Flexible Joints - Test Bench

Table of Contents

- 1. Flexible Joints

- 2. Measurement Test Bench - Bending Stiffness

- 3. Error budget

- 3.1. Finite Element Model

- 3.2. Setup

- 3.3. Effect of Bending

- 3.4. Computation of the bending stiffness

- 3.5. Estimation error due to force and displacement sensors accuracy

- 3.6. Estimation error due to Shear

- 3.7. Estimation error due to force sensor compression

- 3.8. Estimation error due to height estimation error

- 3.9. Conclusion

- 4. First Measurements

- 5. Bending Stiffness Measurement

This report is also available as a pdf.

In this document, we present a test-bench that has been developed in order to measure the bending stiffness of flexible joints.

It is structured as follow:

- Section 1: the geometry of the flexible joints and the expected stiffness and stroke are presented

- Section 2: the measurement bench is presented

- Section 3: an error budget is performed in order to estimate the accuracy of the measured stiffness

- Section 4: first measurements are performed

- Section 5: the bending stiffness of the flexible joints are measured

1 Flexible Joints

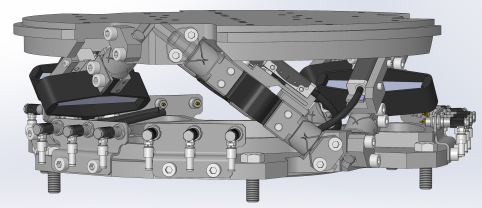

The flexible joints that are going to be measured in this document have been design to be used with a Nano-Hexapod (Figure 1).

Figure 1: CAD view of the Nano-Hexapod containing the flexible joints

Ideally, these flexible joints would behave as perfect ball joints, that is to say:

- no bending and torsional stiffnesses

- infinite shear and axial stiffnesses

- un-limited bending and torsional stroke

- no friction, no backlash

The real characteristics of the flexible joints will influence the dynamics of the Nano-Hexapod. Using a multi-body dynamical model of the nano-hexapod, the specifications in term of stiffness and stroke of the flexible joints have been determined and summarized in Table 1.

| Specification | FEM | |

|---|---|---|

| Axial Stiffness | > 100 [N/um] | 94 |

| Shear Stiffness | > 1 [N/um] | 13 |

| Bending Stiffness | < 100 [Nm/rad] | 5 |

| Torsion Stiffness | < 500 [Nm/rad] | 260 |

| Bending Stroke | > 1 [mrad] | 24.5 |

| Torsion Stroke | > 5 [urad] |

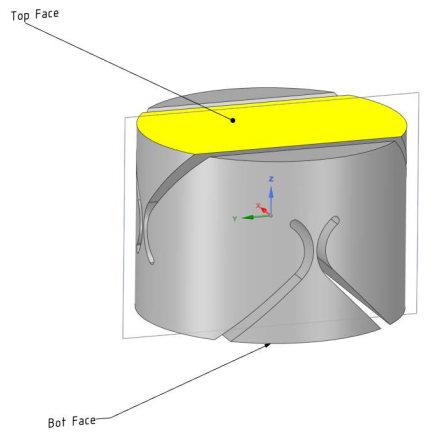

Then, the classical geometry of a flexible ball joint shown in Figure 2 has been optimized in order to meet the requirements. This has been done using a Finite Element Software and the obtained joint’s characteristics are summarized in Table 1.

Figure 2: Flexible part of the Joint used for FEM - CAD view

The obtained geometry are defined in the drawings of the flexible joints. The material is a special kind of stainless steel called “F16PH”..

2 Measurement Test Bench - Bending Stiffness

The most important characteristic of the flexible joint that we want to measure is its bending stiffness \(k_{R_x} \approx k_{R_y}\).

To do so, we have to apply a torque \(T_x\) on the flexible joint and measure its angular deflection \(\theta_x\). The stiffness is then

\begin{equation} k_{R_x} = \frac{T_x}{\theta_x} \end{equation}As it is quite difficult to apply a pure torque, a force will be applied instead. The application point of the force should far enough from the flexible part such that the obtained bending is much larger than the displacement in shear.

