Nano-Hexapod - Test Bench

Table of Contents

- 1. Encoders fixed to the Struts

- 1.1. Introduction

- 1.2. Identification of the dynamics

- 1.3. Comparison with the Simscape Model

- 1.3.1. Load measured FRF

- 1.3.2. Dynamics from Actuator to Force Sensors

- 1.3.3. Dynamics from Actuator to Encoder

- 1.3.4. Effect of a change in bending damping of the joints

- 1.3.5. Effect of a change in damping factor of the APA

- 1.3.6. Effect of a change in stiffness damping coef of the APA

- 1.3.7. Effect of a change in mass damping coef of the APA

- 1.3.8. Using Flexible model

- 1.3.9. Flexible model + encoders fixed to the plates

- 1.4. Integral Force Feedback

- 1.5. Modal Analysis

- 1.6. Accelerometers fixed on the top platform

- 2. Encoders fixed to the plates

- 2.1. Identification of the dynamics

- 2.2. Comparison with the Simscape Model

- 2.3. Integral Force Feedback

- 2.4. HAC Control - Frame of the struts

- 2.5. Reference Tracking

- 2.6. Feedforward (Open-Loop) Control

- 2.7. Feedback/Feedforward control in the frame of the struts

- 3. Functions

This report is also available as a pdf.

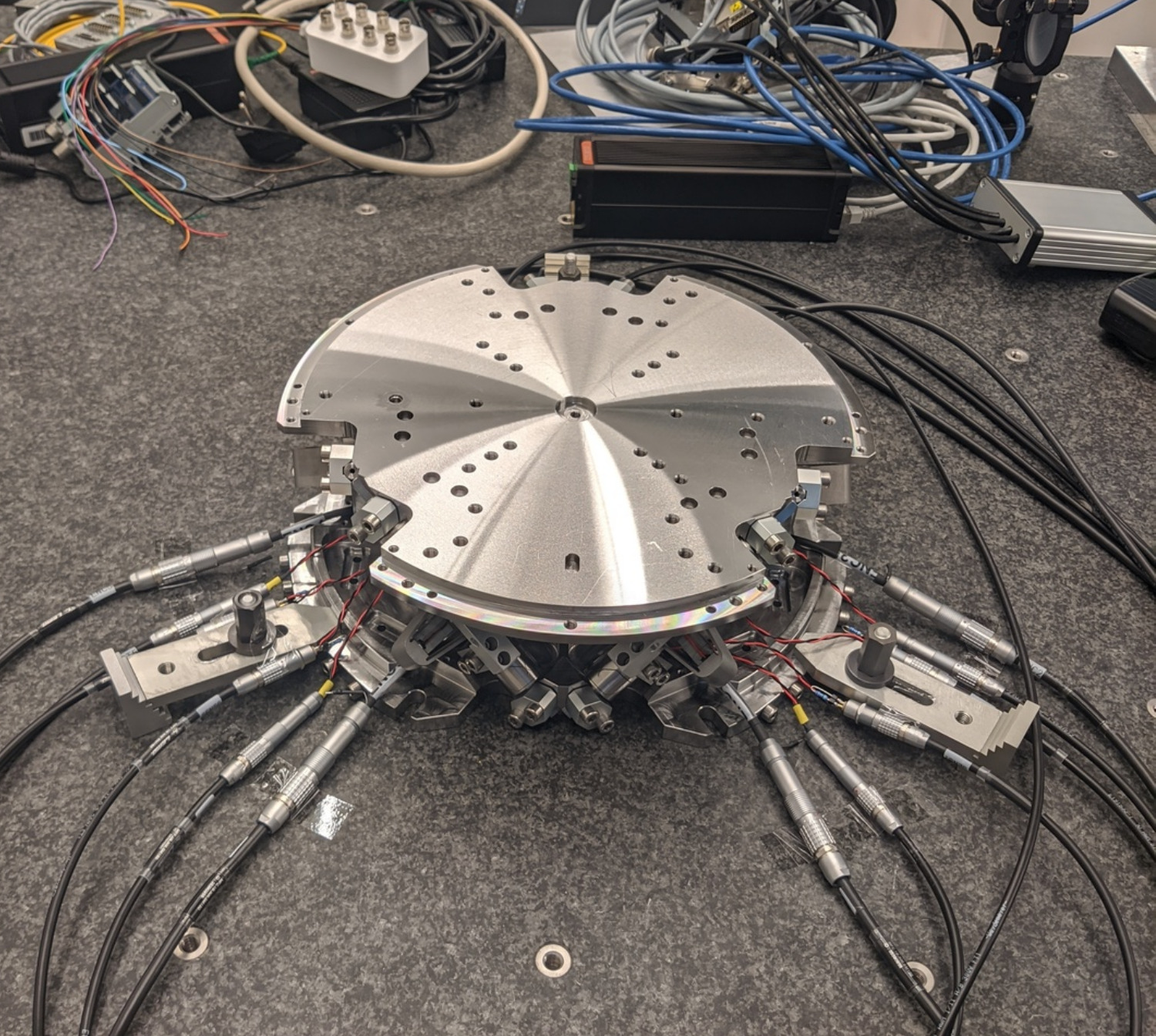

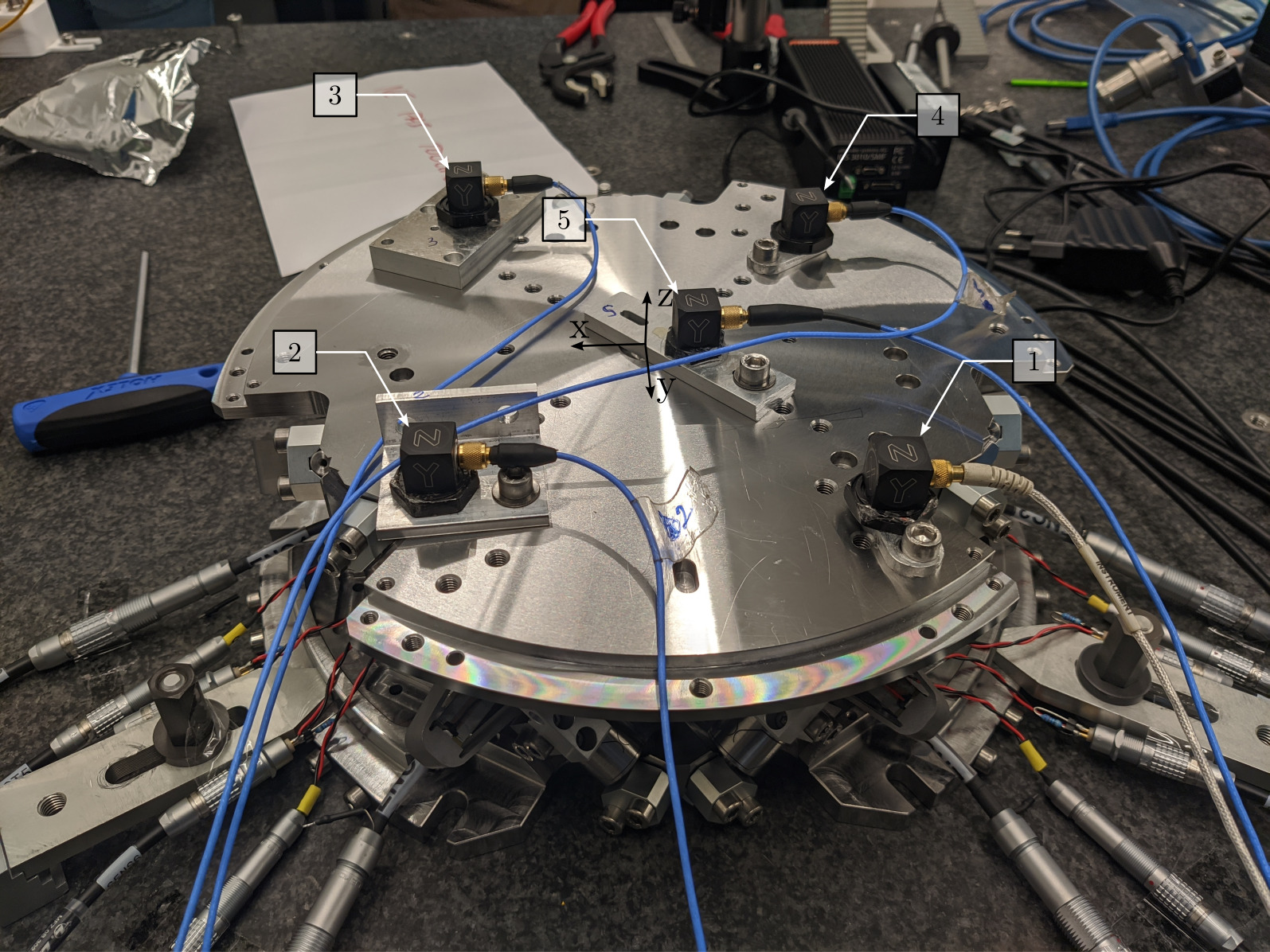

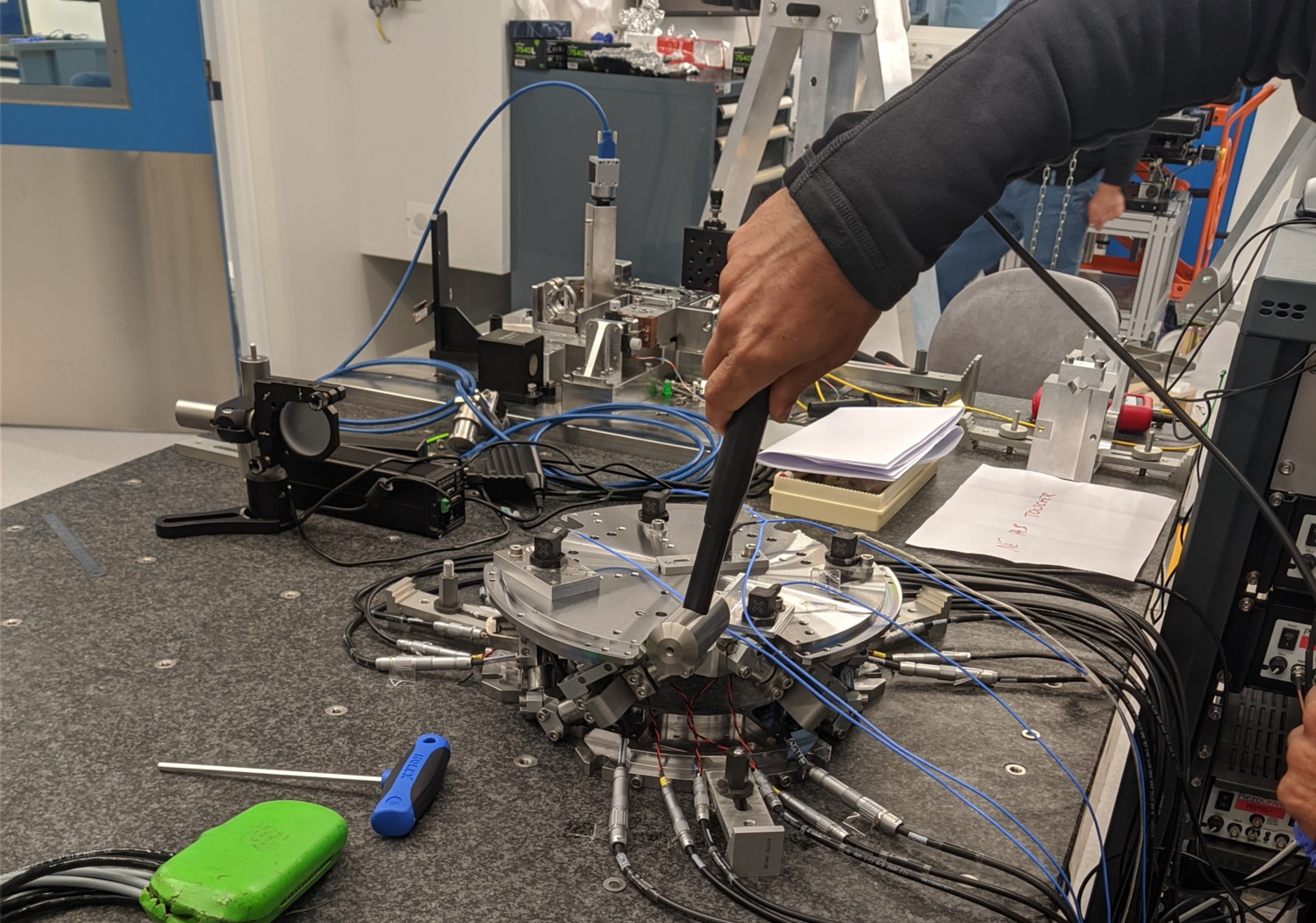

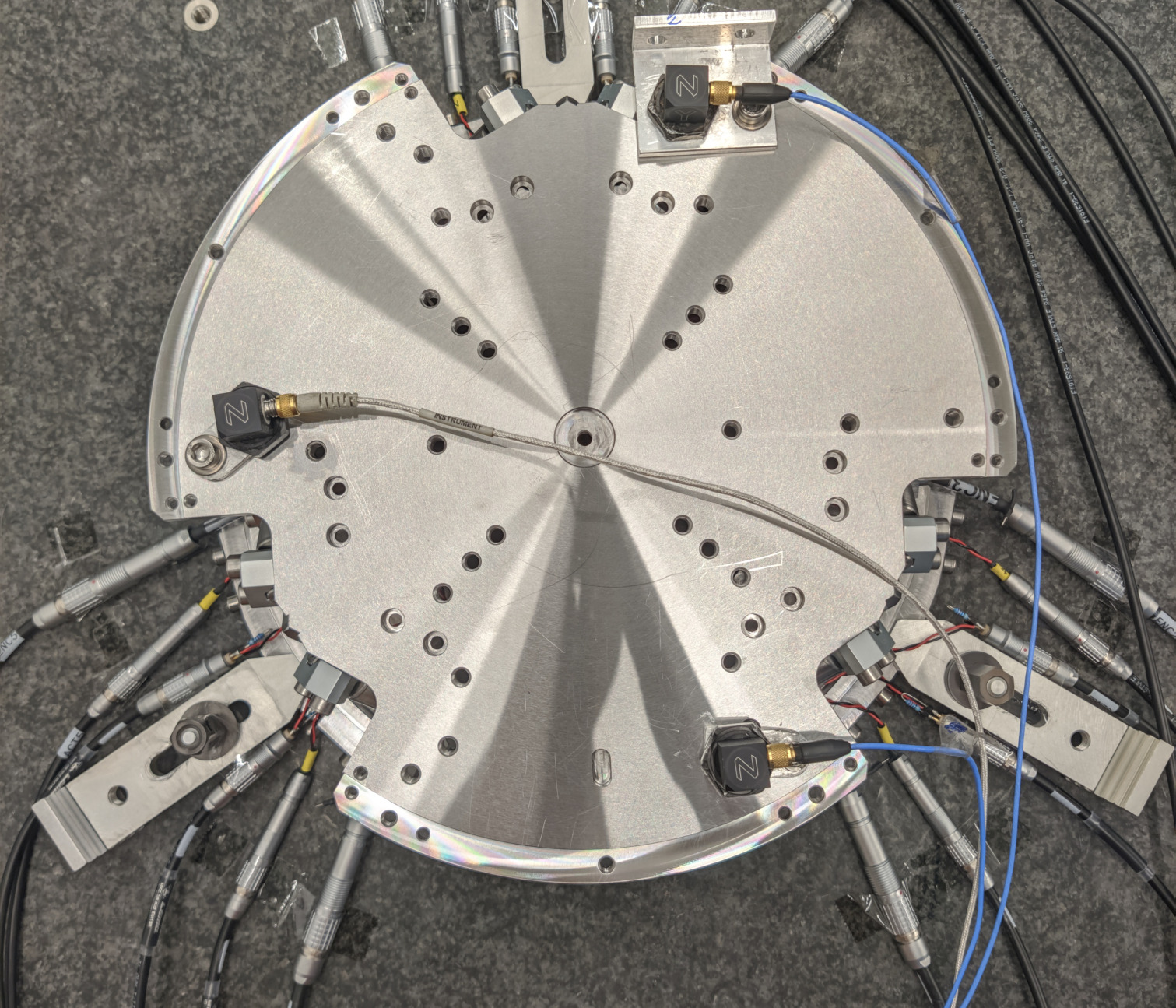

This document is dedicated to the experimental study of the nano-hexapod shown in Figure 1.

