Control Requirements

Table of Contents

- 1. Goal

- 2. Simplify Model for the Nano-Hexapod

- 3. Motion of the micro-station

- 4. Values and Plant

- 5. Control using \(d\)

- 6. Control using \(F_m\)

- 7. Comparison

- 8. Control using \(x\)

- 9. Two degree of freedom control

- 10. Soft nano-hexapod

- 11. Compare Soft and Stiff nano-hexapods

- 12. Estimate the level of vibration

- 13. Requirements on the norm of closed-loop transfer functions

1 Goal

The goal here is to write clear specifications for the NASS.

This can then be used for the control synthesis and for the design of the nano-hexapod.

Ideal, specifications on the norm of closed loop transfer function should be written.

2 Simplify Model for the Nano-Hexapod

2.1 Model of the nano-hexapod

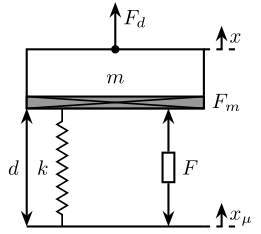

Let’s consider the simple mechanical system in Figure 1.

Figure 1: Simplified mechanical system for the nano-hexapod

The signals are described in table 1.

| Symbol | Meaning | |

|---|---|---|

| Exogenous Inputs | \(x_\mu\) | Motion of the $ν$-hexapod’s base |

| \(F_d\) | External Forces applied to the Payload | |

| \(r\) | Reference signal for tracking | |

| Exogenous Outputs | \(x\) | Absolute Motion of the Payload |

| Sensed Outputs | \(F_m\) | Force Sensors in each leg |

| \(d\) | Measured displacement of each leg | |

| \(x\) | Absolute Motion of the Payload | |

| Control Signals | \(F\) | Actuator Inputs |

For the nano-hexapod alone, we have the following equations: \[ \begin{align*} x &= \frac{1}{ms^2 + k} F + \frac{1}{ms^2 + k} F_d + \frac{k}{ms^2 + k} x_\mu \\ F_m &= \frac{ms^2}{ms^2 + k} F - \frac{k}{ms^2 + k} F_d + \frac{k m s^2}{ms^2 + k} x_\mu \\ d &= \frac{1}{ms^2 + k} F + \frac{1}{ms^2 + k} F_d - \frac{ms^2}{ms^2 + k} x_\mu \end{align*} \]

We can write the equations function of \(\omega_\nu = \sqrt{\frac{k}{m}}\): \[ \begin{align*} x &= \frac{1/k}{1 + \frac{s^2}{\omega_\nu^2}} F + \frac{1/k}{1 + \frac{s^2}{\omega_\nu^2}} F_d + \frac{1}{1 + \frac{s^2}{\omega_\nu^2}} x_\mu \\ F_m &= \frac{\frac{s^2}{\omega_\nu^2}}{1 + \frac{s^2}{\omega_\nu^2}} F - \frac{1}{1 + \frac{s^2}{\omega_\nu^2}} F_d + \frac{k \frac{s^2}{\omega_\nu^2}}{1 + \frac{s^2}{\omega_\nu^2}} x_\mu \\ d &= \frac{1/k}{1 + \frac{s^2}{\omega_\nu^2}} F + \frac{1/k}{1 + \frac{s^2}{\omega_\nu^2}} F_d - \frac{\frac{s^2}{\omega_\nu^2}}{1 + \frac{s^2}{\omega_\nu^2}} x_\mu \end{align*} \]

Assumptions:

- the forces applied by the nano-hexapod have no influence on the micro-station, specifically on the displacement of the top platform of the micro-hexapod.

This means that the nano-hexapod can be considered separately from the micro-station and that the motion \(x_\mu\) is imposed and considered as an external input.