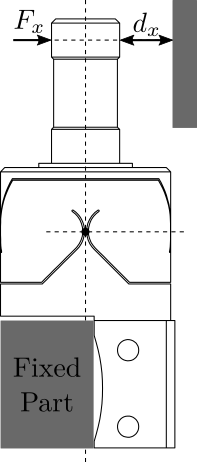

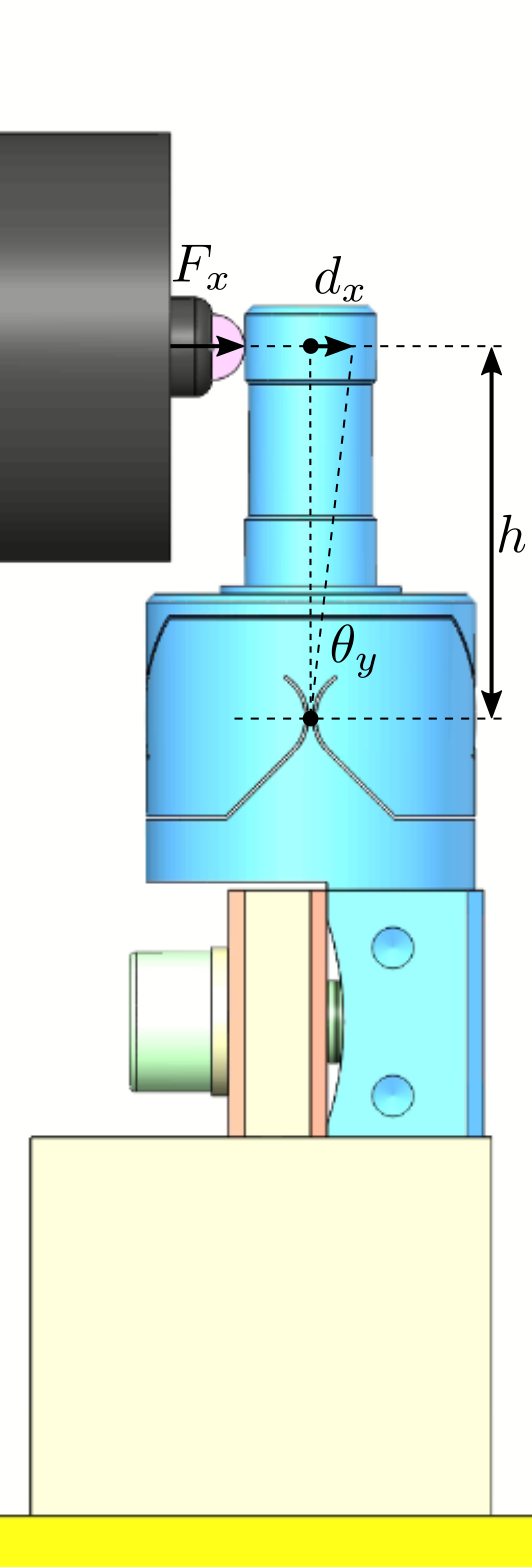

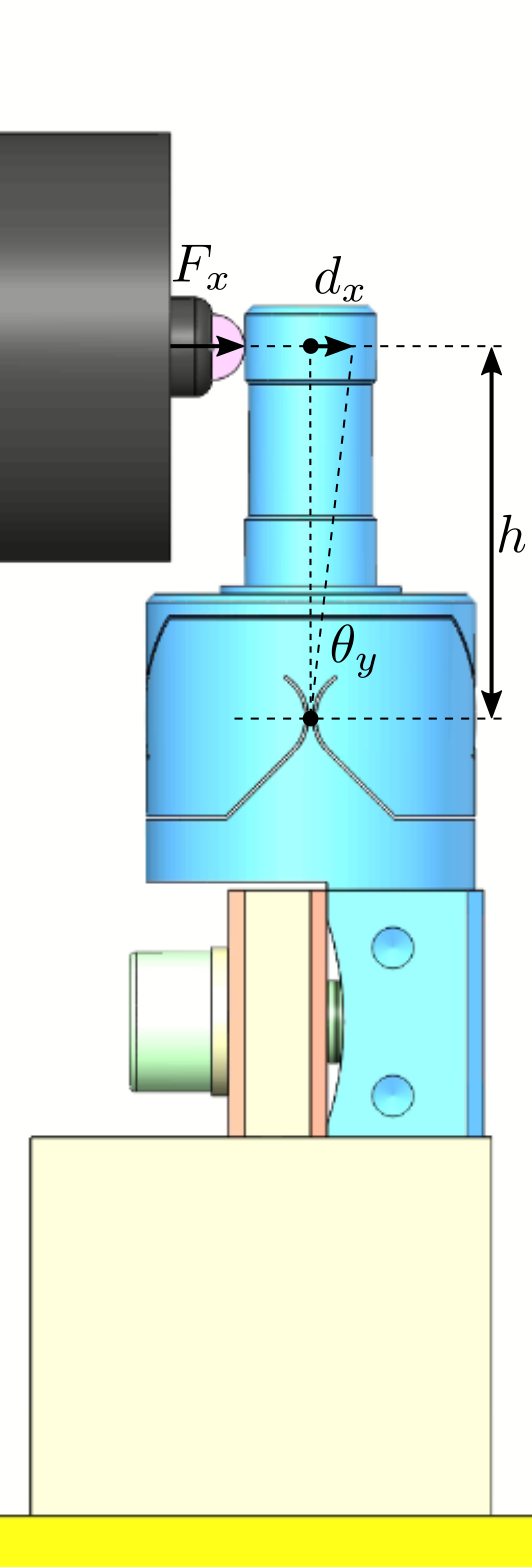

The working principle of the bench is schematically shown in Figure 3. One part of the flexible joint is fixed. On the mobile part, a force \(F_x\) is applied which is equivalent to a torque applied on the flexible joint center. The induced rotation is measured with a displacement sensor \(d_x\).

Figure 3: Test Bench - working principle

This test-bench will be used to have a first approximation of the bending stiffnesss and stroke of the flexible joints. Another test-bench, better engineered will be used to measure the flexible joint’s characteristics with better accuracy.

2.1 Flexible joint Geometry

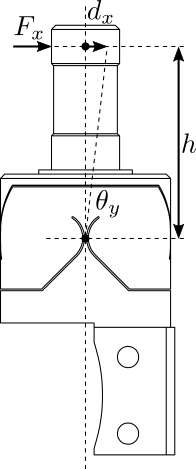

The flexible joint used for the Nano-Hexapod is shown in Figure 4. Its bending stiffness is foreseen to be \(k_{R_y}\approx 5\,\frac{Nm}{rad}\) and its stroke \(\theta_{y,\text{max}}\approx 25\,mrad\).

Figure 4: Geometry of the flexible joint

The height between the flexible point (center of the joint) and the point where external forces are applied is \(h = 20\,mm\).

Let’s define the parameters on Matlab.

