128 KiB

ESRF Double Crystal Monochromator - Lookup Tables

- Introduction

- Schematic

- First Analysis

- LUT creation from experimental data

- Test Matlab LUT

- LUT Without

mcoil - Optimal Trajectory to make the LUT

- Piezoelectric LUT

- Bibliography

This report is also available as a pdf.

Introduction ignore

A Fast Jack is composed of one stepper motor and a piezoelectric stack in series.

The stepper motor is directly driving (i.e. without a reducer) a ball screw with a pitch of 1mm (i.e. 1 stepper motor turn makes a 1mm linear motion).

The stepper motor is doing the coarse displacement while the piezoelectric stack is only there to compensate all the motion errors of the stepper motor.

A Lookup Tables (LUT) is used to compensate for repeatable errors of the stepper motors. This has several goals:

- Reduce errors down to the stroke of the piezoelectric stack actuator

- Reduce errors above the bandwidth of the feedback controller

Schematic

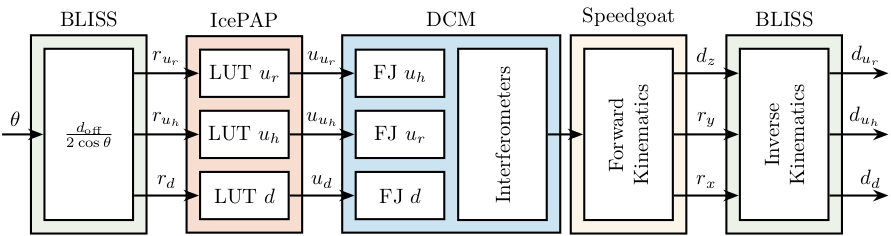

In order to measure the errors induced by the fast jacks, we have to make some scans, and measure simultaneously:

- The wanted fast jack position: signal/step sent by the IcePAP

- The actual (measured) position

The experimental setup to perform this is shown in Figure fig:block_diagram_lut_stepper.

The procedure is the following:

- A scan on the Bragg angle $\theta$ is generated from Bliss

- Reference paths $[r_{u_r},\ r_{u_h},\ r_{d}]$ are sent to the IcePAP

- Initially, the LUT inside the IcePAP is not changing the reference path

- The IcePAP generates some steps $[u_{u_r},\ u_{u_h},\ u_{d}]$ that are sent to the fast jacks

- The motion of the crystals $[d_z,\ r_y,\ r_x]$ is measured with the interferometers and computed in the Speedgoat

- Finally, the corresponding motion $[d_{u_r},\ r_{u_h},\ r_d]$ of the fast jack is computed afterwards in BLISS

The measured motion of the fast jacks $[d_{u_r},\ r_{u_h},\ r_d]$ can be compared with the IcePAP steps $[u_{u_r},\ u_{u_h},\ u_{d}]$ in order to create the LUT inside the IcePAP.

\definecolor{myblue}{rgb}{0, 0.447, 0.741}

\definecolor{myred}{rgb}{0.8500, 0.325, 0.098}

\definecolor{mygreen}{rgb}{0.639, 0.745, 0.549}

\definecolor{myyellow}{rgb}{0.922, 0.796, 0.545}

\begin{tikzpicture}

% Blocks

\node[block={1.5cm}{2.9cm}] (traj) at (0,0){$\frac{d_{\text{off}}}{2 \cos \theta}$};

\node[block={1.5cm}{0.8cm}, right=1.1 of traj] (lut_uh) {LUT $u_h$};

\node[block={1.5cm}{0.8cm}, above=0.2 of lut_uh] (lut_ur) {LUT $u_r$};

\node[block={1.5cm}{0.8cm}, below=0.2 of lut_uh] (lut_d) {LUT $d$};

\node[block={1.5cm}{0.8cm}, right=1.1 of lut_ur] (fj_ur) {FJ $u_h$};

\node[block={1.5cm}{0.8cm}, right=1.1 of lut_uh] (fj_uh) {FJ $u_r$};

\node[block={1.5cm}{0.8cm}, right=1.1 of lut_d] (fj_d) {FJ $d$};

\node[block={1.5cm}{2.9cm}, right=0.2 of fj_uh] (int) {\rotatebox{90}{Interferometers}};

\node[block={1.5cm}{2.9cm}, right=0.6 of int] (Js) {\rotatebox{90}{\parbox[c]{2.0cm}{\centering Forward Kinematics}}};

\node[block={1.5cm}{2.9cm}, right=1.1 of Js] (Ja) {\rotatebox{90}{\parbox[c]{2.0cm}{\centering Inverse Kinematics}}};

% Signals

\draw[->] ($(traj.west) + (-0.7, 0)$)node[above right]{$\theta$} -- (traj.west);

\draw[->] (lut_ur-|traj.east) --node[midway, above]{$r_{u_r}$} (lut_ur.west);

\draw[->] (lut_uh-|traj.east) --node[midway, above]{$r_{u_h}$} (lut_uh.west);

\draw[->] (lut_d -|traj.east) --node[midway, above]{$r_{d}$} (lut_d.west);

\draw[->] (lut_ur.east) --node[midway, above]{$u_{u_r}$} (fj_ur.west);

\draw[->] (lut_uh.east) --node[midway, above]{$u_{u_h}$} (fj_uh.west);

\draw[->] (lut_d.east) --node[midway, above]{$u_{d}$} (fj_d.west);

\draw[->] (int.east) -- (Js.west);

\draw[->] (Js.east|-fj_ur) --node[midway, above]{$d_z$} (Ja.west|-fj_ur);

\draw[->] (Js.east|-fj_uh) --node[midway, above]{$r_y$} (Ja.west|-fj_uh);

\draw[->] (Js.east|-fj_d) --node[midway, above]{$r_x$} (Ja.west|-fj_d) ;

\draw[->] (Ja.east|-fj_ur) -- ++(1.0, 0)node[above left]{$d_{u_r}$};

\draw[->] (Ja.east|-fj_uh) -- ++(1.0, 0)node[above left]{$d_{u_h}$};

\draw[->] (Ja.east|-fj_d) -- ++(1.0, 0)node[above left]{$d_{d}$};

\begin{scope}[on background layer]

\node[fit={(fj_d.south west) (int.north east)}, fill=myblue!20!white, draw, inner sep=6pt] (dcm) {};

\node[fit={(Js.south west) (Js.north east)}, fill=myyellow!20!white, draw, inner sep=6pt] (speedgoat) {};

\node[fit={(lut_d.south west) (lut_ur.north east)}, fill=myred!20!white, draw, inner sep=6pt] (icepap) {};

\node[fit={(traj.south west) (traj.north east)}, fill=mygreen!20!white, draw, inner sep=6pt] (bliss_1) {};

\node[fit={(Ja.south west) (Ja.north east)}, fill=mygreen!20!white, draw, inner sep=6pt] (bliss_2) {};

\node[above] at (dcm.north) {DCM};

\node[above] at (speedgoat.north) {Speedgoat};

\node[above] at (icepap.north) {IcePAP};

\node[above] at (bliss_1.north) {BLISS};

\node[above] at (bliss_2.north) {BLISS};

\end{scope}

\end{tikzpicture}First Analysis

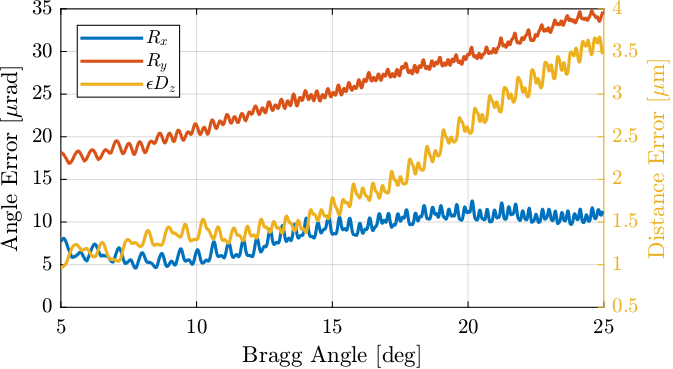

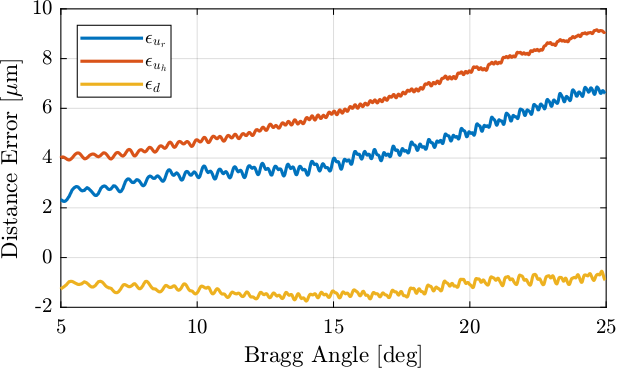

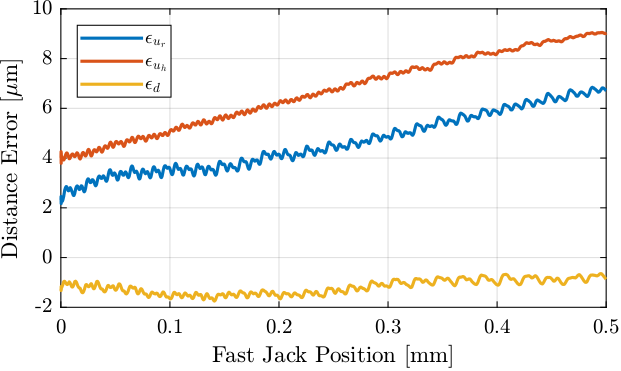

Patterns in the Fast Jack motion errors

In order to understand what should be the "sampling distance" for the lookup table of the stepper motor, we have to analyze the displacement errors induced by the stepper motor.

Let's load the measurements of one bragg angle scan without any LUT.

%% Load Data of the new LUT method

ol_bragg = (pi/180)*1e-5*double(h5read('Qutools_test_0001.h5','/33.1/instrument/trajmot/data')); % Bragg angle [rad]

ol_dzw = 10.5e-3./(2*cos(ol_bragg)); % Wanted distance between crystals [m]

ol_dz = 1e-9*double(h5read('Qutools_test_0001.h5','/33.1/instrument/xtal_111_dz_filter/data')); % Dz distance between crystals [m]

ol_dry = 1e-9*double(h5read('Qutools_test_0001.h5','/33.1/instrument/xtal_111_dry_filter/data')); % Ry [rad]

ol_drx = 1e-9*double(h5read('Qutools_test_0001.h5','/33.1/instrument/xtal_111_drx_filter/data')); % Rx [rad]

ol_t = 1e-6*double(h5read('Qutools_test_0001.h5','/33.1/instrument/time/data')); % Time [s]

ol_ddz = ol_dzw-ol_dz; % Distance Error between crystals [m]Now let's convert the errors from the frame of the crystal to the frame of the fast jacks (inverse kinematics problem) using the Jacobian matrix.

%% Compute Fast Jack position errors

% Jacobian matrix for Fast Jacks and 111 crystal

J_a_111 = [1, 0.14, -0.1525

1, 0.14, 0.0675

1, -0.14, 0.0425];

ol_de_111 = [ol_ddz'; ol_dry'; ol_drx'];

% Fast Jack position errors

ol_de_fj = J_a_111*ol_de_111;

ol_fj_ur = ol_de_fj(1,:);

ol_fj_uh = ol_de_fj(2,:);

ol_fj_d = ol_de_fj(3,:);Let's now identify this pattern as a function of the fast-jack position.

As we want to done frequency Fourier transform, we need to have uniform sampling along the fast jack position.

To do so, the function resample is used.

Xs = 0.1e-6; % Sampling Distance [m]

%% Re-sampled data with uniform spacing [m]

ol_fj_ur_u = resample(ol_fj_ur, ol_dzw, 1/Xs);

ol_fj_uh_u = resample(ol_fj_uh, ol_dzw, 1/Xs);

ol_fj_d_u = resample(ol_fj_d, ol_dzw, 1/Xs);

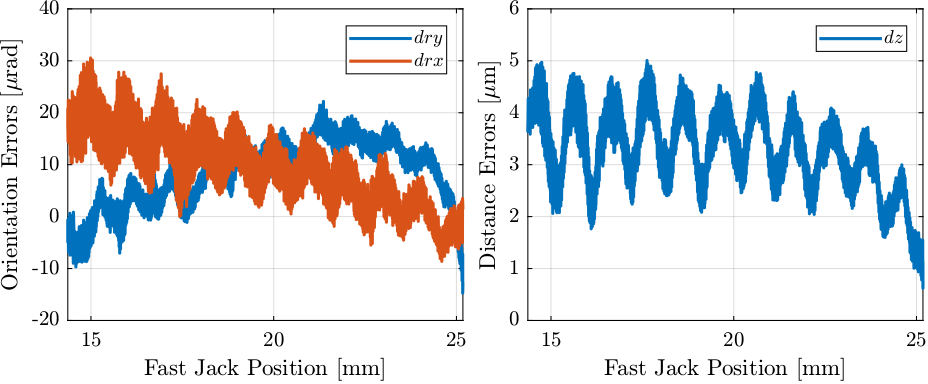

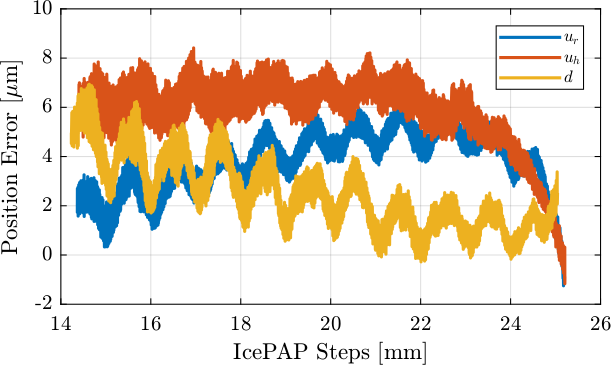

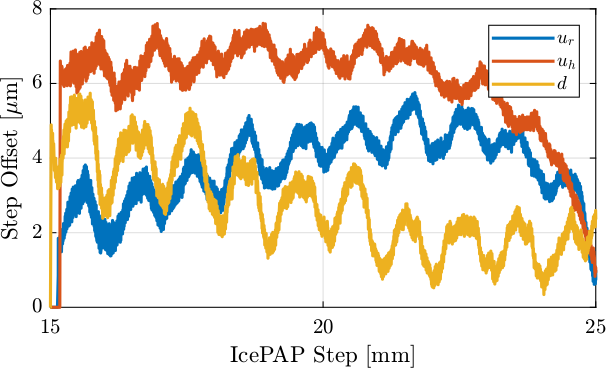

ol_fj_u = Xs*[1:length(ol_fj_ur_u)]; % Sampled Jack PositionThe result is shown in Figure fig:exp_without_lut_fj_pos_errors_distance.