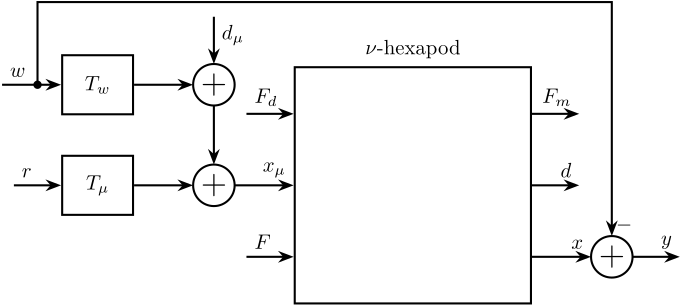

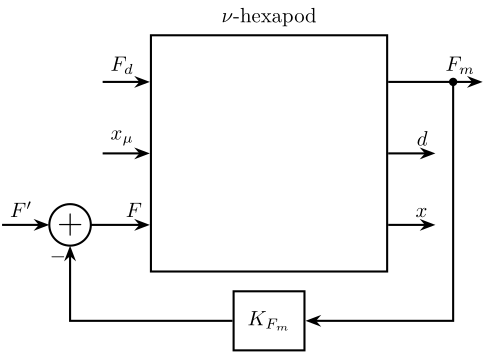

The nano-hexapod can thus be represented as in Figure 2.

Figure 2: Block representation of the nano-hexapod

2.2 How to include Ground Motion in the model?

What we measure is not the absolute motion \(x\), but the relative motion \(x - w\) where \(w\) is the motion of the granite.

Also, \(w\) induces some motion \(x_\mu\) through the transmissibility of the micro-station.

3 Motion of the micro-station

As explained, we consider \(x_\mu\) as an external input (\(F\) has no influence on \(x_\mu\)).

\(x_\mu\) is the motion of the micro-station’s top platform due to the motion of each stage of the micro-station.

We consider that \(x_\mu\) has the following form: \[ x_\mu = T_\mu r + d_\mu \] where:

- \(T_\mu r\) corresponds to the response of the stages due to the reference \(r\)

- \(d_\mu\) is the motion of the hexapod due to all the vibrations of the stages

\(T_\mu\) can be considered to be a low pass filter with a bandwidth corresponding approximatively to the bandwidth of the micro-station’s stages. To simplify, we can consider \(T_\mu\) to be a first order low pass filter: \[ T_\mu = \frac{1}{1 + s/\omega_\mu} \] where \(\omega_\mu\) corresponds to the tracking speed of the micro-station.

What is important to note is that while \(x_\mu\) is viewed as a perturbation from the nano-hexapod point of view, \(x_\mu\) does depend on the reference signal \(r\).

Also, here, we suppose that the granite is not moving.

If we now include the motion of the granite \(w\), we obtain the block diagram shown in Figure 4.

Figure 4: Ground Motion \(w\) included

\(T_w\) is the mechanical transmissibility of the micro-station. We can approximate this transfer function by a second order low pass filter: \[ T_w = \frac{1}{1 + 2 \xi s/\omega_0 + s^2/\omega_0^2} \]

4 Values and Plant

4.1 Definition of the values

Let’s define the mass and stiffness of the nano-hexapod.

m = 50; % [kg] k = 1e7; % [N/m]

Let’s define the Plant as shown in Figure 2:

Gn = 1/(m*s^2 + k)*[-k, k*m*s^2, m*s^2; 1, -m*s^2, 1; 1, k, 1]; Gn.InputName = {'Fd', 'xmu', 'F'}; Gn.OutputName = {'Fm', 'd', 'x'};

Now, define the transmissibility transfer function \(T_\mu\) corresponding to the micro-station motion.

wmu = 2*pi*50; % [rad/s] Tmu = 1/(1 + s/wmu); Tmu.InputName = {'r1'}; Tmu.OutputName = {'ymu'};

w0 = 2*pi*40; xi = 0.5; Tw = 1/(1 + 2*xi*s/w0 + s^2/w0^2); Tw.InputName = {'w1'}; Tw.OutputName = {'dw'};

We add the fact that \(x_\mu = d_\mu + T_\mu r + T_w w\):

Wsplit = [tf(1); tf(1)];

Wsplit.InputName = {'w'};

Wsplit.OutputName = {'w1', 'w2'};

S = sumblk('xmu = ymu + dmu + dw');

Sw = sumblk('y = x - w2');

Gpz = connect(Gn, S, Wsplit, Tw, Tmu, Sw, {'Fd', 'dmu', 'r1', 'F', 'w'}, {'Fm', 'd', 'y'});