kRx = 5; % Bending Stiffness [Nm/rad] Rxmax = 25e-3; % Bending Stroke [rad] h = 20e-3; % Height [m]

2.2 Required external applied force

The bending \(\theta_y\) of the flexible joint due to the force \(F_x\) is:

\begin{equation} \theta_y = \frac{M_y}{k_{R_y}} = \frac{F_x h}{k_{R_y}} \end{equation}Therefore, the applied force to test the full range of the flexible joint is:

\begin{equation} F_{x,\text{max}} = \frac{k_{R_y} \theta_{y,\text{max}}}{h} \end{equation}Fxmax = kRx*Rxmax/h; % Force to induce maximum stroke [N]

And we obtain:

\begin{equation} F_{x,max} = 6.2\, [N] \end{equation}The measurement range of the force sensor should then be higher than \(6.2\,N\).

2.3 Required actuator stroke and sensors range

The flexible joint is designed to allow a bending motion of \(\pm 25\,mrad\). The corresponding stroke at the location of the force sensor is: \[ d_{x,\text{max}} = h \tan(R_{x,\text{max}}) \]

dxmax = h*tan(Rxmax);

In order to test the full range of the flexible joint, the stroke of the translation stage used to move the force sensor should be higher than \(0.5\,mm\). Similarly, the measurement range of the displacement sensor should also be higher than \(0.5\,mm\).

