SVD Control

Table of Contents

- 1. Gravimeter - Simscape Model

- 2. Stewart Platform - Simscape Model

- 2.1. Jacobian

- 2.2. Simscape Model

- 2.3. Identification of the plant

- 2.4. Obtained Dynamics

- 2.5. Real Approximation of \(G\) at the decoupling frequency

- 2.6. Verification of the decoupling using the “Gershgorin Radii”

- 2.7. Decoupled Plant

- 2.8. Diagonal Controller

- 2.9. Centralized Control

- 2.10. SVD Control

- 2.11. Results

- 3. Stewart Platform - Analytical Model

- 3.1. Characteristics

- 3.2. Mass Matrix

- 3.3. Jacobian Matrix

- 3.4. Stifnness matrix and Damping matrix

- 3.5. State Space System

- 3.6. Transmissibility

- 3.7. Real approximation of \(G(j\omega)\) at decoupling frequency

- 3.8. Coupled and Decoupled Plant “Gershgorin Radii”

- 3.9. Decoupled Plant

- 3.10. Controller

- 3.11. Closed Loop System

- 3.12. Results

1 Gravimeter - Simscape Model

1.1 Simulink

open('gravimeter.slx')

%% Name of the Simulink File

mdl = 'gravimeter';

%% Input/Output definition

clear io; io_i = 1;

io(io_i) = linio([mdl, '/F1'], 1, 'openinput'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/F2'], 1, 'openinput'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/F3'], 1, 'openinput'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/Acc_side'], 1, 'openoutput'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/Acc_side'], 2, 'openoutput'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/Acc_top'], 1, 'openoutput'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/Acc_top'], 2, 'openoutput'); io_i = io_i + 1;

G = linearize(mdl, io);

G.InputName = {'F1', 'F2', 'F3'};

G.OutputName = {'Ax1', 'Az1', 'Ax2', 'Az2'};

The plant as 6 states as expected (2 translations + 1 rotation)

size(G)

State-space model with 4 outputs, 3 inputs, and 6 states.

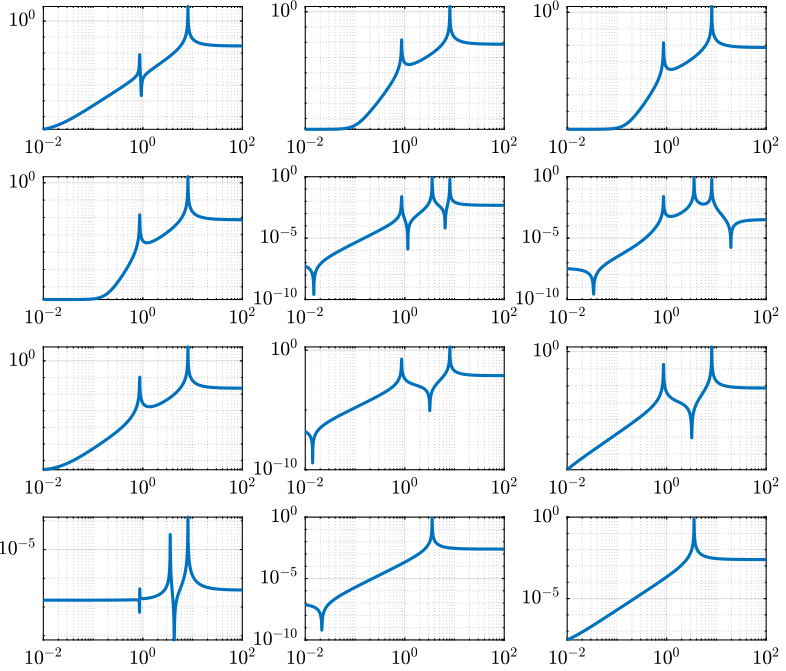

Figure 1: Open Loop Transfer Function from 3 Actuators to 4 Accelerometers

2 Stewart Platform - Simscape Model

2.1 Jacobian

First, the position of the “joints” (points of force application) are estimated and the Jacobian computed.

open('stewart_platform/drone_platform_jacobian.slx');

sim('drone_platform_jacobian');

Aa = [a1.Data(1,:);

a2.Data(1,:);

a3.Data(1,:);

a4.Data(1,:);

a5.Data(1,:);

a6.Data(1,:)]';

Ab = [b1.Data(1,:);

b2.Data(1,:);

b3.Data(1,:);

b4.Data(1,:);

b5.Data(1,:);

b6.Data(1,:)]';

As = (Ab - Aa)./vecnorm(Ab - Aa);

l = vecnorm(Ab - Aa)';

J = [As' , cross(Ab, As)'];

save('./jacobian.mat', 'Aa', 'Ab', 'As', 'l', 'J');

2.2 Simscape Model

open('stewart_platform/drone_platform.slx');

Definition of spring parameters

kx = 50; % [N/m] ky = 50; kz = 50; cx = 0.025; % [Nm/rad] cy = 0.025; cz = 0.025;

We load the Jacobian.

load('./jacobian.mat', 'Aa', 'Ab', 'As', 'l', 'J');

2.3 Identification of the plant

The dynamics is identified from forces applied by each legs to the measured acceleration of the top platform.

%% Name of the Simulink File

mdl = 'drone_platform';

%% Input/Output definition

clear io; io_i = 1;

io(io_i) = linio([mdl, '/Dw'], 1, 'openinput'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/u'], 1, 'openinput'); io_i = io_i + 1;

io(io_i) = linio([mdl, '/Inertial Sensor'], 1, 'openoutput'); io_i = io_i + 1;

G = linearize(mdl, io);

G.InputName = {'Dwx', 'Dwy', 'Dwz', 'Rwx', 'Rwy', 'Rwz', ...

