Amplified Piezoelectric Stack Actuator

Table of Contents

The presented model is based on (Souleille et al. 2018).

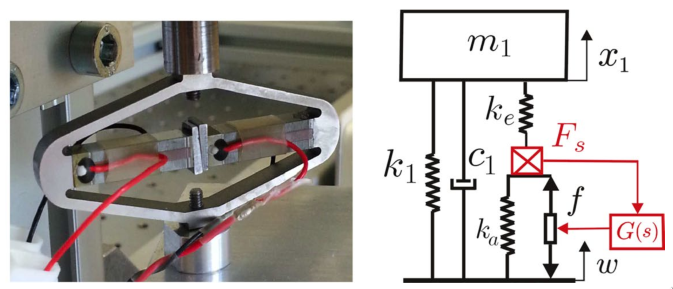

The model represents the amplified piezo APA100M from Cedrat-Technologies (Figure 1). The parameters are shown in the table below.

Figure 1: Picture of an APA100M from Cedrat Technologies. Simplified model of a one DoF payload mounted on such isolator

| Value | Meaning | |

|---|---|---|

| \(m\) | \(1\,[kg]\) | Payload mass |

| \(k_e\) | \(4.8\,[N/\mu m]\) | Stiffness used to adjust the pole of the isolator |

| \(k_1\) | \(0.96\,[N/\mu m]\) | Stiffness of the metallic suspension when the stack is removed |

| \(k_a\) | \(65\,[N/\mu m]\) | Stiffness of the actuator |

| \(c_1\) | \(10\,[N/(m/s)]\) | Added viscous damping |

1 Simplified Model

1.1 Parameters

m = 1; % [kg] ke = 4.8e6; % [N/m] ce = 5; % [N/(m/s)] me = 0.001; % [kg] k1 = 0.96e6; % [N/m] c1 = 10; % [N/(m/s)] ka = 65e6; % [N/m] ca = 5; % [N/(m/s)] ma = 0.001; % [kg] h = 0.2; % [m]

IFF Controller:

Kiff = -8000/s;

1.2 Identification

Identification in open-loop.

%% Name of the Simulink File mdl = 'amplified_piezo_model'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/w'], 1, 'openinput'); io_i = io_i + 1; % Base Motion io(io_i) = linio([mdl, '/f'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/F'], 1, 'openinput'); io_i = io_i + 1; % External Force io(io_i) = linio([mdl, '/Fs'], 3, 'openoutput'); io_i = io_i + 1; % Force Sensors io(io_i) = linio([mdl, '/x1'], 1, 'openoutput'); io_i = io_i + 1; % Mass displacement G = linearize(mdl, io, 0); G.InputName = {'w', 'f', 'F'}; G.OutputName = {'Fs', 'x1'};

Identification in closed-loop.

%% Name of the Simulink File mdl = 'amplified_piezo_model'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/w'], 1, 'input'); io_i = io_i + 1; % Base Motion io(io_i) = linio([mdl, '/f'], 1, 'input'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/F'], 1, 'input'); io_i = io_i + 1; % External Force io(io_i) = linio([mdl, '/Fs'], 3, 'output'); io_i = io_i + 1; % Force Sensors io(io_i) = linio([mdl, '/x1'], 1, 'output'); io_i = io_i + 1; % Mass displacement Giff = linearize(mdl, io, 0); Giff.InputName = {'w', 'f', 'F'}; Giff.OutputName = {'Fs', 'x1'};