Let's now perform a Power Spectral Analysis of the measured displacement errors of the Fast Jack.

% Hanning Windows with 250um width

win = hanning(floor(400e-6/Xs));

% Power Spectral Density [m2/(1/m)]

[S_fj_ur, f] = pwelch(ol_fj_ur_u-mean(ol_fj_ur_u), win, 0, [], 1/Xs);

[S_fj_uh, ~] = pwelch(ol_fj_uh_u-mean(ol_fj_uh_u), win, 0, [], 1/Xs);

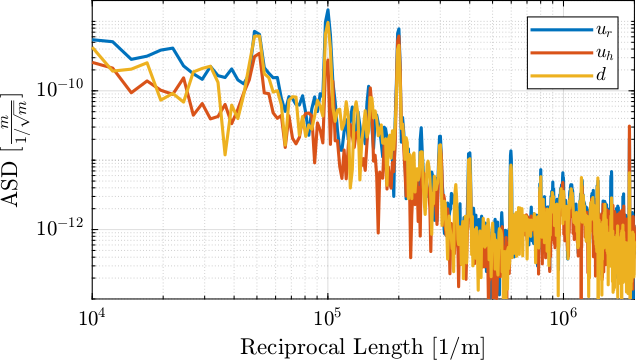

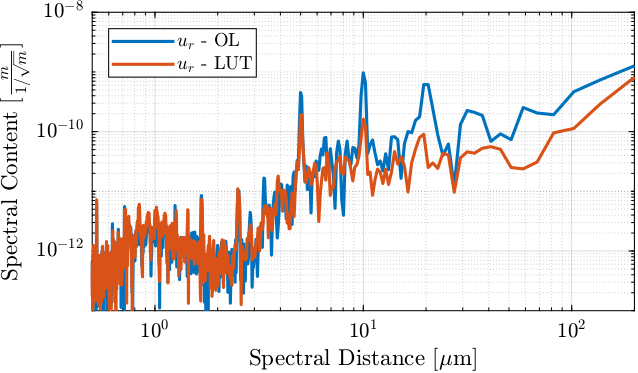

[S_fj_d, ~] = pwelch(ol_fj_d_u -mean(ol_fj_d_u ), win, 0, [], 1/Xs);As shown in Figure fig:exp_without_lut_wavenumber_asd, we can see a fundamental "reciprocal length" of $5 \cdot 10^4\,[1/m]$ and its harmonics. This corresponds to a length of $\frac{1}{5\cdot 10^4} = 20\,[\mu m]$.

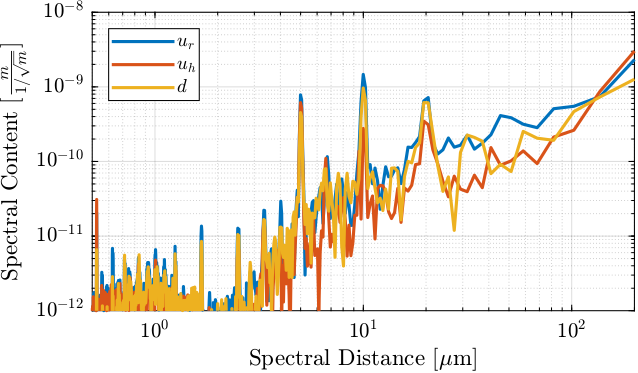

Instead of looking at that as a function of the reciprocal length, we can look at it as a function of the spectral distance (Figure fig:exp_without_lut_spectral_content_fj_error).

We see that the errors have a pattern with "spectral distances" equal to $5\,[\mu m]$, $10\,[\mu m]$, $20\,[\mu m]$ and smaller harmonics.

Let's try to understand these results. One turn of the stepper motor corresponds to a vertical motion of 1mm. The stepper motor has 50 pairs of poles, therefore one pair of pole corresponds to a motion of $20\,[\mu m]$ which is the fundamental "spectral distance" we observe.

CPS_ur = flip(-cumtrapz(flip(f), flip(S_fj_ur)));

CPS_uh = flip(-cumtrapz(flip(f), flip(S_fj_uh)));

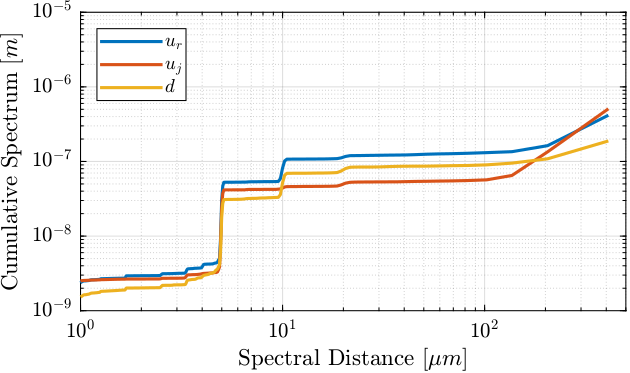

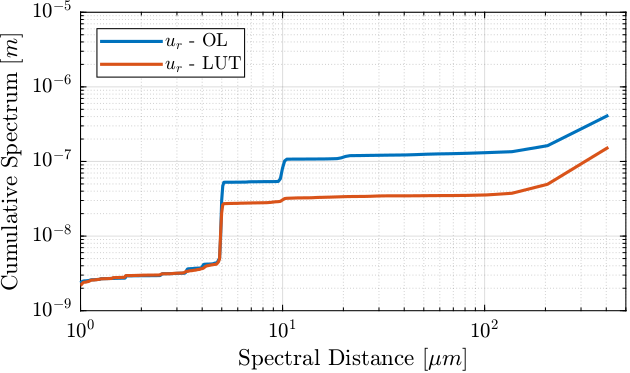

CPS_d = flip(-cumtrapz(flip(f), flip(S_fj_d)));From Figure fig:exp_without_lut_cas_pos_error, we can see that if the motion errors with a period of $5\,[\mu m]$ and $10\,[\mu m]$ can be dealt with the lookup table, this will reduce a lot the positioning errors of the fast jack.

%% Cumulative Spectrum

figure;

hold on;

plot(1e6./f, sqrt(CPS_ur), 'DisplayName', '$u_r$');

plot(1e6./f, sqrt(CPS_uh), 'DisplayName', '$u_j$');

plot(1e6./f, sqrt(CPS_d), 'DisplayName', '$d$');

hold off;

set(gca, 'xscale', 'log'); set(gca, 'yscale', 'log');

xlabel('Spectral Distance [$\mu m$]'); ylabel('Cumulative Spectrum [$m$]')

xlim([1, 500]); ylim([1e-9, 1e-5]);

legend('location', 'northwest');Experimental Data - Current Method

The current used method is an iterative one.

%% Load Experimental Data

ol_bragg = double(h5read('first_beam_0001.h5','/31.1/instrument/trajmot/data'));

ol_drx = h5read('first_beam_0001.h5','/31.1/instrument/xtal_111_drx_filter/data');

lut_1_bragg = double(h5read('first_beam_0001.h5','/32.1/instrument/trajmot/data'));

lut_1_drx = h5read('first_beam_0001.h5','/32.1/instrument/xtal_111_drx_filter/data');

lut_2_bragg = double(h5read('first_beam_0001.h5','/33.1/instrument/trajmot/data'));

lut_2_drx = h5read('first_beam_0001.h5','/33.1/instrument/xtal_111_drx_filter/data');

lut_3_bragg = double(h5read('first_beam_0001.h5','/34.1/instrument/trajmot/data'));

lut_3_drx = h5read('first_beam_0001.h5','/34.1/instrument/xtal_111_drx_filter/data');

lut_4_bragg = double(h5read('first_beam_0001.h5','/36.1/instrument/trajmot/data'));

lut_4_drx = h5read('first_beam_0001.h5','/36.1/instrument/xtal_111_drx_filter/data');

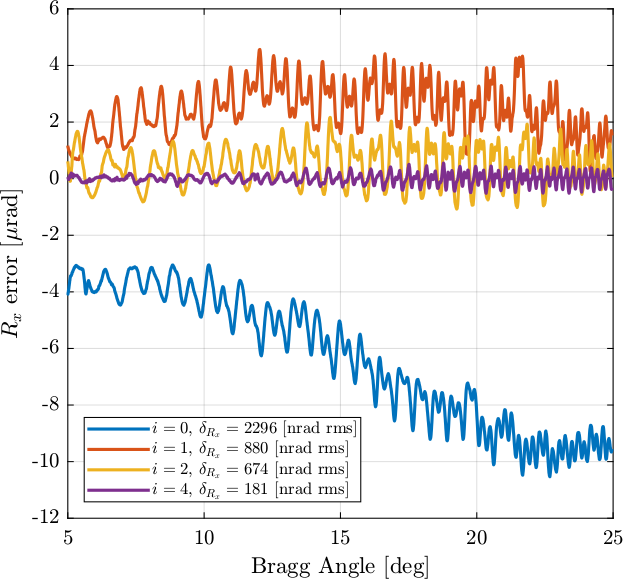

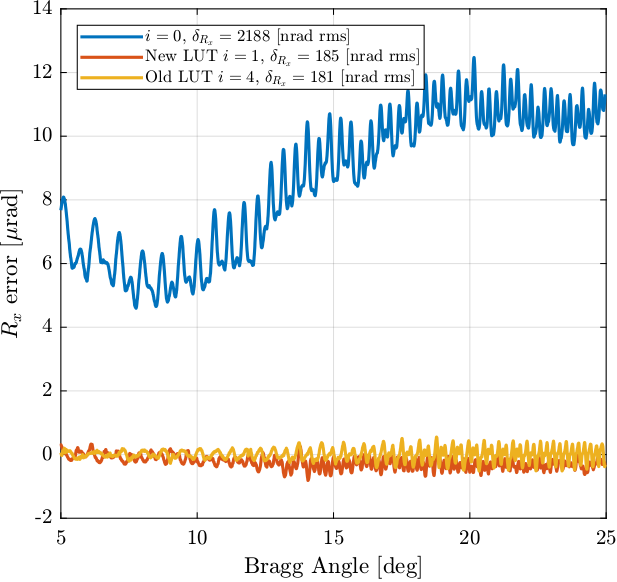

The relative orientation of the two 111 mirrors in the $x$ directions are compared in Figure fig:lut_old_method_exp_data for several iterations.

We can see that after the first iteration, the orientation error has an opposite sign as for the case without LUT.

Simulation

In this section, we suppose that we are in the frame of one fast jack (all transformations are already done), and we wish to create a LUT for one fast jack.

Let's say with make a Bragg angle scan between 10deg and 60deg during 100s.

Fs = 10e3; % Sample Frequency [Hz]

t = 0:1/Fs:10; % Time vector [s]

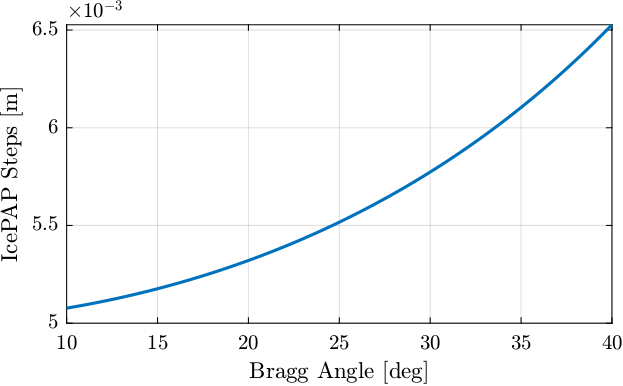

theta = linspace(10, 40, length(t)); % Bragg Angle [deg]The IcePAP steps are following the theoretical formula:

\begin{equation} d_z = \frac{d_{\text{off}}}{2 \cos \theta} \end{equation}with $\theta$ the bragg angle and $d_{\text{off}} = 10\,mm$.

The motion to follow is then:

perfect_motion = 10e-3./(2*cos(theta*pi/180)); % Perfect motion [m]And the IcePAP is generated those steps:

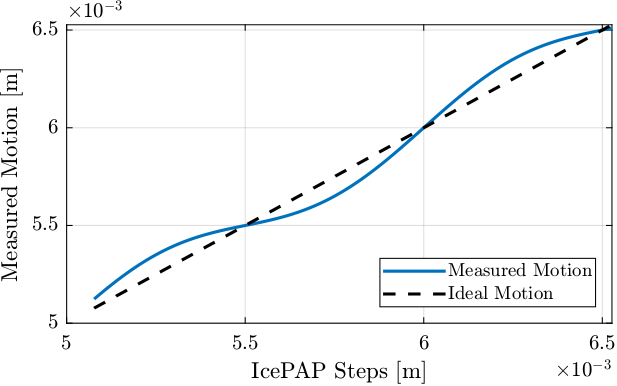

icepap_steps = perfect_motion; % IcePAP steps measured by Speedgoat [m]Then, we are measuring the motion of the Fast Jack using the Interferometer. The motion error is larger than in reality to be angle to see it more easily.

motion_error = 100e-6*sin(2*pi*perfect_motion/1e-3); % Error motion [m]

measured_motion = perfect_motion + motion_error; % Measured motion of the Fast Jack [m]Let's now compute the lookup table. For each micrometer of the IcePAP step, another step is associated that correspond to a position closer to the wanted position.

