and the efficacy of the proposed method is validated with a simple example.

Synthesis Objective

The primary objective is to shape the norms of two filters $H_1(s)$ and $H_2(s)$ while ensuring they maintain their complementary property as defined in eqref:eq:detail_control_sensor_comp_filter. This is equivalent to finding proper and stable transfer functions $H_1(s)$ and $H_2(s)$ that satisfy conditions eqref:eq:detail_control_sensor_hinf_cond_complementarity, eqref:eq:detail_control_sensor_hinf_cond_h1, and eqref:eq:detail_control_sensor_hinf_cond_h2. Weighting transfer functions $W_1(s)$ and $W_2(s)$ are strategically selected to define the maximum desired norm of the complementary filters during the synthesis process.

\begin{subequations}\label{eq:detail_control_sensor_comp_filter_problem_form}

\begin{align} & H_1(s) + H_2(s) = 1 \label{eq:detail_control_sensor_hinf_cond_complementarity} \\ & |H_1(j\omega)| \le \frac{1}{|W_1(j\omega)|} \quad \forall\omega \label{eq:detail_control_sensor_hinf_cond_h1} \\ & |H_2(j\omega)| \le \frac{1}{|W_2(j\omega)|} \quad \forall\omega \label{eq:detail_control_sensor_hinf_cond_h2} \end{align}\end{subequations}

Shaping of Complementary Filters using $\mathcal{H}_\infty$ synthesis

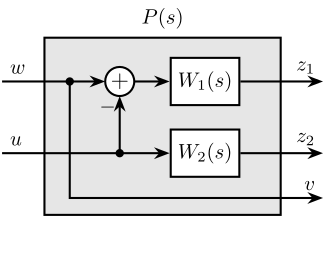

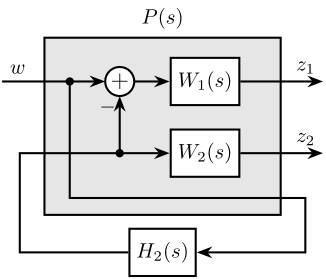

The synthesis objective can be readily expressed as a standard $\mathcal{H}_\infty$ optimization problem and solved using widely available computational tools. Consider the generalized plant $P(s)$ illustrated in Figure ref:fig:detail_control_sensor_h_infinity_robust_fusion_plant and mathematically described by eqref:eq:detail_control_sensor_generalized_plant.

\begin{equation}\label{eq:detail_control_sensor_generalized_plant} \begin{bmatrix} z_1 \\ z_2 \\ v \end{bmatrix} = P(s) \begin{bmatrix} w\\u \end{bmatrix}; \quad P(s) = \begin{bmatrix}W_1(s) & -W_1(s) \\ 0 & \phantom{+}W_2(s) \\ 1 & 0 \end{bmatrix} = P(s) \begin{bmatrix} w\\u \end{bmatrix}; \quad P(s) = \begin{bmatrix}W_1(s) & -W_1(s) \\ 0 & \phantom{+}W_2(s) \\ 1 & 0 \end{bmatrix}; \quad P(s) = \begin{bmatrix}W_1(s) & -W_1(s) \\ 0 & \phantom{+}W_2(s) \\ 1 & 0 \end{bmatrix}

\end{equation}

\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[block={4.0cm}{3.0cm}, fill=black!10!white] (P) {};

\node[above] at (P.north) {$P(s)$};

\node[block, below=0.2 of P, opacity=0] (H2) {$H_2(s)$};

\coordinate[] (inputw) at ($(P.south west)!0.75!(P.north west) + (-0.7, 0)$);

\coordinate[] (inputu) at ($(P.south west)!0.35!(P.north west) + (-0.7, 0)$);

\coordinate[] (output1) at ($(P.south east)!0.75!(P.north east) + ( 0.7, 0)$);

\coordinate[] (output2) at ($(P.south east)!0.35!(P.north east) + ( 0.7, 0)$);

\coordinate[] (outputv) at ($(P.south east)!0.1!(P.north east) + ( 0.7, 0)$);

\node[block, left=1.4 of output1] (W1){$W_1(s)$};

\node[block, left=1.4 of output2] (W2){$W_2(s)$};

\node[addb={+}{}{}{}{-}, left=of W1] (sub) {};

\draw[->] (inputw) node[above right]{$w$} -- (sub.west);

\draw[->] (inputu) node[above right]{$u$} -- (W2.west);

\draw[->] (inputu-|sub) node[branch]{} -- (sub.south);

\draw[->] (sub.east) -- (W1.west);

\draw[->] ($(sub.west)+(-0.6, 0)$) node[branch]{} |- (outputv) node[above left]{$v$};

\draw[->] (W1.east) -- (output1)node[above left]{$z_1$};

\draw[->] (W2.east) -- (output2)node[above left]{$z_2$};

\end{tikzpicture}\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[block={4.0cm}{3.0cm}, fill=black!10!white] (P) {};

\node[above] at (P.north) {$P(s)$};

\node[block, below=0.2 of P] (H2) {$H_2(s)$};

\coordinate[] (inputw) at ($(P.south west)!0.75!(P.north west) + (-0.7, 0)$);

\coordinate[] (inputu) at ($(P.south west)!0.35!(P.north west) + (-0.4, 0)$);

\coordinate[] (output1) at ($(P.south east)!0.75!(P.north east) + ( 0.7, 0)$);

\coordinate[] (output2) at ($(P.south east)!0.35!(P.north east) + ( 0.7, 0)$);

\coordinate[] (outputv) at ($(P.south east)!0.1!(P.north east) + ( 0.4, 0)$);

\node[block, left=1.4 of output1] (W1){$W_1(s)$};

\node[block, left=1.4 of output2] (W2){$W_2(s)$};

\node[addb={+}{}{}{}{-}, left=of W1] (sub) {};

\draw[->] (inputw) node[above right]{$w$} -- (sub.west);

\draw[->] (inputu-|sub) node[branch]{} -- (sub.south);

\draw[->] (sub.east) -- (W1.west);

\draw[->] ($(sub.west)+(-0.6, 0)$) node[branch]{} |- (outputv) |- (H2.east);

\draw[->] (H2.west) -| (inputu) -- (W2.west);

\draw[->] (W1.east) -- (output1)node[above left]{$z_1$};

\draw[->] (W2.east) -- (output2)node[above left]{$z_2$};

\end{tikzpicture}Applying standard $\mathcal{H}_\infty$ synthesis to the generalized plant $P(s)$ is equivalent to finding a stable filter $H_2(s)$ that, based on input $v$, generates an output signal $u$ such that the $\mathcal{H}_\infty$ norm of the system shown in Figure ref:fig:detail_control_sensor_h_infinity_robust_fusion_fb from $w$ to $[z_1, \ z_2]$ does not exceed unity, as expressed in eqref:eq:detail_control_sensor_hinf_syn_obj.

\begin{equation}\label{eq:detail_control_sensor_hinf_syn_obj} ≤ft\|\begin{matrix} \left(1 - H_2(s)\right) W_1(s) \\ H_2(s) W_2(s) \end{matrix}\right\|_∞ ≤ 1

