Alternative Micro-Station Architecture

Table of Contents

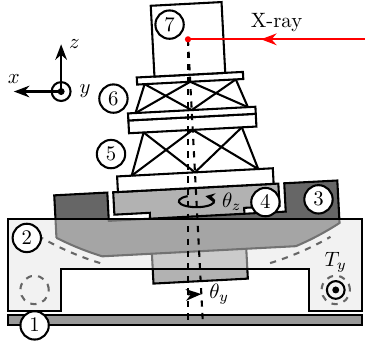

1 Current Micro-Station Architecture

Motion Requirements:

- Vertical rotation of the Sample (360deg)

- Position of the sample with respect to the spindle axis (5mm/3deg)

- Tilt of the spindle axis (3deg)

- Translation of the spindle axis (5mm)

For each of these motion requirements, a position stage is associated:

- Spindle

- Hexapod above the spindle

- Tilt Stage below the spindle

- Translation Stage below the spindle and the Tilt stage

The architecture is shown in Figure 1.

Figure 1: Architecture of the Micro-Station

Such “stacked stage” (serial manipulator) design where one position stage is attributed to one motion requirement is done in order to control each motion independently.

Rough requirements on repeatability:

- Ty: 20nm

- Tz: 10nm

- Ry: 5urad

- Rz: 2urad

Requirements on Tx an Rx motions are not specified.

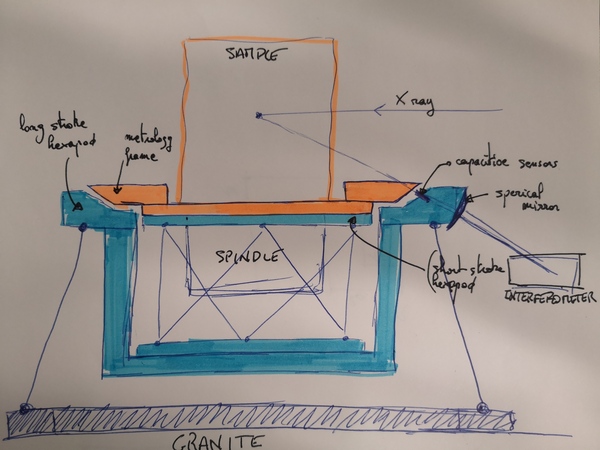

2 Alternative Micro-Station Architecture

If we remove the requirement of having to control each motion with an independent position stage, we can think of other mechanical architectures.

The motion requirements of the Sample can now be expressed in a 6 dimensional space (3 translations and 3 rotations). Roughly, this corresponds to:

- Tx, Ty, Tz: 10mm

- Ry, Rz: 3deg

- Rz: 360deg

To position such sample in this “area”, we can think of using only one hexapod with a spindle on top supporting the sample.

A short stroke hexapod with flexible hinges can be used to compensate the position errors and the vibrations.

The mechanical architecture can then be composed of (see Figures 2 and 3):

- One long stroke hexapod for position

- One short stroke hexapod for vibration control

- One spindle for Rz rotation

Figure 2: Alternative Micro-Station Architecture

Figure 3: Alternative Micro-Station Architecture

3 Alternative Metrology Architecture

As the motion of the sample does not change, the metrology could be the same as the one planned for the current micro-station architecture.

However, we can take advantage of the fact that the spindle is on top of the hexapods to design an alternative metrology architecture consisting of:

- A first metrology that measures the pose of the long stroke Stewart platform with a nano-meter precision over millimeter range. This can be done using the same metrology unit developed for the current architecture. However, the interferometers are not pointing to a rotating mirror anymore. The mirrors fixed to the long stroke hexapods can be calibrated spherical mirrors easily available.

- The second metrology is used to measure the position from hexapod to spindle rotating plate. This can be done with capacitive sensors (similarly to ID16), however, the capacitive sensor support have to sit on top of the long stroke hexapod and thus may experience some deformations. Kinematic mount of the metrology frame supporting both the spherical mirrors and the capacitive sensors have to be carefully designed.

How to precisely measure the Rz motion?

- The problem is similar for both architecture

- Only the Rz motion of the spindle is measured, it is supposed that the Rz motion of all the other stage is negligible, which may not be the case

4 First rough specification of the stages - Maneuverability

The required maneuverability of the long stroke hexapod corresponds to the wanted 6d pose of the sample (except the Rz rotation done by the Spindle):

- Tx, Ty, Tz: 10mm

- Ry, Rz: 3deg

This maneuverability is easily provided by conventional hexapods.

The required stroke of the short stroke hexapod is much easier to estimate with the proposed micro-station architecture than with the current architecture. It corresponds to the dynamical position errors of the long stroke hexapod plus the position error of the spindle. This should be on the order of 10 to 100um in translation and 10urad in rotations.

With the current Architecture, the (6dof) kinematic errors of each stage are added and amplified. Moreover the dynamical errors of each stage are very difficult to estimate, thus the required stage of the short-stroke hexapod is difficult to estimate.

5 Advantages

Mechanics:

- Simpler design (fewer stages / parts)

- Smaller slip-ring / rotary union (used only for experiment: few contacts compaired to +100 contacts now)

- Smaller spindle: only 50kg payload instead of 200kg (?)

- Probably better stiffness properties (advantage of parallel manipulators over serial ones). The vibration of the ground will have a much lower effect on the position errors.

- Lower overall mass, thus higher resonance frequencies.

- The CoM of the payload is always centered with the rotating axis => no centrifugal forces

- Much more space available for the Stewart platforms, thus more optimized architecture can be achieved

- Stewart platforms are not rotating: the use of voice coil actuators is then possible

- Simpler estimation of the required stroke of the nano-hexapod

Metrology:

- Possibly simpler metrology (see section above)

- Much more room for the metrology frame

- No calibration of the spherical reflector is required

Control Notes:

- Everything can be controlled using the Speedgoat. Thus, the synchronization of the motion between the long stroke stages and the nano-hexapod would be much simpler.

- Control architecture combining both hexapods can be developed and result in much better performance.

- Probably better dynamics for the control of the nano-hexapod and less uncertainty (no rotation for instance), thus higher control bandwidth achievable and associated better performances

Versatility and Re-usability:

- Moreover, it would be much more versatile. The possible motion are almost infinite in the defined 6 dimensional space. For instance, the position and orientation of the spindle rotation axis can be virtually chosen. Also Tx scans and Rx scans can be performed.

- Such architecture could be more easily reused for other beamlines as it is more general.

6 Disadvantages

- Possible singularities in the required maneuverability for the Long stroke Hexapod? This is however probably not the case as this maneuverability is provided by many commercial hexapods

- The motion of the spindle should be synchronize with the Hexapods. For instance, using the current architecture for a tomography experiment, the sample is position with the Hexapod and then only the Spindle is rotating. With the alternative architecture, the hexapod will have to move in synchronization with the spindle in order to keep the point of interested on the beam. This may look complicated, but in this is a 1Hz predictable motion.

- Computation of trajectories for the long stroke hexapod for all the wanted experiments. This should not be too complicated (simple 6dof kinematics). The require displacement of each leg of the hexapod can be computed with the inverse kinematics equations.

- The nano-hexapod will support more mass (Spindle) and thus may have a lower first resonance frequency.

- The defect of one actuator will render the system unusable