'F1', 'F2', 'F3', 'F4', 'F5', 'F6'};

G.OutputName = {'Ax', 'Ay', 'Az', 'Arx', 'Ary', 'Arz'};

There are 24 states (6dof for the bottom platform + 6dof for the top platform).

size(G)

State-space model with 6 outputs, 12 inputs, and 24 states.

% G = G*blkdiag(inv(J), eye(6));

% G.InputName = {'Dw1', 'Dw2', 'Dw3', 'Dw4', 'Dw5', 'Dw6', ...

% 'F1', 'F2', 'F3', 'F4', 'F5', 'F6'};

Thanks to the Jacobian, we compute the transfer functions in the frame of the legs and in an inertial frame.

Gx = G*blkdiag(eye(6), inv(J'));

Gx.InputName = {'Dwx', 'Dwy', 'Dwz', 'Rwx', 'Rwy', 'Rwz', ...

'Fx', 'Fy', 'Fz', 'Mx', 'My', 'Mz'};

Gl = J*G;

Gl.OutputName = {'A1', 'A2', 'A3', 'A4', 'A5', 'A6'};

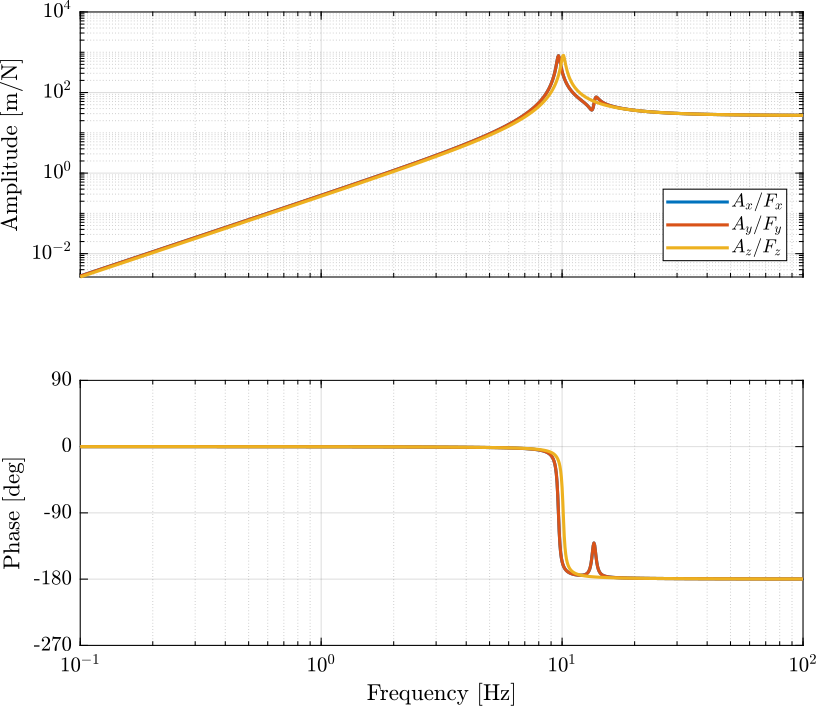

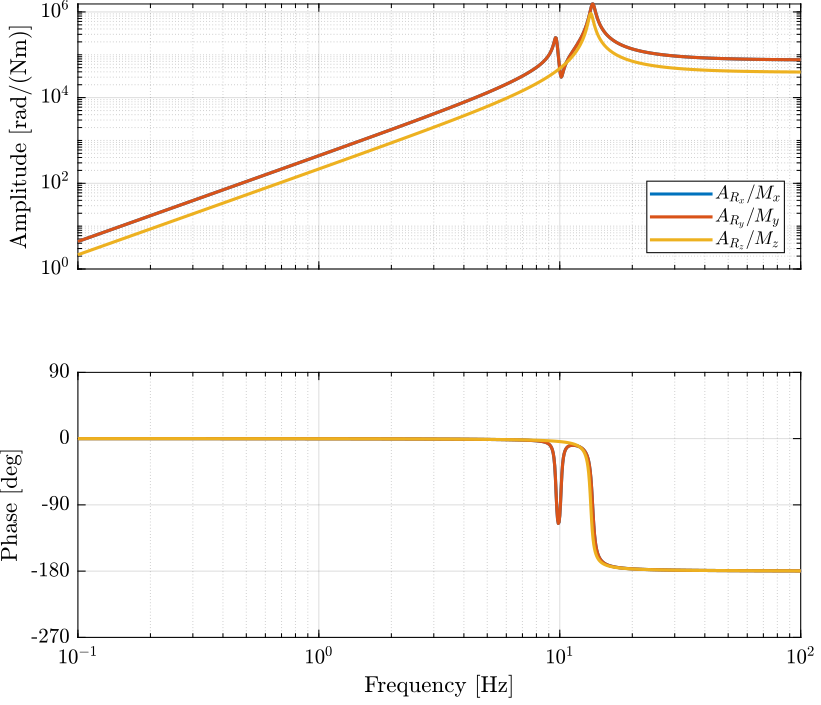

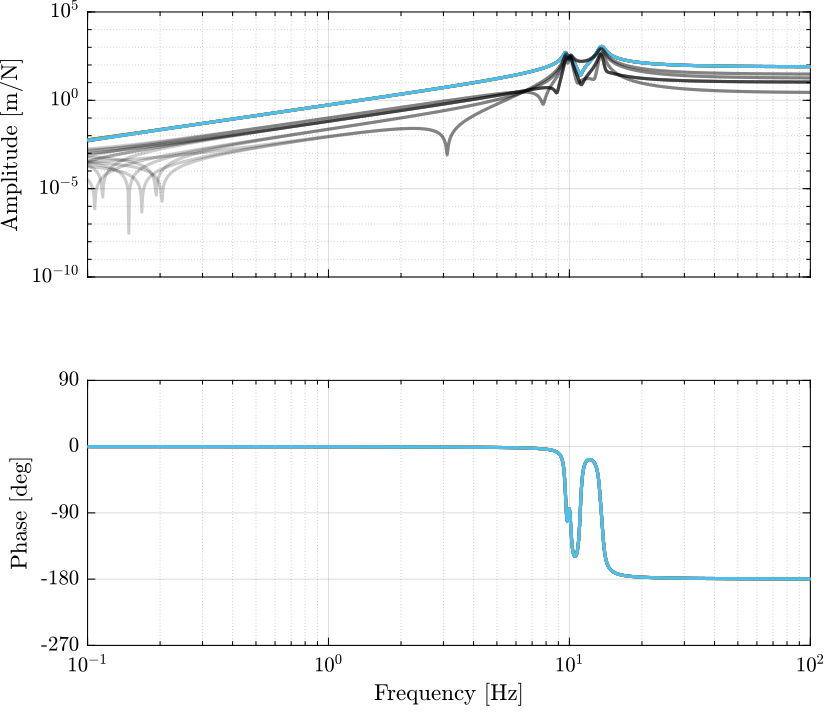