5 Control using \(d\)

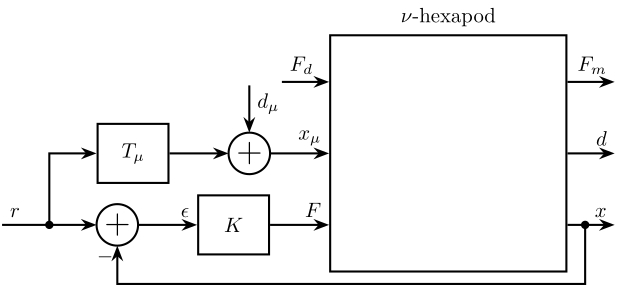

5.1 Control Architecture

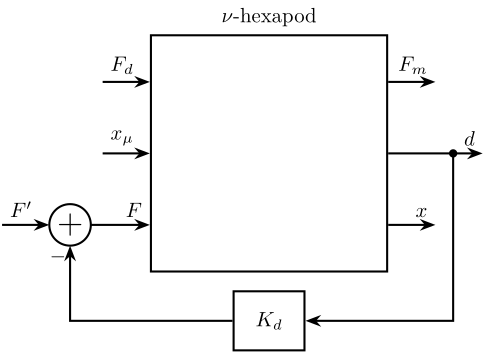

Let’s consider a feedback loop using \(d\) as shown in Figure 5.

Figure 5: Feedback diagram using \(d\)

5.2 Analytical Analysis

Let’s apply a direct velocity feedback by deriving \(d\): \[ F = F^\prime - g s d \]

Thus: \[ d = \frac{1}{ms^2 + gs + k} F^\prime + \frac{1}{ms^2 + gs + k} F_d - \frac{ms^2}{ms^2 + gs + k} x_\mu \]

\[ F = \frac{ms^2 + k}{ms^2 + gs + k} F^\prime - \frac{gs}{ms^2 + gs + k} F_d + \frac{mgs^3}{ms^2 + gs + k} x_\mu \]

and \[ x = \frac{1}{ms^2 + k} (\frac{ms^2 + k}{ms^2 + gs + k} F^\prime - \frac{gs}{ms^2 + gs + k} F_d + \frac{mgs^3}{ms^2 + gs + k} x_\mu) + \frac{1}{ms^2 + k} F_d + \frac{k}{ms^2 + k} x_\mu \]

\[ x = \frac{ms^2 + k}{(ms^2 + k) (ms^2 + gs + k)} F^\prime + \frac{ms^2 + k}{(ms^2 + k) (ms^2 + gs + k)} F_d + \frac{mgs^3 + k(ms^2 + gs + k)}{(ms^2 + k) (ms^2 + gs + k)} x_\mu \]

And we finally obtain: \[ x = \frac{1}{ms^2 + gs + k} F^\prime + \frac{1}{ms^2 + gs + k} F_d + \frac{gs + k}{ms^2 + gs + k} x_\mu \]

K_dvf = 2*sqrt(k*m)*s; K_dvf.InputName = {'d'}; K_dvf.OutputName = {'F'}; Gpz_dvf = feedback(Gpz, K_dvf, 'name');

Now let’s consider that \(x_\mu = d_\mu + T_\mu r\)

\[ x = \frac{1}{ms^2 + gs + k} F^\prime + \frac{1}{ms^2 + gs + k} F_d + \frac{gs + k}{ms^2 + gs + k} d_\mu + T_\mu \frac{gs + k}{ms^2 + gs + k} r \]

And \(\epsilon = r - x\): \[ \epsilon = \frac{1}{ms^2 + gs + k} F^\prime + \frac{1}{ms^2 + gs + k} F_d + \frac{gs + k}{ms^2 + gs + k} d_\mu + \frac{ms^2 + gs + k - T_\mu (gs + k)}{ms^2 + gs + k} r \]

\[ \epsilon = \frac{1}{ms^2 + gs + k} F^\prime + \frac{1}{ms^2 + gs + k} F_d + \frac{gs + k}{ms^2 + gs + k} d_\mu + \frac{ms^2 - S_\mu(gs + k)}{ms^2 + gs + k} r \]

6 Control using \(F_m\)

6.1 Control Architecture

Let’s consider a feedback loop using \(d\) as shown in Figure 5.