%% Get range for the LUT

% We correct only in the range of tested/measured motion

lut_range = round(1e6*min(icepap_steps)):round(1e6*max(icepap_steps)); % IcePAP steps [um]

%% Initialize the LUT

lut = zeros(size(lut_range));

%% For each um in this range

for i = 1:length(lut_range)

% Get points indices where the measured motion is closed to the wanted one

close_points = measured_motion > 1e-6*lut_range(i) - 500e-9 & measured_motion < 1e-6*lut_range(i) + 500e-9;

% Get the corresponding closest IcePAP step

lut(i) = round(1e6*mean(icepap_steps(close_points))); % [um]

endThe current LUT implementation is the following:

motion_error_lut = zeros(size(lut_range));

for i = 1:length(lut_range)

% Get points indices where the icepap step is close to the wanted one

close_points = icepap_steps > 1e-6*lut_range(i) - 500e-9 & icepap_steps < 1e-6*lut_range(i) + 500e-9;

% Get the corresponding motion error

motion_error_lut(i) = lut_range(i) + (lut_range(i) - round(1e6*mean(measured_motion(close_points)))); % [um]

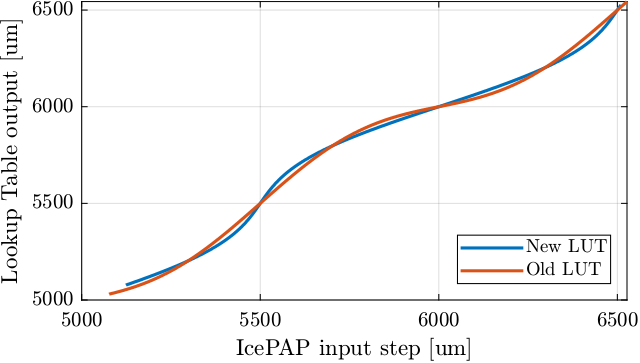

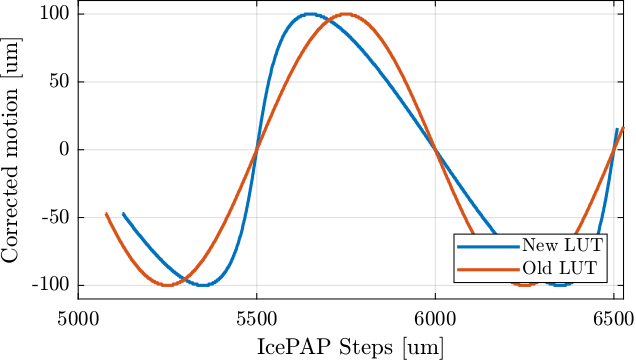

endLet's compare the two Lookup Table in Figure fig:lut_comparison_two_methods.

If we plot the "corrected steps" for all steps for both methods, we clearly see the difference (Figure fig:lut_correct_and_motion_error).

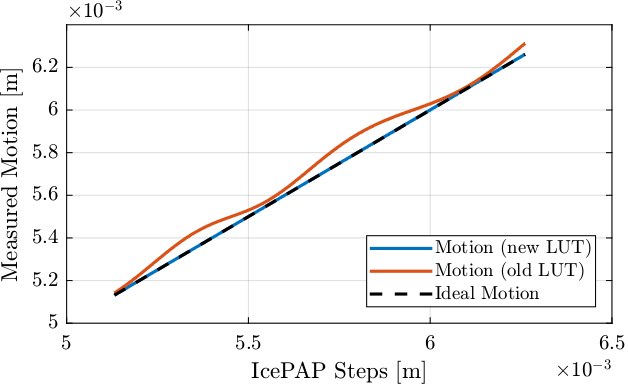

Let's now implement both LUT to see which implementation is correct.

motion_new = zeros(size(icepap_steps_output_new));

motion_old = zeros(size(icepap_steps_output_old));

for i = 1:length(icepap_steps_output_new)

[~, i_step] = min(abs(icepap_steps_output_new(i) - 1e6*icepap_steps));

motion_new(i) = measured_motion(i_step);

[~, i_step] = min(abs(icepap_steps_output_old(i) - 1e6*icepap_steps));

motion_old(i) = measured_motion(i_step);

endThe output motion with both LUT are shown in Figure fig:compare_old_new_lut_motion. It is confirmed that the new LUT is the correct one. Also, it is interesting to note that the old LUT gives an output motion that is above the ideal one, as was seen during the experiments.

Experimental Data - Proposed method (BLISS first implementation)

The new proposed method has been implemented and tested.

The result is shown in Figure fig:lut_comp_old_new_experiment. After only one iteration, the result is close to the previous method.

%% Load Data of the new LUT method

ol_new_bragg = double(h5read('Qutools_test_0001.h5','/33.1/instrument/trajmot/data'));

ol_new_drx = h5read('Qutools_test_0001.h5','/33.1/instrument/xtal_111_drx_filter/data');

lut_new_bragg = double(h5read('Qutools_test_0001.h5','/34.1/instrument/trajmot/data'));

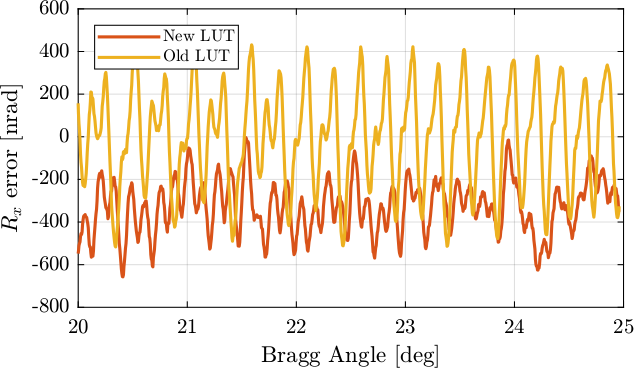

lut_new_drx = h5read('Qutools_test_0001.h5','/34.1/instrument/xtal_111_drx_filter/data');If we zoom on the 20deg to 25deg bragg angles, we can see that the new method has much less "periodic errors" as compared to the previous one which shows some patterns.

Comparison of the errors in the reciprocal length space

%% Load Data of the new LUT method

ol_bragg = (pi/180)*1e-5*double(h5read('Qutools_test_0001.h5','/33.1/instrument/trajmot/data'));

ol_dz = 1e-9*double(h5read('Qutools_test_0001.h5','/33.1/instrument/xtal_111_dz_filter/data'));

ol_dry = 1e-9*double(h5read('Qutools_test_0001.h5','/33.1/instrument/xtal_111_dry_filter/data'));

ol_drx = 1e-9*double(h5read('Qutools_test_0001.h5','/33.1/instrument/xtal_111_drx_filter/data'));

ol_dzw = 10.5e-3./(2*cos(ol_bragg)); % Wanted distance between crystals [m]

ol_t = 1e-6*double(h5read('Qutools_test_0001.h5','/33.1/instrument/time/data')); % Time [s]

ol_ddz = ol_dzw-ol_dz; % Distance Error between crystals [m]

lut_bragg = (pi/180)*1e-5*double(h5read('Qutools_test_0001.h5','/34.1/instrument/trajmot/data'));

lut_dz = 1e-9*double(h5read('Qutools_test_0001.h5','/34.1/instrument/xtal_111_dz_filter/data'));

lut_dry = 1e-9*double(h5read('Qutools_test_0001.h5','/34.1/instrument/xtal_111_dry_filter/data'));

lut_drx = 1e-9*double(h5read('Qutools_test_0001.h5','/34.1/instrument/xtal_111_drx_filter/data'));

lut_dzw = 10.5e-3./(2*cos(lut_bragg)); % Wanted distance between crystals [m]

lut_t = 1e-6*double(h5read('Qutools_test_0001.h5','/34.1/instrument/time/data')); % Time [s]

lut_ddz = lut_dzw-lut_dz; % Distance Error between crystals [m]%% Compute Fast Jack position errors

% Jacobian matrix for Fast Jacks and 111 crystal

J_a_111 = [1, 0.14, -0.1525

1, 0.14, 0.0675

1, -0.14, 0.0425];

ol_de_111 = [ol_ddz'; ol_dry'; ol_drx'];

% Fast Jack position errors

ol_de_fj = J_a_111*ol_de_111;

ol_fj_ur = ol_de_fj(1,:);

ol_fj_uh = ol_de_fj(2,:);

ol_fj_d = ol_de_fj(3,:);

lut_de_111 = [lut_ddz'; lut_dry'; lut_drx'];

% Fast Jack position errors

lut_de_fj = J_a_111*lut_de_111;

lut_fj_ur = lut_de_fj(1,:);

lut_fj_uh = lut_de_fj(2,:);

lut_fj_d = lut_de_fj(3,:);Xs = 0.1e-6; % Sampling Distance [m]

%% Re-sampled data with uniform spacing [m]

ol_fj_ur_u = resample(ol_fj_ur, ol_dzw, 1/Xs);

ol_fj_uh_u = resample(ol_fj_uh, ol_dzw, 1/Xs);

ol_fj_d_u = resample(ol_fj_d, ol_dzw, 1/Xs);

ol_fj_u = Xs*[1:length(ol_fj_ur_u)]; % Sampled Jack Position

% Only take first 500um

ol_fj_ur_u = ol_fj_ur_u(ol_fj_u<0.5e-3);

ol_fj_uh_u = ol_fj_uh_u(ol_fj_u<0.5e-3);

ol_fj_d_u = ol_fj_d_u (ol_fj_u<0.5e-3);

ol_fj_u = ol_fj_u (ol_fj_u<0.5e-3);%% Re-sampled data with uniform spacing [m]

lut_fj_ur_u = resample(lut_fj_ur, lut_dzw, 1/Xs);

lut_fj_uh_u = resample(lut_fj_uh, lut_dzw, 1/Xs);

lut_fj_d_u = resample(lut_fj_d, lut_dzw, 1/Xs);

lut_fj_u = Xs*[1:length(lut_fj_ur_u)]; % Sampled Jack Position

% Only take first 500um

lut_fj_ur_u = lut_fj_ur_u(lut_fj_u<0.5e-3);

lut_fj_uh_u = lut_fj_uh_u(lut_fj_u<0.5e-3);

lut_fj_d_u = lut_fj_d_u (lut_fj_u<0.5e-3);

lut_fj_u = lut_fj_u (lut_fj_u<0.5e-3);% Hanning Windows with 250um width

win = hanning(floor(400e-6/Xs));

% Power Spectral Density [m2/(1/m)]

[S_ol_ur, f] = pwelch(ol_fj_ur_u-mean(ol_fj_ur_u), win, 0, [], 1/Xs);

[S_ol_uh, ~] = pwelch(ol_fj_uh_u-mean(ol_fj_uh_u), win, 0, [], 1/Xs);

[S_ol_d, ~] = pwelch(ol_fj_d_u -mean(ol_fj_d_u ), win, 0, [], 1/Xs);

[S_lut_ur, ~] = pwelch(lut_fj_ur_u-mean(lut_fj_ur_u), win, 0, [], 1/Xs);

[S_lut_uh, ~] = pwelch(lut_fj_uh_u-mean(lut_fj_uh_u), win, 0, [], 1/Xs);

[S_lut_d, ~] = pwelch(lut_fj_d_u -mean(lut_fj_d_u ), win, 0, [], 1/Xs);As seen in Figure fig:effect_lut_on_psd_error_spatial, the LUT as an effect only on spatial errors with a period of at least few $\mu m$. This is very logical considering the $1\,\mu m$ sampling of the LUT in the IcePAP.

Let's now look at it in a cumulative way.

CPS_ol_ur = flip(-cumtrapz(flip(f), flip(S_ol_ur)));

CPS_ol_uh = flip(-cumtrapz(flip(f), flip(S_ol_uh)));

CPS_ol_d = flip(-cumtrapz(flip(f), flip(S_ol_d)));

CPS_lut_ur = flip(-cumtrapz(flip(f), flip(S_lut_ur)));

CPS_lut_uh = flip(-cumtrapz(flip(f), flip(S_lut_uh)));

CPS_lut_d = flip(-cumtrapz(flip(f), flip(S_lut_d)));%% Cumulative Spectrum

figure;

hold on;

plot(1e6./f, sqrt(CPS_ol_ur) , 'DisplayName', '$u_r$ - OL');

plot(1e6./f, sqrt(CPS_lut_ur), 'DisplayName', '$u_r$ - LUT');

hold off;

set(gca, 'xscale', 'log'); set(gca, 'yscale', 'log');

xlabel('Spectral Distance [$\mu m$]'); ylabel('Cumulative Spectrum [$m$]')

xlim([1, 500]); ylim([1e-9, 1e-5]);

legend('location', 'northwest');LUT creation from experimental data

Introduction ignore

In this section, the full process from measurement, filtering of data to generation of the LUT is detailed.

The computation is performed with Matlab.

Load Data

A Bragg scan is performed using thtraj and data are acquired using the fast_DAQ.

%% Load Raw Data

load("scan_10_70_lut_1.mat")Measured data are:

bragg: Bragg angle in degdz: distance between crystals in nmdry,drx: orientation errors between crystals in nradfjur,fjuh,fjd: generated steps by the IcePAP in tens of nm

All are sampled at 10kHz with no filtering.

First, convert all the data to SI units (rad, and m).

%% Convert Data to Standard Units

% Bragg Angle [rad]

bragg = pi/180*bragg;

% Rx rotation of 1st crystal w.r.t. 2nd crystal [rad]

drx = 1e-9*drx;

% Ry rotation of 1st crystal w.r.t. 2nd crystal [rad]

dry = 1e-9*dry;

% Z distance between crystals [m]

dz = 1e-9*dz;

% Z error between second crystal and first crystal [m]

ddz = 10.5e-3./(2*cos(bragg)) - dz;

% Steps for Ur motor [m]

fjur = 1e-8*fjur;

% Steps for Uh motor [m]

fjuh = 1e-8*fjuh;

% Steps for D motor [m]

fjd = 1e-8*fjd;IcePAP generated Steps

Here is how the steps of the IcePAP (fjsur, fjsuh and fjsd) are computed in mode A:

There is a first offset $\text{fjs}_0$ that is initialized once, and a second offset which is a function of fjsry and fjsrx.

