Amplifier Piezoelectric Actuator APA300ML - Test Bench

Table of Contents

- 1. Model of an Amplified Piezoelectric Actuator and Sensor

- 2. First Basic Measurements

- 3. Dynamical measurements - APA

- 3.1. Speedgoat Setup

- 3.2. Measurements on APA 1

- 3.2.1. Excitation Signal

- 3.2.2. FRF Identification - Setup

- 3.2.3. FRF Identification - Displacement

- 3.2.4. FRF Identification - Force Sensor

- 3.2.5. Hysteresis

- 3.2.6. Estimation of the APA axial stiffness

- 3.2.7. Stiffness change due to electrical connections

- 3.2.8. Effect of the resistor on the IFF Plant

- 3.3. Comparison of all the APA

- 4. Dynamical measurements - Struts

- 5. Test Bench APA300ML - Simscape Model

- 6. Test Bench Struts - Simscape Model

- 7. Function

- 7.1.

initializeBotFlexibleJoint- Initialize Flexible Joint - 7.2.

initializeTopFlexibleJoint- Initialize Flexible Joint - 7.3.

initializeAPA- Initialize APA - 7.4.

generateSweepExc: Generate sweep sinus excitation - 7.5.

generateShapedNoise: Generate Shaped Noise excitation - 7.6.

generateSinIncreasingAmpl: Generate Sinus with increasing amplitude

- 7.1.

This report is also available as a pdf.

The goal of this test bench is to extract all the important parameters of the Amplified Piezoelectric Actuator APA300ML.

This include:

- Stroke

- Stiffness

- Hysteresis

- Gain from the applied voltage \(V_a\) to the generated Force \(F_a\)

- Gain from the sensor stack strain \(\delta L\) to the generated voltage \(V_s\)

- Dynamical behavior

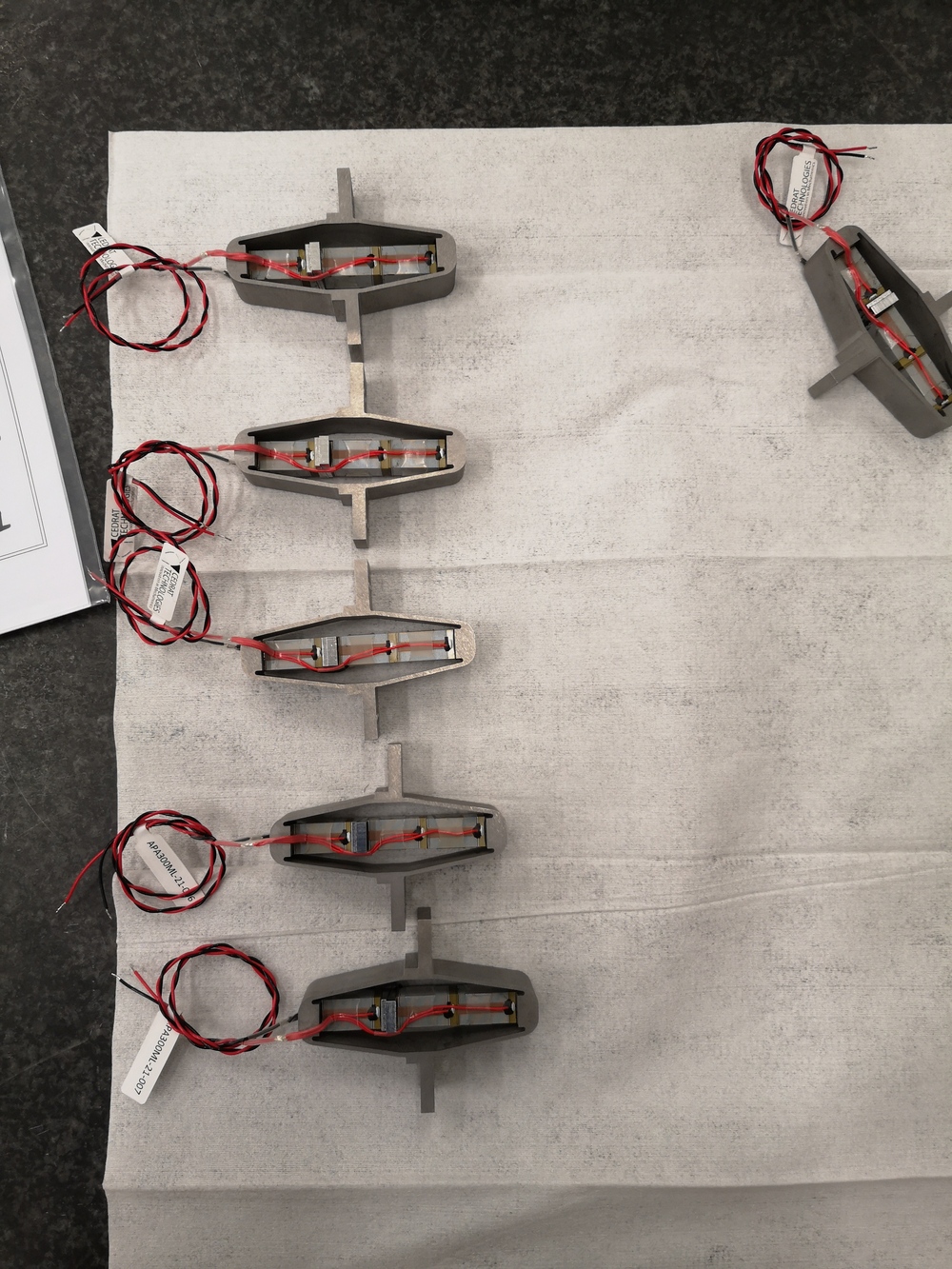

Figure 1: Picture of the APA300ML

1 Model of an Amplified Piezoelectric Actuator and Sensor

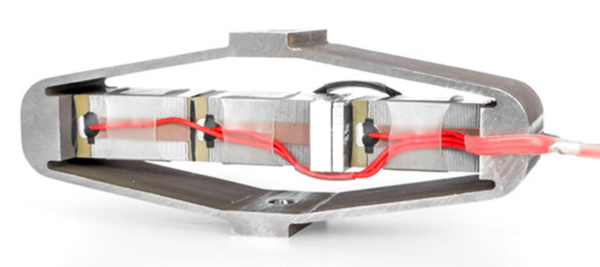

Consider a schematic of the Amplified Piezoelectric Actuator in Figure 2.

Figure 2: Amplified Piezoelectric Actuator Schematic

A voltage \(V_a\) applied to the actuator stacks will induce an actuator force \(F_a\):

\begin{equation} F_a = g_a \cdot V_a \end{equation}A change of length \(dl\) of the sensor stack will induce a voltage \(V_s\):

\begin{equation} V_s = g_s \cdot dl \end{equation}We wish here to experimental measure \(g_a\) and \(g_s\).

The block-diagram model of the piezoelectric actuator is then as shown in Figure 3.

Figure 3: Model of the APA with Simscape/Simulink

2 First Basic Measurements

2.1 Geometrical Measurements

2.1.1 Measurement Setup

The flatness corresponding to the two interface planes are measured as shown in Figure 5.

Figure 5: Measurement Setup

2.1.2 Measurement Results

The height (Z) measurements at the 8 locations (4 points by plane) are defined below.

apa1 = 1e-6*[0, -0.5 , 3.5 , 3.5 , 42 , 45.5, 52.5 , 46]; apa2 = 1e-6*[0, -2.5 , -3 , 0 , -1.5 , 1 , -2 , -4]; apa3 = 1e-6*[0, -1.5 , 15 , 17.5 , 6.5 , 6.5 , 21 , 23]; apa4 = 1e-6*[0, 6.5 , 14.5 , 9 , 16 , 22 , 29.5 , 21]; apa5 = 1e-6*[0, -12.5, 16.5 , 28.5 , -43 , -52 , -22.5, -13.5]; apa6 = 1e-6*[0, -8 , -2 , 5 , -57.5, -62 , -55.5, -52.5]; apa7 = 1e-6*[0, 19.5 , -8 , -29.5, 75 , 97.5, 70 , 48]; apa7b = 1e-6*[0, 9 , -18.5, -30 , 31 , 46.5, 16.5 , 7.5]; apa = {apa1, apa2, apa3, apa4, apa5, apa6, apa7b};

The X/Y Positions of the 8 measurement points are defined below.

W = 20e-3; % Width [m] L = 61e-3; % Length [m] d = 1e-3; % Distance from border [m] l = 15.5e-3; % [m] pos = [[-L/2 + d; W/2 - d], [-L/2 + l - d; W/2 - d], [-L/2 + l - d; -W/2 + d], [-L/2 + d; -W/2 + d], [L/2 - l + d; W/2 - d], [L/2 - d; W/2 - d], [L/2 - d; -W/2 + d], [L/2 - l + d; -W/2 + d]];

Finally, the flatness is estimated by fitting a plane through the 8 points using the fminsearch command.

apa_d = zeros(1, 7); for i = 1:7 fun = @(x)max(abs(([pos; apa{i}]-[0;0;x(1)])'*([x(2:3);1]/norm([x(2:3);1])))); x0 = [0;0;0]; [x, min_d] = fminsearch(fun,x0); apa_d(i) = min_d; end

The obtained flatness are shown in Table 1.

| Flatness \([\mu m]\) | |

|---|---|

| APA 1 | 8.9 |

| APA 2 | 3.1 |

| APA 3 | 9.1 |

| APA 4 | 3.0 |

| APA 5 | 1.9 |

| APA 6 | 7.1 |

| APA 7 | 18.7 |

2.2 Electrical Measurements

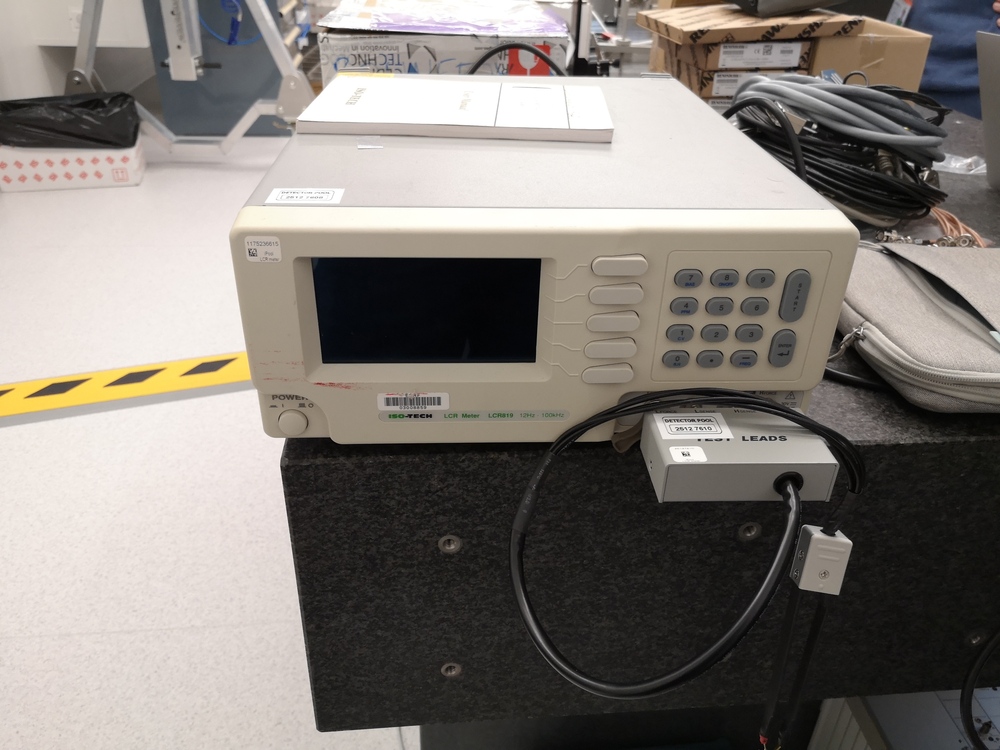

The capacitance of the stacks is measure with the LCR-800 Meter (doc)

Figure 6: LCR Meter used for the measurements

The excitation frequency is set to be 1kHz.

| Sensor Stack | Actuator Stacks | |

|---|---|---|

| APA 1 | 5.10 | 10.03 |

| APA 2 | 4.99 | 9.85 |

| APA 3 | 1.72 | 5.18 |

| APA 4 | 4.94 | 9.82 |

| APA 5 | 4.90 | 9.66 |

| APA 6 | 4.99 | 9.91 |

| APA 7 | 4.85 | 9.85 |

There is clearly a problem with APA300ML number 3

The APA number 3 has ben sent back to Cedrat, and a new APA300ML has been shipped back.

2.3 Stroke measurement

We here wish to estimate the stroke of the APA.

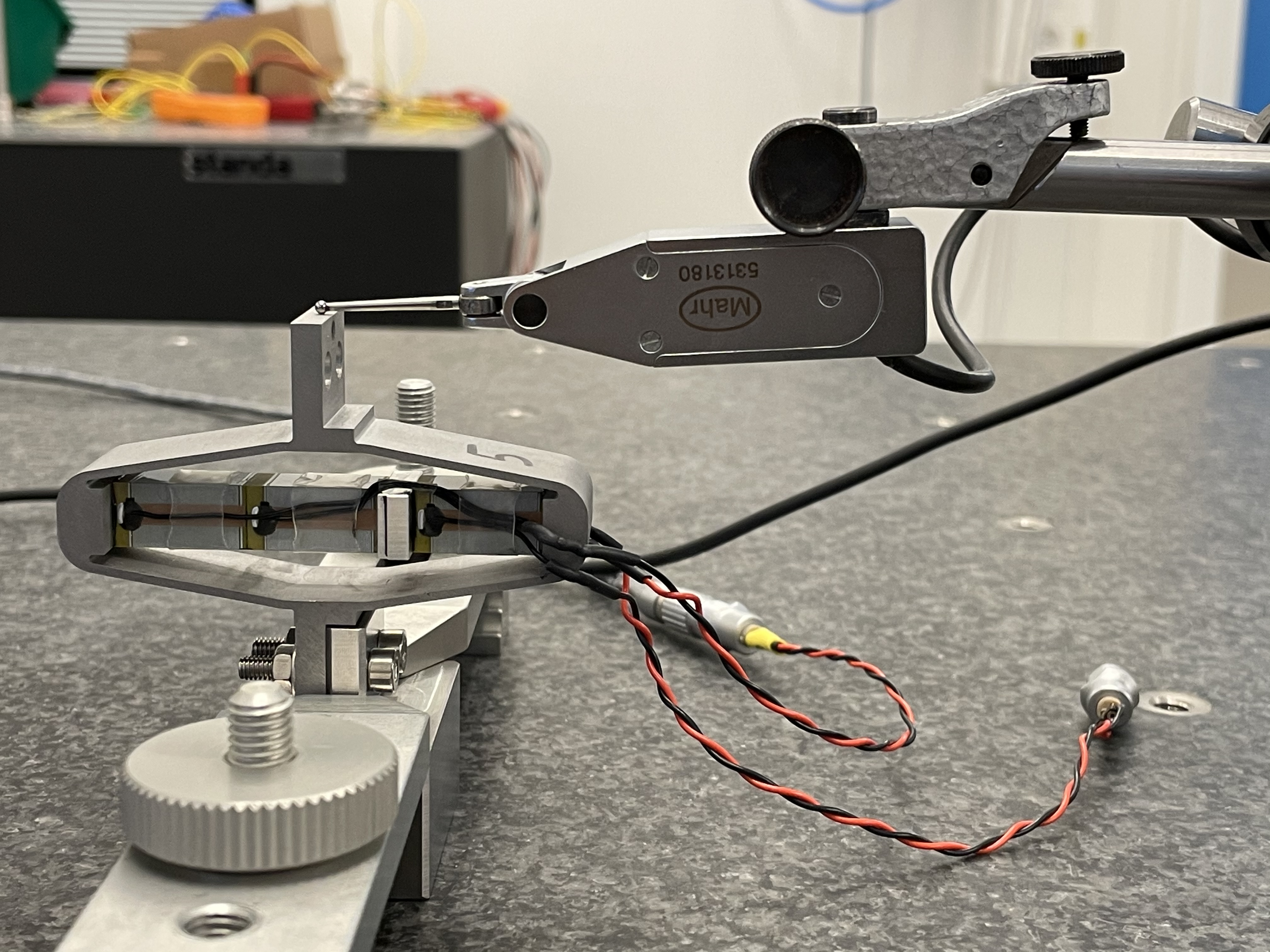

To do so, one side of the APA is fixed, and a displacement probe is located on the other side as shown in Figure 7.

Then, a voltage is applied on either one or two stacks using a DAC and a voltage amplifier.

Here are the documentation of the equipment used for this test bench:

- Voltage Amplifier: PD200 with a gain of 20

- 16bits DAC: IO313 Speedgoat card

- Displacement Probe: Millimar C1216 electronics and Millimar 1318 probe

Figure 7: Bench to measured the APA stroke

2.3.1 Voltage applied on one stack

Let’s first look at the relation between the voltage applied to one stack to the displacement of the APA as measured by the displacement probe.

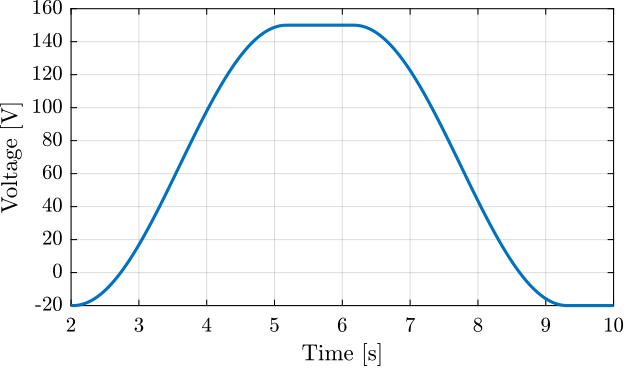

The applied voltage is shown in Figure 8.

Figure 8: Applied voltage as a function of time

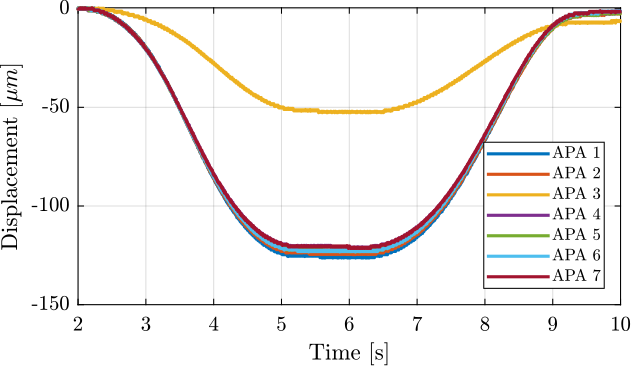

The obtained displacement is shown in Figure 9. The displacement is set to zero at initial time when the voltage applied is -20V.

Figure 9: Displacement as a function of time for all the APA300ML

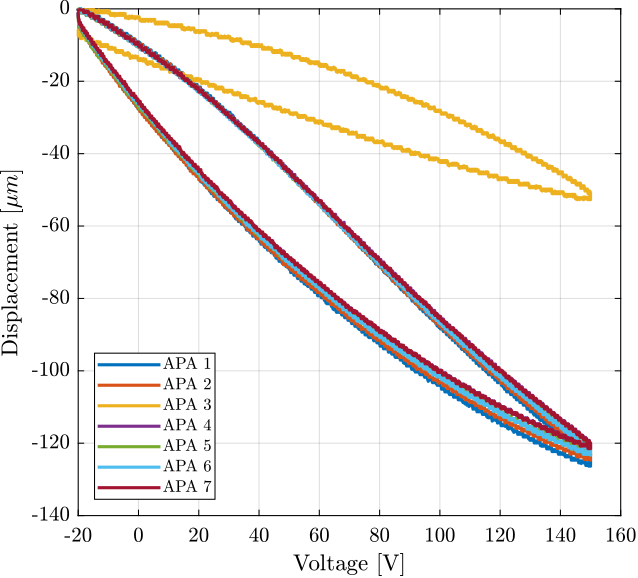

Finally, the displacement is shown as a function of the applied voltage in Figure 10. We can clearly see that there is a problem with the APA 3. Also, there is a large hysteresis.

Figure 10: Displacement as a function of the applied voltage

We can clearly see from Figure 10 that there is a problem with the APA number 3.

2.3.2 Voltage applied on two stacks

Now look at the relation between the voltage applied to the two other stacks to the displacement of the APA as measured by the displacement probe.

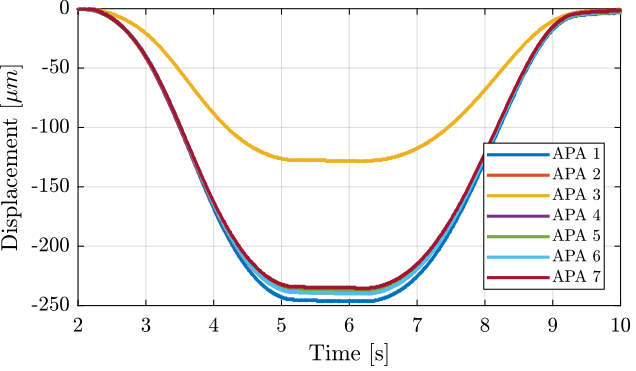

The obtained displacement is shown in Figure 11. The displacement is set to zero at initial time when the voltage applied is -20V.

Figure 11: Displacement as a function of time for all the APA300ML

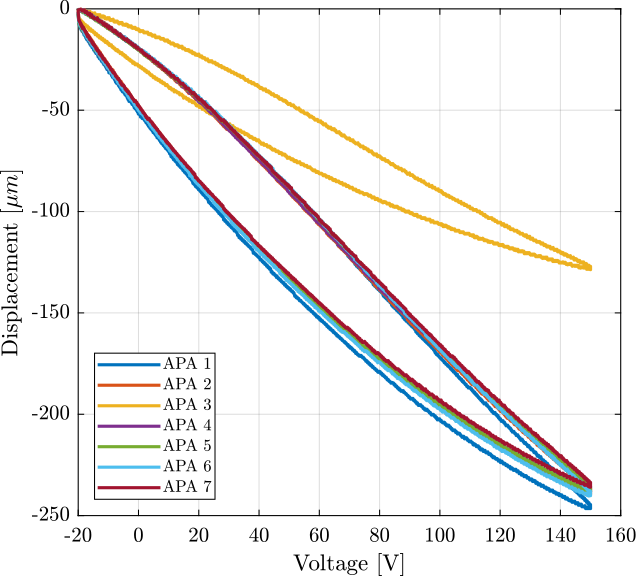

Finally, the displacement is shown as a function of the applied voltage in Figure 12. We can clearly see that there is a problem with the APA 3. Also, there is a large hysteresis.