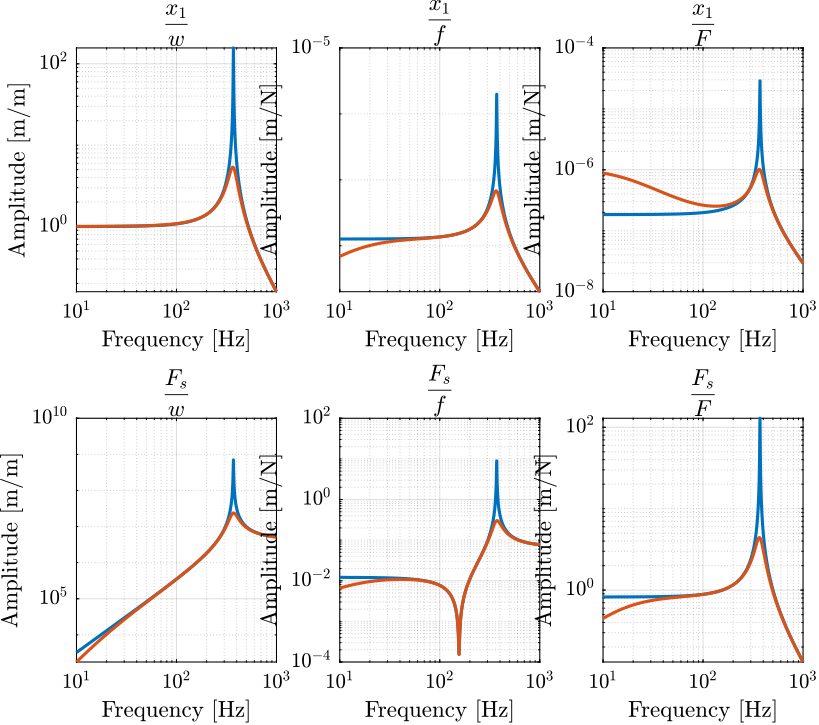

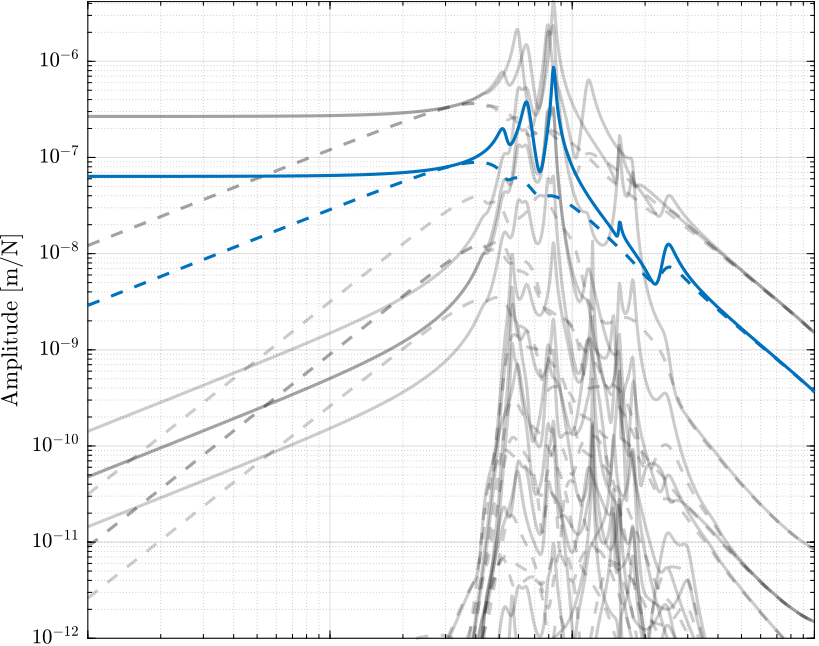

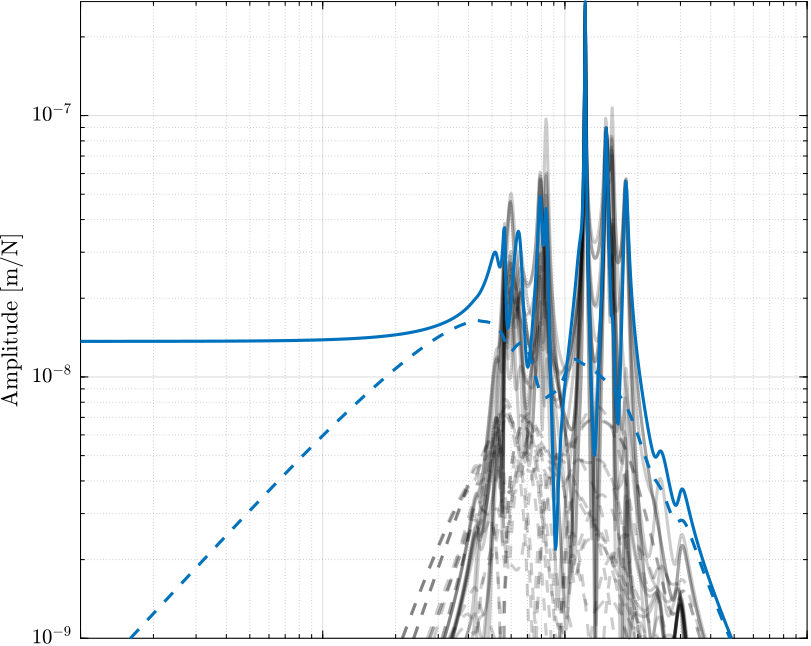

Figure 2: Matrix of transfer functions from input to output in open loop (blue) and closed loop (red)

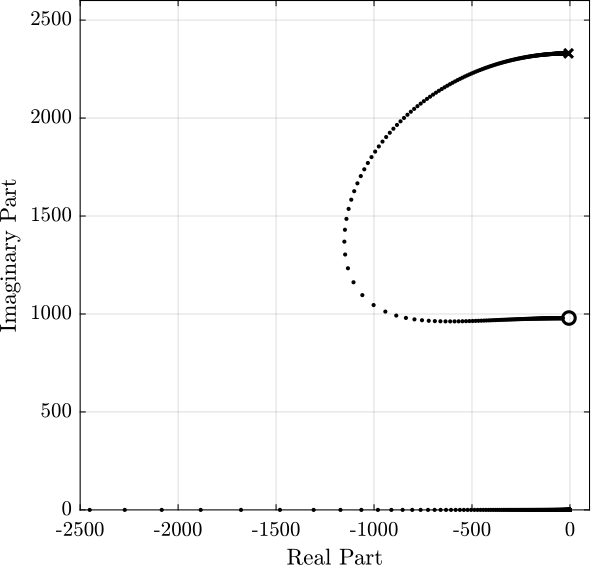

1.3 Root Locus

Figure 3: Root Locus

1.4 Analytical Model

If we apply the Newton’s second law of motion on the top mass, we obtain: \[ ms^2 x_1 = F + k_1 (w - x_1) + k_e (x_e - x_1) \]

Then, we can write that the measured force \(F_s\) is equal to: \[ F_s = k_a(w - x_e) + f = -k_e (x_1 - x_e) \] which gives: \[ x_e = \frac{k_a}{k_e + k_a} w + \frac{1}{k_e + k_a} f + \frac{k_e}{k_e + k_a} x_1 \]

Re-injecting that into the previous equations gives: \[ x_1 = F \frac{1}{ms^2 + k_1 + \frac{k_e k_a}{k_e + k_a}} + w \frac{k_1 + \frac{k_e k_a}{k_e + k_a}}{ms^2 + k_1 + \frac{k_e k_a}{k_e + k_a}} + f \frac{\frac{k_e}{k_e + k_a}}{ms^2 + k_1 + \frac{k_e k_a}{k_e + k_a}} \] \[ F_s = - F \frac{\frac{k_e k_a}{k_e + k_a}}{ms^2 + k_1 + \frac{k_e k_a}{k_e + k_a}} + w \frac{k_e k_a}{k_e + k_a} \Big( \frac{ms^2}{ms^2 + k_1 + \frac{k_e k_a}{k_e + k_a}} \Big) - f \frac{k_e}{k_e + k_a} \Big( \frac{ms^2 + k_1}{ms^2 + k_1 + \frac{k_e k_a}{k_e + k_a}} \Big) \]

Ga = 1/(m*s^2 + k1 + ke*ka/(ke + ka)) * ... [ 1 , k1 + ke*ka/(ke + ka) , ke/(ke + ka) ; -ke*ka/(ke + ka), ke*ka/(ke + ka)*m*s^2 , -ke/(ke+ka)*(m*s^2 + k1)]; Ga.InputName = {'F', 'w', 'f'}; Ga.OutputName = {'x1', 'Fs'};