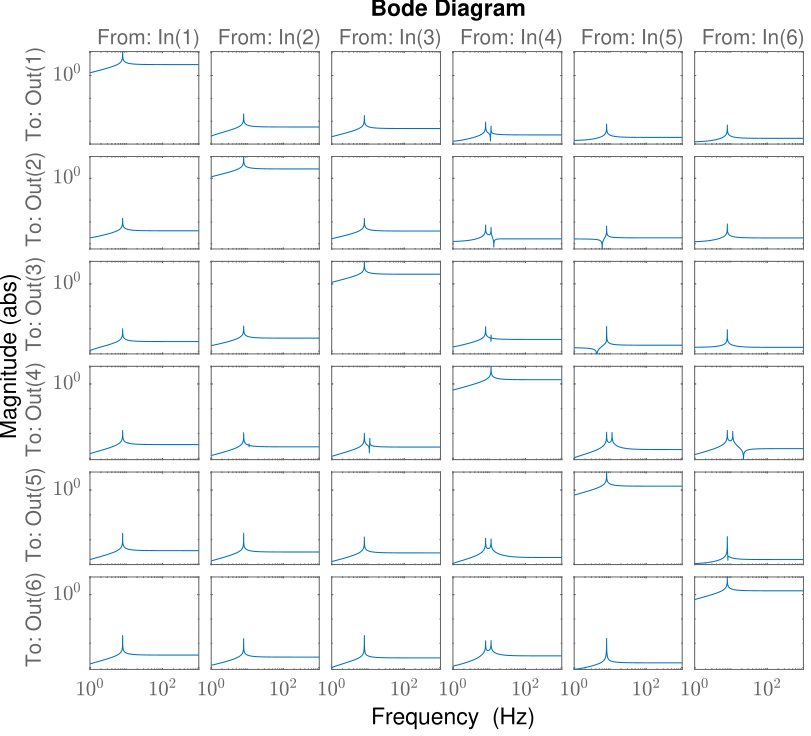

2.4 Obtained Dynamics

Figure 2: Stewart Platform Plant from forces applied by the legs to the acceleration of the platform

Figure 3: Stewart Platform Plant from torques applied by the legs to the angular acceleration of the platform

Figure 4: Stewart Platform Plant from forces applied by the legs to displacement of the legs

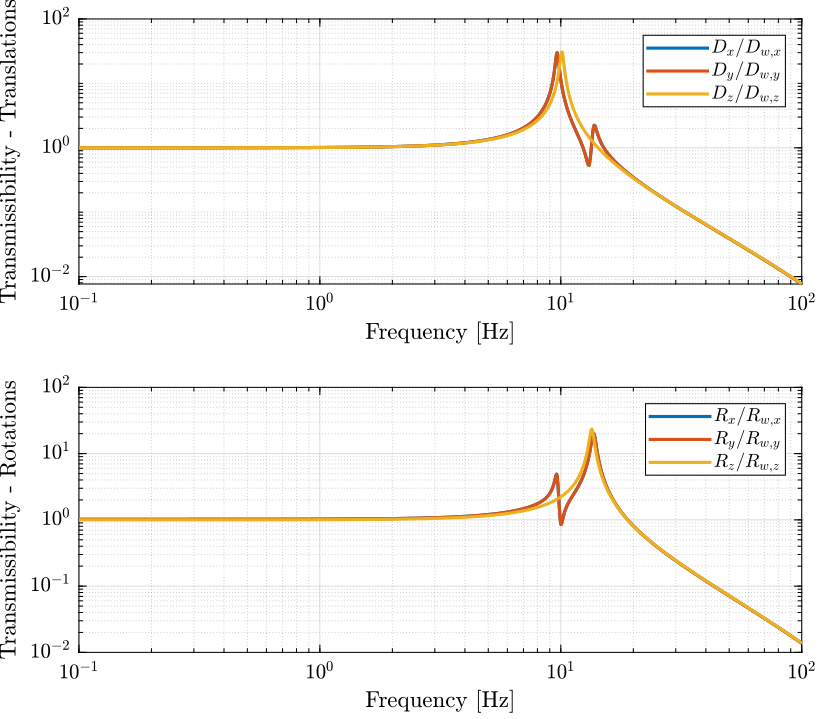

Figure 5: Transmissibility

2.5 Real Approximation of \(G\) at the decoupling frequency

Let’s compute a real approximation of the complex matrix \(H_1\) which corresponds to the the transfer function \(G_c(j\omega_c)\) from forces applied by the actuators to the measured acceleration of the top platform evaluated at the frequency \(\omega_c\).

wc = 2*pi*20; % Decoupling frequency [rad/s]

Gc = G({'Ax', 'Ay', 'Az', 'Arx', 'Ary', 'Arz'}, ...