Figure 1: Nano-Hexapod

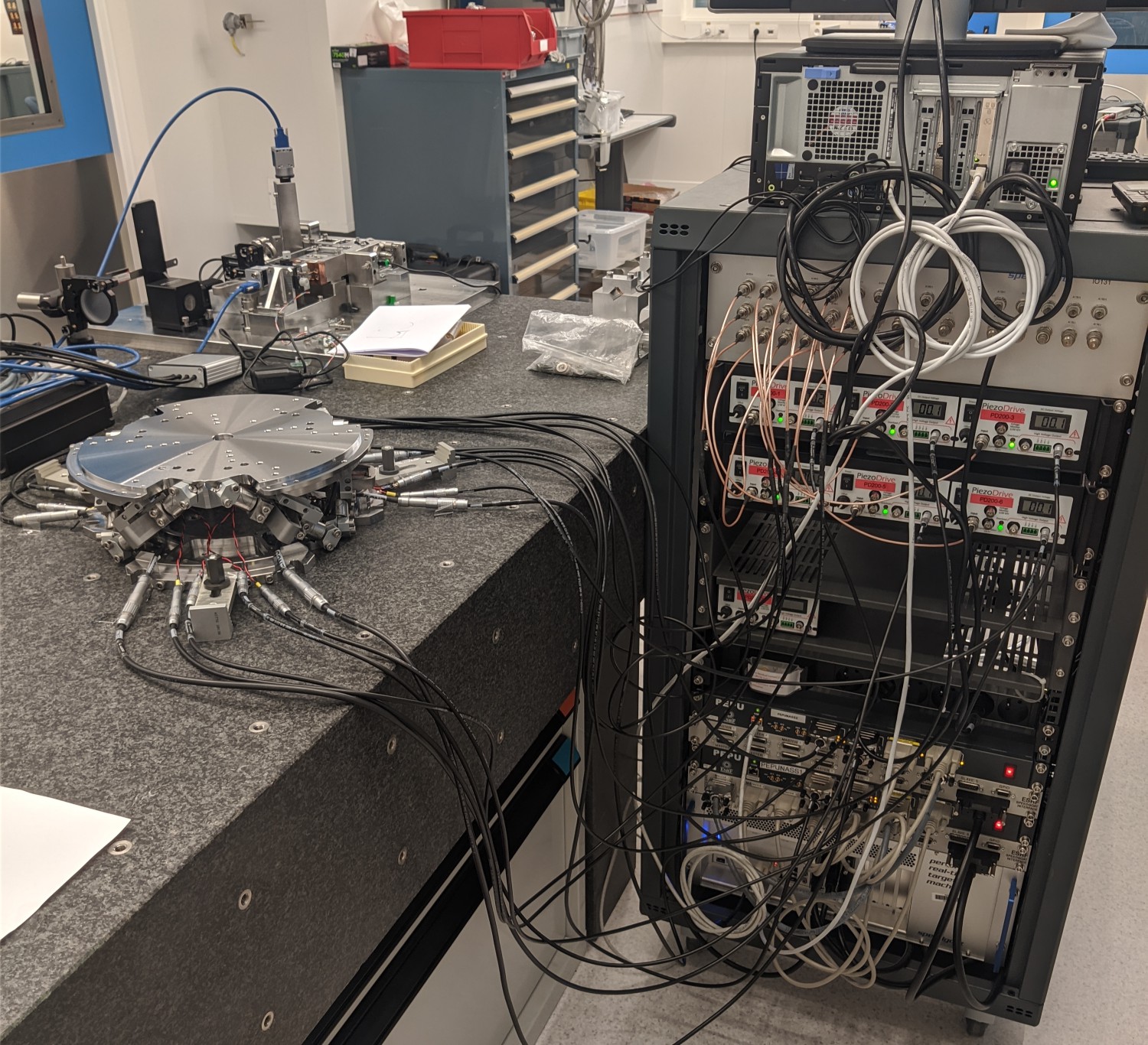

Here are the documentation of the equipment used for this test bench (lots of them are shwon in Figure 2):

Figure 2: Nano-Hexapod and the control electronics

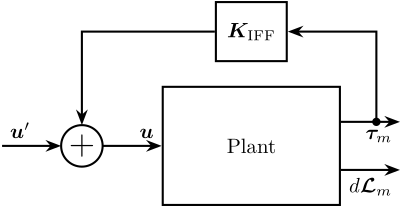

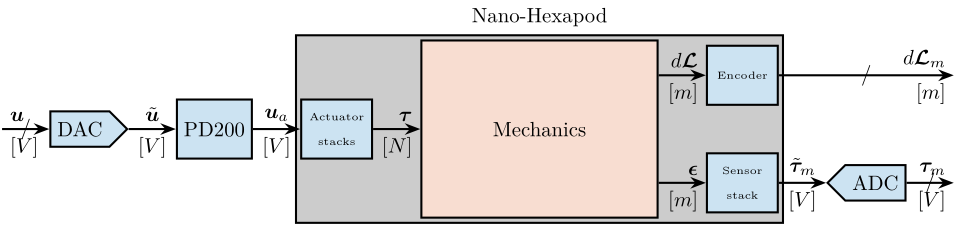

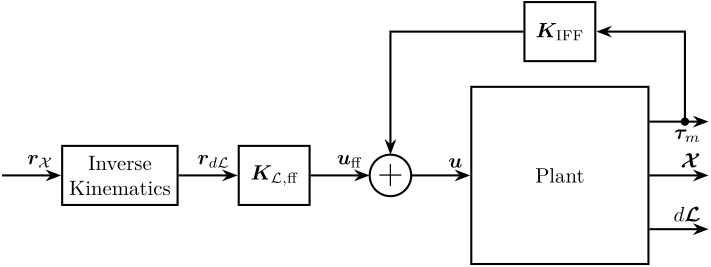

In Figure 3 is shown a block diagram of the experimental setup. When possible, the notations are consistent with this diagram and summarized in Table 1.

Figure 3: Block diagram of the system with named signals

| Unit | Matlab | Vector | Elements | |

|---|---|---|---|---|

| Control Input (wanted DAC voltage) | [V] |

u |

\(\bm{u}\) | \(u_i\) |

| DAC Output Voltage | [V] |

u |

\(\tilde{\bm{u}}\) | \(\tilde{u}_i\) |

| PD200 Output Voltage | [V] |

ua |

\(\bm{u}_a\) | \(u_{a,i}\) |

| Actuator applied force | [N] |

tau |

\(\bm{\tau}\) | \(\tau_i\) |

| Strut motion | [m] |

dL |

\(d\bm{\mathcal{L}}\) | \(d\mathcal{L}_i\) |

| Encoder measured displacement | [m] |

dLm |

\(d\bm{\mathcal{L}}_m\) | \(d\mathcal{L}_{m,i}\) |

| Force Sensor strain | [m] |

epsilon |

\(\bm{\epsilon}\) | \(\epsilon_i\) |

| Force Sensor Generated Voltage | [V] |

taum |

\(\tilde{\bm{\tau}}_m\) | \(\tilde{\tau}_{m,i}\) |

| Measured Generated Voltage | [V] |

taum |

\(\bm{\tau}_m\) | \(\tau_{m,i}\) |

| Motion of the top platform | [m,rad] |

dX |

\(d\bm{\mathcal{X}}\) | \(d\mathcal{X}_i\) |

| Metrology measured displacement | [m,rad] |

dXm |

\(d\bm{\mathcal{X}}_m\) | \(d\mathcal{X}_{m,i}\) |

This document is divided in the following sections:

1 Encoders fixed to the Struts

1.1 Introduction

In this section, the encoders are fixed to the struts.

It is divided in the following sections:

- Section 1.2: the transfer function matrix from the actuators to the force sensors and to the encoders is experimentally identified.

- Section 1.3: the obtained FRF matrix is compared with the dynamics of the simscape model

- Section 1.4: decentralized Integral Force Feedback (IFF) is applied and its performances are evaluated.

- Section 1.5: a modal analysis of the nano-hexapod is performed

1.2 Identification of the dynamics

1.2.1 Load Measurement Data

%% Load Identification Data meas_data_lf = {}; for i = 1:6 meas_data_lf(i) = {load(sprintf('mat/frf_data_exc_strut_%i_noise_lf.mat', i), 't', 'Va', 'Vs', 'de')}; meas_data_hf(i) = {load(sprintf('mat/frf_data_exc_strut_%i_noise_hf.mat', i), 't', 'Va', 'Vs', 'de')}; end

1.2.2 Spectral Analysis - Setup

%% Setup useful variables % Sampling Time [s] Ts = (meas_data_lf{1}.t(end) - (meas_data_lf{1}.t(1)))/(length(meas_data_lf{1}.t)-1); % Sampling Frequency [Hz] Fs = 1/Ts; % Hannning Windows win = hanning(ceil(1*Fs)); % And we get the frequency vector [~, f] = tfestimate(meas_data_lf{1}.Va, meas_data_lf{1}.de, win, [], [], 1/Ts); i_lf = f < 250; % Points for low frequency excitation i_hf = f > 250; % Points for high frequency excitation

1.2.3 DVF Plant

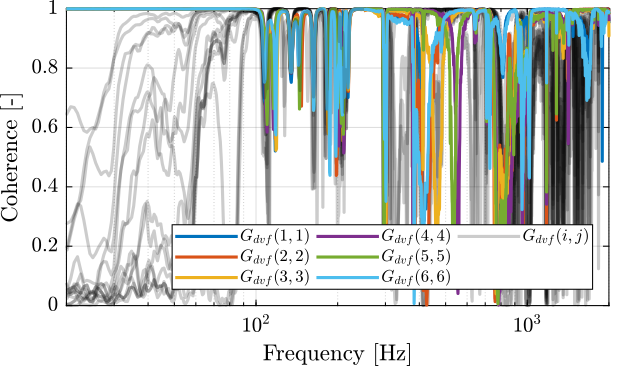

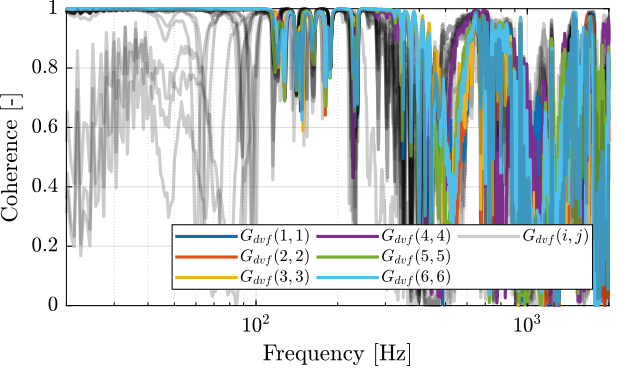

First, let’s compute the coherence from the excitation voltage and the displacement as measured by the encoders (Figure 4).

%% Coherence coh_dvf = zeros(length(f), 6, 6); for i = 1:6 coh_dvf_lf = mscohere(meas_data_lf{i}.Va, meas_data_lf{i}.de, win, [], [], 1/Ts); coh_dvf_hf = mscohere(meas_data_hf{i}.Va, meas_data_hf{i}.de, win, [], [], 1/Ts); coh_dvf(:,:,i) = [coh_dvf_lf(i_lf, :); coh_dvf_hf(i_hf, :)]; end

Figure 4: Obtained coherence for the DVF plant

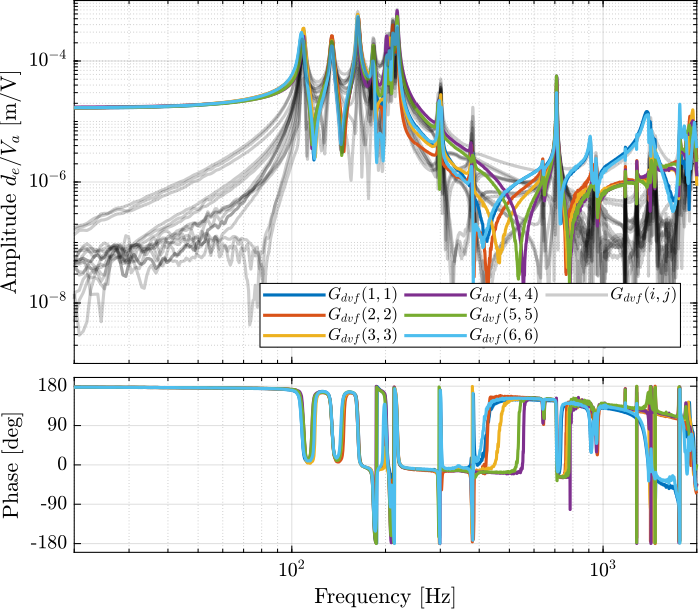

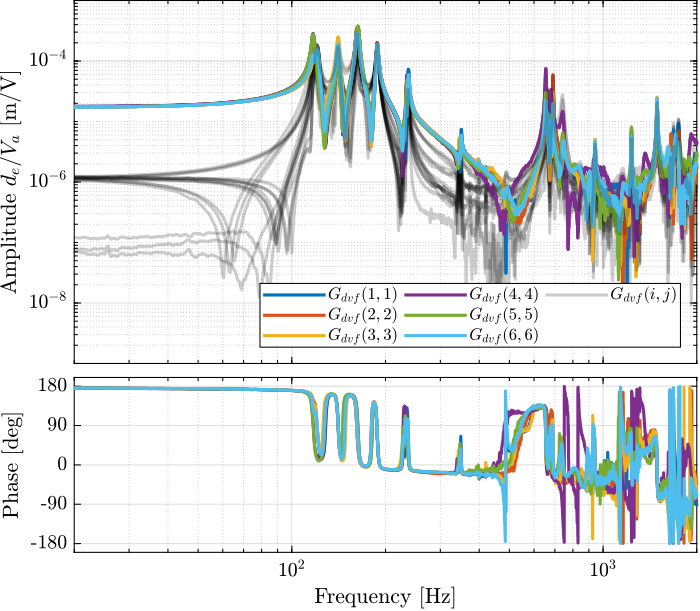

Then the 6x6 transfer function matrix is estimated (Figure 5).

%% DVF Plant (transfer function from u to dLm) G_dvf = zeros(length(f), 6, 6); for i = 1:6 G_dvf_lf = tfestimate(meas_data_lf{i}.Va, meas_data_lf{i}.de, win, [], [], 1/Ts); G_dvf_hf = tfestimate(meas_data_hf{i}.Va, meas_data_hf{i}.de, win, [], [], 1/Ts); G_dvf(:,:,i) = [G_dvf_lf(i_lf, :); G_dvf_hf(i_hf, :)]; end

Figure 5: Measured FRF for the DVF plant

1.2.4 IFF Plant

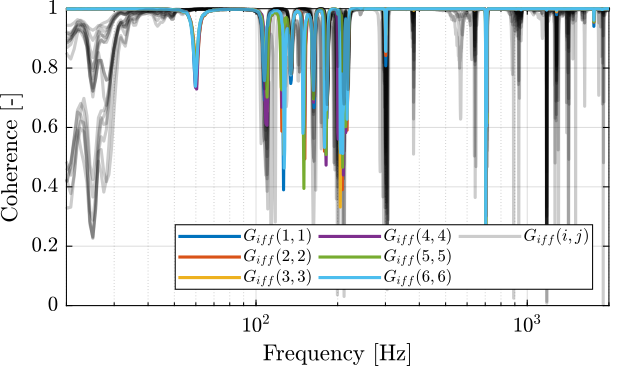

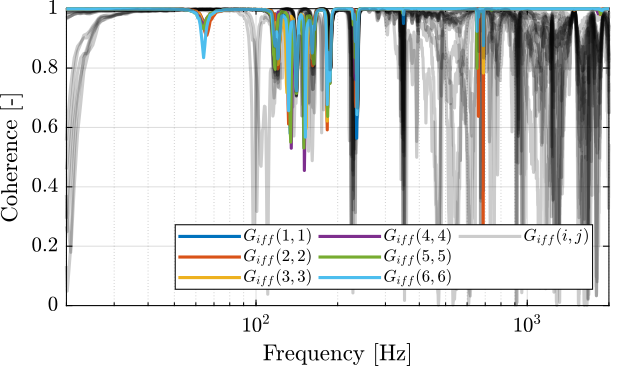

First, let’s compute the coherence from the excitation voltage and the displacement as measured by the encoders (Figure 6).

