Nano-Hexapod

Table of Contents

- 1. Nano-Hexapod

- 1.1. Nano Hexapod - Configuration

- 1.2. Effect of encoders on the decentralized plant

- 1.3. Effect of APA flexibility

- 1.4. Nano Hexapod - Number of DoF

- 1.5. Direct Velocity Feedback Plant

- 1.6. Integral Force Feedback Plant

- 1.7. Decentralized Plant - Cartesian coordinates

- 1.8. Decentralized Plant - Decoupling at the Center of Stiffness

- 1.9. Stiffness matrix

- 2. Active Damping using Integral Force Feedback

- 3. Active Damping using Direct Velocity Feedback - Encoders on the struts

- 4. Active Damping using Direct Velocity Feedback - Encoders on the plates

- 5. Function - Initialize Nano Hexapod

In this document, a Simscape model of the nano-hexapod is developed.

1 Nano-Hexapod

1.1 Nano Hexapod - Configuration

The nano-hexapod can be initialized and configured using the initializeNanoHexapodFinal function (link).

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof', ... 'MO_B', 150e-3);

We initialize the identification parameters.

%% Options for Linearized options = linearizeOptions; options.SampleTime = 0; %% Name of the Simulink File mdl = 'nano_hexapod'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/F'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Relative Motion Outputs

1.2 Effect of encoders on the decentralized plant

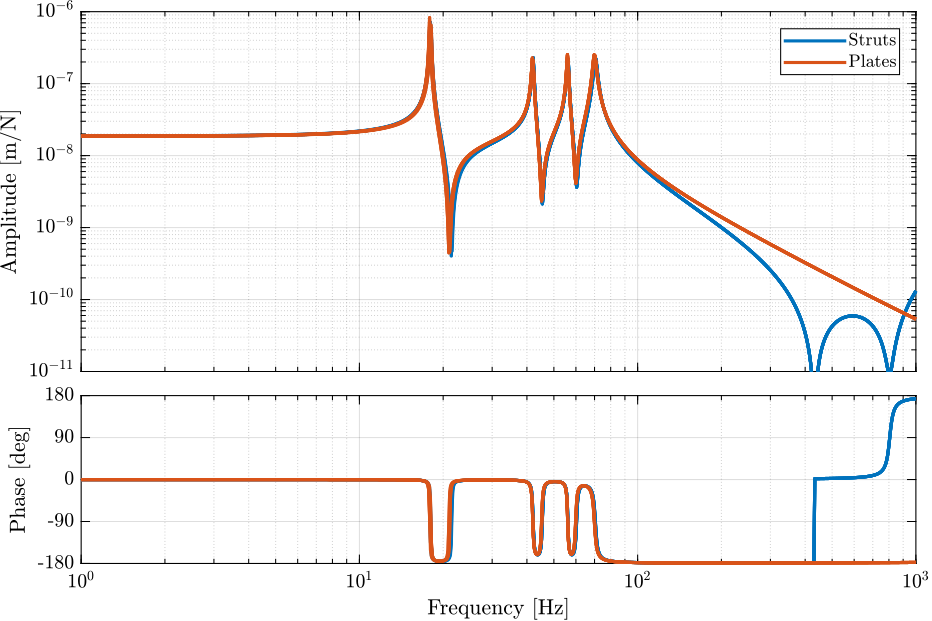

We here wish to compare the plant from actuators to the encoders when the encoders are either fixed on the struts or on the plates.

Identify the plant when the encoders are on the struts:

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof'); Gs = linearize(mdl, io, 0.0, options); Gs.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gs.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

And identify the plant when the encoders are fixed on the plates:

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', '2dof'); Gp = linearize(mdl, io, 0.0, options); Gp.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gp.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

The obtained plants are compared in Figure 1.

Figure 1: Comparison of the plants from actuator to associated encoder when the encoders are either fixed to the struts or to the plates

Why do we have zeros at 400Hz and 800Hz when the encoders are fixed on the struts?

1.3 Effect of APA flexibility

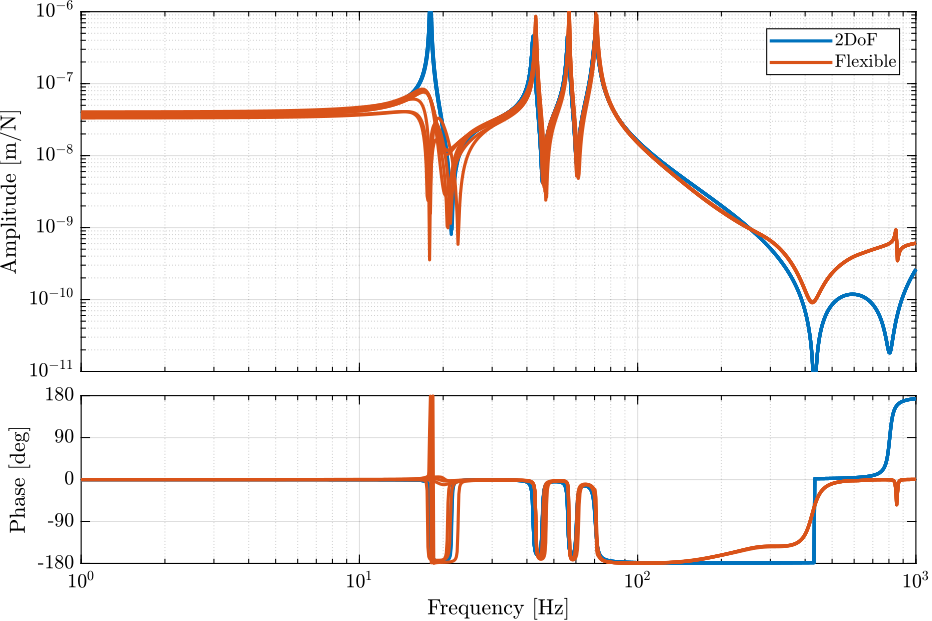

First identify the plant for APA represented by 2DoF system:

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof', ... 'actuator_Ga', 2); Gs = linearize(mdl, io, 0.0, options); Gs.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gs.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

First identify the plant for APA represented by a flexible element:

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', 'flexible'); Gf = linearize(mdl, io, 0.0, options); Gf.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gf.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

Figure 2: Comparison of the plants from actuator to associated strut encoder when the APA are modelled with a 2DoF system of with a flexible one

The first resonance is strange when using the flexible APA model (Figure 2). Moreover the system is unstable. Otherwise, the 2DoF model matches quite well the flexible model considering its simplicity.

1.4 Nano Hexapod - Number of DoF

In this section, we wish to see how the configuration of each element changes the number of the states of the obtained system.

The most minimalist model is the following:

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '3dof', ... 'flex_top_type', '2dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof'); G = linearize(mdl, io, 0.0, options);

There are 24 states.

These states are summarized on table 1.

| Element | States |

|---|---|

| Struts | 2*6 |

| Top Plate | 12 |

| Total: | 24 |

If we add axial stiffness on the top joints, we should add 2 states for each struts.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '2dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof'); G = linearize(mdl, io, 0.0, options);

There are 36 states.

If we add torsional stiffness on the bottom joints, we should again add 2 states for each struts.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof'); G = linearize(mdl, io, 0.0, options);

There are 48 states.

Finally, if we add axial stiffness on the bottom joint, we should add 2 states for each struts.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof'); G = linearize(mdl, io, 0.0, options);

There are 60 states.

Obtained number of states is very comprehensible. Depending on the physical effects we want to model, we therefore know how many states are added when configuring the model.

1.5 Direct Velocity Feedback Plant

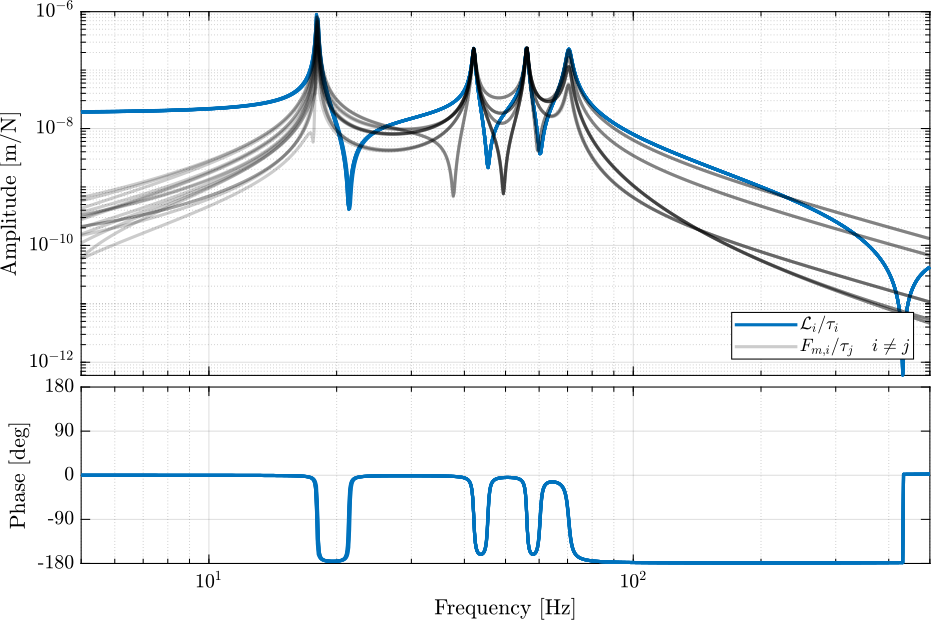

The transfer function from actuator forces \(\tau_i\) to the encoder measurements \(\mathcal{L}_i\) is now identified both when the encoders are fixed to the struts.