Figure 6: Feedback diagram using \(F_m\)

6.2 Pure Integrator

Let’s apply integral force feedback by integration \(F_m\): \[ F = F^\prime - \frac{g}{s} F_m \]

And we finally obtain: \[ x = \frac{1}{ms^2 + mgs + k} F^\prime + \frac{1 + \frac{g}{s}}{ms^2 + mgs + k} F_d + \frac{k}{ms^2 + mgs + k} x_\mu \]

K_iff = 2*sqrt(k/m)/s; K_iff.InputName = {'Fm'}; K_iff.OutputName = {'F'}; Gpz_iff = feedback(Gpz, K_iff, 'name');

Now let’s consider that \(x_\mu = d_\mu + T_\mu r\)

\[ x = \frac{1}{ms^2 + mgs + k} F^\prime + \frac{1 + \frac{g}{s}}{ms^2 + mgs + k} F_d + \frac{k}{ms^2 + mgs + k} d_\mu + \frac{T_\mu k}{ms^2 + mgs + k} r \]

And \(\epsilon = r - x\): \[ \epsilon = \frac{1}{ms^2 + mgs + k} F^\prime + \frac{1 + \frac{g}{s}}{ms^2 + mgs + k} F_d + \frac{k}{ms^2 + mgs + k} d_\mu + \frac{ms^2 + mgs + k - T_\mu k}{ms^2 + mgs + k} r \]

\[ \epsilon = \frac{1}{ms^2 + mgs + k} F^\prime + \frac{1 + \frac{g}{s}}{ms^2 + mgs + k} F_d + \frac{k}{ms^2 + mgs + k} d_\mu + \frac{ms^2 + mgs + S_\mu k}{ms^2 + mgs + k} r \]

6.3 Low pass filter

Instead of a pure integrator, let’s use a low pass filter with a cut-off frequency above the bandwidth of the micro-station \(\omega_mu\)

% K_iff = (2*sqrt(k/m)/(2*wmu))*(1/(1 + s/(2*wmu))); % K_iff.InputName = {'Fm'}; % K_iff.OutputName = {'F'}; % Gpz_iff = feedback(Gpz, K_iff, 'name');