Figure 12: Displacement as a function of the applied voltage

2.3.3 Voltage applied on all three stacks

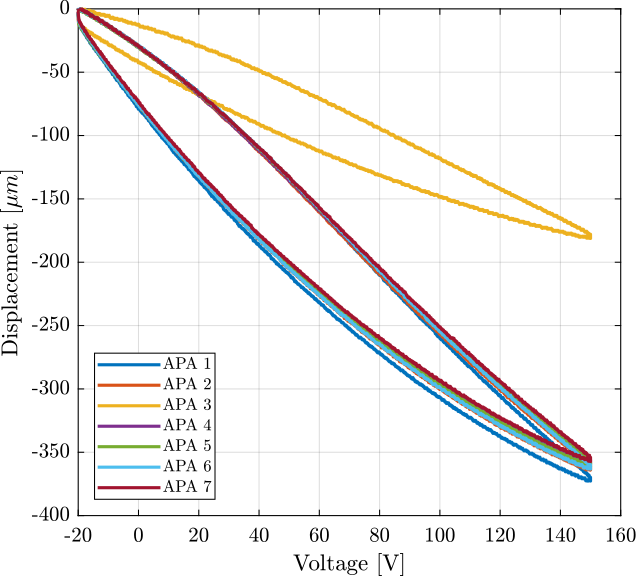

Finally, we can combine the two measurements to estimate the relation between the displacement and the voltage applied to the three stacks (Figure 13).

Figure 13: Displacement as a function of the applied voltage

The obtained maximum stroke for all the APA are summarized in Table 3.

| Stroke \([\mu m]\) | |

|---|---|

| APA 1 | 373.2 |

| APA 2 | 365.5 |

| APA 3 | 181.7 |

| APA 4 | 359.7 |

| APA 5 | 361.5 |

| APA 6 | 363.9 |

| APA 7 | 358.4 |

2.4 Spurious resonances

2.4.1 Introduction

Three main resonances are foreseen to be problematic for the control of the APA300ML:

- Mode in X-bending at 189Hz (Figure 14)

- Mode in Y-bending at 285Hz (Figure 15)

- Mode in Z-torsion at 400Hz (Figure 16)

Figure 14: X-bending mode (189Hz)

Figure 15: Y-bending mode (285Hz)

Figure 16: Z-torsion mode (400Hz)

These modes are present when flexible joints are fixed to the ends of the APA300ML.

In this section, we try to find the resonance frequency of these modes when one end of the APA is fixed and the other is free.

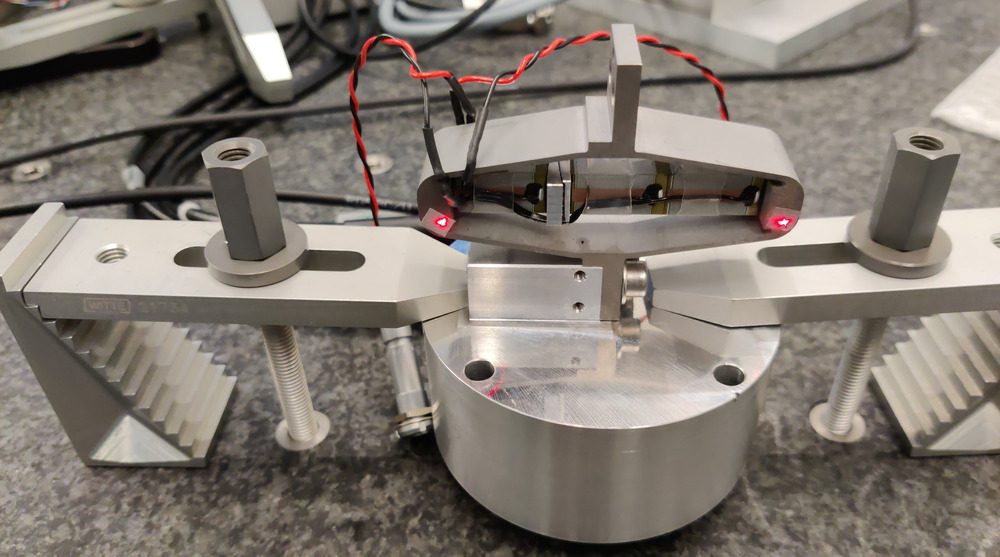

2.4.2 Setup

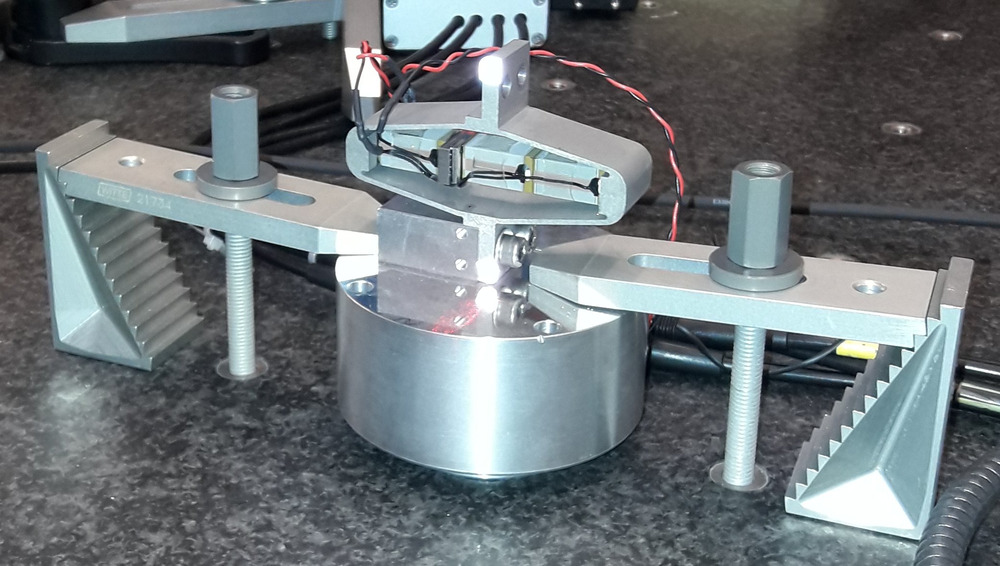

The measurement setup is shown in Figure 17. A Laser vibrometer is measuring the difference of motion of two points. The APA is excited with an instrumented hammer and the transfer function from the hammer to the measured rotation is computed.

- Laser Doppler Vibrometer Polytec OFV512

- Instrumented hammer

Figure 17: Measurement setup with a Laser Doppler Vibrometer and one instrumental hammer

2.4.3 Bending - X

The setup to measure the X-bending motion is shown in Figure 18. The APA is excited with an instrumented hammer having a solid metallic tip. The impact point is on the back-side of the APA aligned with the top measurement point.

Figure 18: X-Bending measurement setup

The data is loaded.

bending_X = load('apa300ml_bending_X_top.mat');

The config for tfestimate is performed:

Ts = bending_X.Track1_X_Resolution; % Sampling frequency [Hz] win = hann(ceil(1/Ts));

The transfer function from the input force to the output “rotation” (difference between the two measured distances).

[G_bending_X, f] = tfestimate(bending_X.Track1, bending_X.Track2, win, [], [], 1/Ts);

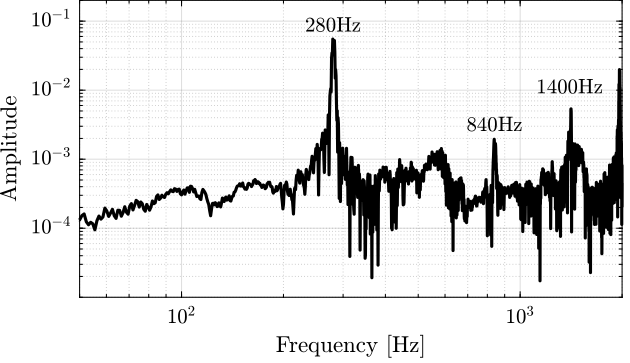

The result is shown in Figure 19.

The can clearly observe a nice peak at 280Hz, and then peaks at the odd “harmonics” (third “harmonic” at 840Hz, and fifth “harmonic” at 1400Hz).

Figure 19: Obtained FRF for the X-bending

2.4.4 Bending - Y

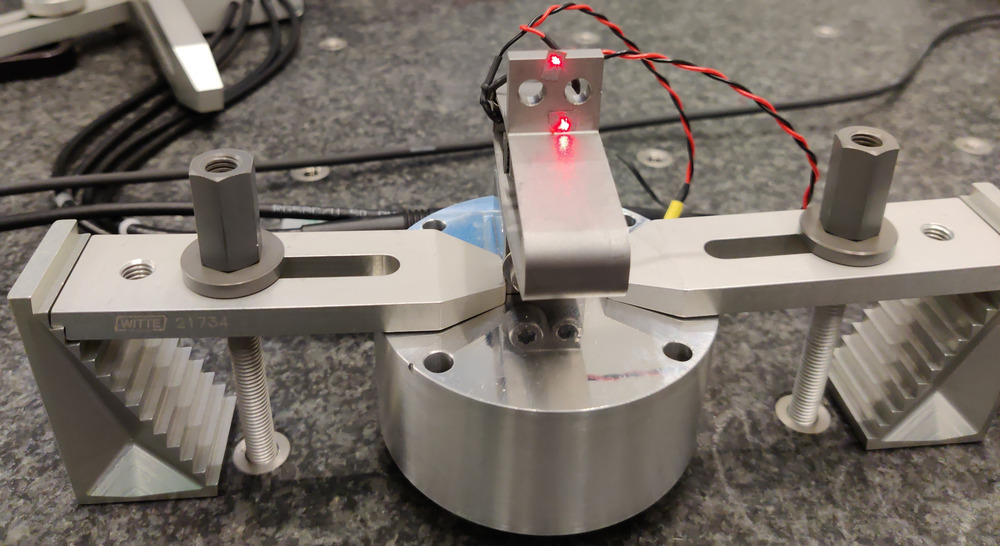

The setup to measure the Y-bending is shown in Figure 20.

The impact point of the instrumented hammer is located on the back surface of the top interface (on the back of the 2 measurements points).

Figure 20: Y-Bending measurement setup

The data is loaded, and the transfer function from the force to the measured rotation is computed.

bending_Y = load('apa300ml_bending_Y_top.mat'); [G_bending_Y, ~] = tfestimate(bending_Y.Track1, bending_Y.Track2, win, [], [], 1/Ts);

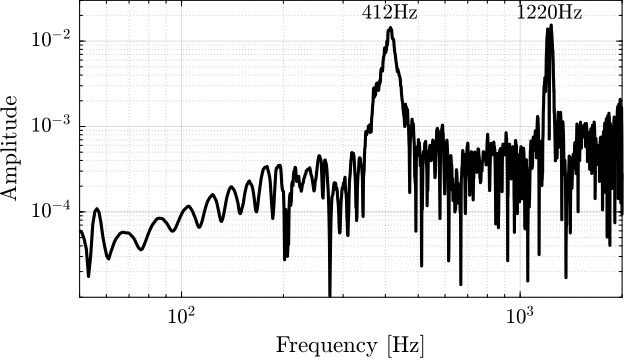

The results are shown in Figure 21. The main resonance is at 412Hz, and we also see the third “harmonic” at 1220Hz.

Figure 21: Obtained FRF for the Y-bending

2.4.5 Torsion - Z

Finally, we measure the Z-torsion resonance as shown in Figure 22.

The excitation is shown on the other side of the APA, on the side to excite the torsion motion.

Figure 22: Z-Torsion measurement setup

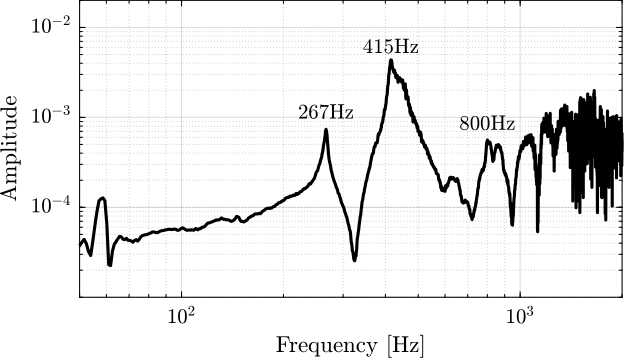

The data is loaded, and the transfer function computed.

torsion = load('apa300ml_torsion_left.mat'); [G_torsion, ~] = tfestimate(torsion.Track1, torsion.Track2, win, [], [], 1/Ts);

The results are shown in Figure 23. We observe a first peak at 267Hz, which corresponds to the X-bending mode that was measured at 280Hz. And then a second peak at 415Hz, which corresponds to the X-bending mode that was measured at 412Hz. The mode in pure torsion is probably at higher frequency (peak around 1kHz?).

Figure 23: Obtained FRF for the Z-torsion

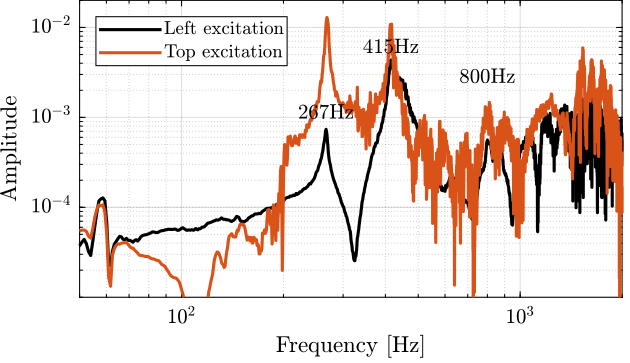

In order to verify that, the APA is excited on the top part such that the torsion mode should not be excited.

torsion = load('apa300ml_torsion_top.mat'); [G_torsion_top, ~] = tfestimate(torsion.Track1, torsion.Track2, win, [], [], 1/Ts);

The two FRF are compared in Figure 24. It is clear that the first two modes does not correspond to the torsional mode. Maybe the resonance at 800Hz, or even higher resonances. It is difficult to conclude here.

Figure 24: Obtained FRF for the Z-torsion

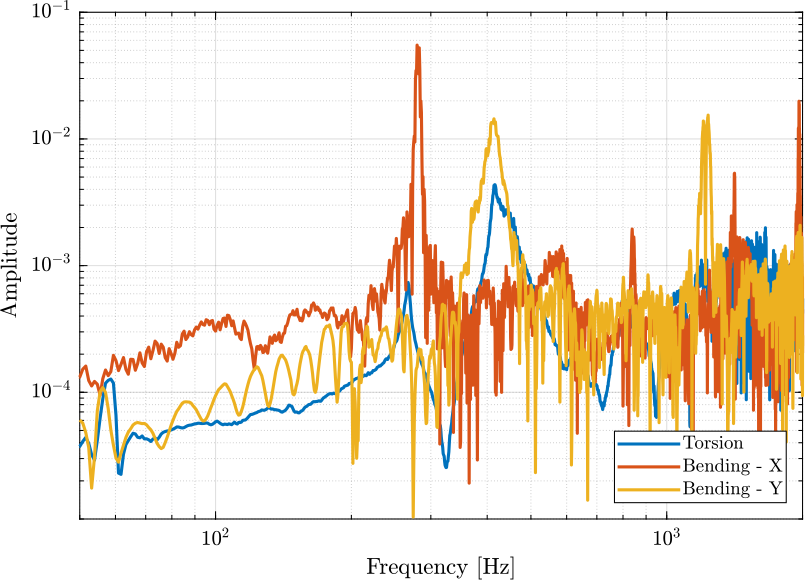

2.4.6 Compare

The three measurements are shown in Figure 25.

Figure 25: Obtained FRF - Comparison

2.4.7 Conclusion

When two flexible joints are fixed at each ends of the APA, the APA is mostly in a free/free condition in terms of bending/torsion (the bending/torsional stiffness of the joints being very small).

In the current tests, the APA are in a fixed/free condition. Therefore, it is quite obvious that we measured higher resonance frequencies than what is foreseen for the struts. It is however quite interesting that there is a factor \(\approx \sqrt{2}\) between the two (increased of the stiffness by a factor 2?).

