101 KiB

Simscape Model - Nano Hexapod

- Introduction

- Active Vibration Platforms

- The Stewart platform

- Multi-Body Model

- Control of Stewart Platforms

- Conclusion

- Bibliography

- Footnotes

Introduction ignore

Now that the multi-body model of the micro-station has been developed and validated using dynamical measurements, a model of the active vibration platform can be integrated.

First, the mechanical architecture of the active platform needs to be carefully chosen. In Section ref:sec:nhexa_platform_review, a quick review of active vibration platforms is performed.

The chosen architecture is the Stewart platform, which is presented in Section ref:sec:nhexa_stewart_platform. It is a parallel manipulator that require the use of specific tools to study its kinematics.

However, to study the dynamics of the Stewart platform, the use of analytical equations is very complex. Instead, a multi-body model of the Stewart platform is developed (Section ref:sec:nhexa_model), that can then be easily integrated on top of the micro-station's model.

From a control point of view, the Stewart platform is a MIMO system with complex dynamics. To control such system, it requires several tools to study interaction (Section ref:sec:nhexa_control).

Active Vibration Platforms

<<sec:nhexa_platform_review>>

Introduction ignore

Goals:

- Quick review of active vibration platforms (5 or 6DoF) similar to NASS

- Explain why Stewart platform architecture is chosen

- Wanted controlled DOF: Y, Z, Ry

- But because of continuous rotation (key specificity): X,Y,Z,Rx,Ry in the frame of the active platform

-

Literature review? (maybe more suited for chapter 2)

- file:~/Cloud/work-projects/ID31-NASS/matlab/stewart-simscape/org/bibliography.org

- Talk about flexible joint? Maybe not so much as it should be topic of second chapter. Just say that we must of flexible joints that can be defined as 3 to 6DoF joints, and it will be optimize in chapter 2.

- cite:&taghirad13_paral

- For some systems, just XYZ control (stack stages), example: holler

- For other systems, Stewart platform (ID16a), piezo based

- Examples of Stewart platforms for general vibration control, some with Piezo, other with Voice coil. IFF, … Show different geometry configuration

- DCM: tripod?

Active vibration control of sample stages

Review of stages with online metrology for Synchrotrons

- Talk about external metrology? Maybe not the topic here.

- Talk about control architecture?

- Comparison with the micro-station / NASS

Serial and Parallel Manipulators

Goal:

- Explain why a parallel manipulator is here preferred

- Compact, 6DoF, higher control bandwidth, linear, simpler

- Show some example of serial and parallel manipulators

- A review of Stewart platform will be given in Chapter related to the detailed design of the Nano-Hexapod

| Serial Robots | Parallel Robots | |

|---|---|---|

| Advantages | Large Workspace | High Stiffness |

| Disadvantages | Low Stiffness | Small Workspace |

| Kinematic Struture | Open | Closed-loop |

The Stewart platform

<<sec:nhexa_stewart_platform>>

Introduction ignore

- Some history about Stewart platforms

- What is so special and why it is so used in different fields: give examples Explain advantages compared to serial architecture

- Little review (very quick: two extreme sizes, piezo + voice coil) Complete review of Stewart platforms will be made in Chapter 2

- Presentation of tools used to analyze the properties of the Stewart platform => useful for design and control

The Stewart Platform is very adapted for the NASS application for the following reasons:

- it is a fully parallel manipulator, thus all the motions errors can be compensated

- it is very compact compared to a serial manipulator

- it has high stiffness and good dynamic performances

The main disadvantage of Stewart platforms is the small workspace when compare the serial manipulators which is not a problem here.

Mechanical Architecture

<<ssec:nhexa_stewart_platform_architecture>>

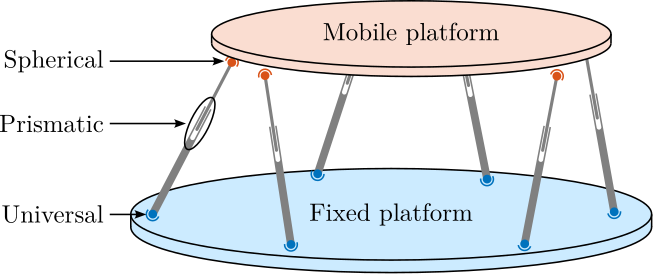

A Stewart manipulator consists of two platforms connected by six struts (Figure ref:fig:nhexa_stewart_architecture). Each strut is connected to the fixed and the mobile platforms with a joint. Typically, a universal joint is used on one side while a spherical joint is used on the other side1. In the strut, there is an active element working as a prismatic joint.