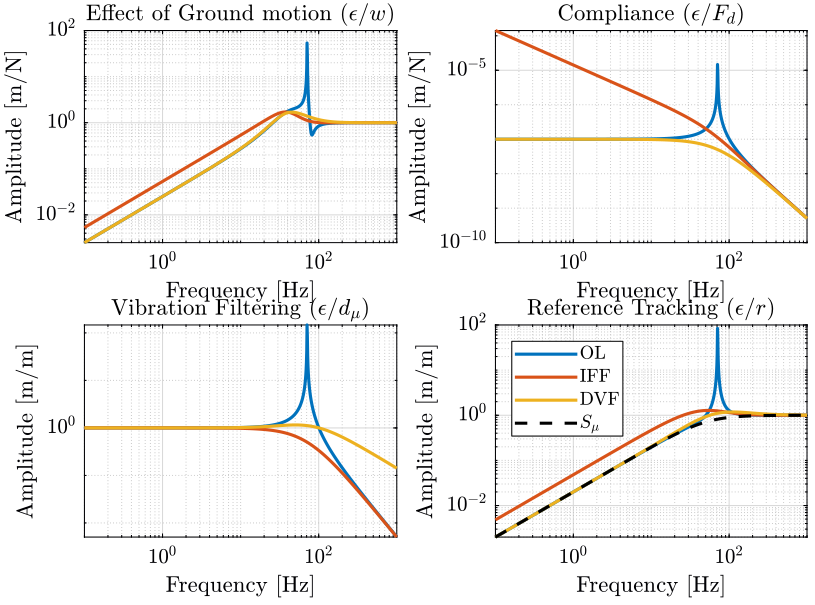

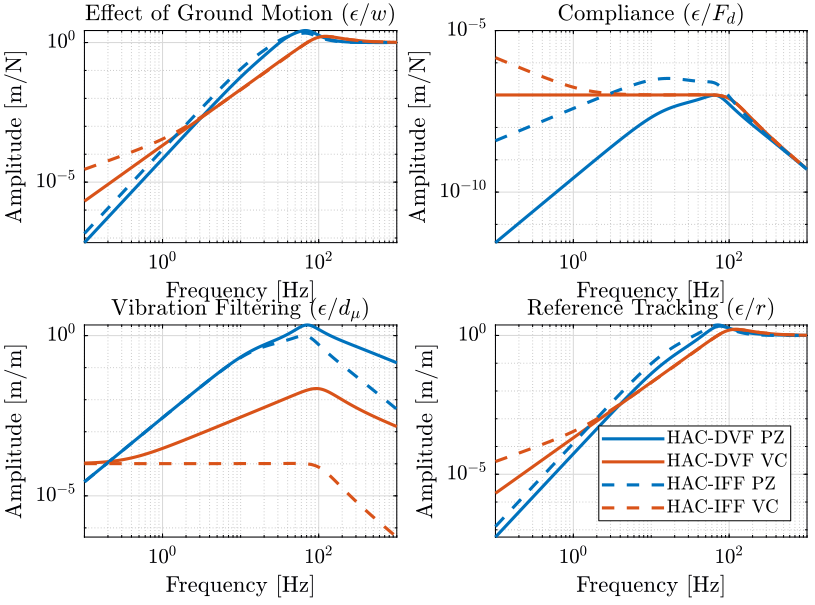

7 Comparison

8 Control using \(x\)

8.1 Analytical analysis

Let’s first consider that only the output \(x\) is used for feedback (Figure 8)

Figure 8: Feedback diagram using \(x\)

We then have: \[ \epsilon &= r - G_{\frac{x}{F}} K \epsilon - G_{\frac{x}{F_d}} F_d - G_{\frac{x}{x_\mu}} d_\mu - G_{\frac{x}{x_\mu}} T_\mu r \]

And then:

\[ \epsilon = \frac{-G_{\frac{x}{F_d}}}{1 + G_{\frac{x}{F}}K} F_d + \frac{-G_{\frac{x}{x_\mu}}}{1 + G_{\frac{x}{F}}K} d_\mu + \frac{1 - G_{\frac{x}{x_\mu}} T_\mu}{1 + G_{\frac{x}{F}}K} r \]

With \(S = \frac{1}{1 + G_{\frac{x}{F}} K}\), we have: \[ \epsilon = - S G_{\frac{x}{F_d}} F_d - S G_{\frac{x}{x_\mu}} d_\mu + S (1 - G_{\frac{x}{x_\mu}} T_\mu) r \]

We have 3 terms that we would like to have small by design:

- \(G_{\frac{x}{F_d}} = \frac{1}{ms^2 + k}\): thus \(k\) and \(m\) should be high to lower the effect of direct forces \(F_d\)

- \(G_{\frac{x}{x_\mu}} = \frac{k}{ms^2 + k} = \frac{1}{1 + \frac{s^2}{\omega_\nu^2}}\): \(\omega_\nu\) should be small enough such that it filters out the vibrations of the micro-station

- \(1 - G_{\frac{x}{x_\mu}} T_\mu\)

\[ 1 - G_{\frac{x}{x_\mu}} T_\mu = 1 - \frac{1}{1 + \frac{s^2}{\omega_\nu^2}} T_\mu \]

We can approximate \(T_\mu \approx \frac{1}{1 + \frac{s}{\omega_\mu}}\) to have:

\begin{align*} 1 - G_{\frac{x}{x_\mu}} T_\mu &= 1 - \frac{1}{1 + \frac{s^2}{\omega_\nu^2}} \frac{1}{1 + \frac{s}{\omega_\mu}} \\ &\approx \frac{\frac{s}{\omega_\mu}}{1 + \frac{s}{\omega_\mu}} = S_\mu \text{ if } \omega_\nu > \omega_\mu \\ &\approx \frac{\frac{s^2}{\omega_\nu^2}}{1 + \frac{s^2}{\omega_\nu^2}} = \text{ if } \omega_\nu < \omega_\mu \end{align*}In our case, we have \(\omega_\nu > \omega_\mu\) and thus we cannot lower this term.