\end{equation}

By defining $H_1(s)$ as the complement of $H_2(s)$ (eqref:eq:detail_control_sensor_definition_H1), the $\mathcal{H}_\infty$ synthesis objective becomes equivalent to eqref:eq:detail_control_sensor_hinf_problem, ensuring that conditions eqref:eq:detail_control_sensor_hinf_cond_h1 and eqref:eq:detail_control_sensor_hinf_cond_h2 are satisfied.

\begin{equation}\label{eq:detail_control_sensor_definition_H1} H_1(s) ≜ 1 - H_2(s)

\end{equation}

\begin{equation}\label{eq:detail_control_sensor_hinf_problem} ≤ft\|\begin{matrix} H_1(s) W_1(s) \\ H_2(s) W_2(s) \end{matrix}\right\|_∞ ≤ 1

\end{equation}

Therefore, applying $\mathcal{H}_\infty$ synthesis to the standard plant $P(s)$ (eqref:eq:detail_control_sensor_generalized_plant) generates two filters, $H_2(s)$ and $H_1(s) \triangleq 1 - H_2(s)$, that are complementary as required by eqref:eq:detail_control_sensor_comp_filter_problem_form, with norms bounded by the specified constraints in eqref:eq:detail_control_sensor_hinf_cond_h1 and eqref:eq:detail_control_sensor_hinf_cond_h2.

It should be noted that there exists only an implication (not an equivalence) between the $\mathcal{H}_\infty$ norm condition in eqref:eq:detail_control_sensor_hinf_problem and the initial synthesis objectives in eqref:eq:detail_control_sensor_hinf_cond_h1 and eqref:eq:detail_control_sensor_hinf_cond_h2. Consequently, the optimization may be somewhat conservative with respect to the set of filters on which it operates (see cite:&skogestad07_multiv_feedb_contr,Chap. 2.8.3).

Weighting Functions Design

Weighting functions play a crucial role during synthesis by specifying the maximum allowable norms for the complementary filters. The proper design of these weighting functions is essential for the successful implementation of the proposed $\mathcal{H}_\infty$ synthesis approach.

Three key considerations should guide the design of weighting functions. First, only proper and stable transfer functions should be employed. Second, the order of the weighting functions should remain reasonably small to minimize computational costs associated with solving the optimization problem and to facilitate practical implementation of the filters (as the order of the synthesized filters equals the sum of the weighting functions' orders). Third, the fundamental limitations imposed by the complementary property (eqref:eq:detail_control_sensor_comp_filter) must be respected, which implies that $|H_1(j\omega)|$ and $|H_2(j\omega)|$ cannot both be made small at the same frequency.

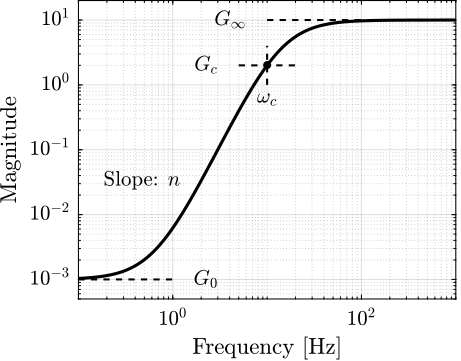

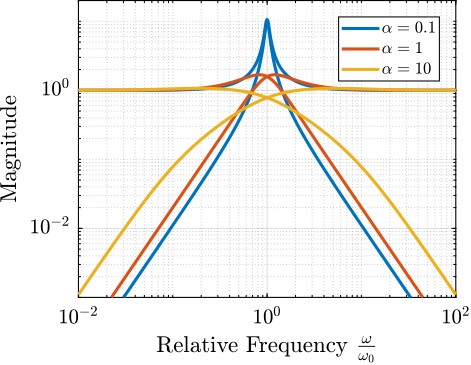

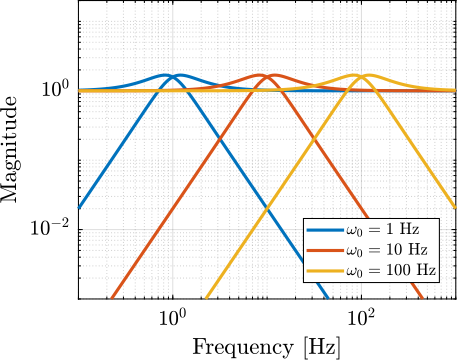

When designing complementary filters, it is typically desirable to specify their slopes, "blending" frequency, and maximum gains at low and high frequencies. To facilitate the expression of these specifications, formula eqref:eq:detail_control_sensor_weight_formula is proposed for the design of weighting functions. The parameters in this formula are $G_0 = \lim_{\omega \to 0} |W(j\omega)|$ (the low-frequency gain), $G_\infty = \lim_{\omega \to \infty} |W(j\omega)|$ (the high-frequency gain), $G_c = |W(j\omega_c)|$ (the gain at a specific frequency $\omega_c$ in $\si{rad/s}$), and $n$ (the slope between high and low frequency, which also corresponds to the order of the weighting function). The typical magnitude response of a weighting function generated using eqref:eq:detail_control_sensor_weight_formula is illustrated in Figure ref:fig:detail_control_sensor_weight_formula.

\hfill

\begin{equation}\label{eq:detail_control_sensor_weight_formula} W(s) = ≤ft( \frac{ \hfill{} \frac{1}{ω_c} \sqrt{\frac{1 - ≤ft(\frac{G_0}{G_c}\right)^{\frac{2}{n}}}{1 - ≤ft(\frac{G_c}{G_∞}\right)^{\frac{2}{n}}}} s + ≤ft(\frac{G_0}{G_c}\right)^{\frac{1}{n}} }{ ≤ft(\frac{1}{G_∞}\right)^{\frac{1}{n}} \frac{1}{ω_c} \sqrt{\frac{1 - ≤ft(\frac{G_0}{G_c}\right)^{\frac{2}{n}}}{1 - ≤ft(\frac{G_c}{G_∞}\right)^{\frac{2}{n}}}} s + ≤ft(\frac{1}{G_c}\right)^{\frac{1}{n}} }\right)^n

\end{equation}

Validation of the proposed synthesis method

The proposed methodology for designing complementary filters is now applied to a simple example. Consider the design of two complementary filters $H_1(s)$ and $H_2(s)$ with the following requirements:

- The blending frequency should be approximately $\SI{10}{Hz}$

- The slope of $|H_1(j\omega)|$ should be $+2$ below $\SI{10}{Hz}$, with a low-frequency gain of $10^{-3}$

- The slope of $|H_2(j\omega)|$ should be $-3$ above $\SI{10}{Hz}$, with a high-frequency gain of $10^{-3}$

The first step involves translating these requirements by appropriately designing the weighting functions. The formula proposed in eqref:eq:detail_control_sensor_weight_formula is employed for this purpose. The parameters used are summarized in Table ref:tab:detail_control_sensor_weights_params. The inverse magnitudes of the designed weighting functions, which represent the maximum allowable norms of the complementary filters, are depicted by the dashed lines in Figure ref:fig:detail_control_sensor_hinf_filters_results.