Let's compute the offset which is a function of fjsry and fjsrx:

fjsry = 0.53171e-3; % [rad]

fjsrx = 0.144e-3; % [rad]

J_a_111 = [1, 0.14, -0.0675

1, 0.14, 0.1525

1, -0.14, 0.0425];

fjs_offset = J_a_111*[0; fjsry; fjsrx]; % ur,uh,d offsets [m]| 6.4719e-05 |

| 9.6399e-05 |

| -6.8319e-05 |

Let's now compute $\text{fjs}_0$ using first second of data where there is no movement and bragg axis is fixed at $\theta_0$:

\begin{equation} \text{fjs}_0 = \begin{bmatrix} \text{fjsur} \\ \text{fjsuh} \\ \text{fjsd} \end{bmatrix} (\theta_0) + \frac{10.5 \cdot 10^{-3}}{2 \cos (\theta_0)} - \bm{J}_{a,111} \cdot \begin{bmatrix} 0 \\ \text{fjsry} \\ \text{fjsrx} \end{bmatrix} \end{equation}FJ0 = ...

mean([fjur(time < 1), fjuh(time < 1), fjd(time < 1)])' ...

+ ones(3,1)*10.5e-3./(2*cos(mean(bragg(time < 1)))) ...

- fjs_offset; % [m]| 0.030427 |

| 0.030427 |

| 0.030427 |

Values are very close for all three axis. Therefore we take the mean of the three values for $\text{fjs}_0$.

FJ0 = mean(FJ0);This approximately corresponds to the distance between the crystals for a Bragg angle of 80 degrees:

10.5e-3/(2*cos(80*pi/180))0.030234

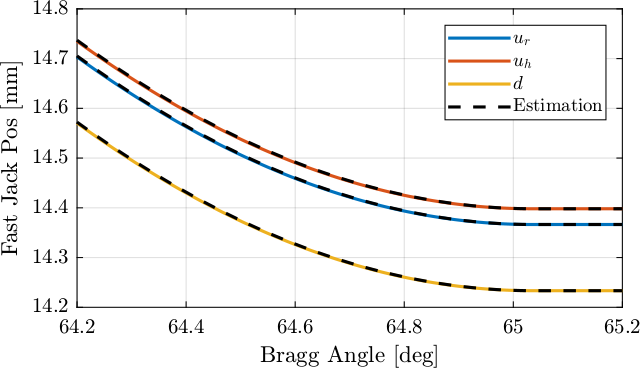

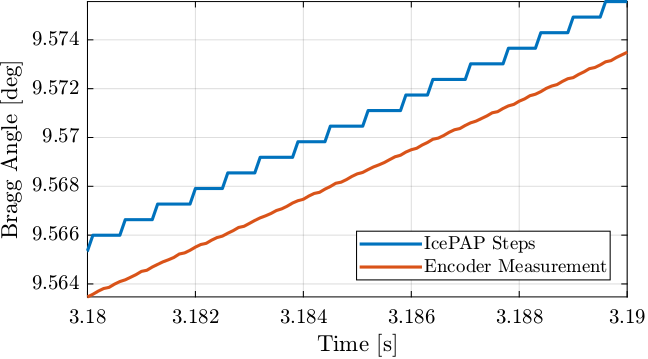

The measured IcePAP steps are compared with the theoretical formulas in Figure fig:step_lut_estimation_wanted_fj_pos.

If we were to zoom a lot, we would see a small delay between the estimation and the steps sent by the IcePAP. This is due to the fact that the estimation is performed based on the measured Bragg angle while the IcePAP steps are based on the "requested" Bragg angle. As will be shown in the next section, there is a small delay between the requested and obtained bragg angle which explains this delay.

Bragg and Fast Jack Velocities

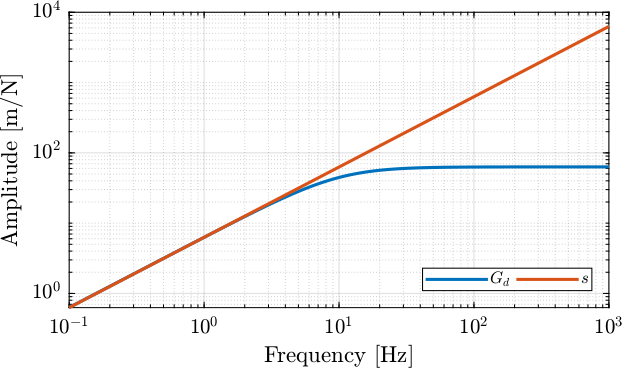

In order to estimate velocities from measured positions, a filter is used which approximate a pure derivative filter.

%% Filter to compute velocities

G_diff = (s/2/pi/10)/(1 + s/2/pi/10);

% Make sure the gain w = 2pi is equal to 2pi

G_diff = 2*pi*G_diff/(abs(evalfr(G_diff, 1j*2*pi)));Only the high frequency amplitude is reduced to not amplified the measurement noise (Figure fig:step_lut_deriv_filter).

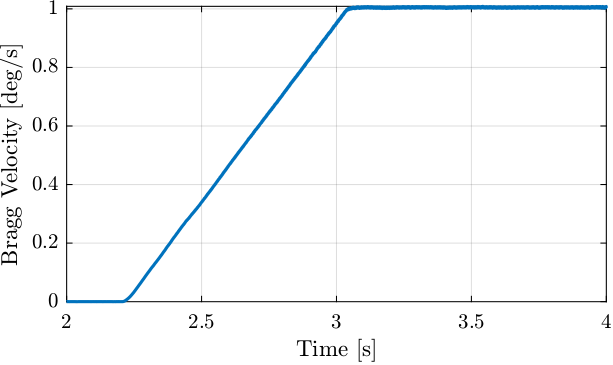

Using the filter, the Bragg velocity is estimated (Figure fig:step_lut_bragg_vel).

%% Bragg Velocity

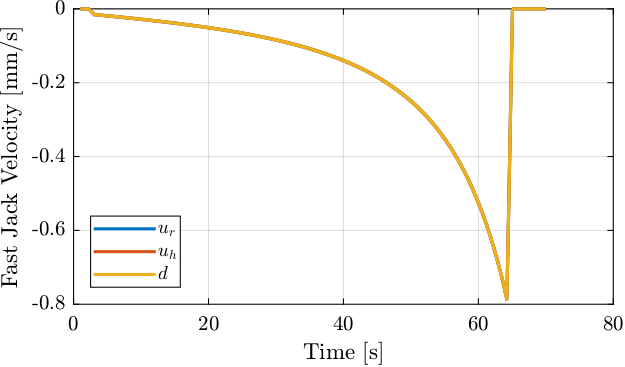

bragg_vel = lsim(G_diff, bragg, time);Now, the Fast Jack velocity is estimated (Figure fig:step_lut_fast_jack_vel).

%% Fast Jack Velocity

fjur_vel = lsim(G_diff, fjur, time);

fjuh_vel = lsim(G_diff, fjuh, time);

fjd_vel = lsim(G_diff, fjd , time);Bragg Angle Errors / Delays

From the measured fjur steps generated by the IcePAP, we can estimate the steps generated corresponding to the Bragg angle.

%% Estimated Bragg angle requested by IcePAP

bragg_icepap = acos(10.5e-3./(2*(FJ0 + fjs_offset(1) - fjur)));The generated steps by the IcePAP and the measured angle are compared in Figure fig:lut_step_bragg_angle_error_aerotech. There is clearly a lag of the Bragg angle compared to the generated IcePAP steps.

% Take only deceleration portion

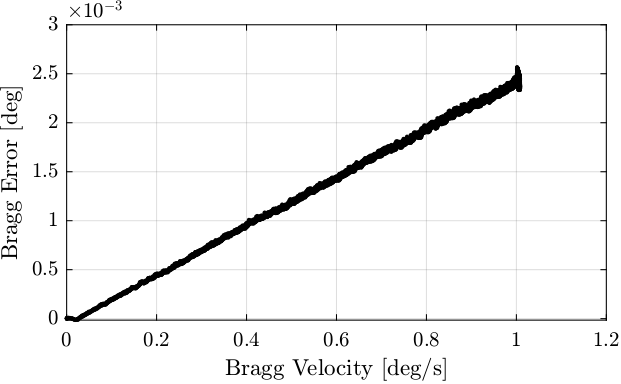

scan_i = time > 60 & time < 65.1;If we plot the error between the measured and the requested bragg angle as a function of the bragg velocity (Figure fig:lut_step_bragg_error_fct_velocity), we can see an almost linear relationship.

This corresponds to a "time lag" of approximately:

2.4 ms

There is a "lag" between the Bragg steps sent by the IcePAP and the measured angle by the encoders. This is probably due to the single integrator in the "Aerotech" controller. Indeed, two integrators are required to have no tracking error during ramp reference signals.

Errors in the Frame of the Crystals

The dz, dry and drx measured relative motion of the crystals are defined as follows:

- An increase of

dzmeans the crystals are moving away from each other - An positive

drymeans the second crystals has positive rotation aroundy - An positive

drxmeans the second crystals has positive rotation aroundx

The error in crystals' distance ddz is defined as:

Therefore, a positive ddz means that the second crystal is too high (fast jacks have to move down).

The errors measured in the frame of the crystals are shown in Figure fig:lut_step_measured_errors.

Errors in the Frame of the Fast Jacks

From ddz,dry,drx, the motion errors of the jast-jacks (fjur_e, fjuh_e and jfd_e) as measured by the interferometers are computed.

%% Actuator Jacobian

J_a_111 = [1, 0.14, -0.0675

1, 0.14, 0.1525

1, -0.14, 0.0425];

%% Computation of the position of the FJ as measured by the interferometers

error = J_a_111 * [ddz, dry, drx]';

fjur_e = error(1,:)'; % [m]

fjuh_e = error(2,:)'; % [m]

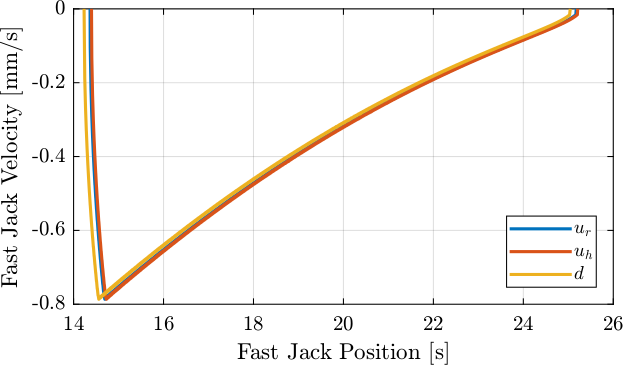

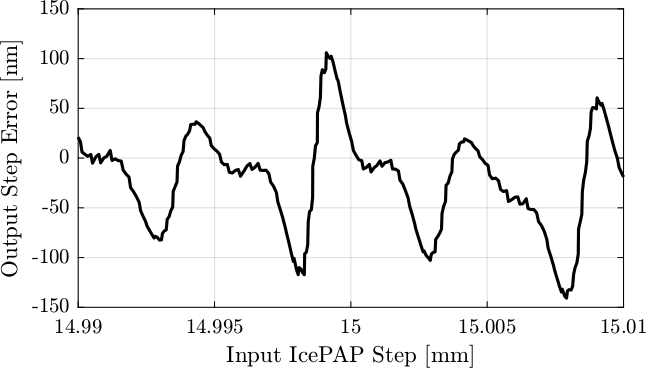

fjd_e = error(3,:)'; % [m]The result is shown in Figure fig:lut_step_measured_error_fj.

Analysis of the obtained error

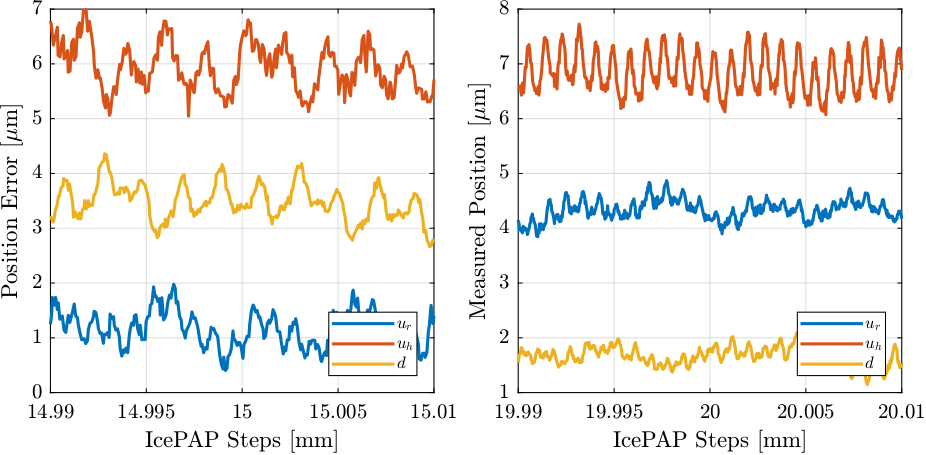

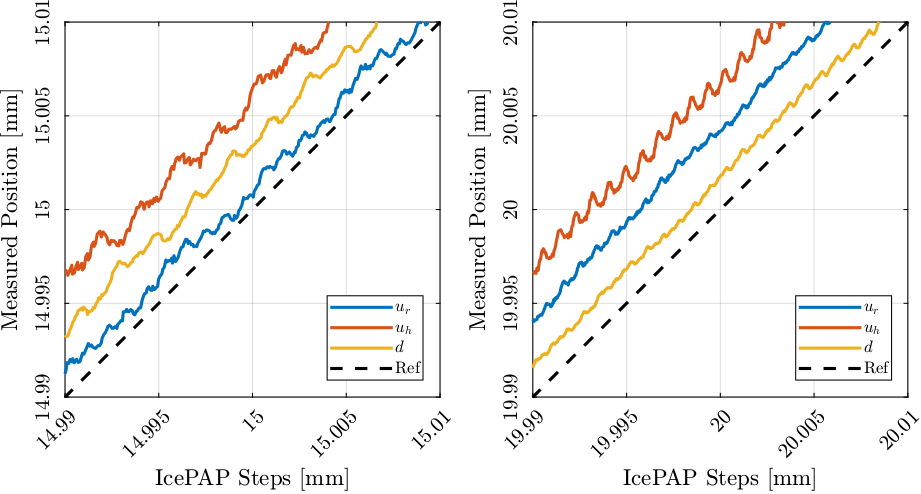

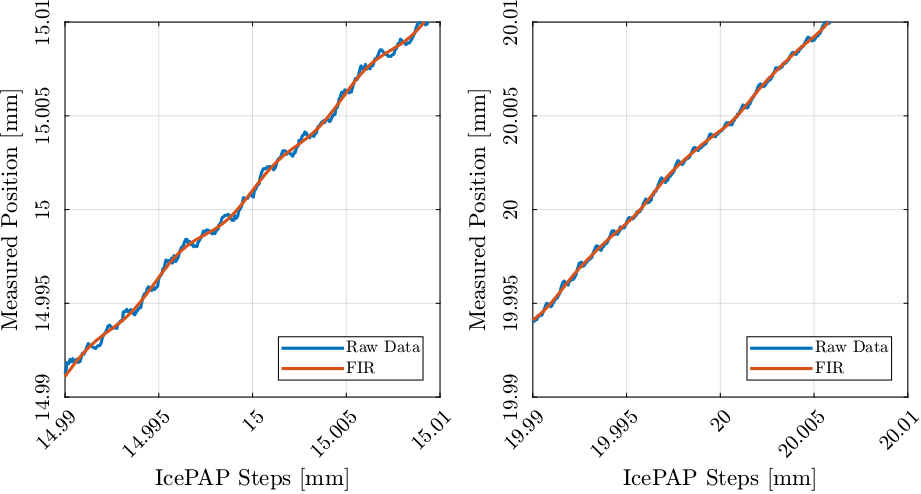

The measured position of the fast jacks are displayed as a function of the IcePAP steps (Figure fig:lut_step_meas_pos_fct_wanted_pos).