%% Options for Linearized options = linearizeOptions; options.SampleTime = 0; %% Name of the Simulink File mdl = 'nano_hexapod'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/F'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs [N] io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Relative displacements [m] n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof'); Gdvf = linearize(mdl, io, 0.0, options);

The DC gain from actuator to relative motion sensor should be equal to (for the 2dof APA): \[ \frac{1}{k + k_a + kk_a/k_e} \]

Which is equal to:

DCgain = 1.87e-08 [m/N]

Let’s verify that by looking at the DC gain of the \(6 \times 6\) DVF plant in Table 2.

| 1.8617e-08 | -1.0408e-10 | 1.3034e-10 | 3.2559e-11 | -1.1188e-10 | 9.0385e-11 |

| -5.1839e-11 | 1.8593e-08 | -4.4868e-11 | 8.016e-11 | 4.3558e-11 | -1.1164e-10 |

| 5.1963e-12 | -6.9001e-12 | 1.8564e-08 | 3.0844e-11 | 4.0097e-11 | -3.4387e-11 |

| 1.9359e-11 | 1.7432e-10 | -5.0928e-11 | 1.855e-08 | 1.6406e-10 | 4.5757e-12 |

| -2.1185e-11 | 2.1724e-10 | 1.5333e-12 | -8.802e-11 | 1.8803e-08 | -4.6946e-11 |

| -1.1728e-11 | -5.7682e-11 | 1.6213e-10 | 2.1934e-12 | -1.6237e-10 | 1.8715e-08 |

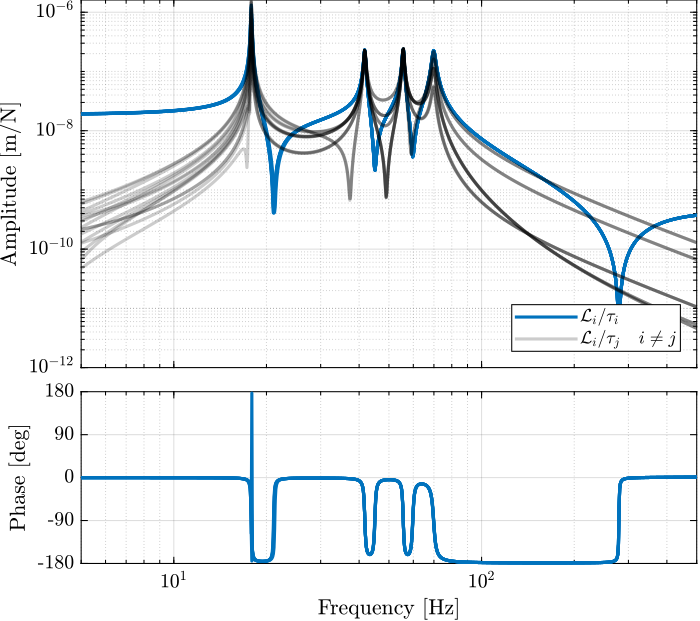

And the bode plot of the DVF plant is shown in Figure 3.

Figure 3: Bode plot of the transfer functions from actuator forces \(\tau_i\) to relative motion sensors attached to the struts \(\mathcal{L}_i\). Diagonal terms are shown in blue, and off-diagonal terms in black.

1.6 Integral Force Feedback Plant

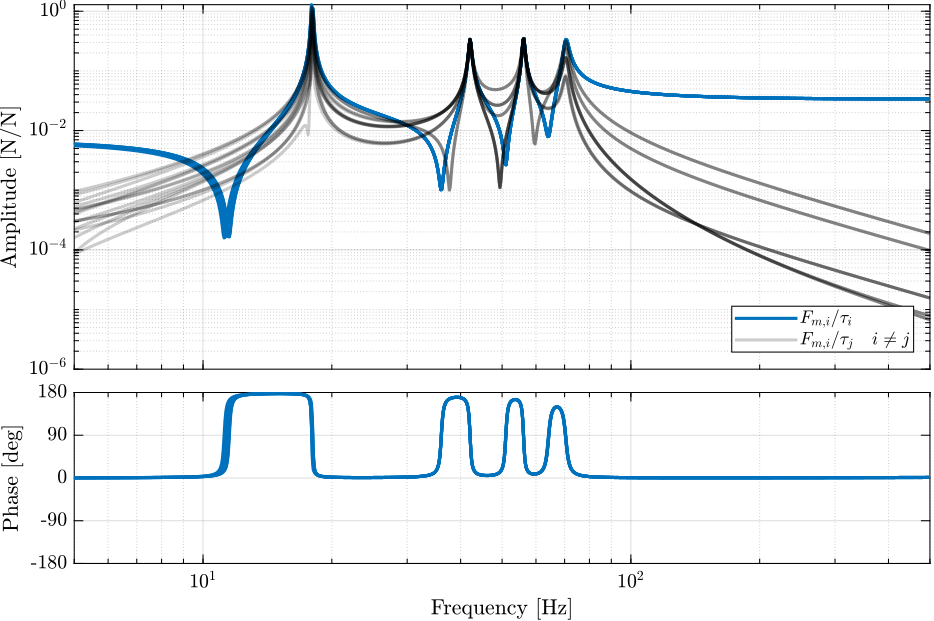

The transfer function from actuators to force sensors is identified.

%% Options for Linearized options = linearizeOptions; options.SampleTime = 0; %% Name of the Simulink File mdl = 'nano_hexapod'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/F'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/Fm'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof'); Giff = linearize(mdl, io, 0.0, options);

This is corresponding to the dynamics for the Integral Force Feedback (IFF) control strategy.

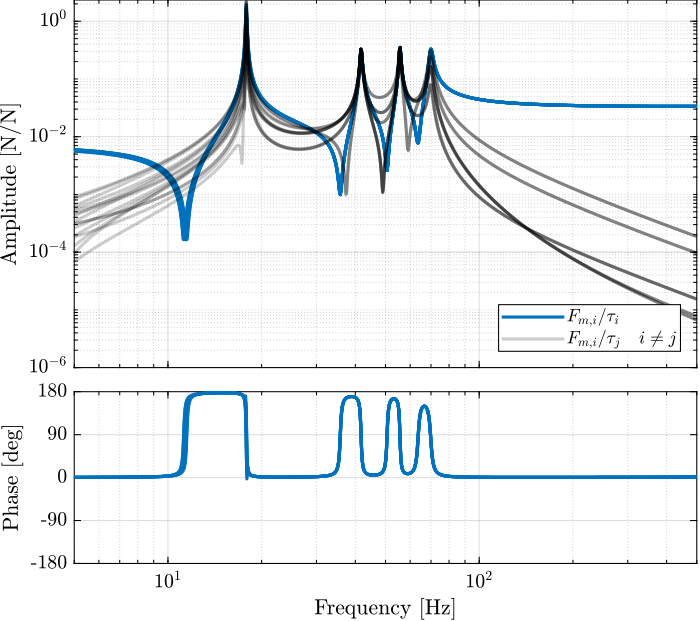

The bode plot is shown in Figure 4.

Figure 4: Bode plot of the transfer functions from actuator forces \(\tau_i\) to force sensors \(F_{m,i}\). Diagonal terms are shown in blue, and off-diagonal terms in black.

1.7 Decentralized Plant - Cartesian coordinates

Consider the plant shown in Figure 5 with:

- \(\tau\) the 6 input forces (APA)

- \(d\mathcal{L}\) the relative motion sensor outputs (encoders)

- \(\mathcal{X}\) the motion of the top platform measured with “perfect” 6-dof sensor

- \(J_a\) and \(J_s\) the Jacobians for the actuators and sensors

Figure 5: Plant in the cartesian Frame

1.7.1 Verification of the Sensor Jacobian

The “perfect” sensor output \(\mathcal{X}\) is used to verify that the sensor Jacobian is working correctly both when the encoders are fixed to the struts and to the plates.

Let’s then identify the plant for both configuration, and compare the transfer functions from \(\mathcal{F}\) to \(d\mathcal{X}\) and to \(\mathcal{X}\).

%% Options for Linearized options = linearizeOptions; options.SampleTime = 0; %% Name of the Simulink File mdl = 'nano_hexapod'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/F'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Relative Motion Outputs io(io_i) = linio([mdl, '/X'], 1, 'openoutput'); io_i = io_i + 1; % Relative Motion Outputs

Start when the encoders are fixed on the struts.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof', ... 'MO_B', 150e-3); Gs = linearize(mdl, io, 0.0, options); Gs.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gs.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6', ... 'Dx', 'Dy', 'Dz', 'Rx', 'Ry', 'Rz'}; % Cartesian plant using the Jacobians Gsc = inv(n_hexapod.geometry.Js)*Gs({'D1', 'D2', 'D3', 'D4', 'D5', 'D6'}, {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'})*inv(n_hexapod.geometry.J)'; % Cartesian plant using the perfect sensor Gsp = -Gs({'Dx', 'Dy', 'Dz', 'Rx', 'Ry', 'Rz'}, {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'})*inv(n_hexapod.geometry.J)';

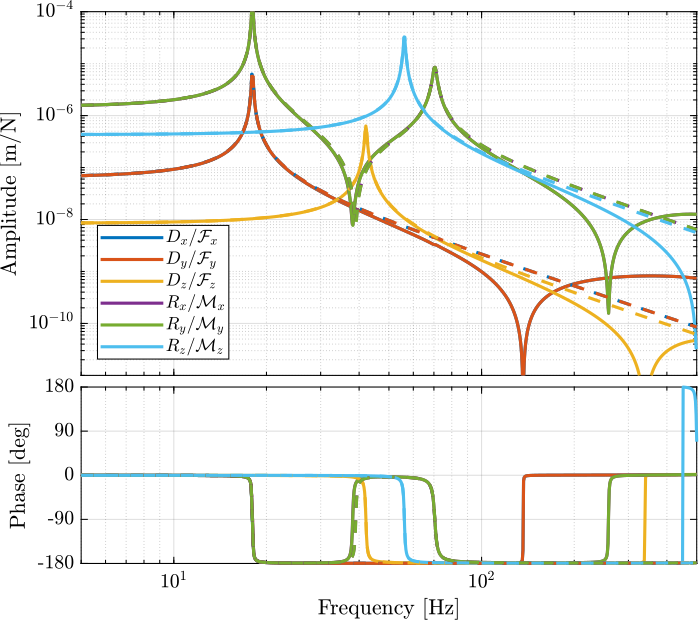

The diagonal elements of the plant are shown in Figure 6.