%% Synthesis of Complementary Filters using H-infinity synthesis

% Design of the Weighting Functions

W1 = generateWF('n', 3, 'w0', 2*pi*10, 'G0', 1000, 'Ginf', 1/10, 'Gc', 0.45);

W2 = generateWF('n', 2, 'w0', 2*pi*10, 'G0', 1/10, 'Ginf', 1000, 'Gc', 0.45);

% Generalized Plant

P = [W1 -W1;

0 W2;

1 0];

% H-Infinity Synthesis

[H2, ~, gamma, ~] = hinfsyn(P, 1, 1,'TOLGAM', 0.001, 'METHOD', 'ric', 'DISPLAY', 'on');

% Define H1 to be the complementary of H2

H1 = 1 - H2;

% The function generateCF can also be used to synthesize the complementary filters.

% [H1, H2] = generateCF(W1, W2);| Parameter | $W_1(s)$ | $W_2(s)$ |

|---|---|---|

| $G_0$ | $0.1$ | $1000$ |

| $G_{\infty}$ | $1000$ | $0.1$ |

| $\omega_c$ | $2 \pi \cdot 10$ | $2 \pi \cdot 10$ |

| $G_c$ | $0.45$ | $0.45$ |

| $n$ | $2$ | $3$ |

\hfill

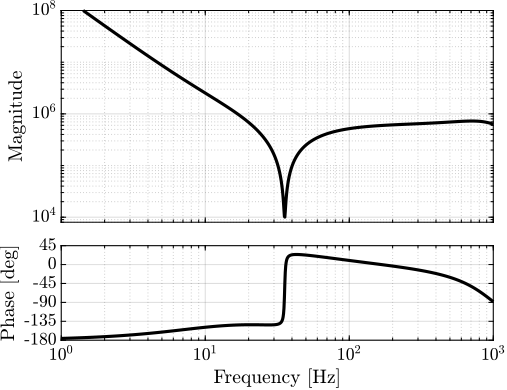

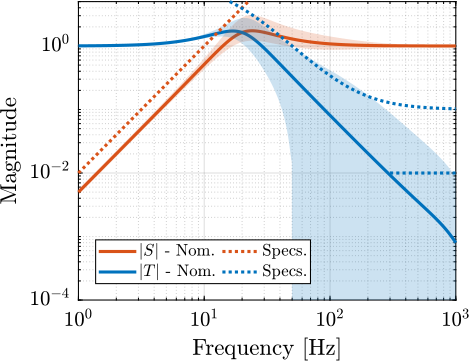

Standard $\mathcal{H}_\infty$ synthesis is then applied to the generalized plant shown in Figure ref:fig:detail_control_sensor_h_infinity_robust_fusion_plant. This yields the filter $H_2(s)$ that minimizes the $\mathcal{H}_\infty$ norm from input $w$ to outputs $[z_1,\ z_2]^{\intercal}$. The resulting $\mathcal{H}_\infty$ norm is found to be close to unity, indicating successful synthesis: the norms of the complementary filters remain below the specified upper bounds. This is confirmed by the Bode plots of the obtained complementary filters in Figure ref:fig:detail_control_sensor_hinf_filters_results. This straightforward example demonstrates that the proposed methodology for shaping complementary filters is both simple and effective.

Synthesis of a set of three complementary filters

<<ssec:detail_control_sensor_hinf_three_comp_filters>>

Certain applications necessitate the fusion of more than two sensors cite:&stoten01_fusion_kinet_data_using_compos_filter;&fonseca15_compl. At LIGO, for example, a super sensor is formed by merging three distinct sensors: an LVDT, a seismometer, and a geophone cite:&matichard15_seism_isolat_advan_ligo.

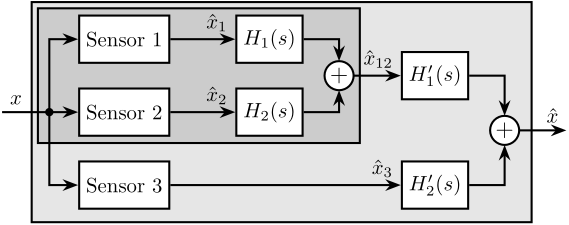

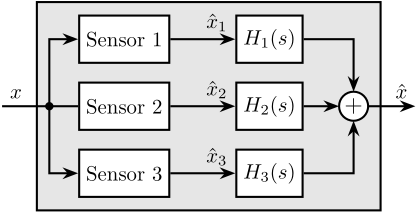

For merging $n>2$ sensors with complementary filters, two architectural approaches are possible, as illustrated in Figure ref:fig:detail_control_sensor_fusion_three. Fusion can be implemented either "sequentially," utilizing $n-1$ sets of two complementary filters (Figure ref:fig:detail_control_sensor_fusion_three_sequential), or "in parallel," employing a single set of $n$ complementary filters (Figure ref:fig:detail_control_sensor_fusion_three_parallel).

While conventional sensor fusion synthesis techniques can be applied to the sequential approach, parallel architecture implementation requires a novel synthesis method for multiple complementary filters. Previous literature has offered only simple analytical formulas for this purpose cite:&stoten01_fusion_kinet_data_using_compos_filter;&fonseca15_compl. This section presents a generalization of the proposed complementary filter synthesis method to address this gap.

\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[branch] (x) at (0, 0);

\node[block, right=0.4 of x] (sensor2) {Sensor 2};

\node[block, above=0.4 of sensor2] (sensor1) {Sensor 1};

\node[block, below=0.4 of sensor2] (sensor3) {Sensor 3};

\node[block, right=1.1 of sensor1](H1){$H_1(s)$};

\node[block, right=1.1 of sensor2](H2){$H_2(s)$};

\node[addb] (add) at ($0.5*(H1.east)+0.5*(H2.east)+(0.6, 0)$){};

\node[block, right=0.8 of add](H1p) {$H_1^\prime(s)$};

\node[block] (H2p) at (H1p|-sensor3) {$H_2^\prime(s)$};

\node[addb] (addp) at ($0.5*(H1p.east)+0.5*(H2p.east)+(0.6, 0)$){};

\draw[->] ($(x)+(-0.8, 0)$) node[above right]{$x$} -- (sensor2.west);

\draw[->] (x.center) |- (sensor1.west);

\draw[->] (x.center) |- (sensor3.west);

\draw[->] (sensor1.east) -- (H1.west) node[above left]{$\hat{x}_1$};

\draw[->] (sensor2.east) -- (H2.west) node[above left]{$\hat{x}_2$};

\draw[->] (sensor3.east) -- (H2p.west) node[above left]{$\hat{x}_3$};

\draw[->] (H1) -| (add.north);

\draw[->] (H2) -| (add.south);

\draw[->] (add.east) -- (H1p.west) node[above left]{$\hat{x}_{12}$};

\draw[->] (H1p) -| (addp.north);

\draw[->] (H2p) -| (addp.south);

\draw[->] (addp.east) -- ++(0.8, 0) node[above left]{$\hat{x}$};

\begin{scope}[on background layer]

\node[fit={(x.west|-sensor3.south) (sensor1.north-|addp.east)}, fill=black!10!white, draw, inner sep=6pt] (supersensor) {};

\node[fit={(x.west|-sensor1.north) (add.east|-sensor2.south)}, fill=black!20!white, draw, inner sep=3pt] (superinertialsensor) {};

\end{scope}

\end{tikzpicture}\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[branch] (x) at (0, 0);

\node[block, right=0.4 of x] (sensor2) {Sensor 2};