| Mode | Strut Mode | Measured Frequency |

|---|---|---|

| X-Bending | 189Hz | 280Hz |

| Y-Bending | 285Hz | 410Hz |

| Z-Torsion | 400Hz | ? |

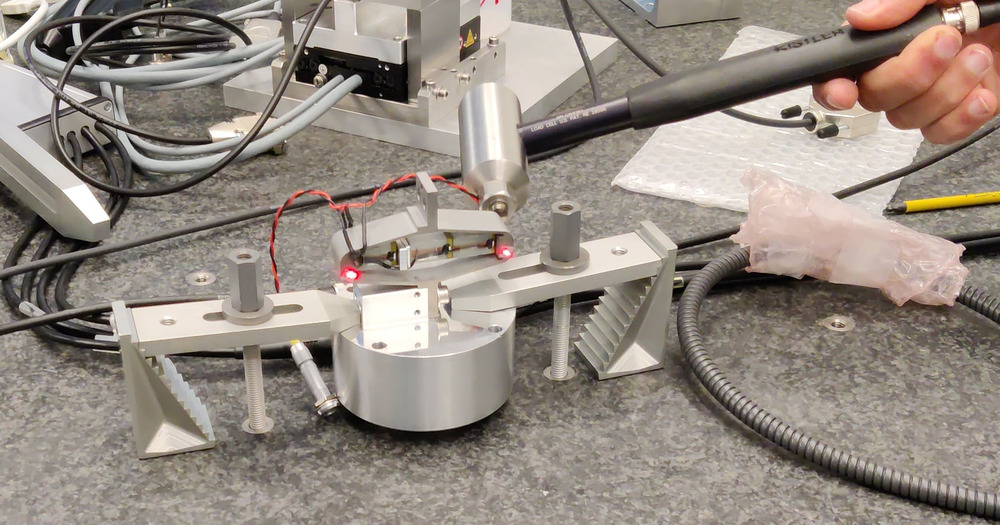

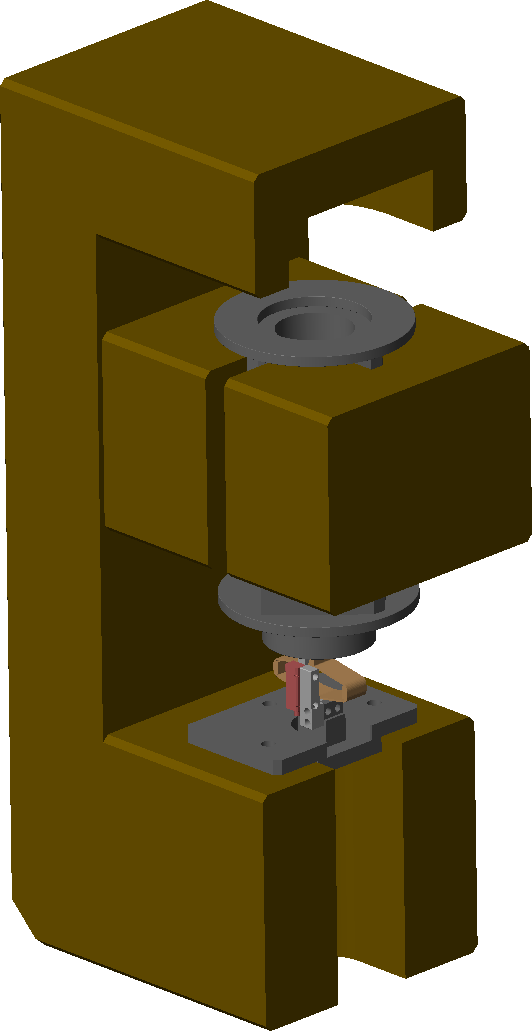

3 Dynamical measurements - APA

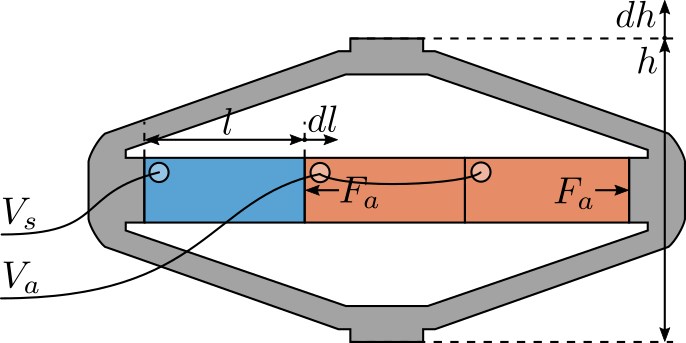

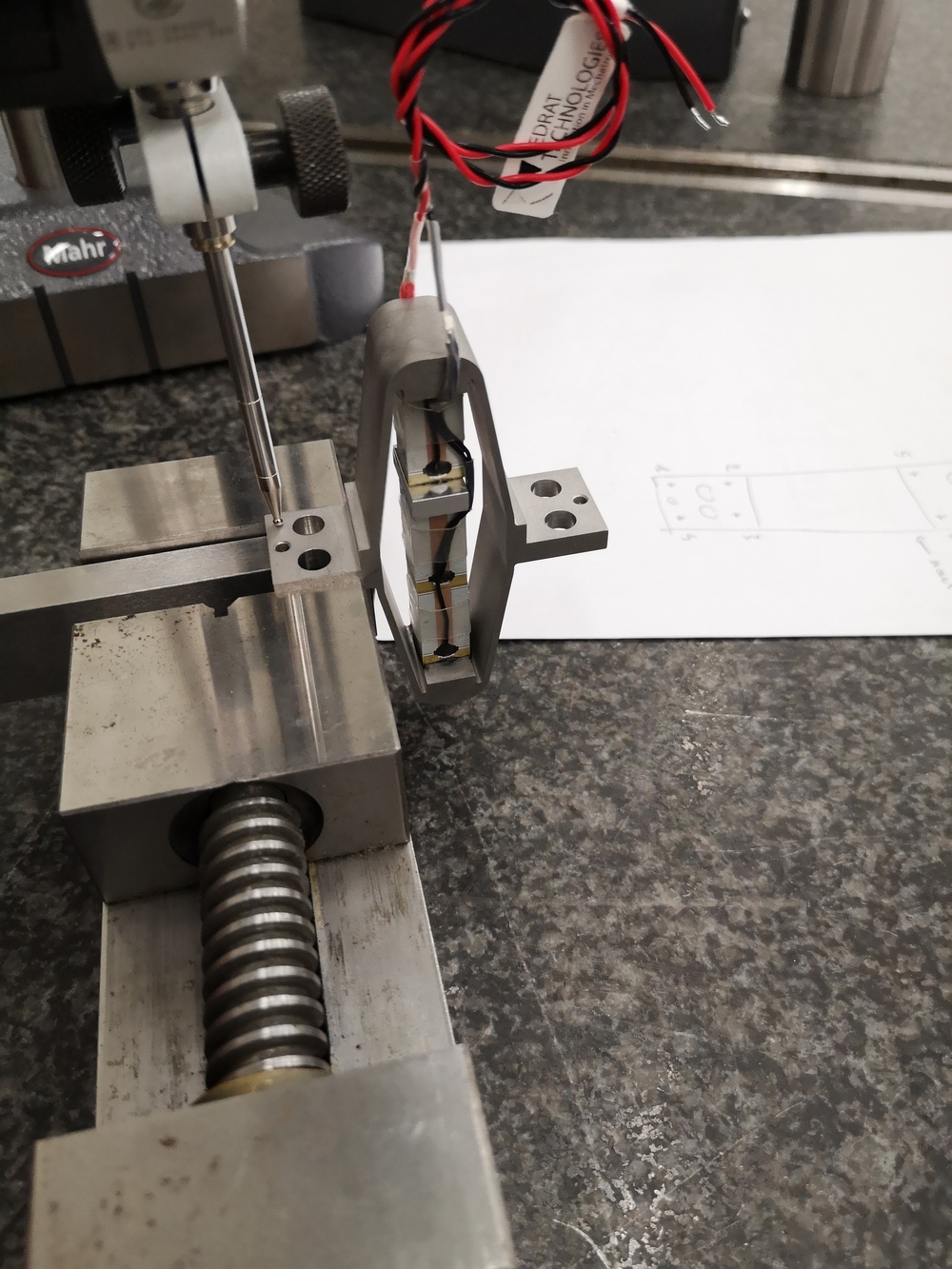

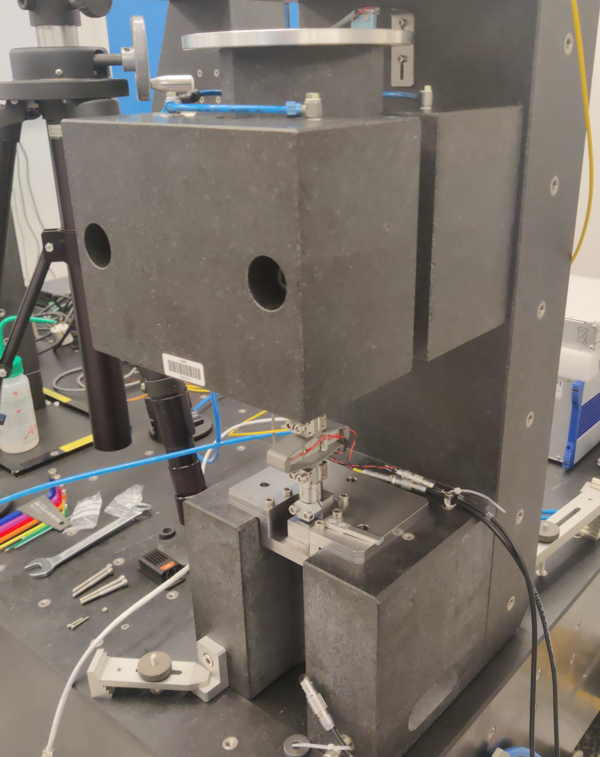

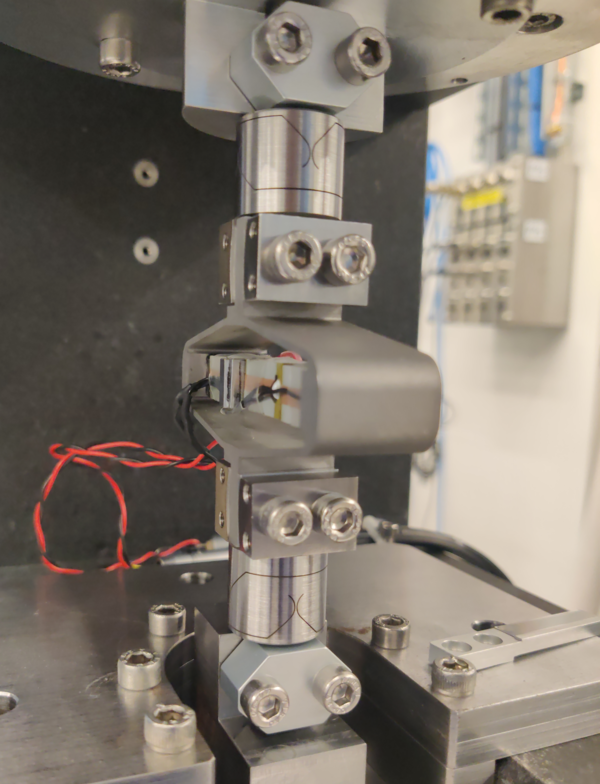

In this section, a measurement test bench is used to identify the dynamics of the APA.

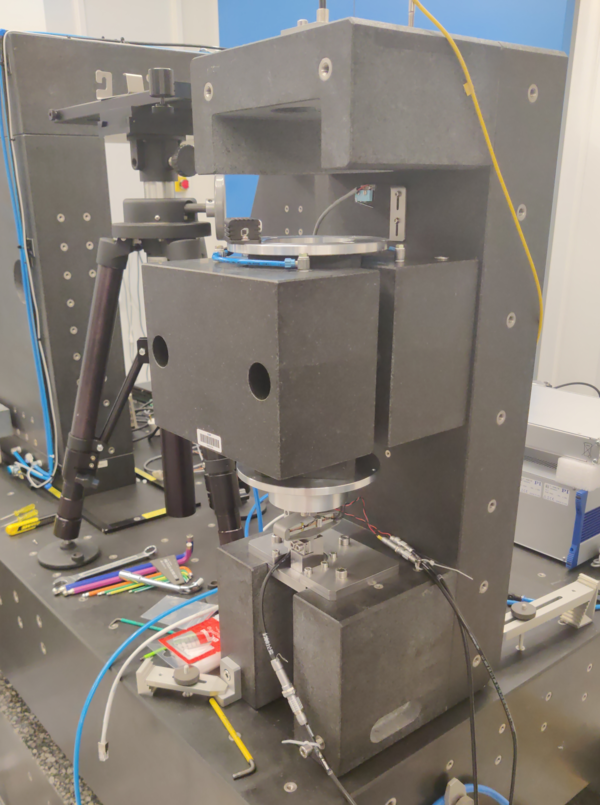

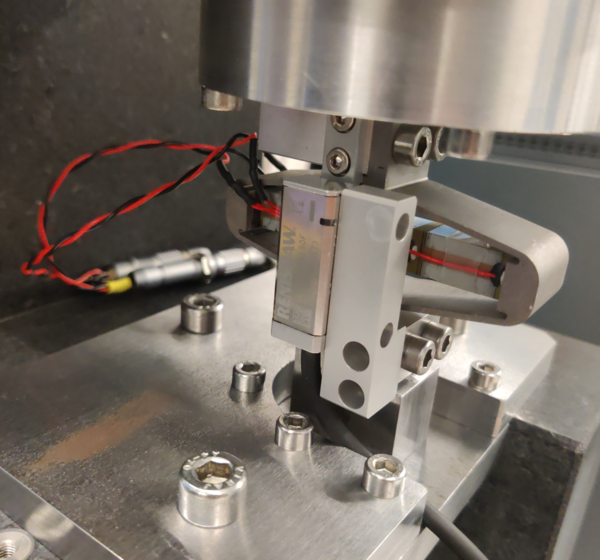

The bench is shown in Figure 26, and a zoom picture on the APA and encoder is shown in Figure 27.

Figure 26: Picture of the test bench

Figure 27: Zoom on the APA with the encoder

Here are the documentation of the equipment used for this test bench:

- Voltage Amplifier: PD200

- Amplified Piezoelectric Actuator: APA300ML

- DAC/ADC: Speedgoat IO313

- Encoder: Renishaw Vionic and used Ruler

- Interferometer: Attocube IDS3010

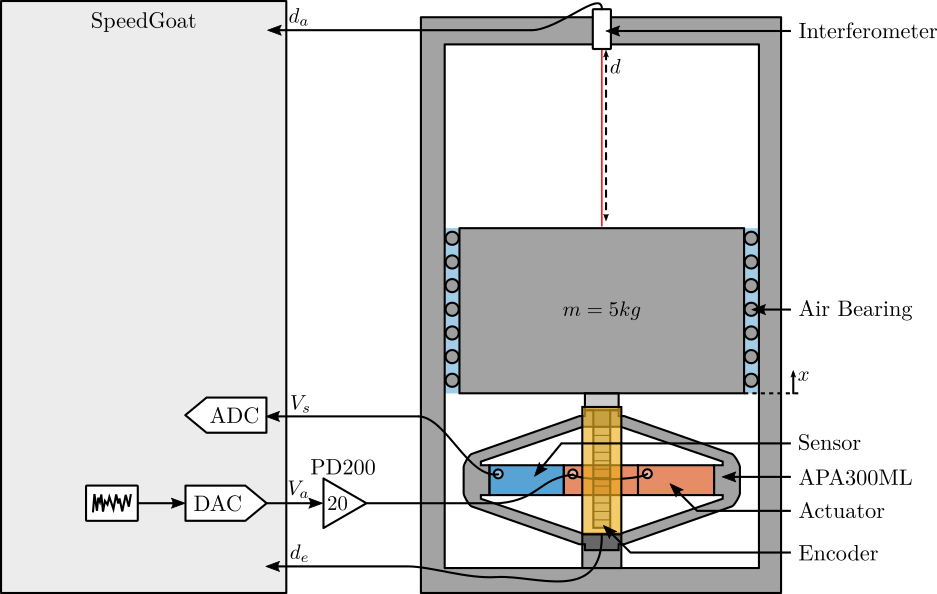

The bench is schematically shown in Figure 28 and the signal used are summarized in Table 5.

Figure 28: Schematic of the Test Bench

| Variable | Description | Unit | Hardware |

|---|---|---|---|

Va |

Output DAC voltage | [V] | DAC - Ch. 1 => PD200 => APA |

Vs |

Measured stack voltage (ADC) | [V] | APA => ADC - Ch. 1 |

de |

Encoder Measurement | [m] | PEPU Ch. 1 - IO318(1) - Ch. 1 |

da |

Attocube Measurement | [m] | PEPU Ch. 2 - IO318(1) - Ch. 2 |

t |

Time | [s] |

This section is structured as follows:

3.1 Speedgoat Setup

3.1.1 frf_setup.m - Measurement Setup

First is defined the sampling frequency:

%% Simulation configuration Fs = 10e3; % Sampling Frequency [Hz] Ts = 1/Fs; % Sampling Time [s]

%% Data record configuration Trec_start = 5; % Start time for Recording [s] Trec_dur = 100; % Recording Duration [s]

Tsim = 2*Trec_start + Trec_dur; % Simulation Time [s]

A white noise excitation signal can be very useful in order to obtain a first idea of the plant FRF. The gain can be gradually increased until satisfactory output is obtained.

%% Shaped Noise V_noise = generateShapedNoise('Ts', 1/Fs, ... 'V_mean', 3.25, ... 't_start', Trec_start, ... 'exc_duration', Trec_dur, ... 'smooth_ends', true, ... 'V_exc', 0.05/(1 + s/2/pi/10));

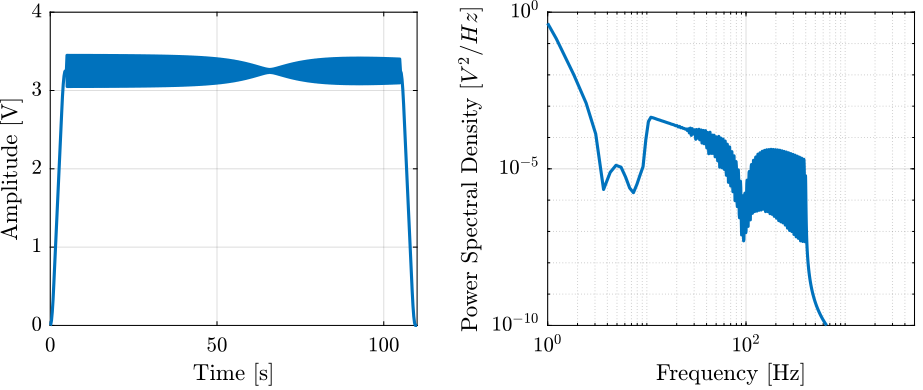

Figure 29: Example of Shaped noise excitation signal

The maximum excitation voltage at resonance is 9Vrms, therefore corresponding to 0.6V of output DAC voltage.

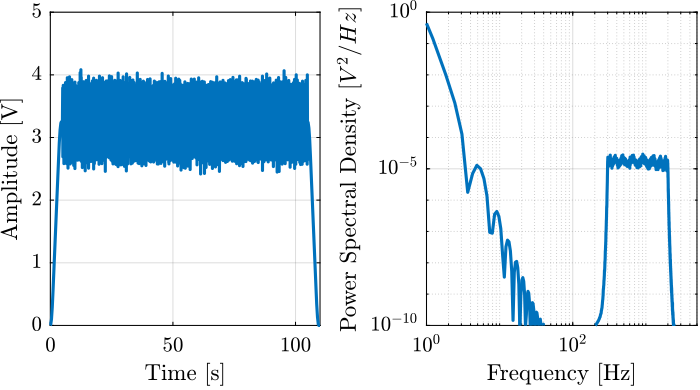

%% Sweep Sine gc = 0.1; xi = 0.5; wn = 2*pi*94.3; % Notch filter at the resonance of the APA G_sweep = 0.2*(s^2 + 2*gc*xi*wn*s + wn^2)/(s^2 + 2*xi*wn*s + wn^2); V_sweep = generateSweepExc('Ts', Ts, ... 'f_start', 10, ... 'f_end', 400, ... 'V_mean', 3.25, ... 't_start', Trec_start, ... 'exc_duration', Trec_dur, ... 'sweep_type', 'log', ... 'V_exc', G_sweep*1/(1 + s/2/pi/500));

Figure 30: Example of Sweep Sin excitation signal

In order to better estimate the high frequency dynamics, a band-limited noise can be used (Figure 31). The frequency content of the noise can be precisely controlled.

%% High Frequency Shaped Noise [b,a] = cheby1(10, 2, 2*pi*[300 2e3], 'bandpass', 's'); wL = 0.005*tf(b, a); V_noise_hf = generateShapedNoise('Ts', 1/Fs, ... 'V_mean', 3.25, ... 't_start', Trec_start, ... 'exc_duration', Trec_dur, ... 'smooth_ends', true, ... 'V_exc', wL);

Figure 31: Example of band-limited noise excitation signal

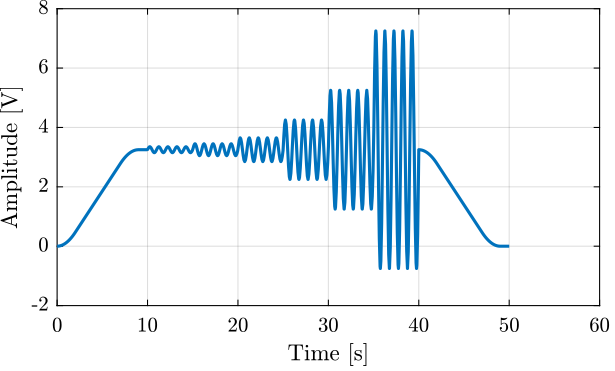

Then a sinus excitation can be used to estimate the hysteresis.

%% Sinus excitation with increasing amplitude V_sin = generateSinIncreasingAmpl('Ts', 1/Fs, ... 'V_mean', 3.25, ... 'sin_ampls', [0.1, 0.2, 0.4, 1, 2, 4], ... 'sin_period', 1, ... 'sin_num', 5, ... 't_start', Trec_start, ... 'smooth_ends', true);

Figure 32: Example of Shaped noise excitation signal

Then, we select the wanted excitation signal.

%% Select the excitation signal V_exc = timeseries(V_noise(2,:), V_noise(1,:));

%% Save data that will be loaded in the Simulink file save('./frf_data.mat', 'Fs', 'Ts', 'Tsim', 'Trec_start', 'Trec_dur', 'V_exc');

3.1.2 frf_save.m - Save Data

First, we get data from the Speedgoat:

tg = slrt;

f = SimulinkRealTime.openFTP(tg);

mget(f, 'data/data.dat');

close(f);

And we load the data on the Workspace:

data = SimulinkRealTime.utils.getFileScopeData('data/data.dat').data; da = data(:, 1); % Excitation Voltage (input of PD200) [V] de = data(:, 2); % Measured voltage (force sensor) [V] Vs = data(:, 3); % Measurment displacement (encoder) [m] Va = data(:, 4); % Measurement displacement (attocube) [m] t = data(:, end); % Time [s]

And we save this to a mat file:

apa_number = 1; save(sprintf('mat/frf_data_%i_huddle.mat', apa_number), 't', 'Va', 'Vs', 'de', 'da');

3.2 Measurements on APA 1

Measurements are first performed on only one APA. Once the measurement procedure is validated, it is performed on all the other APA.

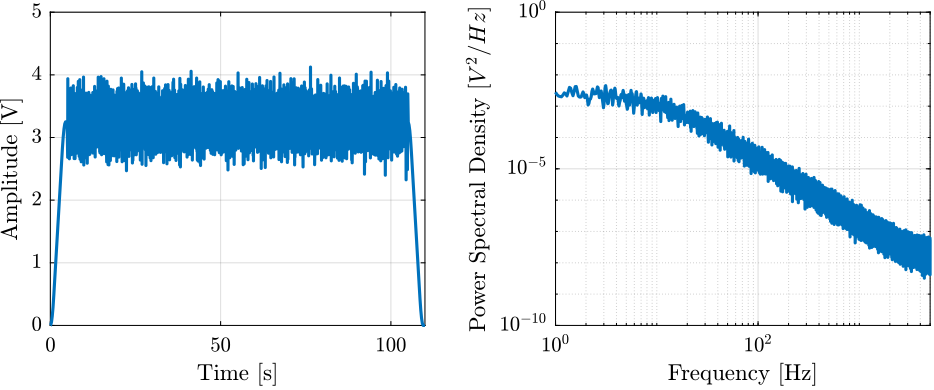

3.2.1 Excitation Signal

For this first measurement, a basic logarithmic sweep is used between 10Hz and 2kHz.

The data are loaded.

apa_sweep = load(sprintf('mat/frf_data_%i_sweep.mat', 1), 't', 'Va', 'Vs', 'da', 'de');

The initial time is set to zero.

%% Time vector t = apa_sweep.t - apa_sweep.t(1) ; % Time vector [s]

The excitation signal is shown in Figure 33. It is a sweep sine from 10Hz up to 2kHz filtered with a notch centered with the main resonance of the system and a low pass filter.

Figure 33: Excitation voltage

3.2.2 FRF Identification - Setup

Let’s define the sampling time/frequency.

%% Sampling Ts = (t(end) - t(1))/(length(t)-1); % Sampling Time [s] Fs = 1/Ts; % Sampling Frequency [Hz]

Then we defined a “Hanning” windows that will be used for the spectral analysis:

win = hanning(ceil(1*Fs)); % Hannning Windows

We get the frequency vector that will be the same for all the frequency domain analysis.

% Only used to have the frequency vector "f" [~, f] = tfestimate(apa_sweep.Va, apa_sweep.de, win, [], [], 1/Ts);

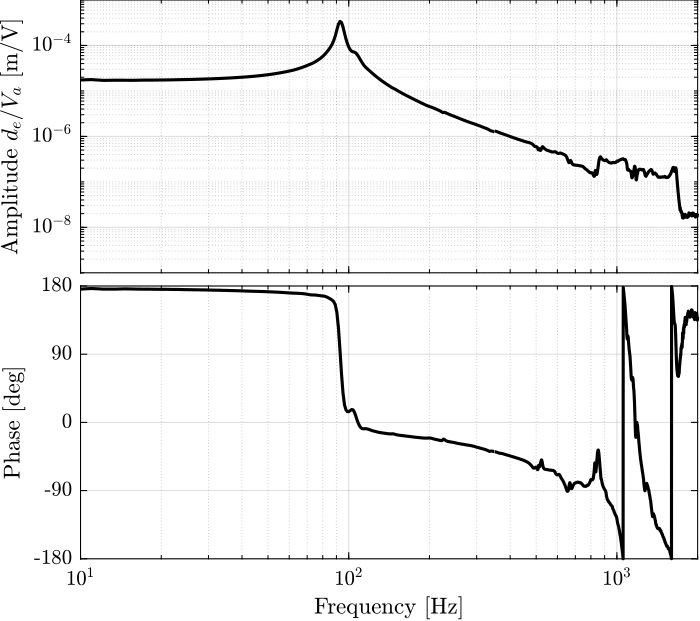

3.2.3 FRF Identification - Displacement

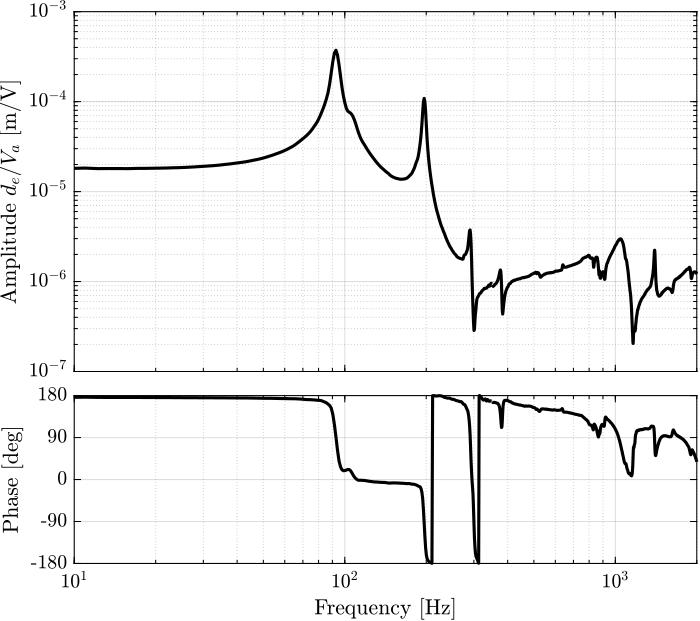

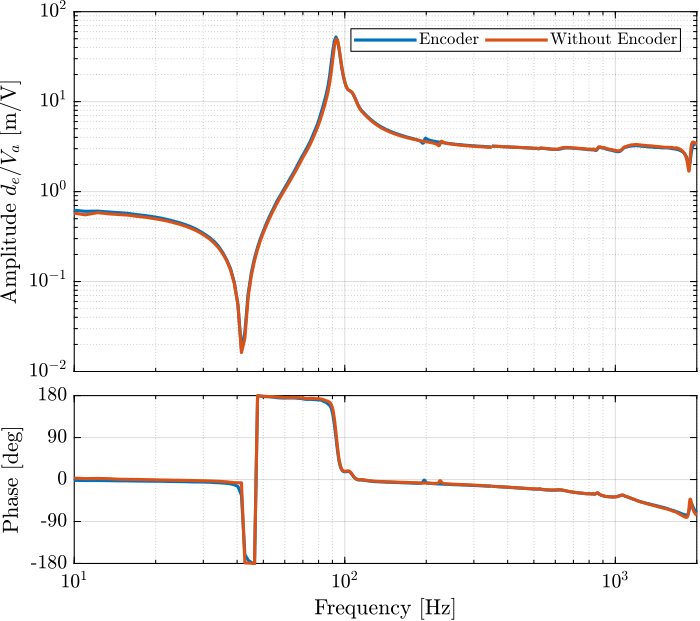

In this section, the transfer function from the excitation voltage \(V_a\) to the encoder measured displacement \(d_e\) and interferometer measurement \(d_a\).