Such architecture allows to move the mobile platform with respect to the fixed platform in 6 degrees-of-freedom. It is therefore a fully parallel manipulator as the number of actuators is equal to the number of DoF. It is also a symmetrical parallel manipulator as typically all the struts are identical.

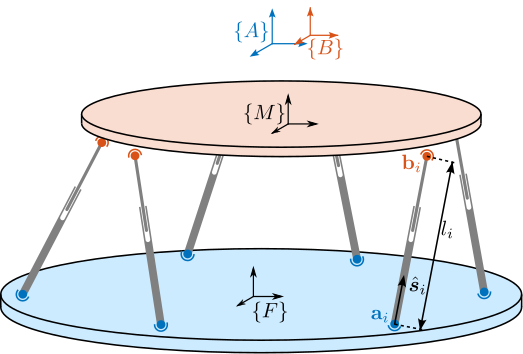

In order to study the Stewart platform, four important frames are typically defined:

- $\{F\}$: Frame fixed on the base and located at the center of its bottom surface. This is used to fix the Stewart platform to some support.

- $\{M\}$: Frame fixed to the moving platform and located at the center of its top surface. This is used to place things on top of the Stewart platform.

- $\{A\}$: Frame fixed to the fixed base, but located at the point-of-interest.

- $\{B\}$: Frame fixed to the moving platform and located at the same point-of-interest than $\{A\}$.

Frames $\{F\}$ and $\{M\}$ are useful to describe the location of the joints in a meaningful frame. On the other hand, frames $\{A\}$ and $\{B\}$ are used to describe the relative motion of the two platforms through the position vector ${}^A\bm{P}_B$ of $\{B\}$ expressed in $\{A\}$ and the rotation matrix ${}^A\bm{R}_B$ expressing the orientation of $\{B\}$ with respect to $\{A\}$. For the nano-hexapod, these frames are chosen to be located at the theoretical focus point of the X-ray light ($150\,mm$ above the top platform, i.e. above $\{M\}$).

Location of the joints and orientation and length of the struts are very important for the study of the Stewart platform as well. The center of rotation for the joint fixed to the base is noted $\bm{a}_i$, while $b_i$ is used for the top joints. The struts orientation are indicated by the unit vectors $\hat{\bm{s}}_i$ and their lengths by the scalars $l_i$. This is summarized in Figure ref:fig:nhexa_stewart_notations.

Kinematic Analysis

<<ssec:nhexa_stewart_platform_kinematics>>

Introduction ignore

Kinematic analysis refers to the study of the geometry of motion of a robot, without considering the forces that cause the motion.

Loop Closure

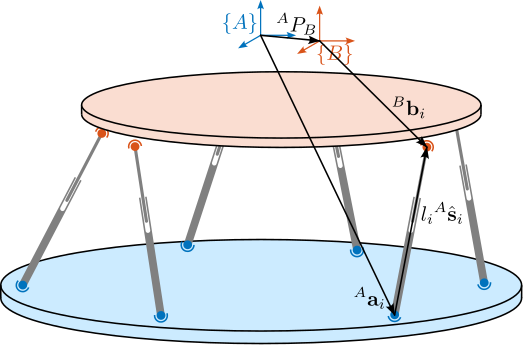

At the displacement level, the closure of each kinematic loop (illustrated in Figure ref:fig:nhexa_stewart_loop_closure) can be express in the vector form as

\begin{equation} \vec{ab} = \vec{aa_i} + \vec{a_ib_i} - \vec{bb_i} \quad \text{for } i = 1 \text{ to } 6 \end{equation}in which $\vec{aa_i}$ and $\vec{bb_i}$ can be easily obtained from the location of the joint on the base and on the moving platform.