%% Coherence for the IFF plant coh_iff = zeros(length(f), 6, 6); for i = 1:6 coh_iff_lf = mscohere(meas_data_lf{i}.Va, meas_data_lf{i}.Vs, win, [], [], 1/Ts); coh_iff_hf = mscohere(meas_data_hf{i}.Va, meas_data_hf{i}.Vs, win, [], [], 1/Ts); coh_iff(:,:,i) = [coh_iff_lf(i_lf, :); coh_iff_hf(i_hf, :)]; end

Figure 6: Obtained coherence for the IFF plant

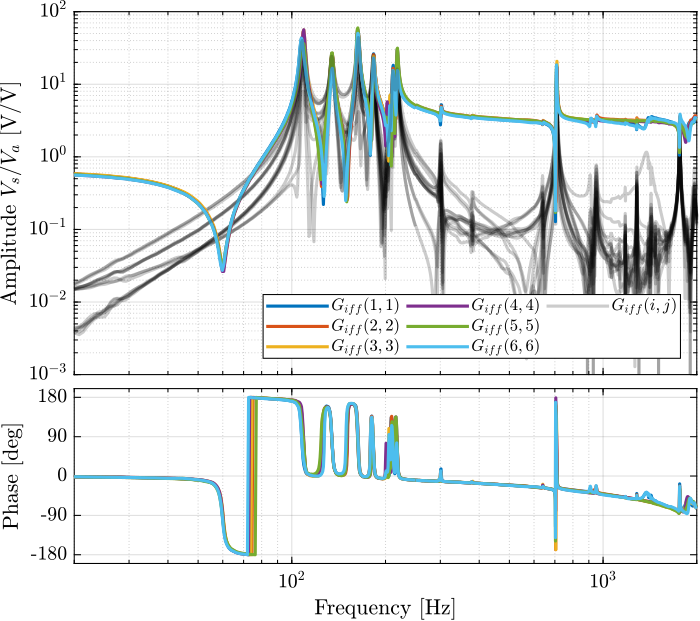

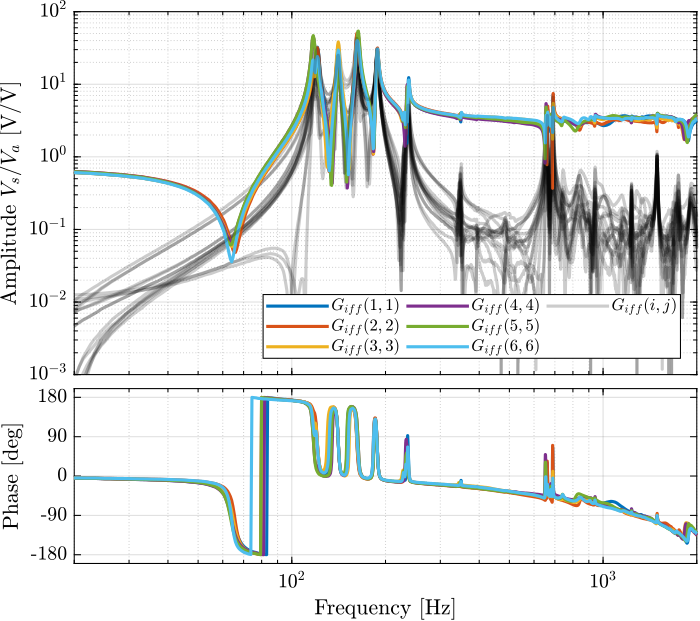

Then the 6x6 transfer function matrix is estimated (Figure 7).

%% IFF Plant G_iff = zeros(length(f), 6, 6); for i = 1:6 G_iff_lf = tfestimate(meas_data_lf{i}.Va, meas_data_lf{i}.Vs, win, [], [], 1/Ts); G_iff_hf = tfestimate(meas_data_hf{i}.Va, meas_data_hf{i}.Vs, win, [], [], 1/Ts); G_iff(:,:,i) = [G_iff_lf(i_lf, :); G_iff_hf(i_hf, :)]; end

Figure 7: Measured FRF for the IFF plant

1.2.5 Save Identified Plants

save('matlab/mat/identified_plants_enc_struts.mat', 'f', 'Ts', 'G_iff', 'G_dvf')

1.3 Comparison with the Simscape Model

In this section, the measured dynamics is compared with the dynamics estimated from the Simscape model.

1.3.1 Load measured FRF

%% Load data load('identified_plants_enc_struts.mat', 'f', 'Ts', 'G_iff', 'G_dvf')

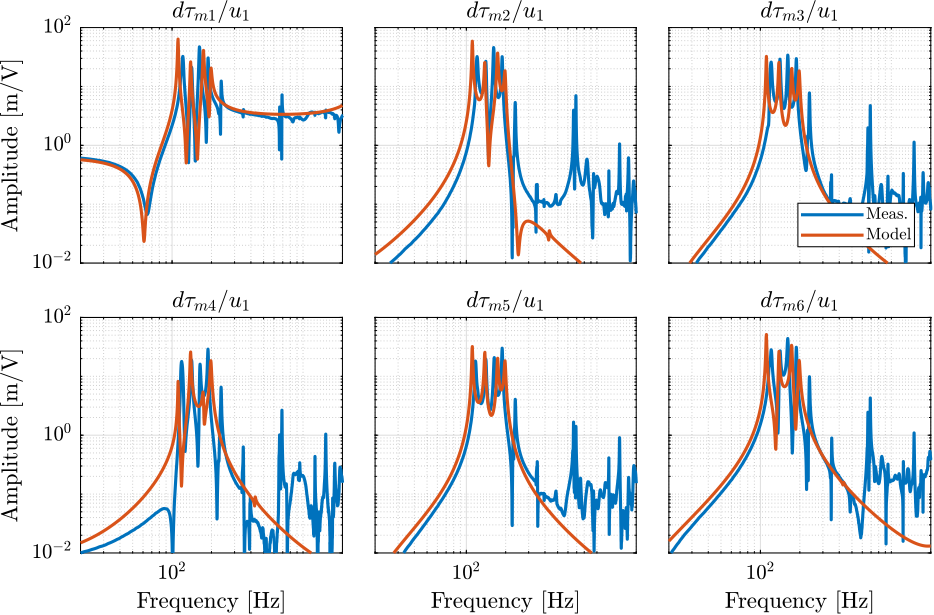

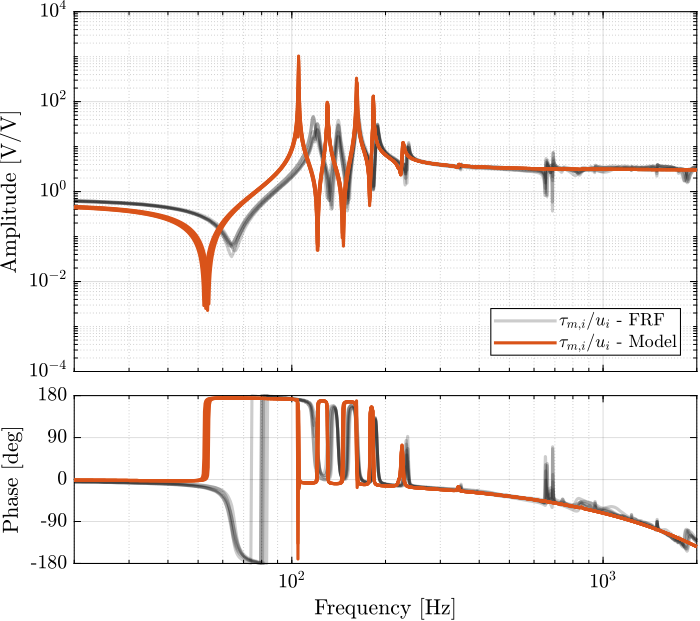

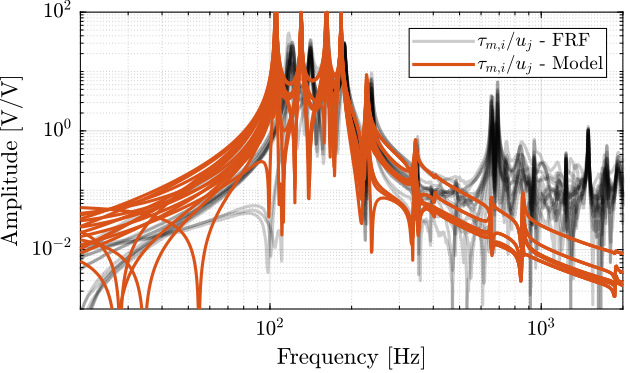

1.3.2 Dynamics from Actuator to Force Sensors

%% Initialize Nano-Hexapod n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof');

%% Identify the IFF Plant (transfer function from u to taum) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/dum'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors Giff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

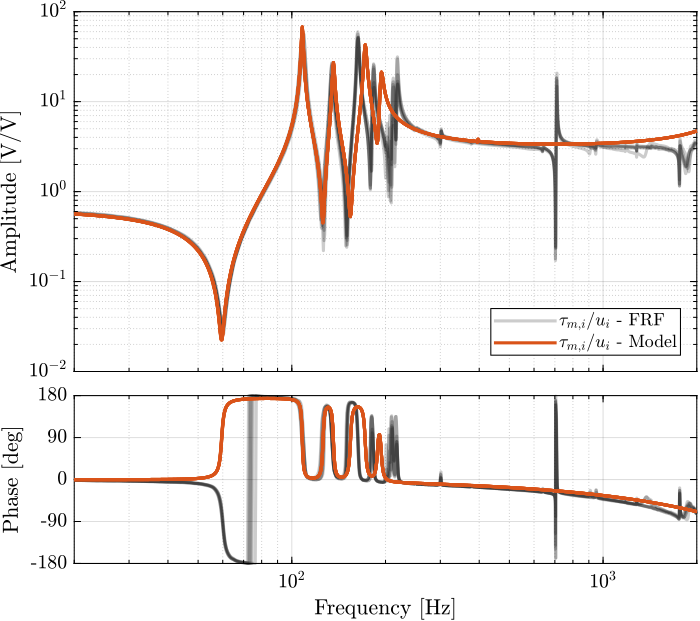

Figure 8: Diagonal elements of the IFF Plant

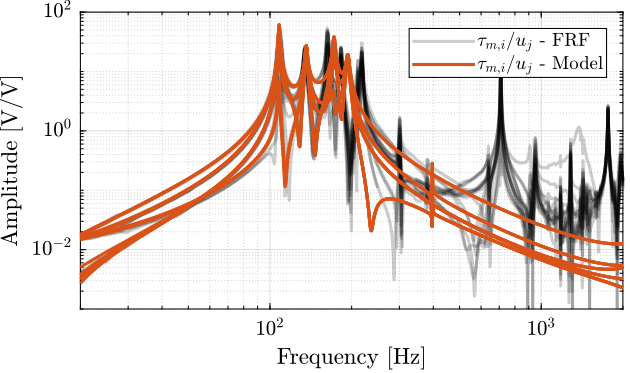

Figure 9: Off diagonal elements of the IFF Plant

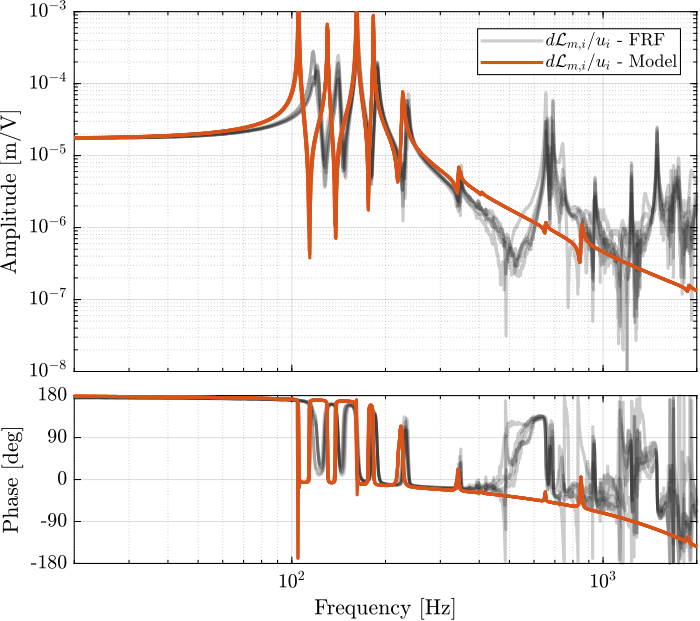

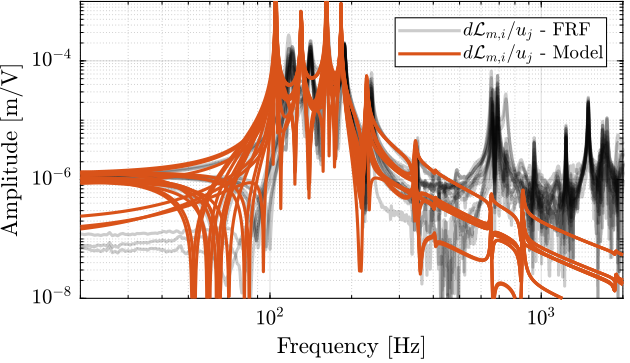

1.3.3 Dynamics from Actuator to Encoder

%% Initialization of the Nano-Hexapod n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', 'flexible');

%% Identify the DVF Plant (transfer function from u to dLm) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Encoders Gdvf = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

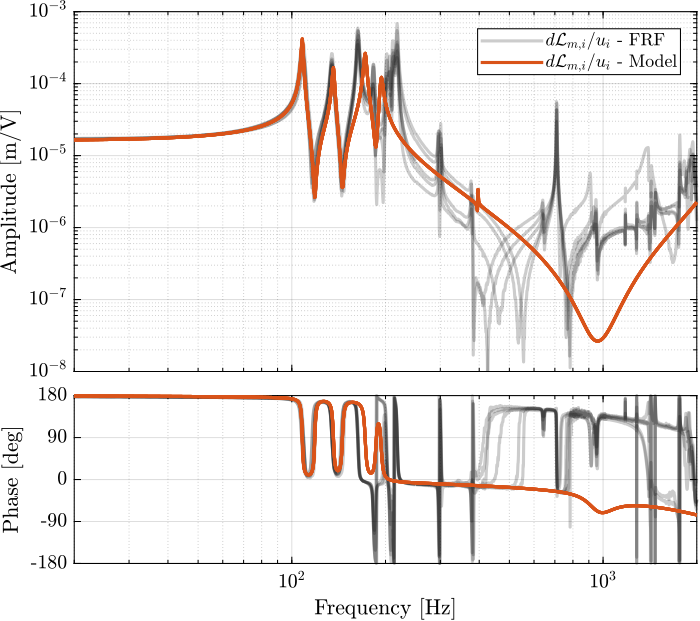

Figure 10: Diagonal elements of the DVF Plant

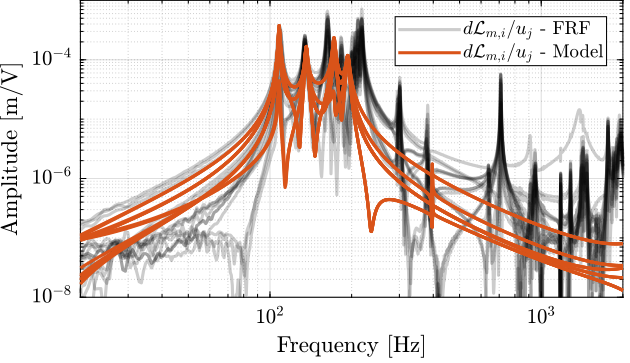

Figure 11: Off diagonal elements of the DVF Plant

1.3.4 Effect of a change in bending damping of the joints

%% Tested bending dampings [Nm/(rad/s)] cRs = [1e-3, 5e-3, 1e-2, 5e-2, 1e-1];

%% Identify the DVF Plant (transfer function from u to dLm) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Encoders

Then the identification is performed for all the values of the bending damping.