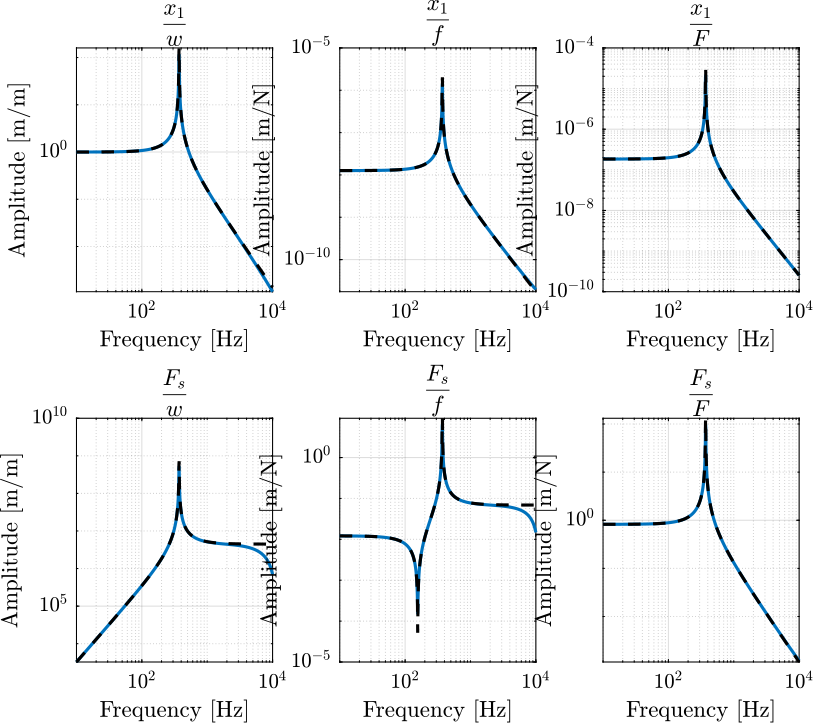

Figure 4: Comparison of the Identified Simscape Dynamics (solid) and the Analytical Model (dashed)

1.5 Analytical Analysis

For Integral Force Feedback Control, the plant is: \[ \frac{F_s}{f} = \frac{k_e}{k_e + k_a} \Big( \frac{ms^2 + k_1}{ms^2 + k_1 + \frac{k_e k_a}{k_e + k_a}} \Big) \]

As high frequency, this converge to: \[ \frac{F_s}{f} \underset{\omega\to\infty}{\longrightarrow} \frac{k_e}{k_e + k_a} \] And at low frequency: \[ \frac{F_s}{f} \underset{\omega\to 0}{\longrightarrow} \frac{k_e}{k_e + k_a} \frac{k_1}{k_1 + \frac{k_e k_a}{k_e + k_a}} \]

It has two complex conjugate zeros at: \[ z = \pm j \sqrt{\frac{k_1}{m}} \] And two complex conjugate poles at: \[ p = \pm j \sqrt{\frac{k_1 + \frac{k_e k_a}{k_e + k_a}}{m}} \]

If maximal damping is to be attained with IFF, the distance between the zero and the pole is to be maximized. Thus, we wish to maximize \(p/z\), which is equivalent as to minimize \(k_1\) and have \(k_e \approx k_a\) (supposing \(k_e + k_a \approx \text{cst}\)).

m = 1;

k1 = 1e6;

ka = 1e6;

ke = 1e6;

Giff.InputName = {'f'};

Giff.OutputName = {'Fs'};

2 Rotating X-Y platform

This analysis gave rise to a paper (Dehaeze and Collette 2020).

2.1 Parameters

m = 1; % [kg] ke = 4.8e6; % [N/m] ce = 5; % [N/(m/s)] me = 0.001; % [kg] k1 = 0.96e6; % [N/m] c1 = 10; % [N/(m/s)] ka = 65e6; % [N/m] ca = 5; % [N/(m/s)] ma = 0.001; % [kg] h = 0.2; % [m]

Kiff = tf(0);

2.2 Identification

Rotating speed in rad/s:

Ws = 2*pi*[0, 1, 10, 100];

Gs = {zeros(length(Ws), 1)};

Identification in open-loop.

%% Name of the Simulink File mdl = 'amplified_piezo_xy_rotating_stage'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/fx'], 1, 'openinput'); io_i = io_i + 1; io(io_i) = linio([mdl, '/fy'], 1, 'openinput'); io_i = io_i + 1; io(io_i) = linio([mdl, '/Fs'], 1, 'openoutput'); io_i = io_i + 1; io(io_i) = linio([mdl, '/Fs'], 2, 'openoutput'); io_i = io_i + 1; for i = 1:length(Ws) ws = Ws(i); G = linearize(mdl, io, 0); G.InputName = {'fx', 'fy'}; G.OutputName = {'Fsx', 'Fsy'}; Gs(i) = {G}; end

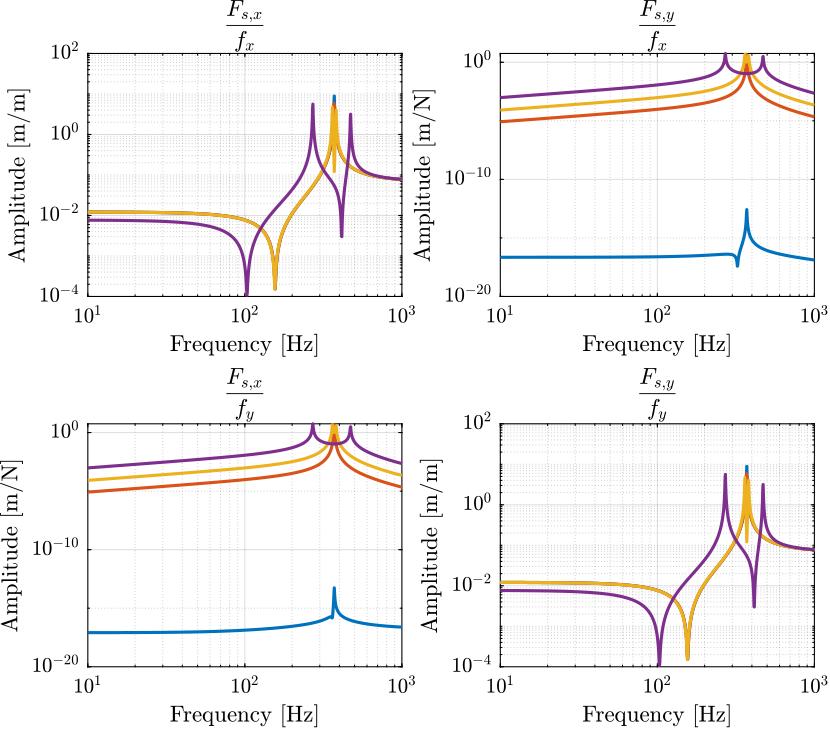

Figure 5: Transfer function matrix from forces to force sensors for multiple rotation speed

2.3 Root Locus

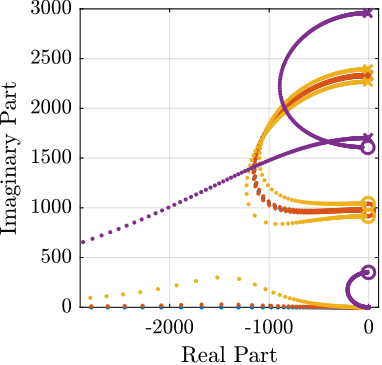

Figure 6: Root locus for 3 rotating speed

2.4 Analysis

The negative stiffness induced by the rotation is equal to \(m \omega_0^2\). Thus, the maximum rotation speed where IFF can be applied is: \[ \omega_\text{max} = \sqrt{\frac{k_1}{m}} \approx 156\,[Hz] \]

Let’s verify that.