The loop closure can be written as the unknown pose variables ${}^A\bm{P}$ and ${}^A\bm{R}_B$, the position vectors describing the known geometry of the base and of the moving platform, $\bm{a}_i$ and $\bm{b}_i$, and the strut vector $l_i {}^A\hat{\bm{s}}_i$: \begin{equation}\label{eq:nhexa_loop_close} {}^A\bm{P} = {}^A\bm{a}_i + l_i{}^A\hat{\bm{s}}_i - {}^A\bm{R}_B {}^B\bm{b}_i \quad \text{for } i=1 \text{ to } 6

\end{equation}

Inverse Kinematics

For inverse kinematic analysis, it is assumed that the position ${}^A\bm{P}$ and orientation of the moving platform ${}^A\bm{R}_B$ are given and the problem is to obtain the joint variables $\bm{\mathcal{L}} = \left[ l_1, l_2, l_3, l_4, l_5, l_6 \right]$. This problem can be easily solved using the loop closures eqref:eq:nhexa_loop_close.

The obtain joint variables are: \begin{equation}\label{eq:nhexa_inverse_kinematics} l_i = \sqrt{{}^A\bm{P}^T {}^A\bm{P} + {}^B\bm{b}_i^T {}^B\bm{b}_i + {}^A\bm{a}_i^T {}^A\bm{a}_i - 2 {}^A\bm{P}^T {}^A\bm{a}_i + 2 {}^A\bm{P}^T ≤ft[{}^A\bm{R}_B {}^B\bm{b}_i\right] - 2 ≤ft[{}^A\bm{R}_B {}^B\bm{b}_i\right]^T {}^A\bm{a}_i}

\end{equation}

If the position and orientation of the platform lie in the feasible workspace, the solution is unique. Otherwise, the solution gives complex numbers.

Forward Kinematics

In forward kinematic analysis, it is assumed that the vector of strut lengths $\bm{\mathcal{L}}$ is given and the problem is to find the position ${}^A\bm{P}$ and the orientation ${}^A\bm{R}_B$. This is a difficult problem that requires to solve nonlinear equations. In a next section, an approximate solution of the forward kinematics problem is proposed for small displacements.

The Jacobian Matrix

Introduction ignore

In vector calculus, the Jacobian matrix represents the best linear approximation of a vector-valued function near a working point. Consider a function $\bm{f}: \mathbb{R}^n \rightarrow \mathbb{R}^m$ with continuous first-order partial derivatives. For any input $\bm{x} \in \mathbb{R}^n$, this function produces an output $\bm{f}(\bm{x}) \in \mathbb{R}^m$. The Jacobian matrix $\bm{J}$ of $\bm{f}$ at point $\bm{x}$ is the $m \times n$ matrix whose $(i,j)$ entry is: $J_{ij} = \frac{\partial f_i}{\partial x_j}$ This matrix represents the linear transformation that best approximates $\bm{f}$ in a neighborhood of $\bm{x}$. In other words, for points sufficiently close to $\bm{x}$, the function $\bm{f}$ behaves approximately like its Jacobian matrix.

Jacobian Computation - Velocity Loop Closure

Let's note:

- $\bm{\mathcal{L}} = \left[ l_1, l_2, \ldots, l_6 \right]^T$: vector of actuated joint coordinates

- $\bm{\mathcal{X}} = \left[ {}^A\bm{P}, \bm{}^A\hat{\bm{s}} \right]^T$: vector of platform motion variables

$\bm{\mathcal{L}}$ and $\bm{\mathcal{X}}$ are related through a system of nonlinear algebraic equations representing the kinematic constraints imposed by the struts, which can be generally written as $f(\bm{\mathcal{L}}, \bm{\mathcal{X}}) = 0$.

We can differentiate this equation with respect to time and obtain:

\begin{equation*} \bm{J}_x \dot{\bm{\mathcal{X}}} = \bm{J}_l \dot{\bm{\mathcal{L}}} \quad \text{where} \quad \bm{J}_x = \frac{\partial f}{\partial \bm{\mathcal{X}}} \quad \text{and} \quad \bm{J}_l = -\frac{\partial f}{\partial \bm{\mathcal{L}}} \end{equation*}With:

- $\dot{\bm{\mathcal{L}}} = [ \dot{l}_1, \dot{l}_2, \dot{l}_3, \dot{l}_4, \dot{l}_5, \dot{l}_6 ]^T$

- $\dot{\bm{X}} = [^A\bm{v}_p, {}^A\bm{\omega}]^T$:

The general Jacobian matrix is defined as:

\begin{equation*} \dot{\bm{\mathcal{L}}} = \bm{J} \dot{\bm{\mathcal{X}}} \quad \text{with} \quad \bm{J} = {\bm{J}_l}^{-1} \bm{J}_x \end{equation*}The velocity loop closures are used for obtaining the Jacobian matrices in a straightforward manner: \[{}^A\bm{P} + {}^A\bm{R}_B {}^B\bm{b}_i = l_i {}^A\hat{\bm{s}}_i + {}^A\bm{a}_i\]

By taking the time derivative of the position loop close eqref:eq:nhexa_loop_close, the velocity loop closure is obtained:

\begin{equation} {}^A\bm{v}_p + {}^A \dot{\bm{R}}_B {}^B\bm{b}_i + {}^A\bm{R}_B \underbrace{{}^B\dot{\bm{b}_i}}_{=0} = \dot{l}_i {}^A\hat{\bm{s}}_i + l_i {}^A\dot{\hat{\bm{s}}}_i + \underbrace{{}^A\dot{a}_i}_{=0} \end{equation}Moreover, we have:

- ${}^A\dot{\bm{R}}_B {}^B\bm{b}_i = {}^A\bm{\omega} \times {}^A\bm{R}_B {}^B\bm{b}_i = {}^A\bm{\omega} \times {}^A\bm{b}_i$ in which ${}^A\bm{\omega}$ denotes the angular velocity of the moving platform expressed in the fixed frame $\{\bm{A}\}$.

- $l_i {}^A\dot{\hat{\bm{s}}}_i = l_i \left( {}^A\bm{\omega}_i \times \hat{\bm{s}}_i \right)$ in which ${}^A\bm{\omega}_i$ is the angular velocity of strut $i$ express in fixed frame $\{\bm{A}\}$.

By multiplying both sides by ${}^A\hat{s}_i$:

\begin{equation} {}^A\hat{\bm{s}}_i {}^A\bm{v}_p + \underbrace{{}^A\hat{\bm{s}}_i ({}^A\bm{\omega} \times {}^A\bm{b}_i)}_{=({}^A\bm{b}_i \times {}^A\hat{\bm{s}}_i) {}^A\bm{\omega}} = \dot{l}_i + \underbrace{{}^A\hat{s}_i l_i \left( {}^A\bm{\omega}_i \times {}^A\hat{\bm{s}}_i \right)}_{=0} \end{equation}Finally:

\begin{equation} \hat{\bm{s}}_i {}^A\bm{v}_p + ({}^A\bm{b}_i \times \hat{\bm{s}}_i) {}^A\bm{\omega} = \dot{l}_i \end{equation}We can rearrange the equations in a matrix form: \[ \dot{\bm{\mathcal{L}}} = \bm{J} \dot{\bm{\mathcal{X}}} \quad \text{with} \ \dot{\bm{\mathcal{L}}} = [ \dot{l}_1 \ \dots \ \dot{l}_6 ]^T \ \text{and} \ \dot{\bm{\mathcal{X}}} = [{}^A\bm{v}_p ,\ {}^A\bm{\omega}]^T \]

\begin{equation}\label{eq:nhexa_jacobian}

\bm{J} = \begin{bmatrix}

{\hat{\bm{s}}_1}^T & (\bm{b}_1 × \hat{\bm{s}}_1)^T

{\hat{\bm{s}}_2}^T & (\bm{b}_2 × \hat{\bm{s}}_2)^T

{\hat{\bm{s}}_3}^T & (\bm{b}_3 × \hat{\bm{s}}_3)^T

{\hat{\bm{s}}_4}^T & (\bm{b}_4 × \hat{\bm{s}}_4)^T

{\hat{\bm{s}}_5}^T & (\bm{b}_5 × \hat{\bm{s}}_5)^T

{\hat{\bm{s}}_6}^T & (\bm{b}_6 × \hat{\bm{s}}_6)^T

\end{bmatrix}

\end{equation}

$\bm{J}$ then depends only on:

- $\hat{\bm{s}}_i$ the orientation of the struts expressed in $\{A\}$

- $\bm{b}_i$ the position of the joints with respect to $O_B$ and express in $\{A\}$

The Jacobian matrix links the rate of change of strut length to the velocity and angular velocity of the top platform with respect to the fixed base. This Jacobian matrix needs to be recomputed for every Stewart platform pose.