%% Idenfity the transfer function from actuator to encoder for all bending dampins Gs = {zeros(length(cRs), 1)}; for i = 1:length(cRs) n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', 'flexible', ... 'flex_bot_cRx', cRs(i), ... 'flex_bot_cRy', cRs(i), ... 'flex_top_cRx', cRs(i), ... 'flex_top_cRy', cRs(i)); G = exp(-s*Ts)*linearize(mdl, io, 0.0, options); G.InputName = {'Va1', 'Va2', 'Va3', 'Va4', 'Va5', 'Va6'}; G.OutputName = {'dL1', 'dL2', 'dL3', 'dL4', 'dL5', 'dL6'}; Gs(i) = {G}; end

- Could be nice

- Actual damping is very small

1.3.5 Effect of a change in damping factor of the APA

%% Tested bending dampings [Nm/(rad/s)] xis = [1e-3, 5e-3, 1e-2, 5e-2, 1e-1];

%% Identify the DVF Plant (transfer function from u to dLm) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Encoders

%% Idenfity the transfer function from actuator to encoder for all bending dampins Gs = {zeros(length(xis), 1)}; for i = 1:length(xis) n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', 'flexible', ... 'actuator_xi', xis(i)); G = exp(-s*Ts)*linearize(mdl, io, 0.0, options); G.InputName = {'Va1', 'Va2', 'Va3', 'Va4', 'Va5', 'Va6'}; G.OutputName = {'dL1', 'dL2', 'dL3', 'dL4', 'dL5', 'dL6'}; Gs(i) = {G}; end

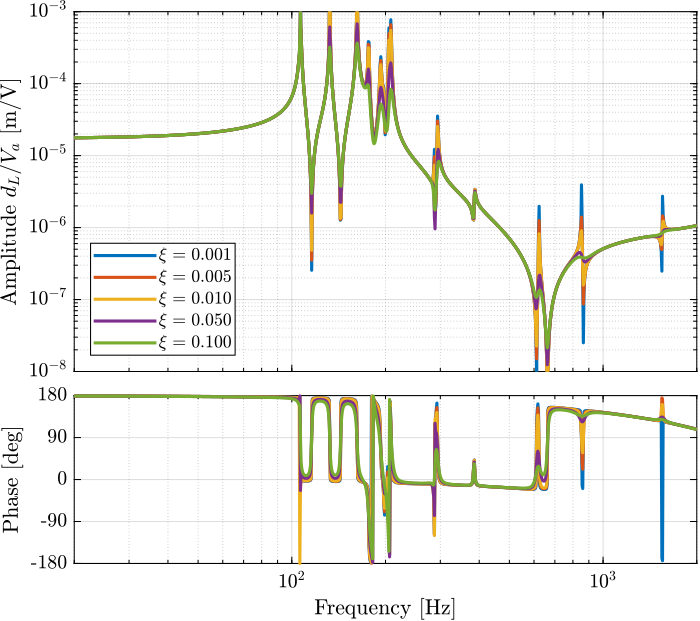

Figure 12: Effect of the APA damping factor \(\xi\) on the dynamics from \(u\) to \(d\mathcal{L}\)

Damping factor \(\xi\) has a large impact on the damping of the “spurious resonances” at 200Hz and 300Hz.

Why is the damping factor does not change the damping of the first peak?

1.3.6 Effect of a change in stiffness damping coef of the APA

m_coef = 1e1;

%% Tested bending dampings [Nm/(rad/s)] k_coefs = [1e-6, 5e-6, 1e-5, 5e-5, 1e-4];

%% Identify the DVF Plant (transfer function from u to dLm) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Encoders

%% Idenfity the transfer function from actuator to encoder for all bending dampins Gs = {zeros(length(k_coefs), 1)}; n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', 'flexible'); for i = 1:length(k_coefs) k_coef = k_coefs(i); G = exp(-s*Ts)*linearize(mdl, io, 0.0, options); G.InputName = {'Va1', 'Va2', 'Va3', 'Va4', 'Va5', 'Va6'}; G.OutputName = {'dL1', 'dL2', 'dL3', 'dL4', 'dL5', 'dL6'}; Gs(i) = {G}; end

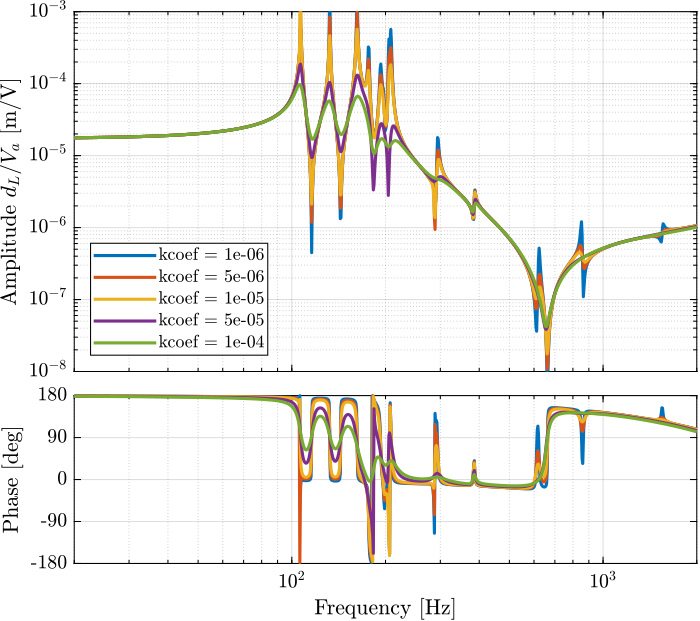

Figure 13: Effect of a change of the damping “stiffness coeficient” on the transfer function from \(u\) to \(d\mathcal{L}\)

1.3.7 Effect of a change in mass damping coef of the APA

k_coef = 1e-6;

%% Tested bending dampings [Nm/(rad/s)]

m_coefs = [1e1, 5e1, 1e2, 5e2, 1e3];

%% Identify the DVF Plant (transfer function from u to dLm) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Encoders

%% Idenfity the transfer function from actuator to encoder for all bending dampins Gs = {zeros(length(m_coefs), 1)}; n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', 'flexible'); for i = 1:length(m_coefs) m_coef = m_coefs(i); G = exp(-s*Ts)*linearize(mdl, io, 0.0, options); G.InputName = {'Va1', 'Va2', 'Va3', 'Va4', 'Va5', 'Va6'}; G.OutputName = {'dL1', 'dL2', 'dL3', 'dL4', 'dL5', 'dL6'}; Gs(i) = {G}; end

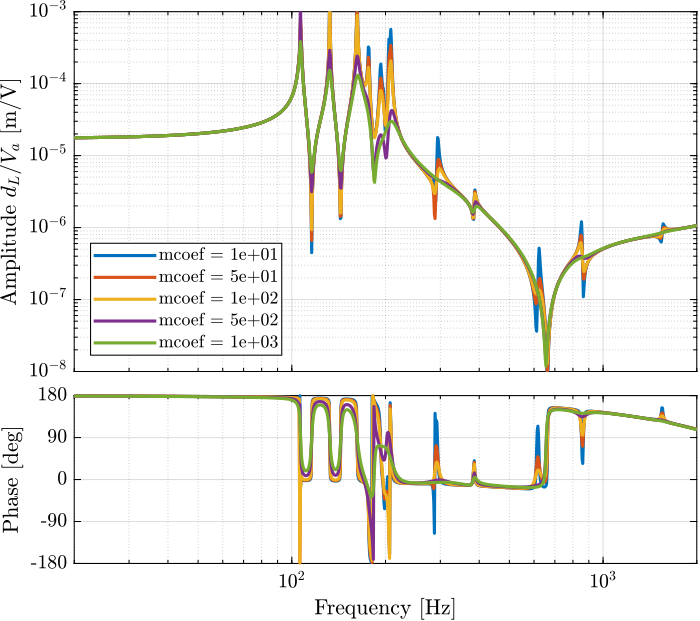

Figure 14: Effect of a change of the damping “mass coeficient” on the transfer function from \(u\) to \(d\mathcal{L}\)

1.3.8 Using Flexible model

d_aligns = [[-0.05, -0.3, 0]; [ 0, 0.5, 0]; [-0.1, -0.3, 0]; [ 0, 0.3, 0]; [-0.05, 0.05, 0]; [0, 0, 0]]*1e-3;

d_aligns = zeros(6,3); % d_aligns(1,:) = [-0.05, -0.3, 0]*1e-3; d_aligns(2,:) = [ 0, 0.3, 0]*1e-3;

%% Initialize Nano-Hexapod n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', 'flexible', ... 'actuator_d_align', d_aligns);

Why do we have smaller resonances when using flexible APA? On the test bench we have the same resonance as the 2DoF model. Could it be due to the compliance in other dof of the flexible model?

%% Identify the DVF Plant (transfer function from u to dLm) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Encoders Gdvf = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

%% Identify the IFF Plant (transfer function from u to taum) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/dum'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors Giff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

1.3.9 Flexible model + encoders fixed to the plates

%% Identify the IFF Plant (transfer function from u to taum) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors

d_aligns = [[-0.05, -0.3, 0]; [ 0, 0.5, 0]; [-0.1, -0.3, 0]; [ 0, 0.3, 0]; [-0.05, 0.05, 0]; [0, 0, 0]]*1e-3;

%% Initialize Nano-Hexapod n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', 'flexible', ... 'actuator_d_align', d_aligns);

Gdvf_struts = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

%% Initialize Nano-Hexapod n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', 'flexible', ... 'actuator_d_align', d_aligns);

Gdvf_plates = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

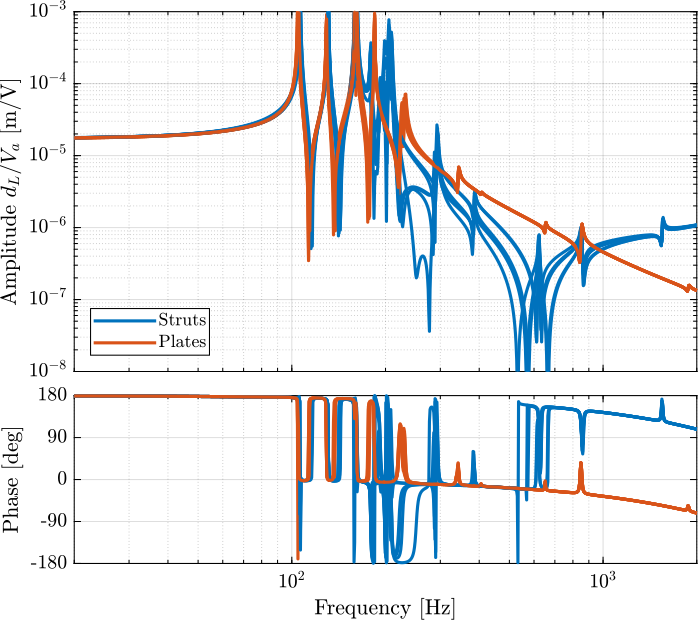

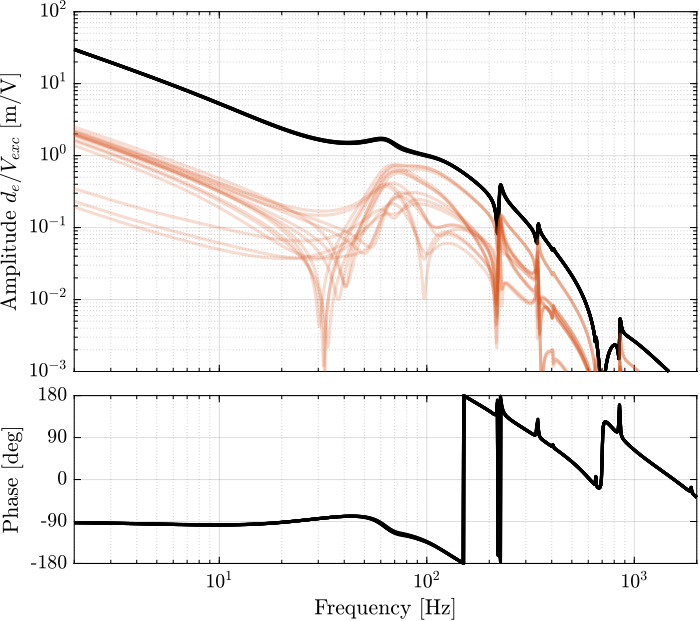

Figure 15: Comparison of the dynamics from \(V_a\) to \(d_L\) when the encoders are fixed to the struts (blue) and to the plates (red). APA are modeled as a flexible element.

1.4 Integral Force Feedback

1.4.1 Identification of the IFF Plant

%% Initialize Nano-Hexapod n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof');

%% Identify the IFF Plant (transfer function from u to taum) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/dum'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors Giff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

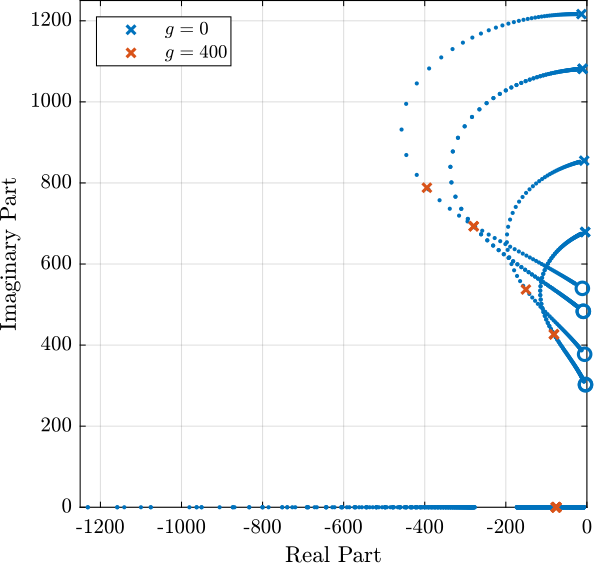

1.4.2 Root Locus and Decentralized Loop gain

%% IFF Controller Kiff_g1 = -(1/(s + 2*pi*40))*... % Low pass filter (provides integral action above 40Hz) (s/(s + 2*pi*30))*... % High pass filter to limit low frequency gain (1/(1 + s/2/pi/500))*... % Low pass filter to be more robust to high frequency resonances eye(6); % Diagonal 6x6 controller

Figure 16: Root Locus for the IFF control strategy

Then the “optimal” IFF controller is:

%% IFF controller with Optimal gain Kiff = g*Kiff_g1;

save('matlab/mat/Kiff.mat', 'Kiff')

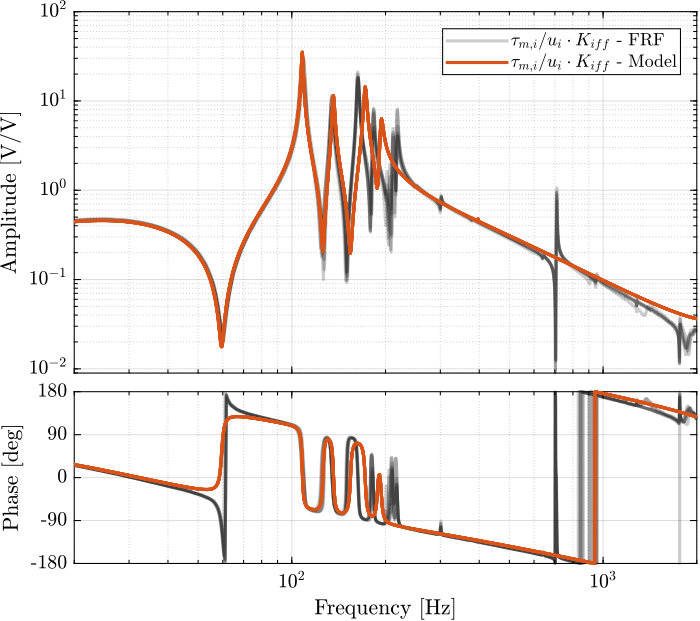

Figure 17: Bode plot of the “decentralized loop gain” \(G_\text{iff}(i,i) \times K_\text{iff}(i,i)\)

1.4.3 Multiple Gains - Simulation

%% Tested IFF gains

iff_gains = [4, 10, 20, 40, 100, 200, 400];

%% Initialize the Simscape model in closed loop n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof', ... 'controller_type', 'iff');

%% Identify the (damped) transfer function from u to dLm for different values of the IFF gain Gd_iff = {zeros(1, length(iff_gains))}; clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Strut Displacement (encoder) for i = 1:length(iff_gains) Kiff = iff_gains(i)*Kiff_g1*eye(6); % IFF Controller Gd_iff(i) = {exp(-s*Ts)*linearize(mdl, io, 0.0, options)}; isstable(Gd_iff{i}) end

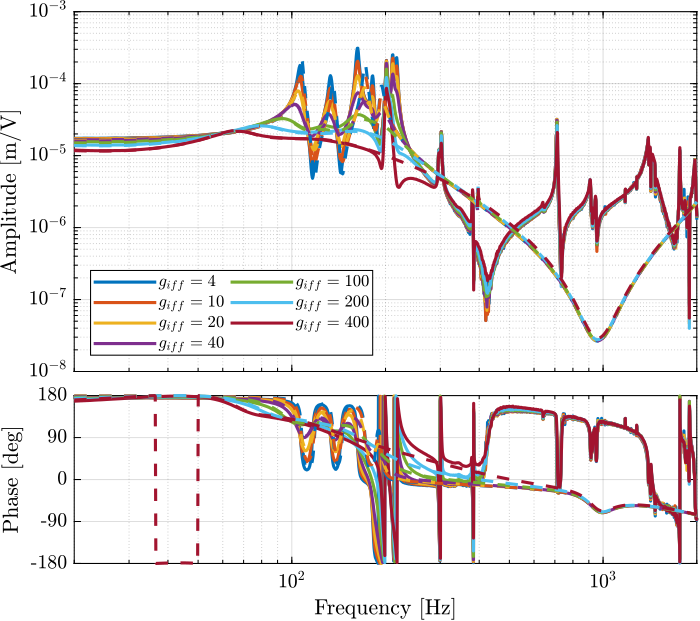

Figure 18: Effect of the IFF gain \(g\) on the transfer function from \(\bm{\tau}\) to \(d\bm{\mathcal{L}}_m\)

1.4.4 Experimental Results - Gains

Let’s look at the damping introduced by IFF as a function of the IFF gain and compare that with the results obtained using the Simscape model.