Some implications on the design are summarized on table 2.

| Exogenous Outputs | Design recommendation |

|---|---|

| \(F_d\) | high \(k\), high \(m\) |

| \(d_\mu\) | low \(k\), high \(m\) |

| \(r\) | no influence if \(\omega_\nu > \omega_\mu\) |

8.2 Control implementation

Controller for the damped plant using DVF.

wb = 2*pi*50; % control bandwidth [rad/s] % Lead h = 2.0; wz = wb/h; % [rad/s] wp = wb*h; % [rad/s] H = 1/h*(1 + s/wz)/(1 + s/wp); % Integrator until 10Hz Hi = (1 + s/2/pi/10)/(s/2/pi/10); K = Hi*H*(1/s); Kpz_dvf = K/abs(freqresp(K*Gpz_dvf('y', 'F'), wb)); Kpz_dvf.InputName = {'e'}; Kpz_dvf.OutputName = {'F'};

Controller for the damped plant using IFF.

wb = 2*pi*50; % control bandwidth [rad/s] % Lead h = 2.0; wz = wb/h; % [rad/s] wp = wb*h; % [rad/s] H = 1/h*(1 + s/wz)/(1 + s/wp); % Integrator until 10Hz Hi = (1 + s/2/pi/10)/(s/2/pi/10); K = Hi*H*(1/s); Kpz_iff = K/abs(freqresp(K*Gpz_iff('y', 'F'), wb)); Kpz_iff.InputName = {'e'}; Kpz_iff.OutputName = {'F'};

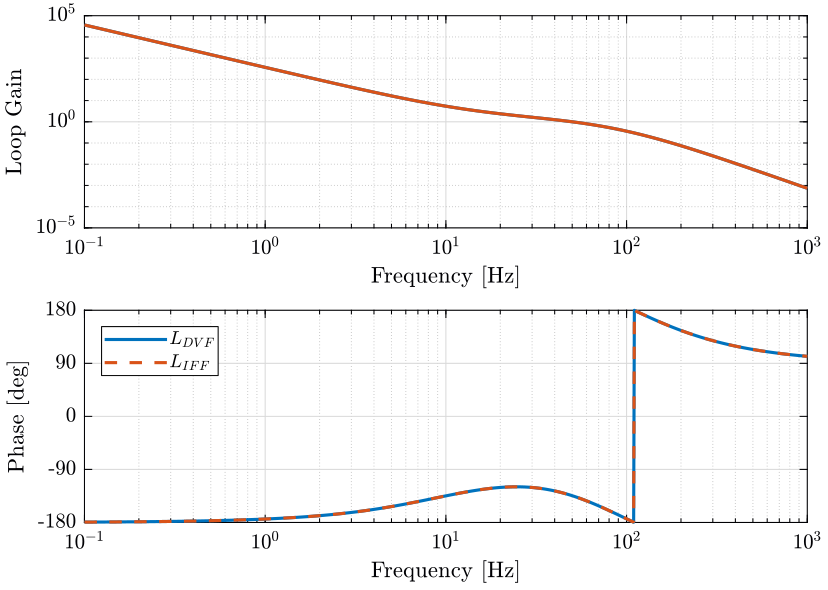

Loop gain

Let’s connect all the systems as shown in Figure 8.

Sfb = sumblk('e = r2 - y'); R = [tf(1); tf(1)]; R.InputName = {'r'}; R.OutputName = {'r1', 'r2'}; Gpz_fb_dvf = connect(Gpz_dvf, Kpz_dvf, R, Sfb, {'r', 'dmu', 'Fd', 'w'}, {'y', 'e', 'Fm', 'd'}); Gpz_fb_iff = connect(Gpz_iff, Kpz_iff, R, Sfb, {'r', 'dmu', 'Fd', 'w'}, {'y', 'e', 'Fm', 'd'});

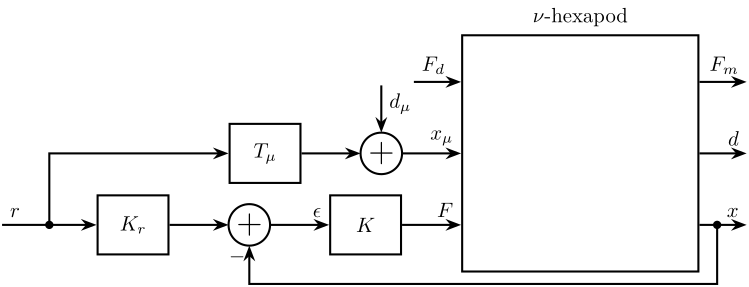

9 Two degree of freedom control

Let’s try to implement the control architecture shown in Figure 11.