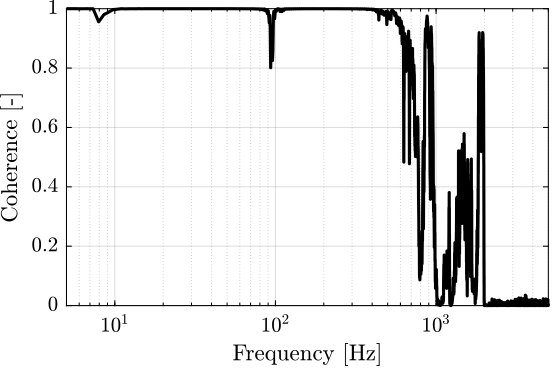

The coherence from \(V_a\) to \(d_e\) is computed and shown in Figure 34. It is quite good from 10Hz up to 500Hz.

%% TF - Encoder [coh_sweep, ~] = mscohere(apa_sweep.Va, apa_sweep.de, win, [], [], 1/Ts);

Figure 34: Coherence for the identification from \(V_a\) to \(d_e\)

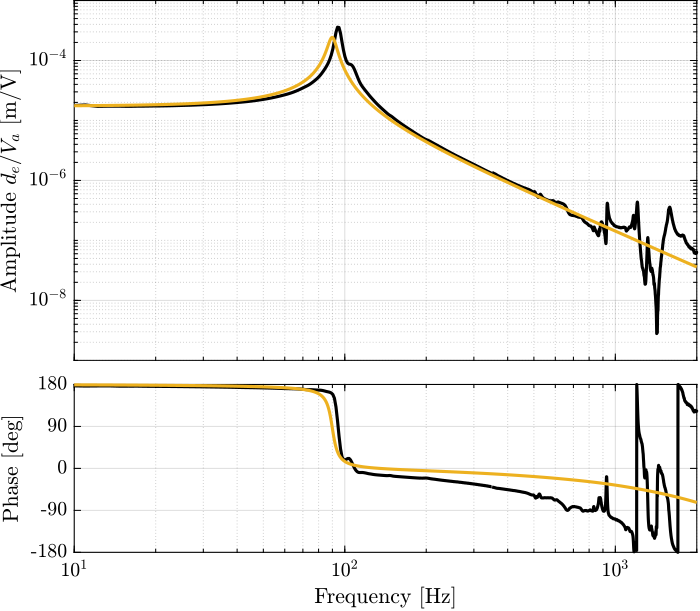

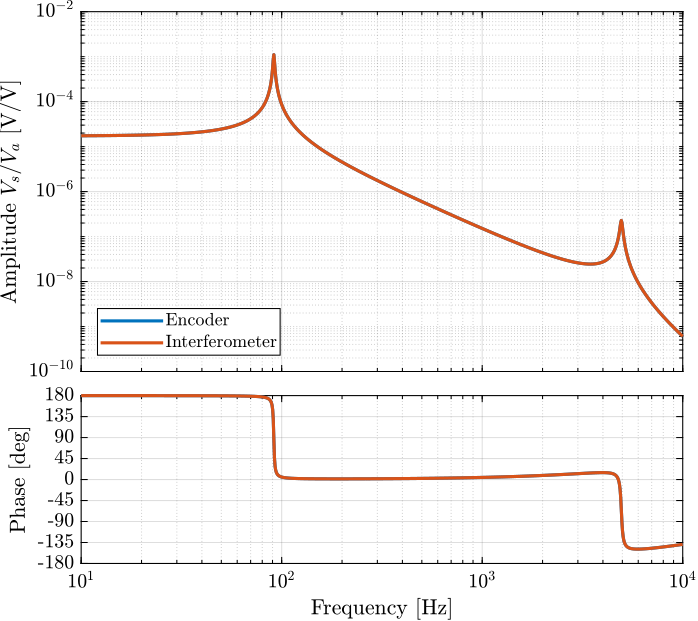

The transfer functions are then estimated and shown in Figure 35.

%% TF - Encoder [dvf_sweep, ~] = tfestimate(apa_sweep.Va, apa_sweep.de, win, [], [], 1/Ts); %% TF - Interferometer [int_sweep, ~] = tfestimate(apa_sweep.Va, apa_sweep.da, win, [], [], 1/Ts);

Figure 35: Obtained transfer functions from \(V_a\) to both \(d_e\) and \(d_a\)

It seems that using the interferometer, we have a lot more time delay than when using the encoder.

3.2.4 FRF Identification - Force Sensor

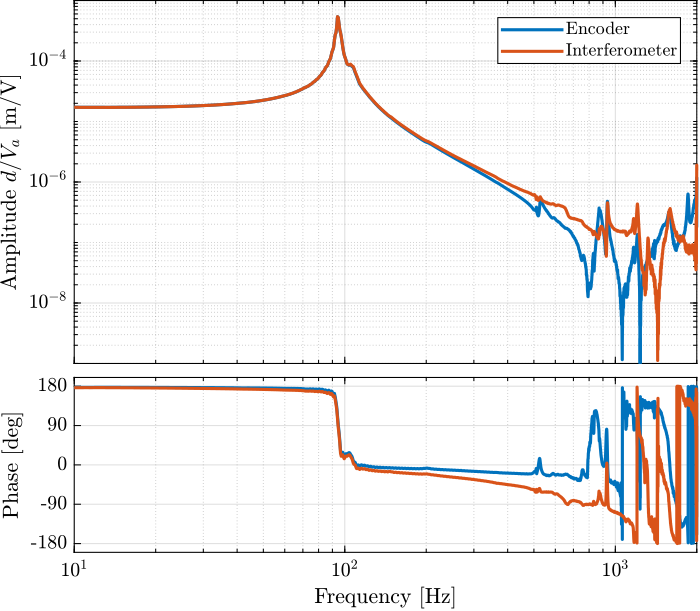

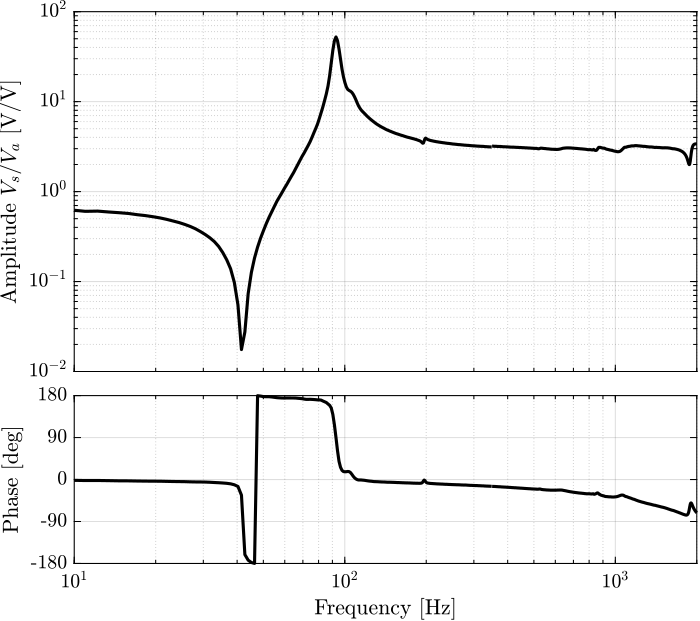

Now the dynamics from excitation voltage \(V_a\) to the force sensor stack voltage \(V_s\) is identified.

The coherence is computed and shown in Figure 36 and found very good from 10Hz up to 2kHz.

%% TF - Encoder [coh_sweep, ~] = mscohere(apa_sweep.Va, apa_sweep.Vs, win, [], [], 1/Ts);

Figure 36: Coherence for the identification from \(V_a\) to \(V_s\)

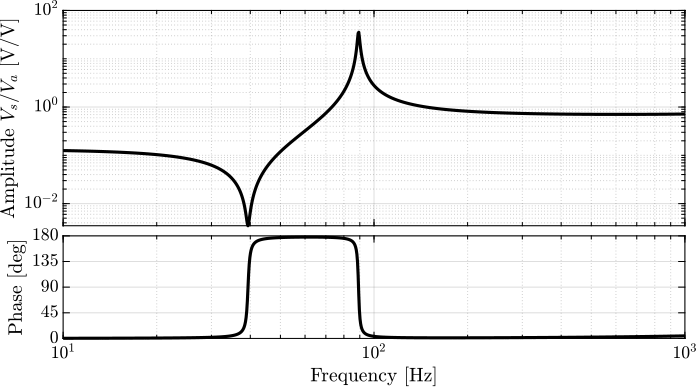

The transfer function is estimated and shown in Figure 37.

%% Transfer function estimation [iff_sweep, ~] = tfestimate(apa_sweep.Va, apa_sweep.Vs, win, [], [], 1/Ts);

Figure 37: Obtained transfer functions from \(V_a\) to \(V_s\)

3.2.5 Hysteresis

We here wish to visually see the amount of hysteresis present in the APA.

To do so, a quasi static sinusoidal excitation \(V_a\) at different voltages is used.

The offset is 65V, and the sin amplitude is ranging from 1V up to 80V.

For each excitation amplitude, the vertical displacement \(d\) of the mass is measured.

Then, \(d\) is plotted as a function of \(V_a\) for all the amplitudes.

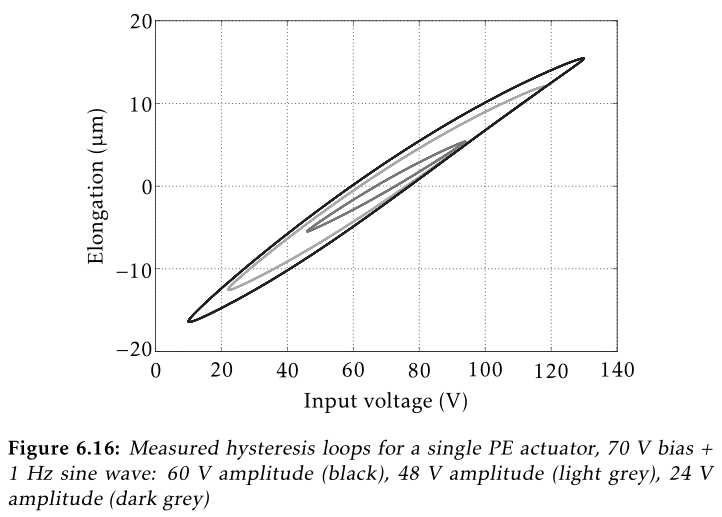

We expect to obtained something like the hysteresis shown in Figure 38.

Figure 38: Expected Hysteresis poel10_explor_activ_hard_mount_vibrat

The data is loaded.

apa_hyst = load('frf_data_1_hysteresis.mat', 't', 'Va', 'de'); % Initial time set to zero apa_hyst.t = apa_hyst.t - apa_hyst.t(1);

The excitation voltage amplitudes are:

ampls = [0.1, 0.2, 0.4, 1, 2, 4]; % Excitation voltage amplitudes

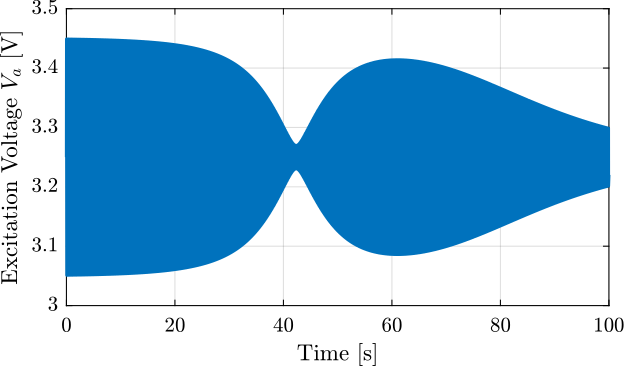

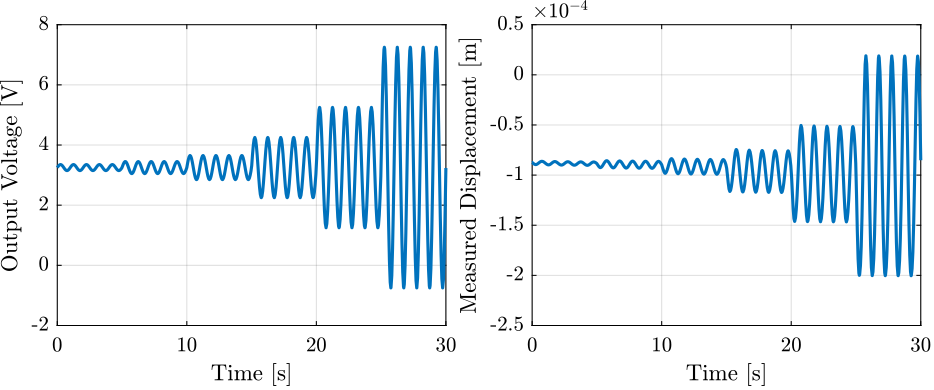

The excitation voltage and the measured displacement are shown in Figure 39.

Figure 39: Excitation voltage and measured displacement

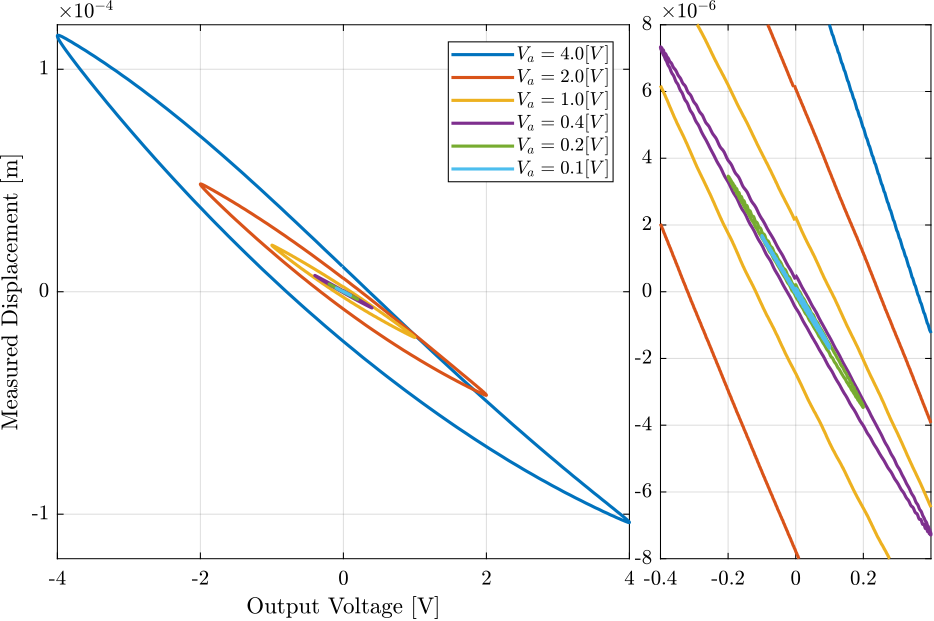

For each amplitude, we only take the last sinus in order to reduce possible transients. Also, it is centered on zero.

The measured displacement at a function of the output voltage are shown in Figure 40.

Figure 40: Obtained hysteresis for multiple excitation amplitudes

It is quite clear that hysteresis is increasing with the excitation amplitude.

Also, no hysteresis is found on the sensor stack voltage.

3.2.6 Estimation of the APA axial stiffness

In order to estimate the stiffness of the APA, a weight with known mass \(m_a\) is added on top of the suspended granite and the deflection \(d_e\) is measured using the encoder. The APA stiffness is then:

\begin{equation} k_{\text{apa}} = \frac{m_a g}{d} \end{equation}Here, a mass of 6.4 kg is used:

added_mass = 6.4; % Added mass [kg]

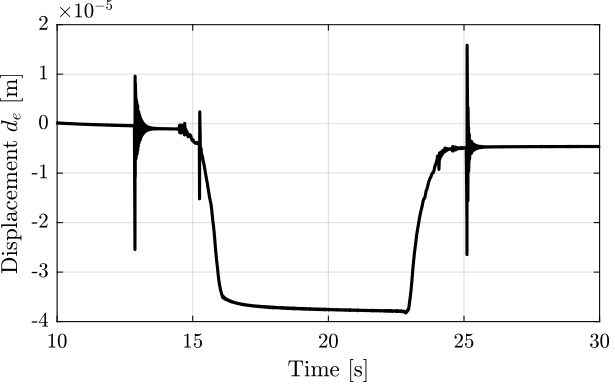

The data is loaded, and the measured displacement is shown in Figure 41.

apa_mass = load(sprintf('frf_data_%i_add_mass_closed_circuit.mat', 1), 't', 'de'); apa_mass.de = apa_mass.de - mean(apa_mass.de(apa_mass.t<11));

Figure 41: Measured displacement when adding the mass and removing the mass

There is some imprecision in the measurement as there are some drifts that are probably due to some creep.

The stiffness is then computed as follows:

k = 9.8 * added_mass / (mean(apa_mass.de(apa_mass.t > 12 & apa_mass.t < 12.5)) - mean(apa_mass.de(apa_mass.t > 20 & apa_mass.t < 20.5)));

And the stiffness obtained is very close to the one specified in the documentation (\(k = 1.794\,[N/\mu m]\)).

k = 1.68 [N/um]

3.2.7 Stiffness change due to electrical connections

We wish here to see if the stiffness changes when the actuator stacks are not connected to the amplifier and the sensor stacks are not connected to the ADC.

Note here that the resistor in parallel to the sensor stack is present in both cases.

First, the data are loaded.

add_mass_oc = load(sprintf('frf_data_%i_add_mass_open_circuit.mat', 1), 't', 'de'); add_mass_cc = load(sprintf('frf_data_%i_add_mass_closed_circuit.mat', 1), 't', 'de');

And the initial displacement is set to zero.

add_mass_oc.de = add_mass_oc.de - mean(add_mass_oc.de(add_mass_oc.t<11)); add_mass_cc.de = add_mass_cc.de - mean(add_mass_cc.de(add_mass_cc.t<11));

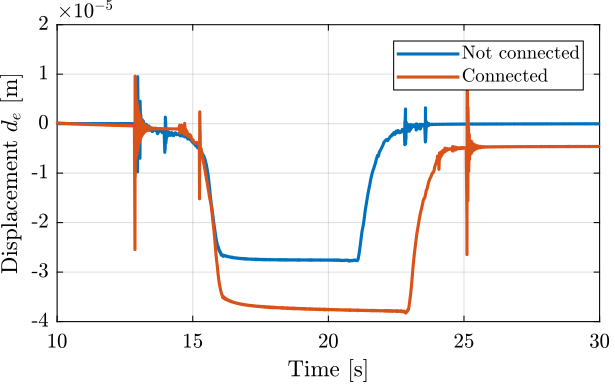

The measured displacements are shown in Figure 42.

Figure 42: Measured displacement

And the stiffness is estimated in both case. The results are shown in Table 6.

apa_k_oc = 9.8 * added_mass / (mean(add_mass_oc.de(add_mass_oc.t > 12 & add_mass_oc.t < 12.5)) - mean(add_mass_oc.de(add_mass_oc.t > 20 & add_mass_oc.t < 20.5))); apa_k_cc = 9.8 * added_mass / (mean(add_mass_cc.de(add_mass_cc.t > 12 & add_mass_cc.t < 12.5)) - mean(add_mass_cc.de(add_mass_cc.t > 20 & add_mass_cc.t < 20.5)));

| \(k [N/\mu m]\) | |

|---|---|

| Not connected | 2.3 |

| Connected | 1.7 |

Clearly, connecting the actuator stacks to the amplified (basically equivalent as to short circuiting them) lowers the stiffness.

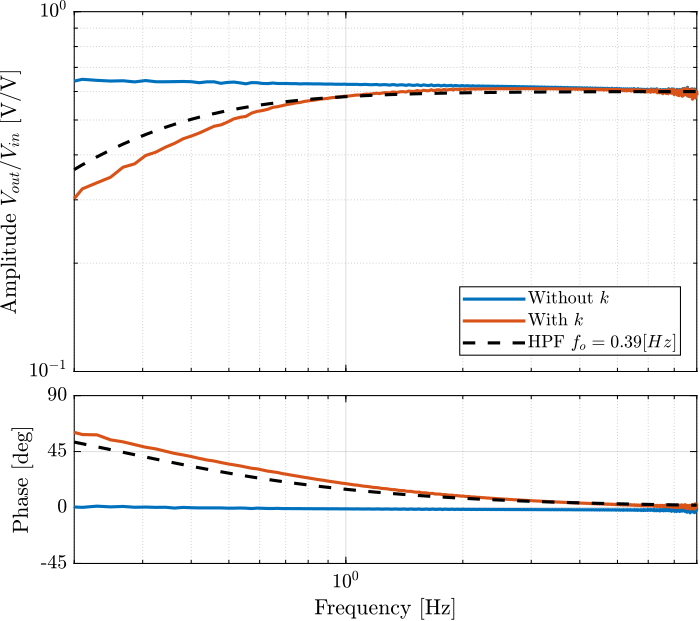

3.2.8 Effect of the resistor on the IFF Plant

A resistor \(R \approx 80.6\,k\Omega\) is added in parallel with the sensor stack. This has the effect to form a high pass filter with the capacitance of the stack.

We here measured the low frequency transfer function from \(V_a\) to \(V_s\) with and without this resistor.