Approximate solution of the Forward and Inverse Kinematic problems

For small displacements mobile platform displacement $\delta \bm{\mathcal{X}} = [\delta x, \delta y, \delta z, \delta \theta_x, \delta \theta_y, \delta \theta_z ]^T$ around $\bm{\mathcal{X}}_0$, the associated joint displacement can be computed using the Jacobian (approximate solution of the inverse kinematic problem): \begin{equation}\label{eq:nhexa_inverse_kinematics_approximate} \boxed{δ\bm{\mathcal{L}} = \bm{J} δ\bm{\mathcal{X}}}

\end{equation}

Similarly, for small joint displacements $\delta\bm{\mathcal{L}} = [ \delta l_1,\ \dots,\ \delta l_6 ]^T$ around $\bm{\mathcal{L}}_0$, it is possible to find the induced small displacement of the mobile platform (approximate solution of the forward kinematic problem): \begin{equation}\label{eq:nhexa_forward_kinematics_approximate} \boxed{δ\bm{\mathcal{X}} = \bm{J}-1 δ\bm{\mathcal{L}}}

\end{equation}

These two relations solve the forward and inverse kinematic problems for small displacement in a approximate way. As the inverse kinematic can be easily solved exactly this is not much useful, however, as the forward kinematic problem is difficult to solve, this approximation can be very useful for small displacements.

Range validity of the approximate inverse kinematics

As we know how to exactly solve the Inverse kinematic problem, we can compare the exact solution with the approximate solution using the Jacobian matrix. For small displacements, the approximate solution is expected to work well. We would like here to determine up to what displacement this approximation can be considered as correct.

Then, we can determine the range for which the approximate inverse kinematic is valid. This will also gives us the range for which the approximate forward kinematic is valid.

Let's first compare the perfect and approximate solution of the inverse for pure $x$ translations.

The approximate and exact required strut stroke to have the wanted mobile platform $x$ displacement are computed. The estimated error is shown in Figure etc…

For small wanted displacements (up to $\approx 1\%$ of the size of the Hexapod), the approximate inverse kinematic solution using the Jacobian matrix is quite correct.

In the case of the Nano-hexapod, the maximum stroke is estimate to the around $100\,\mu m$ while its size is around $100\,mm$, therefore the fixed Jacobian matrix is a very good approximate for the forward and inverse kinematics.

Static Forces

Let's note $\bm{\tau} = [\tau_1, \tau_2, \cdots, \tau_6]^T$ the vector of actuator forces applied in each strut and $\bm{\mathcal{F}} = [\bm{f}, \bm{n}]^T$ external force/torque action on the mobile platform at $\bm{O}_B$.

The principle of virtual work states that the total virtual work $\delta W$, done by all actuators and external forces is equal to zero:

\begin{equation} \delta W = \bm{\tau}^T \delta \bm{\mathcal{L}} - \bm{\mathcal{F}}^T \delta \bm{\mathcal{X}} = 0 \end{equation}From the definition of the Jacobian ($\delta \bm{\mathcal{L}} = \bm{J} \cdot \delta \bm{\mathcal{X}}$), we have $\left( \bm{\tau}^T \bm{J} - \bm{\mathcal{F}}^T \right) \delta \bm{\mathcal{X}} = 0$ that holds for any $\delta \bm{\mathcal{X}}$, hence:

\begin{equation} \bm{\tau}^T \bm{J} - \bm{\mathcal{F}}^T = 0 \quad \Rightarrow \quad \boxed{\bm{\mathcal{F}} = \bm{J}^T \bm{\tau}} \quad \text{and} \quad \boxed{\bm{\tau} = \bm{J}^{-T} \bm{\mathcal{F}}} \end{equation}Therefore, the same Jacobian matrix can also be used to map actuator forces to forces and torques applied on the mobile platform at the defined frame $\{B\}$.

Static Analysis

<<ssec:nhexa_stewart_platform_static>>

How stiffness varies with orientation of struts. Same with stroke? Or maybe in the detailed chapter?