\node[block, above=0.3 of sensor2] (sensor1) {Sensor 1};

\node[block, below=0.3 of sensor2] (sensor3) {Sensor 3};

\node[block, right=1.1 of sensor1](H1){$H_1(s)$};

\node[block, right=1.1 of sensor2](H2){$H_2(s)$};

\node[block, right=1.1 of sensor3](H3){$H_3(s)$};

\node[addb, right=0.6 of H2](add){};

\draw[->] (x.center) |- (sensor1.west);

\draw[] ($(x)+(-0.8, 0)$) node[above right]{$x$} -- (sensor2.west);

\draw[->] (x.center) |- (sensor3.west);

\draw[->] (sensor1.east) -- (H1.west) node[above left]{$\hat{x}_1$};

\draw[->] (sensor2.east) -- (H2.west) node[above left]{$\hat{x}_2$};

\draw[->] (sensor3.east) -- (H3.west) node[above left]{$\hat{x}_3$};

\draw[->] (H1) -| (add.north);

\draw[->] (H2) -- (add.west);

\draw[->] (H3) -| (add.south);

\draw[->] (add.east) -- ++(0.8, 0) node[above left]{$\hat{x}$};

\begin{scope}[on background layer]

\node[fit={(H3.south-|x) (H1.north-|add.east)}, fill=black!10!white, draw, inner sep=6pt] (supersensor) {};

\end{scope}

\end{tikzpicture}The synthesis objective is to compute a set of $n$ stable transfer functions $[H_1(s),\ H_2(s),\ \dots,\ H_n(s)]$ that satisfy conditions eqref:eq:detail_control_sensor_hinf_cond_compl_gen and eqref:eq:detail_control_sensor_hinf_cond_perf_gen.

\begin{subequations}\label{eq:detail_control_sensor_hinf_problem_gen}

\begin{align} & \sum_{i=1}^n H_i(s) = 1 \label{eq:detail_control_sensor_hinf_cond_compl_gen} \\ & \left| H_i(j\omega) \right| < \frac{1}{\left| W_i(j\omega) \right|}, \quad \forall \omega,\ i = 1 \dots n \label{eq:detail_control_sensor_hinf_cond_perf_gen} \end{align}\end{subequations}

The transfer functions $[W_1(s),\ W_2(s),\ \dots,\ W_n(s)]$ are weights selected to specify the maximum complementary filters' norm during synthesis.

This synthesis objective is closely related to the one described in Section ref:ssec:detail_control_sensor_hinf_method, and the proposed synthesis method represents a generalization of the approach previously presented. A set of $n$ complementary filters can be shaped by applying standard $\mathcal{H}_\infty$ synthesis to the generalized plant $P_n(s)$ described by eqref:eq:detail_control_sensor_generalized_plant_n_filters.

\begin{equation}\label{eq:detail_control_sensor_generalized_plant_n_filters}

\begin{bmatrix} z_1 \\ \vdots \\ z_n \\ v \end{bmatrix} = P_n(s) \begin{bmatrix} w \\ u_1 \\ \vdots \\ u_{n-1} \end{bmatrix} = P_n(s) \begin{bmatrix} w \\ u_1 \\ \vdots \\ u_{n-1} \end{bmatrix}; \quad

P_n(s) = \begin{bmatrix}

W_1 & -W_1 & … & … & -W_1

0 & W_2 & 0 & … & 0

\vdots & \ddots & \ddots & \ddots & \vdots

\vdots & & \ddots & \ddots & 0

0 & … & … & 0 & W_n

1 & 0 & … & … & 0

\end{bmatrix}

\end{equation}

If the synthesis is successful, a set of $n-1$ filters $[H_2(s),\ H_3(s),\ \dots,\ H_n(s)]$ is obtained such that eqref:eq:detail_control_sensor_hinf_syn_obj_gen is satisfied.

\begin{equation}\label{eq:detail_control_sensor_hinf_syn_obj_gen} ≤ft\|\begin{matrix} \left(1 - \left[ H_2(s) + H_3(s) + \dots + H_n(s) \right]\right) W_1(s) \\ H_2(s) W_2(s) \\ \vdots \\ H_n(s) W_n(s) \end{matrix}\right\|_∞ ≤ 1

\end{equation}

$H_1(s)$ is then defined using eqref:eq:detail_control_sensor_h1_comp_h2_hn, which ensures the complementary property for the set of $n$ filters eqref:eq:detail_control_sensor_hinf_cond_compl_gen. Condition eqref:eq:detail_control_sensor_hinf_cond_perf_gen is satisfied through eqref:eq:detail_control_sensor_hinf_syn_obj_gen.

\begin{equation}\label{eq:detail_control_sensor_h1_comp_h2_hn} H_1(s) ≜ 1 - \big[ H_2(s) + H_3(s) + … + H_n(s) \big]

\end{equation}

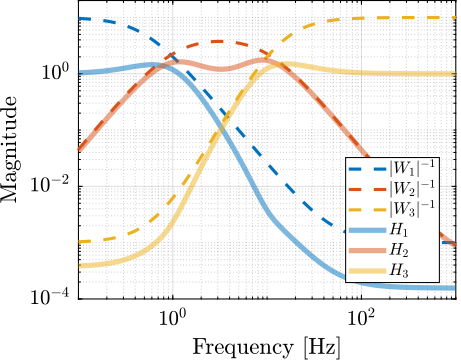

To validate the proposed method for synthesizing a set of three complementary filters, an example is provided. The sensors to be merged are a displacement sensor (effective from DC up to $\SI{1}{Hz}$), a geophone (effective from $1$ to $\SI{10}{Hz}$), and an accelerometer (effective above $\SI{10}{Hz}$). Three weighting functions are designed using formula eqref:eq:detail_control_sensor_weight_formula, and their inverse magnitudes are shown in Figure ref:fig:detail_control_sensor_three_complementary_filters_results (dashed curves).

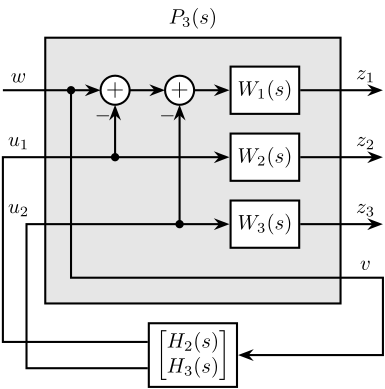

Consider the generalized plant $P_3(s)$ shown in Figure ref:fig:detail_control_sensor_comp_filter_three_hinf_fb, which is also described by eqref:eq:detail_control_sensor_generalized_plant_three_filters.

\begin{equation}\label{eq:detail_control_sensor_generalized_plant_three_filters} \begin{bmatrix} z_1 \\ z_2 \\ z_3 \\ v \end{bmatrix} = P_3(s) \begin{bmatrix} w \\ u_1 \\ u_2 \end{bmatrix}; \quad P_3(s) = \begin{bmatrix}W_1(s) & -W_1(s) & -W_1(s) \\ 0 & \phantom{+}W_2(s) & 0 \\ 0 & 0 & \phantom{+}W_3(s) \\ 1 & 0 & 0 \end{bmatrix} = P_3(s) \begin{bmatrix} w \\ u_1 \\ u_2 \end{bmatrix}; \quad P_3(s) = \begin{bmatrix}W_1(s) & -W_1(s) & -W_1(s) \\ 0 & \phantom{+}W_2(s) & 0 \\ 0 & 0 & \phantom{+}W_3(s) \\ 1 & 0 & 0 \end{bmatrix}; \quad P_3(s) = \begin{bmatrix}W_1(s) & -W_1(s) & -W_1(s) \\ 0 & \phantom{+}W_2(s) & 0 \\ 0 & 0 & \phantom{+}W_3(s) \\ 1 & 0 & 0 \end{bmatrix}