Figure 6: Bode plot of the diagonal elements of the decentralized (cartesian) plant when using the sensor Jacobian (solid) and when using “perfect” 6dof sensor (dashed). The encoders are fixed on the struts.

The same if performed when the encoders are fixed to the plates.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', '2dof', ... 'MO_B', 150e-3); Gp = linearize(mdl, io, 0.0, options); Gp.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gp.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6', ... 'Dx', 'Dy', 'Dz', 'Rx', 'Ry', 'Rz'}; % Cartesian plant using the Jacobians Gpc = inv(n_hexapod.geometry.Js)*Gp({'D1', 'D2', 'D3', 'D4', 'D5', 'D6'}, {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'})*inv(n_hexapod.geometry.J)'; % Cartesian plant using the perfect sensor Gpp = -Gp({'Dx', 'Dy', 'Dz', 'Rx', 'Ry', 'Rz'}, {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'})*inv(n_hexapod.geometry.J)';

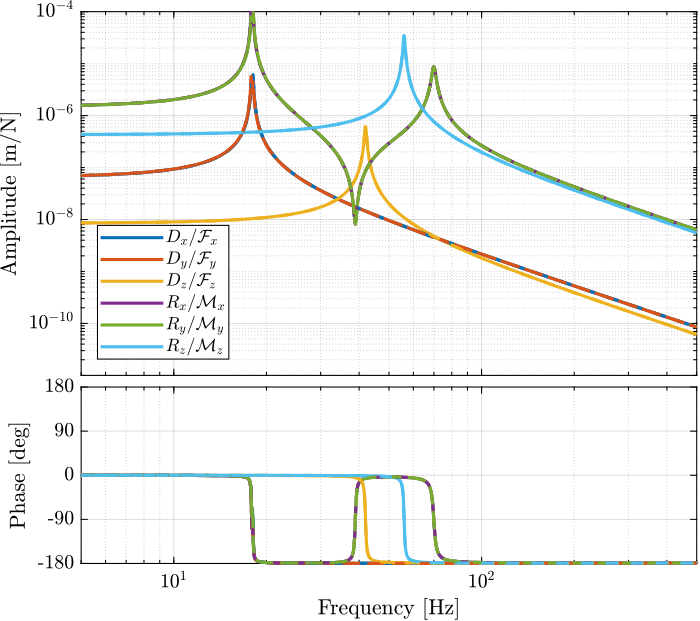

The obtained bode plots are shown in Figure 7.

Figure 7: Bode plot of the diagonal elements of the decentralized (cartesian) plant when using the sensor Jacobian (solid) and when using “perfect” 6dof sensor (dashed). The encoders are fixed on the plates.

The Jacobian for the encoders is working properly both when the encoders are fixed to the plates or to the struts.

However, then the encoders are fixed to the struts, there is a mismatch between the estimated motion and the measured motion above 100Hz due to a complex conjugate zero.

1.7.2 Comparison of the decentralized plants

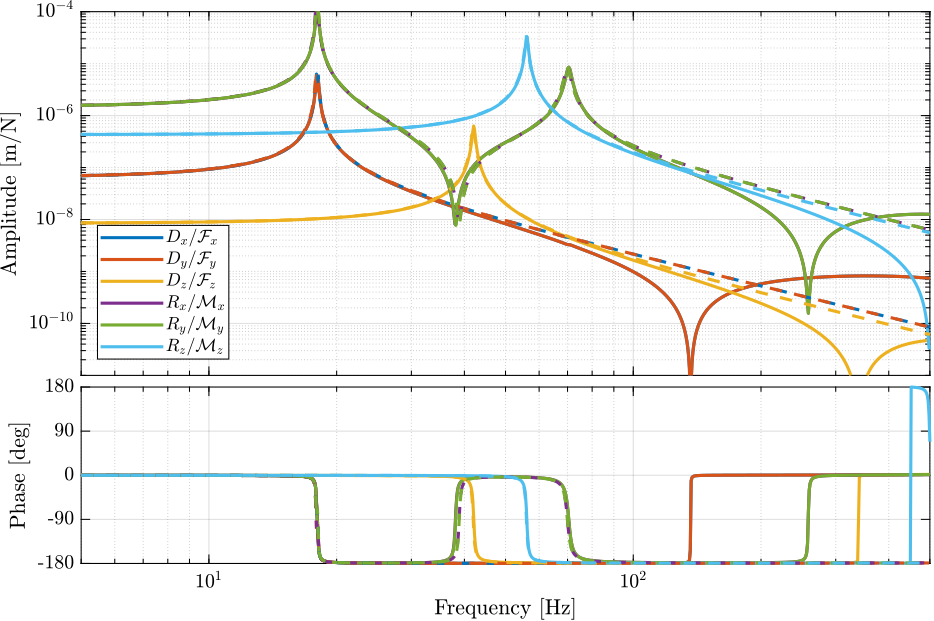

The decentralized plants are now compared whether the encoders are fixed on the struts or on the plates in Figure 8.

Figure 8: Bode plot of the “cartesian” plant (transfer function from \(\mathcal{F}\) to \(d\mathcal{X}\)) when the encoders are fixed on the struts (solid) and on the plates (dashed)

1.8 Decentralized Plant - Decoupling at the Center of Stiffness

1.8.1 Center of Stiffness

Let’s define some parameters that will be used for the computation of the stiffness matrix:

si = n_hexapod.geometry.si; % Orientation of struts bi = n_hexapod.geometry.Fb; % Location of bi w.r.t. {F} ki = ones(1,6); % Normalized strut stiffness

In order to find is the Center of Stiffness (CoK) exists, we have to verify is the following is diagonal:

ki.*si*si'

| 1.8977 | 2.4659e-17 | 5.1838e-19 |

| 2.4659e-17 | 1.8977 | -2.3143e-05 |

| 5.1838e-19 | -2.3143e-05 | 2.2046 |

And we can find the location of the CoK with respect to {F}:

OkX = (ki.*cross(bi, si)*si')/(ki.*si*si'); Ok = [OkX(3,2);OkX(1,3);OkX(2,1)]

| -1.7444e-18 |

| 2.1511e-06 |

| 0.052707 |

The “center of stiffness” is therefore 52.7mm above the bottom platform {F} frame.

Let’s initialize the hexapod with frame {A} and {B} at the CoK:

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof', ... 'MO_B', Ok(3)-95e-3);

And the (normalized) stiffness matrix is computed as follows:

n_hexapod.geometry.J'*diag(ki)*n_hexapod.geometry.J

| 1.8977 | 0 | 0 | 0 | -2.0817e-17 | -1.5311e-06 |

| 0 | 1.8977 | -2.3143e-05 | 4.175e-06 | 0 | 0 |

| 0 | -2.3143e-05 | 2.2046 | 4.7422e-06 | 0 | 0 |

| 0 | 4.175e-06 | 4.7422e-06 | 0.012594 | 2.1684e-19 | -8.6736e-19 |

| -1.8521e-17 | 0 | 0 | 0 | 0.012594 | -9.3183e-08 |

| -1.5311e-06 | -6.9389e-18 | 2.7756e-17 | -8.6736e-19 | -9.3183e-08 | 0.043362 |

And we indeed obtain a diagonal stiffness matrix.

1.8.2 Obtained plant

Let’s identify the transfer function from \(\tau\) to \(d\mathcal{L}\) and from \(\tau\) to \(\mathcal{X}\).

%% Options for Linearized options = linearizeOptions; options.SampleTime = 0; %% Name of the Simulink File mdl = 'nano_hexapod'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/F'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Relative Motion Outputs io(io_i) = linio([mdl, '/X'], 1, 'openoutput'); io_i = io_i + 1; % 6DoF perfect measurement G = linearize(mdl, io, 0.0, options); G.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; G.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6', ... 'Dx', 'Dy', 'Dz', 'Rx', 'Ry', 'Rz'};

Then use the Jacobian matrices to obtain the “cartesian” centralized plant.

Gc = inv(n_hexapod.geometry.J)*... G({'D1', 'D2', 'D3', 'D4', 'D5', 'D6'}, {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'})*... inv(n_hexapod.geometry.J');

The DC gain of the obtained plant is shown in Table 4.

| 9.8602e-09 | 7.8692e-11 | 1.4426e-11 | -2.663e-10 | 2.8e-10 | -4.7559e-11 |

| 8.457e-11 | 9.8788e-09 | -2.4002e-11 | -2.9502e-11 | -1.3262e-10 | -8.7346e-11 |

| -4.3244e-11 | 2.4075e-13 | 8.4775e-09 | 1.1442e-11 | -2.5809e-10 | 2.8796e-11 |

| -1.8326e-09 | -9.318e-10 | 6.8188e-10 | 1.4697e-06 | 5.5936e-09 | 8.7632e-10 |

| 4.6906e-10 | 1.5911e-09 | 1.6989e-10 | -5.223e-09 | 1.4729e-06 | -2.6059e-10 |

| -6.5754e-11 | -3.0408e-12 | 5.394e-11 | -1.0917e-10 | 6.9479e-10 | 4.2979e-07 |

As the rotations and translations have very different gains, we normalize each motion to one.