The stiffness of the actuator $k_i$ links the applied actuator force $\delta \tau_i$ and the corresponding small deflection $\delta l_i$:

\begin{equation*} \tau_i = k_i \delta l_i, \quad i = 1,\ \dots,\ 6 \end{equation*}If we combine these 6 relations:

\begin{equation*} \bm{\tau} = \mathcal{K} \delta \bm{\mathcal{L}} \quad \mathcal{K} = \text{diag}\left[ k_1,\ \dots,\ k_6 \right] \end{equation*}Substituting $\bm{\tau} = \bm{J}^{-T} \bm{\mathcal{F}}$ and $\delta \bm{\mathcal{L}} = \bm{J} \cdot \delta \bm{\mathcal{X}}$ gives

\begin{equation} \bm{\mathcal{F}} = \bm{J}^T \mathcal{K} \bm{J} \cdot \delta \bm{\mathcal{X}} \end{equation}And then we identify the stiffness matrix $\bm{K}$:

\begin{equation} \bm{K} = \bm{J}^T \mathcal{K} \bm{J} \end{equation}If the stiffness matrix $\bm{K}$ is inversible, the compliance matrix of the manipulator is defined as

\begin{equation} \bm{C} = \bm{K}^{-1} = (\bm{J}^T \mathcal{K} \bm{J})^{-1} \end{equation}The compliance matrix of a manipulator shows the mapping of the moving platform wrench applied at $\bm{O}_B$ to its small deflection by

\begin{equation} \delta \bm{\mathcal{X}} = \bm{C} \cdot \bm{\mathcal{F}} \end{equation}Conclusion: stiffness/compliance of the Stewart platform depends on the Jacobian matrix, therefore on the position and orientation of the struts.

Dynamic Analysis

<<ssec:nhexa_stewart_platform_dynamics>>

If one wants to study the dynamics of the Stewart platform, …

Let's suppose that the struts are mass-less, that the joints are perfect. Suppose the

Very complex => multi-body model For instance, compute the plant for massless struts and perfect joints (will be compared with Simscape model). But say that if we want to model more complex cases, it becomes impractical (cite papers).

\begin{equation} M s^2 \mathcal{X} = \Sigma \mathcal{F} \end{equation}Forces are:

- Actuator forces: $\mathcal{F} = \bm{J}^T \tau$

- Stiffness of the struts: $-J^T \mathcal{K} J \mathcal{X}$

- Damping of the struts: $-J^T \mathcal{C} J \dot{\mathcal{X}}$

Equation in the cartesian frame:

\begin{equation} \frac{\mathcal{X}}{\mathcal{F}}(s) = ( M s^2 + \bm{J}^{T} \mathcal{C} J s + \bm{J}^{T} \mathcal{K} J )^{-1} \end{equation}Using the Jacobian, equation in the strut frame:

\begin{equation} \frac{\mathcal{L}}{\tau}(s) = ( \bm{J}^{-T} M \bm{J}^{-1} s^2 + \mathcal{C} + \mathcal{K} )^{-1} \end{equation}It becomes much more complex when:

- model the mass of the struts, or more complex strut dynamics

- take into account flexible joint stiffnesses

- would not be practical to combine with the dynamical equations of the micro-station

%% Plant using Analytical Equations

% Stewart platform definition

k = 1e6; % Actuator stiffness [N/m]

c = 1e1; % Actuator damping [N/(m/s)]

stewart = initializeSimplifiedNanoHexapod('Mpm', 1e-3, 'actuator_type', '1dof', 'actuator_k', k, 'actuator_c', c);

% Payload: Cylinder

h = 300e-3; % Height of the cylinder [m]

r = 110e-3; % Radius of the cylinder [m]

m = 10; % Mass of the payload [kg]

initializeSample('type', 'cylindrical', 'm', m, 'H', h, 'R', r);

% Mass Matrix

M = zeros(6,6);

M(1,1) = m;

M(2,2) = m;

M(3,3) = m;

M(4,4) = 1/12*m*(3*r^2 + h^2);

M(5,5) = 1/12*m*(3*r^2 + h^2);

M(6,6) = 1/2*m*r^2;

% Stiffness and Damping matrices

K = k*eye(6);

C = c*eye(6);

% Compute plant in the frame of the struts

G_analytical = inv(ss(inv(stewart.geometry.J')*M*inv(stewart.geometry.J)*s^2 + C*s + K));