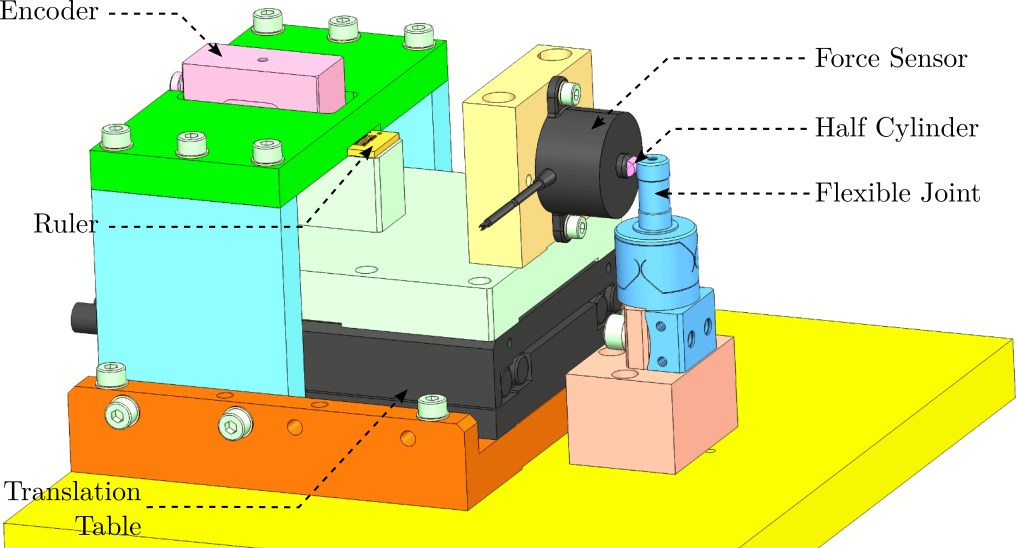

2.4 Test Bench

A CAD view of the measurement bench is shown in Figure 5.

Here are the different elements used in this bench:

- Translation Stage: V-408

- Load Cells: FC2231-0000-0010-L

- Encoder: Renishaw Resolute 1nm

Both the measured force and displacement are acquired at the same time using a Speedgoat machine.

Figure 5: Schematic of the test bench to measure the bending stiffness of the flexible joints

A side view of the bench with the important quantities are shown in Figure 6.

Figure 6: Schematic of the test bench to measure the bending stiffness of the flexible joints

3 Error budget

Many things can impact the accuracy of the measured bending stiffness such as:

- Errors in the force and displacement measurement

- Shear effects

- Deflection of the Force sensor

- Errors in the geometry of the bench

In this section, we wish to estimate the attainable accuracy with the current bench, and identified the limiting factors.

3.1 Finite Element Model

From the Finite Element Model, the stiffness and stroke of the flexible joint have been computed and summarized in Tables 2 and 3.

| Stiffness [N/um] | Max Force [N] | Stroke [um] | |

|---|---|---|---|

| Axial | 94 | 469 | 5 |

| Shear | 13 | 242 | 19 |

| Stiffness [Nm/rad] | Max Torque [Nmm] | Stroke [mrad] | |

|---|---|---|---|

| Bending | 5 | 118 | 24 |

| Torsional | 260 | 1508 | 6 |

3.2 Setup

The setup is schematically represented in Figure 7.

The force is applied on top of the flexible joint with a distance \(h\) with the joint’s center. The displacement of the flexible joint is also measured at the same height.