Ws = 2*pi*[140, 160];

Identification

%% Name of the Simulink File mdl = 'amplified_piezo_xy_rotating_stage'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/fx'], 1, 'openinput'); io_i = io_i + 1; io(io_i) = linio([mdl, '/fy'], 1, 'openinput'); io_i = io_i + 1; io(io_i) = linio([mdl, '/Fs'], 1, 'openoutput'); io_i = io_i + 1; io(io_i) = linio([mdl, '/Fs'], 2, 'openoutput'); io_i = io_i + 1; for i = 1:length(Ws) ws = Ws(i); G = linearize(mdl, io, 0); G.InputName = {'fx', 'fy'}; G.OutputName = {'Fsx', 'Fsy'}; Gs(i) = {G}; end

Figure 7: Root Locus for the two considered rotation speed. For the red curve, the system is unstable.

3 Stewart Platform with Amplified Actuators

3.1 Initialization

initializeGround(); initializeGranite(); initializeTy(); initializeRy(); initializeRz(); initializeMicroHexapod(); initializeAxisc(); initializeMirror(); initializeSimscapeConfiguration(); initializeDisturbances('enable', false); initializeLoggingConfiguration('log', 'none'); initializeController('type', 'hac-iff');

We set the stiffness of the payload fixation:

Kp = 1e8; % [N/m]

3.2 APA-100 Amplified Actuator

3.2.1 Identification

K = tf(zeros(6)); Kiff = tf(zeros(6));

We identify the system for the following payload masses:

Ms = [1, 10, 50];

The nano-hexapod has the following leg’s stiffness and damping.

initializeNanoHexapod('actuator', 'amplified');

3.2.2 Controller Design

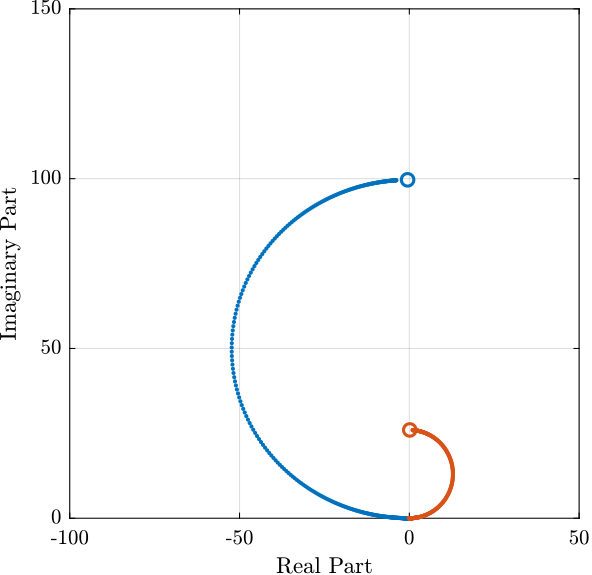

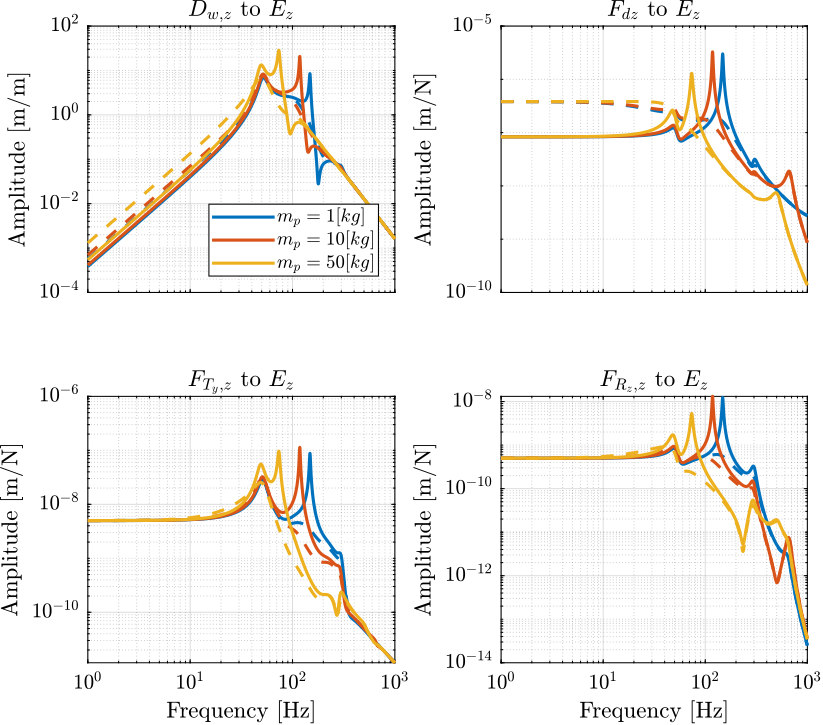

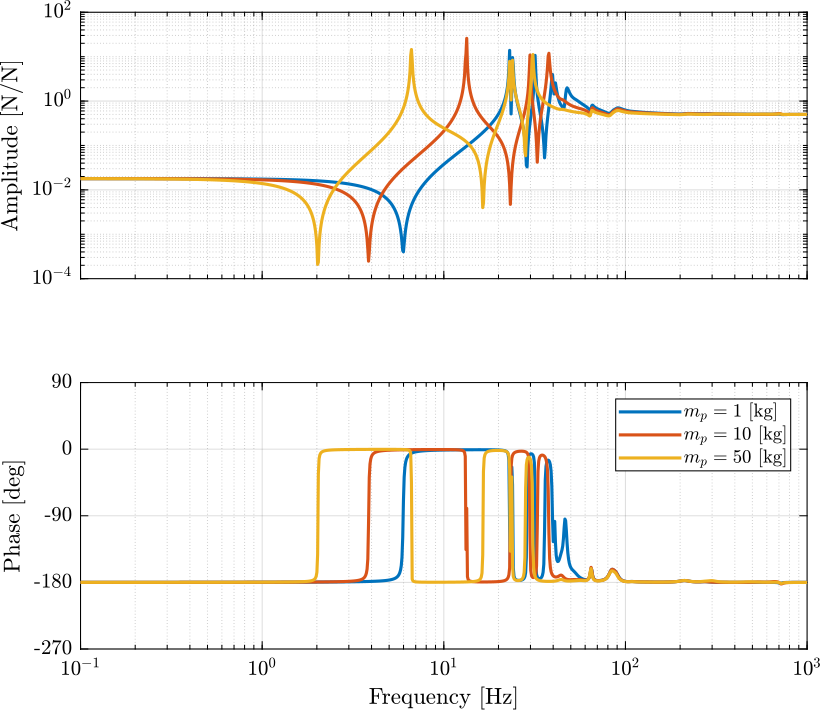

The loop gain for IFF is shown in Figure 8.