1.4.4.1 Load Data

%% Load Identification Data meas_iff_gains = {}; for i = 1:length(iff_gains) meas_iff_gains(i) = {load(sprintf('mat/iff_strut_1_noise_g_%i.mat', iff_gains(i)), 't', 'Vexc', 'Vs', 'de', 'u')}; end

1.4.4.2 Spectral Analysis - Setup

%% Setup useful variables % Sampling Time [s] Ts = (meas_iff_gains{1}.t(end) - (meas_iff_gains{1}.t(1)))/(length(meas_iff_gains{1}.t)-1); % Sampling Frequency [Hz] Fs = 1/Ts; % Hannning Windows win = hanning(ceil(1*Fs)); % And we get the frequency vector [~, f] = tfestimate(meas_iff_gains{1}.Vexc, meas_iff_gains{1}.de, win, [], [], 1/Ts);

1.4.4.3 DVF Plant

%% DVF Plant (transfer function from u to dLm) G_iff_gains = {}; for i = 1:length(iff_gains) G_iff_gains{i} = tfestimate(meas_iff_gains{i}.Vexc, meas_iff_gains{i}.de(:,1), win, [], [], 1/Ts); end

Figure 19: Transfer function from \(u\) to \(d\mathcal{L}_m\) for multiple values of the IFF gain

Figure 20: Transfer function from \(u\) to \(d\mathcal{L}_m\) for multiple values of the IFF gain (Zoom)

The IFF control strategy is very effective for the damping of the suspension modes. It however does not damp the modes at 200Hz, 300Hz and 400Hz (flexible modes of the APA). This is very logical.

Also, the experimental results and the models obtained from the Simscape model are in agreement.

1.4.4.4 Experimental Results - Comparison of the un-damped and fully damped system

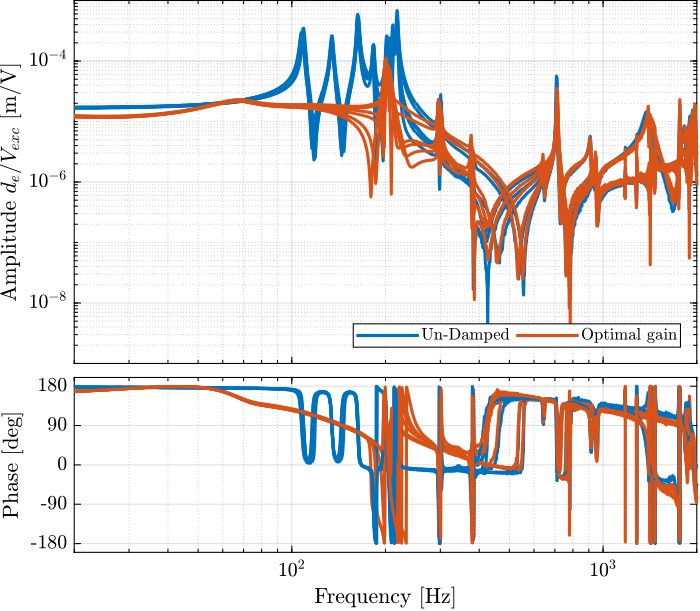

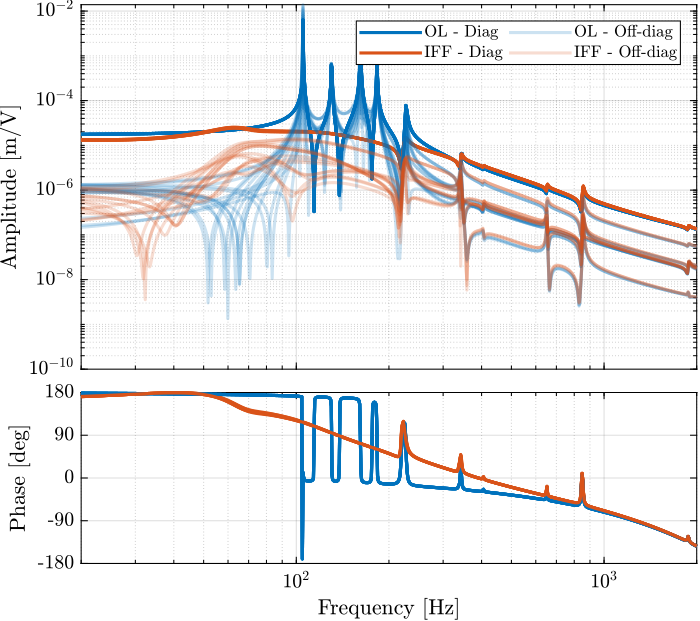

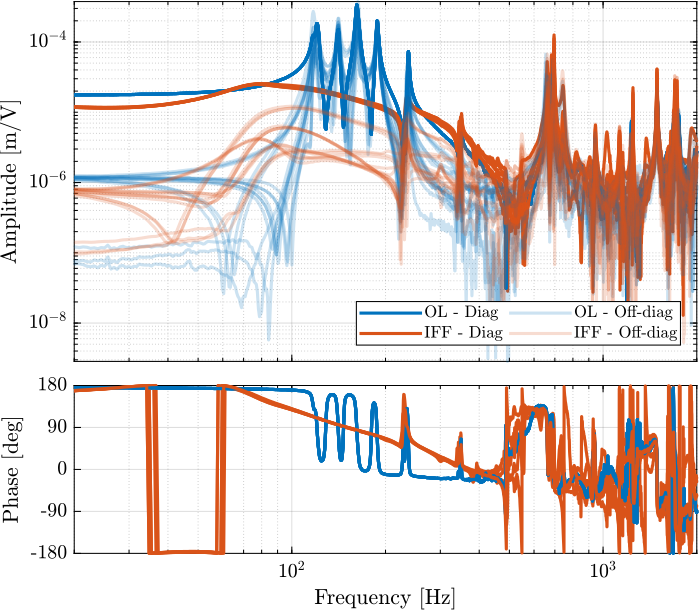

Figure 21: Comparison of the diagonal elements of the tranfer function from \(\bm{u}\) to \(d\bm{\mathcal{L}}_m\) without active damping and with optimal IFF gain

A series of modes at around 205Hz are also damped.

Are these damped modes at 205Hz additional “suspension” modes or flexible modes of the struts?

1.4.5 Experimental Results - Damped Plant with Optimal gain

Let’s now look at the \(6 \times 6\) damped plant with the optimal gain \(g = 400\).

1.4.5.1 Load Data

%% Load Identification Data meas_iff_struts = {}; for i = 1:6 meas_iff_struts(i) = {load(sprintf('mat/iff_strut_%i_noise_g_400.mat', i), 't', 'Vexc', 'Vs', 'de', 'u')}; end

1.4.5.2 Spectral Analysis - Setup

%% Setup useful variables % Sampling Time [s] Ts = (meas_iff_struts{1}.t(end) - (meas_iff_struts{1}.t(1)))/(length(meas_iff_struts{1}.t)-1); % Sampling Frequency [Hz] Fs = 1/Ts; % Hannning Windows win = hanning(ceil(1*Fs)); % And we get the frequency vector [~, f] = tfestimate(meas_iff_struts{1}.Vexc, meas_iff_struts{1}.de, win, [], [], 1/Ts);

1.4.5.3 DVF Plant

%% DVF Plant (transfer function from u to dLm) G_iff_opt = {}; for i = 1:6 G_iff_opt{i} = tfestimate(meas_iff_struts{i}.Vexc, meas_iff_struts{i}.de, win, [], [], 1/Ts); end

Figure 22: Comparison of the diagonal elements of the transfer functions from \(\bm{u}\) to \(d\bm{\mathcal{L}}_m\) with active damping (IFF) applied with an optimal gain \(g = 400\)

Figure 23: Comparison of the off-diagonal elements of the transfer functions from \(\bm{u}\) to \(d\bm{\mathcal{L}}_m\) with active damping (IFF) applied with an optimal gain \(g = 400\)

With the IFF control strategy applied and the optimal gain used, the suspension modes are very well damped. Remains the undamped flexible modes of the APA (200Hz, 300Hz, 400Hz), and the modes of the plates (700Hz).

The Simscape model and the experimental results are in very good agreement.

1.5 Modal Analysis

Several 3-axis accelerometers are fixed on the top platform of the nano-hexapod as shown in Figure 26.

Figure 24: Location of the accelerometers on top of the nano-hexapod

The top platform is then excited using an instrumented hammer as shown in Figure 25.

Figure 25: Example of an excitation using an instrumented hammer

1.5.1 Effectiveness of the IFF Strategy - Compliance

In this section, we wish to estimated the effectiveness of the IFF strategy concerning the compliance.

The top plate is excited vertically using the instrumented hammer two times:

- no control loop is used

- decentralized IFF is used

The data is loaded.

frf_ol = load('Measurement_Z_axis.mat'); % Open-Loop frf_iff = load('Measurement_Z_axis_damped.mat'); % IFF

The mean vertical motion of the top platform is computed by averaging all 5 accelerometers.

%% Multiply by 10 (gain in m/s^2/V) and divide by 5 (number of accelerometers) d_frf_ol = 10/5*(frf_ol.FFT1_H1_4_1_RMS_Y_Mod + frf_ol.FFT1_H1_7_1_RMS_Y_Mod + frf_ol.FFT1_H1_10_1_RMS_Y_Mod + frf_ol.FFT1_H1_13_1_RMS_Y_Mod + frf_ol.FFT1_H1_16_1_RMS_Y_Mod)./(2*pi*frf_ol.FFT1_H1_16_1_RMS_X_Val).^2; d_frf_iff = 10/5*(frf_iff.FFT1_H1_4_1_RMS_Y_Mod + frf_iff.FFT1_H1_7_1_RMS_Y_Mod + frf_iff.FFT1_H1_10_1_RMS_Y_Mod + frf_iff.FFT1_H1_13_1_RMS_Y_Mod + frf_iff.FFT1_H1_16_1_RMS_Y_Mod)./(2*pi*frf_iff.FFT1_H1_16_1_RMS_X_Val).^2;

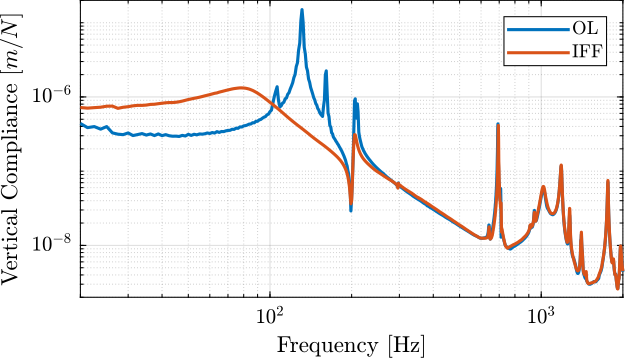

The vertical compliance (magnitude of the transfer function from a vertical force applied on the top plate to the vertical motion of the top plate) is shown in Figure 26.

Figure 26: Measured vertical compliance with and without IFF

From Figure 26, it is clear that the IFF control strategy is very effective in damping the suspensions modes of the nano-hexapode. It also has the effect of degrading (slightly) the vertical compliance at low frequency.

It also seems some damping can be added to the modes at around 205Hz which are flexible modes of the struts.

1.5.2 Comparison with the Simscape Model

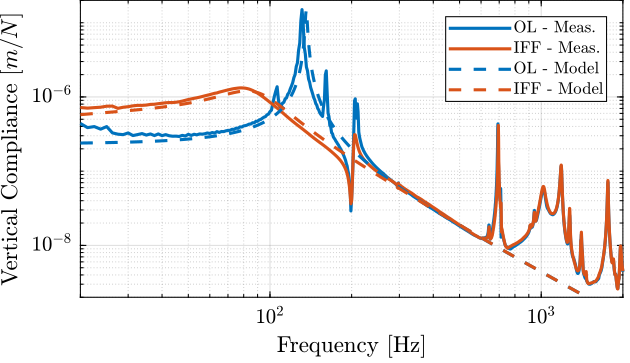

Let’s now compare the measured vertical compliance with the vertical compliance as estimated from the Simscape model.

The transfer function from a vertical external force to the absolute motion of the top platform is identified (with and without IFF) using the Simscape model. The comparison is done in Figure 27. Again, the model is quite accurate!

Figure 27: Measured vertical compliance with and without IFF

1.5.3 Obtained Mode Shapes

Then, several excitation are performed using the instrumented Hammer and the mode shapes are extracted.

We can observe the mode shapes of the first 6 modes that are the suspension modes (the plate is behaving as a solid body) in Figure 28.

Figure 28: Measured mode shapes for the first six modes

Then, there is a mode at 692Hz which corresponds to a flexible mode of the top plate (Figure 29).

Figure 29: First flexible mode at 692Hz

The obtained modes are summarized in Table 2.

| Mode | Freq. [Hz] | Description |

|---|---|---|

| 1 | 105 | Suspension Mode: Y-translation |

| 2 | 107 | Suspension Mode: X-translation |

| 3 | 131 | Suspension Mode: Z-translation |

| 4 | 161 | Suspension Mode: Y-tilt |

| 5 | 162 | Suspension Mode: X-tilt |

| 6 | 180 | Suspension Mode: Z-rotation |

| 7 | 692 | (flexible) Membrane mode of the top platform |

1.6 Accelerometers fixed on the top platform

Figure 30: Accelerometers fixed on the top platform

1.6.1 Experimental Identification

%% Load Identification Data meas_acc = {}; for i = 1:6 meas_acc(i) = {load(sprintf('mat/meas_acc_top_plat_strut_%i.mat', i), 't', 'Va', 'de', 'Am')}; end

%% Setup useful variables % Sampling Time [s] Ts = (meas_acc{1}.t(end) - (meas_acc{1}.t(1)))/(length(meas_acc{1}.t)-1); % Sampling Frequency [Hz] Fs = 1/Ts; % Hannning Windows win = hanning(ceil(1*Fs)); % And we get the frequency vector [~, f] = tfestimate(meas_acc{1}.Va, meas_acc{1}.de, win, [], [], 1/Ts);

The sensibility of the accelerometers are \(0.1 V/g \approx 0.01 V/(m/s^2)\).

%% Compute the 6x6 transfer function matrix G_acc = zeros(length(f), 6, 6); for i = 1:6 G_acc(:,:,i) = tfestimate(meas_acc{i}.Va, 1/0.01*meas_acc{i}.Am, win, [], [], 1/Ts); end

1.6.2 Location and orientation of accelerometers

Opm = [ 0.047, -0.112, 10e-3; 0.047, -0.112, 10e-3; -0.113, 0.011, 10e-3; -0.113, 0.011, 10e-3; 0.040, 0.113, 10e-3; 0.040, 0.113, 10e-3]'; Osm = [-1, 0, 0; 0, 0, 1; 0, -1, 0; 0, 0, 1; -1, 0, 0; 0, 0, 1]';

1.6.3 COM

Hbm = -15e-3; M = getTransformationMatrixAcc(Opm-[0;0;Hbm], Osm); J = getJacobianNanoHexapod(Hbm);

G_acc_CoM = zeros(size(G_acc)); for i = 1:length(f) G_acc_CoM(i, :, :) = inv(M)*squeeze(G_acc(i, :, :))*inv(J'); end

1.6.4 COK

Hbm = -42.3e-3; M = getTransformationMatrixAcc(Opm-[0;0;Hbm], Osm); J = getJacobianNanoHexapod(Hbm);

G_acc_CoK = zeros(size(G_acc)); for i = 1:length(f) G_acc_CoK(i, :, :) = inv(M)*squeeze(G_acc(i, :, :))*inv(J'); end

1.6.5 Comp with the Simscape Model

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', 'flexible', ... 'MO_B', -42.3e-3);

%% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Relative Motion Outputs G = linearize(mdl, io, 0.0, options); G.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; G.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

Then use the Jacobian matrices to obtain the “cartesian” centralized plant.