Gc = diag(1./diag(dcgain(Gc)))*Gc;

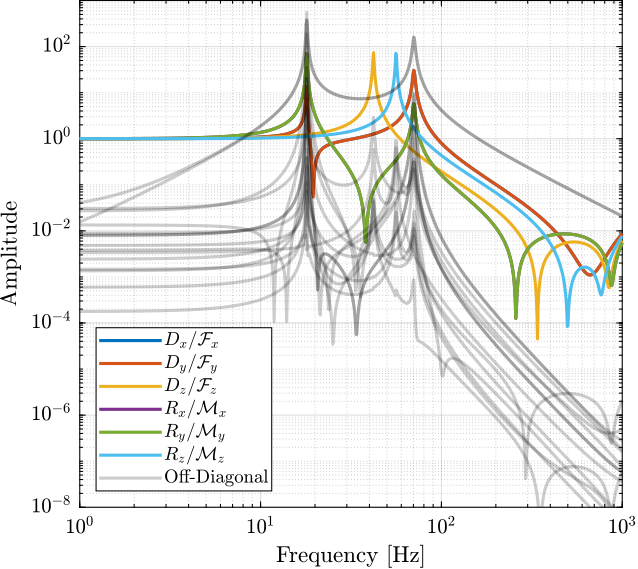

The diagonal and off-diagonal elements are shown in Figure 9, and we can see good decoupling at low frequency.

Figure 9: Diagonal and off-diagonal elements of the (normalized) decentralized plant with the Jacobians estimated at the “center of stiffness”

The Jacobian matrices can be used to decoupled the plant at low frequency.

1.9 Stiffness matrix

The stiffness matrix of the nano-hexapod describes its induced static displacement/rotation when a force/torque is applied on its top platform. The location of the applied force/torque and the expressed displacement/rotation can be defined as wanted. Such location (or frame) is then used for the computation of the Jacobian which in turns is used to compute the stiffness matrix.

1.9.1 Compute the theoretical stiffness of the nano-hexapod

Neglecting stiffness of the joints, we have: \[ K = J^t \mathcal{K} J \] where \(\mathcal{K}\) is a diagonal 6x6 matrix with axial stiffness of the struts on the diagonal.

Let’s note the axial stiffness of the APA: \[ k_{\text{APA}} = k + \frac{k_e k_a}{k_e + k_a} \]

Them axial stiffness of the struts \(k_s\): \[ k_s = \frac{k_z k_{\text{APA}}}{k_z + 2 k_{\text{APA}}} \] with \(k_z\) the axial stiffness of the flexible joints.

Let’s initialize the nano-hexapod.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof');

The axial stiffness of the joints and stiffnesses of the 2-DoF actuators are defined below.

k = n_hexapod.actuator.k(1);

ke = n_hexapod.actuator.ke(1);

ka = n_hexapod.actuator.ka(1);

kz = n_hexapod.flex_top.kz(1); % Joint's axial stiffness [m/N]

The total axial stiffness of the APA is:

kAPA = k + ke*ka/(ke + ka);

kAPA = 1.799e+06 [N/m]

And the total axial stiffness of the struts is:

ks = kz*kAPA/(kz + 2*kAPA);

ks = 1.737e+06 [N/m]

We can see that the axial stiffness of the flexible joint as little impact on the total axial stiffness of the struts.

Let’s now compute the stiffness matrix corresponding to an hexapod with perfect joints and the above computed axial strut stiffness:

Ks = n_hexapod.geometry.J'*(ks*eye(6))*n_hexapod.geometry.J;

And the compliance matrix can be computed as the inverse of the stiffness matrix.

C = inv(Ks);

The obtained compliance matrix is shown in Table 5.

| 1.9938e-06 | -2.3138e-22 | 3.3403e-23 | 1.0202e-21 | 8.7906e-06 | 2.9603e-11 |

| -3.1875e-23 | 1.9938e-06 | 2.2094e-11 | -8.7909e-06 | -1.6576e-22 | -3.5622e-28 |

| 6.6811e-23 | 2.2094e-11 | 2.6115e-07 | -9.8337e-11 | 3.4744e-22 | 7.4663e-28 |

| 1.4054e-22 | -8.7909e-06 | -9.8337e-11 | 4.5715e-05 | 7.3086e-22 | 1.5706e-27 |

| 8.7906e-06 | -1.0202e-21 | 1.7371e-22 | 4.498e-21 | 4.5714e-05 | 9.8237e-11 |

| 2.9603e-11 | -1.9261e-22 | -1.7611e-27 | 8.4925e-22 | 9.8237e-11 | 1.3277e-05 |

1.9.2 Comparison with Simscape Model

Let’s now identify the compliance matrix using Simscape.

%% Options for Linearized options = linearizeOptions; options.SampleTime = 0; %% Name of the Simulink File mdl = 'nano_hexapod'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/Fe'], 1, 'openinput'); io_i = io_i + 1; % External forces [N, Nm/rad] io(io_i) = linio([mdl, '/X'], 1, 'openoutput'); io_i = io_i + 1; % Induced motion [m, rad] G = linearize(mdl, io, 0.0, options);

The DC gain of the identified plant is therefore the compliance matrix of the nano-hexapod. It takes into account the bending and torsional stiffness of the flexible joints.

The obtained compliance matrix is shown in Table 6.

| 1.9863e-06 | 2.4683e-08 | 2.2859e-09 | -6.4768e-08 | 8.7307e-06 | 3.2754e-10 |

| -3.693e-09 | 1.9663e-06 | -7.4503e-09 | -8.615e-06 | -6.7926e-08 | -2.0193e-08 |

| -3.5525e-09 | -8.8671e-10 | 2.6042e-07 | 4.7504e-09 | -9.9677e-09 | 1.7242e-10 |

| 2.1133e-08 | -8.6554e-06 | 3.2841e-08 | 4.4849e-05 | 3.0873e-07 | 8.1525e-08 |

| 8.7375e-06 | 9.9165e-08 | 8.135e-09 | -2.5208e-07 | 4.5331e-05 | 3.0602e-09 |

| 6.1611e-09 | 6.1733e-09 | 2.6778e-09 | -3.3188e-08 | 3.3887e-08 | 1.3212e-05 |

2 Active Damping using Integral Force Feedback

In this section Integral Force Feedback (IFF) strategy is used to damp the nano-hexapod resonances.

It is structured as follows:

- Section 2.1: the IFF plant is identified

- Section 2.2: the optimal control gain is identified using the Root Locus plot

- Section 2.3: the IFF is applied, and the effect on the damped plant is identified and compared with the un-damped one

- Section 2.4: the IFF is applied, and the effect on the compliance is identified

2.1 Plant Identification

The nano-hexapod is initialized as usual.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof');

The transfer function from actuator inputs to force sensors outputs is identified.

%% Options for Linearized options = linearizeOptions; options.SampleTime = 0; %% Name of the Simulink File mdl = 'nano_hexapod'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/F'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/Fm'], 1, 'openoutput'); io_i = io_i + 1; % Force Sensors Giff = linearize(mdl, io, 0.0, options); Giff.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Giff.OutputName = {'Fm1', 'Fm2', 'Fm3', 'Fm4', 'Fm5', 'Fm6'};

Its bode plot is shown in Figure

Figure 10: Integral Force Feedback plant

2.2 Root Locus

The controller is a diagonal (i.e. decentralized) controller with simple low pass filters (i.e. pseudo integrators) on the diagonal:

\begin{equation} K_{\text{IFF}} = \frac{g}{s + \omega_c} \bm{I}_{6 \times 6} \end{equation}The value of \(\omega_c\) has quite a large impact both on the attainable damping and on the compliance degradation at low frequency.

It is here chosen to have quite a large \(\omega_c\) in order to not modify the plant at low frequency.

wc = 2*pi*20;

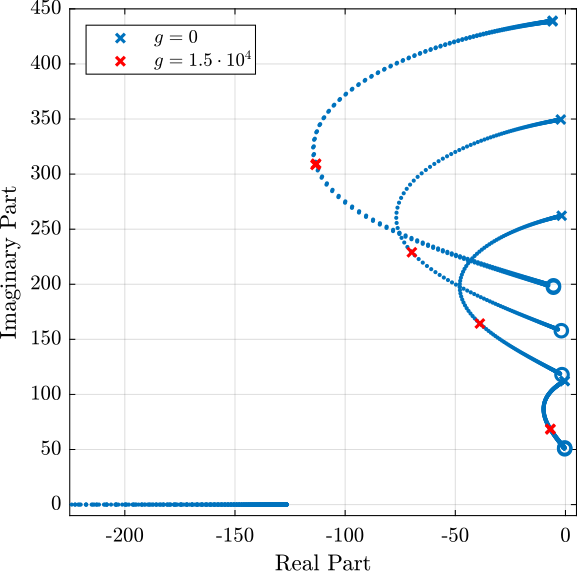

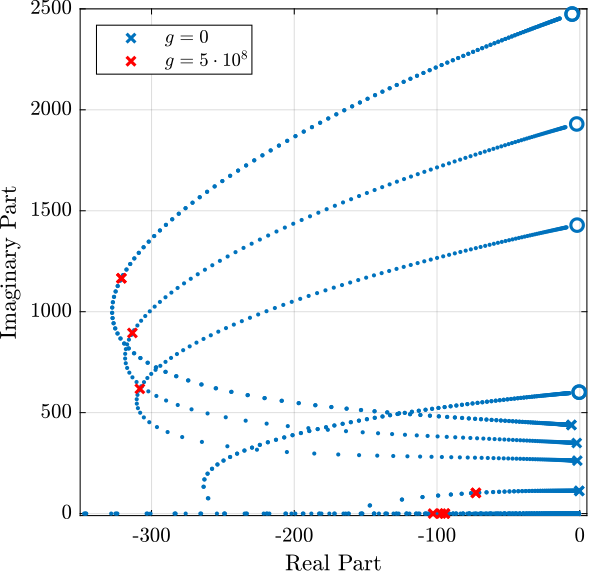

The obtained Root Locus is shown in Figure 11. The control gain chosen for future plots is shown by the red crosses.