From Figure fig:lut_step_meas_pos_fct_wanted_pos, it seems the position as a function of the IcePAP steps is not a bijection function. Therefore, a measured position can corresponds to several IcePAP Steps. This is very problematic for building a LUT that will be used to compensated the measured errors.

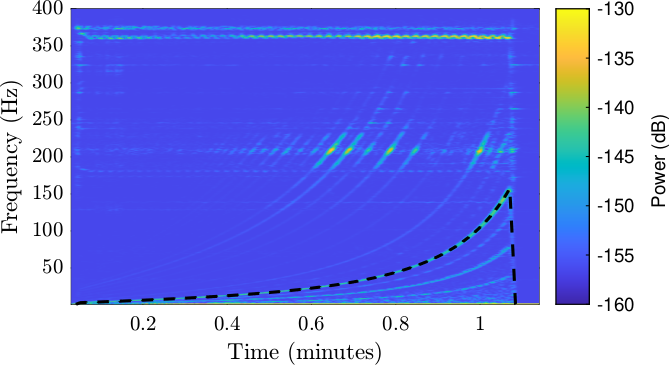

Also, it seems that the (spatial) period of the error depends on the actual position of the Fast Jack (and therefore of its velocity). If we compute the equivalent temporal period, we find a frequency of around 370 Hz.

In order to better investigate what is going on, a spectrogram is computed (Figure fig:lut_step_meas_pos_error_spectrogram).

We clearly observe:

- Some rather constant vibrations with a frequency at around 363Hz and 374Hz.

This corresponds to the clear periods in Figure fig:lut_step_meas_pos_fct_wanted_pos.

These are due to the

mcoilstepper motor (magnetic period). - Several frequencies which are increasing with time. These corresponds to (spatial) periodic errors of the stepper motor. The frequency of these errors are increasing because the velocity of the fast jack is also increasing with time (see Figure fig:step_lut_fast_jack_vel). The black dashed line in Figure fig:lut_step_meas_pos_error_spectrogram shows the frequency of errors with a period of $5\,\mu m$. We can also see lower frequencies corresponding to periods of $10\,\mu m$ and $20\,\mu m$ and lots of higher frequencies with are also exciting resonances of the system (second crystal) at around 200Hz

As we would like to only measure the repeatable mechanical errors of the fast jacks and not the vibrations of natural frequencies of the system, we have to filter the data.

Filtering of Data

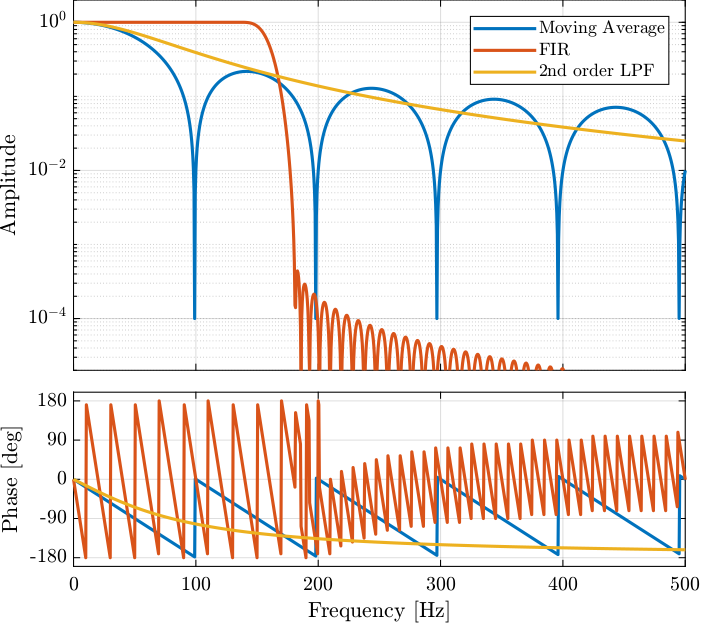

As seen in Figure fig:lut_step_meas_pos_error_spectrogram, the errors we wish to calibrate are below 160Hz while the vibrations we wish to ignore are above 200Hz. We have to use a low pass filter that does not affects frequencies below 160Hz while having good rejection above 200Hz.

The filter used for current LUT is a moving average filter with a length of 100:

%% Moving Average Filter

B_mov_avg = 1/101*ones(101,1); % FIR Filter coeficientsWe may also try a second order low pass filter:

%% 2nd order Low Pass Filter

G_lpf = 1/(1 + 2*s/(2*pi*80) + s^2/(2*pi*80)^2);And a FIR filter with linear phase:

%% FIR with Linear Phase

Fs = 1e4; % Sampling Frequency [Hz]

B_fir = firls(1000, ... % Filter's order

[0 140/(Fs/2) 180/(Fs/2) 1], ... % Frequencies [Hz]

[1 1 0 0]); % Wanted MagnitudesFilters' responses are computed and compared in the Bode plot of Figure fig:step_lut_filters_bode_plot.

%% Computation of filters' responses

[h_mov_avg, f] = freqz(B_mov_avg, 1, 10000, Fs);

[h_fir, ~] = freqz(B_fir, 1, 10000, Fs);

h_lpf = squeeze(freqresp(G_lpf, f, 'Hz'));Clearly, the currently used moving average filter is filtering too much below 160Hz and too little above 200Hz. The FIR filter seems more suited for this case.

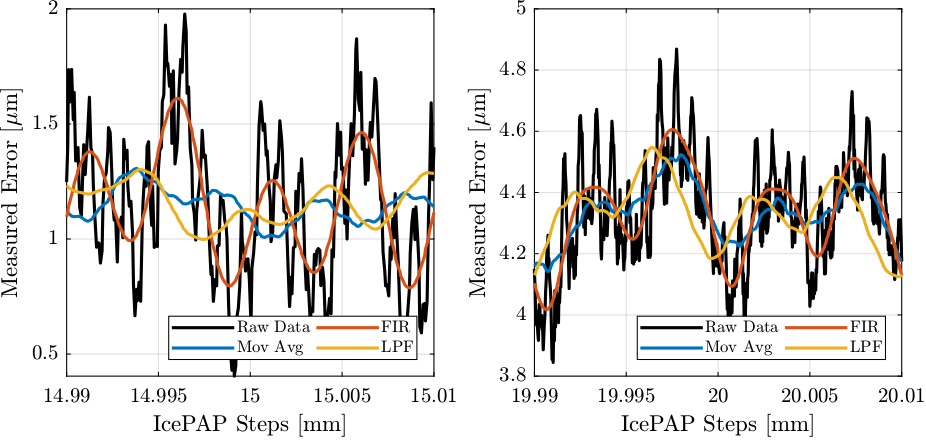

Let's now compare the filtered data.

fjur_e_cur = filter(B_mov_avg, 1, fjur_e);

fjur_e_fir = filter(B_fir, 1, fjur_e);

fjur_e_lpf = lsim(G_lpf, fjur_e, time);As the FIR filter introduce some delays, we can identify this relay and shift the filtered data:

%% Compensate the FIR delay

delay = mean(grpdelay(B_fir));500

fjur_e_fir(1:end-delay) = fjur_e_fir(delay+1:end);The same is done for the moving average filter

%% Compensate the Moving average delay

delay = mean(grpdelay(B_mov_avg));

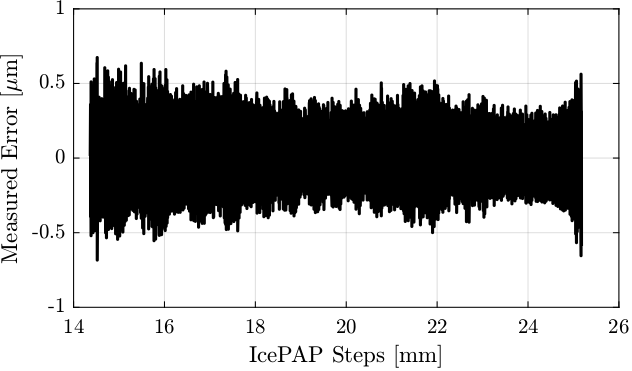

fjur_e_cur(1:end-delay) = fjur_e_cur(delay+1:end);The raw and filtered motion errors are displayed in Figure fig:step_lut_filtered_errors_comp.

It is shown that while the moving average average filter is working relatively well for low speeds (at around 20mm) it is not for high speeds (near 15mm). This is because the frequency of the error is above 100Hz and the moving average is flipping the sign of the filtered data.

The IIR low pass filter has some phase issues.

Finally the FIR filter is perfectly in phase while showing good attenuation of the disturbances.

If we now look at the measured position as a function of the IcePAP steps (Figure fig:step_lut_filtered_motion_comp), we can see that we obtain a monotonous function for the FIR filtered data which is great to make the LUT.

If we subtract the raw data with the FIR filtered data, we obtain the remaining motion shown in Figure fig:step_lut_remain_motion_remove_filtered that only contains the high frequency motion not filtered.

LUT creation

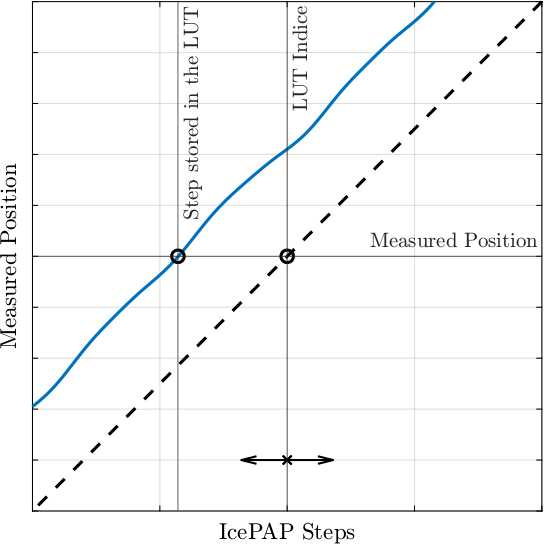

The procedure used to make the Lookup Table is schematically represented in Figure fig:step_lut_schematic_principle.

For each IcePAP step separated by a constant value (typically $1\,\mu m$) a point of the LUT is computed:

- Points where the measured position is close to the wanted ideal position (i.e. the current IcePAP step) are found

- The corresponding IcePAP step at which the Fast Jack is at the wanted position is stored in the LUT

Therefore the LUT gives the IcePAP step for which the fast jack is at the wanted position as measured by the metrology, which is what we want.

Let's first initialize the LUT which is table with 4 columns and 26001 rows. The columns are:

- IcePAP Step indices from 0 to 26mm with a step of $1\,\mu m$ (thus the 26001 rows)

- IcePAP step for

fjurat which point the fast jack is at the wanted position - Same for

fjuh - Same for

fjd

All the units of the LUT are in mm. We will work in meters and convert to mm at the end.

Let's initialize the Lookup table:

%% Initialization of the LUT

lut = [0:1e-6:26e-3]'*ones(1,4);And verify that it has the wanted size:

size(lut)

ans =

26001 4

The measured Fast Jack position are filtered using the FIR filter:

%% FIR Filter

Fs = 1e4; % Sampling Frequency [Hz]

fir_order = 1000; % Filter's order

delay = fir_order/2; % Delay induced by the filter

B_fir = firls(fir_order, ... % Filter's order

[0 140/(Fs/2) 180/(Fs/2) 1], ... % Frequencies [Hz]

[1 1 0 0]); % Wanted Magnitudes

%% Filtering all measured Fast Jack Position using the FIR filter

fjur_e_filt = filter(B_fir, 1, fjur_e);

fjuh_e_filt = filter(B_fir, 1, fjuh_e);

fjd_e_filt = filter(B_fir, 1, fjd_e);

%% Compensation of the delay introduced by the FIR filter

fjur_e_filt(1:end-delay) = fjur_e_filt(delay+1:end);

fjuh_e_filt(1:end-delay) = fjuh_e_filt(delay+1:end);

fjd_e_filt( 1:end-delay) = fjd_e_filt( delay+1:end);The indices where the LUT will be populated are initialized.