Gc = inv(n_hexapod.geometry.J)*... G*... inv(n_hexapod.geometry.J');

2 Encoders fixed to the plates

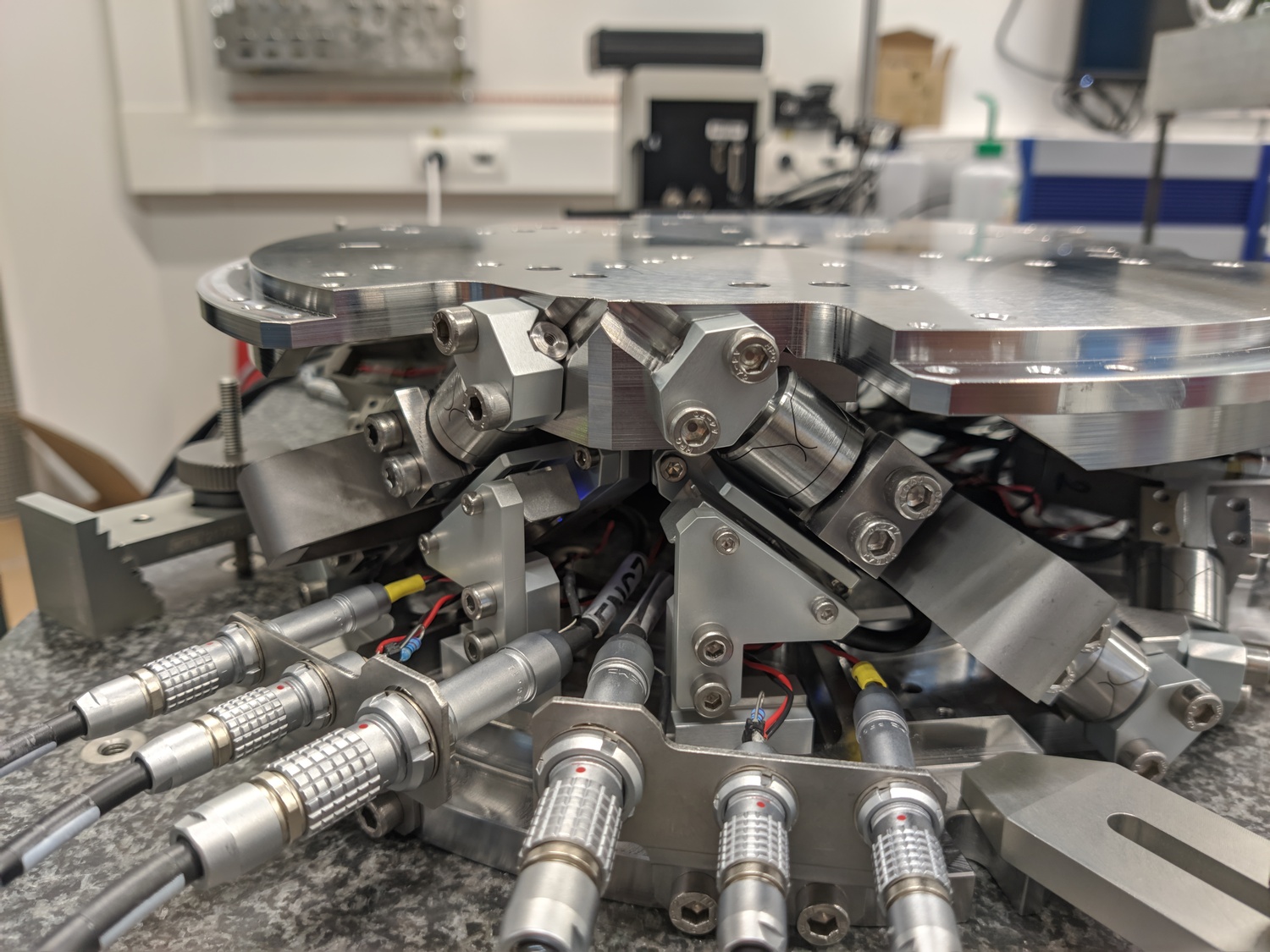

In this section, the encoders are fixed to the plates rather than to the struts as shown in Figure 31.

Figure 31: Nano-Hexapod with encoders fixed to the struts

It is structured as follow:

- Section 2.1: The dynamics of the nano-hexapod is identified

- Section 2.2: The identified dynamics is compared with the Simscape model

- Section 2.3: The Integral Force Feedback (IFF) control strategy is applied and the dynamics of the damped nano-hexapod is identified and compare with the Simscape model

- Section 2.4: The High Authority Control (HAC) in the frame of the struts is developed

- Section 2.5: Some reference tracking tests are performed in order to experimentally validate the HAC-LAC control strategy.

2.1 Identification of the dynamics

2.1.1 Load Measurement Data

%% Load Identification Data meas_data_lf = {}; for i = 1:6 meas_data_lf(i) = {load(sprintf('mat/frf_exc_strut_%i_enc_plates_noise.mat', i), 't', 'Va', 'Vs', 'de')}; end

2.1.2 Spectral Analysis - Setup

%% Setup useful variables % Sampling Time [s] Ts = (meas_data_lf{1}.t(end) - (meas_data_lf{1}.t(1)))/(length(meas_data_lf{1}.t)-1); % Sampling Frequency [Hz] Fs = 1/Ts; % Hannning Windows win = hanning(ceil(1*Fs)); % And we get the frequency vector [~, f] = tfestimate(meas_data_lf{1}.Va, meas_data_lf{1}.de, win, [], [], 1/Ts);

2.1.3 DVF Plant

First, let’s compute the coherence from the excitation voltage and the displacement as measured by the encoders (Figure 32).

%% Coherence coh_dvf = zeros(length(f), 6, 6); for i = 1:6 coh_dvf(:, :, i) = mscohere(meas_data_lf{i}.Va, meas_data_lf{i}.de, win, [], [], 1/Ts); end

Figure 32: Obtained coherence for the DVF plant

Then the 6x6 transfer function matrix is estimated (Figure 33).

%% DVF Plant (transfer function from u to dLm) G_dvf = zeros(length(f), 6, 6); for i = 1:6 G_dvf(:,:,i) = tfestimate(meas_data_lf{i}.Va, meas_data_lf{i}.de, win, [], [], 1/Ts); end

Figure 33: Measured FRF for the DVF plant

2.1.4 IFF Plant

First, let’s compute the coherence from the excitation voltage and the displacement as measured by the encoders (Figure 34).

%% Coherence for the IFF plant coh_iff = zeros(length(f), 6, 6); for i = 1:6 coh_iff(:,:,i) = mscohere(meas_data_lf{i}.Va, meas_data_lf{i}.Vs, win, [], [], 1/Ts); end

Figure 34: Obtained coherence for the IFF plant

Then the 6x6 transfer function matrix is estimated (Figure 35).

%% IFF Plant G_iff = zeros(length(f), 6, 6); for i = 1:6 G_iff(:,:,i) = tfestimate(meas_data_lf{i}.Va, meas_data_lf{i}.Vs, win, [], [], 1/Ts); end

Figure 35: Measured FRF for the IFF plant

2.1.5 Save Identified Plants

save('matlab/mat/identified_plants_enc_plates.mat', 'f', 'Ts', 'G_iff', 'G_dvf')

2.2 Comparison with the Simscape Model

In this section, the measured dynamics is compared with the dynamics estimated from the Simscape model.

2.2.1 Load measured FRF

%% Load data load('identified_plants_enc_plates.mat', 'f', 'Ts', 'G_iff', 'G_dvf')

2.2.2 Dynamics from Actuator to Force Sensors

%% Initialize Nano-Hexapod n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', 'flexible');

%% Identify the IFF Plant (transfer function from u to taum) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/dum'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors Giff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

Figure 36: IFF Plant for the first actuator input and all the force senosrs

Figure 37: Diagonal elements of the IFF Plant

Figure 38: Off diagonal elements of the IFF Plant

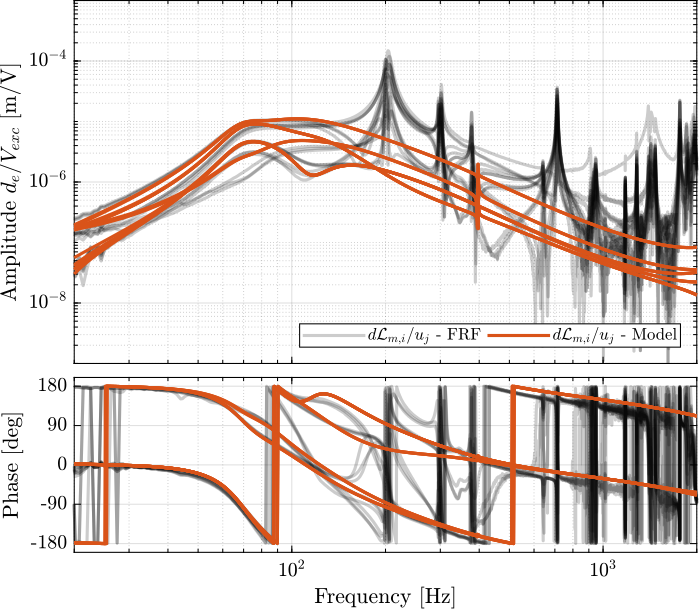

2.2.3 Dynamics from Actuator to Encoder

%% Initialization of the Nano-Hexapod n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', 'flexible');

%% Identify the DVF Plant (transfer function from u to dLm) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Encoders Gdvf = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

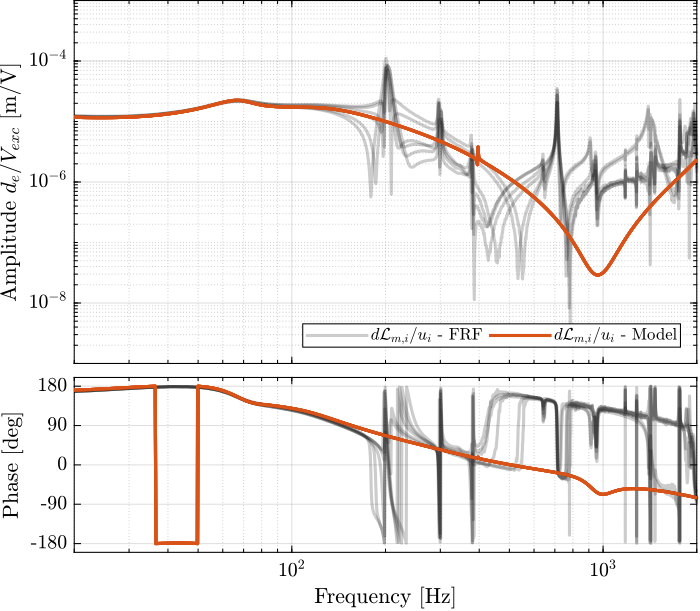

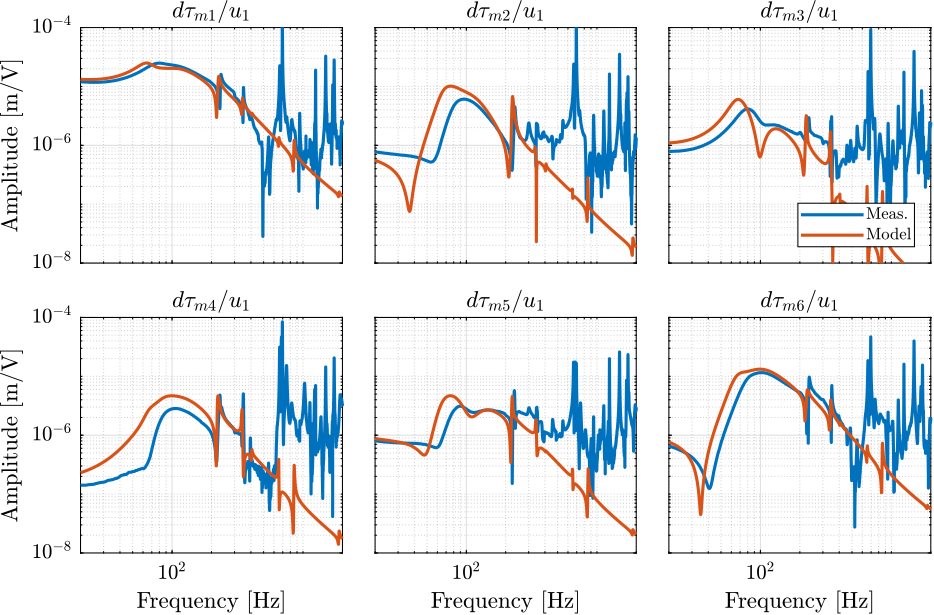

Figure 39: DVF Plant for the first actuator input and all the encoders

Figure 40: Diagonal elements of the DVF Plant

Figure 41: Off diagonal elements of the DVF Plant

2.3 Integral Force Feedback

2.3.1 Identification of the IFF Plant

%% Initialize Nano-Hexapod n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', '2dof');

%% Identify the IFF Plant (transfer function from u to taum) clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/Fm'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors Giff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

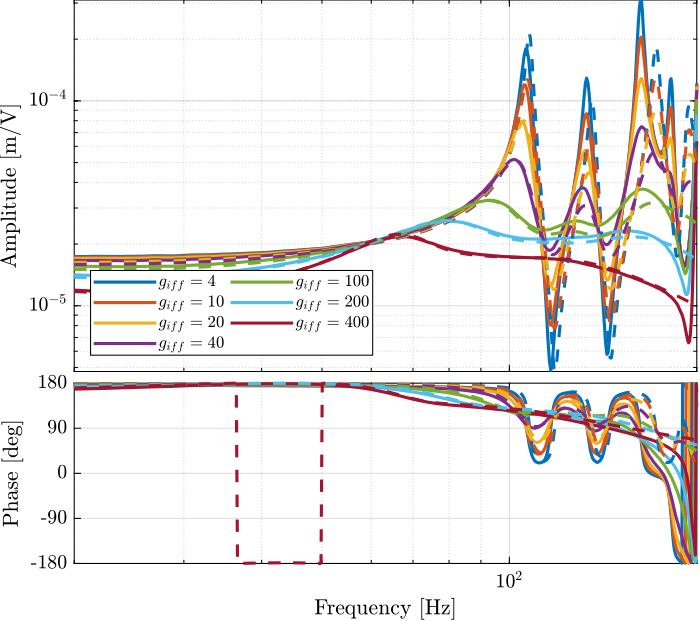

2.3.2 Effect of IFF on the plant - Simscape Model

load('Kiff.mat', 'Kiff')

%% Identify the (damped) transfer function from u to dLm for different values of the IFF gain clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Plate Displacement (encoder)

%% Initialize the Simscape model in closed loop n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', 'flexible');

Gd_ol = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

%% Initialize the Simscape model in closed loop n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', 'flexible', ... 'controller_type', 'iff');

Gd_iff = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

1

Figure 43: Effect of the IFF control strategy on the transfer function from \(\bm{\tau}\) to \(d\bm{\mathcal{L}}_m\)

2.3.3 Experimental Results - Damped Plant with Optimal gain

Let’s now look at the \(6 \times 6\) damped plant with the optimal gain \(g = 400\).