Figure 11: Root locus for the decentralized IFF control strategy

The obtained controller is then:

Kiff = 1.5e4/(s + 2*pi*20)*eye(6); % IFF Controller

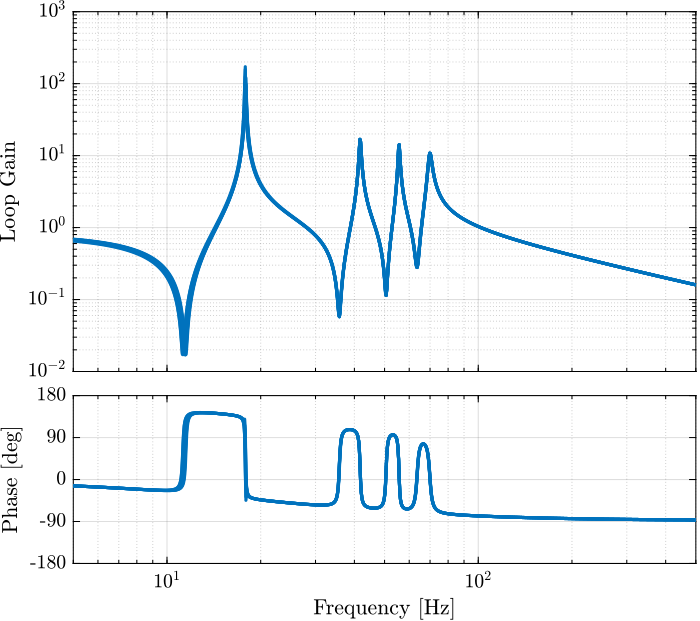

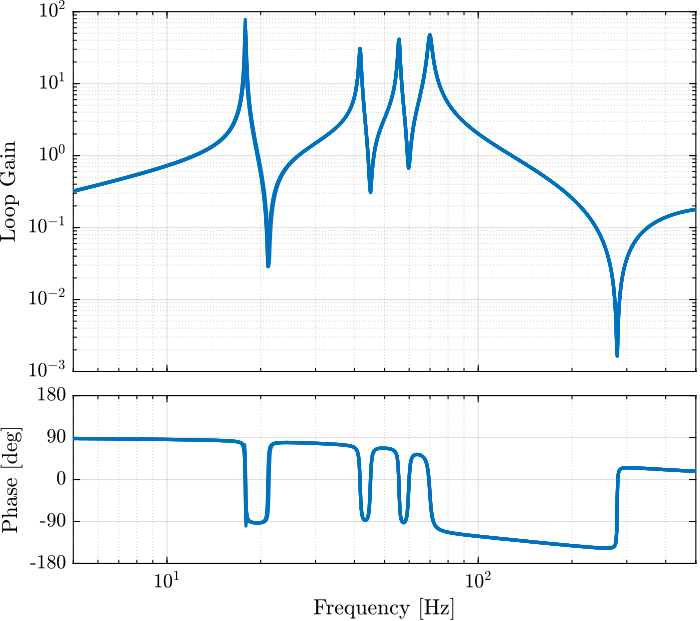

The corresponding loop gain of the diagonal terms are shown in Figure 12. It is shown that the loop gain is quite large around resonances (which allows to add lots of damping) and less than one at low frequency thanks to the large value of \(\omega_c\).

Figure 12: Loop gain of the diagonal terms \(G(i,i) \cdot K_{\text{IFF}}(i,i)\)

2.3 Effect of IFF on the plant

Let’s now see how the IFF control strategy effectively damps the plant and how it affects the transfer functions from the actuator forces to the relative motion sensors (encoders). First identify the plant in open-loop.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof', ... 'controller_type', 'none'); Gol = linearize(mdl, io, 0.0, options); Gol.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gol.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

And then with the IFF controller.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '3dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof', ... 'controller_type', 'iff'); Giff = linearize(mdl, io, 0.0, options); Giff.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Giff.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

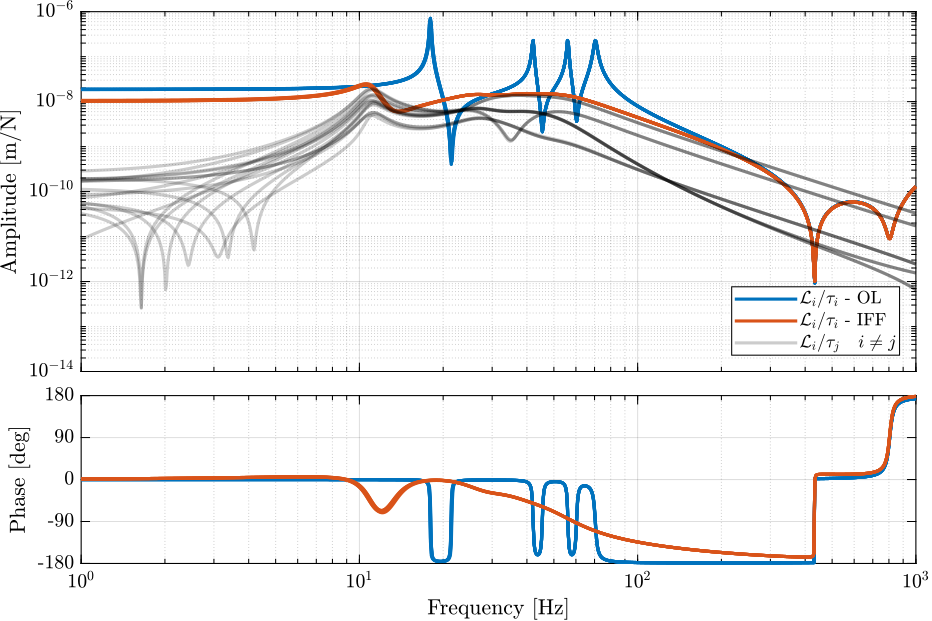

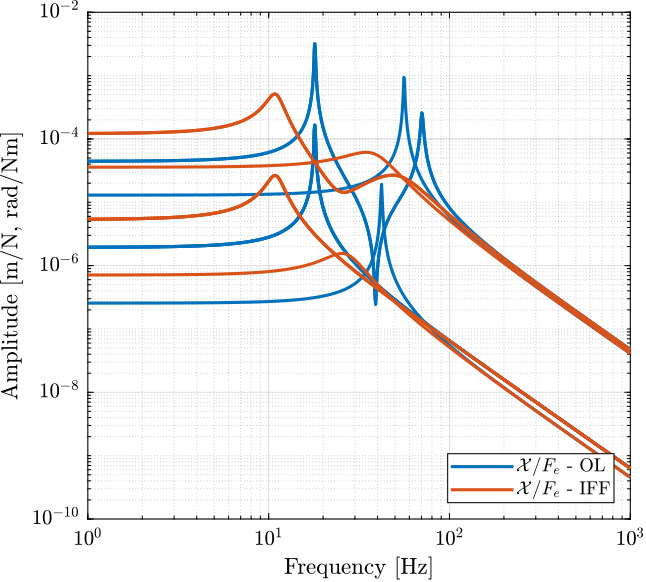

The obtained plants are compared in Figure 13.

Figure 13: Bode plots of the transfer functions from actuator forces \(\tau_i\) to relative motion sensors \(\mathcal{L}_i\) with and without the IFF controller.

The Integral Force Feedback Strategy is very effective to damp the 6 suspension modes of the nano-hexapod.

2.4 Effect of IFF on the compliance

The IFF strategy has the well known drawback of degrading the compliance (transfer function from external forces/torques applied to the top platform to the motion of the top platform), especially at low frequency where the control gain is large. Let’s quantify that for the nano-hexapod. The obtained compliances are compared in Figure

Figure 14: Comparison of the compliances in Open Loop and with Integral Force Feedback controller

The use of IFF induces a degradation of the compliance. This degradation is limited due to the use of a pseudo integrator (instead of a pure integrator). Also, it should not be a major problem for the NASS, as no direct forces should be applied to the top platform.

3 Active Damping using Direct Velocity Feedback - Encoders on the struts

In this section, the Direct Velocity Feedback (DVF) strategy is used to damp the nano-hexapod resonances.

It is structured as follows:

- Section 3.1: the DVF plant is identified

- Section 3.2: the optimal control gain is identified using the Root Locus plot

- Section 3.3: the DVF is applied, and the effect on the damped plant is identified and compared with the un-damped one

- Section 3.4: the DVF is applied, and the effect on the compliance is identified

3.1 Plant Identification

The nano-hexapod is initialized as usual.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof');

The transfer function from actuator inputs to force sensors outputs is identified.