% Compare with Simscape model

initializeLoggingConfiguration('log', 'none');

initializeController('type', 'open-loop');

% Input/Output definition

clear io; io_i = 1;

io(io_i) = linio([mdl, '/Controller'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs [N]

io(io_i) = linio([mdl, '/plant'], 2, 'openoutput', [], 'dL'); io_i = io_i + 1; % Encoders [m]

G_simscape = linearize(mdl, io);

G_simscape.InputName = {'f1', 'f2', 'f3', 'f4', 'f5', 'f6'};

G_simscape.OutputName = {'dL1', 'dL2', 'dL3', 'dL4', 'dL5', 'dL6'};bodeFig({G_analytical(1,1), G_simscape(1,1), G_analytical(1,2), G_simscape(1,2)})Conclusion

Dynamic analysis of parallel manipulators presents an inherent complexity due to their closed-loop structure and kinematic constraints.

All depends on the geometry. Reasonable choice of geometry is made in chapter 1. Optimization of the geometry will be made in chapter 2.

The static analysis supposed that joints are perfect. It gets more complex if flexible joints are used with stiffnesses that are not negligible. cite:&mcinroy00_desig_contr_flexur_joint_hexap;&mcinroy02_model_desig_flexur_joint_stewar

Multi-Body Model

<<sec:nhexa_model>>

Introduction ignore

Goal:

- Study the dynamics of Stewart platform

- Instead of working with complex analytical models: a multi-body model is used. Complex because has to model the inertia of the struts. Cite papers that tries to model the stewart platform analytically Advantage: it will be easily included in the model of the NASS

- Mention the Toolbox (maybe make a DOI for that)

-

Have a table somewhere that summarizes the main characteristics of the nano-hexapod model

- location of joints

- size / mass of platforms, etc…

Model Definition

<<ssec:nhexa_model_def>>

- Make a schematic of the definition process (for instance knowing the ai, bi points + {A} and {B} allows to compute Jacobian, etc…)

-

What is important for the model:

- Inertia of plates and struts

- Positions of joints / Orientation of struts

- Definition of frames (for Jacobian, stiffness analysis, etc…)

Then, several things can be computed:

- Kinematics, stiffness, platform mobility, dynamics, etc…

- Joints: can be 2dof to 6dof

- Actuators: can be modelled as wanted

Nano Hexapod

<<ssec:nhexa_model_nano_hexapod>>

Start simple:

- Perfect joints, massless actuators

Joints: perfect 2dof/3dof (+ mass-less) Actuators: APA + Encoder (mass-less)

- k = 1N/um

- Force sensor

Definition of each part + Plant with defined inputs/outputs (force sensor, relative displacement sensor, etc…)

Model Dynamics

<<ssec:nhexa_model_dynamics>>

- If all is perfect (mass-less struts, perfect joints, etc…), maybe compare analytical model with simscape model?

- Say something about the model order Model order is 12, and that we can compute modes from matrices M and K, compare with the Simscape model

- 4 observed modes (due to symmetry, in reality 6 modes)

- Compare with analytical formulas (see number of states)

- Effect of 2DoF APA on IFF plant?

initializeSimplifiedNanoHexapod('flex_type_F', '2dof', 'flex_type_M', '3dof', 'actuator_type', '1dof');

initializeSample('type', 'cylindrical', 'm', 50, 'H', 300e-3);

initializeLoggingConfiguration('log', 'none');

initializeController('type', 'open-loop');

% Input/Output definition

clear io; io_i = 1;

io(io_i) = linio([mdl, '/Controller'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs [N]

io(io_i) = linio([mdl, '/plant'], 2, 'openoutput', [], 'dL'); io_i = io_i + 1; % Encoders [m]

io(io_i) = linio([mdl, '/plant'], 2, 'openoutput', [], 'fn'); io_i = io_i + 1; % Force Sensors [N]

% With no payload

G = linearize(mdl, io);

G.InputName = {'f1', 'f2', 'f3', 'f4', 'f5', 'f6'};

G.OutputName = {'dL1', 'dL2', 'dL3', 'dL4', 'dL5', 'dL6', ...