The pre-filter \(K_r\) is added in order to improve the reference tracking performances.

Figure 11: Two degrees of freedom feedback control

In order to design the pre-filter \(K_r\), the dynamics of the system should be known quite precisely (Dynamics of the nano-hexapod + \(T_\mu\)).

Krpz = inv(Gpz_fb('y', 'r')); Krpz.InputName = {'r2'}; Krpz.OutputName = {'r3'};

Sfb = sumblk('e = r3 - y'); R = [tf(1); tf(1)]; R.InputName = {'r'}; R.OutputName = {'r1', 'r2'}; Gpz_2dof = connect(Gpz_dvf, Krpz, Kpz, R, Sfb, {'r', 'dmu', 'Fd', 'w'}, {'y', 'e', 'Fm', 'd'});

10 Soft nano-hexapod

m = 50; % [kg] k = 1e3; % [N/m] Gn = 1/(m*s^2 + k)*[-k, k*m*s^2, m*s^2; 1, -m*s^2, 1; 1, k, 1]; Gn.InputName = {'Fd', 'xmu', 'F'}; Gn.OutputName = {'Fm', 'd', 'x'};

wmu = 2*pi*50; % [rad/s] Tmu = 1/(1 + s/wmu); Tmu.InputName = {'r1'}; Tmu.OutputName = {'ymu'};

w0 = 2*pi*40; xi = 0.5; Tw = 1/(1 + 2*xi*s/w0 + s^2/w0^2); Tw.InputName = {'w1'}; Tw.OutputName = {'dw'};

Wsplit = [tf(1); tf(1)];

Wsplit.InputName = {'w'};

Wsplit.OutputName = {'w1', 'w2'};

S = sumblk('xmu = ymu + dmu + dw');

Sw = sumblk('y = x - w2');

Gvc = connect(Gn, S, Wsplit, Tw, Tmu, Sw, {'Fd', 'dmu', 'r1', 'F', 'w'}, {'Fm', 'd', 'y'});

Kvc_dvf = 2*sqrt(k*m)*s; Kvc_dvf.InputName = {'d'}; Kvc_dvf.OutputName = {'F'}; Gvc_dvf = feedback(Gvc, Kvc_dvf, 'name'); Kvc_iff = 2*sqrt(k/m)/s; Kvc_iff.InputName = {'Fm'}; Kvc_iff.OutputName = {'F'}; Gvc_iff = feedback(Gvc, Kvc_iff, 'name');

wb = 2*pi*100; % control bandwidth [rad/s] % Lead h = 2.0; wz = wb/h; % [rad/s] wp = wb*h; % [rad/s] H = 1/h*(1 + s/wz)/(1 + s/wp); Kvc_dvf = H/abs(freqresp(H*Gvc_dvf('y', 'F'), wb)); Kvc_dvf.InputName = {'e'}; Kvc_dvf.OutputName = {'F'}; Kvc_iff = H/abs(freqresp(H*Gvc_iff('y', 'F'), wb)); Kvc_iff.InputName = {'e'}; Kvc_iff.OutputName = {'F'};

Sfb = sumblk('e = r2 - y'); R = [tf(1); tf(1)]; R.InputName = {'r'}; R.OutputName = {'r1', 'r2'}; Gvc_fb_dvf = connect(Gvc_dvf, Kvc_dvf, R, Sfb, {'r', 'dmu', 'Fd', 'w'}, {'y', 'e', 'Fm', 'd'}); Gvc_fb_iff = connect(Gvc_iff, Kvc_iff, R, Sfb, {'r', 'dmu', 'Fd', 'w'}, {'y', 'e', 'Fm', 'd'});