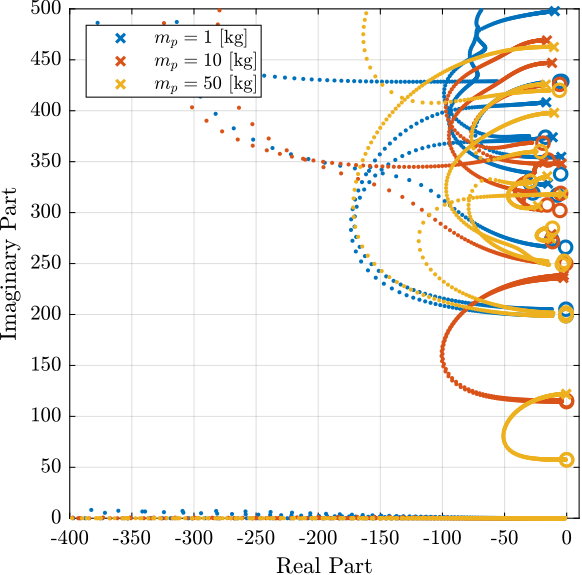

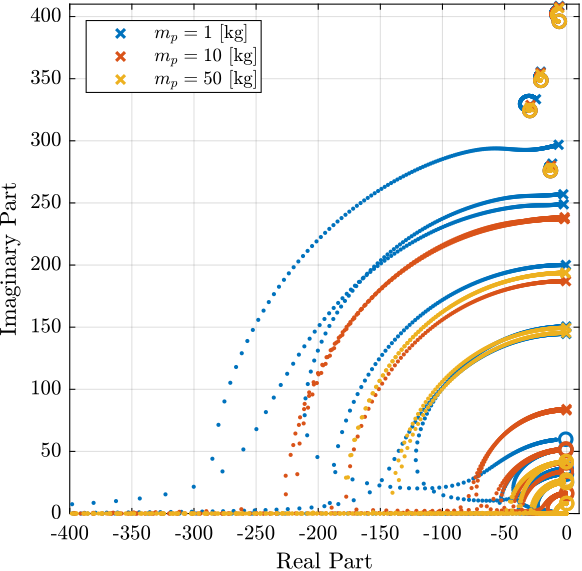

The corresponding root locus is shown in Figure 9.

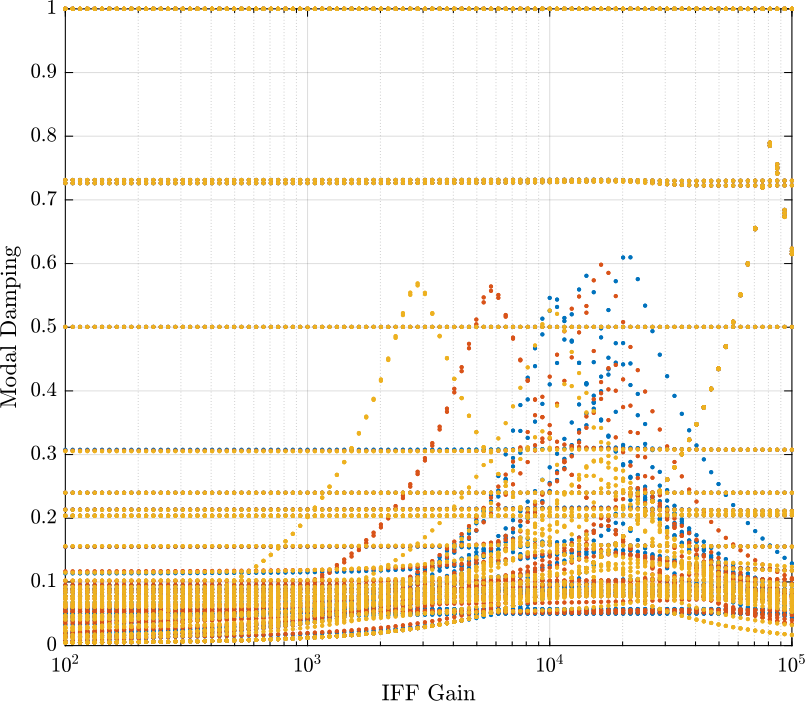

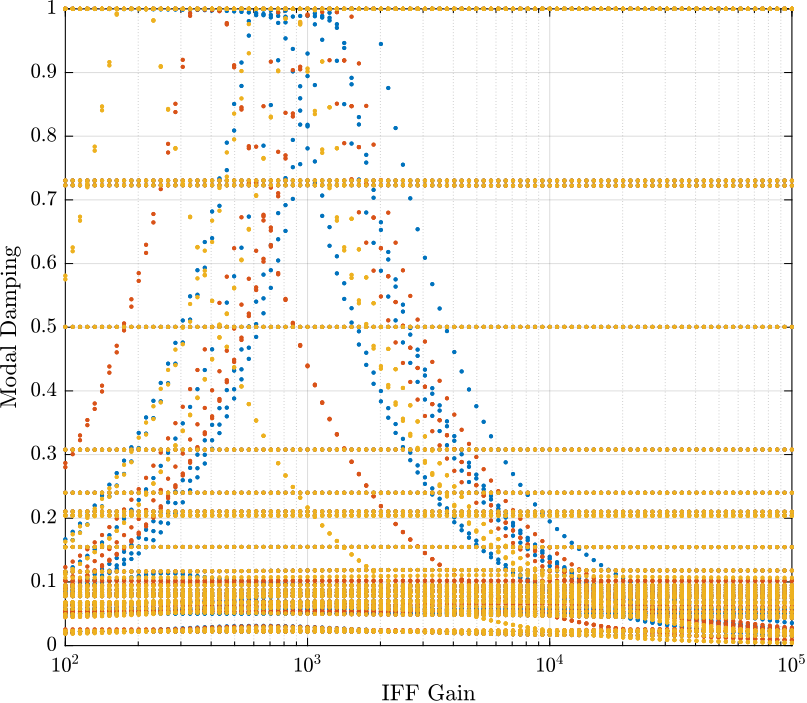

Finally, the damping as function of the gain is display in Figure 10.