\end{equation}

\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[block={5.0cm}{4.5cm}, fill=black!10!white] (P) {};

\node[above] at (P.north) {$P_3(s)$};

\coordinate[] (inputw) at ($(P.south west)!0.8!(P.north west) + (-0.7, 0)$);

\coordinate[] (inputu) at ($(P.south west)!0.4!(P.north west) + (-0.7, 0)$);

\coordinate[] (output1) at ($(P.south east)!0.8!(P.north east) + (0.7, 0)$);

\coordinate[] (output2) at ($(P.south east)!0.55!(P.north east) + (0.7, 0)$);

\coordinate[] (output3) at ($(P.south east)!0.3!(P.north east) + (0.7, 0)$);

\coordinate[] (outputv) at ($(P.south east)!0.1!(P.north east) + (0.7, 0)$);

\node[block, left=1.4 of output1] (W1){$W_1(s)$};

\node[block, left=1.4 of output2] (W2){$W_2(s)$};

\node[block, left=1.4 of output3] (W3){$W_3(s)$};

\node[addb={+}{}{}{}{-}, left=of W1] (sub1) {};

\node[addb={+}{}{}{}{-}, left=of sub1] (sub2) {};

\node[block, below=0.3 of P, opacity=0] (H) {$\begin{bmatrix}H_2(s) \\ H_3(s)\end{bmatrix}$};

\draw[->] (inputw) node[above right](w){$w$} -- (sub2.west);

\draw[->] (W3-|sub1)node[branch]{} -- (sub1.south);

\draw[->] (W2-|sub2)node[branch]{} -- (sub2.south);

\draw[->] ($(sub2.west)+(-0.5, 0)$) node[branch]{} |- (outputv);

\draw[->] (inputu|-W2) -- (W2.west);

\draw[->] (inputu|-W3) -- (W3.west);

\draw[->] (sub2.east) -- (sub1.west);

\draw[->] (sub1.east) -- (W1.west);

\draw[->] (W1.east) -- (output1)node[above left](z){$z_1$};

\draw[->] (W2.east) -- (output2)node[above left]{$z_2$};

\draw[->] (W3.east) -- (output3)node[above left]{$z_3$};

\node[above] at (W2-|w){$u_1$};

\node[above] at (W3-|w){$u_2$};

\node[above] at (outputv-|z){$v$};

\end{tikzpicture}\tikzset{block/.default={0.8cm}{0.8cm}}

\tikzset{addb/.append style={scale=0.7}}

\tikzset{node distance=0.6}

\begin{tikzpicture}

\node[block={5.0cm}{4.5cm}, fill=black!10!white] (P) {};

\node[above] at (P.north) {$P_3(s)$};

\coordinate[] (inputw) at ($(P.south west)!0.8!(P.north west) + (-0.7, 0)$);

\coordinate[] (inputu) at ($(P.south west)!0.4!(P.north west) + (-0.7, 0)$);

\coordinate[] (output1) at ($(P.south east)!0.8!(P.north east) + (0.7, 0)$);

\coordinate[] (output2) at ($(P.south east)!0.55!(P.north east) + (0.7, 0)$);

\coordinate[] (output3) at ($(P.south east)!0.3!(P.north east) + (0.7, 0)$);

\coordinate[] (outputv) at ($(P.south east)!0.1!(P.north east) + (0.7, 0)$);

\node[block, left=1.4 of output1] (W1){$W_1(s)$};

\node[block, left=1.4 of output2] (W2){$W_2(s)$};

\node[block, left=1.4 of output3] (W3){$W_3(s)$};

\node[addb={+}{}{}{}{-}, left=of W1] (sub1) {};

\node[addb={+}{}{}{}{-}, left=of sub1] (sub2) {};

\node[block, below=0.3 of P] (H) {$\begin{bmatrix}H_2(s) \\ H_3(s)\end{bmatrix}$};

\draw[->] (inputw) node[above right](w){$w$} -- (sub2.west);

\draw[->] (W3-|sub1)node[branch]{} -- (sub1.south);

\draw[->] (W2-|sub2)node[branch]{} -- (sub2.south);

\draw[->] ($(sub2.west)+(-0.5, 0)$) node[branch]{} |- (outputv) |- (H.east);

\draw[->] ($(H.south west)!0.7!(H.north west)$) -| (inputu|-W2) -- (W2.west);

\draw[->] ($(H.south west)!0.3!(H.north west)$) -| ($(inputu|-W3)+(0.4, 0)$) -- (W3.west);

\draw[->] (sub2.east) -- (sub1.west);

\draw[->] (sub1.east) -- (W1.west);

\draw[->] (W1.east) -- (output1)node[above left](z){$z_1$};

\draw[->] (W2.east) -- (output2)node[above left]{$z_2$};

\draw[->] (W3.east) -- (output3)node[above left]{$z_3$};

\node[above] at (W2-|w){$u_1$};

\node[above] at (W3-|w){$u_2$};

\node[above] at (outputv-|z){$v$};

\end{tikzpicture}Standard $\mathcal{H}_\infty$ synthesis is performed on the generalized plant $P_3(s)$. Two filters, $H_2(s)$ and $H_3(s)$, are obtained such that the $\mathcal{H}_\infty$ norm of the closed-loop transfer from $w$ to $[z_1,\ z_2,\ z_3]$ of the system in Figure ref:fig:detail_control_sensor_comp_filter_three_hinf_fb is less than one. Filter $H_1(s)$ is defined using eqref:eq:detail_control_sensor_h1_compl_h2_h3, thus ensuring the complementary property of the obtained set of filters.

\begin{equation}\label{eq:detail_control_sensor_h1_compl_h2_h3} H_1(s) ≜ 1 - \big[ H_2(s) + H_3(s) \big]

\end{equation}

Figure ref:fig:detail_control_sensor_three_complementary_filters_results displays the three synthesized complementary filters (solid lines), confirming the successful synthesis.