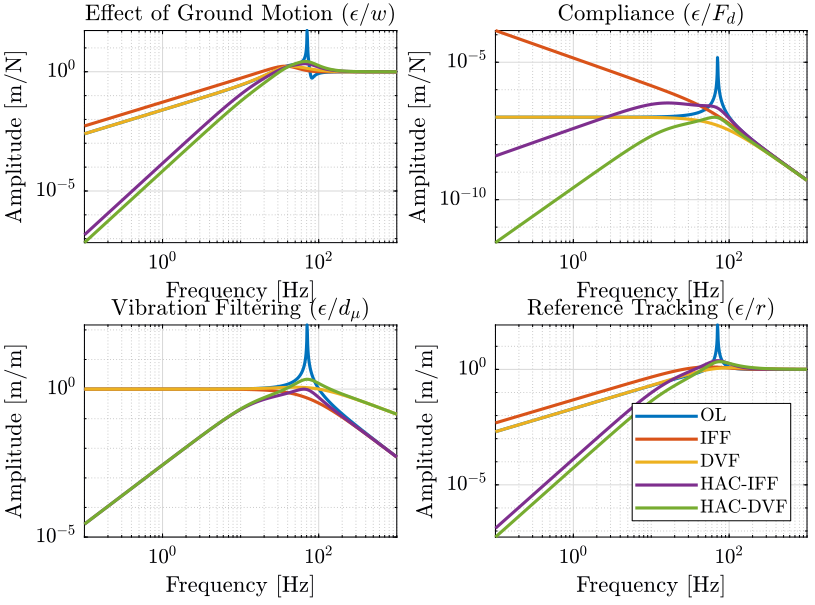

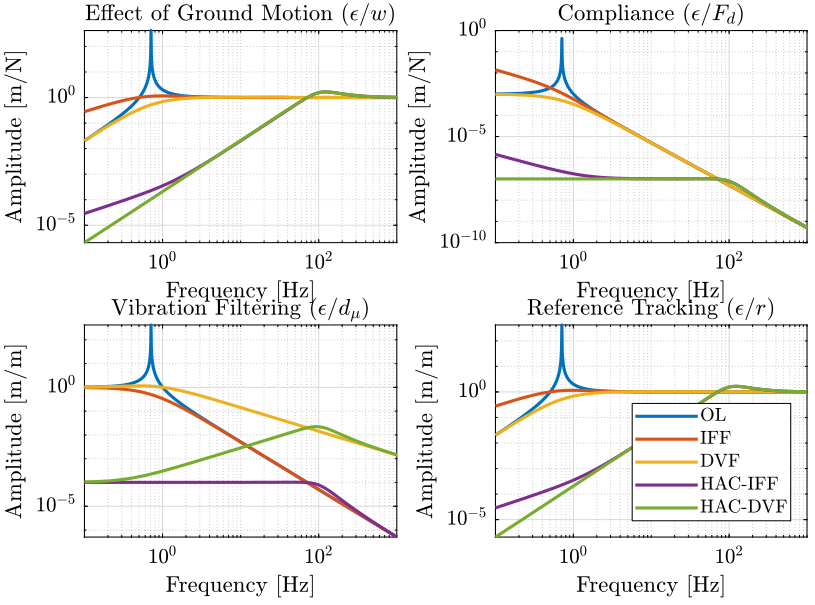

11 Compare Soft and Stiff nano-hexapods

12 Estimate the level of vibration

gm = load('./mat/psd_gm.mat', 'f', 'psd_gm'); rz = load('./mat/pxsp_r.mat', 'f', 'pxsp_r'); tyz = load('./mat/pxz_ty_r.mat', 'f', 'pxz_ty_r');

x_pz = sqrt(abs(squeeze(freqresp(Gpz_fb_iff('y', 'dmu'), f, 'Hz'))).^2.*(psd_rz + psd_ty) + abs(squeeze(freqresp(Gpz_fb_iff('y', 'w'), f, 'Hz'))).^2.*(psd_gm)); x_vc = sqrt(abs(squeeze(freqresp(Gvc_fb_iff('y', 'dmu'), f, 'Hz'))).^2.*(psd_rz + psd_ty) + abs(squeeze(freqresp(Gvc_fb_iff('y', 'w'), f, 'Hz'))).^2.*(psd_gm));

13 Requirements on the norm of closed-loop transfer functions

| reference tracking | \(\epsilon/r\) | -120dB at 1Hz |

| vibration isolation | \(x/x_\mu\) | -60dB above 10Hz |

| compliance | \(x/F_d\) |