% With the resistor wi_k = load('frf_data_1_sweep_lf_with_R.mat', 't', 'Vs', 'Va'); % Without the resistor wo_k = load('frf_data_1_sweep_lf.mat', 't', 'Vs', 'Va');

We use a very long “Hanning” window for the spectral analysis in order to estimate the low frequency behavior.

win = hanning(ceil(50*Fs)); % Hannning Windows

And we estimate the transfer function from \(V_a\) to \(V_s\) in both cases:

[frf_wo_k, f] = tfestimate(wo_k.Va, wo_k.Vs, win, [], [], 1/Ts); [frf_wi_k, ~] = tfestimate(wi_k.Va, wi_k.Vs, win, [], [], 1/Ts);

With the following values of the resistor and capacitance, we obtain a first order high pass filter with a crossover frequency equal to:

C = 5.1e-6; % Sensor Stack capacitance [F] R = 80.6e3; % Parallel Resistor [Ohm] f0 = 1/(2*pi*R*C); % Crossover frequency of RC HPF [Hz]

f0 = 0.39 [Hz]

The transfer function of the corresponding high pass filter is:

G_hpf = 0.6*(s/2*pi*f0)/(1 + s/2*pi*f0);

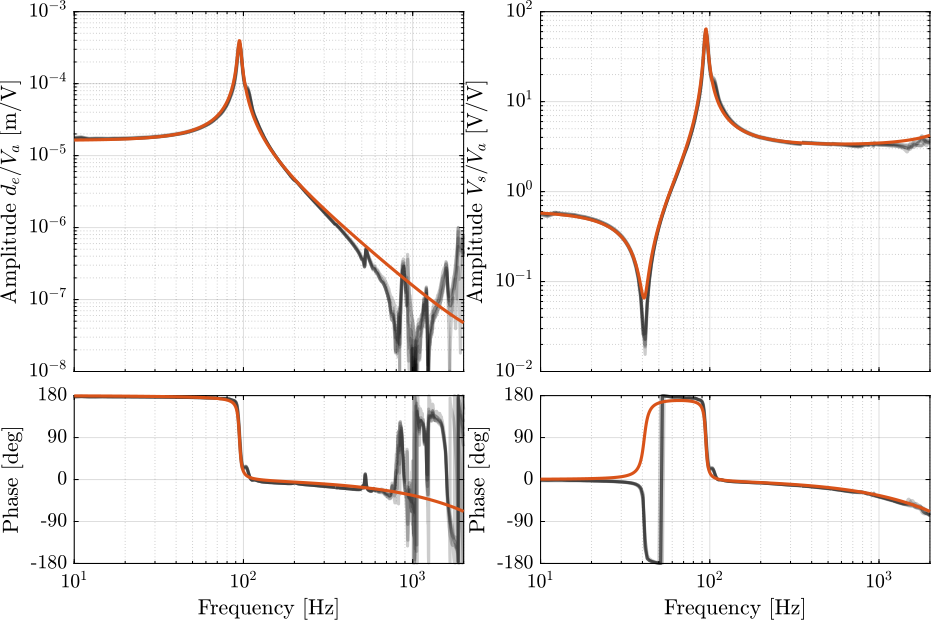

Let’s compare the transfer function from actuator stack to sensor stack with and without the added resistor in Figure 43.

Figure 43: Transfer function from \(V_a\) to \(V_s\) with and without the resistor \(k\)

The added resistor has indeed the expected effect.

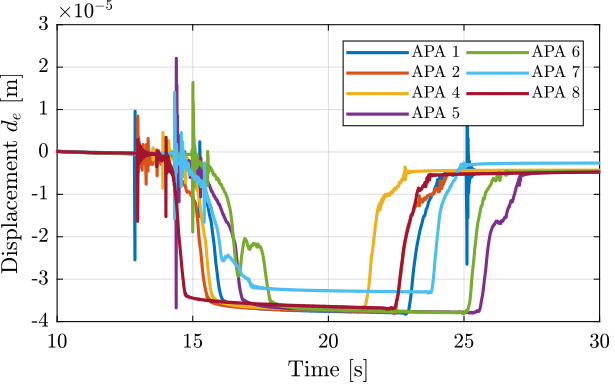

3.3 Comparison of all the APA

The same measurements that was performed in Section 3.2 are now performed on all the APA and then compared.

3.3.1 Axial Stiffnesses - Comparison

Let’s first compare the APA axial stiffnesses.

The added mass is:

added_mass = 6.4; % Added mass [kg]

Here are the number of the APA that have been measured:

apa_nums = [1 2 4 5 6 7 8];

The data are loaded.

apa_mass = {};

for i = 1:length(apa_nums)

apa_mass(i) = {load(sprintf('frf_data_%i_add_mass_closed_circuit.mat', apa_nums(i)), 't', 'de')};

% The initial displacement is set to zero

apa_mass{i}.de = apa_mass{i}.de - mean(apa_mass{i}.de(apa_mass{i}.t<11));

end

The raw measurements are shown in Figure 44. All the APA seems to have similar stiffness except the APA 7 which should have an higher stiffness.

It is however strange that the displacement \(d_e\) when the mass is removed is higher for the APA 7 than for the other APA. What could cause that?

Figure 44: Raw measurements for all the APA. A mass of 6.4kg is added at arround 15s and removed at arround 22s

The stiffnesses are computed for all the APA and are summarized in Table 7.

| APA Num | \(k [N/\mu m]\) |

|---|---|

| 1 | 1.68 |

| 2 | 1.69 |

| 4 | 1.7 |

| 5 | 1.7 |

| 6 | 1.7 |

| 7 | 1.93 |

| 8 | 1.73 |

The APA300ML manual specifies the nominal stiffness to be \(1.8\,[N/\mu m]\) which is very close to what have been measured. Only the APA number 7 is a little bit off.

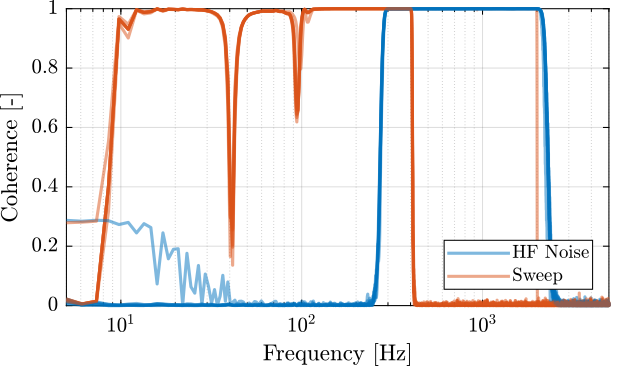

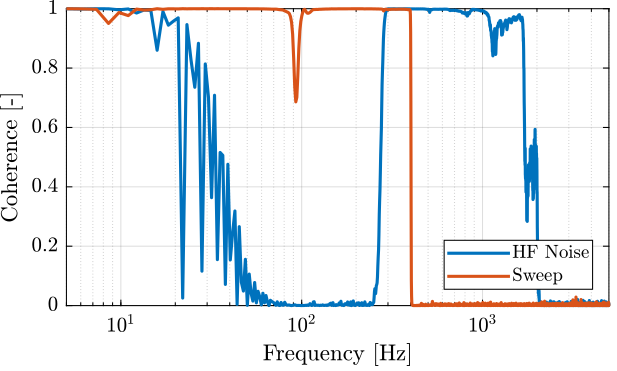

3.3.2 FRF Identification - Setup

The identification is performed in three steps:

- White noise excitation with small amplitude. This is used to determine the main resonance of the system.

- Sweep sine excitation with the amplitude lowered around the resonance. The sweep sine is from 10Hz to 400Hz.

- High frequency noise. The noise is band-passed between 300Hz and 2kHz.

Then, the result of the second identification is used between 10Hz and 350Hz and the result of the third identification if used between 350Hz and 2kHz.

Here are the APA numbers that have been measured.

apa_nums = [1 2 4 5 6 7 8];

The data are loaded for both the second and third identification:

%% Second identification apa_sweep = {}; for i = 1:length(apa_nums) apa_sweep(i) = {load(sprintf('frf_data_%i_sweep.mat', apa_nums(i)), 't', 'Va', 'Vs', 'de', 'da')}; end %% Third identification apa_noise_hf = {}; for i = 1:length(apa_nums) apa_noise_hf(i) = {load(sprintf('frf_data_%i_noise_hf.mat', apa_nums(i)), 't', 'Va', 'Vs', 'de', 'da')}; end

The time is the same for all measurements.

%% Time vector t = apa_sweep{1}.t - apa_sweep{1}.t(1) ; % Time vector [s] %% Sampling Ts = (t(end) - t(1))/(length(t)-1); % Sampling Time [s] Fs = 1/Ts; % Sampling Frequency [Hz]

Then we defined a “Hanning” windows that will be used for the spectral analysis:

win = hanning(ceil(0.5*Fs)); % Hannning Windows

We get the frequency vector that will be the same for all the frequency domain analysis.

% Only used to have the frequency vector "f" [~, f] = tfestimate(apa_sweep{1}.Va, apa_sweep{1}.de, win, [], [], 1/Ts);

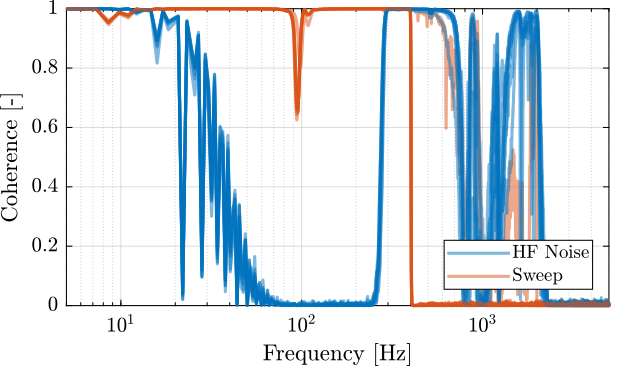

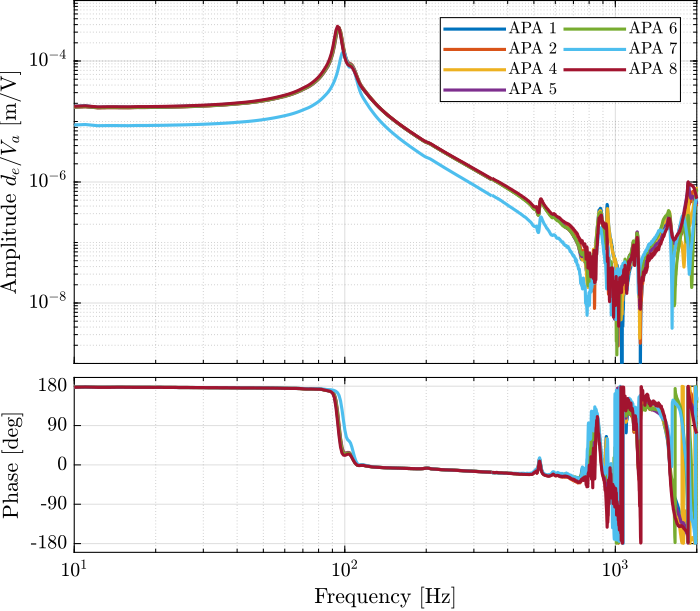

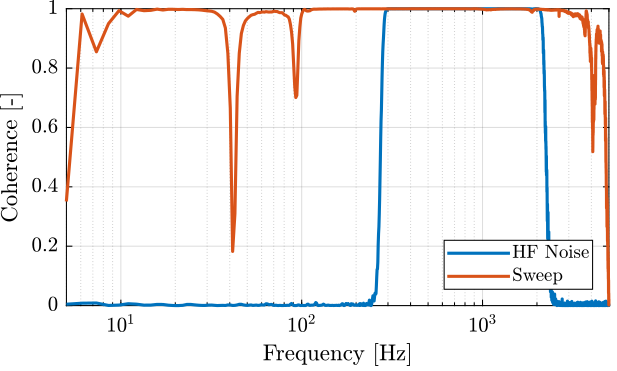

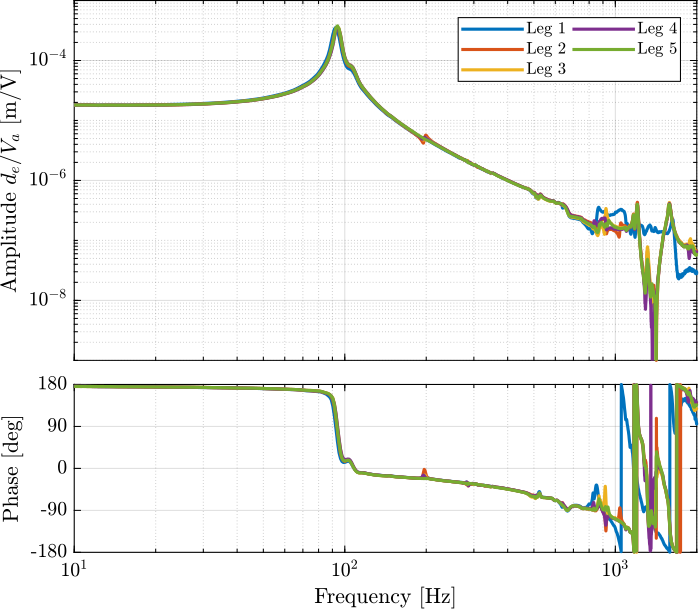

3.3.3 FRF Identification - DVF

In this section, the dynamics from excitation voltage \(V_a\) to encoder measured displacement \(d_e\) is identified.

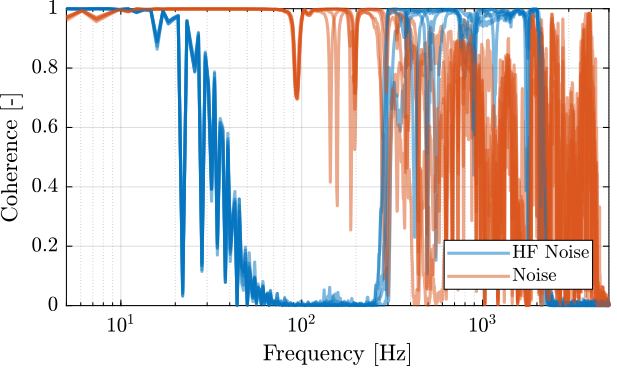

We compute the coherence for 2nd and 3rd identification:

%% Coherence computation coh_sweep = zeros(length(f), length(apa_nums)); for i = 1:length(apa_nums) [coh, ~] = mscohere(apa_sweep{i}.Va, apa_sweep{i}.de, win, [], [], 1/Ts); coh_sweep(:, i) = coh; end coh_noise_hf = zeros(length(f), length(apa_nums)); for i = 1:length(apa_nums) [coh, ~] = mscohere(apa_noise_hf{i}.Va, apa_noise_hf{i}.de, win, [], [], 1/Ts); coh_noise_hf(:, i) = coh; end

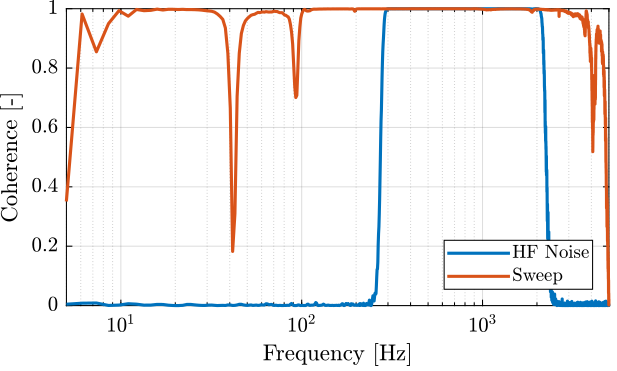

The coherence is shown in Figure 45. It is clear that the Sweep sine gives good coherence up to 400Hz and that the high frequency noise excitation signal helps increasing a little bit the coherence at high frequency.

Figure 45: Obtained coherence for the plant from \(V_a\) to \(d_e\)

Then, the transfer function from the DAC output voltage \(V_a\) to the measured displacement by the encoders is computed:

%% Transfer function estimation dvf_sweep = zeros(length(f), length(apa_nums)); for i = 1:length(apa_nums) [frf, ~] = tfestimate(apa_sweep{i}.Va, apa_sweep{i}.de, win, [], [], 1/Ts); dvf_sweep(:, i) = frf; end dvf_noise_hf = zeros(length(f), length(apa_nums)); for i = 1:length(apa_nums) [frf, ~] = tfestimate(apa_noise_hf{i}.Va, apa_noise_hf{i}.de, win, [], [], 1/Ts); dvf_noise_hf(:, i) = frf; end

The obtained transfer functions are shown in Figure 46. They are all superimposed except for the APA7.

Why is the APA7 off? We could think that the APA7 is stiffer, but also the mass line is off.

It seems that there is a “gain” problem. The encoder seems fine (it measured the same as the Interferometer). Maybe it could be due to the amplifier?

Figure 46: Estimated FRF for the DVF plant (transfer function from \(V_a\) to the encoder \(d_e\))

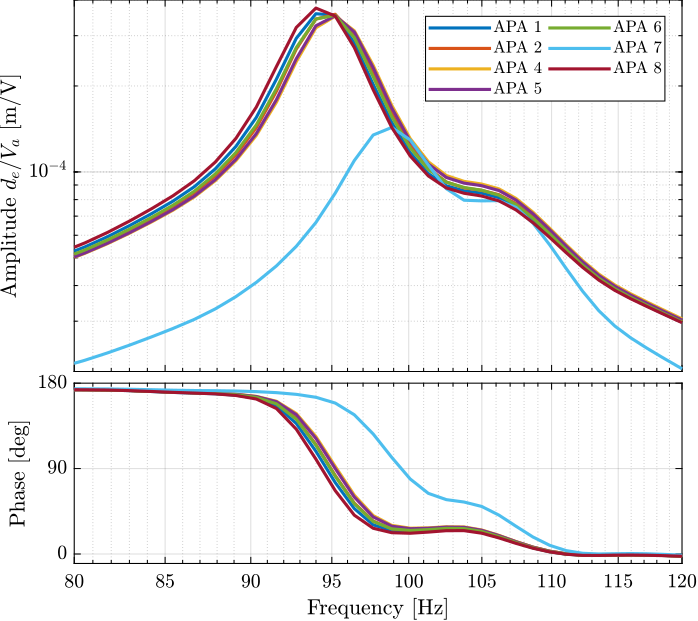

A zoom on the main resonance is shown in Figure 47. It is clear that expect for the APA 7, the response around the resonances are well matching for all the APA.

It is also clear that there is not a single resonance but two resonances, a first one at 95Hz and a second one at 105Hz.

Why is there a double resonance at around 94Hz?

Figure 47: Estimated FRF for the DVF plant (transfer function from \(V_a\) to the encoder \(d_e\)) - Zoom on the main resonance