%% Synthesis of a set of three complementary filters

% Design of the Weighting Functions

W1 = generateWF('n', 2, 'w0', 2*pi*1, 'G0', 1/10, 'Ginf', 1000, 'Gc', 0.5);

W2 = 0.22*(1 + s/2/pi/1)^2/(sqrt(1e-4) + s/2/pi/1)^2*(1 + s/2/pi/10)^2/(1 + s/2/pi/1000)^2;

W3 = generateWF('n', 3, 'w0', 2*pi*10, 'G0', 1000, 'Ginf', 1/10, 'Gc', 0.5);

% Generalized plant for the synthesis of 3 complementary filters

P = [W1 -W1 -W1;

0 W2 0 ;

0 0 W3;

1 0 0];

% Standard H-Infinity Synthesis

[H, ~, gamma, ~] = hinfsyn(P, 1, 2,'TOLGAM', 0.001, 'METHOD', 'ric', 'DISPLAY', 'on');

% Synthesized H2 and H3 filters

H2 = tf(H(1));

H3 = tf(H(2));

% H1 is defined as the complementary filter of H2 and H3

H1 = 1 - H2 - H3;Conclusion

A new method for designing complementary filters using the $\mathcal{H}_\infty$ synthesis has been proposed. This approach allows shaping of the filter magnitudes through the use of weighting functions during synthesis. This capability is particularly valuable in practice since the characteristics of the super sensor are directly linked to the complementary filters' magnitude. Consequently, typical sensor fusion objectives can be effectively translated into requirements on the magnitudes of the filters.

For the Nano Active Stabilization System (NASS), the High Authority Control-Integral Force Feedback (HAC-IFF) strategy was found to perform well and to offer the advantages of being both intuitive to understand and straightforward to tune. Looking forward, it would be interesting to investigate how sensor fusion (particularly between the force sensor and external metrology) compares to the HAC-IFF approach in terms of performance and robustness.

Decoupling

<<sec:detail_control_decoupling>>

Introduction ignore

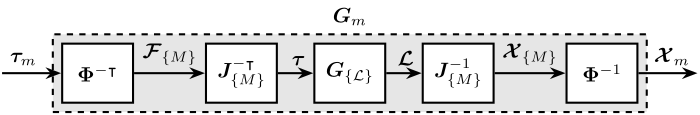

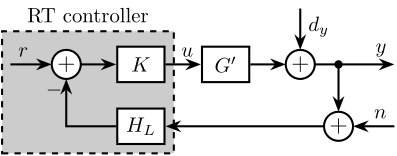

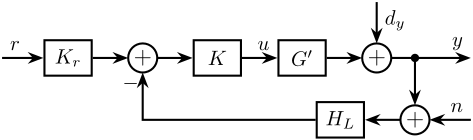

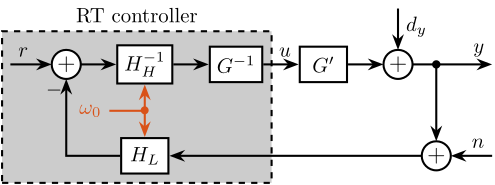

The control of parallel manipulators (and any MIMO system in general) typically involves a two-step approach: first decoupling the plant dynamics using various strategies, which will be discussed in this section, followed by the application of SISO control for the decoupled plant (discussed in section ref:sec:detail_control_cf).

When sensors are integrated within the struts, decentralized control may be applied, as the system is already well decoupled at low frequency. For instance, cite:&furutani04_nanom_cuttin_machin_using_stewar implemented a system where each strut consists of piezoelectric stack actuators and eddy current displacement sensors, with separate PI controllers for each strut. A similar control architecture was proposed in cite:&du14_piezo_actuat_high_precis_flexib using strain gauge sensors integrated in each strut.

An alternative strategy involves decoupling the system in the Cartesian frame using Jacobian matrices. As demonstrated during the study of Stewart platform kinematics, Jacobian matrices can be utilized to map actuator forces to forces and torques applied on the top platform. This approach enables the implementation of controllers in a defined frame. It has been applied with various sensor types including force sensors cite:&mcinroy00_desig_contr_flexur_joint_hexap, relative displacement sensors cite:&kim00_robus_track_contr_desig_dof_paral_manip, and inertial sensors cite:&li01_simul_vibrat_isolat_point_contr;&abbas14_vibrat_stewar_platf. The Cartesian frame in which the system is decoupled is typically chosen at the point of interest (i.e., where the motion is of interest) or at the center of mass.

Modal control represents another noteworthy decoupling strategy, wherein the "local" plant inputs and outputs are mapped to the modal space. In this approach, multiple SISO plants, each corresponding to a single mode, can be controlled independently. This decoupling strategy has been implemented for active damping applications cite:&holterman05_activ_dampin_based_decoup_colloc_contr, which is logical as it is often desirable to dampen specific modes. The strategy has also been employed in cite:&pu11_six_degree_of_freed_activ for vibration isolation purposes using geophones, and in cite:&yang19_dynam_model_decoup_contr_flexib using force sensors.

Another completely different strategy, is to use implement a multivariable control directly on the coupled system. $\mathcal{H}_\infty$ and $\mu\text{-synthesis}$ were applied to a Stewart platform model in cite:&lei08_multi_objec_robus_activ_vibrat. In cite:&xie17_model_contr_hybrid_passiv_activ, decentralized force feedback was first applied, followed by $\mathcal{H}_2$ synthesis for vibration isolation based on accelerometers. $\mathcal{H}_\infty$ synthesis was also employed in cite:&jiao18_dynam_model_exper_analy_stewar for active damping based on accelerometers. cite:&thayer02_six_axis_vibrat_isolat_system compared $\mathcal{H}_\infty$ synthesis with decentralized control in the frame of the struts. Their experimental closed-loop results indicated that the $\mathcal{H}_\infty$ controller did not outperform the decentralized controller in the frame of the struts. These limitations were attributed to the model's poor ability to predict off-diagonal dynamics, which is crucial for $\mathcal{H}_\infty$ synthesis.

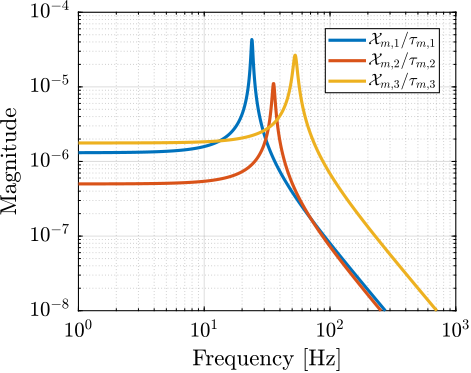

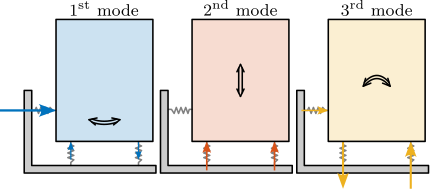

The purpose of this section is to compare several methods for the decoupling of parallel manipulators, an analysis that appears to be lacking in the literature. The analysis begins in Section ref:ssec:detail_control_decoupling_model with the introduction of a simplified parallel manipulator model that serves as the foundation for evaluating various decoupling strategies. Sections ref:ssec:detail_control_decoupling_jacobian through ref:ssec:detail_control_decoupling_svd systematically examine three distinct approaches: Jacobian matrix decoupling, modal decoupling, and Singular Value Decomposition (SVD) decoupling, respectively. The comparative assessment of these three methodologies, along with concluding observations, is provided in Section ref:ssec:detail_control_decoupling_comp.