2.3.3.1 Load Data

%% Load Identification Data meas_iff_plates = {}; for i = 1:6 meas_iff_plates(i) = {load(sprintf('mat/frf_exc_iff_strut_%i_enc_plates_noise.mat', i), 't', 'Va', 'Vs', 'de', 'u')}; end

2.3.3.2 Spectral Analysis - Setup

%% Setup useful variables % Sampling Time [s] Ts = (meas_iff_plates{1}.t(end) - (meas_iff_plates{1}.t(1)))/(length(meas_iff_plates{1}.t)-1); % Sampling Frequency [Hz] Fs = 1/Ts; % Hannning Windows win = hanning(ceil(1*Fs)); % And we get the frequency vector [~, f] = tfestimate(meas_iff_plates{1}.Va, meas_iff_plates{1}.de, win, [], [], 1/Ts);

2.3.3.3 Simscape Model

load('Kiff.mat', 'Kiff')

%% Initialize the Simscape model in closed loop n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', 'flexible', ... 'controller_type', 'iff');

%% Identify the (damped) transfer function from u to dLm for different values of the IFF gain clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Plate Displacement (encoder)

Gd_iff_opt = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

2.3.3.4 DVF Plant

%% IFF Plant G_enc_iff_opt = zeros(length(f), 6, 6); for i = 1:6 G_enc_iff_opt(:,:,i) = tfestimate(meas_iff_plates{i}.Va, meas_iff_plates{i}.de, win, [], [], 1/Ts); end

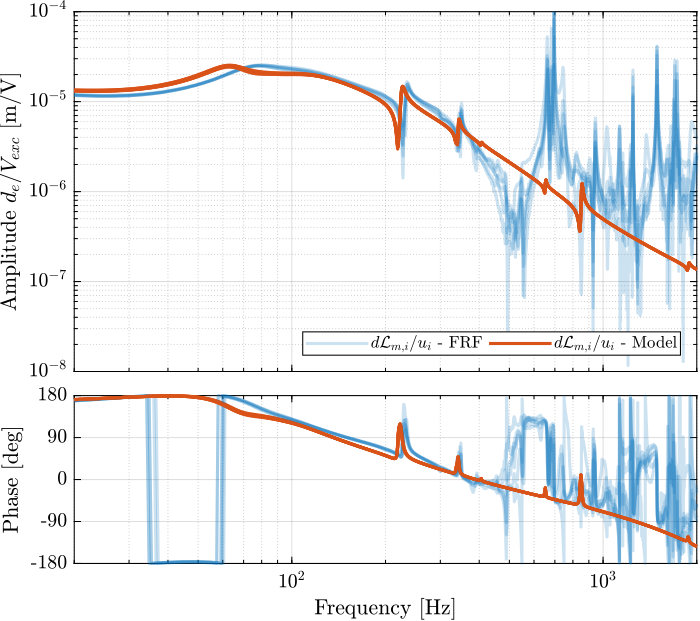

Figure 44: FRF from one actuator to all the encoders when the plant is damped using IFF

Figure 45: Comparison of the diagonal elements of the transfer functions from \(\bm{u}\) to \(d\bm{\mathcal{L}}_m\) with active damping (IFF) applied with an optimal gain \(g = 400\)

Figure 46: Comparison of the off-diagonal elements of the transfer functions from \(\bm{u}\) to \(d\bm{\mathcal{L}}_m\) with active damping (IFF) applied with an optimal gain \(g = 400\)

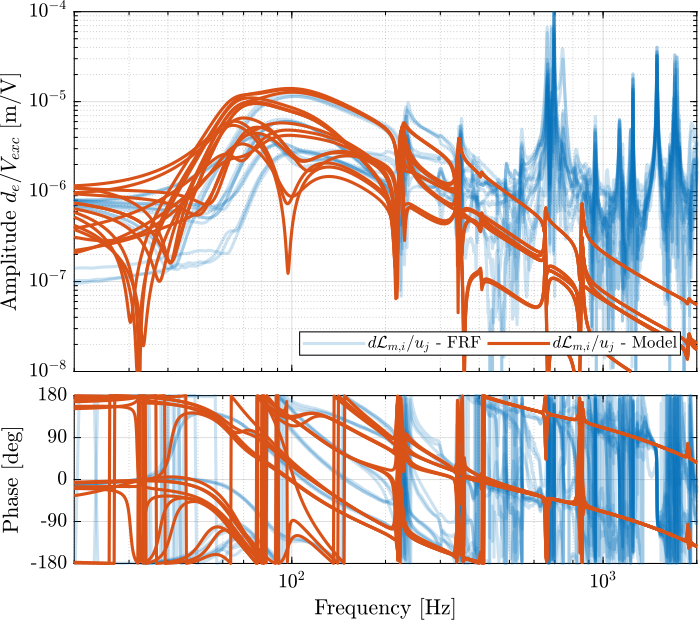

2.3.4 Effect of IFF on the plant - FRF

load('identified_plants_enc_plates.mat', 'f', 'G_dvf');

Figure 47: Effect of the IFF control strategy on the transfer function from \(\bm{\tau}\) to \(d\bm{\mathcal{L}}_m\)

2.3.5 Save Damped Plant

save('matlab/mat/damped_plant_enc_plates.mat', 'f', 'Ts', 'G_enc_iff_opt')

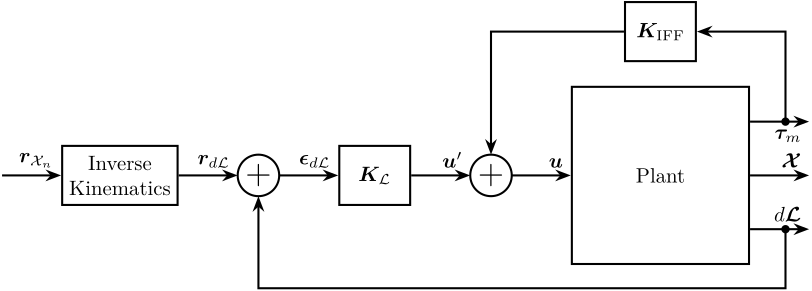

2.4 HAC Control - Frame of the struts

In a first approximation, the Jacobian matrix can be used instead of using the inverse kinematic equations.

Figure 48: HAC-LAC: IFF + Control in the frame of the legs

2.4.1 Simscape Model

Let’s start with the Simscape model and the damped plant.

Apply HAC control and verify the system is stable.

Then, try the control strategy on the real plant.

load('Kiff.mat', 'Kiff')

%% Initialize the Simscape model in closed loop n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', 'flexible', ... 'controller_type', 'iff');

%% Identify the (damped) transfer function from u to dLm for different values of the IFF gain clear io; io_i = 1; io(io_i) = linio([mdl, '/du'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Plate Displacement (encoder)

Gd_iff_opt = exp(-s*Ts)*linearize(mdl, io, 0.0, options);

isstable(Gd_iff_opt)

1

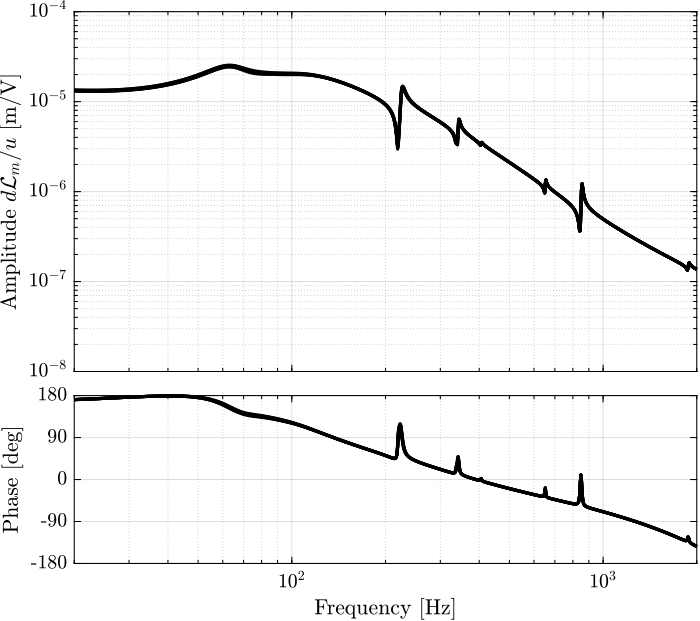

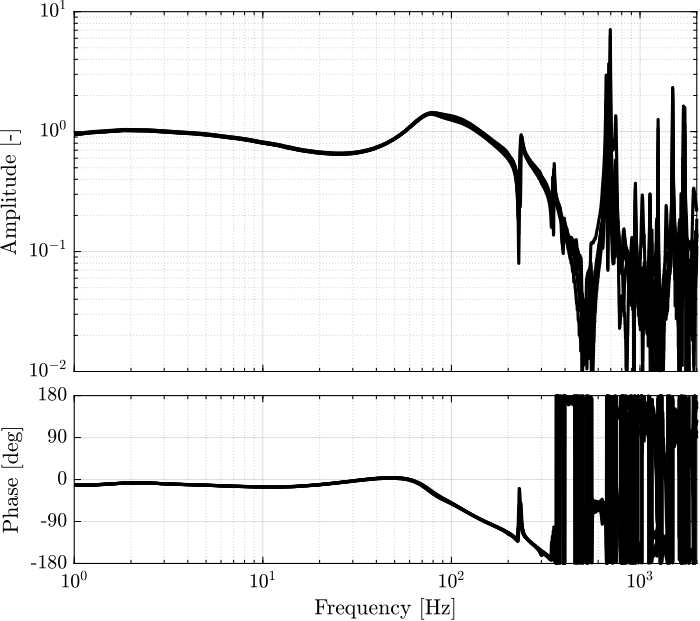

Figure 49: Transfer function from \(u\) to \(d\mathcal{L}_m\) with IFF (diagonal elements)

2.4.2 HAC Controller

Let’s try to have 100Hz bandwidth:

%% Lead a = 2; % Amount of phase lead / width of the phase lead / high frequency gain wc = 2*pi*100; % Frequency with the maximum phase lead [rad/s] H_lead = (1 + s/(wc/sqrt(a)))/(1 + s/(wc*sqrt(a))); %% Low Pass filter H_lpf = 1/(1 + s/2/pi/200); %% Notch gm = 0.02; xi = 0.3; wn = 2*pi*700; H_notch = (s^2 + 2*gm*xi*wn*s + wn^2)/(s^2 + 2*xi*wn*s + wn^2);

Khac_iff_struts = -(1/(2.87e-5)) * ... % Gain H_lead * ... % Lead H_notch * ... % Notch (2*pi*100/s) * ... % Integrator eye(6); % 6x6 Diagonal

save('matlab/mat/Khac_iff_struts.mat', 'Khac_iff_struts')

Lhac_iff_struts = Khac_iff_struts*Gd_iff_opt;

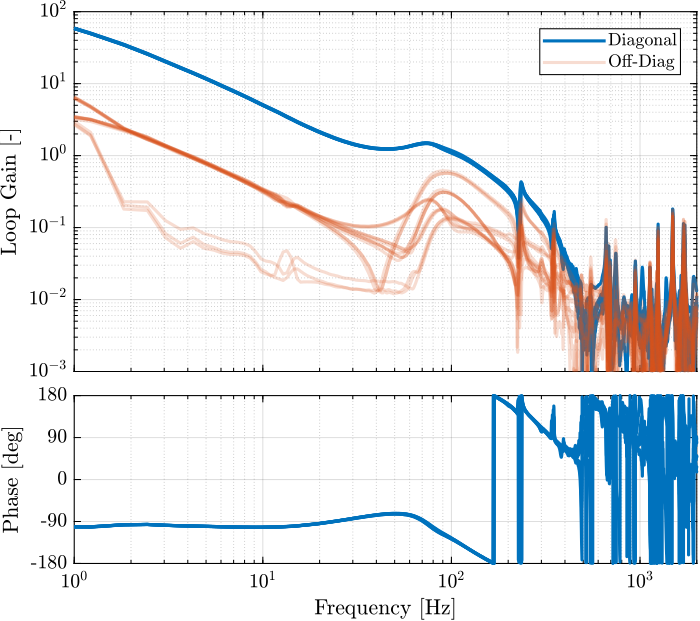

Figure 50: Diagonal and off-diagonal elements of the Loop gain for “HAC-IFF-Struts”

2.4.3 Experimental Loop Gain

[ ]Find a more clever way to do the multiplication

L_frf = zeros(size(G_enc_iff_opt)); for i = 1:size(G_enc_iff_opt, 1) L_frf(i, :, :) = squeeze(G_enc_iff_opt(i,:,:))*freqresp(Khac_iff_struts, f(i), 'Hz'); end

Figure 51: Diagonal and Off-diagonal elements of the Loop gain (experimental data)

2.4.4 Verification of the Stability using the Simscape model

%% Initialize the Simscape model in closed loop n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', 'flexible', ... 'controller_type', 'hac-iff-struts');

Gd_iff_hac_opt = linearize(mdl, io, 0.0, options);

isstable(Gd_iff_hac_opt)

1

2.5 Reference Tracking

2.5.1 Load

load('Khac_iff_struts.mat', 'Khac_iff_struts')

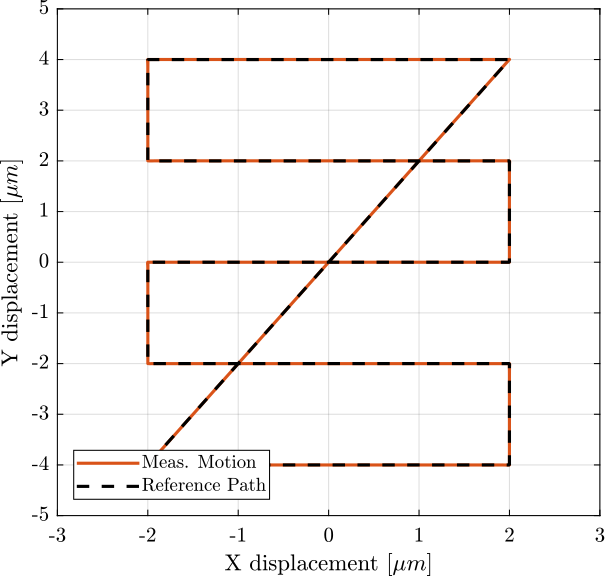

2.5.2 Y-Z Scans

2.5.2.1 Generate the Scan

Rx_yz = generateYZScanTrajectory(...

'y_tot', 4e-6, ...

'z_tot', 8e-6, ...

'n', 5, ...

'Ts', 1e-3, ...

'ti', 2, ...

'tw', 0.5, ...

'ty', 2, ...

'tz', 1);

figure; hold on; plot(Rx_yz(:,1), Rx_yz(:,3), ... 'DisplayName', 'Y motion') plot(Rx_yz(:,1), Rx_yz(:,4), ... 'DisplayName', 'Z motion') hold off; xlabel('Time [s]'); ylabel('Displacement [m]'); legend('location', 'northeast');

figure; plot(Rx_yz(:,3), Rx_yz(:,4)); xlabel('y [m]'); ylabel('z [m]');

2.5.2.2 Reference Signal for the Strut lengths

Let’s use the Jacobian to estimate the wanted strut length as a function of time.

dL_ref = [n_hexapod.geometry.J*Rx_yz(:, 2:7)']';

figure; hold on; for i=1:6 plot(Rx_yz(:,1), dL_ref(:, i)) end xlabel('Time [s]'); ylabel('Displacement [m]');

2.5.2.3 Time domain simulation with 2DoF model

%% Initialize the Simscape model in closed loop n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '2dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', '2dof', ... 'controller_type', 'hac-iff-struts');

set_param(mdl,'StopTime', num2str(Rx_yz(end,1))) set_param(mdl,'SimulationCommand','start')

out.X.Data = out.X.Data - out.X.Data(1,:);

Figure 52: Simulated Y-Z motion

Figure 53: Y and Z motion as a function of time as well as the reference signals

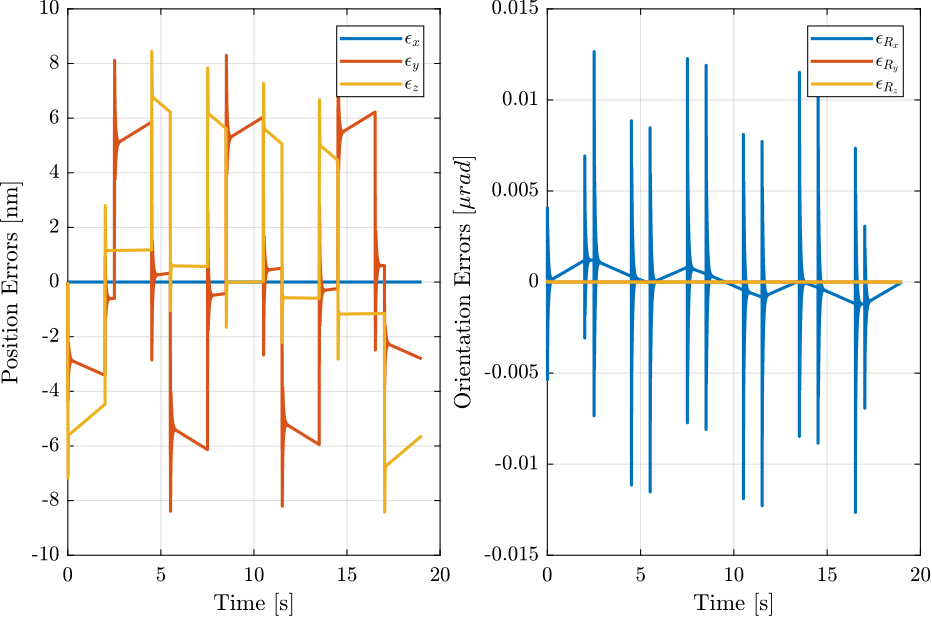

Figure 54: Positioning errors as a function of time

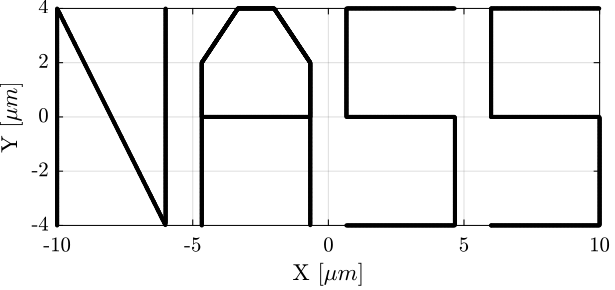

2.5.3 “NASS” reference path

2.5.3.1 Generate Path

ref_path = [ ...