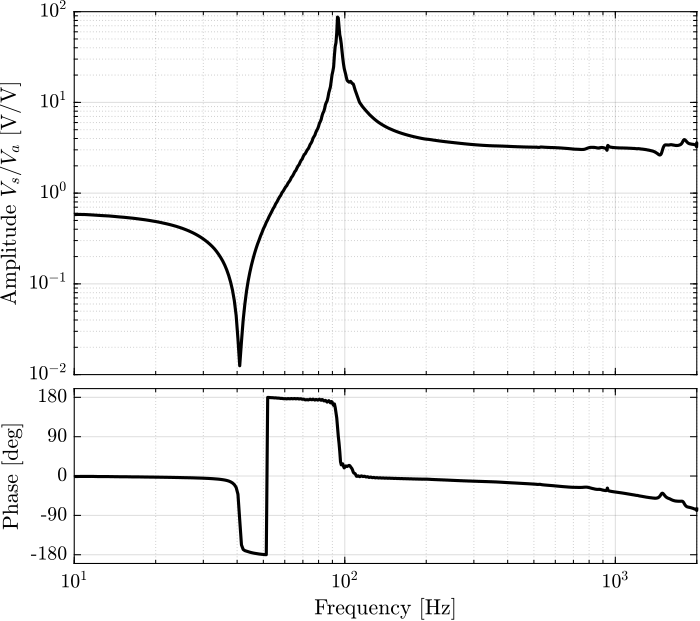

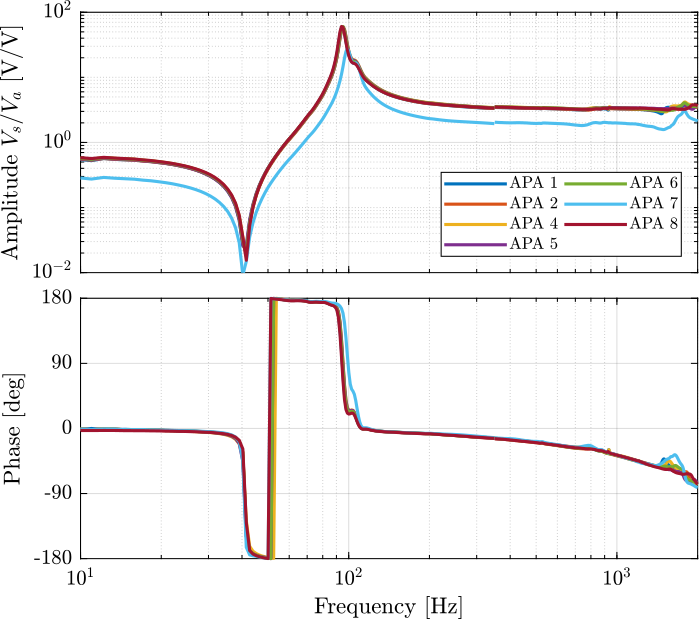

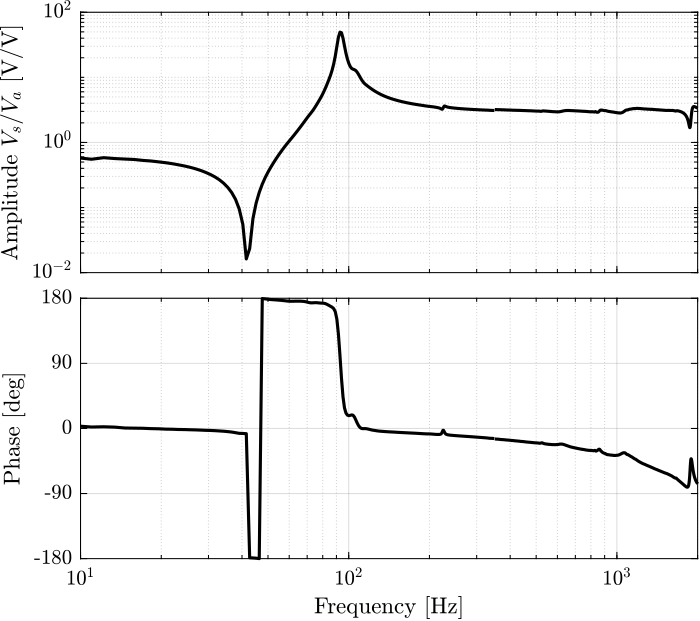

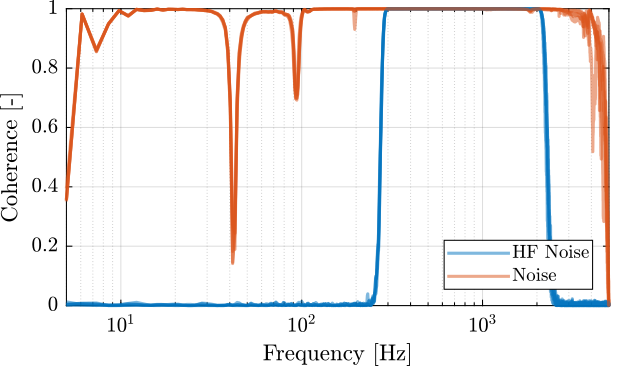

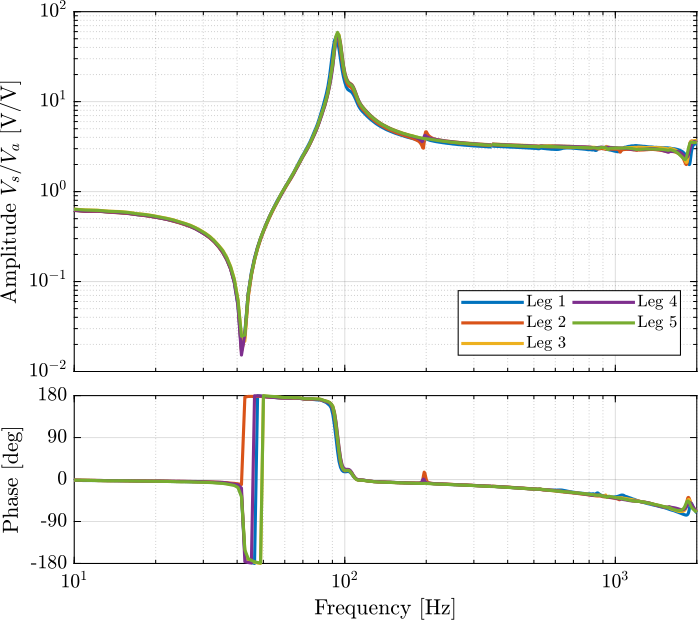

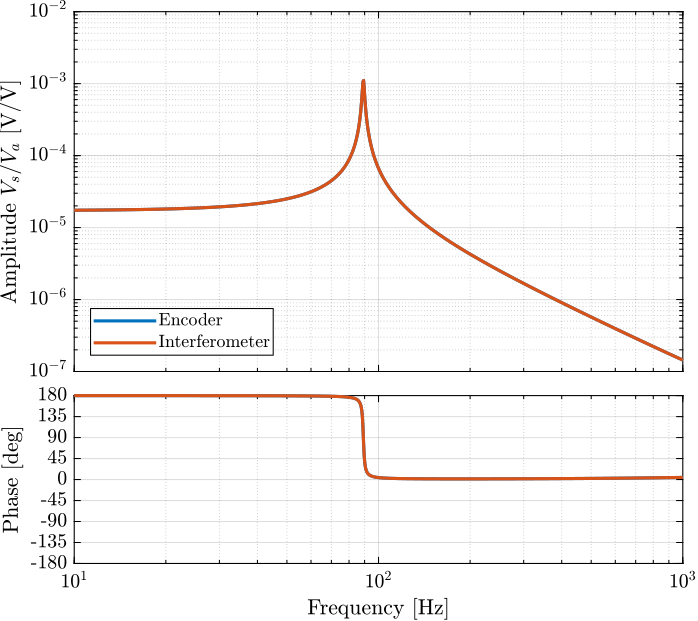

3.3.4 FRF Identification - IFF

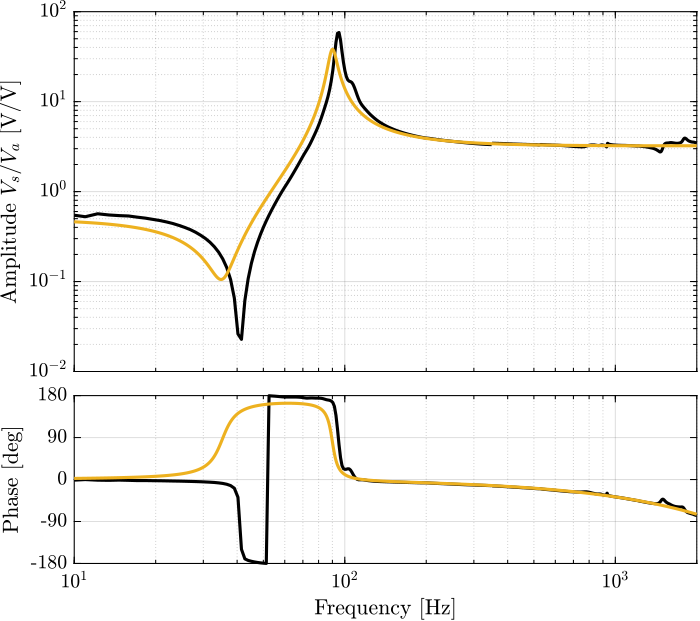

In this section, the dynamics from \(V_a\) to \(V_s\) is identified.

First the coherence is computed and shown in Figure 48. The coherence is very nice from 10Hz to 2kHz. It is only dropping near a zeros at 40Hz, and near the resonance at 95Hz (the excitation amplitude being lowered).

%% Coherence coh_sweep = zeros(length(f), length(apa_nums)); for i = 1:length(apa_nums) [coh, ~] = mscohere(apa_sweep{i}.Va, apa_sweep{i}.Vs, win, [], [], 1/Ts); coh_sweep(:, i) = coh; end coh_noise_hf = zeros(length(f), length(apa_nums)); for i = 1:length(apa_nums) [coh, ~] = mscohere(apa_noise_hf{i}.Va, apa_noise_hf{i}.Vs, win, [], [], 1/Ts); coh_noise_hf(:, i) = coh; end

Figure 48: Obtained coherence for the IFF plant

Then the FRF are estimated and shown in Figure 49

%% FRF estimation of the transfer function from Va to Vs iff_sweep = zeros(length(f), length(apa_nums)); for i = 1:length(apa_nums) [frf, ~] = tfestimate(apa_sweep{i}.Va, apa_sweep{i}.Vs, win, [], [], 1/Ts); iff_sweep(:, i) = frf; end iff_noise_hf = zeros(length(f), length(apa_nums)); for i = 1:length(apa_nums) [frf, ~] = tfestimate(apa_noise_hf{i}.Va, apa_noise_hf{i}.Vs, win, [], [], 1/Ts); iff_noise_hf(:, i) = frf; end

Figure 49: Identified IFF Plant

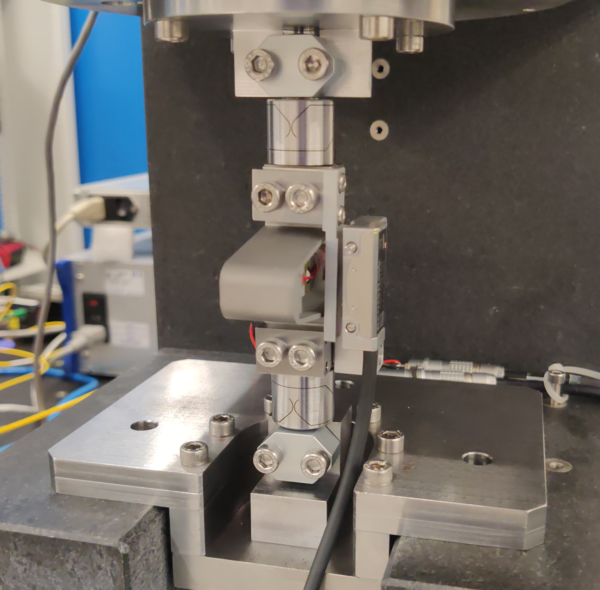

4 Dynamical measurements - Struts

The same bench used in Section 3 is here used with the strut instead of only the APA.

The bench is shown in Figure 50. Measurements are performed either when no encoder is fixed to the strut (Figure 51) or when one encoder is fixed to the strut (Figure 50).

Figure 50: Test Bench with Strut - Overview

Figure 51: Test Bench with Strut - Zoom on the strut

Figure 52: Test Bench with Strut - Zoom on the strut with the encoder

4.1 Measurement on Strut 1

4.1.1 Without Encoder

4.1.1.1 FRF Identification - Setup

The identification is performed in three steps:

- White noise excitation with small amplitude. This is used to determine the main resonance of the system.

- Sweep sine excitation with the amplitude lowered around the resonance. The sweep sine is from 10Hz to 400Hz.

- High frequency noise. The noise is band-passed between 300Hz and 2kHz.

Then, the result of the second identification is used between 10Hz and 350Hz and the result of the third identification if used between 350Hz and 2kHz.

leg_sweep = load(sprintf('frf_data_leg_%i_sweep.mat', 1), 't', 'Va', 'Vs', 'de', 'da'); leg_noise_hf = load(sprintf('frf_data_leg_%i_noise_hf.mat', 1), 't', 'Va', 'Vs', 'de', 'da');

The time is the same for all measurements.

%% Time vector t = leg_sweep.t - leg_sweep.t(1) ; % Time vector [s] %% Sampling Ts = (t(end) - t(1))/(length(t)-1); % Sampling Time [s] Fs = 1/Ts; % Sampling Frequency [Hz]

Then we defined a “Hanning” windows that will be used for the spectral analysis:

win = hanning(ceil(0.5*Fs)); % Hannning Windows

We get the frequency vector that will be the same for all the frequency domain analysis.

% Only used to have the frequency vector "f" [~, f] = tfestimate(leg_sweep.Va, leg_sweep.de, win, [], [], 1/Ts);

4.1.1.2 FRF Identification - Displacement

In this section, the dynamics from the excitation voltage \(V_a\) to the interferometer \(d_a\) is identified.

We compute the coherence for 2nd and 3rd identification:

[coh_sweep, ~] = mscohere(leg_sweep.Va, leg_sweep.da, win, [], [], 1/Ts); [coh_noise_hf, ~] = mscohere(leg_noise_hf.Va, leg_noise_hf.da, win, [], [], 1/Ts);

Figure 53: Obtained coherence for the plant from \(V_a\) to \(d_a\)

The transfer function from \(V_a\) to the interferometer measured displacement \(d_a\) is estimated and shown in Figure 54.

[dvf_sweep, ~] = tfestimate(leg_sweep.Va, leg_sweep.da, win, [], [], 1/Ts); [dvf_noise_hf, ~] = tfestimate(leg_noise_hf.Va, leg_noise_hf.da, win, [], [], 1/Ts);

Figure 54: Estimated FRF for the DVF plant (transfer function from \(V_a\) to the interferometer \(d_a\))

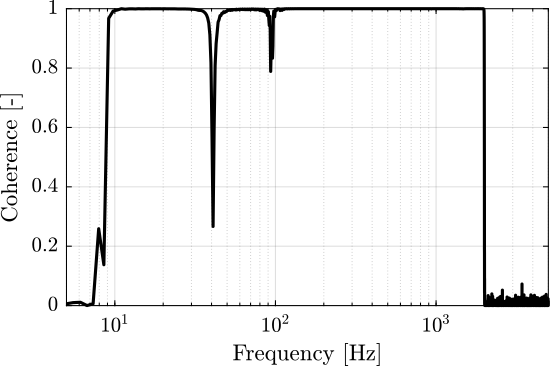

4.1.1.3 FRF Identification - IFF

In this section, the dynamics from \(V_a\) to \(V_s\) is identified.

First the coherence is computed and shown in Figure 55. The coherence is very nice from 10Hz to 2kHz. It is only dropping near a zeros at 40Hz, and near the resonance at 95Hz (the excitation amplitude being lowered).

[coh_sweep, ~] = mscohere(leg_sweep.Va, leg_sweep.Vs, win, [], [], 1/Ts); [coh_noise_hf, ~] = mscohere(leg_noise_hf.Va, leg_noise_hf.Vs, win, [], [], 1/Ts);

Figure 55: Obtained coherence for the IFF plant

Then the FRF are estimated and shown in Figure 56

[iff_sweep, ~] = tfestimate(leg_sweep.Va, leg_sweep.Vs, win, [], [], 1/Ts); [iff_noise_hf, ~] = tfestimate(leg_noise_hf.Va, leg_noise_hf.Vs, win, [], [], 1/Ts);

Figure 56: Identified IFF Plant for the Strut 1

4.1.2 With Encoder

4.1.2.1 Measurement Data

leg_enc_sweep = load(sprintf('frf_data_leg_coder_badly_align_%i_noise.mat', 1), 't', 'Va', 'Vs', 'de', 'da'); leg_enc_noise_hf = load(sprintf('frf_data_leg_coder_badly_align_%i_noise_hf.mat', 1), 't', 'Va', 'Vs', 'de', 'da');

4.1.2.2 FRF Identification - DVF

In this section, the dynamics from \(V_a\) to \(d_e\) is identified.

We compute the coherence for 2nd and 3rd identification:

[coh_enc_sweep, ~] = mscohere(leg_enc_sweep.Va, leg_enc_sweep.de, win, [], [], 1/Ts); [coh_enc_noise_hf, ~] = mscohere(leg_enc_noise_hf.Va, leg_enc_noise_hf.de, win, [], [], 1/Ts);

Figure 57: Obtained coherence for the plant from \(V_a\) to \(d_e\)

[dvf_enc_sweep, ~] = tfestimate(leg_enc_sweep.Va, leg_enc_sweep.de, win, [], [], 1/Ts); [dvf_enc_noise_hf, ~] = tfestimate(leg_enc_noise_hf.Va, leg_enc_noise_hf.de, win, [], [], 1/Ts);

[dvf_int_sweep, ~] = tfestimate(leg_enc_sweep.Va, leg_enc_sweep.da, win, [], [], 1/Ts); [dvf_int_noise_hf, ~] = tfestimate(leg_enc_noise_hf.Va, leg_enc_noise_hf.da, win, [], [], 1/Ts);

The obtained transfer functions are shown in Figure 58.

They are all superimposed except for the APA7.

Why is the APA7 off? We could think that the APA7 is stiffer, but also the mass line is off.

It seems that there is a “gain” problem. The encoder seems fine (it measured the same as the Interferometer). Maybe it could be due to the amplifier?

Why is there a double resonance at around 94Hz?

Figure 58: Estimated FRF for the DVF plant (transfer function from \(V_a\) to the encoder \(d_e\))

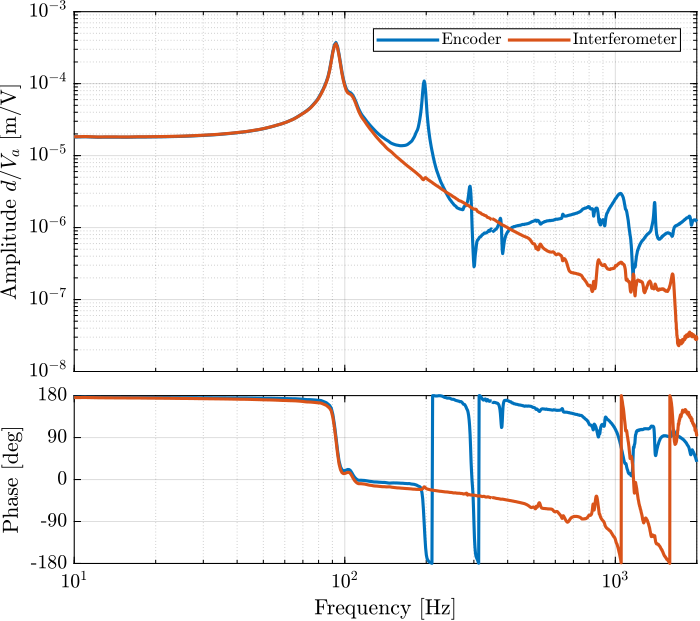

4.1.2.3 Comparison of the Encoder and Interferometer

The interferometer could here represent the case where the encoders are fixed to the plates and not the APA.

The dynamics from \(V_a\) to \(d_e\) and from \(V_a\) to \(d_a\) are compared in Figure 59.

Figure 59: Comparison of the transfer functions from excitation voltage \(V_a\) to either the encoder \(d_e\) or the interferometer \(d_a\)

It will clearly be difficult to do something (except some low frequency positioning) with the encoders fixed to the APA.

4.1.2.4 APA Resonances Frequency

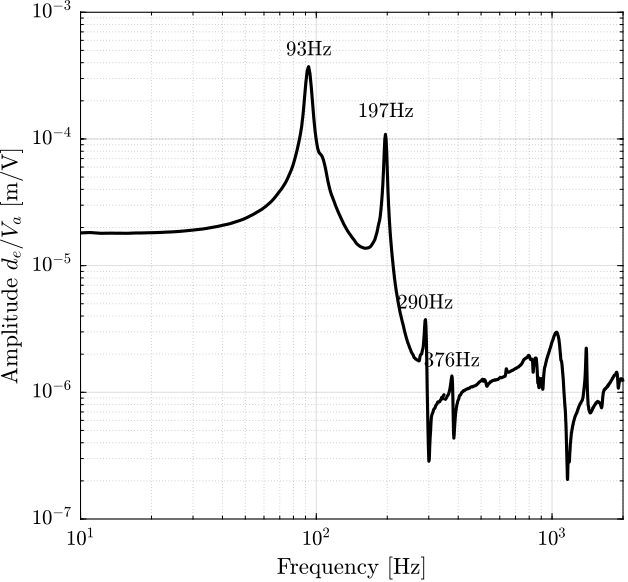

As shown in Figure 60, we can clearly see three spurious resonances at 197Hz, 290Hz and 376Hz.

Figure 60: Magnitude of the transfer function from excitation voltage \(V_a\) to encoder measurement \(d_e\). The frequency of the resonances are noted.

These resonances correspond to parasitic resonances of the APA itself. They are very close to what was estimated using the FEM:

- X-bending mode at around 190Hz (Figure 61)

- Y-bending mode at around 290Hz (Figure 62)

- Z-torsion mode at around 400Hz (Figure 63)

Figure 61: X-bending mode (189Hz)

Figure 62: Y-bending mode (285Hz)

Figure 63: Z-torsion mode (400Hz)

The resonances are indeed due to limited stiffness of the APA.

4.1.2.5 Estimated Flexible Joint axial stiffness

load(sprintf('frf_data_leg_coder_%i_add_mass_closed_circuit.mat', 1), 't', 'Va', 'Vs', 'de', 'da'); de = de - de(1); da = da - da(1);

figure; hold on; plot(t, de, 'DisplayName', 'Encoder') plot(t, da, 'DisplayName', 'Interferometer') hold off; xlabel('Time [s]'); ylabel('Displacement [m]'); legend('location', 'northeast');

de_steps = [mean(de(t > 13 & t < 14)); mean(de(t > 19 & t < 20)); mean(de(t > 24 & t < 25)); mean(de(t > 28.5 & t < 29.5)); mean(de(t > 49 & t < 50))] - mean(de(t > 13 & t < 14)); da_steps = [mean(da(t > 13 & t < 14)); mean(da(t > 19 & t < 20)); mean(da(t > 24 & t < 25)); mean(da(t > 28.5 & t < 29.5)); mean(da(t > 49 & t < 50))] - mean(da(t > 13 & t < 14));

added_mass = [0; 1; 2; 3; 4];

lin_fit = (added_mass\abs(de_steps-da_steps) - abs(de_steps(1)-da_steps(1)));

figure; hold on; plot(added_mass, abs(de_steps-da_steps) - abs(de_steps(1)-da_steps(1)), 'ok') plot(added_mass, added_mass*lin_fit, '-r') hold off;

What is strange is that the encoder is measuring a larger displacement than the interferometer. That should be the opposite. Maybe is is caused by the fact that the APA is experiencing some bending and therefore a larger motion is measured on the encoder.

4.1.2.6 FRF Identification - IFF

In this section, the dynamics from \(V_a\) to \(V_s\) is identified.

First the coherence is computed and shown in Figure 55. The coherence is very nice from 10Hz to 2kHz. It is only dropping near a zeros at 40Hz, and near the resonance at 95Hz (the excitation amplitude being lowered).

[coh_enc_sweep, ~] = mscohere(leg_enc_sweep.Va, leg_enc_sweep.Vs, win, [], [], 1/Ts); [coh_enc_noise_hf, ~] = mscohere(leg_enc_noise_hf.Va, leg_enc_noise_hf.Vs, win, [], [], 1/Ts);

Figure 64: Obtained coherence for the IFF plant

Then the FRF are estimated and shown in Figure 65

[iff_enc_sweep, ~] = tfestimate(leg_enc_sweep.Va, leg_enc_sweep.Vs, win, [], [], 1/Ts); [iff_enc_noise_hf, ~] = tfestimate(leg_enc_noise_hf.Va, leg_enc_noise_hf.Vs, win, [], [], 1/Ts);

Figure 65: Identified IFF Plant

Let’s now compare the IFF plants whether the encoders are fixed to the APA or not (Figure 66).

Figure 66: Effect of the encoder on the IFF plant

We can see that the IFF does not change whether of not the encoder are fixed to the struts.

4.2 Comparison of all the Struts

4.2.1 FRF Identification - Setup

The identification is performed in two steps:

- White noise excitation with small amplitude. This is used to estimate the low frequency dynamics.

- High frequency noise. The noise is band-passed between 300Hz and 2kHz.

Then, the result of the first identification is used between 10Hz and 350Hz and the result of the second identification if used between 350Hz and 2kHz.

Here are the LEG numbers that have been measured.

leg_nums = [1 2 3 4 5];

The data are loaded for both the first and second identification:

%% Second identification leg_noise = {}; for i = 1:length(leg_nums) leg_noise(i) = {load(sprintf('frf_data_leg_coder_%i_noise.mat', leg_nums(i)), 't', 'Va', 'Vs', 'de', 'da')}; end %% Third identification leg_noise_hf = {}; for i = 1:length(leg_nums) leg_noise_hf(i) = {load(sprintf('frf_data_leg_coder_%i_noise_hf.mat', leg_nums(i)), 't', 'Va', 'Vs', 'de', 'da')}; end

The time is the same for all measurements.

%% Time vector t = leg_noise{1}.t - leg_noise{1}.t(1) ; % Time vector [s] %% Sampling Ts = (t(end) - t(1))/(length(t)-1); % Sampling Time [s] Fs = 1/Ts; % Sampling Frequency [Hz]

Then we defined a “Hanning” windows that will be used for the spectral analysis:

win = hanning(ceil(0.5*Fs)); % Hannning Windows

We get the frequency vector that will be the same for all the frequency domain analysis.

% Only used to have the frequency vector "f" [~, f] = tfestimate(leg_noise{1}.Va, leg_noise{1}.de, win, [], [], 1/Ts);

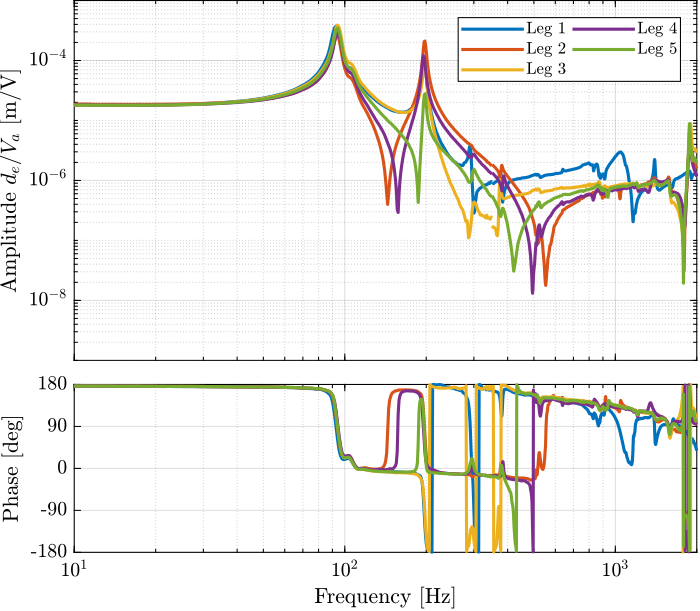

4.2.2 FRF Identification - DVF

In this section, the dynamics from \(V_a\) to \(d_e\) is identified.