Figure 8: Dynamics for the Integral Force Feedback for three payload masses

Figure 9: Root Locus for the IFF control for three payload masses

Figure 10: Damping ratio of the poles as a function of the IFF gain

The following controller for the Decentralized Integral Force Feedback is used:

Kiff = -1e4/s*eye(6);

3.2.3 Effect of the Low Authority Control on the Primary Plant

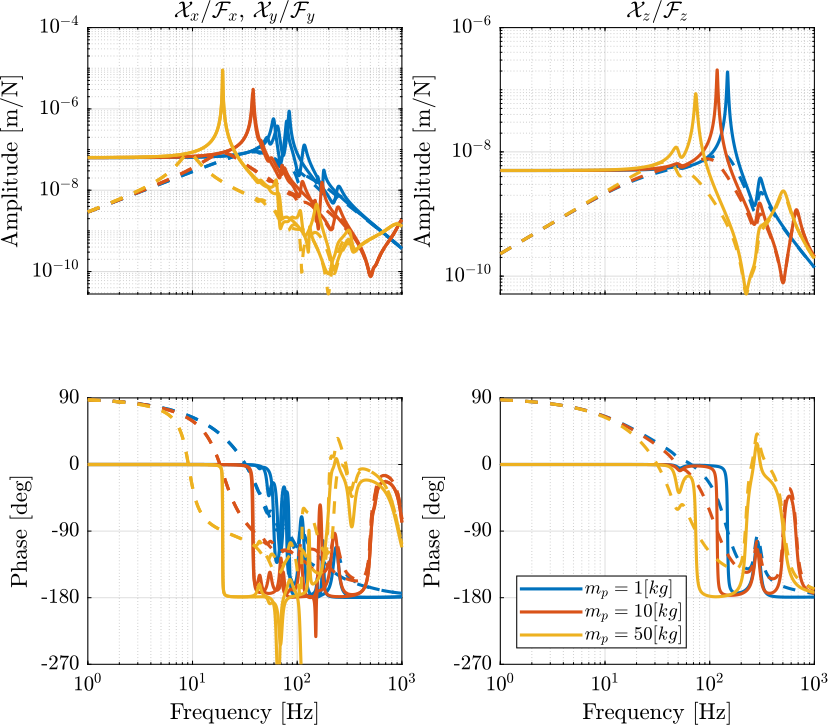

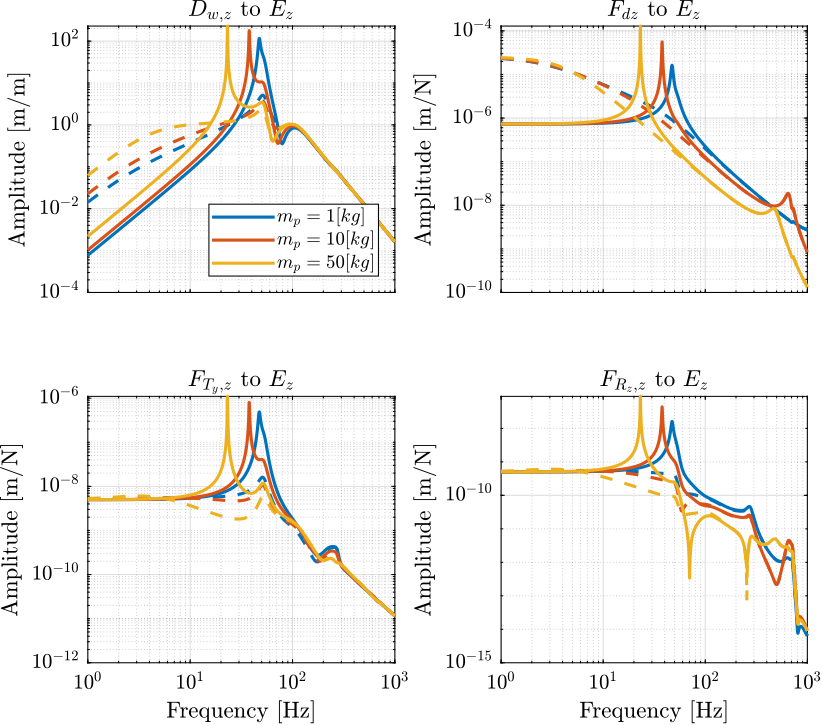

Figure 11: Primary plant in the task space with (dashed) and without (solid) IFF

Figure 12: Primary plant in the space of the legs with (dashed) and without (solid) IFF

Figure 13: Coupling in the primary plant in the task with (dashed) and without (solid) IFF

Figure 14: Coupling in the primary plant in the space of the legs with (dashed) and without (solid) IFF

3.2.4 Effect of the Low Authority Control on the Sensibility to Disturbances

Figure 15: Norm of the transfer function from vertical disturbances to vertical position error with (dashed) and without (solid) Integral Force Feedback applied

3.3 Optimal Stiffnesses

Based on the analytical analysis, we can determine the parameters of the amplified piezoelectric actuator in order to be able to add a lots of damping using IFF:

- \(k_1\) should be minimized.

- \(k_e \approx k_a \approx 10^5 - 10^6\,[N/m]\)

However, this might not be realizable.

3.3.1 Low Authority Controller

3.3.1.1 Identification

The nano-hexapod is initialized with the following parameters:

initializeNanoHexapod('actuator', 'amplified', ... 'k1', 1e4, ... 'ke', 1e6, ... 'ka', 1e6);