The height between the joint’s center and the force application point is:

h = 25e-3; % Height [m]

Figure 7: Schematic of the test bench to measure the bending stiffness of the flexible joints

3.3 Effect of Bending

The torque applied is:

\begin{equation} M_y = F_x \cdot h \end{equation}The flexible joint is experiencing a rotation \(\theta_y\) due to the torque \(M_y\):

\begin{equation} \theta_y = \frac{M_y}{k_{R_y}} = \frac{F_x \cdot h}{k_{R_y}} \end{equation}This rotation is then measured by the displacement sensor. The measured displacement is:

\begin{equation} D_b = h \tan(\theta_y) = h \tan\left( \frac{F_x \cdot h}{k_{R_y}} \right) \label{eq:bending_stiffness_formula} \end{equation}3.4 Computation of the bending stiffness

From equation \eqref{eq:bending_stiffness_formula}, we can compute the bending stiffness:

\begin{equation} k_{R_y} = \frac{F_x \cdot h}{\tan^{-1}\left( \frac{D_b}{h} \right)} \end{equation}For small displacement, we have

\begin{equation} \boxed{k_{R_y} \approx h^2 \frac{F_x}{d_x}} \end{equation}And therefore, to precisely measure \(k_{R_y}\), we need to:

- precisely measure the motion \(d_x\)

- precisely measure the applied force \(F_x\)

- precisely now the height of the force application point \(h\)

3.5 Estimation error due to force and displacement sensors accuracy

The maximum error on the measured displacement with the encoder is 40 nm. This quite negligible compared to the measurement range of 0.5 mm.

The accuracy of the force sensor is around 1% and therefore, we should expect to have an accuracy on the measured stiffness of at most 1%.

3.6 Estimation error due to Shear

The effect of Shear on the measured displacement is simply:

\begin{equation} D_s = \frac{F_x}{k_s} \end{equation}The measured displacement will be the effect of shear + effect of bending

\begin{equation} d_x = D_b + D_s = h \tan\left( \frac{F_x \cdot h}{k_{R_y}} \right) + \frac{F_x}{k_s} \approx F_x \left( \frac{h^2}{k_{R_y}} + \frac{1}{k_s} \right) \end{equation}The estimated bending stiffness \(k_{\text{est}}\) will then be:

\begin{equation} k_{\text{est}} = h^2 \frac{F_x}{d_x} \approx k_{R_y} \frac{1}{1 + \frac{k_{R_y}}{k_s h^2}} \end{equation}The measurement error due to Shear is 0.1 %

3.7 Estimation error due to force sensor compression

The measured displacement is not done directly at the joint’s location. The force sensor compression will then induce an error on the joint’s stiffness.

The force sensor stiffness \(k_F\) is estimated to be around:

kF = 50/0.05e-3; % [N/m]

k_F = 1.0e+06 [N/m]

The measured displacement will be the sum of the displacement induced by the bending and by the compression of the force sensor:

\begin{equation} d_x = D_b + \frac{F_x}{k_F} = h \tan\left( \frac{F_x \cdot h}{k_{R_y}} \right) + \frac{F_x}{k_F} \approx F_x \left( \frac{h^2}{k_{R_y}} + \frac{1}{k_F} \right) \end{equation}The estimated bending stiffness \(k_{\text{est}}\) will then be:

\begin{equation} k_{\text{est}} = h^2 \frac{F_x}{d_x} \approx k_{R_y} \frac{1}{1 + \frac{k_{R_y}}{k_F h^2}} \end{equation}The measurement error due to height estimation errors is 0.8 %

3.8 Estimation error due to height estimation error

Let’s consider an error in the estimation of the height from the application of the force to the joint’s center:

\begin{equation} h_{\text{est}} = h (1 + \epsilon) \end{equation}The computed bending stiffness will be:

\begin{equation} k_\text{est} \approx h_{\text{est}}^2 \frac{F_x}{d_x} \end{equation}And the stiffness estimation error is:

\begin{equation} \frac{k_{\text{est}}}{k_{R_y}} = (1 + \epsilon)^2 \end{equation}h_err = 0.2e-3; % Height estimation error [m]

The measurement error due to height estimation errors of 0.2 [mm] is 1.6 %

3.9 Conclusion

Based on the above analysis, we should expect no better than few percent of accuracy using the current test-bench. This is well enough for a first estimation of the bending stiffness of the flexible joints.

Another measurement bench allowing better accuracy will be developed.