We compute the coherence for 2nd and 3rd identification:

%% Coherence computation coh_noise = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [coh, ~] = mscohere(leg_noise{i}.Va, leg_noise{i}.de, win, [], [], 1/Ts); coh_noise(:, i) = coh; end coh_noise_hf = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [coh, ~] = mscohere(leg_noise_hf{i}.Va, leg_noise_hf{i}.de, win, [], [], 1/Ts); coh_noise_hf(:, i) = coh; end

The coherence is shown in Figure 67. It is clear that the Noise sine gives good coherence up to 400Hz and that the high frequency noise excitation signal helps increasing a little bit the coherence at high frequency.

Figure 67: Obtained coherence for the plant from \(V_a\) to \(d_e\)

Then, the transfer function from the DAC output voltage \(V_a\) to the measured displacement by the encoders is computed:

%% Transfer function estimation dvf_noise = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [frf, ~] = tfestimate(leg_noise{i}.Va, leg_noise{i}.de, win, [], [], 1/Ts); dvf_noise(:, i) = frf; end dvf_noise_hf = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [frf, ~] = tfestimate(leg_noise_hf{i}.Va, leg_noise_hf{i}.de, win, [], [], 1/Ts); dvf_noise_hf(:, i) = frf; end

The obtained transfer functions are shown in Figure 68.

They are all superimposed except for the LEG7.

Figure 68: Estimated FRF for the DVF plant (transfer function from \(V_a\) to the encoder \(d_e\))

Depending on how the APA are mounted with the flexible joints, the dynamics can change a lot as shown in Figure 68. In the future, a “pin” will be used to better align the APA with the flexible joints. We can expect the amplitude of the spurious resonances to decrease.

4.2.3 FRF Identification - DVF with interferometer

In this section, the dynamics from \(V_a\) to \(d_a\) is identified.

We compute the coherence.

%% Coherence computation coh_noise = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [coh, ~] = mscohere(leg_noise{i}.Va, leg_noise{i}.da, win, [], [], 1/Ts); coh_noise(:, i) = coh; end coh_noise_hf = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [coh, ~] = mscohere(leg_noise_hf{i}.Va, leg_noise_hf{i}.da, win, [], [], 1/Ts); coh_noise_hf(:, i) = coh; end

The coherence is shown in Figure 69. It is clear that the Noise sine gives good coherence up to 400Hz and that the high frequency noise excitation signal helps increasing a little bit the coherence at high frequency.

Figure 69: Obtained coherence for the plant from \(V_a\) to \(d_e\)

Then, the transfer function from the DAC output voltage \(V_a\) to the measured displacement by the Attocube is computed:

%% Transfer function estimation dvf_a_noise = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [frf, ~] = tfestimate(leg_noise{i}.Va, leg_noise{i}.da, win, [], [], 1/Ts); dvf_a_noise(:, i) = frf; end dvf_a_noise_hf = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [frf, ~] = tfestimate(leg_noise_hf{i}.Va, leg_noise_hf{i}.da, win, [], [], 1/Ts); dvf_a_noise_hf(:, i) = frf; end

The obtained transfer functions are shown in Figure 70.

They are all superimposed except for the LEG7.

Figure 70: Estimated FRF for the DVF plant (transfer function from \(V_a\) to the encoder \(d_e\))

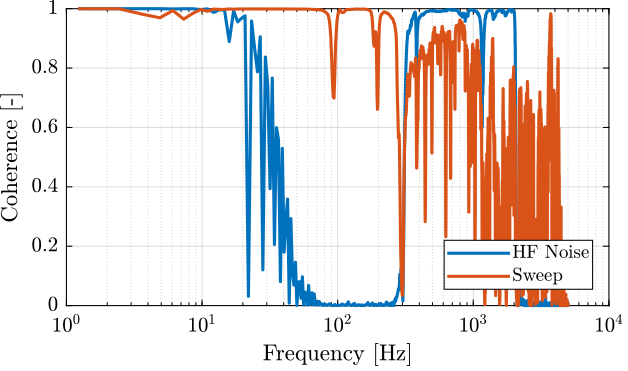

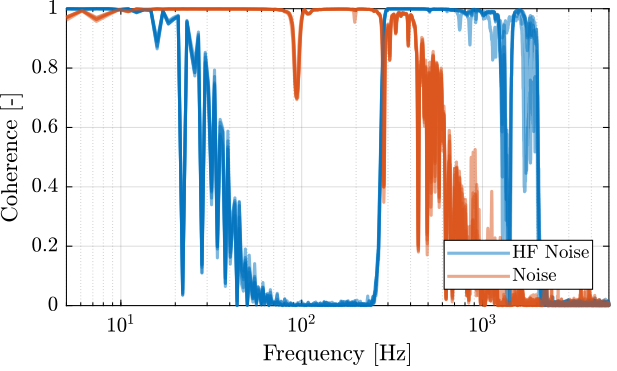

4.2.4 FRF Identification - IFF

In this section, the dynamics from \(V_a\) to \(V_s\) is identified.

First the coherence is computed and shown in Figure 71. The coherence is very nice from 10Hz to 2kHz. It is only dropping near a zeros at 40Hz, and near the resonance at 95Hz (the excitation amplitude being lowered).

%% Coherence coh_noise = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [coh, ~] = mscohere(leg_noise{i}.Va, leg_noise{i}.Vs, win, [], [], 1/Ts); coh_noise(:, i) = coh; end coh_noise_hf = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [coh, ~] = mscohere(leg_noise_hf{i}.Va, leg_noise_hf{i}.Vs, win, [], [], 1/Ts); coh_noise_hf(:, i) = coh; end

Figure 71: Obtained coherence for the IFF plant

Then the FRF are estimated and shown in Figure 72

%% FRF estimation of the transfer function from Va to Vs iff_noise = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [frf, ~] = tfestimate(leg_noise{i}.Va, leg_noise{i}.Vs, win, [], [], 1/Ts); iff_noise(:, i) = frf; end iff_noise_hf = zeros(length(f), length(leg_nums)); for i = 1:length(leg_nums) [frf, ~] = tfestimate(leg_noise_hf{i}.Va, leg_noise_hf{i}.Vs, win, [], [], 1/Ts); iff_noise_hf(:, i) = frf; end

Figure 72: Identified IFF Plant

5 Test Bench APA300ML - Simscape Model

5.1 Introduction

A simscape model (Figure 73) of the measurement bench is used.

Figure 73: Screenshot of the Simscape model

5.2 First Identification

The APA is first initialized with default parameters and the transfer function from excitation voltage \(V_a\) (before the amplification of 20 due to the PD200 amplifier) to the sensor stack voltage \(V_s\), encoder \(d_L\) and interferometer \(z\) is identified.

%% Initialize the structure containing the data used in the model n_hexapod = struct(); n_hexapod.actuator = initializeAPA('type', '2dof');

%% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/Va'], 1, 'openinput'); io_i = io_i + 1; % Actuator Voltage io(io_i) = linio([mdl, '/Vs'], 1, 'openoutput'); io_i = io_i + 1; % Sensor Voltage io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Relative Motion Outputs io(io_i) = linio([mdl, '/z'], 1, 'openoutput'); io_i = io_i + 1; % Vertical Motion %% Run the linearization Ga = linearize(mdl, io, 0.0, options); Ga.InputName = {'Va'}; Ga.OutputName = {'Vs', 'dL', 'z'};

The obtain dynamics are shown in Figure 74 and 75.

Figure 74: Bode plot of the transfer function from \(V_a\) to \(V_s\)

Figure 75: Bode plot of the transfer function from \(V_a\) to \(d_L\) and to \(z\)

5.3 Identify Sensor/Actuator constants and compare with measured FRF

5.3.1 How to identify these constants?

5.3.1.1 Piezoelectric Actuator Constant

Using the measurement test-bench, it is rather easy the determine the static gain between the applied voltage \(V_a\) to the induced displacement \(d\).

\begin{equation} d = g_{d/V_a} \cdot V_a \end{equation}Using the Simscape model of the APA, it is possible to determine the static gain between the actuator force \(F_a\) to the induced displacement \(d\):

\begin{equation} d = g_{d/F_a} \cdot F_a \end{equation}From the two gains, it is then easy to determine \(g_a\):

\begin{equation} g_a = \frac{F_a}{V_a} = \frac{F_a}{d} \cdot \frac{d}{V_a} = \frac{g_{d/V_a}}{g_{d/F_a}} \end{equation}5.3.1.2 Piezoelectric Sensor Constant

Similarly, it is easy to determine the gain from the excitation voltage \(V_a\) to the voltage generated by the sensor stack \(V_s\):

\begin{equation} V_s = g_{V_s/V_a} V_a \end{equation}Note here that there is an high pass filter formed by the piezo capacitor and parallel resistor.

The gain can be computed from the dynamical identification and taking the gain at the wanted frequency (above the first resonance).

Using the simscape model, compute the gain at the same frequency from the actuator force \(F_a\) to the strain of the sensor stack \(dl\):

\begin{equation} dl = g_{dl/F_a} F_a \end{equation}Then, the “sensor” constant is:

\begin{equation} g_s = \frac{V_s}{dl} = \frac{V_s}{V_a} \cdot \frac{V_a}{F_a} \cdot \frac{F_a}{dl} = \frac{g_{V_s/V_a}}{g_a \cdot g_{dl/F_a}} \end{equation}5.3.2 Identification Data

%% Load the identification Data leg_sweep = load(sprintf('frf_data_%i_sweep.mat', 1), 't', 'Va', 'Vs', 'de', 'da'); leg_noise_hf = load(sprintf('frf_data_%i_noise_hf.mat', 1), 't', 'Va', 'Vs', 'de', 'da');

The time is the same for all measurements.

%% Time vector t = leg_sweep.t - leg_sweep.t(1) ; % Time vector [s] %% Sampling Time / Frequency Ts = (t(end) - t(1))/(length(t)-1); % Sampling Time [s] Fs = 1/Ts; % Sampling Frequency [Hz]

Then we defined a “Hanning” windows that will be used for the spectral analysis:

%% Window used for spectral analysis win = hanning(ceil(0.5*Fs)); % Hannning Windows

We get the frequency vector that will be the same for all the frequency domain analysis.

%% Get the frequency vector "f" common to all further spectral data [~, f] = tfestimate(leg_sweep.Va, leg_sweep.de, win, [], [], 1/Ts);

%% Estimate the transfer function from u to dLm [dvf_sweep, ~] = tfestimate(leg_sweep.Va, leg_sweep.da, win, [], [], 1/Ts); [dvf_noise_hf, ~] = tfestimate(leg_noise_hf.Va, leg_noise_hf.da, win, [], [], 1/Ts);

%% Estimate the transfer function from u to taum [iff_sweep, ~] = tfestimate(leg_sweep.Va, leg_sweep.Vs, win, [], [], 1/Ts); [iff_noise_hf, ~] = tfestimate(leg_noise_hf.Va, leg_noise_hf.Vs, win, [], [], 1/Ts);

5.3.3 2DoF APA

5.3.3.1 2DoF APA

%% Initialize a 2DoF APA with Ga=Gs=1 n_hexapod.actuator = initializeAPA('type', '2dof', 'ga', 1, 'gs', 1);

5.3.3.2 Identification without actuator or sensor constants

%% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/Va'], 1, 'openinput'); io_i = io_i + 1; % Actuator Voltage io(io_i) = linio([mdl, '/Vs'], 1, 'openoutput'); io_i = io_i + 1; % Sensor Voltage io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Relative Motion Outputs io(io_i) = linio([mdl, '/z'], 1, 'openoutput'); io_i = io_i + 1; % Vertical Motion %% Identification Gs = linearize(mdl, io, 0.0, options); Gs.InputName = {'Va'}; Gs.OutputName = {'Vs', 'dL', 'z'};

5.3.3.3 Actuator Constant

%% Estimated Actuator Constant ga = -mean(abs(dvf_sweep(f>10 & f<20)))./dcgain(Gs('dL', 'Va')); % [N/V]

ga = -32.1 [N/V]

n_hexapod.actuator.Ga = ones(6,1)*ga; % Actuator gain [N/V]

5.3.3.4 Sensor Constant

%% Estimated Sensor Constant gs = -mean(abs(iff_sweep(f>400 & f<500)))./(ga*abs(squeeze(freqresp(Gs('Vs', 'Va'), 1e3, 'Hz')))); % [V/m]

gs = 0.085 [V/m]

n_hexapod.actuator.Gs = ones(6,1)*gs; % Sensor gain [V/m]

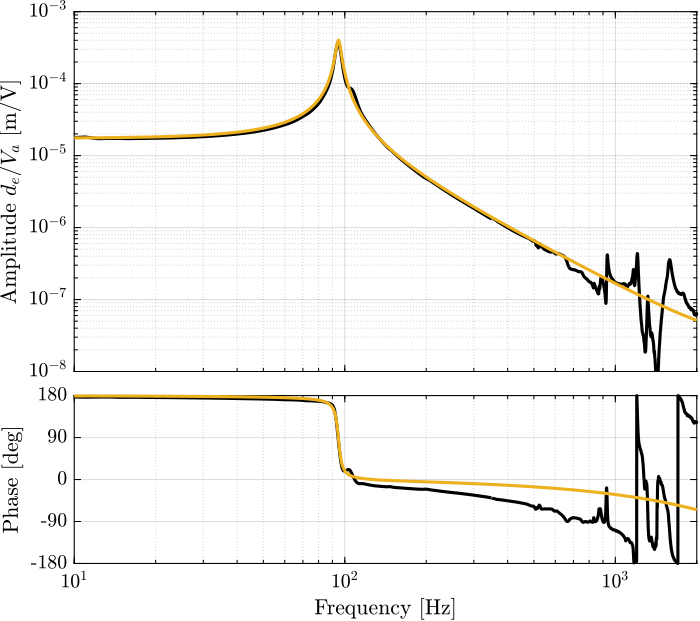

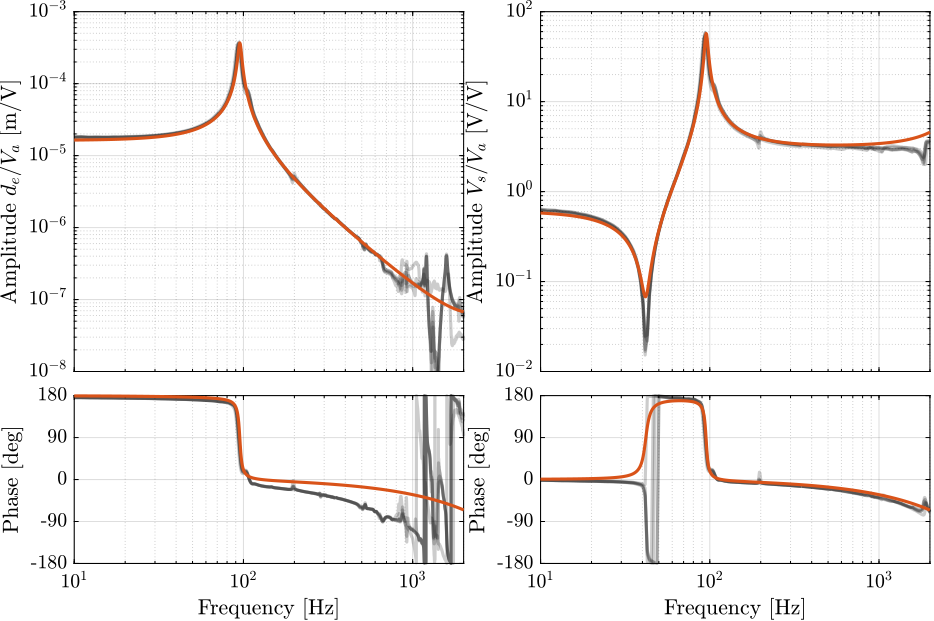

5.3.3.5 Comparison

Identify the dynamics with included constants.

%% Identify again the dynamics with correct Ga,Gs Gs = linearize(mdl, io, 0.0, options); Gs = Gs*exp(-Ts*s); Gs.InputName = {'Va'}; Gs.OutputName = {'Vs', 'dL', 'z'};

Figure 76: Comparison of the experimental data and Simscape model (\(u\) to \(d\mathcal{L}_m\))

Figure 77: Comparison of the experimental data and Simscape model (\(V_a\) to \(V_s\))

5.3.4 Flexible APA

5.3.4.1 Flexible APA

%% Initialize the APA as a flexible body n_hexapod.actuator = initializeAPA('type', 'flexible', 'ga', 1, 'gs', 1);

5.3.4.2 Identification without actuator or sensor constants

%% Identify the dynamics Gs = linearize(mdl, io, 0.0, options); Gs.InputName = {'Va'}; Gs.OutputName = {'Vs', 'dL', 'z'};

5.3.4.3 Actuator Constant

%% Actuator Constant ga = -mean(abs(dvf_sweep(f>10 & f<20)))./dcgain(Gs('dL', 'Va')); % [N/V]

ga = 23.4 [N/V]

n_hexapod.actuator.Ga = ones(6,1)*ga; % Actuator gain [N/V]

5.3.4.4 Sensor Constant

%% Sensor Constant gs = -mean(abs(iff_sweep(f>400 & f<500)))./(ga*abs(squeeze(freqresp(Gs('Vs', 'Va'), 1e3, 'Hz')))); % [V/m]

gs = -4674826.805 [V/m]

n_hexapod.actuator.Gs = ones(6,1)*gs; % Sensor gain [V/m]

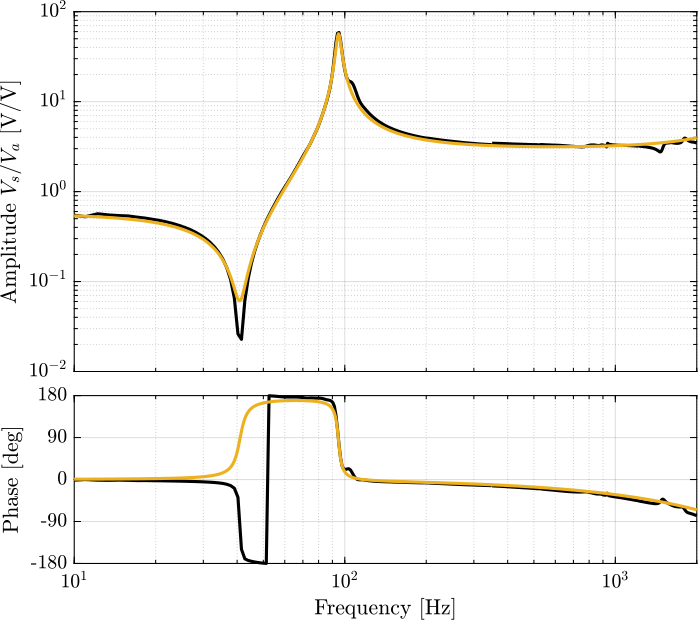

5.3.4.5 Comparison

%% Identify with updated constants Gs = linearize(mdl, io, 0.0, options); Gs = Gs*exp(-Ts*s); Gs.InputName = {'Va'}; Gs.OutputName = {'Vs', 'dL', 'z'};

Figure 78: Comparison of the experimental data and Simscape model (\(u\) to \(d\mathcal{L}_m\))

Figure 79: Comparison of the experimental data and Simscape model (\(u\) to \(\tau_m\))

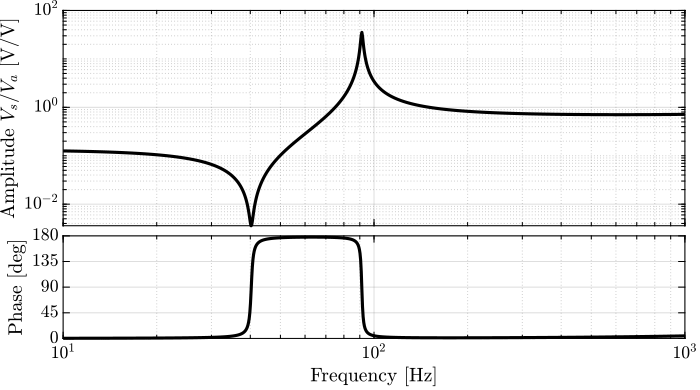

5.4 Optimize 2-DoF model to fit the experimental Data

%% Optimized parameters n_hexapod.actuator = initializeAPA('type', '2dof', ... 'Ga', -30.0, ... 'Gs', 0.098, ... 'k', ones(6,1)*0.38e6, ... 'ke', ones(6,1)*1.75e6, ... 'ka', ones(6,1)*3e7, ... 'c', ones(6,1)*1.3e2, ... 'ce', ones(6,1)*1e1, ... 'ca', ones(6,1)*1e1 ... );

Figure 80: Comparison of the measured FRF and the optimized model

6 Test Bench Struts - Simscape Model

6.1 Introduction

6.2 First Identification

The object containing all the data is created.