%% Options for Linearized options = linearizeOptions; options.SampleTime = 0; %% Name of the Simulink File mdl = 'nano_hexapod'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/F'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Relative Motion Outputs Gdvf = linearize(mdl, io, 0.0, options); Gdvf.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gdvf.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

Its bode plot is shown in Figure 15.

Figure 15: Direct Velocity Feedback plant

3.2 Root Locus

The controller is a diagonal (i.e. decentralized) controller with simple high pass filters (i.e. pseudo derivators) on the diagonal:

\begin{equation} K_{\text{DVF}} = g \frac{s}{s + \omega_d} \bm{I}_{6 \times 6} \end{equation}The value of \(\omega_d\) sets the frequency above high the derivative action is stopped.

wd = 2*pi*150;

The obtained Root Locus is shown in Figure 16. The control gain chosen for future plots is shown by the red crosses.

Figure 16: Root locus for the decentralized DVF control strategy

The obtained controller is then:

Kdvf = 5e8*s/(s + wd)*eye(6); % DVF Controller

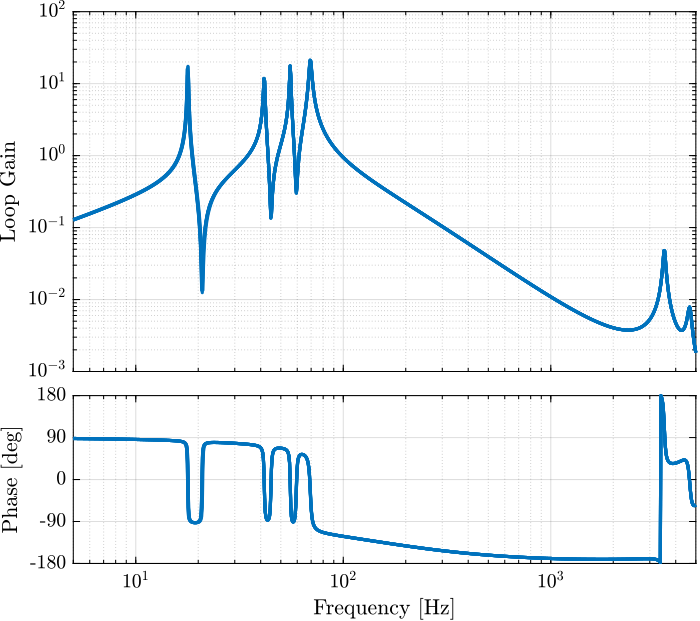

The corresponding loop gain of the diagonal terms are shown in Figure 17. It is shown that the loop gain is quite large around resonances (which allows to add lots of damping) and less than one at low frequency thanks to the large value of \(\omega_c\).

Figure 17: Loop gain of the diagonal terms \(G(i,i) \cdot K_{\text{DVF}}(i,i)\)

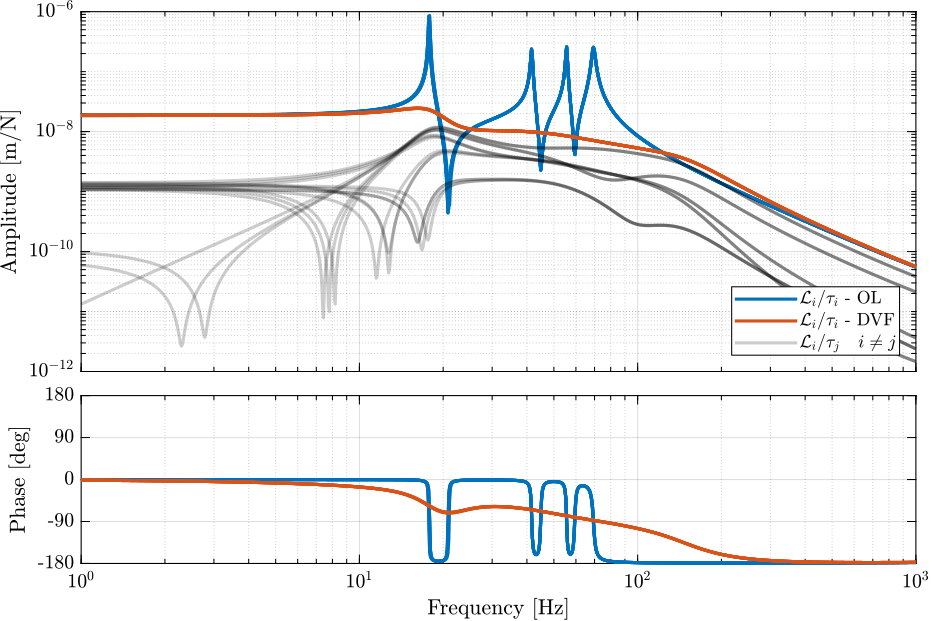

3.3 Effect of DVF on the plant

Let’s now see how the DVF control strategy effectively damps the plant and how it affects the transfer functions from the actuator forces to the relative motion sensors (encoders). First identify the plant in open-loop.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof', ... 'controller_type', 'none'); Gol = linearize(mdl, io, 0.0, options); Gol.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gol.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

And then with the DVF controller.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'struts', ... 'actuator_type', '2dof', ... 'controller_type', 'dvf'); Gdvf = linearize(mdl, io, 0.0, options); Gdvf.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gdvf.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

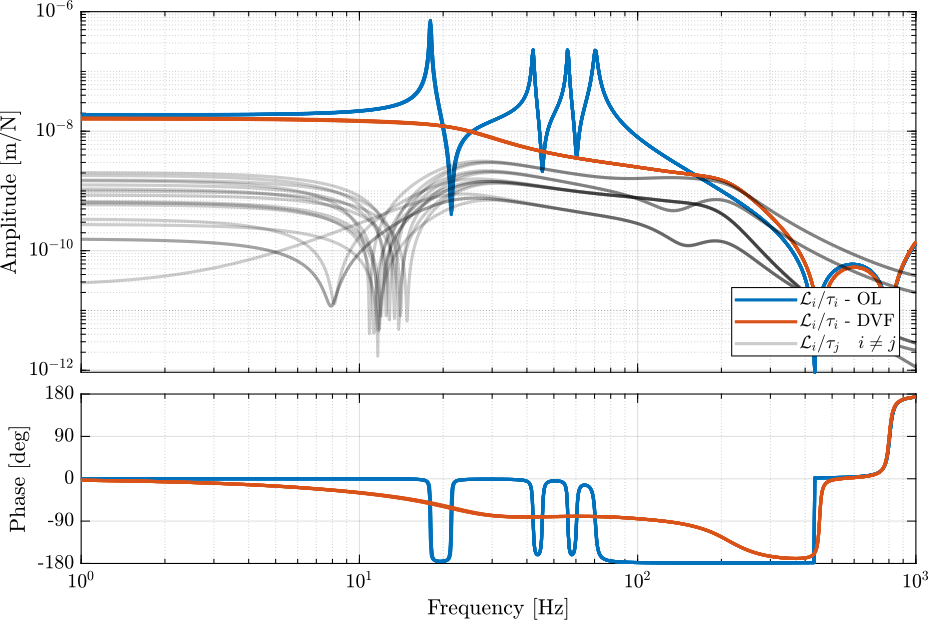

The obtained plants are compared in Figure 18.

Figure 18: Bode plots of the transfer functions from actuator forces \(\tau_i\) to relative motion sensors \(\mathcal{L}_i\) with and without the DVF controller.

The Direct Velocity Feedback Strategy is very effective to damp the 6 suspension modes of the nano-hexapod.

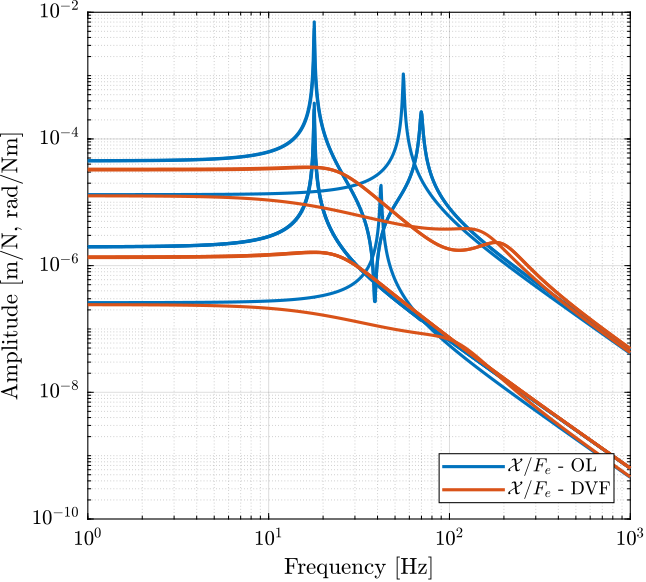

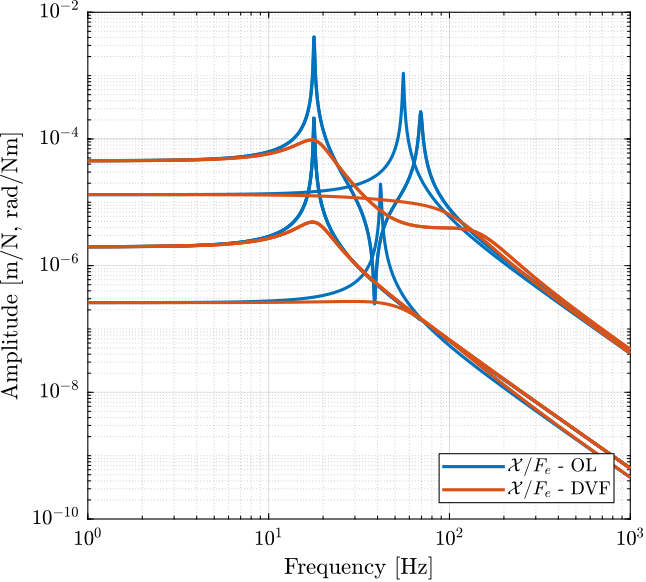

3.4 Effect of DVF on the compliance

The DVF strategy has the well known drawback of degrading the compliance (transfer function from external forces/torques applied to the top platform to the motion of the top platform), especially at low frequency where the control gain is large. Let’s quantify that for the nano-hexapod. The obtained compliances are compared in Figure 19.