4 First Measurements

4.1 Agreement between the probe and the encoder

- Load Cells: FC2231-0000-0010-L (and XFL212R)

- Encoder: Renishaw Resolute 1nm

- Displacement Probe: Millimar C1216 electronics and Millimar 1318 probe

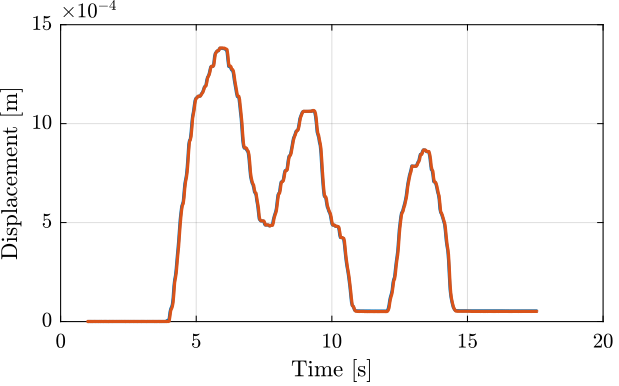

The measurement setup is made such that the probe measured the translation table displacement. It should then measure the same displacement as the encoder. Using this setup, we should be able to compare the probe and the encoder.

Let’s load the measurements.

load('meas_probe_against_encoder.mat', 't', 'd', 'dp', 'F')

The time domain measured displacement by the probe and by the encoder is shown in Figure 8.

Figure 8: Time domain measurement

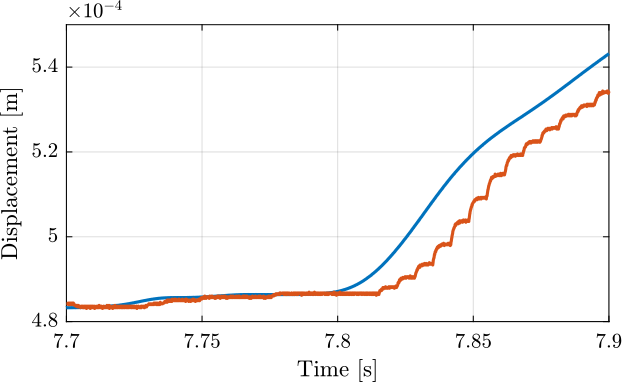

If we zoom, we see that there is some delay between the encoder and the probe (Figure 9).

Figure 9: Time domain measurement (Zoom)

This delay is estimated using the finddelay command.

The time delay is approximately 15.8 [ms]

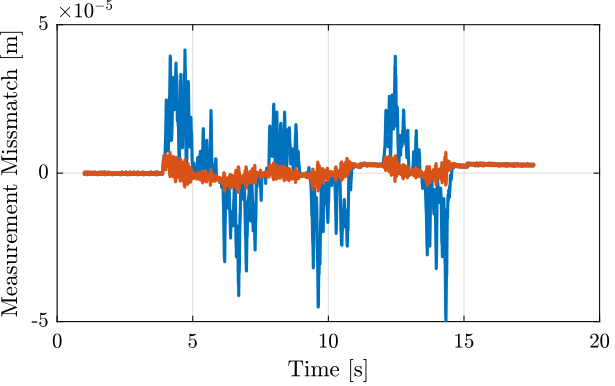

The measured mismatch between the encoder and the probe with and without compensating for the time delay are shown in Figure 10.

Figure 10: Measurement mismatch, with and without delay compensation

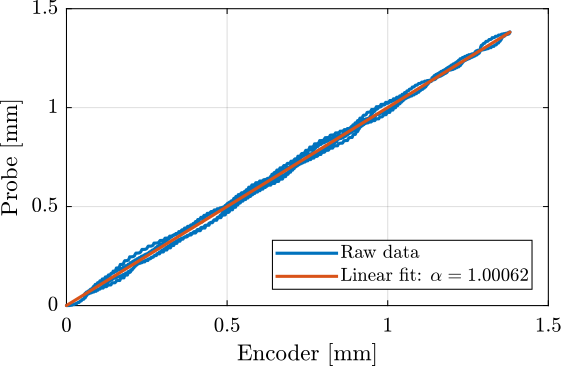

Finally, the displacement of the probe is shown as a function of the displacement of the encoder and a linear fit is made (Figure 11).