%% Initialize structure containing data for the Simscape model n_hexapod = struct(); n_hexapod.flex_bot = initializeBotFlexibleJoint('type', '2dof'); n_hexapod.flex_top = initializeTopFlexibleJoint('type', '2dof'); n_hexapod.actuator = initializeAPA('type', '2dof');

%% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/Va'], 1, 'openinput'); io_i = io_i + 1; % Actuator Voltage io(io_i) = linio([mdl, '/Vs'], 1, 'openoutput'); io_i = io_i + 1; % Sensor Voltage io(io_i) = linio([mdl, '/dL'], 1, 'openoutput'); io_i = io_i + 1; % Relative Motion Outputs io(io_i) = linio([mdl, '/z'], 1, 'openoutput'); io_i = io_i + 1; % Vertical Motion

%% Run the linearization Gs = linearize(mdl, io, 0.0, options); Gs.InputName = {'Va'}; Gs.OutputName = {'Vs', 'dL', 'z'};

Figure 81: Identified transfer function from \(V_a\) to \(V_s\)

Figure 82: Identified transfer function from \(V_a\) to \(d_L\)

6.3 Effect of flexible joints

Perfect

%% Perfect Joints n_hexapod.flex_bot = initializeBotFlexibleJoint('type', '2dof'); n_hexapod.flex_top = initializeTopFlexibleJoint('type', '3dof'); Gp = linearize(mdl, io, 0.0, options); Gp.InputName = {'Va'}; Gp.OutputName = {'Vs', 'dL', 'z'};

Top Flexible

%% Top joint with Axial stiffness n_hexapod.flex_bot = initializeBotFlexibleJoint('type', '2dof'); n_hexapod.flex_top = initializeTopFlexibleJoint('type', '4dof'); Gt = linearize(mdl, io, 0.0, options); Gt.InputName = {'Va'}; Gt.OutputName = {'Vs', 'dL', 'z'};

Bottom Flexible

%% Bottom joint with Axial stiffness n_hexapod.flex_bot = initializeBotFlexibleJoint('type', '4dof'); n_hexapod.flex_top = initializeTopFlexibleJoint('type', '3dof'); Gb = linearize(mdl, io, 0.0, options); Gb.InputName = {'Va'}; Gb.OutputName = {'Vs', 'dL', 'z'};

Both Flexible

%% Both joints with Axial stiffness n_hexapod.flex_bot = initializeBotFlexibleJoint('type', '4dof'); n_hexapod.flex_top = initializeTopFlexibleJoint('type', '4dof'); Gf = linearize(mdl, io, 0.0, options); Gf.InputName = {'Va'}; Gf.OutputName = {'Vs', 'dL', 'z'};

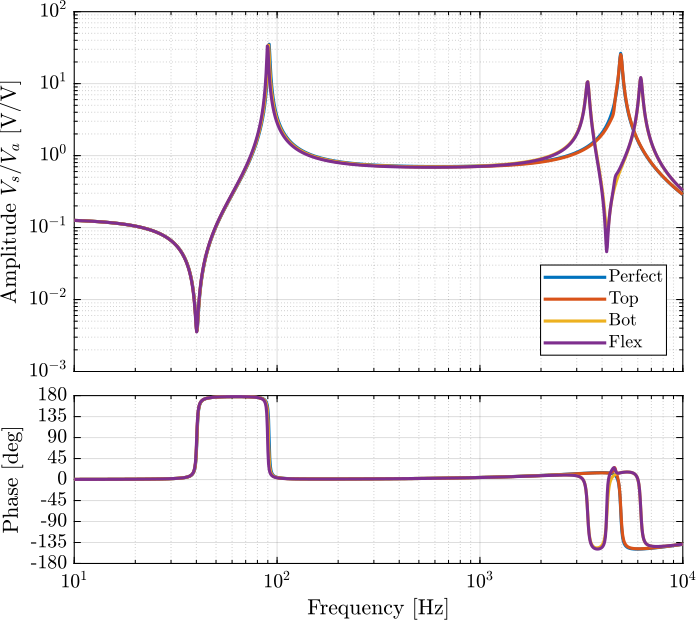

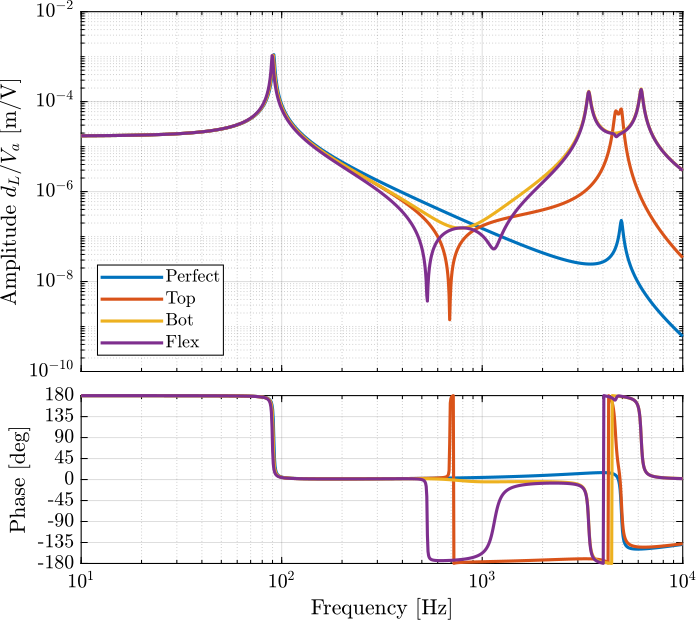

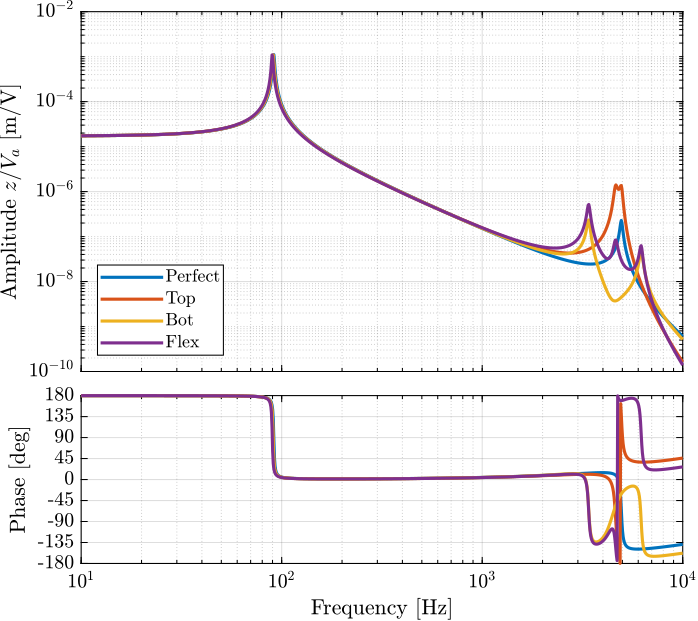

Comparison in Figures 83, 84 and 85.

Figure 83: Effect of the joint’s flexibility on the transfer function from \(V_a\) to \(V_s\)

Figure 84: Effect of the joint’s flexibility on the transfer function from \(V_a\) to \(d_L\) (encoder)

Figure 85: Effect of the joint’s flexibility on the transfer function from \(V_a\) to \(z\) (interferometer)

Imperfection of the flexible joints has the largest impact on the transfer function from \(V_a\) to \(d_L\). However, it has relatively small impact on the transfer functions from \(V_a\) to \(V_s\) and to \(z\).

6.4 Integral Force Feedback

6.4.1 Initialize the system

%% Initialize typical system n_hexapod = struct(); n_hexapod.flex_bot = initializeBotFlexibleJoint('type', '2dof'); n_hexapod.flex_top = initializeTopFlexibleJoint('type', '3dof'); n_hexapod.actuator = initializeAPA('type', '2dof');

6.4.2 Plant Identification

%% Identify th edynamics G = linearize(mdl, io, 0.0, options); G.InputName = {'Va'}; G.OutputName = {'Vs', 'dL', 'z'};

%% IFF Plant (transfer function from u to taum) Giff = G('Vs', 'Va');

6.4.3 Root Locus

%% Cut-off frequency of the LPF wc = 2*pi*20;

6.5 Comparison with the experimental Data

%% Initialize Simscape data n_hexapod.flex_bot = initializeBotFlexibleJoint('type', '4dof'); n_hexapod.flex_top = initializeTopFlexibleJoint('type', '4dof'); n_hexapod.actuator = initializeAPA('type', '2dof');

%% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/Va'], 1, 'openinput'); io_i = io_i + 1; % Actuator Voltage io(io_i) = linio([mdl, '/Vs'], 1, 'openoutput'); io_i = io_i + 1; % Sensor Voltage io(io_i) = linio([mdl, '/z'], 1, 'openoutput'); io_i = io_i + 1; % Relative Motion Outputs %% Identification Gs = exp(-s*Ts)*linearize(mdl, io, 0.0, options); Gs.InputName = {'Va'}; Gs.OutputName = {'Vs', 'z'};

Figure 86: Comparison of the measured FRF and the optimized model

7 Function

7.1 initializeBotFlexibleJoint - Initialize Flexible Joint

Function description

function [flex_bot] = initializeBotFlexibleJoint(args) % initializeBotFlexibleJoint - % % Syntax: [flex_bot] = initializeBotFlexibleJoint(args) % % Inputs: % - args - % % Outputs: % - flex_bot -

Optional Parameters

arguments args.type char {mustBeMember(args.type,{'2dof', '3dof', '4dof'})} = '2dof' args.kRx (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*5 args.kRy (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*5 args.kRz (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*260 args.kz (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*1e8 args.cRx (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*0.1 args.cRy (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*0.1 args.cRz (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*0.1 args.cz (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*1e2 end

Initialize the structure

flex_bot = struct();

Set the Joint’s type

switch args.type case '2dof' flex_bot.type = 1; case '3dof' flex_bot.type = 2; case '4dof' flex_bot.type = 3; end

Set parameters

flex_bot.kRx = args.kRx; flex_bot.kRy = args.kRy; flex_bot.kRz = args.kRz; flex_bot.kz = args.kz;

flex_bot.cRx = args.cRx; flex_bot.cRy = args.cRy; flex_bot.cRz = args.cRz; flex_bot.cz = args.cz;

7.2 initializeTopFlexibleJoint - Initialize Flexible Joint

Function description

function [flex_top] = initializeTopFlexibleJoint(args) % initializeTopFlexibleJoint - % % Syntax: [flex_top] = initializeTopFlexibleJoint(args) % % Inputs: % - args - % % Outputs: % - flex_top -

Optional Parameters

arguments args.type char {mustBeMember(args.type,{'2dof', '3dof', '4dof'})} = '2dof' args.kRx (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*5 args.kRy (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*5 args.kRz (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*260 args.kz (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*1e8 args.cRx (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*0.1 args.cRy (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*0.1 args.cRz (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*0.1 args.cz (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*1e2 end

Initialize the structure

flex_top = struct();

Set the Joint’s type

switch args.type case '2dof' flex_top.type = 1; case '3dof' flex_top.type = 2; case '4dof' flex_top.type = 3; end

Set parameters

flex_top.kRx = args.kRx; flex_top.kRy = args.kRy; flex_top.kRz = args.kRz; flex_top.kz = args.kz;

flex_top.cRx = args.cRx; flex_top.cRy = args.cRy; flex_top.cRz = args.cRz; flex_top.cz = args.cz;

7.3 initializeAPA - Initialize APA

Function description

function [actuator] = initializeAPA(args) % initializeAPA - % % Syntax: [actuator] = initializeAPA(args) % % Inputs: % - args - % % Outputs: % - actuator -

Optional Parameters

arguments args.type char {mustBeMember(args.type,{'2dof', 'flexible frame', 'flexible'})} = '2dof' args.Ga (1,1) double {mustBeNumeric} = 0 args.Gs (1,1) double {mustBeNumeric} = 0 % For 2DoF args.k (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*0.38e6 args.ke (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*1.75e6 args.ka (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*3e7 args.c (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*3e1 args.ce (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*2e1 args.ca (6,1) double {mustBeNumeric, mustBePositive} = ones(6,1)*2e1 args.Leq (6,1) double {mustBeNumeric} = ones(6,1)*0.056 % Force Flexible APA args.xi (1,1) double {mustBeNumeric, mustBePositive} = 0.5 % For Flexible Frame args.ks (1,1) double {mustBeNumeric, mustBePositive} = 235e6 args.cs (1,1) double {mustBeNumeric, mustBePositive} = 1e1 end

Initialize Structure

actuator = struct();

Type

switch args.type case '2dof' actuator.type = 1; case 'flexible frame' actuator.type = 2; case 'flexible' actuator.type = 3; end

Actuator/Sensor Constants

if args.Ga == 0 switch args.type case '2dof' actuator.Ga = -30.0; case 'flexible frame' actuator.Ga = 1; % TODO case 'flexible' actuator.Ga = 23.4; end else actuator.Ga = args.Ga; % Actuator gain [N/V] end

if args.Gs == 0 switch args.type case '2dof' actuator.Gs = 0.098; case 'flexible frame' actuator.Gs = 1; % TODO case 'flexible' actuator.Gs = -4674824; end else actuator.Gs = args.Gs; % Sensor gain [V/m] end

2DoF parameters

actuator.k = args.k; % [N/m] actuator.ke = args.ke; % [N/m] actuator.ka = args.ka; % [N/m] actuator.c = args.c; % [N/(m/s)] actuator.ce = args.ce; % [N/(m/s)] actuator.ca = args.ca; % [N/(m/s)] actuator.Leq = args.Leq; % [m]

Flexible frame and fully flexible

switch args.type case 'flexible frame' actuator.K = readmatrix('APA300ML_b_mat_K.CSV'); % Stiffness Matrix actuator.M = readmatrix('APA300ML_b_mat_M.CSV'); % Mass Matrix actuator.P = extractNodes('APA300ML_b_out_nodes_3D.txt'); % Node coordinates [m] case 'flexible' actuator.K = readmatrix('full_APA300ML_K.CSV'); % Stiffness Matrix actuator.M = readmatrix('full_APA300ML_M.CSV'); % Mass Matrix actuator.P = extractNodes('full_APA300ML_out_nodes_3D.txt'); % Node coordiantes [m] end actuator.xi = args.xi; % Damping ratio actuator.ks = args.ks; % Stiffness of one stack [N/m] actuator.cs = args.cs; % Damping of one stack [N/m]

7.4 generateSweepExc: Generate sweep sinus excitation

Function description

function [U_exc] = generateSweepExc(args) % generateSweepExc - Generate a Sweep Sine excitation signal % % Syntax: [U_exc] = generateSweepExc(args) % % Inputs: % - args - Optinal arguments: % - Ts - Sampling Time - [s] % - f_start - Start frequency of the sweep - [Hz] % - f_end - End frequency of the sweep - [Hz] % - V_mean - Mean value of the excitation voltage - [V] % - V_exc - Excitation Amplitude for the Sweep, could be numeric or TF - [V] % - t_start - Time at which the sweep begins - [s] % - exc_duration - Duration of the sweep - [s] % - sweep_type - 'logarithmic' or 'linear' - [-] % - smooth_ends - 'true' or 'false': smooth transition between 0 and V_mean - [-]

Optional Parameters

arguments args.Ts (1,1) double {mustBeNumeric, mustBePositive} = 1e-4 args.f_start (1,1) double {mustBeNumeric, mustBePositive} = 1 args.f_end (1,1) double {mustBeNumeric, mustBePositive} = 1e3 args.V_mean (1,1) double {mustBeNumeric} = 0 args.V_exc = 1 args.t_start (1,1) double {mustBeNumeric, mustBeNonnegative} = 5 args.exc_duration (1,1) double {mustBeNumeric, mustBePositive} = 10 args.sweep_type char {mustBeMember(args.sweep_type,{'log', 'lin'})} = 'lin' args.smooth_ends logical {mustBeNumericOrLogical} = true end

Sweep Sine part

t_sweep = 0:args.Ts:args.exc_duration; if strcmp(args.sweep_type, 'log') V_exc = sin(2*pi*args.f_start * args.exc_duration/log(args.f_end/args.f_start) * (exp(log(args.f_end/args.f_start)*t_sweep/args.exc_duration) - 1)); elseif strcmp(args.sweep_type, 'lin') V_exc = sin(2*pi*(args.f_start + (args.f_end - args.f_start)/2/args.exc_duration*t_sweep).*t_sweep); else error('sweep_type should either be equal to "log" or to "lin"'); end

if isnumeric(args.V_exc) V_sweep = args.V_mean + args.V_exc*V_exc; elseif isct(args.V_exc) if strcmp(args.sweep_type, 'log') V_sweep = args.V_mean + abs(squeeze(freqresp(args.V_exc, args.f_start*(args.f_end/args.f_start).^(t_sweep/args.exc_duration), 'Hz')))'.*V_exc; elseif strcmp(args.sweep_type, 'lin') V_sweep = args.V_mean + abs(squeeze(freqresp(args.V_exc, args.f_start+(args.f_end-args.f_start)/args.exc_duration*t_sweep, 'Hz')))'.*V_exc; end end

Smooth Ends

if args.t_start > 0 t_smooth_start = args.Ts:args.Ts:args.t_start; V_smooth_start = zeros(size(t_smooth_start)); V_smooth_end = zeros(size(t_smooth_start)); if args.smooth_ends Vd_max = args.V_mean/(0.7*args.t_start); V_d = zeros(size(t_smooth_start)); V_d(t_smooth_start < 0.2*args.t_start) = t_smooth_start(t_smooth_start < 0.2*args.t_start)*Vd_max/(0.2*args.t_start); V_d(t_smooth_start > 0.2*args.t_start & t_smooth_start < 0.7*args.t_start) = Vd_max; V_d(t_smooth_start > 0.7*args.t_start & t_smooth_start < 0.9*args.t_start) = Vd_max - (t_smooth_start(t_smooth_start > 0.7*args.t_start & t_smooth_start < 0.9*args.t_start) - 0.7*args.t_start)*Vd_max/(0.2*args.t_start); V_smooth_start = cumtrapz(V_d)*args.Ts; V_smooth_end = args.V_mean - V_smooth_start; end else V_smooth_start = []; V_smooth_end = []; end

Combine Excitation signals

V_exc = [V_smooth_start, V_sweep, V_smooth_end]; t_exc = args.Ts*[0:1:length(V_exc)-1];

U_exc = [t_exc; V_exc];

7.5 generateShapedNoise: Generate Shaped Noise excitation

Function description

function [U_exc] = generateShapedNoise(args) % generateShapedNoise - Generate a Shaped Noise excitation signal % % Syntax: [U_exc] = generateShapedNoise(args) % % Inputs: % - args - Optinal arguments: % - Ts - Sampling Time - [s] % - V_mean - Mean value of the excitation voltage - [V] % - V_exc - Excitation Amplitude, could be numeric or TF - [V rms] % - t_start - Time at which the noise begins - [s] % - exc_duration - Duration of the noise - [s] % - smooth_ends - 'true' or 'false': smooth transition between 0 and V_mean - [-]

Optional Parameters

arguments args.Ts (1,1) double {mustBeNumeric, mustBePositive} = 1e-4 args.V_mean (1,1) double {mustBeNumeric} = 0 args.V_exc = 1 args.t_start (1,1) double {mustBeNumeric, mustBePositive} = 5 args.exc_duration (1,1) double {mustBeNumeric, mustBePositive} = 10 args.smooth_ends logical {mustBeNumericOrLogical} = true end

Shaped Noise

t_noise = 0:args.Ts:args.exc_duration;

if isnumeric(args.V_exc) V_noise = args.V_mean + args.V_exc*sqrt(1/args.Ts/2)*randn(length(t_noise), 1)'; elseif isct(args.V_exc) V_noise = args.V_mean + lsim(args.V_exc, sqrt(1/args.Ts/2)*randn(length(t_noise), 1), t_noise)'; end

Smooth Ends

t_smooth_start = args.Ts:args.Ts:args.t_start; V_smooth_start = zeros(size(t_smooth_start)); V_smooth_end = zeros(size(t_smooth_start)); if args.smooth_ends Vd_max = args.V_mean/(0.7*args.t_start); V_d = zeros(size(t_smooth_start)); V_d(t_smooth_start < 0.2*args.t_start) = t_smooth_start(t_smooth_start < 0.2*args.t_start)*Vd_max/(0.2*args.t_start); V_d(t_smooth_start > 0.2*args.t_start & t_smooth_start < 0.7*args.t_start) = Vd_max; V_d(t_smooth_start > 0.7*args.t_start & t_smooth_start < 0.9*args.t_start) = Vd_max - (t_smooth_start(t_smooth_start > 0.7*args.t_start & t_smooth_start < 0.9*args.t_start) - 0.7*args.t_start)*Vd_max/(0.2*args.t_start); V_smooth_start = cumtrapz(V_d)*args.Ts; V_smooth_end = args.V_mean - V_smooth_start; end

Combine Excitation signals

V_exc = [V_smooth_start, V_noise, V_smooth_end]; t_exc = args.Ts*[0:1:length(V_exc)-1];

U_exc = [t_exc; V_exc];

7.6 generateSinIncreasingAmpl: Generate Sinus with increasing amplitude

Function description

function [U_exc] = generateSinIncreasingAmpl(args) % generateSinIncreasingAmpl - Generate Sinus with increasing amplitude % % Syntax: [U_exc] = generateSinIncreasingAmpl(args) % % Inputs: % - args - Optinal arguments: % - Ts - Sampling Time - [s] % - V_mean - Mean value of the excitation voltage - [V] % - sin_ampls - Excitation Amplitudes - [V] % - sin_freq - Excitation Frequency - [Hz] % - sin_num - Number of period for each amplitude - [-] % - t_start - Time at which the excitation begins - [s] % - smooth_ends - 'true' or 'false': smooth transition between 0 and V_mean - [-]

Optional Parameters

arguments args.Ts (1,1) double {mustBeNumeric, mustBePositive} = 1e-4 args.V_mean (1,1) double {mustBeNumeric} = 0 args.sin_ampls double {mustBeNumeric, mustBePositive} = [0.1, 0.2, 0.3] args.sin_period (1,1) double {mustBeNumeric, mustBePositive} = 1 args.sin_num (1,1) double {mustBeNumeric, mustBePositive, mustBeInteger} = 3 args.t_start (1,1) double {mustBeNumeric, mustBePositive} = 5 args.smooth_ends logical {mustBeNumericOrLogical} = true end

Sinus excitation

t_noise = 0:args.Ts:args.sin_period*args.sin_num; sin_exc = [];

for sin_ampl = args.sin_ampls sin_exc = [sin_exc, args.V_mean + sin_ampl*sin(2*pi/args.sin_period*t_noise)]; end

Smooth Ends

t_smooth_start = args.Ts:args.Ts:args.t_start; V_smooth_start = zeros(size(t_smooth_start)); V_smooth_end = zeros(size(t_smooth_start)); if args.smooth_ends Vd_max = args.V_mean/(0.7*args.t_start); V_d = zeros(size(t_smooth_start)); V_d(t_smooth_start < 0.2*args.t_start) = t_smooth_start(t_smooth_start < 0.2*args.t_start)*Vd_max/(0.2*args.t_start); V_d(t_smooth_start > 0.2*args.t_start & t_smooth_start < 0.7*args.t_start) = Vd_max; V_d(t_smooth_start > 0.7*args.t_start & t_smooth_start < 0.9*args.t_start) = Vd_max - (t_smooth_start(t_smooth_start > 0.7*args.t_start & t_smooth_start < 0.9*args.t_start) - 0.7*args.t_start)*Vd_max/(0.2*args.t_start); V_smooth_start = cumtrapz(V_d)*args.Ts; V_smooth_end = args.V_mean - V_smooth_start; end

Combine Excitation signals

V_exc = [V_smooth_start, sin_exc, V_smooth_end]; t_exc = args.Ts*[0:1:length(V_exc)-1];

U_exc = [t_exc; V_exc];