%% Vector of Fast Jack positions [unit of lut_inc]

fjur_pos = floor(min(1e6*fjur)):floor(max(1e6*fjur));

fjuh_pos = floor(min(1e6*fjuh)):floor(max(1e6*fjuh));

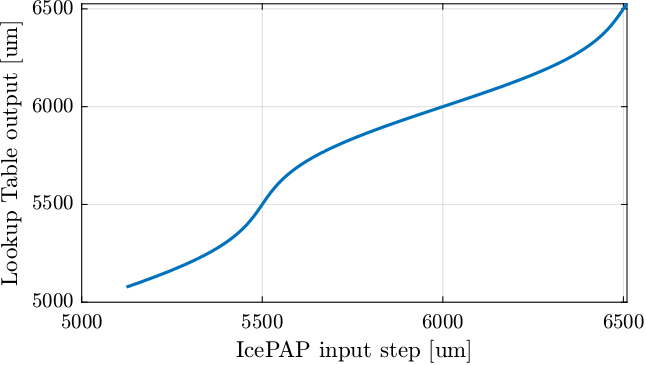

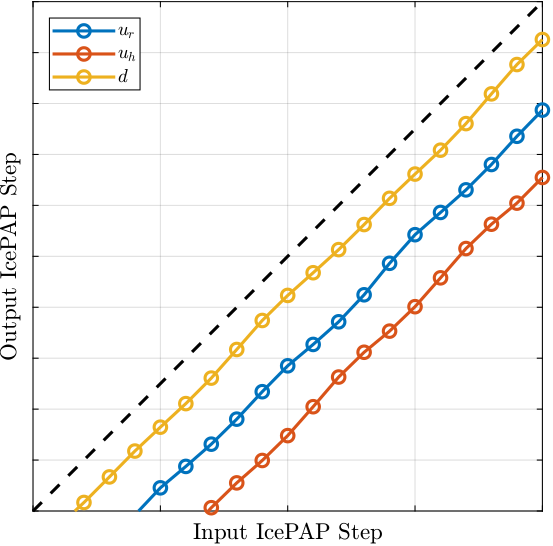

fjd_pos = floor(min(1e6*fjd )):floor(max(1e6*fjd ));And the LUT is computed and shown in Figure fig:step_lut_obtained_lut.

%% Build the LUT

for i = fjur_pos

% Find indices where measured motion is close to the wanted one

indices = fjur + fjur_e_filt > lut(i,1) - 500e-9 & ...

fjur + fjur_e_filt < lut(i,1) + 500e-9;

% Poputate the LUT with the mean of the IcePAP steps

lut(i,2) = mean(fjur(indices));

end

for i = fjuh_pos

% Find indices where measuhed motion is close to the wanted one

indices = fjuh + fjuh_e_filt > lut(i,1) - 500e-9 & ...

fjuh + fjuh_e_filt < lut(i,1) + 500e-9;

% Poputate the LUT with the mean of the IcePAP steps

lut(i,3) = mean(fjuh(indices));

end

for i = fjd_pos

% Poputate the LUT with the mean of the IcePAP steps

indices = fjd + fjd_e_filt > lut(i,1) - 500e-9 & ...

fjd + fjd_e_filt < lut(i,1) + 500e-9;

% Poputate the LUT

lut(i,4) = mean(fjd(indices));

endCubic Interpolation of the LUT

Once the LUT is built and loaded to the IcePAP, generated steps are taking the step values in the LUT and cubic spline interpolation is performed.

%% Estimation of the IcePAP output steps after interpolation

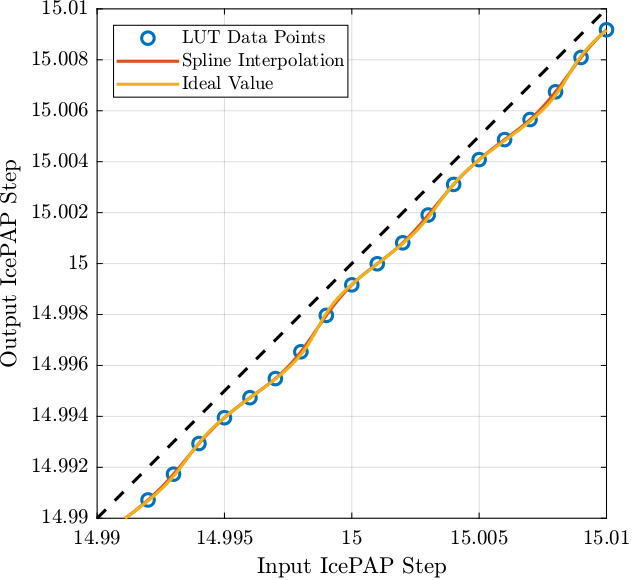

fjur_out_steps = spline(lut(:,1), lut(:,2), fjur);The LUT data points as well as the spline interpolation values and the ideal values are compared in Figure fig:step_lut_spline_interpolation_lut. It is shown that the spline interpolation seems to be quite accurate.

The difference between the perfect step generation and the step generated after spline interpolation is shown in Figure fig:step_lut_error_after_interpolation. The remaining position error is in the order of 100nm peak to peak which is acceptable here.

Test Matlab LUT

LUT Creation

A thtraj scan from 10 to 70 deg is performed.

%% Extract measurement Data make from BLISS

data_ol = extractDatData("/home/thomas/mnt/data_id21/21Nov/blc13420/id21/LUT_Matlab/lut_matlab_22122021_1610.dat", ...

{"bragg", "dz", "dry", "drx", "fjur", "fjuh", "fjd"}, ...

ones(7,1));

data_ol.time = 1e-4*[1:1:length(data_ol.bragg)];

save("/tmp/data_lut.mat", "-struct", "data_ol");A LUT is generated from this Data.

%% Generate LUT

createLUT("/tmp/data_lut.mat", "lut_matlab_22122021_1610_10_70_table.dat");%% Load the generated LUT

data_lut = importdata("lut_matlab_22122021_1610_10_70_table.dat");The generated LUT is shown in Figure fig:generated_matlab_lut_10_70.

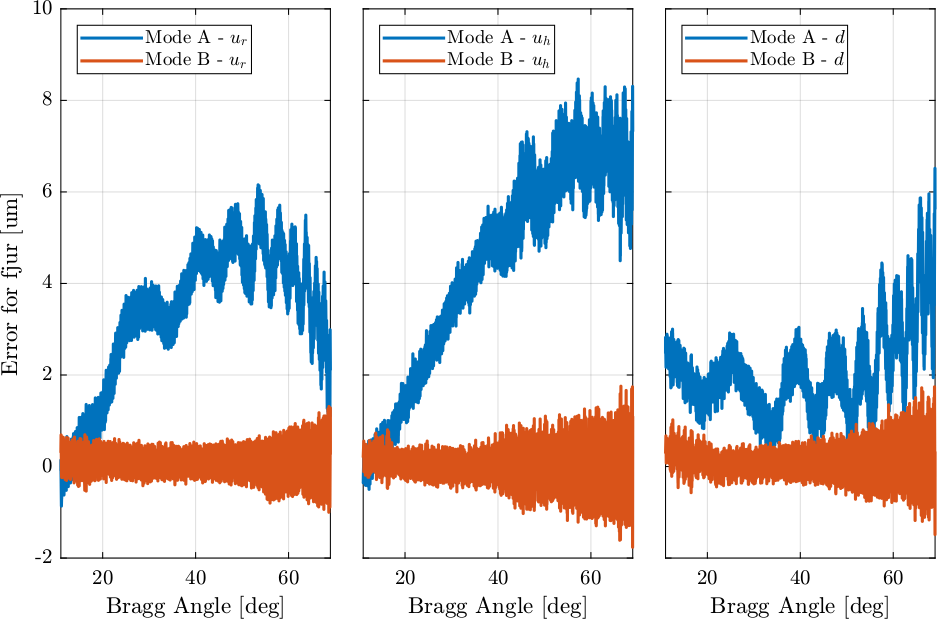

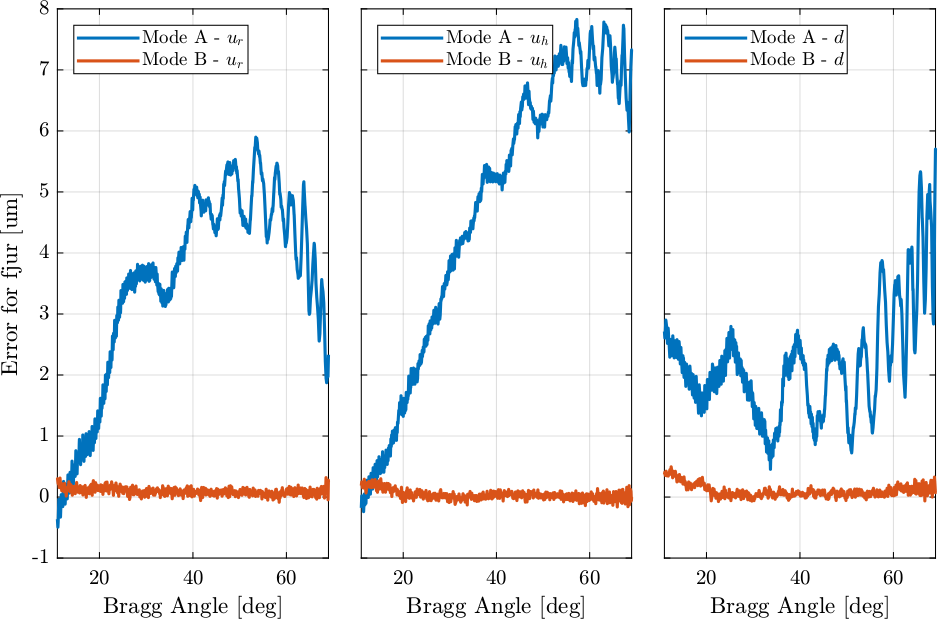

Compare Mode A and Mode B

The LUT is loaded into BLISS and a new scan in mode B is performed.

%% Load mode B scan data

data_B = extractDatData("/home/thomas/mnt/data_id21/21Nov/blc13420/id21/LUT_Matlab/lut_matlab_result_22122021_1616.dat", ...

{"bragg", "dz", "dry", "drx", "fjur", "fjuh", "fjd"}, ...

ones(7,1));

data_B.time = 1e-4*[1:1:length(data_B.bragg)];

save("/tmp/data_lut.mat", "-struct", "data_ol");Now look at the low frequency motion by using a low pass filter

%% FIR Filter

Fs = 1e4; % Sampling Frequency [Hz]

fir_order = 1000; % Filter's order

delay = fir_order/2; % Delay induced by the filter

B_fir = firls(fir_order, ... % Filter's order

[0 5/(Fs/2) 10/(Fs/2) 1], ... % Frequencies [Hz]

[1 1 0 0]); % Wanted Magnitudes

%% Filtering all measured Fast Jack Position using the FIR filter

data_B_fjur_f = filter(B_fir, 1, data_B_fjur_e);

data_B_fjuh_f = filter(B_fir, 1, data_B_fjuh_e);

data_B_fjd_f = filter(B_fir, 1, data_B_fjd_e);

data_ol_fjur_f = filter(B_fir, 1, data_ol_fjur_e);

data_ol_fjuh_f = filter(B_fir, 1, data_ol_fjuh_e);

data_ol_fjd_f = filter(B_fir, 1, data_ol_fjd_e);

%% Compensation of the delay introduced by the FIR filter

data_B_fjur_f(1:end-delay) = data_B_fjur_f(delay+1:end);

data_B_fjuh_f(1:end-delay) = data_B_fjuh_f(delay+1:end);

data_B_fjd_f( 1:end-delay) = data_B_fjd_f( delay+1:end);

data_ol_fjur_f(1:end-delay) = data_ol_fjur_f(delay+1:end);

data_ol_fjuh_f(1:end-delay) = data_ol_fjuh_f(delay+1:end);

data_ol_fjd_f( 1:end-delay) = data_ol_fjd_f( delay+1:end);Check IcePAP Steps with LUT

Compare the theoretical steps and the measured steps when the LUT is on.

Estimate wanted fjur steps.

FJ0 = 0.030427;

fjsry = 0.53171e-3; % [rad]

fjsrx = 0.144e-3; % [rad]

J_a_111 = [1, 0.14, -0.0675

1, 0.14, 0.1525

1, -0.14, 0.0425];

fjs_offset = J_a_111*[0; fjsry; fjsrx]; % ur,uh,d offsets [m]

fjur_th = 1e3*(FJ0 + fjs_offset(1) - 10.5e-3./(2*cos(pi/180*data_B.bragg)));%% Estimation of the IcePAP output steps after interpolation

fjur_out_steps = spline(data_lut(:,1), data_lut(:,2), fjur_th);Difference between theoretical step using LUT and sent step using IcePAP

figure;

plot(data_B.bragg, 1e-2*data_B.fjur - 1e3*fjur_out_steps)

xlabel('Bragg [deg]'); ylabel('Difference on fjpur [$\mu$m]');

xlim([10, 70]);This difference can be explained by the fact that we are basing the theoretical step after LUT on the measured Bragg angle and not on the requested one (there is a delay).

LUT Without mcoil

Load

%% Extract measurement Data make from BLISS

data_ol = extractDatData("/home/thomas/mnt/data_id21/21Nov/blc13420/id21/LUT_without_mcoil/lut_without_mcoil_06012022_1644.dat", ...

{"bragg", "dz", "dry", "drx", "fjur", "fjuh", "fjd"}, ...

ones(7,1));

data_ol.time = 1e-4*[1:1:length(data_ol.bragg)];

% save("/tmp/data_lut.mat", "-struct", "data_ol");%% Extract measurement Data make from BLISS

data_bis = extractDatData("/home/thomas/mnt/data_id21/21Nov/blc13420/id21/LUT_Matlab/lut_matlab_06012022_1651.dat", ...

{"bragg", "dz", "dry", "drx", "fjur", "fjuh", "fjd"}, ...

ones(7,1));

data_bis.time = 1e-4*[1:1:length(data_bis.bragg)];

% save("/tmp/data_lut.mat", "-struct", "data_ol");%% FIR Filter

Fs = 1e4; % Sampling Frequency [Hz]

fir_order = 1000; % Filter's order

delay = fir_order/2; % Delay induced by the filter

B_fir = firls(fir_order, ... % Filter's order

[0 5/(Fs/2) 10/(Fs/2) 1], ... % Frequencies [Hz]

[1 1 0 0]); % Wanted MagnitudesOptimal Trajectory to make the LUT

<<sec:optimal_traj_dist>>

Introduction ignore

In this section, the problem of generating an adequate trajectory to make the LUT is studied.