Figure 11: Measured displacement by the probe as a function of the measured displacement by the encoder

From the measurement, it is shown that the probe is well calibrated. However, there is some time delay of tens of milliseconds that could induce some measurement errors.

4.2 Measurement of the Millimar 1318 probe stiffness

- Translation Stage: V-408

- Load Cell: FC2231-0000-0010-L

- Encoder: Renishaw Resolute 1nm

- Displacement Probe: Millimar C1216 electronics and Millimar 1318 probe

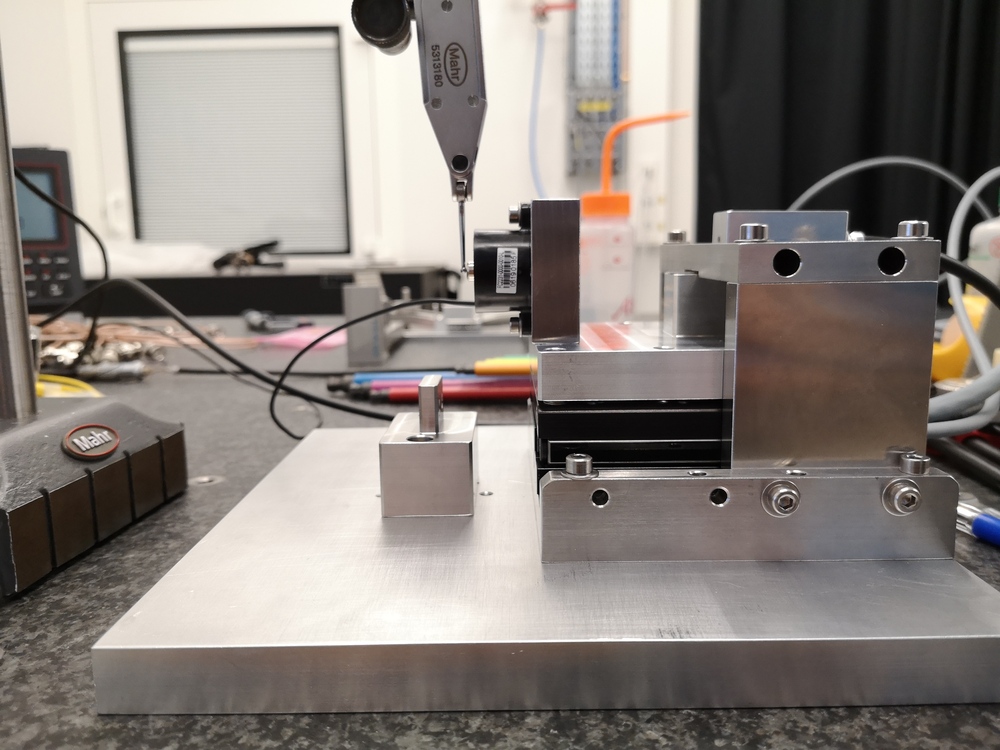

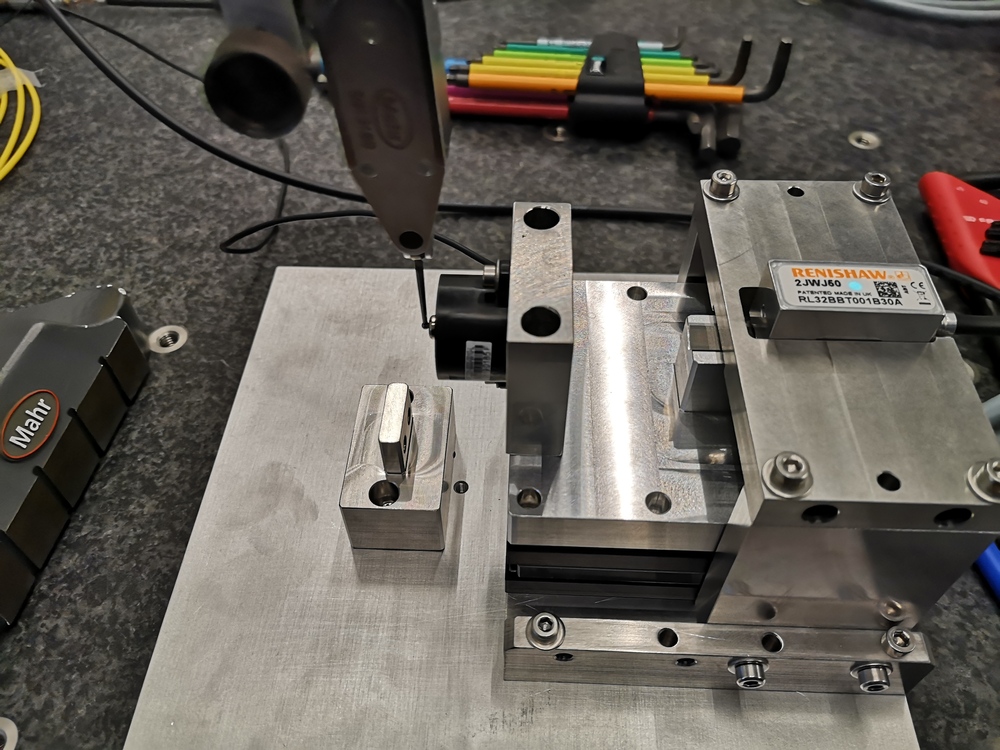

Figure 12: Setup - Side View

Figure 13: Setup - Top View

Let’s load the measurement results.