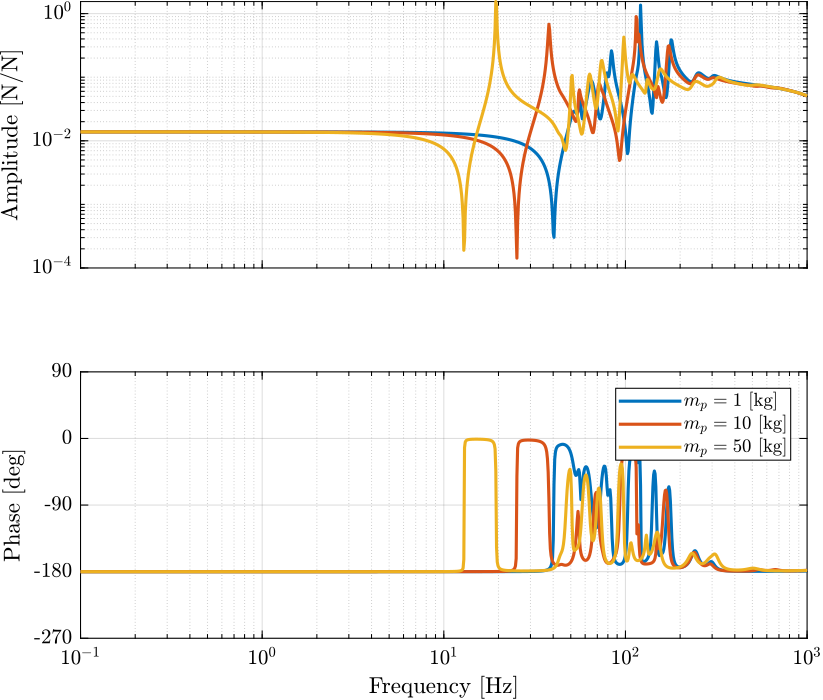

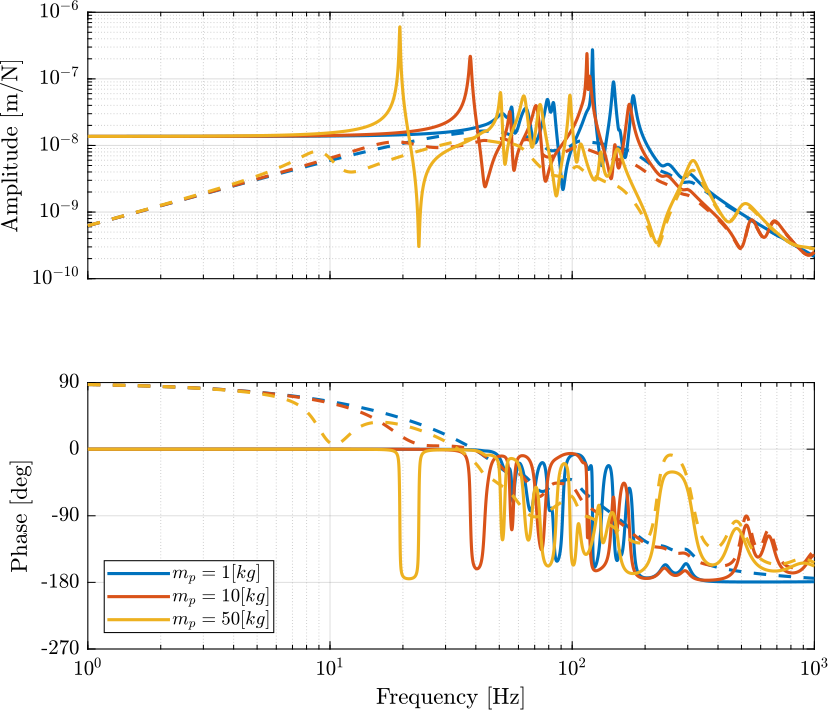

The obtain plan for the IFF control is shown in Figure 16. The associated Root Locus is shown in Figure 17.

Based on that, the following IFF gain is chosen:

Kiff = -1e3/s*eye(6);

Figure 16: Plant dynamics for IFF with the amplified piezoelectric stack actuator

Figure 17: Root Locus for IFF with the amplified piezoelectric stack actuator

Figure 18: Damping of the modes as a function of the IFF gain

3.3.1.2 Effect of the Low Authority Control on the Primary Plant

3.3.1.3 Effect of the Low Authority Control on the Sensibility to Disturbances

Figure 19: Effect of disturbance with and without IFF

3.3.2 High Authority Controller

3.3.2.1 Controller Design

h = 2.5; Kl = 5e6 * eye(6) * ... 1/h*(s/(2*pi*40/h) + 1)/(s/(2*pi*40*h) + 1) * ... 1/h*(s/(2*pi*100/h) + 1)/(s/(2*pi*100*h) + 1) * ... (s/2/pi/50 + 1)/(s/2/pi/50) * ... (s/2/pi/10 + 1)/(s/2/pi/10) * ... 1/(1 + s/2/pi/200);

Kl = 3e10 * eye(6) * ... 1/s * ... (s+0.8)/s * ... (s+50)/(s+0.01) * ... (s+120)/(s+1000) * ... (s+150)/(s+1000);

Finally, we include the Jacobian in the control and we ignore the measurement of the vertical rotation as for the real system.

load('mat/stages.mat', 'nano_hexapod'); K = Kl*nano_hexapod.kinematics.J*diag([1, 1, 1, 1, 1, 0]);

3.3.2.2 Sensibility to Disturbances and Noise Budget

We identify the transfer function from disturbances to the position error of the sample when the HAC-LAC control is applied.

3.3.2.3 Simulations of Tomography Experiment

Let’s now simulate a tomography experiment. To do so, we include all disturbances except vibrations of the translation stage.

initializeDisturbances(); initializeSimscapeConfiguration('gravity', false); initializeLoggingConfiguration('log', 'all');

And we run the simulation for all three payload Masses.

3.3.2.4 Results

3.4 Direct Velocity Feedback with Amplified Actuators

Lack of collocation.

initializeController('type', 'hac-dvf'); K = tf(zeros(6)); Kdvf = tf(zeros(6));

We identify the system for the following payload masses:

Ms = [1, 10, 50];

initializeNanoHexapod('actuator', 'amplified', ... 'k1', 1e4, ... 'ke', 1e6, ... 'ka', 1e6);

4 APA300ML

4.1 Initialization

initializeGround(); initializeGranite(); initializeTy(); initializeRy(); initializeRz(); initializeMicroHexapod(); initializeAxisc(); initializeMirror(); initializeSimscapeConfiguration(); initializeDisturbances('enable', false); initializeLoggingConfiguration('log', 'none'); initializeController('type', 'hac-dvf');

We set the stiffness of the payload fixation:

Kp = 1e8; % [N/m]

4.2 Identification

K = tf(zeros(6)); Kdvf = tf(zeros(6));

We identify the system for the following payload masses:

Ms = [1, 10, 50];

The nano-hexapod has the following leg’s stiffness and damping.

initializeNanoHexapod('actuator', 'amplified', 'k1', 0.4e6, 'ka', 43e6, 'ke', 1.5e6);

4.3 Controller Design

Damping as function of the gain Finally, we use the following controller for the Decentralized Direct Velocity Feedback:

Kdvf = 5e5*s/(1+s/2/pi/1e3)*eye(6);

4.4 Effect of the Low Authority Control on the Primary Plant

4.5 Control in the leg space

We design a diagonal controller with all the same diagonal elements.