{'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}); % Transfer function to find a real approximation

H1 = evalfr(Gc, j*wc);

The real approximation is computed as follows:

D = pinv(real(H1'*H1)); H1 = inv(D*real(H1'*diag(exp(j*angle(diag(H1*D*H1.'))/2))));

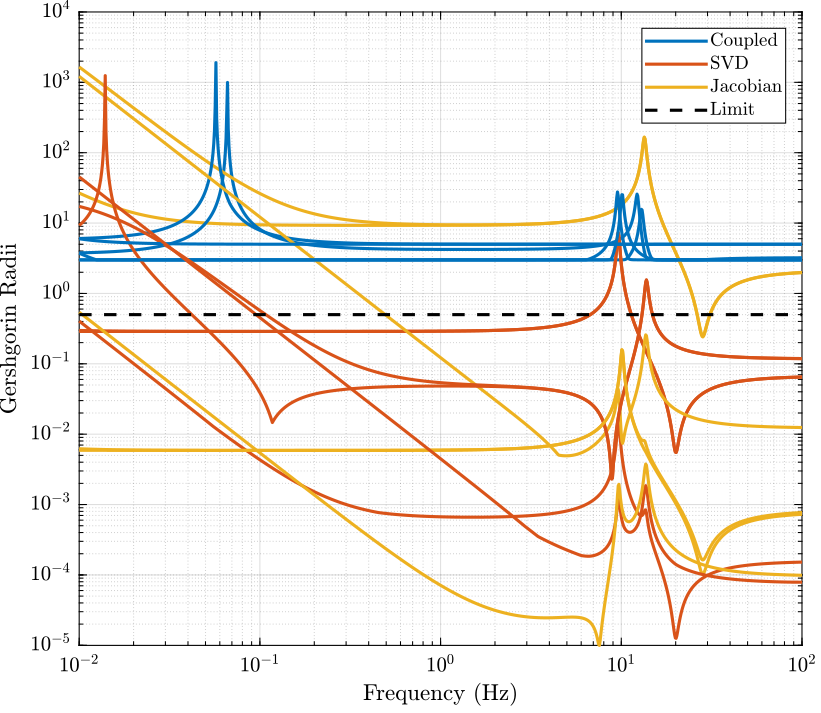

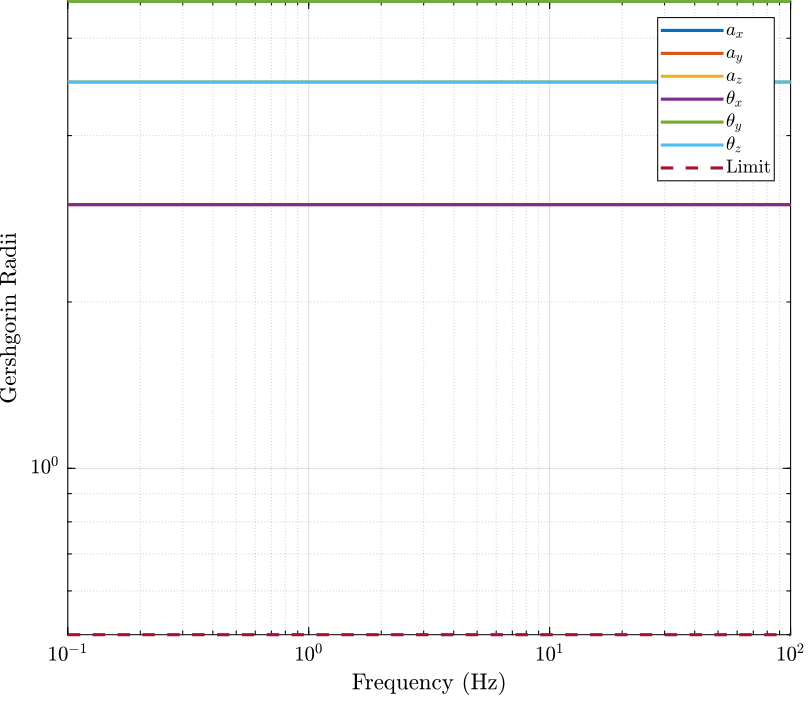

2.6 Verification of the decoupling using the “Gershgorin Radii”

First, the Singular Value Decomposition of \(H_1\) is performed: \[ H_1 = U \Sigma V^H \]

[U,S,V] = svd(H1);

Then, the “Gershgorin Radii” is computed for the plant \(G_c(s)\) and the “SVD Decoupled Plant” \(G_d(s)\): \[ G_d(s) = U^T G_c(s) V \]

This is computed over the following frequencies.

freqs = logspace(-2, 2, 1000); % [Hz]

Gershgorin Radii for the coupled plant:

Gr_coupled = zeros(length(freqs), size(Gc,2));