load('meas_stiff_probe.mat', 't', 'd', 'dp', 'F')

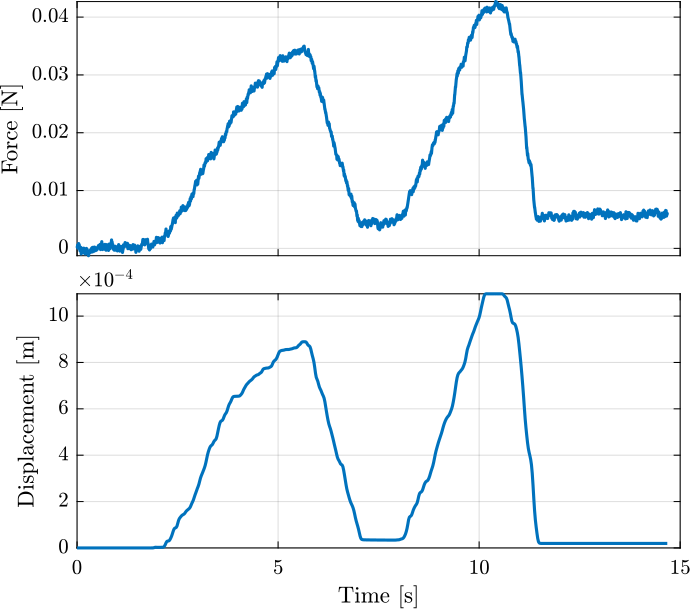

The time domain measured force and displacement are shown in Figure 14.

Figure 14: Time domain measurements

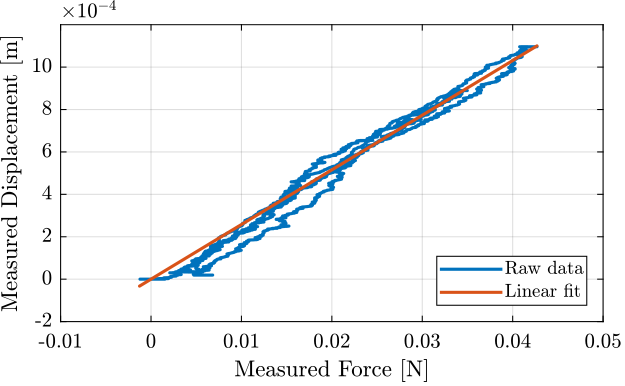

Now we can estimate the stiffness with a linear fit.

Stiffness is 0.039 [N/mm]

This is very close to the 0.04 [N/mm] written in the Millimar 1318 probe datasheet.

And compare the linear fit with the raw measurement data (Figure 15).

Figure 15: Measured displacement as a function of the measured force. Raw data and linear fit

The Millimar 1318 probe has a stiffness of \(\approx 0.04\,[N/mm]\).