0, 0, 0;

0, 0, 1; % N

0, 4, 1;

3, 0, 1;

3, 4, 1;

3, 4, 0;

4, 0, 0;

4, 0, 1; % A

4, 3, 1;

5, 4, 1;

6, 4, 1;

7, 3, 1;

7, 2, 1;

4, 2, 1;

4, 3, 1;

5, 4, 1;

6, 4, 1;

7, 3, 1;

7, 0, 1;

7, 0, 0;

8, 0, 0;

8, 0, 1; % S

11, 0, 1;

11, 2, 1;

8, 2, 1;

8, 4, 1;

11, 4, 1;

11, 4, 0;

12, 0, 0;

12, 0, 1; % S

15, 0, 1;

15, 2, 1;

12, 2, 1;

12, 4, 1;

15, 4, 1;

15, 4, 0;

];

% Center the trajectory arround zero

ref_path = ref_path - (max(ref_path) - min(ref_path))/2;

% Define the X-Y-Z cuboid dimensions containing the trajectory

X_max = 10e-6;

Y_max = 4e-6;

Z_max = 2e-6;

ref_path = ([X_max, Y_max, Z_max]./max(ref_path)).*ref_path; % [m]

Rx_nass = generateXYZTrajectory('points', ref_path);

figure; plot(1e6*Rx_nass(Rx_nass(:,4)>0, 2), 1e6*Rx_nass(Rx_nass(:,4)>0, 3), 'k.') xlabel('X [$\mu m$]'); ylabel('Y [$\mu m$]'); axis equal; xlim(1e6*[min(Rx_nass(:,2)), max(Rx_nass(:,2))]); ylim(1e6*[min(Rx_nass(:,3)), max(Rx_nass(:,3))]);

Figure 55: Reference path corresponding to the “NASS” acronym

figure; plot3(Rx_nass(:,2), Rx_nass(:,3), Rx_nass(:,4), 'k-'); xlabel('x'); ylabel('y'); zlabel('z');

figure; hold on; plot(Rx_nass(:,1), Rx_nass(:,2)); plot(Rx_nass(:,1), Rx_nass(:,3)); plot(Rx_nass(:,1), Rx_nass(:,4)); hold off;

figure; scatter(Rx_nass(:,2), Rx_nass(:,3), 1, Rx_nass(:,4), 'filled') colormap winter

2.5.3.2 Simscape Simulations

%% Initialize the Simscape model in closed loop n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '2dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', '2dof', ... 'controller_type', 'hac-iff-struts');

set_param(mdl,'StopTime', num2str(Rx_nass(end,1))) set_param(mdl,'SimulationCommand','start')

out.X.Data = out.X.Data - out.X.Data(1,:);

2.5.4 Save Reference paths

save('matlab/mat/reference_path.mat', 'Rx_yz', 'Rx_nass')

2.5.5 Experimental Results

2.6 Feedforward (Open-Loop) Control

2.6.1 Introduction

Figure 56: Feedforward control in the frame of the legs

2.6.2 Simple Feedforward Controller

Let’s estimate the mean DC gain for the damped plant (diagonal elements:)

1.773e-05

The feedforward controller is then taken as the inverse of this gain (the minus sign is there manually added as it is “removed” by the abs function):

Kff_iff_L = -1/mean(diag(abs(squeeze(mean(G_enc_iff_opt(f>2 & f<4,:,:))))));

The open-loop gain (feedforward controller times the damped plant) is shown in Figure 57.

Figure 57: Diagonal elements of the “open loop gain”

And save the feedforward controller for further use:

Kff_iff_L = zpk(Kff_iff_L)*eye(6);

save('matlab/mat/feedforward_iff.mat', 'Kff_iff_L')

2.6.3 Test with Simscape Model

load('reference_path.mat', 'Rx_yz');

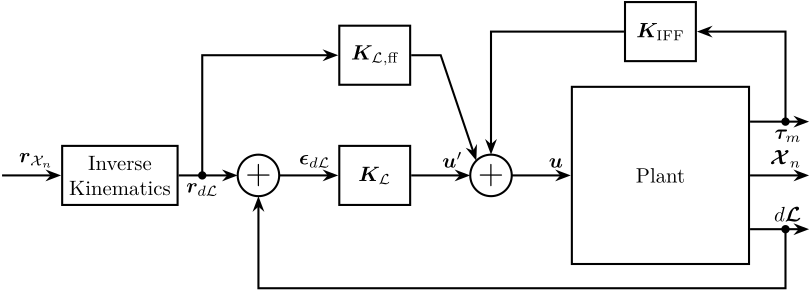

2.7 Feedback/Feedforward control in the frame of the struts

Figure 58: Feedback/Feedforward control in the frame of the legs

3 Functions

3.1 generateXYZTrajectory

Function description

function [ref] = generateXYZTrajectory(args) % generateXYZTrajectory - % % Syntax: [ref] = generateXYZTrajectory(args) % % Inputs: % - args % % Outputs: % - ref - Reference Signal

Optional Parameters

arguments args.points double {mustBeNumeric} = zeros(2, 3) % [m] args.ti (1,1) double {mustBeNumeric, mustBePositive} = 1 % Time to go to first point and after last point [s] args.tw (1,1) double {mustBeNumeric, mustBePositive} = 0.5 % Time wait between each point [s] args.tm (1,1) double {mustBeNumeric, mustBePositive} = 1 % Motion time between points [s] args.Ts (1,1) double {mustBeNumeric, mustBePositive} = 1e-3 % Sampling Time [s] end

Initialize Time Vectors

time_i = 0:args.Ts:args.ti; time_w = 0:args.Ts:args.tw; time_m = 0:args.Ts:args.tm;

XYZ Trajectory

% Go to initial position xyz = (args.points(1,:))'*(time_i/args.ti); % Wait xyz = [xyz, xyz(:,end).*ones(size(time_w))]; % Scans for i = 2:size(args.points, 1) % Go to next point xyz = [xyz, xyz(:,end) + (args.points(i,:)' - xyz(:,end))*(time_m/args.tm)]; % Wait a litle bit xyz = [xyz, xyz(:,end).*ones(size(time_w))]; end % End motion xyz = [xyz, xyz(:,end) - xyz(:,end)*(time_i/args.ti)];

Reference Signal

t = 0:args.Ts:args.Ts*(length(xyz) - 1);

ref = zeros(length(xyz), 7); ref(:, 1) = t; ref(:, 2:4) = xyz';

3.2 generateYZScanTrajectory

Function description

function [ref] = generateYZScanTrajectory(args) % generateYZScanTrajectory - % % Syntax: [ref] = generateYZScanTrajectory(args) % % Inputs: % - args % % Outputs: % - ref - Reference Signal

Optional Parameters

arguments args.y_tot (1,1) double {mustBeNumeric} = 10e-6 % [m] args.z_tot (1,1) double {mustBeNumeric} = 10e-6 % [m] args.n (1,1) double {mustBeInteger, mustBePositive} = 10 % [-] args.Ts (1,1) double {mustBeNumeric, mustBePositive} = 1e-4 % [s] args.ti (1,1) double {mustBeNumeric, mustBePositive} = 1 % [s] args.tw (1,1) double {mustBeNumeric, mustBePositive} = 1 % [s] args.ty (1,1) double {mustBeNumeric, mustBePositive} = 1 % [s] args.tz (1,1) double {mustBeNumeric, mustBePositive} = 1 % [s] end

Initialize Time Vectors

time_i = 0:args.Ts:args.ti; time_w = 0:args.Ts:args.tw; time_y = 0:args.Ts:args.ty; time_z = 0:args.Ts:args.tz;

Y and Z vectors

% Go to initial position y = (time_i/args.ti)*(args.y_tot/2); % Wait y = [y, y(end)*ones(size(time_w))]; % Scans for i = 1:args.n if mod(i,2) == 0 y = [y, -(args.y_tot/2) + (time_y/args.ty)*args.y_tot]; else y = [y, (args.y_tot/2) - (time_y/args.ty)*args.y_tot]; end if i < args.n y = [y, y(end)*ones(size(time_z))]; end end % Wait a litle bit y = [y, y(end)*ones(size(time_w))]; % End motion y = [y, y(end) - y(end)*time_i/args.ti];

% Go to initial position z = (time_i/args.ti)*(args.z_tot/2); % Wait z = [z, z(end)*ones(size(time_w))]; % Scans for i = 1:args.n z = [z, z(end)*ones(size(time_y))]; if i < args.n z = [z, z(end) - (time_z/args.tz)*args.z_tot/(args.n-1)]; end end % Wait a litle bit z = [z, z(end)*ones(size(time_w))]; % End motion z = [z, z(end) - z(end)*time_i/args.ti];

Reference Signal

t = 0:args.Ts:args.Ts*(length(y) - 1);

ref = zeros(length(y), 7); ref(:, 1) = t; ref(:, 3) = y; ref(:, 4) = z;

3.3 getTransformationMatrixAcc

Function description

function [M] = getTransformationMatrixAcc(Opm, Osm) % getTransformationMatrixAcc - % % Syntax: [M] = getTransformationMatrixAcc(Opm, Osm) % % Inputs: % - Opm - Nx3 (N = number of accelerometer measurements) X,Y,Z position of accelerometers % - Opm - Nx3 (N = number of accelerometer measurements) Unit vectors representing the accelerometer orientation % % Outputs: % - M - Transformation Matrix

Transformation matrix from motion of the solid body to accelerometer measurements

Let’s try to estimate the x-y-z acceleration of any point of the solid body from the acceleration/angular acceleration of the solid body expressed in \(\{O\}\). For any point \(p_i\) of the solid body (corresponding to an accelerometer), we can write:

\begin{equation} \begin{bmatrix} a_{i,x} \\ a_{i,y} \\ a_{i,z} \end{bmatrix} = \begin{bmatrix} \dot{v}_x \\ \dot{v}_y \\ \dot{v}_z \end{bmatrix} + p_i \times \begin{bmatrix} \dot{\omega}_x \\ \dot{\omega}_y \\ \dot{\omega}_z \end{bmatrix} \end{equation}We can write the cross product as a matrix product using the skew-symmetric transformation:

\begin{equation} \begin{bmatrix} a_{i,x} \\ a_{i,y} \\ a_{i,z} \end{bmatrix} = \begin{bmatrix} \dot{v}_x \\ \dot{v}_y \\ \dot{v}_z \end{bmatrix} + \underbrace{\begin{bmatrix} 0 & p_{i,z} & -p_{i,y} \\ -p_{i,z} & 0 & p_{i,x} \\ p_{i,y} & -p_{i,x} & 0 \end{bmatrix}}_{P_{i,[\times]}} \cdot \begin{bmatrix} \dot{\omega}_x \\ \dot{\omega}_y \\ \dot{\omega}_z \end{bmatrix} \end{equation}If we now want to know the (scalar) acceleration \(a_i\) of the point \(p_i\) in the direction of the accelerometer direction \(\hat{s}_i\), we can just project the 3d acceleration on \(\hat{s}_i\):

\begin{equation} a_i = \hat{s}_i^T \cdot \begin{bmatrix} a_{i,x} \\ a_{i,y} \\ a_{i,z} \end{bmatrix} = \hat{s}_i^T \cdot \begin{bmatrix} \dot{v}_x \\ \dot{v}_y \\ \dot{v}_z \end{bmatrix} + \left( \hat{s}_i^T \cdot P_{i,[\times]} \right) \cdot \begin{bmatrix} \dot{\omega}_x \\ \dot{\omega}_y \\ \dot{\omega}_z \end{bmatrix} \end{equation}Which is equivalent as a simple vector multiplication:

\begin{equation} a_i = \begin{bmatrix} \hat{s}_i^T & \hat{s}_i^T \cdot P_{i,[\times]} \end{bmatrix} \begin{bmatrix} \dot{v}_x \\ \dot{v}_y \\ \dot{v}_z \\ \dot{\omega}_x \\ \dot{\omega}_y \\ \dot{\omega}_z \end{bmatrix} = \begin{bmatrix} \hat{s}_i^T & \hat{s}_i^T \cdot P_{i,[\times]} \end{bmatrix} {}^O\vec{x} \end{equation}And finally we can combine the 6 (line) vectors for the 6 accelerometers to write that in a matrix form. We obtain Eq. \eqref{eq:M_matrix}.

The transformation from solid body acceleration \({}^O\vec{x}\) from sensor measured acceleration \(\vec{a}\) is:

\begin{equation} \label{eq:M_matrix} \vec{a} = \underbrace{\begin{bmatrix} \hat{s}_1^T & \hat{s}_1^T \cdot P_{1,[\times]} \\ \vdots & \vdots \\ \hat{s}_6^T & \hat{s}_6^T \cdot P_{6,[\times]} \end{bmatrix}}_{M} {}^O\vec{x} \end{equation}with \(\hat{s}_i\) the unit vector representing the measured direction of the i’th accelerometer expressed in frame \(\{O\}\) and \(P_{i,[\times]}\) the skew-symmetric matrix representing the cross product of the position of the i’th accelerometer expressed in frame \(\{O\}\).

Let’s define such matrix using matlab:

M = zeros(length(Opm), 6); for i = 1:length(Opm) Ri = [0, Opm(3,i), -Opm(2,i); -Opm(3,i), 0, Opm(1,i); Opm(2,i), -Opm(1,i), 0]; M(i, 1:3) = Osm(:,i)'; M(i, 4:6) = Osm(:,i)'*Ri; end

end

3.4 getJacobianNanoHexapod

Function description

function [J] = getJacobianNanoHexapod(Hbm) % getJacobianNanoHexapod - % % Syntax: [J] = getJacobianNanoHexapod(Hbm) % % Inputs: % - Hbm - Height of {B} w.r.t. {M} [m] % % Outputs: % - J - Jacobian Matrix

Transformation matrix from motion of the solid body to accelerometer measurements

Fa = [[-86.05, -74.78, 22.49], [ 86.05, -74.78, 22.49], [ 107.79, -37.13, 22.49], [ 21.74, 111.91, 22.49], [-21.74, 111.91, 22.49], [-107.79, -37.13, 22.49]]'*1e-3; % Ai w.r.t. {F} [m] Mb = [[-28.47, -106.25, -22.50], [ 28.47, -106.25, -22.50], [ 106.25, 28.47, -22.50], [ 77.78, 77.78, -22.50], [-77.78, 77.78, -22.50], [-106.25, 28.47, -22.50]]'*1e-3; % Bi w.r.t. {M} [m] H = 95e-3; % Stewart platform height [m] Fb = Mb + [0; 0; H]; % Bi w.r.t. {F} [m] si = Fb - Fa; si = si./vecnorm(si); % Normalize Bb = Mb - [0; 0; Hbm]; J = [si', cross(Bb, si)'];