H = abs(squeeze(freqresp(Gc, freqs, 'Hz')));

for out_i = 1:size(Gc,2)

Gr_coupled(:, out_i) = squeeze((sum(H(out_i,:,:)) - H(out_i,out_i,:))./H(out_i, out_i, :));

end

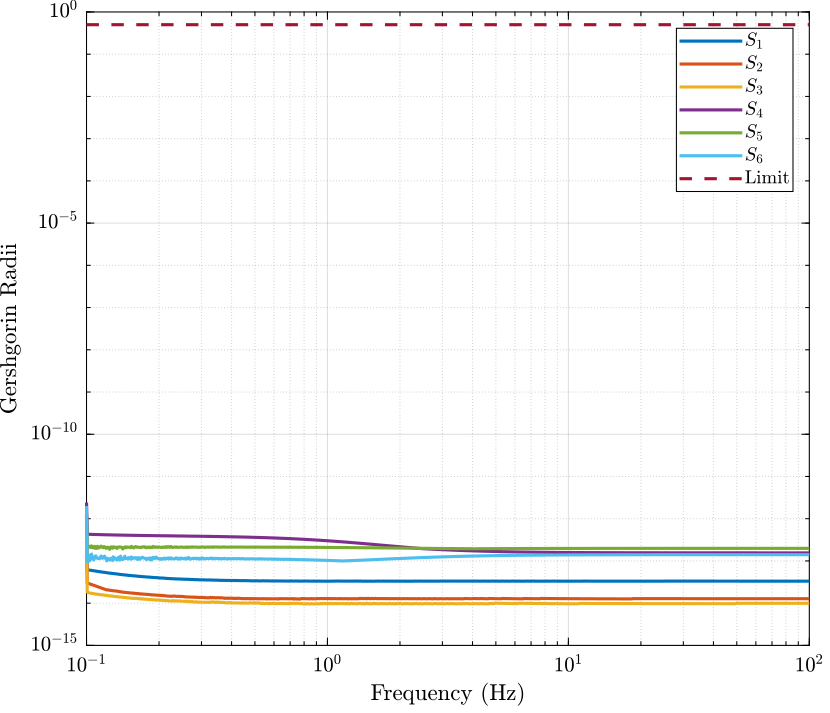

Gershgorin Radii for the decoupled plant using SVD:

Gd = U'*Gc*V;

Gr_decoupled = zeros(length(freqs), size(Gd,2));

H = abs(squeeze(freqresp(Gd, freqs, 'Hz')));

for out_i = 1:size(Gd,2)

Gr_decoupled(:, out_i) = squeeze((sum(H(out_i,:,:)) - H(out_i,out_i,:))./H(out_i, out_i, :));

end

Gershgorin Radii for the decoupled plant using the Jacobian:

Gj = Gc*inv(J');

Gr_jacobian = zeros(length(freqs), size(Gj,2));

H = abs(squeeze(freqresp(Gj, freqs, 'Hz')));

for out_i = 1:size(Gj,2)

Gr_jacobian(:, out_i) = squeeze((sum(H(out_i,:,:)) - H(out_i,out_i,:))./H(out_i, out_i, :));

end

Figure 6: Gershgorin Radii of the Coupled and Decoupled plants

2.7 Decoupled Plant

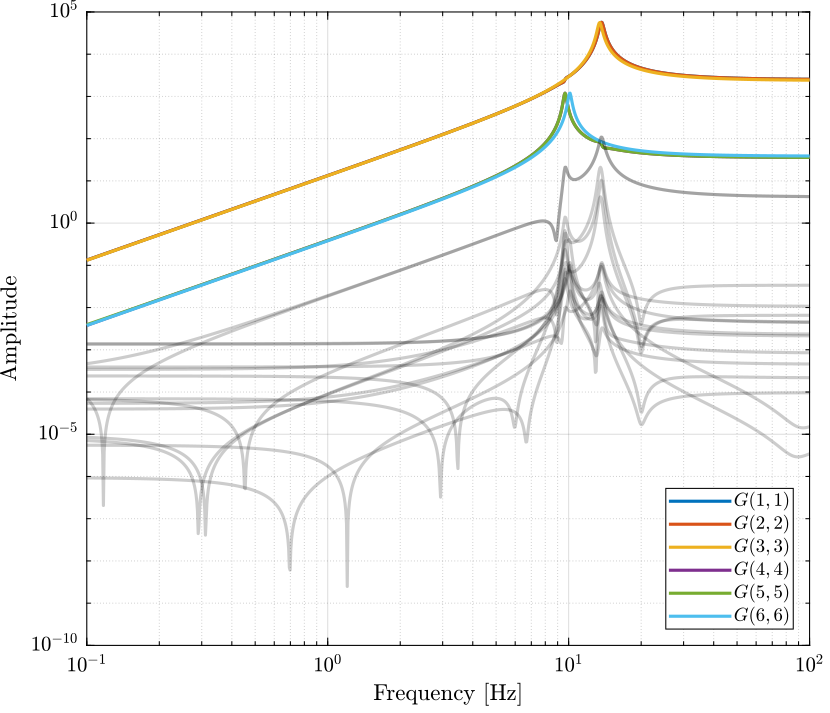

Let’s see the bode plot of the decoupled plant \(G_d(s)\). \[ G_d(s) = U^T G_c(s) V \]