Figure 19: Comparison of the compliances in Open Loop and with Direct Velocity Feedback controller

4 Active Damping using Direct Velocity Feedback - Encoders on the plates

In this section, the Direct Velocity Feedback (DVF) strategy is used to damp the nano-hexapod resonances.

It is structured as follows:

- Section 4.1: the DVF plant is identified

- Section 4.2: the optimal control gain is identified using the Root Locus plot

- Section 4.3: the DVF is applied, and the effect on the damped plant is identified and compared with the un-damped one

- Section 4.4: the DVF is applied, and the effect on the compliance is identified

4.1 Plant Identification

The nano-hexapod is initialized as usual.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', '2dof');

The transfer function from actuator inputs to force sensors outputs is identified.

%% Options for Linearized options = linearizeOptions; options.SampleTime = 0; %% Name of the Simulink File mdl = 'nano_hexapod'; %% Input/Output definition clear io; io_i = 1; io(io_i) = linio([mdl, '/F'], 1, 'openinput'); io_i = io_i + 1; % Actuator Inputs io(io_i) = linio([mdl, '/D'], 1, 'openoutput'); io_i = io_i + 1; % Relative Motion Outputs Gdvf = linearize(mdl, io, 0.0, options); Gdvf.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gdvf.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

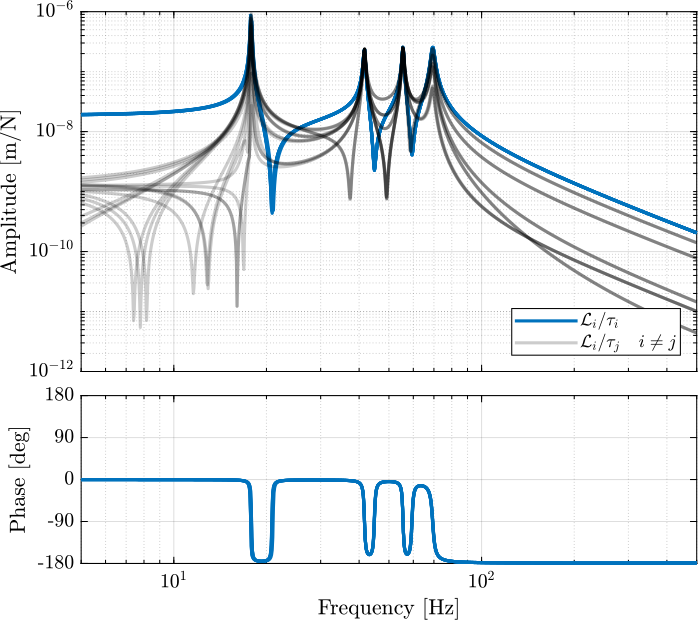

Its bode plot is shown in Figure 20.

Figure 20: Direct Velocity Feedback plant

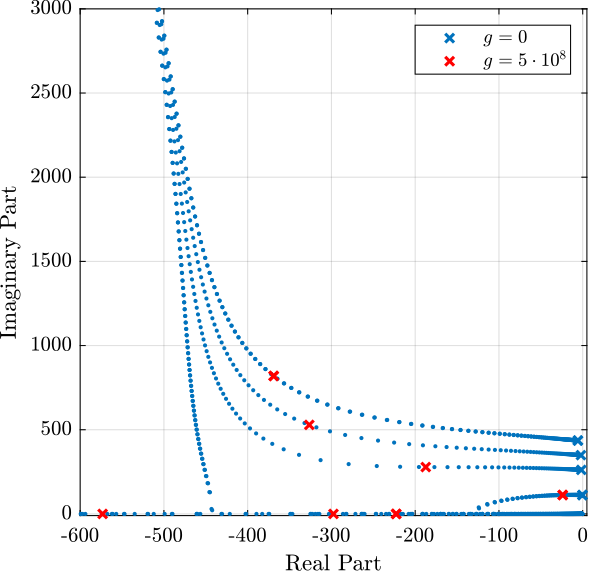

4.2 Root Locus

The controller is a diagonal (i.e. decentralized) controller with simple high pass filters (i.e. pseudo derivators) on the diagonal:

\begin{equation} K_{\text{DVF}} = g \frac{s}{s + \omega_d} \bm{I}_{6 \times 6} \end{equation}The value of \(\omega_d\) sets the frequency above high the derivative action is stopped.

wd = 2*pi*150;

The obtained Root Locus is shown in Figure 21. The control gain chosen for future plots is shown by the red crosses.

Figure 21: Root locus for the decentralized DVF control strategy

The obtained controller is then:

Kdvf = 2e8*s/(s + wd)*eye(6); % DVF Controller

The corresponding loop gain of the diagonal terms are shown in Figure 22. It is shown that the loop gain is quite large around resonances (which allows to add lots of damping).

Figure 22: Loop gain of the diagonal terms \(G(i,i) \cdot K_{\text{DVF}}(i,i)\)

4.3 Effect of DVF on the plant

Let’s now see how the DVF control strategy effectively damps the plant and how it affects the transfer functions from the actuator forces to the relative motion sensors (encoders). First identify the plant in open-loop.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', '2dof', ... 'controller_type', 'none'); Gol = linearize(mdl, io, 0.0, options); Gol.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gol.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

And then with the DVF controller.

n_hexapod = initializeNanoHexapodFinal('flex_bot_type', '4dof', ... 'flex_top_type', '4dof', ... 'motion_sensor_type', 'plates', ... 'actuator_type', '2dof', ... 'controller_type', 'dvf'); Gdvf = linearize(mdl, io, 0.0, options); Gdvf.InputName = {'F1', 'F2', 'F3', 'F4', 'F5', 'F6'}; Gdvf.OutputName = {'D1', 'D2', 'D3', 'D4', 'D5', 'D6'};

The obtained plants are compared in Figure 23.

Figure 23: Bode plots of the transfer functions from actuator forces \(\tau_i\) to relative motion sensors \(\mathcal{L}_i\) with and without the DVF controller.

The Direct Velocity Feedback Strategy is very effective in damping the 6 suspension modes of the nano-hexapod.

4.4 Effect of DVF on the compliance

The DVF strategy has the well known drawback of degrading the compliance (transfer function from external forces/torques applied to the top platform to the motion of the top platform), especially at low frequency where the control gain is large. Let’s quantify that for the nano-hexapod. The obtained compliances are compared in Figure 24.

Figure 24: Comparison of the compliances in Open Loop and with Direct Velocity Feedback controller

5 Function - Initialize Nano Hexapod

Function description

function [nano_hexapod] = initializeNanoHexapodFinal(args)

Optional Parameters

arguments %% Bottom Flexible Joints args.flex_bot_type char {mustBeMember(args.flex_bot_type,{'2dof', '3dof', '4dof', 'flexible'})} = '4dof' args.flex_bot_kRx (6,1) double {mustBeNumeric} = ones(6,1)*5 % X bending stiffness [Nm/rad] args.flex_bot_kRy (6,1) double {mustBeNumeric} = ones(6,1)*5 % Y bending stiffness [Nm/rad] args.flex_bot_kRz (6,1) double {mustBeNumeric} = ones(6,1)*260 % Torsionnal stiffness [Nm/rad] args.flex_bot_kz (6,1) double {mustBeNumeric} = ones(6,1)*1e8 % Axial Stiffness [N/m] args.flex_bot_cRx (6,1) double {mustBeNumeric} = ones(6,1)*0.1 % X bending Damping [Nm/(rad/s)] args.flex_bot_cRy (6,1) double {mustBeNumeric} = ones(6,1)*0.1 % Y bending Damping [Nm/(rad/s)] args.flex_bot_cRz (6,1) double {mustBeNumeric} = ones(6,1)*0.1 % Torsionnal Damping [Nm/(rad/s)] args.flex_bot_cz (6,1) double {mustBeNumeric} = ones(6,1)*1e2 % Axial Damping [N/(m/s)] %% Top Flexible Joints args.flex_top_type char {mustBeMember(args.flex_top_type,{'2dof', '3dof', '4dof', 'flexible'})} = '4dof' args.flex_top_kRx (6,1) double {mustBeNumeric} = ones(6,1)*5 % X bending stiffness [Nm/rad] args.flex_top_kRy (6,1) double {mustBeNumeric} = ones(6,1)*5 % Y bending stiffness [Nm/rad] args.flex_top_kRz (6,1) double {mustBeNumeric} = ones(6,1)*260 % Torsionnal stiffness [Nm/rad] args.flex_top_kz (6,1) double {mustBeNumeric} = ones(6,1)*1e8 % Axial Stiffness [N/m] args.flex_top_cRx (6,1) double {mustBeNumeric} = ones(6,1)*0.1 % X bending Damping [Nm/(rad/s)] args.flex_top_cRy (6,1) double {mustBeNumeric} = ones(6,1)*0.1 % Y bending Damping [Nm/(rad/s)] args.flex_top_cRz (6,1) double {mustBeNumeric} = ones(6,1)*0.1 % Torsionnal Damping [Nm/(rad/s)] args.flex_top_cz (6,1) double {mustBeNumeric} = ones(6,1)*1e2 % Axial Damping [N/(m/s)] %% Jacobian - Location of frame {A} and {B} args.MO_B (1,1) double {mustBeNumeric} = 150e-3 % Height of {B} w.r.t. {M} [m] %% Relative Motion Sensor args.motion_sensor_type char {mustBeMember(args.motion_sensor_type,{'struts', 'plates'})} = 'struts' %% Actuators args.actuator_type char {mustBeMember(args.actuator_type,{'2dof', 'flexible frame', 'flexible'})} = 'flexible' args.actuator_Ga (6,1) double {mustBeNumeric} = ones(6,1)*1 % Actuator gain [N/V] args.actuator_Gs (6,1) double {mustBeNumeric} = ones(6,1)*1 % Sensor gain [V/m] % For 2DoF args.actuator_k (6,1) double {mustBeNumeric} = ones(6,1)*0.35e6 % [N/m] args.actuator_ke (6,1) double {mustBeNumeric} = ones(6,1)*1.5e6 % [N/m] args.actuator_ka (6,1) double {mustBeNumeric} = ones(6,1)*43e6 % [N/m] args.actuator_c (6,1) double {mustBeNumeric} = ones(6,1)*3e1 % [N/(m/s)] args.actuator_ce (6,1) double {mustBeNumeric} = ones(6,1)*1e1 % [N/(m/s)] args.actuator_ca (6,1) double {mustBeNumeric} = ones(6,1)*1e1 % [N/(m/s)] args.actuator_Leq (6,1) double {mustBeNumeric} = ones(6,1)*0.056 % [m] % For Flexible Frame args.actuator_ks (6,1) double {mustBeNumeric} = ones(6,1)*235e6 % Stiffness of one stack [N/m] args.actuator_cs (6,1) double {mustBeNumeric} = ones(6,1)*1e1 % Stiffness of one stack [N/m] % For Flexible args.actuator_xi (1,1) double {mustBeNumeric} = 0.01 % Damping Ratio %% Controller args.controller_type char {mustBeMember(args.controller_type,{'none', 'iff', 'dvf'})} = 'none' end