The requirements for the controller are:

- Crossover frequency of around 100Hz

- Stable for all the considered payload masses

- Sufficient phase and gain margin

- Integral action at low frequency

The design controller is as follows:

- Lead centered around the crossover

- An integrator below 10Hz

- A low pass filter at 250Hz

h = 2.0; Kl = 1e9 * eye(6) * ... 1/h*(s/(2*pi*100/h) + 1)/(s/(2*pi*100*h) + 1) * ... 1/h*(s/(2*pi*200/h) + 1)/(s/(2*pi*200*h) + 1) * ... (s/2/pi/10 + 1)/(s/2/pi/10) * ... 1/(1 + s/2/pi/300);

load('mat/stages.mat', 'nano_hexapod'); K = Kl*nano_hexapod.kinematics.J*diag([1, 1, 1, 1, 1, 0]);

4.6 Sensibility to Disturbances and Noise Budget

We identify the transfer function from disturbances to the position error of the sample when the HAC-LAC control is applied.

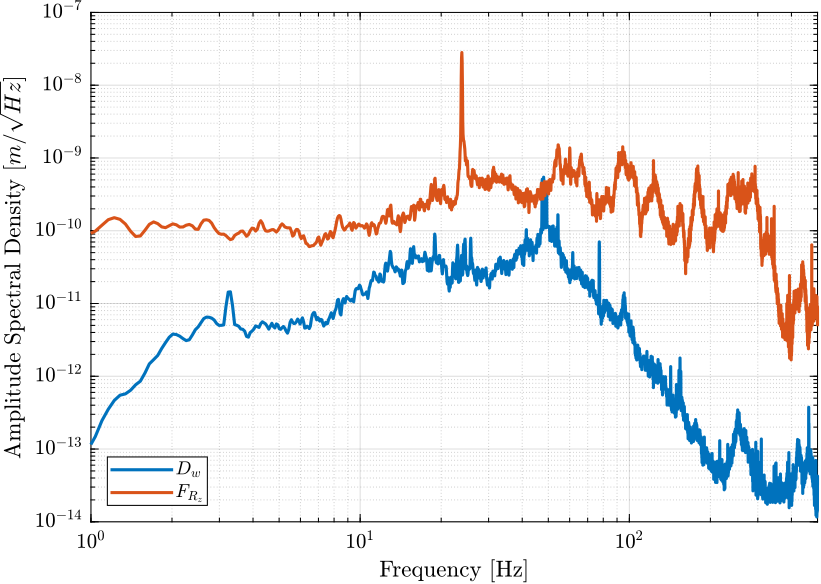

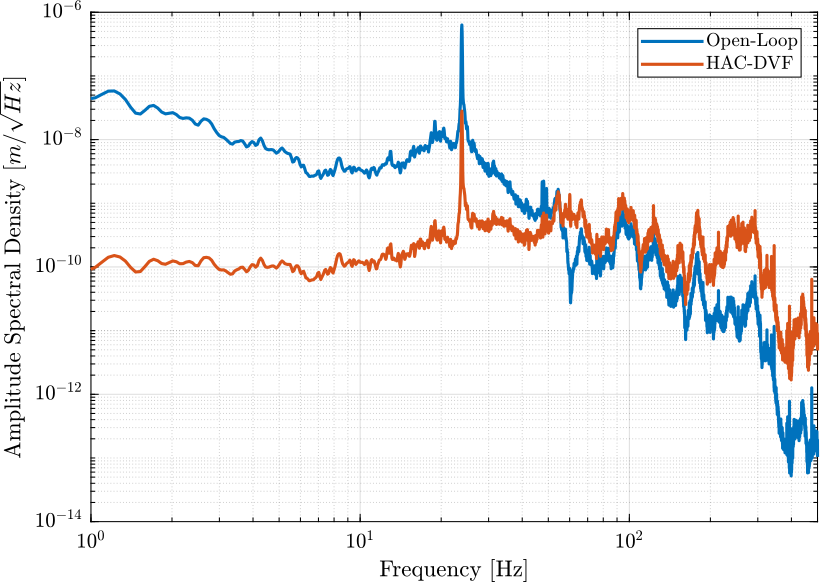

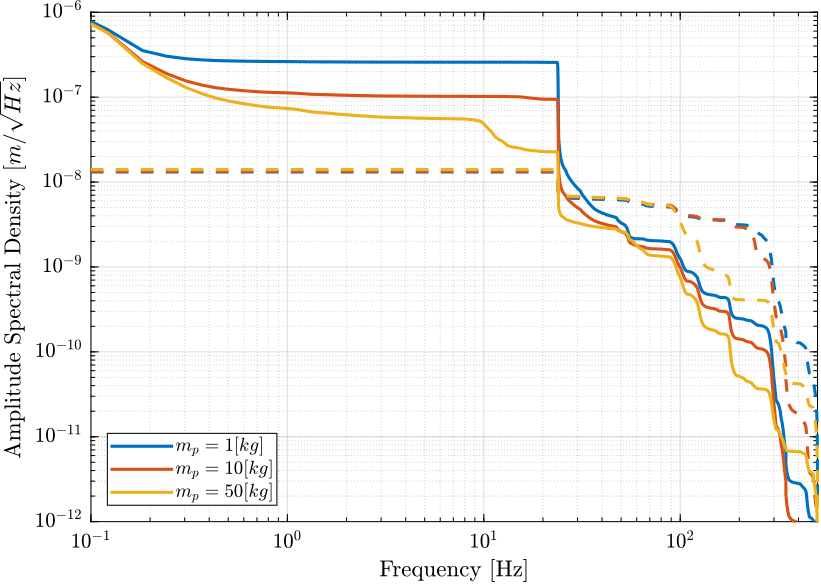

Figure 20: Amplitude Spectral Density of the vertical position error of the sample when the HAC-DVF control is applied due to both the ground motion and spindle vibrations

Figure 21: Amplitude Spectral Density of the vertical position error of the sample in Open-Loop and when the HAC-DVF control is applied

Figure 22: Cumulative Amplitude Spectrum of the vertical position error of the sample in Open-Loop and when the HAC-DVF control is applied

4.7 Simulations of Tomography Experiment

Let’s now simulate a tomography experiment. To do so, we include all disturbances except vibrations of the translation stage.

initializeDisturbances(); initializeSimscapeConfiguration('gravity', false); initializeLoggingConfiguration('log', 'all');

And we run the simulation for all three payload Masses.