The problematic is the following:

- the positioning errors of the fast jack should be measured

- all external disturbances and measurement noise should be filtered out.

The main difficulty is that the frequency of both the positioning errors errors and the disturbances are a function of the scanning velocity.

First, the frequency of the disturbances as well as the errors to be measured are described and a filter is designed to optimally separate disturbances from positioning errors (Section sec:optimal_traj_dist). The relation between the Bragg angular velocity and fast jack velocity is studied in Section sec:bragg_and_fj_velocities. Next, a trajectory with constant fast jack velocity (Section sec:optimal_traj_const_fj_velocity) and with constant Bragg angular velocity (Section sec:optimal_traj_const_bragg_velocity) are simulated to understand their limitations. Finally, it is proposed to perform a scan in two parts (one part with constant fast jack velocity and the other part with constant bragg angle velocity) in Section sec:optimal_traj_const_bragg_velocity.

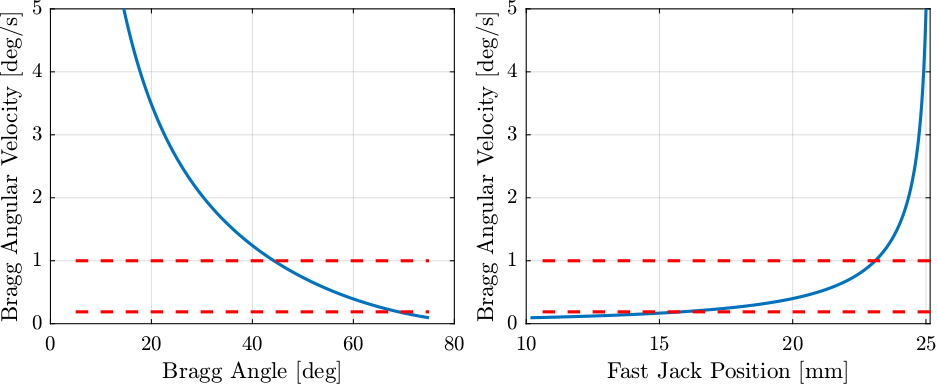

Filtering Disturbances and Noise

<<sec:disturbances_noise_filtering>>

Introduction ignore

Based on measurements made in mode A (without LUT or feedback control), several disturbances could be identified:

- vibrations coming from from the

mcoilmotor - vibrations with constant frequencies at 29Hz (pump), 34Hz (air conditioning) and 45Hz (un-identified)

These disturbances as well as the noise of the interferometers should be filtered out, and only the fast jack motion errors should be left untouched.

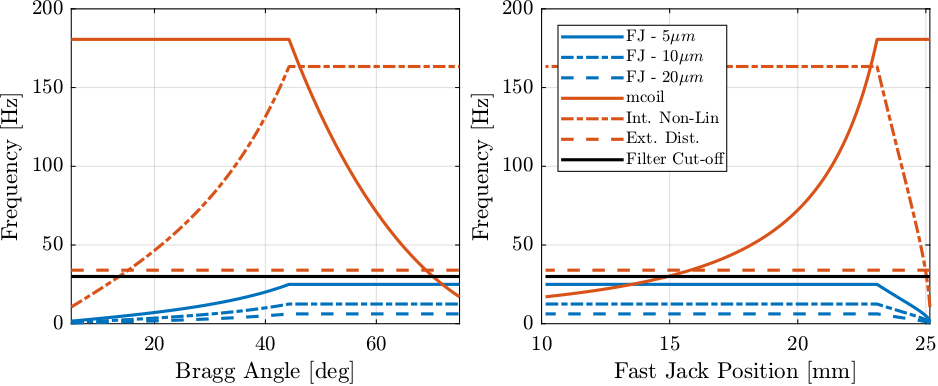

Therefore, the goal is to make a scan such that during all the scan, the frequencies of the errors induced by the fast jack have are smaller than the frequencies of all other disturbances. Then, it is easy to use a filter to separate the disturbances and noise from the positioning errors of the fast jack.

Errors induced by the Fast Jack

The Fast Jack is composed of one stepper motor, and a planetary roller screw with a pitch of 1mm/turn. The stepper motor as 50 pairs of magnetic poles, and therefore positioning errors are to be expected every 1/50th of turn (and its harmonics: 1/100th of turn, 1/200th of turn, etc.).

One pair of magnetic pole corresponds to an axial motion of $20\,\mu m$. Therefore, errors are to be expected with a period of $20\,\mu m$ and harmonics at $10\,\mu m$, $5\,\mu m$, $2.5\,\mu m$, etc.

As the LUT has one point every $1\,\mu m$, we wish to only measure errors with a period of $20\,\mu m$, $10\,\mu m$ and $5\,\mu m$. Indeed, errors with smaller periods are small in amplitude (i.e. not worth to compensate) and are difficult to model with the limited number of points in the LUT.

The frequency corresponding to errors with a period of $5\,\mu m$ at 1mm/s is:

Frequency or errors with period of 5um/s at 1mm/s is: 200.0 [Hz]

We wish that the frequency of the error corresponding to a period of $5\,\mu m$ to be smaller than the smallest disturbance to be filtered.

As the main disturbances are at 34Hz and 45Hz, we constrain the the maximum axial velocity of the Fast Jack such that the positioning error has a frequency bellow 25Hz:

max_fj_vel = 25*1e-3/(1e-3/5e-6); % [m/s]Maximum Fast Jack velocity: 0.125 [mm/s]

Therefore, the Fast Jack scans should be scanned at rather low velocity for the positioning errors to be at sufficiently low frequency.

Vibrations induced by mcoil

The mcoil system is composed of one stepper motor and a reducer such that one stepper motor turns makes the mcoil axis to rotate 0.2768 degrees.

When scanning the mcoil motor, periodic vibrations can be measured by the interferometers.

It has been identified that the period of these vibrations are corresponding to the period of the magnetic poles (50 per turn as for the Fast Jack stepper motors).

Therefore, the frequency of these periodic errors are a function of the angular velocity. With an angular velocity of 1deg/s, the frequency of the vibrations are expected to be at:

Fundamental frequency at 1deg/s: 180.6 [Hz]

We wish the frequency of these errors to be at minimum 34Hz (smallest frequency of other disturbances).

The corresponding minimum mcoil velocity is:

min_bragg_vel = 34/(50/0.2768); % [deg/s]Min mcoil velocity is 0.19 [deg/s]

Regarding the mcoil motor, the problematic is to not scan too slowly.

It should however be checked whether the amplitude of the induced vibrations is significant of not.

Note that the maximum bragg angular velocity is:

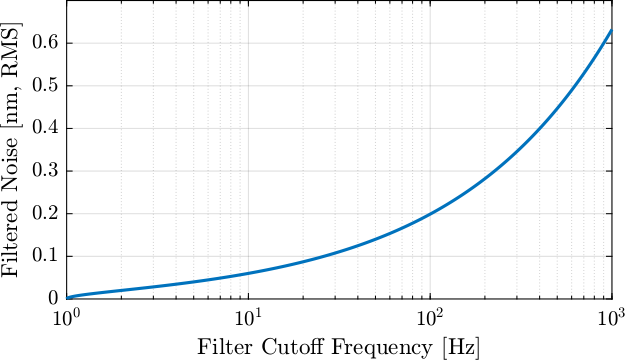

max_bragg_vel = 1; % [deg/s]Measurement noise of the interferometers

The motion of the fast jacks are measured by interferometers which have some measurement noise. It is wanted to filter this noise to acceptable values to have a clean measured position.

As the interferometer noise has a rather flat spectral density, it is easy to estimate its RMS value as a function of the cut-off frequency of the filter.

The RMS value of the filtered interferometer signal as a function of the cutoff frequency of the low pass filter is computed and shown in Figure fig:interferometer_noise_cutoff_freq.

As the filter will have a cut-off frequency between 25Hz (maximum frequency of the positioning errors) and 34Hz (minimum frequency of disturbances), a filtered measurement noise of 0.1nm RMS is to be expected.

Figure fig:interferometer_noise_cutoff_freq is a rough estimate. Precise estimation can be done by measuring the spectral density of the interferometer noise experimentally.

Interferometer - Periodic non-linearity

Interferometers can also show periodic non-linearity with a (fundamental) period equal to half the wavelength of its light (i.e. 765nm for Attocube) and with unacceptable amplitudes (up to tens of nanometers).

The minimum frequency associated with these errors is therefore a function of the fast jack velocity. With a velocity of 1mm/s, the frequency is:

Fundamental frequency at 1mm/s: 1307.2 [Hz]

We wish these errors to be at minimum 34Hz (smallest frequency of other disturbances). The corresponding minimum velocity of the Fast Jack is:

min_fj_vel = 34*1e-3/(1e-3/765e-9); % [m/s]Minimum Fast Jack velocity is 0.026 [mm/s]

The Fast Jack Velocity should not be too low or the frequency of the periodic non-linearity of the interferometer would be too small to be filtered out (i.e. in the pass-band of the filter).

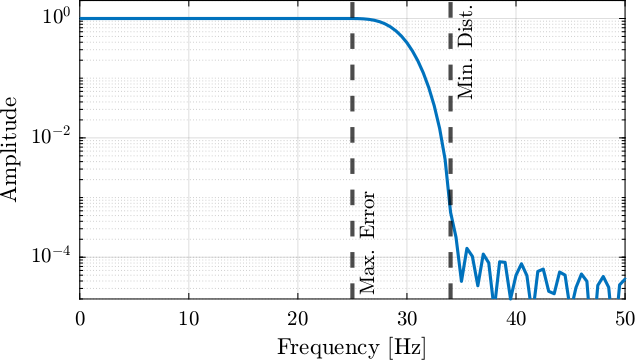

Implemented Filter

Let's now verify that it is possible to implement a filter that keep everything untouched below 25Hz and filters everything above 34Hz.

To do so, a FIR linear phase filter is designed:

%% FIR with Linear Phase

Fs = 1e4; % Sampling Frequency [Hz]

B_fir = firls(5000, ... % Filter's order

[0 25/(Fs/2) 34/(Fs/2) 1], ... % Frequencies [Hz]

[1 1 0 0]); % Wanted MagnitudesIts amplitude response is shown in Figure fig:fir_filter_response_freq_ranges. It is confirmed that the errors to be measured (below 25Hz) are left untouched while the disturbances above 34Hz are reduced by at least a factor $10^4$.

To have such a steep change in gain, the order of the filter is rather large. This has the negative effect of inducing large time delays:

Induced time delay is 0.25 [s]

This time delay is only requiring us to start the acquisition 0.25 seconds before the important part of the scan is performed (i.e. the first 0.25 seconds of data cannot be filtered).

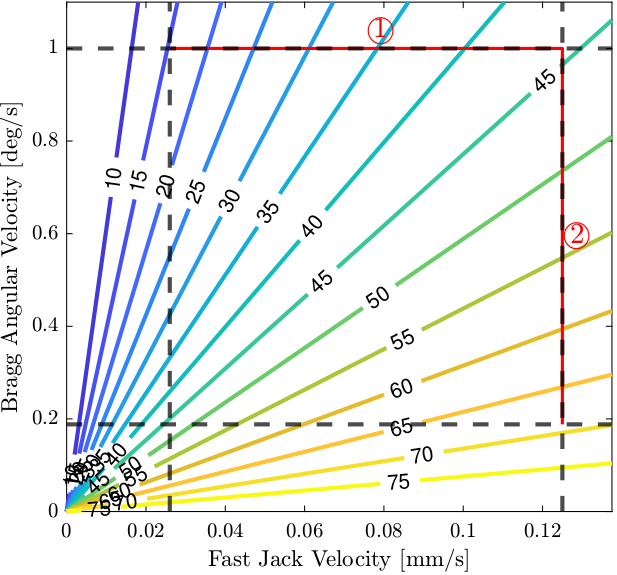

First Estimation of the optimal trajectory

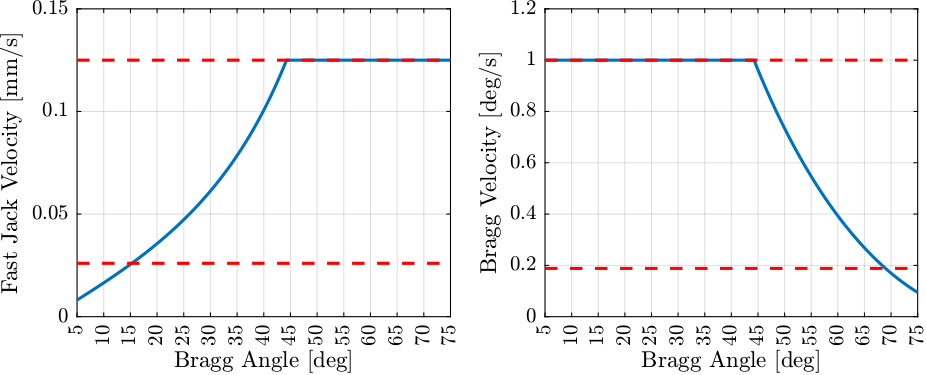

<<sec:bragg_and_fj_velocities>> Based on previous analysis (Section sec:disturbances_noise_filtering), minimum and maximum fast jack velocities and bragg angular velocities could be determined. These values are summarized in Table tab:max_min_vel. Therefore, if during the scan the velocities are within the defined bounds, it will be very easy to filter the data and extract only the relevant information (positioning error of the fast jack).

| Min | Max | |

|---|---|---|

| Bragg Angular Velocity [deg/s] | 0.188 | 1.0 |

| Fast Jack Velocity [mm/s] | 0.026 | 0.125 |

We now wish to see if it is possible to perform a scan from 5deg to 75deg of bragg angle while keeping the velocities within the bounds in Table tab:max_min_vel.

To study that, we can compute the relation between the Bragg angular velocity and the Fast Jack velocity as a function of the Bragg angle.