Nano Hexapod Object

nano_hexapod = struct();

Flexible Joints - Bot

nano_hexapod.flex_bot = struct(); switch args.flex_bot_type case '2dof' nano_hexapod.flex_bot.type = 1; case '3dof' nano_hexapod.flex_bot.type = 2; case '4dof' nano_hexapod.flex_bot.type = 3; case 'flexible' nano_hexapod.flex_bot.type = 4; end nano_hexapod.flex_bot.kRx = args.flex_bot_kRx; % X bending stiffness [Nm/rad] nano_hexapod.flex_bot.kRy = args.flex_bot_kRy; % Y bending stiffness [Nm/rad] nano_hexapod.flex_bot.kRz = args.flex_bot_kRz; % Torsionnal stiffness [Nm/rad] nano_hexapod.flex_bot.kz = args.flex_bot_kz; % Axial stiffness [N/m] nano_hexapod.flex_bot.cRx = args.flex_bot_cRx; % [Nm/(rad/s)] nano_hexapod.flex_bot.cRy = args.flex_bot_cRy; % [Nm/(rad/s)] nano_hexapod.flex_bot.cRz = args.flex_bot_cRz; % [Nm/(rad/s)] nano_hexapod.flex_bot.cz = args.flex_bot_cz; %[N/(m/s)]

Flexible Joints - Top

nano_hexapod.flex_top = struct(); switch args.flex_top_type case '2dof' nano_hexapod.flex_top.type = 1; case '3dof' nano_hexapod.flex_top.type = 2; case '4dof' nano_hexapod.flex_top.type = 3; case 'flexible' nano_hexapod.flex_top.type = 4; end nano_hexapod.flex_top.kRx = args.flex_top_kRx; % X bending stiffness [Nm/rad] nano_hexapod.flex_top.kRy = args.flex_top_kRy; % Y bending stiffness [Nm/rad] nano_hexapod.flex_top.kRz = args.flex_top_kRz; % Torsionnal stiffness [Nm/rad] nano_hexapod.flex_top.kz = args.flex_top_kz; % Axial stiffness [N/m] nano_hexapod.flex_top.cRx = args.flex_top_cRx; % [Nm/(rad/s)] nano_hexapod.flex_top.cRy = args.flex_top_cRy; % [Nm/(rad/s)] nano_hexapod.flex_top.cRz = args.flex_top_cRz; % [Nm/(rad/s)] nano_hexapod.flex_top.cz = args.flex_top_cz; %[N/(m/s)]

Relative Motion Sensor

nano_hexapod.motion_sensor = struct(); switch args.motion_sensor_type case 'struts' nano_hexapod.motion_sensor.type = 1; case 'plates' nano_hexapod.motion_sensor.type = 2; end

Amplified Piezoelectric Actuator

nano_hexapod.actuator = struct(); switch args.actuator_type case '2dof' nano_hexapod.actuator.type = 1; case 'flexible frame' nano_hexapod.actuator.type = 2; case 'flexible' nano_hexapod.actuator.type = 3; end

nano_hexapod.actuator.Ga = args.actuator_Ga; % Actuator gain [N/V] nano_hexapod.actuator.Gs = args.actuator_Gs; % Sensor gain [V/m]

2dof

nano_hexapod.actuator.k = args.actuator_k; % [N/m] nano_hexapod.actuator.ke = args.actuator_ke; % [N/m] nano_hexapod.actuator.ka = args.actuator_ka; % [N/m] nano_hexapod.actuator.c = args.actuator_c; % [N/(m/s)] nano_hexapod.actuator.ce = args.actuator_ce; % [N/(m/s)] nano_hexapod.actuator.ca = args.actuator_ca; % [N/(m/s)] nano_hexapod.actuator.Leq = args.actuator_Leq; % [m]

Flexible frame and fully flexible

switch args.actuator_type case 'flexible frame' nano_hexapod.actuator.K = readmatrix('APA300ML_b_mat_K.CSV'); % Stiffness Matrix nano_hexapod.actuator.M = readmatrix('APA300ML_b_mat_M.CSV'); % Mass Matrix nano_hexapod.actuator.P = extractNodes('APA300ML_b_out_nodes_3D.txt'); % Node coordinates [m] case 'flexible' nano_hexapod.actuator.K = readmatrix('full_APA300ML_K.CSV'); % Stiffness Matrix nano_hexapod.actuator.M = readmatrix('full_APA300ML_M.CSV'); % Mass Matrix nano_hexapod.actuator.P = extractNodes('full_APA300ML_out_nodes_3D.txt'); % Node coordiantes [m] end nano_hexapod.actuator.xi = args.actuator_xi; % Damping ratio nano_hexapod.actuator.ks = args.actuator_ks; % Stiffness of one stack [N/m] nano_hexapod.actuator.cs = args.actuator_cs; % Damping of one stack [N/m]

Geometry

nano_hexapod.geometry = struct();

Center of joints \(a_i\) with respect to {F}:

Fa = [[-86.05, -74.78, 22.49], [ 86.05, -74.78, 22.49], [ 107.79, -37.13, 22.49], [ 21.74, 111.91, 22.49], [-21.74, 111.91, 22.49], [-107.79, -37.13, 22.49]]'*1e-3; % Ai w.r.t. {F} [m]

Center of joints \(b_i\) with respect to {M}:

Mb = [[-28.47, -106.25, -22.50], [ 28.47, -106.25, -22.50], [ 106.25, 28.47, -22.50], [ 77.78, 77.78, -22.50], [-77.78, 77.78, -22.50], [-106.25, 28.47, -22.50]]'*1e-3; % Bi w.r.t. {M} [m]

Now compute the positions \(b_i\) with respect to {F}:

Fb = Mb + [0; 0; 95e-3]; % Bi w.r.t. {F} [m]

The unit vector representing the orientation of the struts can then be computed:

si = Fb - Fa; si = si./vecnorm(si); % Normalize

Location of encoder measurement points when fixed on the plates:

Fc = [[-29.362, -105.765, 52.605] [ 29.362, -105.765, 52.605] [ 106.276, 27.454, 52.605] [ 76.914, 78.31, 52.605] [-76.914, 78.31, 52.605] [-106.276, 27.454, 52.605]]'*1e-3; % Meas pos w.r.t. {F} Mc = Fc - [0; 0; 95e-3]; % Meas pos w.r.t. {M}

nano_hexapod.geometry.Fa = Fa; nano_hexapod.geometry.Fb = Fb; nano_hexapod.geometry.Fc = Fc; nano_hexapod.geometry.Mb = Mb; nano_hexapod.geometry.Mc = Mc; nano_hexapod.geometry.si = si; nano_hexapod.geometry.MO_B = args.MO_B;

Jacobian for Actuators

Bb = Mb - [0; 0; args.MO_B]; nano_hexapod.geometry.J = [nano_hexapod.geometry.si', cross(Bb, nano_hexapod.geometry.si)'];

Jacobian for Sensors

switch args.motion_sensor_type case 'struts' nano_hexapod.geometry.Js = nano_hexapod.geometry.J; case 'plates' Bc = Mc - [0; 0; args.MO_B]; nano_hexapod.geometry.Js = [nano_hexapod.geometry.si', cross(Bc, nano_hexapod.geometry.si)']; end

Controller

switch args.controller_type case 'none' nano_hexapod.controller.type = 1; case 'iff' nano_hexapod.controller.type = 2; case 'dvf' nano_hexapod.controller.type = 3; end

Save the Structure

if nargout == 0 save('./mat/stages.mat', 'nano_hexapod', '-append'); end