Figure 7: Decoupled Plant using SVD

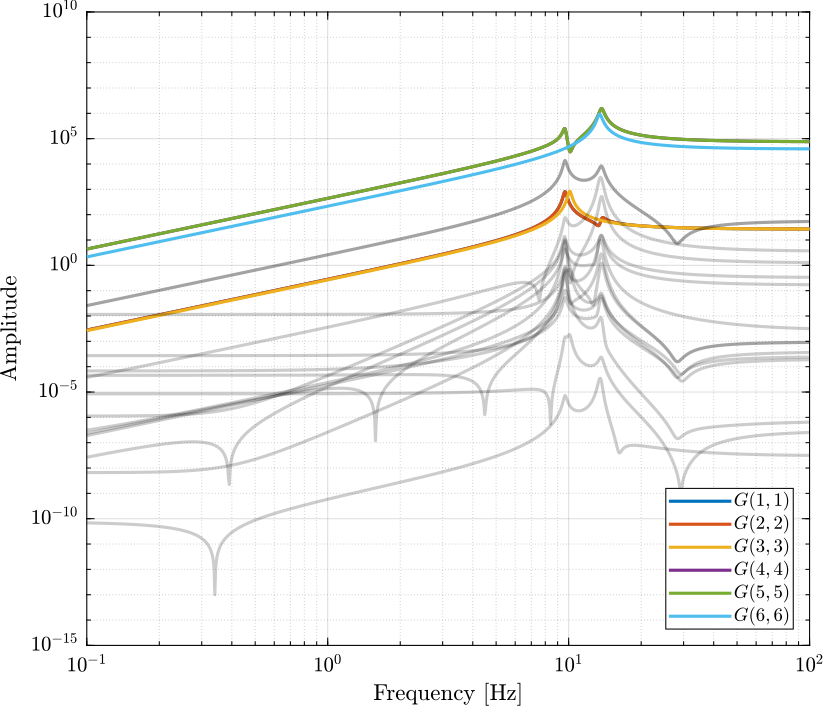

Figure 8: Decoupled Plant using the Jacobian

2.8 Diagonal Controller

The controller \(K\) is a diagonal controller consisting a low pass filters with a crossover frequency \(\omega_c\) and a DC gain \(C_g\).

wc = 2*pi*0.1; % Crossover Frequency [rad/s] C_g = 50; % DC Gain K = eye(6)*C_g/(s+wc);

2.9 Centralized Control

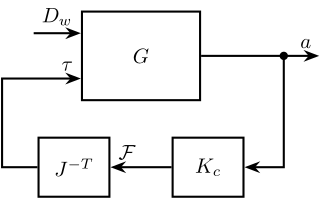

The control diagram for the centralized control is shown below.

The controller \(K_c\) is “working” in an cartesian frame. The Jacobian is used to convert forces in the cartesian frame to forces applied by the actuators.

G_cen = feedback(G, inv(J')*K, [7:12], [1:6]);

2.10 SVD Control

The SVD control architecture is shown below. The matrices \(U\) and \(V\) are used to decoupled the plant \(G\).

SVD Control

G_svd = feedback(G, pinv(V')*K*pinv(U), [7:12], [1:6]);

2.11 Results

Let’s first verify the stability of the closed-loop systems:

isstable(G_cen)

ans = logical 1

isstable(G_svd)

ans = logical 1

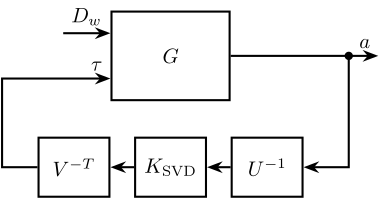

The obtained transmissibility in Open-loop, for the centralized control as well as for the SVD control are shown in Figure 11.

Figure 11: Obtained Transmissibility

3 Stewart Platform - Analytical Model

3.1 Characteristics

L = 0.055; Zc = 0; m = 0.2; k = 1e3; c = 2*0.1*sqrt(k*m); Rx = 0.04; Rz = 0.04; Ix = m*Rx^2; Iy = m*Rx^2; Iz = m*Rz^2;

3.2 Mass Matrix

M = m*[1 0 0 0 Zc 0;

0 1 0 -Zc 0 0;

0 0 1 0 0 0;

0 -Zc 0 Rx^2+Zc^2 0 0;

Zc 0 0 0 Rx^2+Zc^2 0;

0 0 0 0 0 Rz^2];

3.3 Jacobian Matrix

Bj=1/sqrt(6)*[ 1 1 -2 1 1 -2;

sqrt(3) -sqrt(3) 0 sqrt(3) -sqrt(3) 0;

sqrt(2) sqrt(2) sqrt(2) sqrt(2) sqrt(2) sqrt(2);

0 0 L L -L -L;

-L*2/sqrt(3) -L*2/sqrt(3) L/sqrt(3) L/sqrt(3) L/sqrt(3) L/sqrt(3);

L*sqrt(2) -L*sqrt(2) L*sqrt(2) -L*sqrt(2) L*sqrt(2) -L*sqrt(2)];

3.4 Stifnness matrix and Damping matrix

kv = k/3; % [N/m] kh = 0.5*k/3; % [N/m] K = diag([3*kh,3*kh,3*kv,3*kv*Rx^2/2,3*kv*Rx^2/2,3*kh*Rx^2]); % Stiffness Matrix C = c*K/100000; % Damping Matrix

3.5 State Space System

A = [zeros(6) eye(6); -M\K -M\C]; Bw = [zeros(6); -eye(6)]; Bu = [zeros(6); M\Bj]; Co = [-M\K -M\C]; D = [zeros(6) M\Bj]; ST = ss(A,[Bw Bu],Co,D);

- OUT 1-6: 6 dof

- IN 1-6 : ground displacement in the directions of the legs

- IN 7-12: forces in the actuators.