Test Model

<<ssec:detail_control_decoupling_model>>

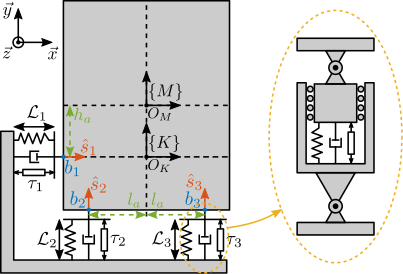

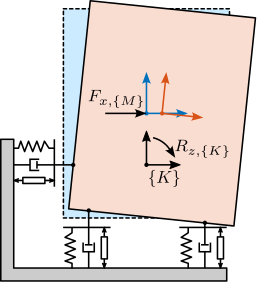

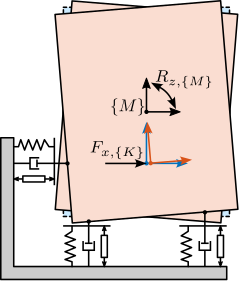

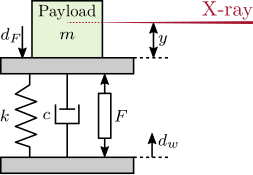

Instead of utilizing the Stewart platform for comparing decoupling strategies, a simplified parallel manipulator is employed to facilitate a more straightforward analysis. The system illustrated in Figure ref:fig:detail_control_decoupling_model_test is used for this purpose. It possesses three degrees of freedom (DoF) and incorporates three parallel struts. Being a fully parallel manipulator, it is therefore quite similar to the Stewart platform.

Two reference frames are defined within this model: frame $\{M\}$ with origin $O_M$ at the center of mass of the solid body, and frame $\{K\}$ with origin $O_K$ at the center of stiffness of the parallel manipulator.

\hfill

| Description | Value | |

|---|---|---|

| $l_a$ | $0.5\,m$ | |

| $h_a$ | $0.2\,m$ | |

| $k$ | Actuator stiffness | $10\,N/\mu m$ |

| $c$ | Actuator damping | $200\,Ns/m$ |

| $m$ | Payload mass | $40\,\text{kg}$ |

| $I$ | Payload $R_z$ inertia | $5\,\text{kg}m^2$ |

The equations of motion are derived by applying Newton's second law to the suspended mass, expressed at its center of mass eqref:eq:detail_control_decoupling_model_eom, where $\bm{\mathcal{X}}_{\{M\}}$ represents the two translations and one rotation with respect to the center of mass, and $\bm{\mathcal{F}}_{\{M\}}$ denotes the forces and torque applied at the center of mass.

\begin{equation}\label{eq:detail_control_decoupling_model_eom}

\bm{M}_{\{M\}} \ddot{\bm{\mathcal{X}}}_{\{M\}}(t) = ∑ \bm{\mathcal{F}}_{\{M\}}(t), \quad

\bm{\mathcal{X}}_{\{M\}} = \begin{bmatrix}

x \\

y \\

R_z

\end{bmatrix}, \quad \bm{\mathcal{F}}_{\{M\}} = \begin{bmatrix}

F_x

F_y

M_z

\end{bmatrix}

\end{equation}

The Jacobian matrix $\bm{J}_{\{M\}}$ is employed to map the spring, damping, and actuator forces to XY forces and Z torque expressed at the center of mass eqref:eq:detail_control_decoupling_jacobian_CoM.

\begin{equation}\label{eq:detail_control_decoupling_jacobian_CoM}

\bm{J}_{\{M\}} = \begin{bmatrix}

1 & 0 & h_a

0 & 1 & -l_a

0 & 1 & l_a \\

\end{bmatrix}

\end{equation}

Subsequently, the equation of motion relating the actuator forces $\tau$ to the motion of the mass $\bm{\mathcal{X}}_{\{M\}}$ is derived eqref:eq:detail_control_decoupling_plant_cartesian.

\begin{equation}\label{eq:detail_control_decoupling_plant_cartesian} \bm{M}_{\{M\}} \ddot{\bm{\mathcal{X}}}_{\{M\}}(t) + \bm{J}_{\{M\}}∫ercal \bm{\mathcal{C}} \bm{J}_{\{M\}} \dot{\bm{\mathcal{X}}}_{\{M\}}(t) + \bm{J}_{\{M\}}∫ercal \bm{\mathcal{K}} \bm{J}_{\{M\}} \bm{\mathcal{X}}_{\{M\}}(t) = \bm{J}_{\{M\}}∫ercal \bm{τ}(t)

\end{equation}

The matrices representing the payload inertia, actuator stiffness, and damping are shown in eqref:eq:detail_control_decoupling_system_matrices.

\begin{equation}\label{eq:detail_control_decoupling_system_matrices}

\bm{M}_{\{M\}} = \begin{bmatrix}

m & 0 & 0 \\

0 & m & 0 \\

0 & 0 & I

\end{bmatrix}, \quad

\bm{\mathcal{K}} = \begin{bmatrix}

k & 0 & 0 \\

0 & k & 0 \\

0 & 0 & k

\end{bmatrix}, \quad

\bm{\mathcal{K}} = \begin{bmatrix}

k & 0 & 0 \\

0 & k & 0 \\

0 & 0 & k

\end{bmatrix}, \quad

\bm{\mathcal{C}} = \begin{bmatrix}

c & 0 & 0

0 & c & 0

0 & 0 & c

\end{bmatrix}

\end{equation}

The parameters employed for the subsequent analysis are summarized in Table ref:tab:detail_control_decoupling_test_model_params, which includes values for geometric parameters ($l_a$, $h_a$), mechanical properties (actuator stiffness $k$ and damping $c$), and inertial characteristics (payload mass $m$ and rotational inertia $I$).

Control in the frame of the struts

<<ssec:detail_control_decoupling_decentralized>>

The dynamics in the frame of the struts are first examined. The equation of motion relating actuator forces $\bm{\mathcal{\tau}}$ to strut relative motion $\bm{\mathcal{L}}$ is derived from equation eqref:eq:detail_control_decoupling_plant_cartesian by mapping the Cartesian motion of the mass to the relative motion of the struts using the Jacobian matrix $\bm{J}_{\{M\}}$ defined in eqref:eq:detail_control_decoupling_jacobian_CoM. The obtained transfer function from $\bm{\mathcal{\tau}}$ to $\bm{\mathcal{L}}$ is shown in eqref:eq:detail_control_decoupling_plant_decentralized.

\begin{tikzpicture}

\node[block] (Gl) {$\bm{G}_{\{\mathcal{L}\}}$};

% Connections and labels

\draw[<-] (Gl.west) -- ++(-0.8, 0) node[above right]{$\bm{\tau}$};

\draw[->] (Gl.east) -- ++( 0.8, 0) node[above left]{$\bm{\mathcal{L}}$};

\end{tikzpicture}\begin{equation}\label{eq:detail_control_decoupling_plant_decentralized} \frac{\bm{\mathcal{L}}}{\bm{\mathcal{τ}}}(s) = \bm{G}_{\mathcal{L}}(s) = ≤ft( \bm{J}_{\{M\}}-∫ercal \bm{M}_{\{M\}} \bm{J}_{\{M\}}-1 s^2 + \bm{\mathcal{C}} s + \bm{\mathcal{K}} \right)-1

\end{equation}

At low frequencies, the plant converges to a diagonal constant matrix whose diagonal elements are related to the actuator stiffnesses eqref:eq:detail_control_decoupling_plant_decentralized_low_freq. At high frequencies, the plant converges to the mass matrix mapped in the frame of the struts, which is generally highly non-diagonal.