'fn1', 'fn2', 'fn3', 'fn4', 'fn5', 'fn6'};

size(G)Conclusion

- Validation of multi-body model in a simple case

-

Possible to increase the model complexity when required

- If considered 6dof joint stiffness, model order increases

- Can have an effect on IFF performances: cite:&preumont07_six_axis_singl_stage_activ

- Conclusion: during the conceptual design, we consider a perfect, but will be taken into account later

- Optimization of the Flexible joint will be performed in Chapter 2.2

- MIMO system: how to control? => next section

Control of Stewart Platforms

<<sec:nhexa_control>>

Introduction ignore

MIMO control: much more complex than SISO control because of interaction. Possible to ignore interaction when good decoupling is achieved. Important to have tools to study interaction Different ways to try to decouple a MIMO plant.

Reference book: cite:&skogestad07_multiv_feedb_contr

Centralized and Decentralized Control

<<ssec:nhexa_control_centralized_decentralized>>

-

Explain what is centralized and decentralized:

- linked to the sensor position relative to the actuators

- linked to the fact that sensors and actuators pairs are "independent" or each other (related to the control architecture, not because there is no coupling)

- When can decentralized control be used and when centralized control is necessary? Study of interaction: RGA

Choice of the control space

<<ssec:nhexa_control_space>>

- file:~/Cloud/research/matlab/decoupling-strategies/svd-control.org

- Jacobian matrices, CoK, CoM, control in the frame of the struts, SVD, Modal, …

- Combined CoM and CoK => Discussion of cubic architecture ? (quick, as it is going to be in detailed in chapter 2)

- Explain also the link with the setpoint: it is interesting to have the controller in the frame of the performance variables Also speak about disturbances? (and how disturbances can be mixed to different outputs due to control and interaction)

- Table that summarizes the trade-off for each strategy

- Say that in this study, we will do the control in the frame of the struts for simplicity (even though control in the cartesian frame was also tested)

Maybe all details about control should be in chapter 2, dedicated to control Here, just say that using kinematics, we control in the frame of the struts

%% Control at the CoM

stewart = initializeSimplifiedNanoHexapod('Mpm', 1e-3); % Massless top platform

initializeSample('type', 'cylindrical', 'm', 10, 'H', 300e-3);

initializeLoggingConfiguration('log', 'none');

initializeController('type', 'open-loop');

% Input/Output definition

clear io; io_i = 1;

io(io_i) = linio([mdl, '/Controller'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs [N]

io(io_i) = linio([mdl, '/plant'], 2, 'openoutput', [], 'dL'); io_i = io_i + 1; % Encoders [m]

% With no payload

G = linearize(mdl, io);

G.InputName = {'f1', 'f2', 'f3', 'f4', 'f5', 'f6'};

G.OutputName = {'dL1', 'dL2', 'dL3', 'dL4', 'dL5', 'dL6'};

J = stewart.geometry.J;

Gm = inv(J)*G*inv(J');Active Damping with Decentralized IFF

<<ssec:nhexa_control_iff>>

Guaranteed stability: cite:&preumont08_trans_zeros_struc_contr_with

- I think there is another paper about that

For decentralized control: "MIMO root locus" can be used to estimate the damping / optimal gain Poles and converging towards transmission zeros

How to optimize the added damping to all modes?

- Add some papers citations

Compute:

- Plant dynamics

- Root Locus

MIMO High-Authority Control - Low-Authority Control

<<ssec:nhexa_control_hac_lac>>

Compute:

- compare open-loop and damped plant (outputs are the encoders)

- Implement decentralized control?

-

Check stability:

- Characteristic Loci: Eigenvalues of $G(j\omega)$ plotted in the complex plane

- Generalized Nyquist Criterion: If $G(s)$ has $p_0$ unstable poles, then the closed-loop system with return ratio $kG(s)$ is stable if and only if the characteristic loci of $kG(s)$, taken together, encircle the point $-1$, $p_0$ times anti-clockwise, assuming there are no hidden modes

- Show some performance metric? For instance compliance?

Conclusion

Conclusion

<<sec:nhexa_conclusion>>

- Configurable Stewart platform model

- Will be included in the multi-body model of the micro-station => nass multi body model

- Control: complex problem, try to use simplest architecture

Bibliography ignore

Footnotes

1Different architecture exists, typically referred as "6-SPS" (Spherical, Prismatic, Spherical) or "6-UPS" (Universal, Prismatic, Spherical)