ST.StateName = {'x';'y';'z';'theta_x';'theta_y';'theta_z';...

'dx';'dy';'dz';'dtheta_x';'dtheta_y';'dtheta_z'};

ST.InputName = {'w1';'w2';'w3';'w4';'w5';'w6';...

'u1';'u2';'u3';'u4';'u5';'u6'};

ST.OutputName = {'ax';'ay';'az';'atheta_x';'atheta_y';'atheta_z'};

3.6 Transmissibility

TR=ST*[eye(6); zeros(6)];

figure subplot(231) bodemag(TR(1,1),opts); subplot(232) bodemag(TR(2,2),opts); subplot(233) bodemag(TR(3,3),opts); subplot(234) bodemag(TR(4,4),opts); subplot(235) bodemag(TR(5,5),opts); subplot(236) bodemag(TR(6,6),opts);

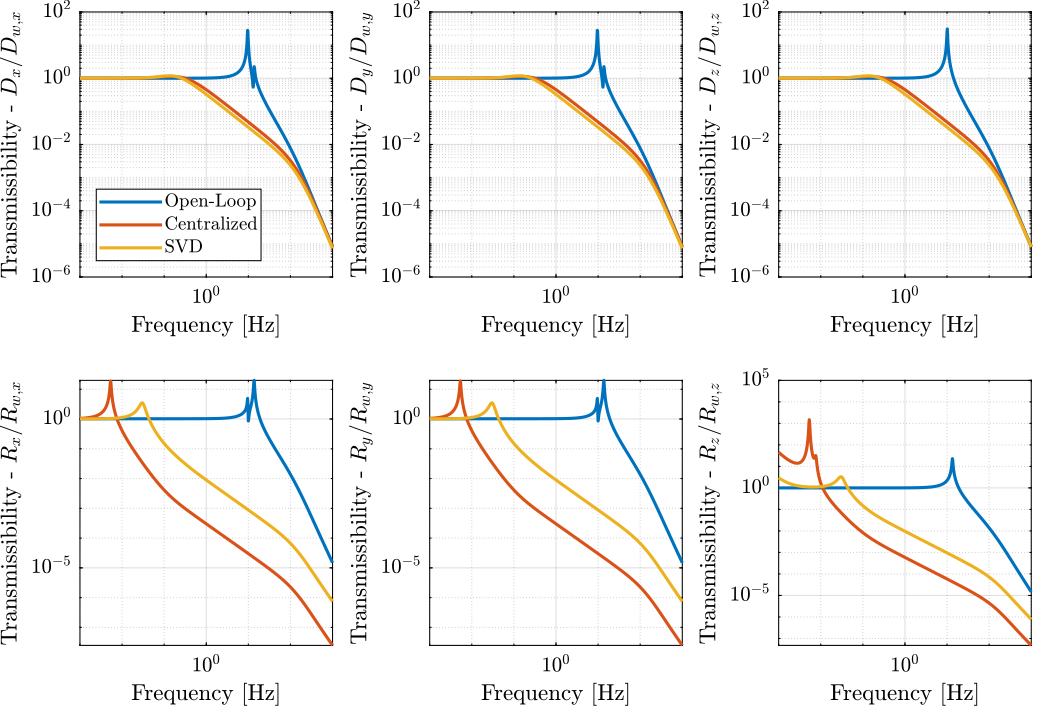

Figure 12: Transmissibility

3.7 Real approximation of \(G(j\omega)\) at decoupling frequency

sys1 = ST*[zeros(6); eye(6)]; % take only the forces inputs

dec_fr = 20;

H1 = evalfr(sys1,j*2*pi*dec_fr);

H2 = H1;

D = pinv(real(H2'*H2));

H1 = inv(D*real(H2'*diag(exp(j*angle(diag(H2*D*H2.'))/2)))) ;

[U,S,V] = svd(H1);

wf = logspace(-1,2,1000);

for i = 1:length(wf)

H = abs(evalfr(sys1,j*2*pi*wf(i)));

H_dec = abs(evalfr(U'*sys1*V,j*2*pi*wf(i)));

for j = 1:size(H,2)

g_r1(i,j) = (sum(H(j,:))-H(j,j))/H(j,j);

g_r2(i,j) = (sum(H_dec(j,:))-H_dec(j,j))/H_dec(j,j);

% keyboard

end

g_lim(i) = 0.5;

end

3.8 Coupled and Decoupled Plant “Gershgorin Radii”

figure;

title('Coupled plant')

loglog(wf,g_r1(:,1),wf,g_r1(:,2),wf,g_r1(:,3),wf,g_r1(:,4),wf,g_r1(:,5),wf,g_r1(:,6),wf,g_lim,'--');

legend('$a_x$','$a_y$','$a_z$','$\theta_x$','$\theta_y$','$\theta_z$','Limit');

xlabel('Frequency (Hz)'); ylabel('Gershgorin Radii')

Figure 13: Gershorin Raddi for the coupled plant

figure;

title('Decoupled plant (10 Hz)')

loglog(wf,g_r2(:,1),wf,g_r2(:,2),wf,g_r2(:,3),wf,g_r2(:,4),wf,g_r2(:,5),wf,g_r2(:,6),wf,g_lim,'--');

legend('$S_1$','$S_2$','$S_3$','$S_4$','$S_5$','$S_6$','Limit');

xlabel('Frequency (Hz)'); ylabel('Gershgorin Radii')

Figure 14: Gershorin Raddi for the decoupled plant

3.9 Decoupled Plant

figure; bodemag(U'*sys1*V,opts)