\begin{equation}\label{eq:detail_control_decoupling_plant_decentralized_low_freq} \bm{G}_{\mathcal{L}}(jω) \xrightarrow[ω → 0]{} \bm{\mathcal{K}-1}

\end{equation}

%% Compute Equation of motion

l = 1; h=2;

la = 0.5; % Horizontal position of actuators [m]

ha = 0.2; % Vertical of actuators [m]

m = 40; % Payload mass [kg]

I = 5; % Payload rotational inertia [kg m^2]

c = 2e2; % Actuator Damping [N/(m/s)]

k = 1e6; % Actuator Stiffness [N/m]

% Unit vectors of the actuators

s1 = [1;0];

s2 = [0;1];

s3 = [0;1];

% Stiffnesss and Damping matrices of the struts

Kr = diag([k,k,k]);

Cr = diag([c,c,c]);

% Location of the joints with respect to the center of mass

Mb1 = [-l/2;-ha];

Mb2 = [-la; -h/2];

Mb3 = [ la; -h/2];

% Jacobian matrix (Center of Mass)

J_CoM = [s1', Mb1(1)*s1(2)-Mb1(2)*s1(1);

s2', Mb2(1)*s2(2)-Mb2(2)*s2(1);

s3', Mb3(1)*s3(2)-Mb3(2)*s3(1)];

% Mass Matrix in frame {M}

M = diag([m,m,I]);

% Stiffness Matrix in frame {M}

K = J_CoM'*Kr*J_CoM;

% Damping Matrix in frame {M}

C = J_CoM'*Cr*J_CoM;

% Plant in the frame of the struts

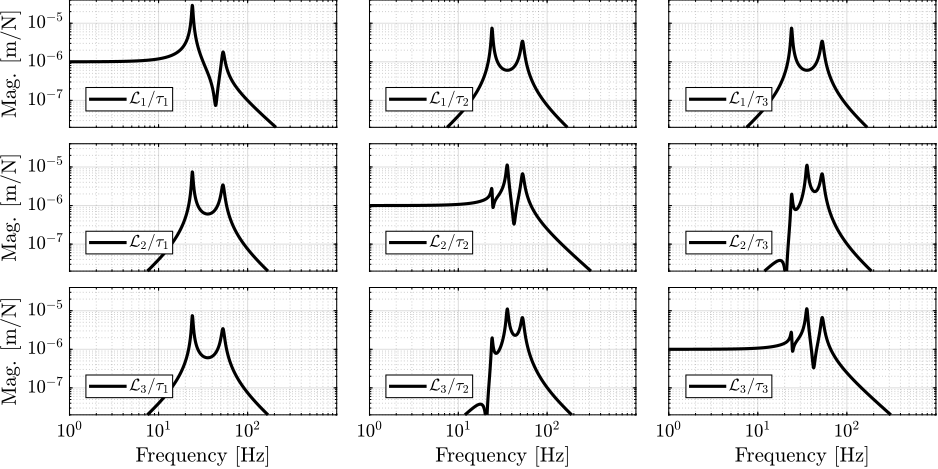

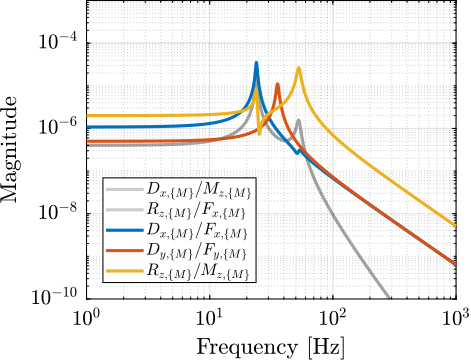

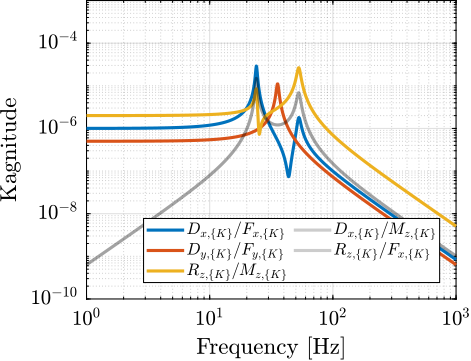

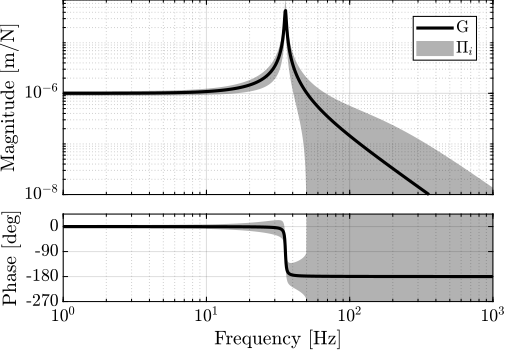

G_L = J_CoM*inv(M*s^2 + C*s + K)*J_CoM';The magnitude of the coupled plant $\bm{G}_{\mathcal{L}}$ is illustrated in Figure ref:fig:detail_control_decoupling_coupled_plant_bode. This representation confirms that at low frequencies (below the first suspension mode), the plant is well decoupled. Depending on the symmetry present in the system, certain diagonal elements may exhibit identical values, as demonstrated for struts 2 and 3 in this example.

Jacobian Decoupling

<<ssec:detail_control_decoupling_jacobian>>

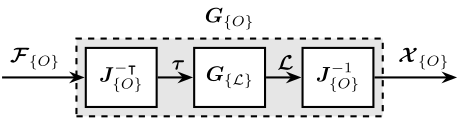

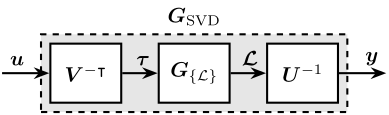

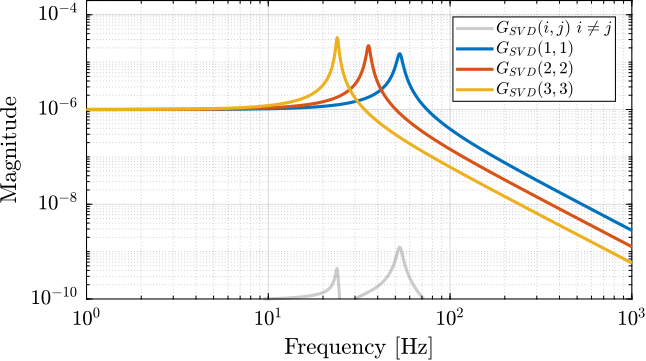

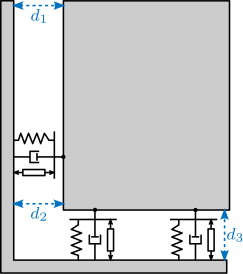

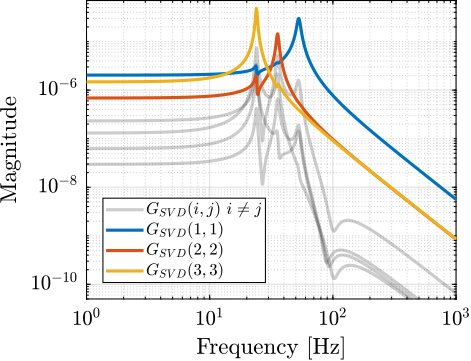

Jacobian Matrix