To do so, we first look at the relation between the Bragg angle $\theta_b$ and the Fast Jack position $d_{\text{FJ}}$:

\begin{equation} d_{FJ}(t) = d_0 - \frac{10.5 \cdot 10^{-3}}{2 \cos \theta_b(t)} \end{equation}with $d_0 \approx 0.030427\,m$.

Then, by taking the time derivative, we obtain the relation between the Fast Jack velocity $\dot{d}_{\text{FJ}}$ and the Bragg angular velocity $\dot{\theta}_b$ as a function of the bragg angle $\theta_b$: \begin{equation} \label{eq:bragg_angle_formula} \boxed{\dot{d}FJ(t) = - \dot{θ_b}(t) ⋅ \frac{10.5 ⋅ 10-3}{2} ⋅ \frac{tan θ_b(t)}{cos θ_b(t)}}

\end{equation}

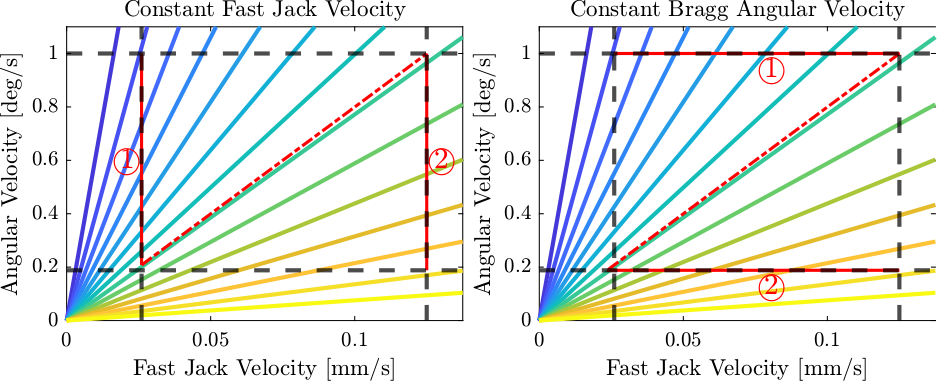

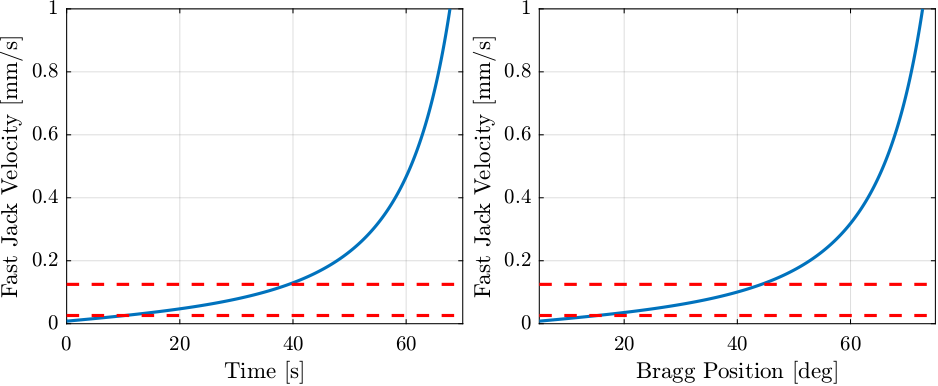

The relation between the Bragg angular velocity and the Fast Jack velocity is computed for several angles starting from 5degrees up to 75 degrees and this is shown in Figure fig:bragg_vel_fct_fj_vel.

From Figure fig:bragg_vel_fct_fj_vel, it is clear that only Bragg angles from apprimately 15 to 70 degrees can be scanned by staying in the "perfect" zone (defined by the dashed black lines).

To scan smaller bragg angles, either the maximum bragg angular velocity should be increased or the minimum fast jack velocity decreased (accepting some periodic non-linearity to be measured).

To scan higher bragg angle, either the maximum fast jack velocity should be increased or the minimum bragg angular velocity decreased (taking the risk to have some disturbances from the mcoil motion in the signal).

For Bragg angles between 15 degrees and 70 degrees, several strategies can be chosen:

-

Constant Fast Jack velocity (Figure fig:bragg_vel_fct_fj_vel_example_traj - Left):

- Go from 15 degrees to 44 degrees at minimum fast jack velocity

- Go from 44 degrees to 70 degrees at maximum fast jack velocity

-

Constant Bragg angular velocity (Figure fig:bragg_vel_fct_fj_vel_example_traj - Right):

- Go from 15 degrees to 44 degrees at maximum angular velocity

- Go from 44 to 70 degrees at minimum angular velocity

-

A mixed of constant bragg angular velocity and constant fast jack velocity (Figure fig:bragg_vel_fct_fj_vel - Red line)

- from 15 to 44 degrees with maximum Bragg angular velocity

- from 44 to 70 degrees with maximum Bragg angular velocity

The third option is studied in Section sec:optimal_traj_const_bragg_velocity

Constant Fast Jack Velocity

<<sec:optimal_traj_const_fj_velocity>>

In this section, a scan with constant fast jack velocity is studied.

It was shown in Section sec:optimal_traj_dist that the maximum Fast Jack velocity should be 0.125mm/s in order for the frequency corresponding to the period of $5\,\mu m$ to be smaller than 25Hz.

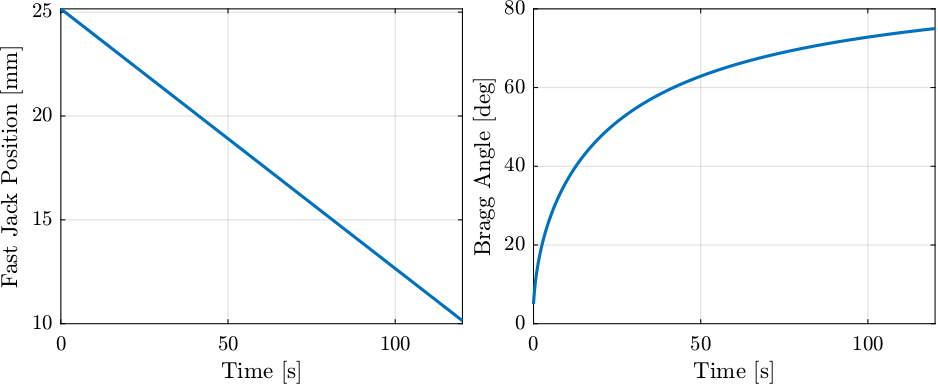

Let's generate a trajectory between 5deg and 75deg Bragg angle with constant Fast Jack velocity at 0.125mm/s.

%% Compute extreme fast jack position

fj_max = 0.030427 - 10.5e-3/(2*cos(pi/180*5)); % Smallest FJ position [m]

fj_min = 0.030427 - 10.5e-3/(2*cos(pi/180*75)); % Largest FJ position [m]

%% Compute Fast Jack Trajectory

t = 0:0.1:(fj_max - fj_min)/max_fj_vel; % Time vector [s]

fj_pos = fj_max - t*max_fj_vel; % Fast Jack Position [m]

%% Compute corresponding Bragg trajectory

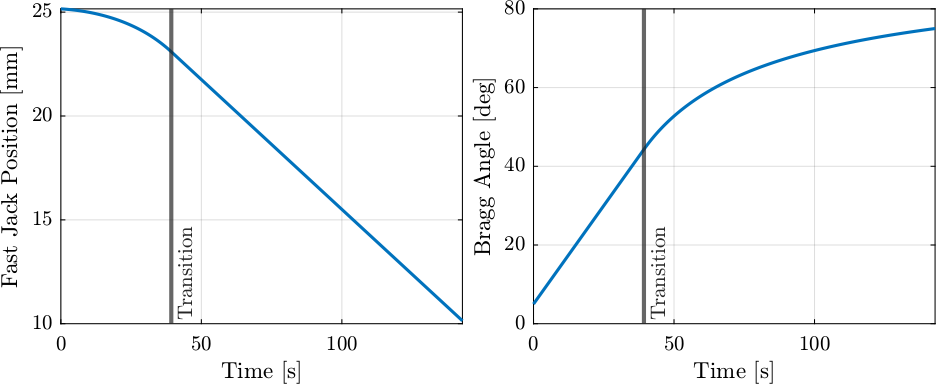

bragg_pos = acos(10.5e-3./(2*(0.030427 - fj_pos))); % [rad]The Fast Jack position as well as the Bragg angle are shown as a function of time in Figure fig:trajectory_constant_fj_velocity.

Let's now compute the Bragg angular velocity for this scan (Figure fig:trajectory_constant_fj_velocity_bragg_velocity). It is shown that for large Fast Jack positions / small bragg angles, the bragg angular velocity is too large.

Between 45 and 70 degrees, the scan can be performed with constant Fast Jack velocity equal to 0.125 mm/s.

Constant Bragg Angular Velocity

<<sec:optimal_traj_const_bragg_velocity>>

Let's now study a scan with a constant Bragg angular velocity of 1deg/s.

%% Time vector for the Scan with constant angular velocity

t = 0:0.1:(75 - 5)/max_bragg_vel; % Time vector [s]

%% Bragg angle during the scan

bragg_pos = 5 + t*max_bragg_vel; % Bragg Angle [deg]

%% Computation of the Fast Jack Position

fj_pos = 0.030427 - 10.5e-3./(2*cos(pi/180*bragg_pos)); % FJ position [m]Between 15 and 45 degrees, the scan can be performed with a constant Bragg angular velocity equal to 1 deg/s.

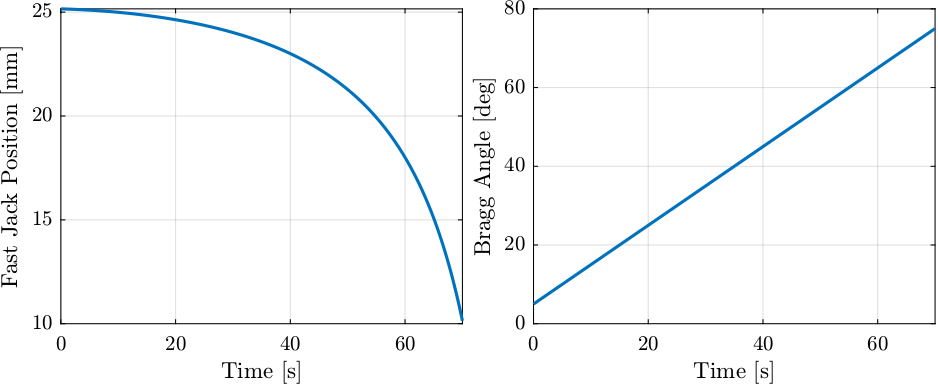

Mixed Trajectory

<<sec:optimal_traj_const_bragg_velocity>>

Let's combine a scan with constant Bragg angular velocity for small bragg angles (< 44.3 deg) with a scan with constant Fast Jack velocity for large Bragg angle (> 44.3 deg). The scan is performed from 5 degrees to 75 degrees.

Parameters for the scan are defined below:

%% Bragg Positions

bragg_start = 5; % Start Bragg angle [deg]

bragg_mid = 44.3; % Transition between constant FJ vel and constant Bragg vel [deg]

bragg_end = 75; % End Bragg angle [deg]

%% Fast Jack Positions

fj_start = 0.030427 - 10.5e-3/(2*cos(pi/180*bragg_start)); % Start FJ position [m]

fj_mid = 0.030427 - 10.5e-3/(2*cos(pi/180*bragg_mid)); % Mid FJ position [m]

fj_end = 0.030427 - 10.5e-3/(2*cos(pi/180*bragg_end)); % End FJ position [m]

%% Time vectors

Ts = 0.1; % Sampling Time [s]

t_c_bragg = 0:Ts:(bragg_mid-bragg_start)/max_bragg_vel; % Time Vector for constant bragg velocity [s]

t_c_fj = Ts+[0:Ts:(fj_mid-fj_end)/max_fj_vel]; % Time Vector for constant Fast Jack velocity [s]Positions for the first part of the scan at constant Bragg angular velocity are computed:

%% Constant Bragg Angular Velocity

bragg_c_bragg = bragg_start + t_c_bragg*max_bragg_vel; % [deg]

fj_c_bragg = 0.030427 - 10.5e-3./(2*cos(pi/180*bragg_c_bragg)); % FJ position [m]And positions for the part of the scan with constant Fast Jack Velocity are computed:

%% Constant Bragg Angular Velocity

fj_c_fj = fj_mid - t_c_fj*max_fj_vel; % FJ position [m]

bragg_c_fj = 180/pi*acos(10.5e-3./(2*(0.030427 - fj_c_fj))); % [deg]Fast Jack position as well as Bragg angle are displayed as a function of time in Figure fig:combined_scan_trajectories.

The Fast Jack velocity as well as the Bragg angular velocity are shown as a function of the Bragg angle in Figure fig:combined_scan_velocities.

From Figure fig:combined_scan_velocities, it is shown that the fast jack velocity as well as the bragg angular velocity are within the bounds except:

- Below 15 degrees where the fast jack velocity is too small. The frequency of the non-linear periodic errors of the interferometers would be at too low frequency (in the pass-band of the filter, see Figure fig:optimal_lut_trajectory_frequencies). One easy option is to use an interferometer without periodic non-linearity. Another option is to increase the maximum Bragg angular velocity to 3 deg/s.

- Above 70 degrees where the Bragg angular velocity is too small.

This may introduce low frequency disturbances induced by the

mcoilmotor that would be in the pass-band of the filter (see Figure fig:optimal_lut_trajectory_frequencies). It should be verified if this is indeed problematic of not. An other way would be to scan without themcoilmotor at very high bragg angle.

In order to better visualize the filtering problem, the frequency of all the signals are shown as a function of the Bragg angle during the scan in Figure fig:optimal_lut_trajectory_frequencies.

Piezoelectric LUT

Introduction ignore

On main issue with implementing the LUT inside

The idea is to:

- Correct the low frequency errors inside the IcePAP (1mm period motor error).

- This should reduce the errors to an acceptable range (within the piezoelectric stack stroke).

- Correct the high frequency errors (periods of $5\,\mu m$, $10\,\mu m$ and $20\,\mu m$) using the piezoelectric stack.