Figure 15: Decoupled Plant

3.10 Controller

fc = 2*pi*0.1; % Crossover Frequency [rad/s] c_gain = 50; % cont = eye(6)*c_gain/(s+fc);

3.11 Closed Loop System

FEEDIN = [7:12]; % Input of controller FEEDOUT = [1:6]; % Output of controller

Centralized Control

STcen = feedback(ST, inv(Bj)*cont, FEEDIN, FEEDOUT); TRcen = STcen*[eye(6); zeros(6)];

SVD Control

STsvd = feedback(ST, pinv(V')*cont*pinv(U), FEEDIN, FEEDOUT); TRsvd = STsvd*[eye(6); zeros(6)];

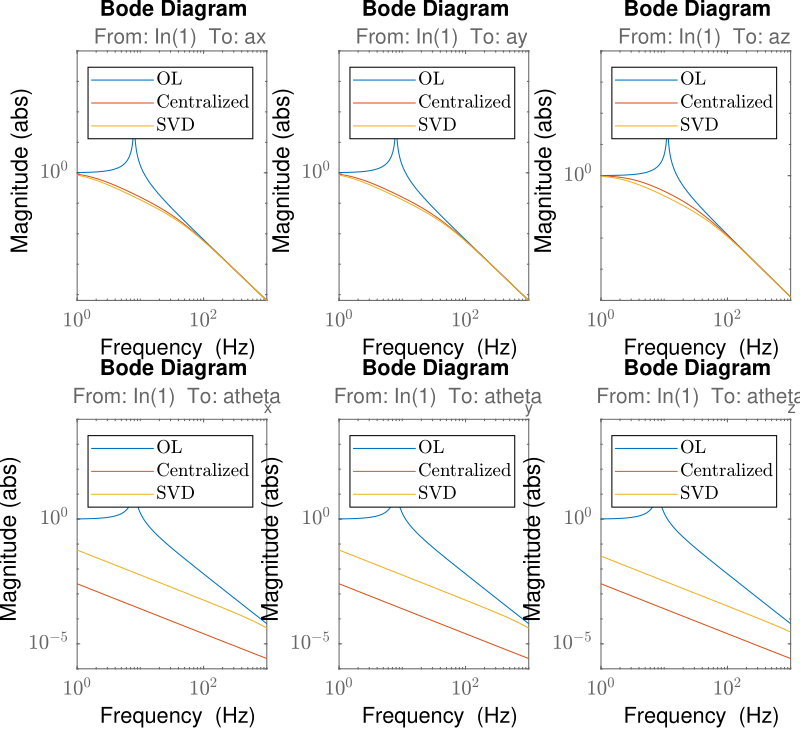

3.12 Results

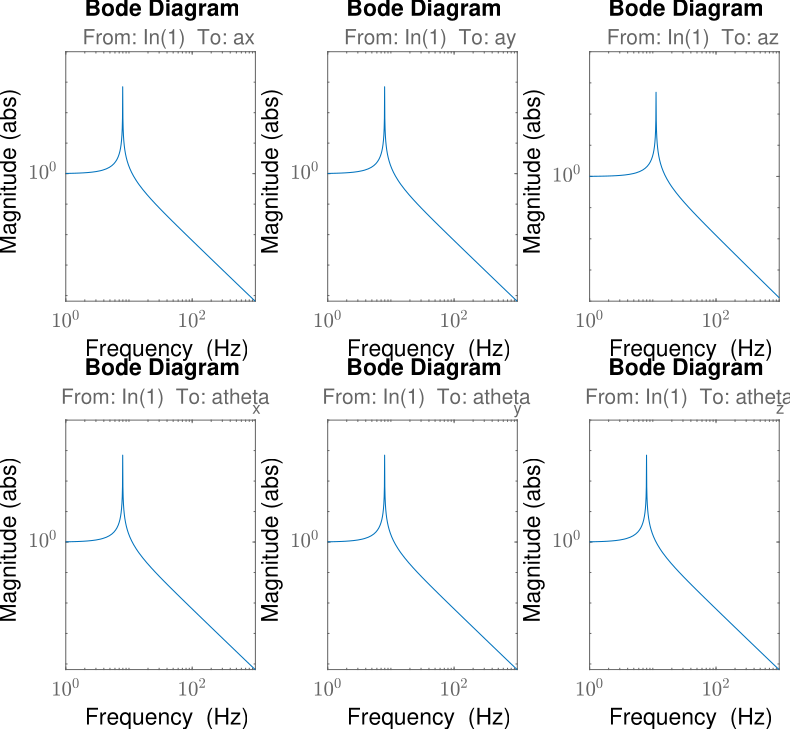

figure

subplot(231)

bodemag(TR(1,1),TRcen(1,1),TRsvd(1,1),opts)

legend('OL','Centralized','SVD')

subplot(232)

bodemag(TR(2,2),TRcen(2,2),TRsvd(2,2),opts)

legend('OL','Centralized','SVD')

subplot(233)

bodemag(TR(3,3),TRcen(3,3),TRsvd(3,3),opts)

legend('OL','Centralized','SVD')

subplot(234)

bodemag(TR(4,4),TRcen(4,4),TRsvd(4,4),opts)

legend('OL','Centralized','SVD')

subplot(235)

bodemag(TR(5,5),TRcen(5,5),TRsvd(5,5),opts)

legend('OL','Centralized','SVD')

subplot(236)

bodemag(TR(6,6),TRcen(6,6),TRsvd(6,6),opts)

legend('OL','Centralized','SVD')

Figure 16: Comparison of the obtained transmissibility for the centralized control and the SVD control